Goodman AC 18, AC 24, AC 36, AC 30 Installation & Operating Instructions Manual

INSTALLATION

FOR CANADA

& OPERATING

INSTRUCTIONS

CEILING MOUNT AIR HANDLER

IO-162C 2550 North Loop West Suite 400 AC SERIES 4/02

AC SERIES

CERTIFIED

Made in the USA by:

Goodman Manufacturing Company, L.P.

Houston, Texas 77092

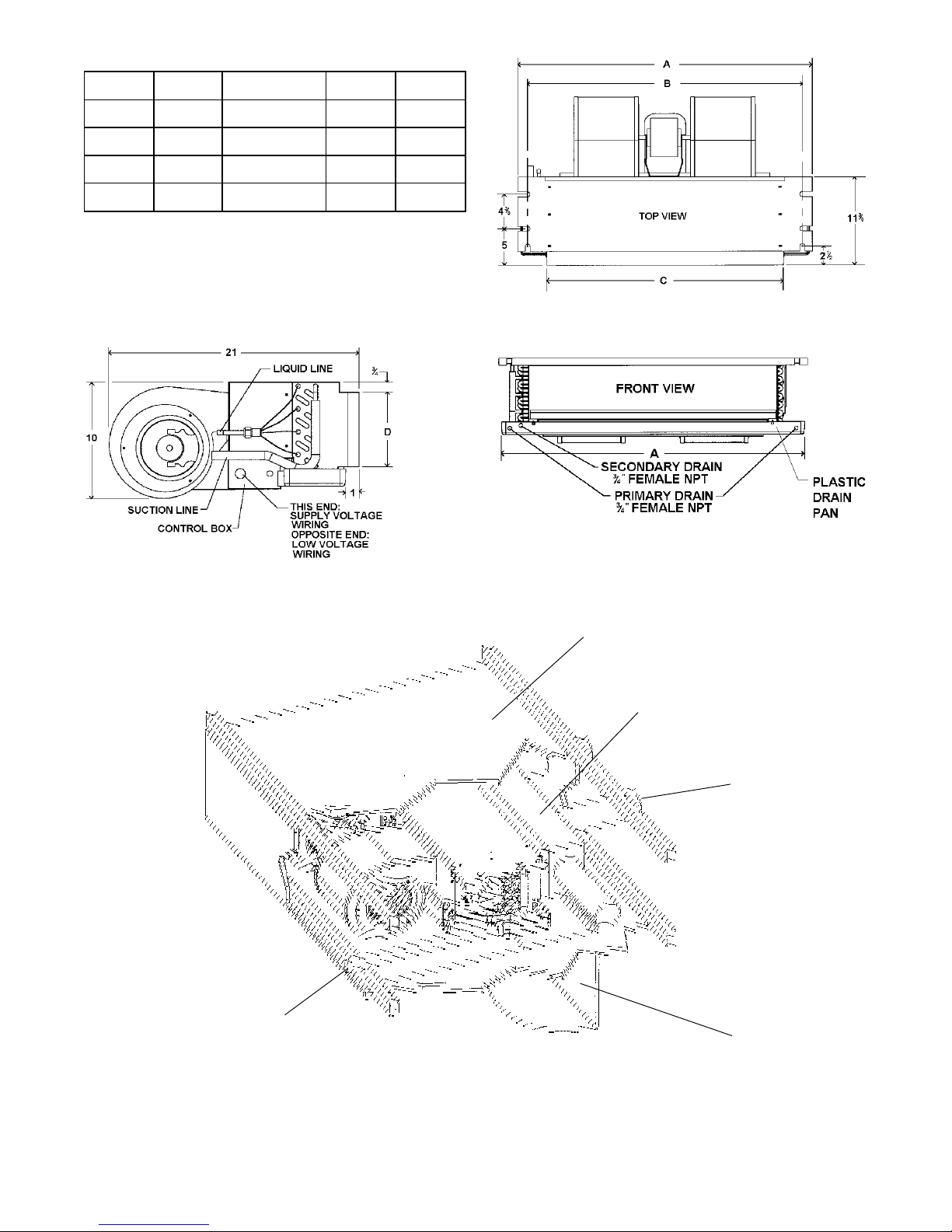

Dimensions

Model A B C D

AC 18 37 1/4 37 11/16 30 6 1/2

AC 24 37 1/4 37 11/16 30 6 1/2

AC 30 43 1/4 40 11/16 36 6 1/2

AC 36 49 1/4 46 11/16 42 6 1/2

ELECT. HEATER

LOCATION

AC 18, 24, 30, 36

FIGURE 1

LAYOUT FOR

To Drain

Drop Ceiling

Plenum

Outlet Duct

Grill For Return Air

And Service

FIGURE 2

DROP CEILING

INSTALLATION

2

SPECIAL INSTRUCTIONS

This indoor coil contains the flowrator distributor assembly, which consist of a flare nut, distributor body, copper tubes

feeding the coil, and the internal flow check piston. Reference the enclosed “Piston Sizing Chart” for mix-matching of

outdoor / indoor units.

CHANGE THE PISTON

This coil is furnished with a flow control piston installed that matches the BTUH capacity of the coil. A piston size that is

too small will cause starving and one that is too large will cause flooding. The following chart indicates the condensing

unit capacity and the recommended piston size.

CONDENSING UNIT

MODEL NOM. COOLING (BTUH) PART NO. PISTON SIZE

AC18 18,000 BT 13690-04 52

AC24 24,000 BT 13690-01 59

AC30 30,000 BT 13690-05 65

AC36 36,000 BT 13690-06 71

1. Using a back-up wrench on the flare fitting, remove the

3/8" flare nut.

2. Using the back-up wrench on the distributor body,

6. Replace 3/8" flare fitting with Teflon seal using back-up

remove the 3/8" flare fitting and Teflon seal.

3. Using the wire provided with replacement pistons, run

wire (hooked end) through hole in piston.

7. Replace 3/8" flare nut using back-up wrench on flare

4. Hook nose end of piston and lift gently from distributor

body.

8. Remove old piston size label from outside of distributor

5. Replace piston with one of proper size listed above,

install piston with Teflon seal end of piston in distributor

first. Do not force piston into distributor.

