Page 1

INSTALLATION

FOR CANADA

& OPERATING

INSTRUCTIONS

CEILING MOUNT AIR HANDLER

IO-162C 2550 North Loop West Suite 400 AC SERIES 4/02

AC SERIES

CERTIFIED

Made in the USA by:

Goodman Manufacturing Company, L.P.

Houston, Texas 77092

Page 2

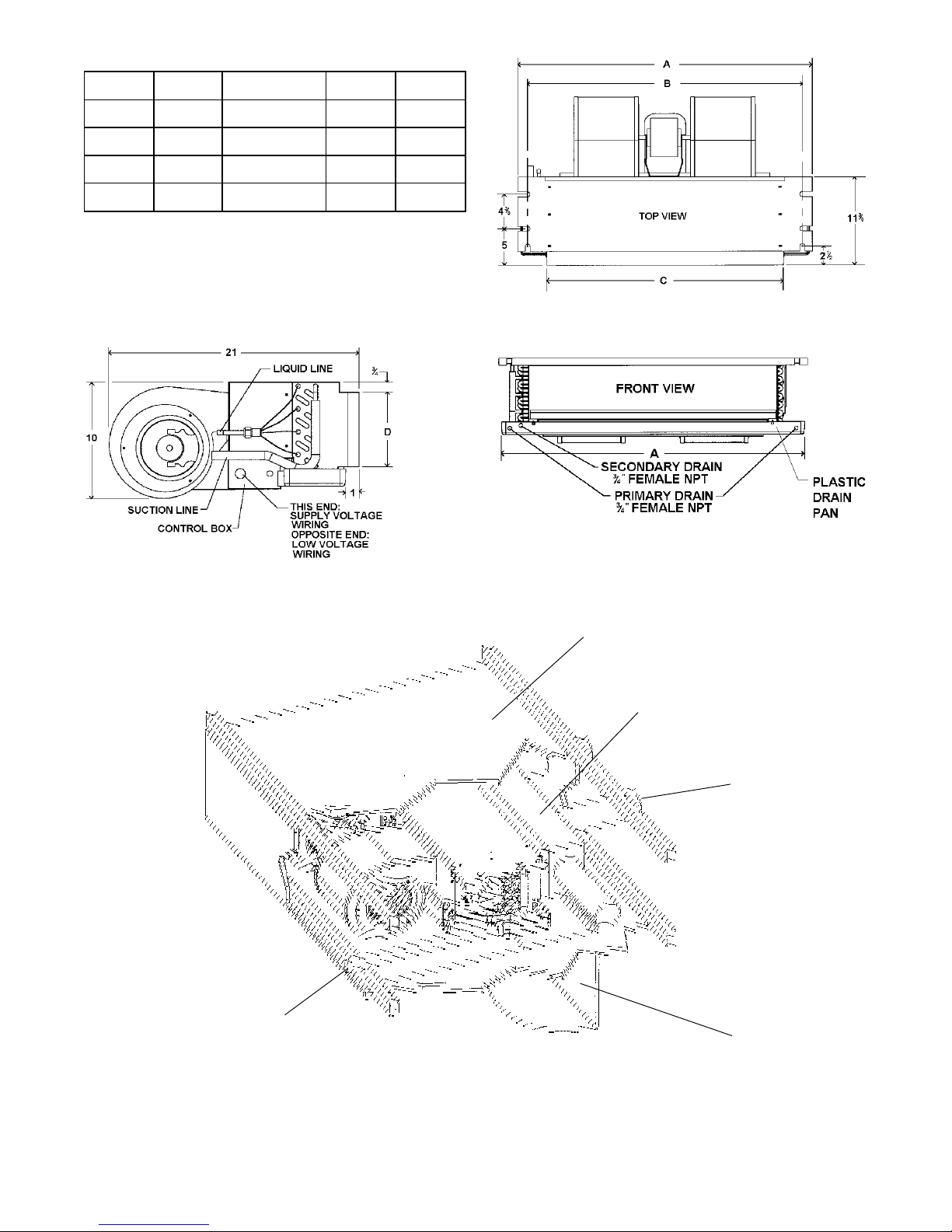

Dimensions

Model A B C D

AC 18 37 1/4 37 11/16 30 6 1/2

AC 24 37 1/4 37 11/16 30 6 1/2

AC 30 43 1/4 40 11/16 36 6 1/2

AC 36 49 1/4 46 11/16 42 6 1/2

ELECT. HEATER

LOCATION

AC 18, 24, 30, 36

FIGURE 1

LAYOUT FOR

To Drain

Drop Ceiling

Plenum

Outlet Duct

Grill For Return Air

And Service

FIGURE 2

DROP CEILING

INSTALLATION

2

Page 3

SPECIAL INSTRUCTIONS

This indoor coil contains the flowrator distributor assembly, which consist of a flare nut, distributor body, copper tubes

feeding the coil, and the internal flow check piston. Reference the enclosed “Piston Sizing Chart” for mix-matching of

outdoor / indoor units.

CHANGE THE PISTON

This coil is furnished with a flow control piston installed that matches the BTUH capacity of the coil. A piston size that is

too small will cause starving and one that is too large will cause flooding. The following chart indicates the condensing

unit capacity and the recommended piston size.

CONDENSING UNIT

MODEL NOM. COOLING (BTUH) PART NO. PISTON SIZE

AC18 18,000 BT 13690-04 52

AC24 24,000 BT 13690-01 59

AC30 30,000 BT 13690-05 65

AC36 36,000 BT 13690-06 71

1. Using a back-up wrench on the flare fitting, remove the

3/8" flare nut.

2. Using the back-up wrench on the distributor body,

6. Replace 3/8" flare fitting with Teflon seal using back-up

remove the 3/8" flare fitting and Teflon seal.

3. Using the wire provided with replacement pistons, run

wire (hooked end) through hole in piston.

7. Replace 3/8" flare nut using back-up wrench on flare

4. Hook nose end of piston and lift gently from distributor

body.

8. Remove old piston size label from outside of distributor

5. Replace piston with one of proper size listed above,

install piston with Teflon seal end of piston in distributor

first. Do not force piston into distributor.

9. Check fitting for leaks after installation, evacuation and

