Page 1

ACNF CEILING MOUNT AIR HANDLER

INSTALLATION INSTRUCTIONS

SHIPPING INSTRUCTIONS ..................................................... 2

APPLICATION INFORMATION ................................................... 2

P

RE-INSTALLATION CONSIDERATIONS ...................................... 2

INSTALLATION ORDER .......................................................... 3

LAYOUT FOR CEILING MOUNT AIR HANDLERS ......................... 3

OUTDOOR UNIT INSTALLATION ............................................... 9

INSTALLING THE CONNECTING PIPE ...................................... 10

REFRIGERANT PIPE CONNECTION ........................................ 11

CONNECTING THE AIR HANDLER TO THE OUTDOOR UNIT ......... 12

CONNECTING THE DRAIN PIPE - INDOOR UNIT ....................... 12

UNITS WITH FRESH AIR DUCT INSTALLATION ......................... 14

MOTOR AND DRAIN PUMP MAINTENANCE ............................. 14

ELECTRICAL WIRING ........................................................ 14

TESTING THE UNIT’S OPERATION ......................................... 15

WIRING DIAGRAMS ........................................................... 18

Important Safety Instructions

The following symbols and labels are used throughout this

manual to indicate immediate or potential safety hazards. It

is the owner’s and installer’s responsibility to read and comply with all safety information and instructions accompanying these symbols. Failure to heed safety information increases the risk of personal injury, property damage, and/or

product damage.

HIGH VOLT AGE!

D

ISCONNECT

INSTALLING

MAY

BE

DAMAGE

IRING MUST CONFORM WITH

W

CODES

PERFORMANCE

G

OODMAN WILL NOT BE RESPONSIBLE FOR ANY INJURY OR

PROPERTY

SERVICE

OWN

PERSONAL

ALL

POWER BEFORE SERVICING OR

THIS UNIT

PRESENT

,

PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK

. U

NDERSIZED WIRES COULD CAUSE POOR EQUIPMENT

DAMAGE ARISING FROM IMPROPER SERVICE OR

PROCEDURES

PRODUCT, YOU ASSUME RESPONSIBILITY FOR ANY

INJURY OR PROPERTY DAMAGE WHICH MAY RESULT

. M

ULTIPLE POWER SOURCES

. F

AILURE TO DO SO MAY CAUSE PROPERTY

NEC OR CEC

,

EQUIPMENT DAMAGE OR FIRE

. IF

YOU PERFORM SERVICE ON YOUR

AND ALL LOCAL

.

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unventilated garages, utility rooms or parking areas because of

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parking area and a carbon monox i de produc ing

device is operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device continues to operate in

the enclosed area. Carbon monoxide emissions can be (re)circulated

throughout the structur e if the furnace or air handle r is operating in any

mode.

CO can cause serious illness including permanent brain damage or death.

B10259-216

-

.

.

Codes & Regulations

This product is designed and manufactured to comply with

local, national and international laws, codes and regulations.

Installation in accordance with such codes and/or prevailing

local codes/regulations is the responsibility of the installer.

The manufacturer assumes no responsibility for equipment

installed in violation of any codes or regulations.

© 2011 Goodman Manufacturing Company, L.P.

IO- 422

10/2011

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

TO

PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH, DO NOT STORE COMBUSTIBLE MATERIALS OR USE

GASOLINE

VICINITY

OR

OTHER FLAMMABLE LIQUIDS OR VAPORS IN THE

OF

THS APPLIANCE

.

1

,

Page 2

WARNING

Do not connect to or use any device that is not design

certified by Goodman for use with this unit. Serious

property damage, personal injury, reduced unit

perform ance and/O R haza rdou s cond itio ns m ay resu lt

from the use of such non-approved devices.

CAUTION

Have your contractor identify all the various cutoff switches

and devices that service this unit. Know where the switch is

that will cut off energy to the heating system in the event of

overheating.

Special Notes for European Consumers:

Do not dispose of this product as unsorted municipal waste.

Collection of such waste for special treatment is necessary.

It is strictly prohibited to dispose of this unit in domestic

household waste. Disposal options:

1. Some municipalities have established collection systems

to collect electronic waste for disposal.

2. Your purchase point retailer (or manufacturer) may take

back the unit for disposal.

3. Used products contain valuable resources and can be

sold to scrap metal dealers.

Illegal disposal in forests and landscapes endanger your

health and the environment. Hazardous materials leak into

ground water.

SHIPPING INSPECTION

Upon receiving the product, inspect it for damage from shipment. Shipping damage, and subsequent investigation is the

responsibility of the carrier. Verify the model number, specifications, electrical characteristics, and accessories are correct prior to installation. The distributor or manufacturer will

not accept claims from dealers for transportation damage or

installation of incorrectly shipped units.

APPLICATION INFORMATION

This ceiling mount air handler is available in cooling capacities of 1.0, 1.5, 2, 2.5, 3.0, 3.5, 4.0 and 6.0 nominal tons of

cooling. Electric heat models are available in capacities of 0,

5, 6, 8 and 10 kW.

The unit is designed to be installed in a horizontal position

above a dropped ceiling. Do NOT install this unit outside

the structure. These models are designed for INDOOR

USE ONLY.

PRE-INSTALLATION CONSIDERATIONS

Carefully read all instructions for the installation prior to installing product. Make sure each step or procedure is understood and any special considerations are taken into account

before starting installation. Assemble all tools, hardware

and supplies needed to complete the installation. Some items

may need to be purchased locally. Make sure everything

needed to install the product is on hand before starting.

Before attempting any installation, the following points should

be considered:

• Structural strength of supporting members

• Clearances and provision for servicing

• Power supply and wiring - Routing of wires must be

arranged so the control board cover is fixed properly.

If not, a possibility of overheating, fire or electrical

shock may occur at the connection point of the terminal.

• Air duct connections - Ductwork should be fabricated

in accordance with local codes and sized to accommodate 375-425 CFM per ton of cooling with the static

pressure not to exceed 0.5” W.C. Inadequate ductwork

that restricts airflow can result in improper performance

and compressor or heater failure.

• Drain facilities and connections

• Installation of unit must be, at a minimum, of 91” (2.3m)

above the floor.

Tubes

&

Fittings

Drain Pipe

Fittings for

cooling/heating

Wire controller

Literature

* As applicable

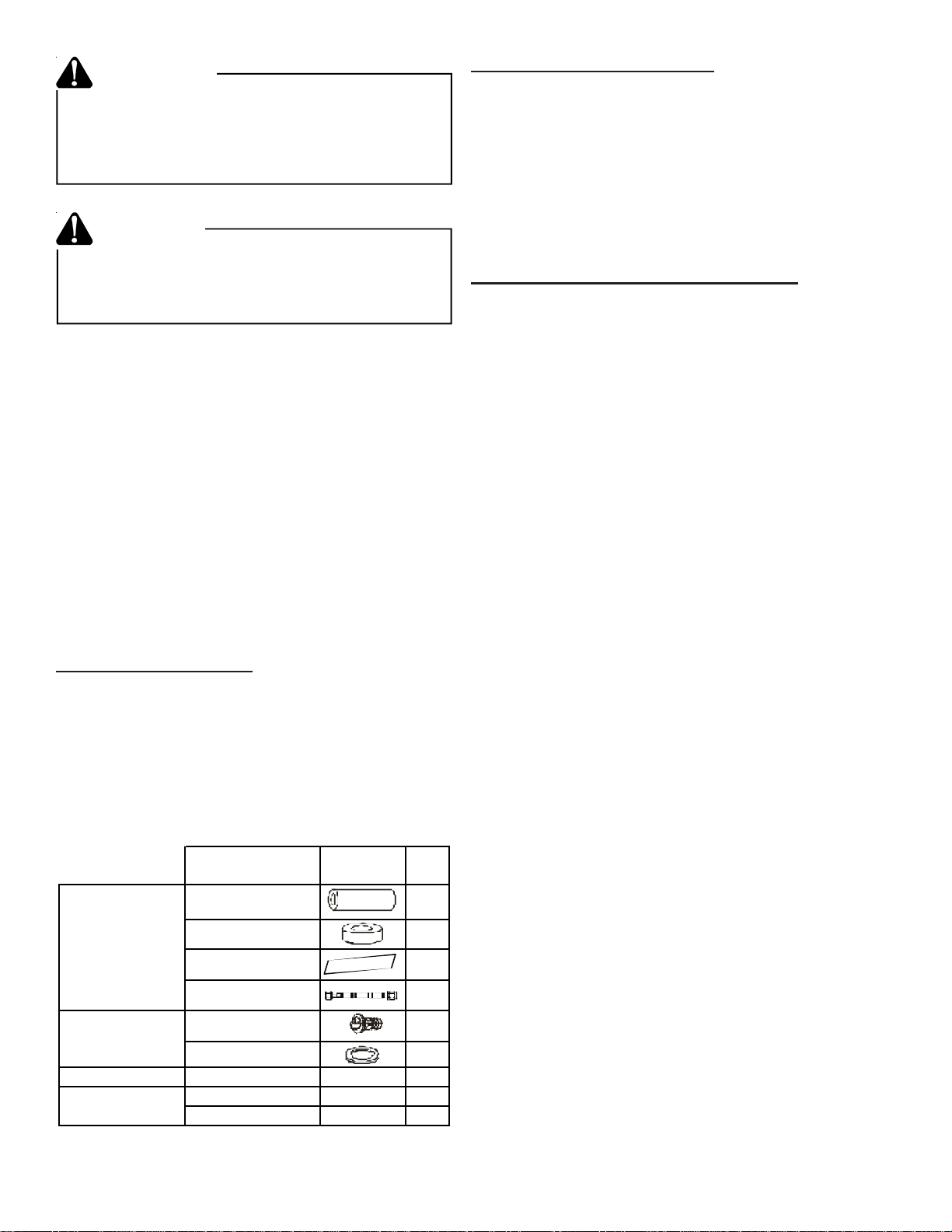

Name Shape Qty.