9. Check fitting for leaks after installation, evacuation and

NOTE: With piston in distributor, seal end should be

shown and should not be seen looking in end of

distributor. Piston must be free to rotate and move up

If a combination is used that requires

a piston size change, change the

piston in the distributor on the indoor

coil before installing the coil and

follow the procedure shown below.

and down. Make sure piston is free to move in distributor

body.

wrench on distributor body. Torque fitting with 8 to 10 ft.

lb. Do not over tighten.

fitting. Torque 3/8" flare nut with 40 to 45 ft. lb.

body. Remove new piston size label from poly bag new

piston came in and install new size label on outside of

distributor.

charging of the low side is complete.

INTRODUCTION

WARNING: DO NOT CONNECT TO OR USE IN CONJUNCTION WITH THIS UNIT ANY DEVICES FOR THE PURPOSE OF SAVING

ENERGY OR INCREASING OPERATING EFFICIENCIES, WHICH HAVE NOT BEEN TESTED AND APPROVED BY GOODMAN

OR DESIGN CERTIFIED FOR USE WITH THIS UNIT. SERIOUS DAMAGE, REDUCED UNIT PERFORMANCE AND HAZARDOUS

CONDITIONS MAY RESULT FROM THE USE OF DEVICES WHICH HAVE NOT BEEN APPROVED OR CERTIFIED BY

GOODMAN.

This booklet contains the installation and operating instructions

for your ceiling mount air handler. There are a few precautions

that should be taken to derive maximum satisfaction from it.

Improper installation can result in unsatisfactory operation or

dangerous conditions and void the warranty. Read this booklet

and any instructions packaged with accessories prior to

installation. Give this booklet to the user and explain its

provisions. The user should retain this booklet for future

reference.

CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment.

Claims for damage, either shipping or concealed, should be

filed immediately with the shipping company. Check the unit

model number, specifications, electrical characteristics,

and accessories to determine if they are correct.

ORDERING PARTS

When reporting shortages or damages, or ordering repair parts,

give the complete unit model and serial numbers as stamped

on the unit’s nameplate. Order parts through your local

contractor.

3

Loading...

Loading...