NOTE: With piston in distributor, seal end should be

shown and should not be seen looking in end of

distributor. Piston must be free to rotate and move up

If a combination is used that requires

a piston size change, change the

piston in the distributor on the indoor

coil before installing the coil and

follow the procedure shown below.

and down. Make sure piston is free to move in distributor

body.

wrench on distributor body. Torque fitting with 8 to 10 ft.

lb. Do not over tighten.

fitting. Torque 3/8" flare nut with 40 to 45 ft. lb.

body. Remove new piston size label from poly bag new

piston came in and install new size label on outside of

distributor.

charging of the low side is complete.

INTRODUCTION

WARNING: DO NOT CONNECT TO OR USE IN CONJUNCTION WITH THIS UNIT ANY DEVICES FOR THE PURPOSE OF SAVING

ENERGY OR INCREASING OPERATING EFFICIENCIES, WHICH HAVE NOT BEEN TESTED AND APPROVED BY GOODMAN

OR DESIGN CERTIFIED FOR USE WITH THIS UNIT. SERIOUS DAMAGE, REDUCED UNIT PERFORMANCE AND HAZARDOUS

CONDITIONS MAY RESULT FROM THE USE OF DEVICES WHICH HAVE NOT BEEN APPROVED OR CERTIFIED BY

GOODMAN.

This booklet contains the installation and operating instructions

for your ceiling mount air handler. There are a few precautions

that should be taken to derive maximum satisfaction from it.

Improper installation can result in unsatisfactory operation or

dangerous conditions and void the warranty. Read this booklet

and any instructions packaged with accessories prior to

installation. Give this booklet to the user and explain its

provisions. The user should retain this booklet for future

reference.

CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment.

Claims for damage, either shipping or concealed, should be

filed immediately with the shipping company. Check the unit

model number, specifications, electrical characteristics,

and accessories to determine if they are correct.

ORDERING PARTS

When reporting shortages or damages, or ordering repair parts,

give the complete unit model and serial numbers as stamped

on the unit’s nameplate. Order parts through your local

contractor.