Soundproof/

Insulation sheath

Binding Tape 1

Seal Sponge 1

*Orifice 1

Drain joint 1

Seal ring 1

Wire controller

Owner's Manual

Installation Manual

---

--- 1

--- 1

• Electrical installations must be in accordance with local national wiring standards, regulations and this installation instruction. An independent circuit and single

2

outlet must be used. If installed without the proper

electrical circuit capacity, or installed defectively, possibility of electrical shock or fire may occur.

• To ensure proper performance of unit, use the specified cable, and clamp the cable securely to prevent

disconnection as this will cause overheating or fire at

the connection.

• An all-pole disconnect switch, having a contact sepa-

1

ration of at least 3mm in all poles, should be connected in the fixed wiring.

2

Page 3

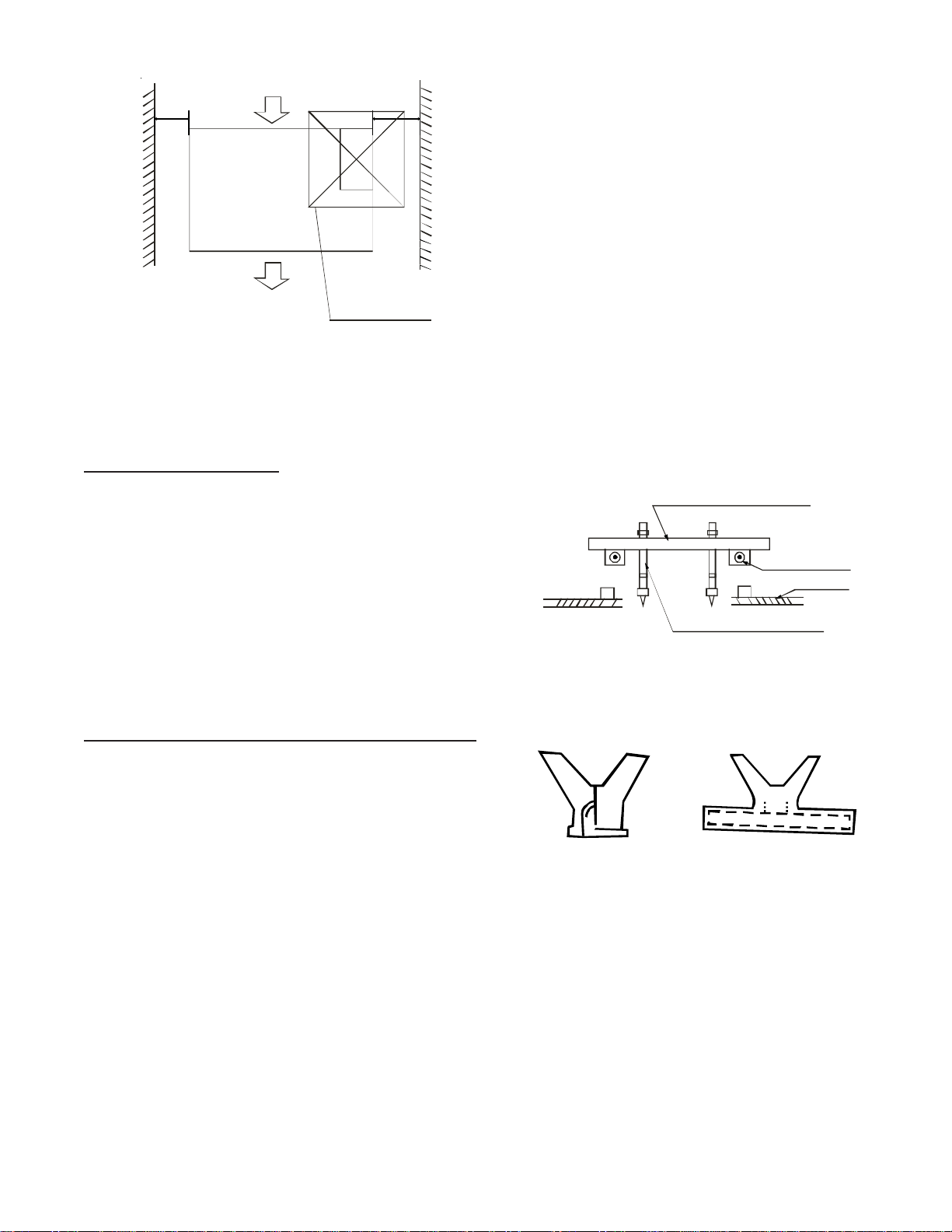

8” (200mm)

or more

12” (300mm)

or more

24” x 24”

(600mm x 600mm)

(Checking orifice)

3. The installation to ceilings varies with construction. Con-

sult construction personnel for the specific procedures.

4. Install pipes and lines in the ceiling after completion of

the installation of the ACNF air handler. The first consideration of installation is to determine the direction of

the pipes. When installing in a ceiling, position the refrigerant pipes, drain pipes, indoor and outdoor lines to

the connections before hanging the unit.

5. Install the hanging screw bolts.

6. After the selection of installation location, position the

refrigerant pipes, drain pipes, indoor and outdoor lines

to the connections before hanging the unit.

7. Attach the hanging screw bolts.

Figure 1 - Room clearances

NOTE: To prevent interference, keep indoor unit, outdoor

unit, power supply wiring and transmission wiring at

least 39” (1 meter) from televisions and radios.

INSTALLATION ORDER

Install your unit in the following order:

1. Select the mounting locations.

2. Install the indoor unit.

3. Instal the outdoor unit.

4. Install the connecting pipe

5. Connect the drain pipe.

6. Wiring.

7. Test operation.

LAYOUT FOR CEILING MOUNT AIR HANDLERS

NOTE: The location of the unit is based on thorough consid-

eration of the PRE-INSTALLATION CHECK POINTS below:

NOTE: The minimum drain tilt is at least 1/100.

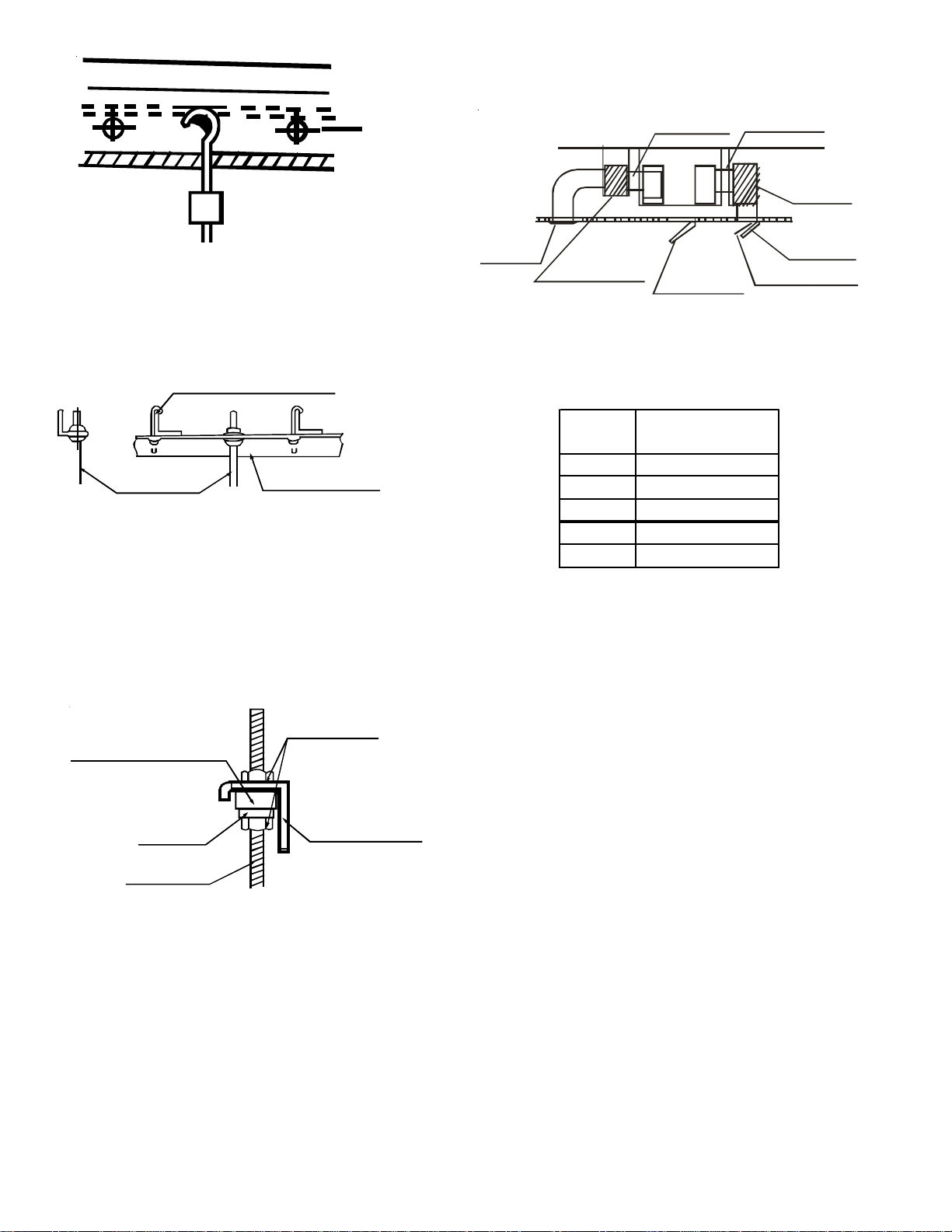

Wooden construction

Put the square timber traversely over the roof beam, then

install the hanging screw bolts.

Timber over the beam

Roof Beam

Ceiling

Hanging Screw Bolts

Figure 2

New Concrete or Bricks

Embedding the screw bolts, Figure 3.

• Structural strength of supporting members

• Clearances and provision for servicing

• Power supply and wiring

• Air duct connections

• Drain facilities and connections

1. Before locating the unit on the dropped ceiling, ensure

the strength of the ceiling and beams is adequate to

support the weight involved. This is an important step

and the installers responsibility.

Installing the four (4) 3/8” (Ø 10) Hanging Screw Bolts

2. Mount the unit in a horizontal position above a dropped

ceiling of adequate strength with four 3/8” (Ø 10) hanging screw bolts. Refer to the following figures for distance between the screw bolts.

Blade Shape

Insertion

Slide

Insertion

Figure 3

Installation for Existing Concrete Bricks

Use embedding screw bolt, crock and stick harness as shown

in Figure 4.

3

Page 4

2. A dust filter is located on the indoor unit.

Recommended duct connections:

Steel Bar

Canvas tie-in

Canvas tie-in

Embedding screw bolt

(Pipe hanging & embedding screw bolt)

Figure 4

Steel Room Beam Structure

Install directly on the supporting angle steel. See Figure 5.

Hanging Screw Bolt

Hanging Bolts

Hanging Bolts

Supporting Angle Steel

Figure 5

Hanging the Indoor Unit

1. Place the indoor unit onto the hanging screw bolts with

block.

2. Using a level, position the unit to hang flat to prevent

leaks, Figure 6.

Isolation

booth

Air

outlet

Isolation

booth

Checking

orifice

Air inlet

Air dust filter

Figure 7

3. It is important to maintain the static pressure below to

alleviate excessive noise, blowing water or other abnormalities.

Model

(Kw)

12 0.16 (40)

18 0.28 (70)

24 0.28 (70)

30-36 0.32 (80)

42-60 0.40 (100)

Static Pressure

Inches H

0 (Pa)

2

NOTES:

1. The indoor unit should not bear the connecting duct’s

weight.

2. Use the fire retardant canvas tie-in to prevent vibrating.

Screw Nut

Shock-proof cushioningShock-proof cushioningShock-proof cushioning

Washer

Overhang

Hanging Screw Bolt

Figure 6

Installing the dust proof net and canvas air passage

1. Install the dust proof net according to the installation

manual.

2. Install the canvas air passage underneath the dust proof

net.

Duct Design

1. Air inlet/outlet ducts must be spaced to prevent air from

the outlet from entering the air inlet.

3. When connecting the ductwork, install in a location

where maintenance can be done easily.

4. The fan motor static pressure should correspond to the

external static pressure.

5. When installed in a noise-sensitive setting, install an

isolation booth and internal duct underlayer to help muffle

the duct noise. (Figure 7.)

4

Page 5

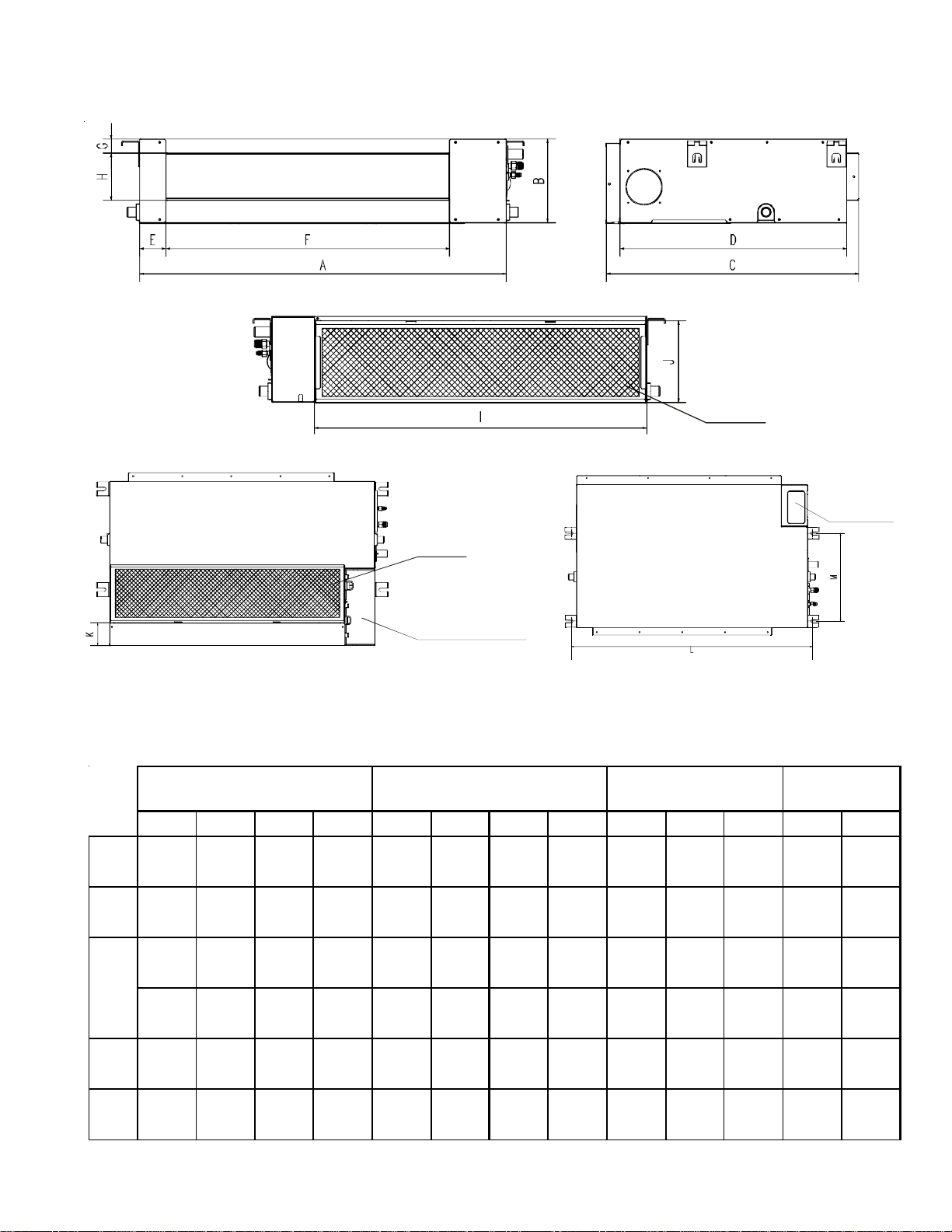

Positioning the ceiling hole, indoor unit and hanging screw bolts.

See table below for dimensions.

Air

filter

Air

filter

Electric

control

cabinet

12

12, 18

24

30-36

Electric

control cabinet

Figure 8

Outline dimemsion

ABCDE FGH I JKLM

27 1/2"

700mm8"210mm

36"

920mm8"210mm

45"

1140mm8"210mm

36"

920mm

45"

1140mm

10 1/2"

270mm

10 1/2"

270mm

25"

635mm

25"

635mm

25"

635mm

25"

635mm

30 1/2"

775mm

22 1/4"

570mm

22 1/4"

570mm

22 1/4"

570mm

22 1/4"

570mm

28"

710mm

2 1/2"

65mm

2 1/2"

65mm

2 1/2"

65mm

2 1/2"

65mm

2 1/2"

65mm

Air outlet

opening size

19 1/4"

493mm

28"

713mm

36 3/4"

933mm

28"

713mm

36 3/4"

933mm

1 1/4"

35mm

1 1/4"

35mm

1 1/4"

35mm

1 1/4"

35mm7"179mm

1 1/4"

35mm7"179mm

4 3/4"

119mm

4 3/4"

119mm

4 3/4"

119mm

23 1/4"

595mm8"200mm3"80mm

815mm8"200mm3"80mm

40 3/4"

1035mm8"200mm3"80mm

815mm

40 3/4"

1035mm

32"

32"

Air return

opening size

10"

260mm

10"

260mm

3/4"

20mm

3/4"

20mm

Size of

mounted lug

29"

740mm

37 3/4"

960mm

46 1/2"

1180mm

37 3/4"

960mm

46 1/2"

1180mm

13 3/4"

350mm

13 3/4"

350mm

13 3/4"

350mm

13 3/4"

350mm

19 1/4"

490mm

42-60

47"

1200mm

11 3/4"

300mm

34"

865mm

31 1/2"

800mm

31"