3

Page 4

I. SPECIFICATIONS

A. GENERAL

These Ceiling mount air handlers are available in

cooling capacities of 1.5, 2, 2.5 and 3 nominal tons of

cooling. Electric heat models are available in capacities of 5, 8 and 10 KW.

B. INSTALLATION

1. Before locating the unit on the dropped ceiling, make

sure that the strength of the ceiling and beams is

adequate at the point to support the weight involved.

This is very important and installers responsibility. The

following list shows approximate weight of unit.

The units are designed to be installed in a horizontal

position above a dropped ceiling. Units are not to be

installed outside the structure. These models are

designed for INDOOR USE ONLY.

The information on the rating plate is in compliance with

the FTC and DOE rating for single phase units in the

U.S.A..

IMPORTANT: The United States Environmental

Protection Agency (EPA) has issued various regulations regarding the introduction and disposal of

refrigerants in this unit. Failure to follow these

regulations may harm the environment and can

lead to the imposition of substantial fines. Because these regulations may vary due to the

passage of new laws we suggest that any work on

this unit be done by a certified technician. Should

you have any questions please contact the local

office of the EPA.

B. MAJOR COMPONENTS

The unit includes a evaporator coil with flowrator assembly, an indoor blower and all necessary internal

electrical wiring. The cooling system of these units is

factory-evacuated, charged and performance tested.

Refrigerant amount and type are indicated on rating

plate.

MODEL WEIGHT (lb.)

AC18 59

AC24 59

AC30 69

AC36 79

2. The unit should be mounded on a horizontal position

above a dropped ceiling of adequate strength (see

Figure 2)

3. The location of the unit should provide proper access for

inspection and servicing.

C. DUCTING

Duct work should be fabricated by the installing contractor in accordance with local codes. Industry manuals may be used as a guide when sizing and designing

the duct system - such as NESCA (National Environmental Systems Contractors Association, 1501 Wilson Blvd., Arlington, Virginia 22209).

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT DUCT WORK TO ANY OTHER HEAT PRODUCING DEVICE SUCH AS FIREPLACE INSERT, STOVE,

ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY

RESULT IN FIRE, CARBON MONOXIDE POISONING,

EXPLOSION, PERSONAL INJURY OR PROPERTY

DAMAGE.

II. INSTALLATION

A. GENERAL

1a. INSTALLATION — This product is designed and

manufactured to permit installation in accordance

with National Codes. It is the installer’s responsibility to install the product in accordance with

National Codes and/or prevailing local codes and

regulations.

1b. PRE-INSTALLATION CHECK-POINTS — Before at-

tempting any installation, the following points

should be considered:

Structural strength of supporting members

Clearances and provision for servicing

Power supply and wiring

Air duct connections

Drain facilities and connections

2b. LOCATION - These units are designed to be in-

stalled in a horizontal position above a dropped

ceiling. The location of the unit should be based

on thorough consideration of the PRE-INSTALLATION CHECK POINTS.

This unit should be placed as close to the space to be

air conditioned as possible. Adequate clearance must

be maintained as indicated in Section F “Clearances”.

Ducts should be run as directly as possible to supply

and return outlets. Use of non-flammable weatherproof

flexible connectors on both supply and return connections at unit to reduce noise transmission is recommended.

D. FILTERS

Filters are not provided with unit, and must be supplied

and installed in the return air system by the installer. A

field installed filter grille is recommended for easy and

convenient access to the filters, for periodic inspection

and cleaning. Filters must have adequate face area for

the rated air quantity of the unit. The minimum filter size

is 20" x 20" x 1".

E. CLEARANCES

These units are U.L. listed for installations with zero

clearance to combustible materials, reference should

be made to the marking on the particular unit being

installed where specific information regarding clearances is provided. Access must be provided for servic-

4

Page 5

ing the unit. If these units are installed in a removable

200

SUPPLY WIRE

150

TW (60C)

100

50

BRANCH CIRCUIT AMPACITY

ceiling panel, ample space must be provided for servicing the unit.

III. PIPING

CONDENSATE DRAIN

FIGURE 3

The condensate drain connection of the evaporator is a half

coupling of 3/4" N.P.T. A trap must be provided to have

proper condensate drainage. See Figure 3.