80mm

38"

968mm

1 1/2"

40mm8"204mm

5

43"

1094mm

11 1/4"

288mm

1 3/4"

45mm

48 3/4"

1240mm

19 3/4"

500mm

Page 6

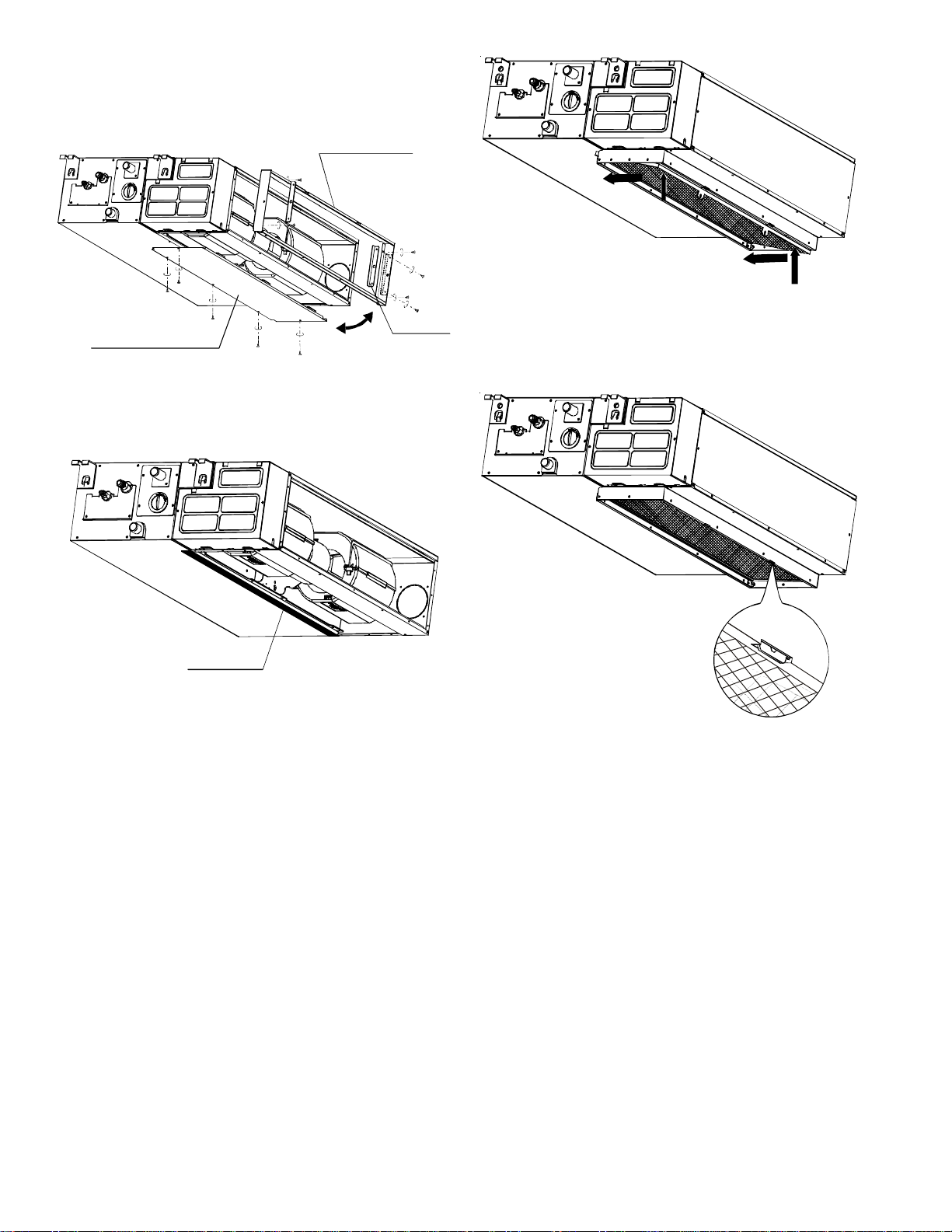

Adjusting the airflow direction

1. Remove the ventilation panel and flange; cut off the

staples at the side rail.

Air return flange

Ventilation panel

Figure 9

2. Attach the seal sponge as shown below. Change the

mounting positions of the air return panel and air return

flange.

Side rail

Figure 11

4. Insert the clips in the flange holes as shown in Figure

12.

Seal sponge

Figure 10

3. When installing the filter mesh, place the filter mesh in

the flange and push up to set it in place, as shown by

the arrows in the following Figure 11.

Figure 12

6

Page 7

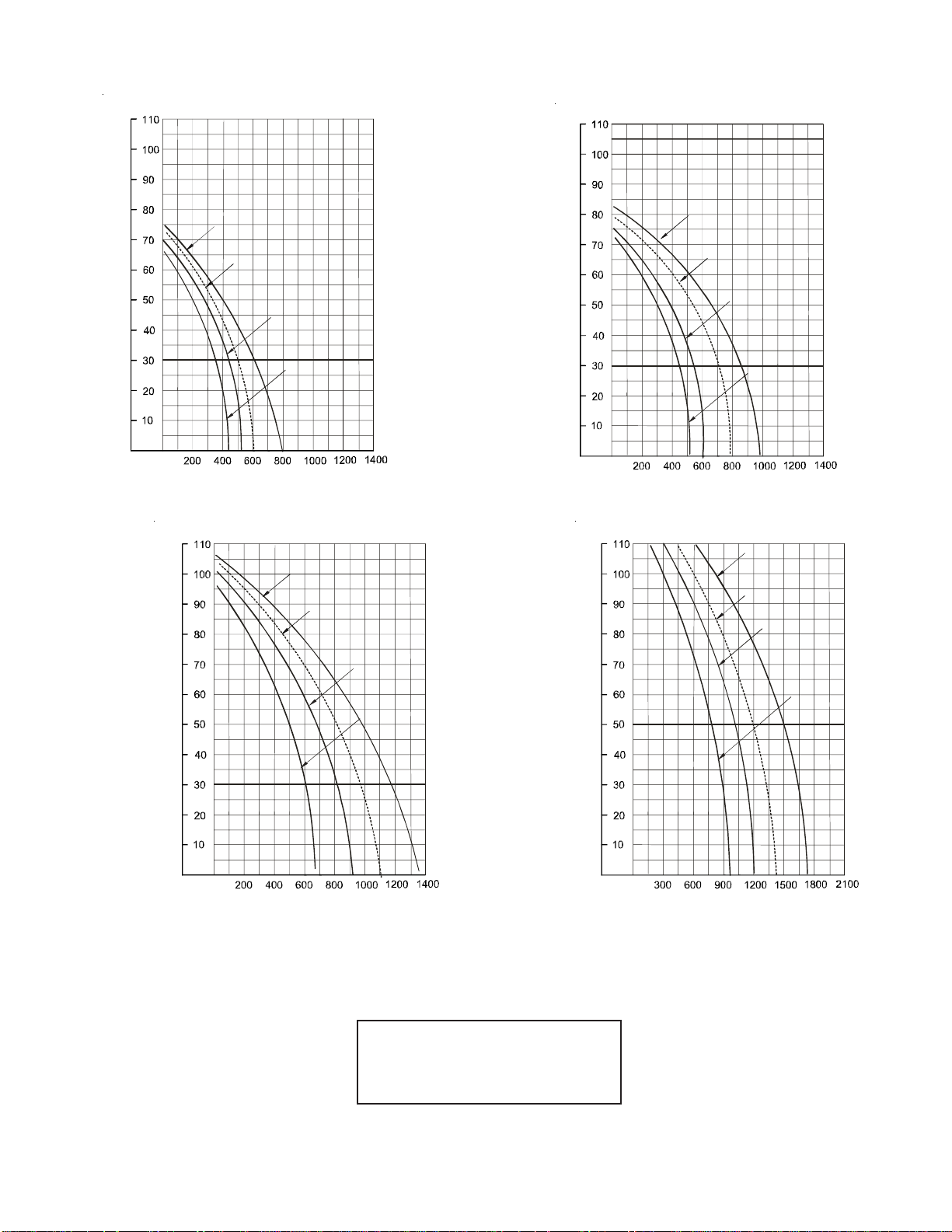

Fan Performance - Stactic Pressure Curve

(Pa)

Model 12

)

a

P

(

e

r

u

s

s

e

r

P

c

i

t

a

t

S

l

a

n

r

e

t

x

E

Super High Speed

High Speed (reserved)

Medium Speed

Low Speed

(Pa)

Air volume (m3/h)

(Pa)

Model 24

Super High Speed

(Pa)

Model 18

Super High Speed

High Speed (reserved)

Medium Speed

Low Speed

Air volume (m3/h)

Model 30

Super High Speed

)

a

P

(

e

r

u

s

s

e

r

P

c

i

t

a

t

S

l

a

n

r

e

t

x

E

Air volume (m3/h)

High Speed (reserved)

Medium Speed

Low Speed

Air volume (m3/h)

High Speed (reserved)

Medium Speed

Low Speed

NOTE:

1 m3/hr = 0.586 CFM

100 Pa = 0.4015 Inches of water

7

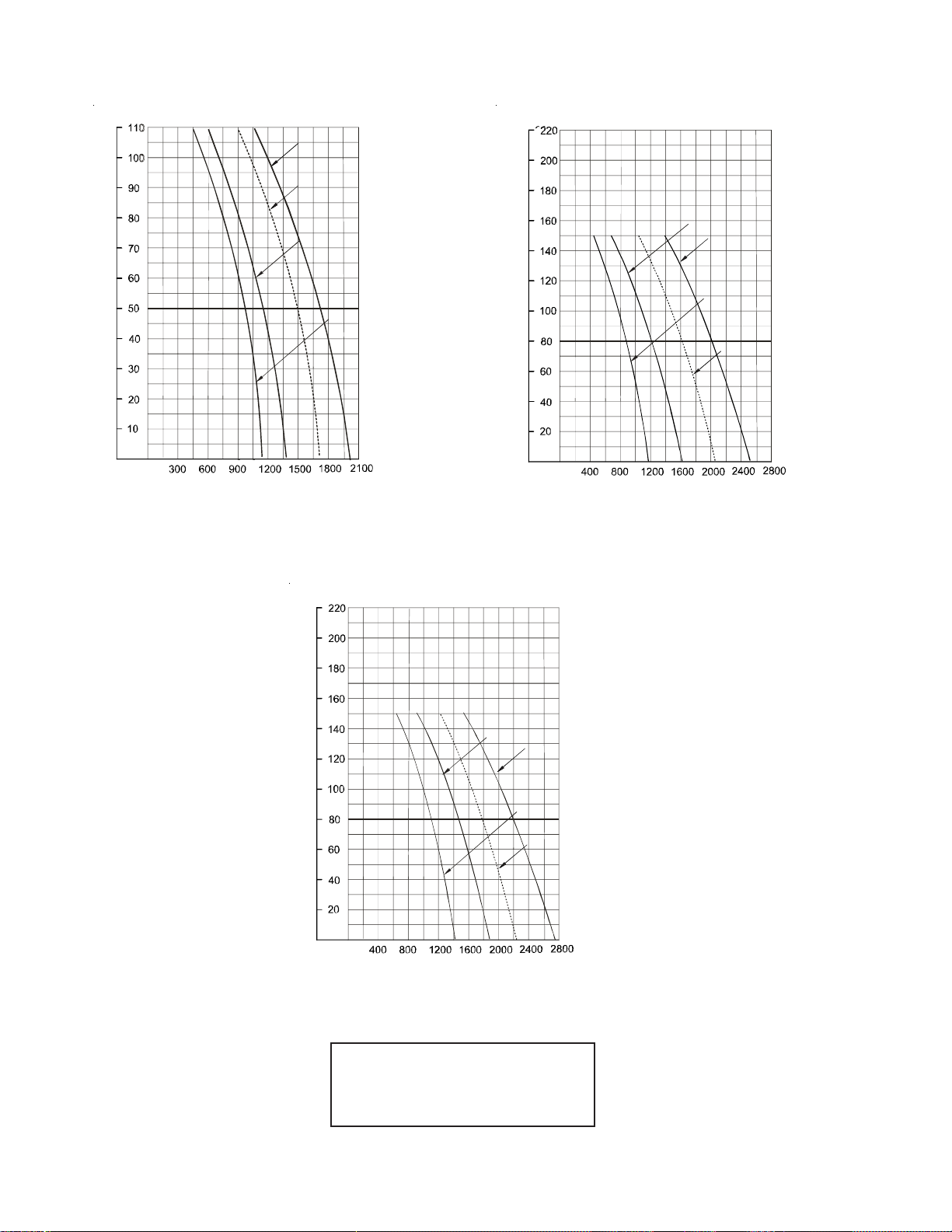

Page 8

Fan Performance - Static Pressure Curve

(Pa)

Model 36

Super High Speed

)

a

P

(

e

r

u

s

s

e

r

P

c

i

t

a

t

S

l

a

n

r

e

t

x

E

High Speed (reserved)

Medium Speed

Low SpeedLow Speed

Air volume (m3/h)

(Pa)

Model 42-48

)

a

P

(

e

r

u

s

s

e

r

P

c

i

t

a

t

S

l

a

n

r

e

t

x

E

Medium Speed

Super High Speed

Low Speed

High Speed (reserved)

Air volume (m3/h)

(Pa)

Model 60

)

a

P

(

e

r

u

s

s

e

r

P

c

i

t

a

t

S

l

a

n

r

e

t

x

E

Medium Speed

Super High Speed

Low Speed

High Speed (reserved)

Air volume (m3/h)

NOTE:

1 m3/hr = 0.586 CFM

100 Pa = 0.4015 Inches of water

8

Page 9

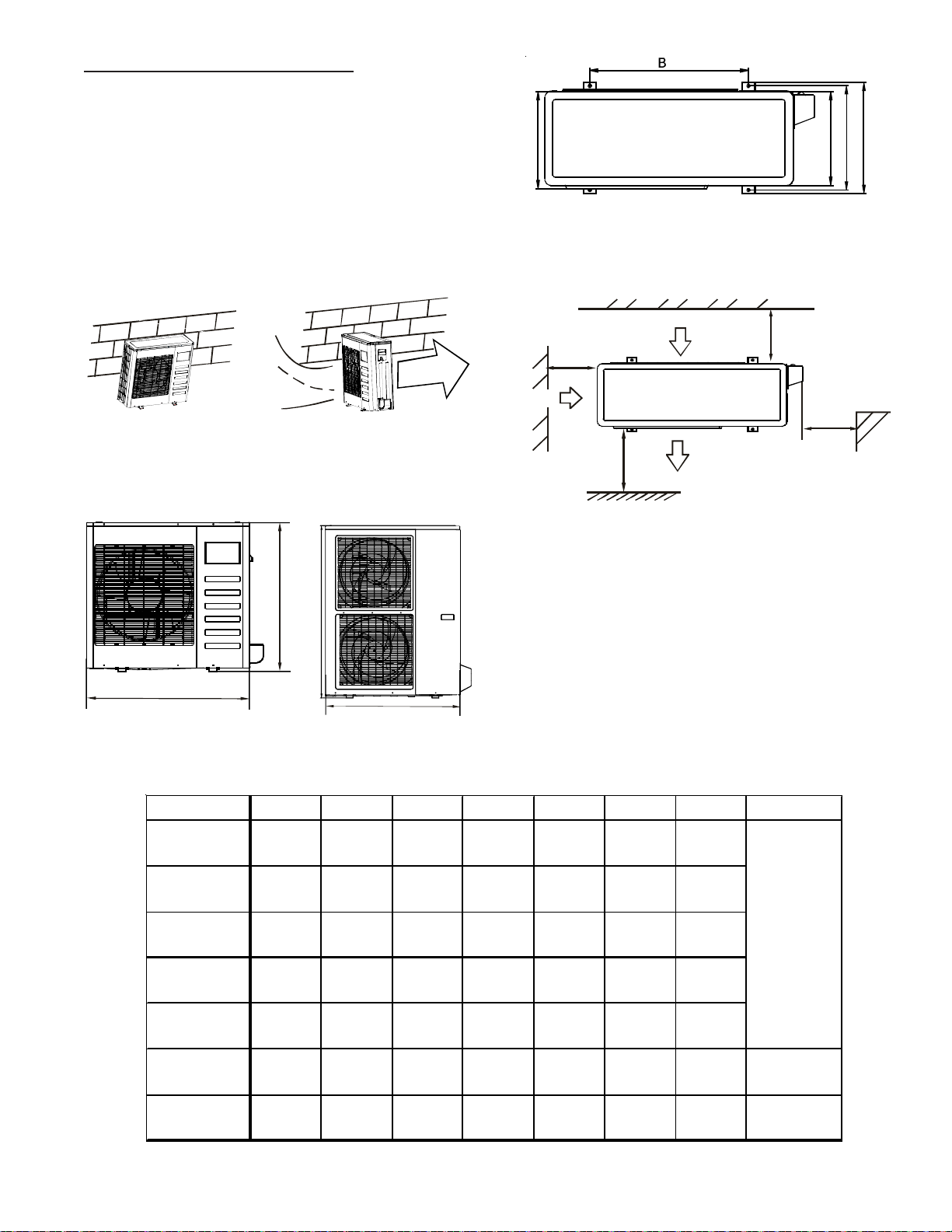

OUTDOOR UNIT INSTALLATION

The following are considerations before installing the outdoor unit.

• Install the outdoor unit on a rigid base to prevent noise

and vibration.

• Place the outdoor unit in such a manner to minimize

restriction of discharge air.

• Protect the unit from prevailing winds. To ensure the

unit operates correctly, place the unit lengthwise along

a wall or use a dust or shield plate.

S

T

R

O

N

G

W

I

N

D

Figure 13A

• Install in a place where the unit is easily accessible

for installation and maintenance.

Figure 13B

F

D

E

C

Figure 14C

• See Figure 15 for minimum distances to obstacles.

Two of the three must remain unobstructed.

Wall or obstacle

)

”

m

2

c

1

0

>

3

(

>24”

(60cm)

P

Air Inlet

>12”

(30cm)

N

Air Inlet

)

”

m

c

9

0

7

0

>

2

(

M

Air Outlet

Figure 15

Moving and Installation

Notes:

H

• The inlet of the unit should not be used as a “handle”

when moving the unit.

• Use caution when moving the unit with a sling, since

the center of gravity is not in the unit’s physical cen-

A

A

ter.

• The fan should not be touched with hands or any foreign objects.