IV.ELECTRICAL WIRING

GENERAL

All wiring should be made in accordance with the

National Electrical Code in the U.S.A. Determine the

availability of sufficient power to operate the unit. The

voltage at the power supply should be checked to make

sure it corresponds to the unit’s RATED VOLTAGE

REQUIREMENT. Wire sizes should be determined

from the unit nameplate ampacity and in accordance

with Table 1, the National Electrical Code. Under no

circumstances should wiring be sized smaller than is

recommended by either of these two sources.

The unit must be permanently grounded in accordance

with local codes, or in the absence of local codes, with

the N.E.C. ANSI/NFPA NO. 70-1987 or latest edition in

the U.S.A. To wire units, make the following high and

low voltage connections at either location.

1. High Voltage Wiring:

These units are designed for Single phase 208/230 Volt

only, two leads should be connected to terminals L1

and L2 on the breaker in the electrical control section,

using wire sizes specified in table 1.

Install condensate drain trap as shown. Use 3/4" drain

connection size or larger. Do not operate without trap.

Unit must be level or slightly inclined toward drain.

TABLE 1

BRANCH CIRCUIT COPPER WIRE SIZE

(Base on 1% Voltage Drop)

6 4 4 4 3 3 2 2

8 6 6 4 4 4 3 3

10 8 8 6 6 6 4 4

LENGTH - FEET 75

12 10 8 8 6 6 4 4

14 12 18 10 8 8 6 6

15 20 25 30 35 40 45 50

NOTE: (Wiring for unit only, no heat kit installed)

a. Wire size based on 60°C rated wire insulation and 30°C

Ambient Temp. (86°F).

b. For branch circuit wiring (main power supply to unit

disconnect), the minimum wire size for the length of run

can be determined from Table 2 using the circuit

ampacity found on the unit rating plate. From the unit

disconnect to unit, the smallest wire size allowable in

Table 2 may be used, as the disconnect must be in

sight of the unit.

c. For more than 3 conductors in a raceway or cable, see

the N.E.C. for derating the ampacity of each conductor.

2. Low Voltage Wiring: See Figure 4 for cooling unit

with electric heat, Figure 5 for heat pump with

electric heat.

Connect 24V. wires from the thermostat to the corresponding wires in control box using No. 18 AWG as

follows:

LEAD THERMOSTAT NOTES

PINK R (24V) -

GREEN G (FAN) -

- Y TO CONDENSING UNIT 24V

CONNECTIONS

WHITE W -

BLUE - TO CONDENSING UNIT 24V

CONNECTIONS

BROWN E TO BE USED FOR

EMERGENCY HEAT ONLY

5

Page 6

3. Internal Wiring

A diagram of the internal wiring of this unit is located

under the electrical box cover. If any of the original wire

as supplied with the appliance must be replaced, the

wire gauge and insulation must be same as original

wiring.

4. Transformer is factory wired for 230 volts on 208/ 230 volt

models. See wiring diagram for 208 volt wiring. For 208V

operation, move the white transformer lead from 240V to

208V tap.

BLUE

YELLOW

Figure 4

R Y G W

THERMOSTAT

24 V CONNECTIONS

TO CONDENSING UNIT

MODEL

AC18, 24, 30, 36 2

THERMOSTAT HEAT

ANTICIPATOR SETTING

MAINTENANCE

1) Room Thermostat - This is the device that controls the

operation of your heating and/or cooling unit. It senses

the indoor temperature and signals the equipment to

start or stop maintaining the temperature you have

selected for your comfort. The room thermostat should

be in a central, draft free inside wall location for best

operation. Do not place any heat producing apparatus

such as lights, radio, etc., near the thermostat as this

will cause erratic operation of the comfort system.

2) Air Filter(s) - All central air moving comfort systems

must include air filter(s). These filters will be located

either in the equipment or in the return air duct system

upstream of the equipment. The filter(s) removes dust

and debris from the air thus helping to keep your

conditioned space clean. More important, the filter

keeps dust and debris from collecting on heat transfer

surfaces thus maintaining optimum equipment efficiency and performance. Inspect and clean or replace

filters every month. This routine maintenance procedure

will pay big dividends in reduced operating cost and

reduced service expense. Never operate comfort equipment without filter(s).