Figure 14A Figure 14B

• Do not lean the unit more than 45° or lay it on its side.

ModelABC DEFHFigure Ref.

12,000

R-22 & R-410A

18,000

R-22 & R-410A

24,000

R-22 & R-410A

30,000/36,000

R-22 & R-410A

31"

780mm

30"

762mm

33"

842mm

39"

990mm

21 1/2"

548mm

21"

530mm

22"

560mm

24 1/5"

624mm

10 1/2"

266mm

11"

290mm

13"

335mm

14"

366mm

11 1/2"

300mm

12"

315mm

14"

360mm

15 1/2"

396mm

9 1/2"

241mm

10 1/2"

270mm

12"

312mm

13"

340mm

9 1/2"

250mm

11"

282mm

12 1/2"

324mm

13 3/4"

354mm

21 1/2"

547mm

23"

593mm

27"

695mm

38"

966mm

Figure 14A

48,000

R-22 Only

48,000

R-410A Only

60,000

R-22 & R-410A

39"

990mm

35"

900mm

35"

900mm

24 1/5"

624mm

23"

590mm

23"

590mm

14"

366mm

14 3/4"

378mm

14 3/4"

378mm

15 1/2"

396mm

15 1/2"

400mm

15 1/2"

400mm

9

13"

340mm

13"

330mm

13"

330mm

13 3/4"

354mm

13 1/4"

340mm

13 1/4"

340mm

38"

966mm

45 3/4"

1167m m

45 3/4"

1167m m

Figure 14B

Figure 14B

Page 10

• See Figure 16 for securing the outdoor unit horizon-

A

tally to a concrete foundation. Fasten the feet of the

outside unit securely with bolt to prevent movement of

the unit in adverse weather conditions, such as high

winds or earthquake.

”

½

m

c

3

0

2

6

>

ttach

with bolt

Figure 16

INSTALLING THE CONNECTING PIPE

The following chart lists the proper height drop between the

indoor unit and outdoor, the length of refrigerant pipe and the

number of bends.

R-22

Model

Refrigerant

Pipe Length

12 49' (15 m) 26' (8 m)

18/24 98' (30 m) 33' (10 m)

30-42 164' (50 m) 66' (20)

48-60 164' (50 m) 82' (25 m)

Uni t i n fe et & me ters

R-410A

Model

Refrigerant

Pipe Length

12 49' (15 m) 26' (8 m)

18/24 82' (25 m) 49' (15 m)

30/36 98' (30 m) 66' (20)

48 98' (30 m) 66' (20)

60 98' (30 m) 66' (20)

Uni t i n fe et & me ters

The outdoor unit is factory charged with refrigerant.

Some systems require additional charging of refrigerant

depending upon pipe length. The additional charge can

be calculated with the following formula:

D(mm)

R(g)

L(m)

Less than 16 1/2' (5m)

(one way)

Added Refrigerant

when over 16 1/2' (5m)

(one way)

1/4"

(Ø 6.4)

--- --- ---

2.6 in/lb x (L-5)

30g/m x (L-5)

Maxium

Height Drop

Maxium

Height Drop

3/8"

Ø9.5

5.6 in/lb x (L-5)

65g/m x (L-5)

1/2"

Ø12.7

10.0 in/l b x (L-5)

115g/m x (L-5)

NOTES:

1. Avoid letting air, dust or other impurities get into the pipe

system during installation.

2. The connecting pipe should not be installed until the indoor and outdoor units are installed. The connecting

pipe should be kept dry during the installation operation.

3. If additional refrigerant is added, record the amount and

retain a copy for future maintenance.

Connection of piping

All field piping must be provided by a licensed refrigeration

technician and must comply with the applicable local and

national codes.

1. Measure the necessary length of the connecting pipe,

following the instructions below. Connect the indoor unit

first and then the outdoor unit.

• Carefully bend the tubing as shown below.

Bend the pipe with the thumbs

Minimum radius - 4” (100mm)

Figure 17

• Daub the surfaces of the flare pipe and the joint nuts

with refrigeration oil. Rotate it 3 to 4 rounds with your

hands before fastening the flare nuts.

Use

Refrigeration oil

Figure 18

• Always use two (2) wrenches simultaneously when

you connect or disconnect the pipes.

Marking the ends

Figure 19

• Make sure the stop valve of the outdoor unit is closed

completely. When loosening it for connecting, first

loosen the nuts on the stop valve. Connect the flare

pipe immediately (within 5 minutes) to prevent dust

and debris from contaminating the system. Always

expel the air from the pipes with refrigerant before connection.

10

Page 11

• Expel the air after connecting the refrigerant pipe with

the indoor and outdoor units. Fasten nuts at the repair points.

• Bend the connecting pipe of small wall thickness.

Cut out a desired concave at the bending part of the

insulating pipe. Cover exposed portions of the pipe

with tape after bending to prevent impurities from entering.

Bend the connecting pipe of small wall thickness.

Cut out a desired concave at the bending part of the

insulating pipe.

To prevent collapsing or deforming, bend the pipe at

its biggest radius.

Use a bender to get small radius pipes.

NOTES: The bending angle should not exceed 90°

The middle of the pipe is the best place to bend, since

a large bending radius is preferable.

0

9

Figure 20A

Incorrect alignment is show below, Figure 20B.

Lean

Crude

Burr

Pipes should not be bent more than three times.

Be sure to use the same insulating materials when

you buy brass pipe (more than 9mm thick).

Installing the pipe

1. Drill a hole in the wall to accommodate the wall conduit.

Install the fittings such as the wall conduit and its cover.

2. Bind the connecting pipe and the cables together tightly

with binding tape.

3. Pass the bound connecting pipe through the all conduit

from the outside, being careful not to damage the tubing.

4. Connect the pipes (see Connection of Piping).

5. Expel the air with a vacuum pump.

6. Open the stop valves of the outdoor unit to make the

refrigerant pipe connecting the indoor unit with the outdoor unit flow sufficiently.

7. Check for leakage, checking all joints with the leak detector or soapy water.

8. Cover the joints of the connecting pipe with the soundproof / insulating sheath (fittings) and bind it well with

tape to prevent leaking.

Figure 20B

2. Insert a flare nut into a pipe and flare the pipe.

Fasten the nut

1. Align the center of the pipes and finger-tighten the flare

nut. Using a spanner and torque wrench (Figure 21),

continue tightening the flare nut until the nut is firmly on

the pipe.

Figure 21

Do not over-tighten. Excessive torque can

break the nut and/or crimp the pipe.

REFRIGERANT PIPE CONNECTION

Expelling the air

Flaring:

1. Cut the pipe with a pipe cutter. See Figure 20A for correct alignment.

See the following table to determine torque ranges.

11

Page 12

Pipe

Gauge

1/4"

(Ø 6.4)

3/8"

Ø9.5

1/2"

Ø12.7

5/8"

Ø15.9

3/4"

Ø19.1

Tightening

Torque

10.5~12.7 ft/lbs

(124.9~152.7 lb/in)

14.2~17.2 N.m

(144~176 kgf.cm)

24.1~29.4 ft/lbs

(289.0~353.2 lb/in)

32.7~39.9 N.m

(333~407 kgf.cm)

36.5~44.6 ft/lbs

(437.4~534.6 lb/in)

49.5~60.3 N.m

(504~616 kgf.cm)

45.6~556.0 ft/lbs

(546.8~668.3 lb/in)

61.8~75.4 N.m

(630~770 kgf.cm)

71.7~87.5 ft/lbs

(859.2~1050 lb/in)

97.2~118.6 N.m

(990~1210 kgf.cm)

Flare

Dimension A

Min Max

5/16"

11/32"

8.3

15/32"

19/32"

23/32"

29/32"

'12.0

15.4

18.6

22.9

1/2"

12.4

5/8"

15.8

3/4"

'19.0

29/32"

23.3

8.7

Flar e

Shape

90° 4+

A

4

5

°

+

2

R0.4~0.8

Leak Testing (Nitrogen or Nitrogen-Traced)

Pressure test the system, using dry nitrogen and soapy water

to locate any leaks in the system. If you wish to use a leak

detector, charge the system to 10 psi using the appropriate

refrigerant, then use nitrogen to finish charging the system

to working pressure. Apply the detector to suspect areas. If

leaks are found, repair them. After repair, repeat the pressure test. If no leaks exist, proceed to System Evacuation.

Insulation

Cover all exposed parts of the flare pipe joints and refrigerant

pipe on both the liquid and gas sides, with insulating materials. Incomplete coverage may cause water condensation.

CONNECTING THE AIR HANDLER TO THE

OUTDOOR UNIT

To receive optimum throttle efficiency, mount the orifice as

level horizontally as possible. Anti-shock rubber should be

wrapped on the external parts of the orifice to reduce noise.

Gas side

Liquid side

Orifice

COOLING & HEATING: Correct installation, Figure 23.

Liquid side

INDOOR

OUTDOOR

Liquid side

Figure 23

COOLING & HEATING: Do not install as shown in Figure 24.

INDOOR

Liquid side

OUTDOOR

INDOOR

Liquid side

OUTDOOR

Figure 24

CONNECTING THE DRAIN PIPE - INDOOR UNIT

Purchased from your dealer, polyethylene tubing can be used

as the drain pipe (outside diameter 1” - 1/10” (29-31mm);

(inside diameter 1” or 25mm).

To prevent water from ingressing into the air conditioner when

the air conditioner is not operating, the drain pipe should be

slanted down toward the outdoor (outlet side) at a degree of

over 1/50. Avoid any bulges or water deposits.

Take care not to put undue stress on the drain pipe when

connecting to prevent its pulling away from the body. One

support point should be set every 39” - 59” (1-1.5m) to help

support the drain pipe and prevent it from pulling. The drain

pipe can also be tied to the connecting pipe for support.

If the drain pipe is long, tighten the indoor part with a sealant

to prevent its loosening.

If the drain pipe’s outlet is higher than the body’s pump joint,

arrange the pipe as vertically as possible, with the left distance less than 8” (200mm). Otherwise, the water will over-

flow when the air conditioner ceases operation. Only avail-

able with units with plugs.

The end of the drain pipe should be over 2” (50mm) higher

than the ground or the bottom of the drainage chute. Do not

immerse it in water. If water is discharge directly into sewage, make a U-form aqua seal by bending the pipe up to

prevent odorous gases from entering the home through the

drain pipe.

Drain Pipe Installation for the unit with pump: Figure 25.

Figure 22

1. Mark the data plate with the orifice installed.

2. Purchase the fittings according to the requirements in

the manuals.

3. Refer to the diagrams for reference while installing.

12

(200mm)

Figure 25

<8.0”

39” - 59” (1-1.5m)

Lean over 1/50

Page 13

39” - 59” (1-1.5m)

Lean over 1/50

Figure 26

Drainage Test

Make sure drain pipe is draining properly. Recently constructed homes should have this tested before finishing the

ceiling.

UNITS WITH PUMPS:

1. Turn power off.

HIGH VOLTAGE!

D

ISCONNECT

M

ULTIPLE POWER SOURCES MAY BE PRESENT

F

AILURE TO DO SO MAY CAUSE PROPERTY DAMAGE

PERSONAL INJURY OR DEATH

2. Remove the test cap cover by rotating the cover to the

“open” position (Figure 27). Slowly run approximately 4

US pints (2000ml) of water to the water receiver through

the stow tube. See Figure 28

ALL

POWER BEFORE SERVICING

.

.

.

,

Stow Tube

Figure 28

3. Restore power to the unit and operate the air conditioner

under the COOLING mode. While listening to the sound

of the drain pump, check to see if the water is discharge

properly.

NOTE: According to the length of the drain pipe, there is

an approximate one minute wait time before the water

begins discharging. Check joints to see if there is leaking.

4. Stop the air conditioner. Turn off power and reset the

test cover to it original position.

5. Remove the test cover and add approximately 4 US pints

(2000ml) of water to the water received through the side

stow tube to see if the water is draining properly through

the drain pipe. See Figure 29.

Closed

Tes t Ca p

O

p

e

n

Figure 27

Stow Tube

Figure 29

Installing the drain join of the outdoor unit

1. Fit the seal in to the drain joint. Insert the drain joint into

the base pan hole of the outdoor unit. Rotate 90°.

n

p

e

O

d

e

s

o

l

C

2. Connect the drain joint with an extension drain hose (installer purchased). This procedure will drain any condensate that may be produced during the HEATING

mode.

13

Page 14

Seal

Drain joint

Base pan hole

of the outdoor unit

Motor

Seal

Base pan of

outdoor unit

Drain joint

Figure 30

UNITS WITH FRESH AIR DUCT INSTALLATION

For unit’s having a fresh air duct, see Figure 31 below for

dimensions.

Duct Joint for fresh air duct

MODELS

18-24 30-60

5” ( 125mm)Φ

6 1/4” ( 160mm)Φ

Blower Housing

Ventilated Panel

Figure 32

PUMP MAINTENANCE

1. Remove the four screws from the drain pump. See Figure

33.

2. Plug off pump power supply and water level switch cable.

3. Remove pump.

)

m

m

3 ½” ( 90mm)Φ

3 ” ( 80mm)Φ

0

8

Φ

(

”

3

Figure 31

MOTOR AND DRAIN PUMP MAINTENANCE

Example shown is rear ventilated.

MOTOR MAINTENANCE

1. Remove the ventilated panel.

2. Remove half of the motor housing and remove motor, as

shown in Figure 32.

Pump

Figure 33

WIRING

IMPORTANT NOTES:

1. This unit is to be installed in accordance with national

and local wiring regulations.

2. Install unit with a separate power supply with rated voltage.

3. The external power supply to the air conditioner requires

ground wiring, which is linked to the ground wiring of the

indoor and outdoor units.

4. Wiring should be done by qualified persons and according to the wiring and circuit drawings.

14

Page 15

WARNING

INSTALLATION AND REPAIR OF THIS UNIT SHOULD BE PERFORMED

BY INDIVIDUALS MEETING THE REQUIREMENTS OF AN

ONLY

“ENTRY LEVEL TECHNICIAN” AS SPECIFIED BY THE AIR-CONDITIONING,

HEATING, AND REFRIGERATION INSTITUTE (AHRI). ATTEMPTING

TO

INSTALL OR REPAIR THIS UNIT WITHOUT SUCH BACKGROUND

RESULT IN PRODUCT DAMAGE, PERSONAL INJURY OR DEATH.

MAY

G

OODMAN WILL NOT BE RESPONSIBLE FOR ANY INJURY OR

PROPERTY

SERVICE

OWN

PERSONAL

DAMAGE ARISING FROM IMPROPER SERVICE OR

PROCEDURES

PRODUCT, YOU ASSUME RESPONSIBILITY FOR ANY

INJURY OR PROPERTY DAMAGE WHICH MAY RESULT

. IF

YOU PERFORM SERVICE ON YOUR

1. Remove the bolts from the cover. If there is no cover on

the outdoor unit, remove the bolts from the maintenance

board. Pull in the direction of the arrow on Figure 34 to

remove the protection board.

.

Protection board

Cover

Fig.

5. An all-pole disconnection device with at least 3mm separation distance in all poles and a residual current device

(RCD) with a rating above 10mA should be incorporated

in the fixed wiring, according to national codes.

6. Located the power wiring and signal wiring so there is no

cross disturbance.

7. Check wiring carefully before turning on power.

8. Power cord type designation is H07RN-F.

As per EMC Directive 2004/108/EC:

To prevent flicker impressions during the start of the compressor (technical process), the following installation conditions apply:

1. The power connection for the air conditioner has to be

done at the main power distribution. The distribution has

to be of a low impedance. Normally, the required impedance reaches at a 32A fusing point.

2. No other equipment has to be connected with this power

line.

3. For detailed installation acceptance, please refer to your

power supplier, if restrictions do apply for products like

washing machines, air conditioners or electrical ovens.

4. For power details of the air conditioner, refer to the rating

plate of the product.

5. For any questions, contact your local dealer.

Connecting the cable

HIGH VOLTAGE!

D

ISCONNECT

ULTIPLE POWER SOURCES MAY BE PRESENT

M

F

AILURE TO DO SO MAY CAUSE PROPERTY DAMAGE

PERSONAL INJURY OR DEATH

ALL

POWER BEFORE SERVICING

.

.

.

,

Figure 34

2. Connect the connective cables to the terminals with their

corresponding, respective numbers on the terminal block

of the indoor and outdoor units.

3. Reinstall the cover or the protection board.

Power Specifications:

Refer to charts 1 - 4 on the following pages.

Wiring Diagrams

Refer to the wiring diagrams beginning on page 18.

TESTING THE UNIT’S OPERATION

Perform a test operation after the installation of the entire

system has been completed. Confirm the following have

been done before the test operation:

1. The indoor and outdoor units are properly installed.

2. Tubing and wiring are correctly completed.

3. The refrigerante pipe system has been checked for leaks.

4. There are no obstructions and the pipes are draining freely.

5. Heating insulation is working.

6. Ground wiring is connected correctly.

7. The length of the tubing and the added charge of the

refrigerant have been recorded.

8. The power voltage matches the rated voltage of the air

conditioner.

9. There are no obstacles at the outlet and inlet of the outdoor and indoor units.

10. The gas side and liquid side valves are both open.

11. The air conditioner is pre-heated by turning on the power.

15

Page 16

According the the user’s requirement, install the remote con-

5

trol frame where the remote control’s signal can reach the

indoor unit smoothly.

Testing the unit:

With the remote control, set the air conditioner in COOLING

mode; check the following. If there is any malfunction, resolve it according to the “Troubleshootin” section in the User’s

Manual.

THE INDOOR UNIT:

1. Do the switches and buttons on the remote control work

properly?

2. Do the air flow louvers move normally?

3. Is the room temperature comfortable?

4. Are the indicator lights working normally?

5. Are the temporary buttons working?

6. Is drainage normal?

7. Are there any vibrations or abnormal noises during operation?

8. If the unit is a heating/cooling model, does the unit heat

as well as cool?

THE OUTDOOR UNIT:

1. Are there any vibrations or abnormal noises during operation?

2. Are the noises, air or condensation created by the unit of

sufficient levels that they would create a problem for your

neighbors?

3. Are there any refrigerant leaks?

NOTE: The unit is equipped with a three minute compressor

delay feature. When the unit is restarted immediately

after shut off (or power outage), the unit will begin operation in three minutes.