Figure 5

Electrical Installation Diagram For Cooling

Electrical Installation Diagram For Heat pump

unit with Electric Heat.

With Electric Heat.

NOTE: In case of heat pump failure, switch to

“E” on T’stat for emergency heat.

3) Fuses and/or Circuit breakers - This comfort equipment should be connected to the building electric

service in accordance with local and National Electric

codes. This electrical connection will include over

current protection in the form of fuses or circuit breakers. Have your contractor identify the circuits and the

location of over current protection so that you may be in

a position to make inspections or replacements in the

event the equipment fails to operate. Keep replacement

fuses of the proper size on hand.

6

Page 7

WARNING

a. Dirty condenser coil

a. Clean coil

b. Correct system charge

a. Incorrect capillary tube

a. Replace evaporator assembly

a. Power off or loose electrical connection

b. Thermostat cut off calibration set too high

c. Defective contactor

d. Blown fuses or tripped breaker

e. Tansformer defective

f. High or low pressure control open (Optional)

a. Check for unit voltage at contactor in unit

b. Reset

contacts are open

d. Replace fuse or reset breaker

e. Check wiring-replace transformer

f. Reset high pressure control or check unit charge

High pressure control opens at 425psi

Low pressure control opens at 25psi

g. Replace compressor

a. Loose connection

winding/open internal overload

tighten all connections

open, replace the compressor

10% of nameplate voltage when unit is operating

a. Defective overload protector

a. Check for correct voltage/replace overload

replace air filters

a. Excessive load

a. Recheck load calculation

a. Improperly sized unit

b. Improper airflow

c. Incorrect refrigerant charge

a. Recalculate load

b. Check (should be approximately 400 cfm/ton)

c. Charge per unit service panel

a. Low airflow

b. Low refrigerant charge

dirty air filters, all duct outlets open

b. Properly charge unit

open below 65 degrees F outdoor temperature

a) Do not store combustible materials or use gasoline or other flammable liquids or vapors in the vicinity of

this appliance so as to prevent the risk of property damage or personal injury.

b) Have your contractor point out and identify the various cut-off devices, switches, etc., that serve your

comfort equipment. There is a switch that will cut off energy to your heating system. Know where they are

so that you may cut off the flow of energy in the event of overheating.

4) Periodic Checkup and Service - This product is designed to provide many years of dependable, trouble-free comfort

when properly maintained. Proper maintenance will consist of annual checkups and cleaning of the internal electrical

and heat transfer components by a qualified service technician. Failure to provide periodic checkup and cleaning can

result in excessive operating cost and/or equipment malfunction.

TROUBLESHOOTING CHART

WARNING: DISCONNECT ALL POWER TO UNIT BEFORE SERVICING

SYMPTOM POSSIBLE CAUSE REMEDY

High head-low suction a. Restriction in liquid line or capillary tube a. Remove or replace defective component

High head-high or normal

suction

Low head-high suction

Unit will not run

b. Overcharged

c.Condenser fan not running

b. Defective compressor valves

c. repair or replace

b. Replace compressor

c. Check for 24 volts at contactor coil replace if

g. Compressor overload contacts open

NOTE: Wait at least 2 hours for overload to reset

Condenser fan runs,

compressor does not

Low suction-cool

compressor

Compressor short cycles

Registers sweat a. Low airflow a. Increase speed of blower or reduce restriction-

High suction pressure

Insufficient cooling

Evaporator coil freezing or

frosting

b. Compressor stuck, grounded or open

c. Low voltage connection

a. Low indoor airflow a. Increase speed of blower or reduce restriction-

b. Unit cycling on low pressure control

b. Deffective compressor

d. Incorrect voltage

c. Operating unit in cooling mode below 65

degrees F outdoor temperature

a. Check for unit voltage at compressor check and

b. Wait at least 2 hours for overload to reset if still

c. At compressor terminals, voltage must be within

replace air filters

b. Check refrigerant charge and airflow

b. Replace

d. At compressor terminals, voltage must be within

10% of nameplate voltage when unit is operating

a. Check (should be approximately 400 cfm/ton),

c. Install or check low ambient control, should be

7

Loading...

Loading...