Model (R -22, 50 Hz)

Cooling Only

Phase

Power

Circuit Breaker /F us e (A)

In doo r Un it P ower Wir ing (mm

Indoor/Outdoor

Connecting

Wi rin g (mm

Frequency

Vo lt

Grou nd Wi r ing

Ou t door U nit

Power Wirin g

Strong Electric

3

Signal

)

Weak Electric

Signal

12-182430-3636-60

1-Phase 1-Phase 1-Phase 3-Phase

220-240v~

50 Hz

3

)

20/16 30/25 35/30 40/30

3x2 .5 3x2.5 3x4.0 5x4.0

2.5 2.

---- 3x2.5 3x4.0 5x4.0

3x2 .5 1x1.5 1x1.5 1x1.5

'---- '---- '---- '----

220-240v~

50 Hz

220-240v~

50 Hz

4.0 4.0

318-415v 3N~

50 Hz

Chart 1

16

Page 17

Model (R-22 & R-410A, 50 Hz)

Cool i ng & H eat in g

Phase

Power

Frequency

Volt

Circuit Breaker /F us e (A)

In doo r Un it P ower Wir ing (mm

Grou nd Wi r ing

Ou t door U nit

Indoor/Outdoor

Connecting

Wi rin g (mm

Power Wirin g

Strong Electric

3

Signal

)

Weak Electric

Signal

12-182430-3636-60

1-Phase 1-Phase 1-Phase 3-Phase

220-240v~

50 Hz

220-240v~

50 Hz

220-240v~

50 Hz

318-415v 3N~

50 Hz

20/16 30/25 35/30 40/30

3

)

3x2 .5 3x2.5 3x4.0 5x4 .0

2.5 2.5 4.0 4.0

---- 3x2.5 3x4.0 5x4.0

5x2 .5 3x1.5 3x1.5 3x1 .5

2x0.75 2x0.75 2x0.75 '----

Chart 2

Model (R-22, 60 Hz)

Cooling Only

Phase

Power

Circuit Breaker /F use (A )

Indoor Unit Power Wiring (mm

Indoor/Outdoor

Connecting

Wiring (mm

Frequency

Volts

Groun d Wir in g

Outdoor Un it

Power Wiring

Strong Electric

3

)

Signal

Weak E le ctr i c

Signal

3

)

Model (R - 22, 60 Hz )

Cool i ng & H eat in g

Phase

Power

Frequency

Volt

Circuit Breaker /F us e (A)

In doo r Un it P ower Wirin g (mm

Grou nd Wi r ing

Ou t door U nit

Indoor/Outdoor

Connecting

Wi rin g (mm

Power Wirin g

Strong Electric

3

Signal

)

Weak Electric

Signal

12-18 18 24 30-36 48-60

1-Phase 1-Phase 1-Phase 1-Phase 1-Phase

208-230v~

60 Hz

20/16 20/16 30/25 35/25 50/45

3x2.5 3x2.5 3x2.5 3x2.5 3x2.5

2.5 2.5 2.5 4.0 8.0

---- 3x2.5 3x2.5 3x4.0 3x8.0

3x2.5 ---- ---- --- - ----

---- 2x1.5 2x1.5 2x1.5 2x1.5

208-230v~

60 Hz

208-230v~

60 Hz

208-230v

60 Hz

Chart 3

12-182430-3636-60

1-Phase 1-Phase 1-Phase 3-Phase

208-230v~

60 Hz

208-230v~

60 Hz

208-230v~

60 Hz

20/16 30/25 35/30 50/45

3

)

3x2 .5 3x2 .5 3x2 .5 3x2 .5

2.5 2.5 4.0 4.0

3x2 .5 3x2 .5 3x4 .0 3x8 .0

--- --- --- ---

4x1 .5 4x1 .5 4x1 .5 4x1 .5

208-230v~

60 Hz

208-230v~

60 Hz

Chart 4

17

Page 18

WIRING DIAGRAMS

Power Supply

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

Switch/Fuse

(Available locally)

Power wiring

Power linking wiring

(Only for 24-60)

Indoor

Unit

Ground wiring

Power supply

Outdoor

Unit

CENTRAL CONTROL

MONITOR (CCM)

Strong elec-signal link wiring

COMPUTER

Switch/Fuse

(Available locally)

Power wiring

Power supply

Indoor

Unit

Ground wiring

Outdoor

Unit

CENTRAL CONT ROL

MONITOR (CCM)

COMPUTER

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

18

Page 19

WIRING DIAGRAMS

2-core cable

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

34

L

2

N

220-2405V~, 50Hz

3-core cable

5-core cable

MODEL: 12-18 (1 PHASE, 50 Hz)

Air conditioner Link-circuit

(For R-410A, Cooling/Heating)

MODEL: 12-18 (1PHASE, 50 Hz)

Air conditioner Link-circuit

(For R-22, Cooling/Heating)

234

N

L

2-core cable

220-2405V~, 50Hz

3-core cable

3-core cable

3-core cable

1

N

L

MODEL: 24 (1 PHASE, 50 Hz)

Air conditioner Link-circuit

(For R-410A, Cooling/Heating)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

19

Page 20

WIRING DIAGRAMS

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

2-core cable

220-240V~, 50Hz

3-core cable

3-core cable

3-core cable

L N 1 2 3

4

3

1

3-core cable

MODEL: 30-36 (1 PHASE, 50 Hz)

Air conditioner Link-circuit

(For R-410A, Cooling/Heating)

ABCN1234

5-core cable

5-core cable5-core cable

MODEL: 30-36 (3 PHASE, 50 Hz)

Air conditioner Link-circuit

(For R-410A, Cooling/Heating)

MODEL: 30-48 (3 PHASE, 50 Hz)

Air conditioner Link-circuit

(For R-22, Cooling/Heating)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

20

Page 21

WIRING DIAGRAMS

A

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

T4

T3

3-core cable

1 2 3 4

ABCN123 4

380-415V~,50Hz

5-core cable

MODEL: 48-60 (3 PHASE, 50 Hz)

A B C N

5-core cable

Air Conditioner Link-circuit

(For R410A, Cooling/Heating)

MODEL: 60 (3 PHASE, 50 Hz)

Air Conditioner Link-circuit

(For R422, Cooling/Heating)

220-240V~, 50Hz

3-core cable

MODEL: 24-36 (1PHASE, 50Hz)

ir Conditioner Link-circuit

(For R-22, Cooling/Heating)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

21

Page 22

WIRING DIAGRAMS

A

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

220-240V~, 50Hz

3-core cable

3-core cable

MODEL: 12 (1 PHASE, 50Hz)

ir Conditioner Link-circuit

(For R-22, Cooling Only)

220-240V~, 50Hz

3-core cable

3-core cable

MODEL: 18 (1 PHASE, 50Hz)

Air Conditioner Link-circuit

(For R-22, Cooling Only)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

22

Page 23

WIRING DIAGRAMS

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

220-240V~, 50Hz

3-core cable

3-core cable

1-core cable

MODEL: 24 (1 PHASE, 50Hz)

Air Conditioner Link-circuit

(For R-22, Cooling Only)

2-core cable

220-240V~, 50Hz

3-core cable

3-core cable

1-core cable

MODEL: 36 (1 PHASE, 50Hz)

Air Conditioner Link-circuit

(For R-22, Cooling Only)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

23

Page 24

WIRING DIAGRAMS

A

A

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

1-core cable

380-415V~, 50Hz

5-core cable

1-core cable

5-core cable

5-core cable

MODEL: 36-48 (3 PHASE, 50Hz)

ir Conditioner Link-circuit

(For R-22, Cooling Only)

380-415V~, 50Hz

5-core cable

MODEL: 60 (3 PHASE, 50Hz)

ir Conditioner Link-circuit

(For R-22, Cooling Only)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

24

Page 25

WIRING DIAGRAMS

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

208-230V~, 60Hz

3-core cable

4-core cable

MODEL: 18-24 (1 PHASE, 60Hz)

Air Conditioner Link-circuit

3-core cable

(For R-22, Cooling and Heating)

208-230V~, 60Hz

3-core cable

3-core cable

3-core cable

CN5

3

C

N

CN4

/

E

RROR

MODEL: 12-60 (1 PHASE, 60Hz)

Air Conditioner Link-circuit

CN1

CN2

Q

E

Y

P

X

.

(For R-22, Cooling)

E

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

25

Page 26

WIRING DIAGRAMS

2-core cable

2-core cable

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

208-230V~, 60Hz

208-230V~, 60Hz

3-core cable

3-core cable

MODEL: 18-60 (1 PHASE, 60Hz)

MODEL: 18-60 (1 PHASE, 60Hz)

Air Conditioner Link-circuit

3-core cable

3-core cable

Air Conditioner Link-circuit

(For R-22, Cooling Only)

(For R-22, Cooling Only)

208-230V~, 60Hz

3-core cable

4-core cable

MODEL: 36-48 (1 PHASE, 60Hz)

Air Conditioner Link-circuit

(For R-22, Cooling and Heating)

3-core cable

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

26

Page 27

WIRING DIAGRAMS

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INST ALLING THIS

UNIT . MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

208-230V~, 60Hz

3-core cable

4-core cable

MODEL: 60 (1 PHASE 60Hz)

Air Conditioner Link-circuit

3-core cable

(For R-22, Cooling and Heating)

Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring.

27

Page 28

Due to our commitment to continuing improvement, design and specifications are subject to change without prior notice.

© 2011 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

28

Loading...

Loading...