Goodman 0170K00000S Installation Manual

DIRECT VENT FURNACE

SIDE W ALL VENT K I T (0170K00000S)

INSTALLATION INSTRUCTIONS

WARNING

T

HIS VENT KIT IS ONLY TO BE USED FOR VENTING CATEGORY

(CONDENSING) FURNACES. DO NOT USE THIS KIT TO VENT CATEGORY I,

, OR

FURNACES. DO NOT APPLY TO NON-CONDENSING FURNACES.

II

III

D

O NOT USE FOR ROOF TOP VENTING. USE THIS KIT FOR SIDE WALL

VENTING ONLY.

FIRE, PERSONAL INJURY OR DEATH.

AILURE TO FOLLOW THIS WARNING COULD RESULT IN

F

IV

Description

This vent kit is to be used with 2” or 3” vent systems. The vent kit

must terminate outside the structure and may be installed with the

intake and exhaust pipes located side-by side or with one pipe above

the other. This kit is NOT intended for use with single pipe (indirect

vent) installations.

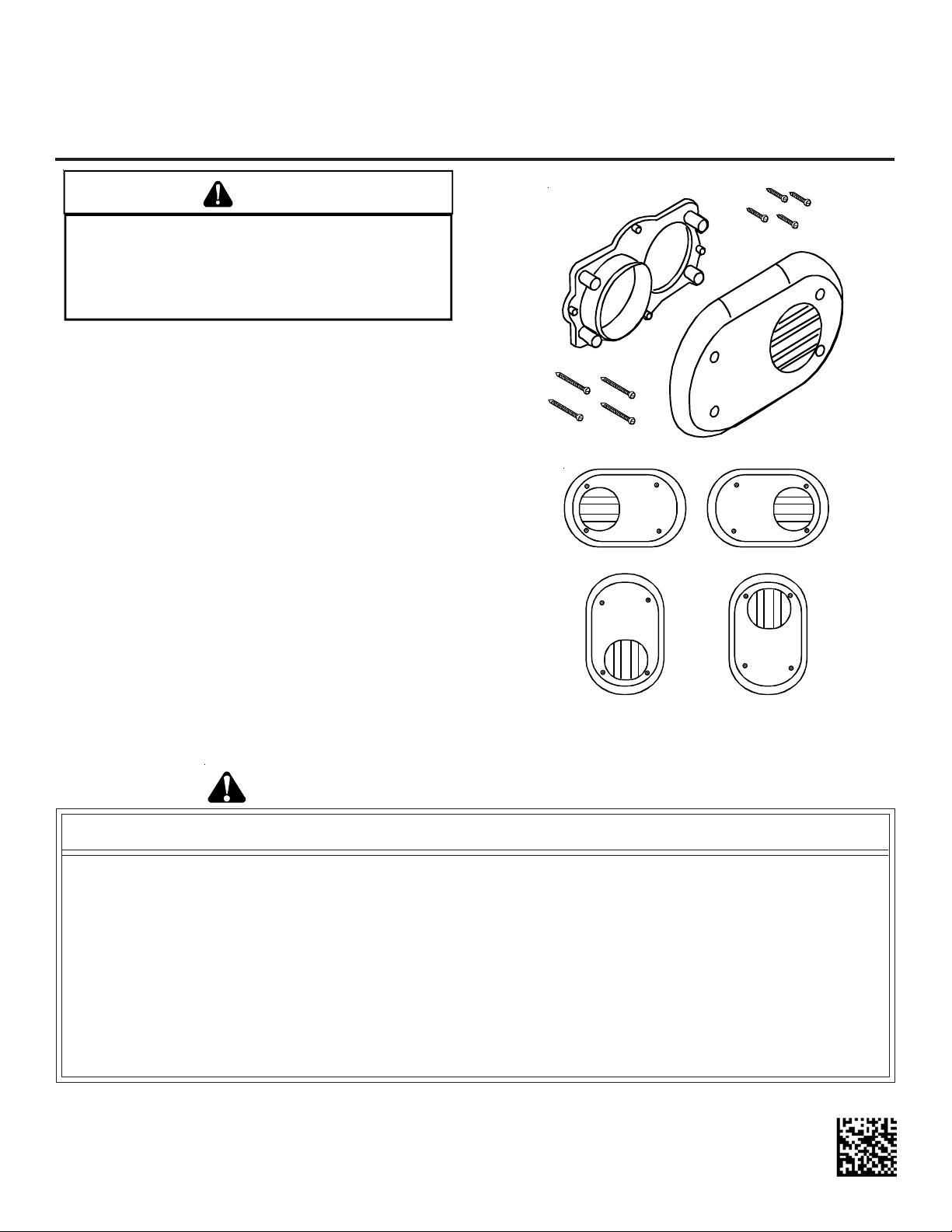

Contents

• Vent Terminal Base

• Vent T erminal Cap

• Four (4) 1” long stainless screws

• Four (4) 2” long stainless screws

• Instruction Sheet

Field-supplied pipe and fittings are required in order to complete the

installation. All combustion air and vent piping must conform to American National Standards Institute (ANSI) S tandards and American Society for T esting and Materials (ASTM) S tandards D1785 (Schedule

40 PVC), D2665 (PVC-DWV), F891 (PVC-DMV Cellular Core), D2241

(SDR-21 and SDR-26 PVC), D2261 (ABS-DWV), or F628 (Schedule 40 ABS). Pipe cement and primer must conform to ASTM S tandards D2564 (PVC) or D2235 (ABS).

Horizontal Installation

V e rtic a l In s ta llation

NOTE: If these instructions differ from those included with your furnace, follow these instructions.

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the product better than the customer.

This includes all safety precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with this Instruction Manual. Pay special attention to all safety warnings.

Often during installation or repair it is possible to place yourself in a position which is more hazardous than when the unit is in operation.

Remember, it is your responsibility to install the product safely and to know it well enough

to be able to instruct a customer in its safe use.

Safety is a matter of common sense...a matter of thinking before acting.

Most dealers have a list of specific good safety practices...follow them.

The precautions listed in this Installation Manual are intended as supplemental to existing practices. However , if there is a direct conflict

between existing practices and the content of this manual, the precautions listed here take precedence.

I0-635A

September 2013

Installation

®

WARNING

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK,

T

DISCONNECT THE ELECTRICAL POWER SUPPLY TO THE FURNACE BEFORE

INSTALLING THIS KIT OR PERFORMING ANY SERVICE.

WARNING

HIS KIT MUST BE INSTALLED IN STRICT COMPLIANCE WITH THESE

T

INSTALLATION INSTRUCTIONS AND ANY APPLICABLE LOCAL, STATE, AND

NATIONAL CODES.

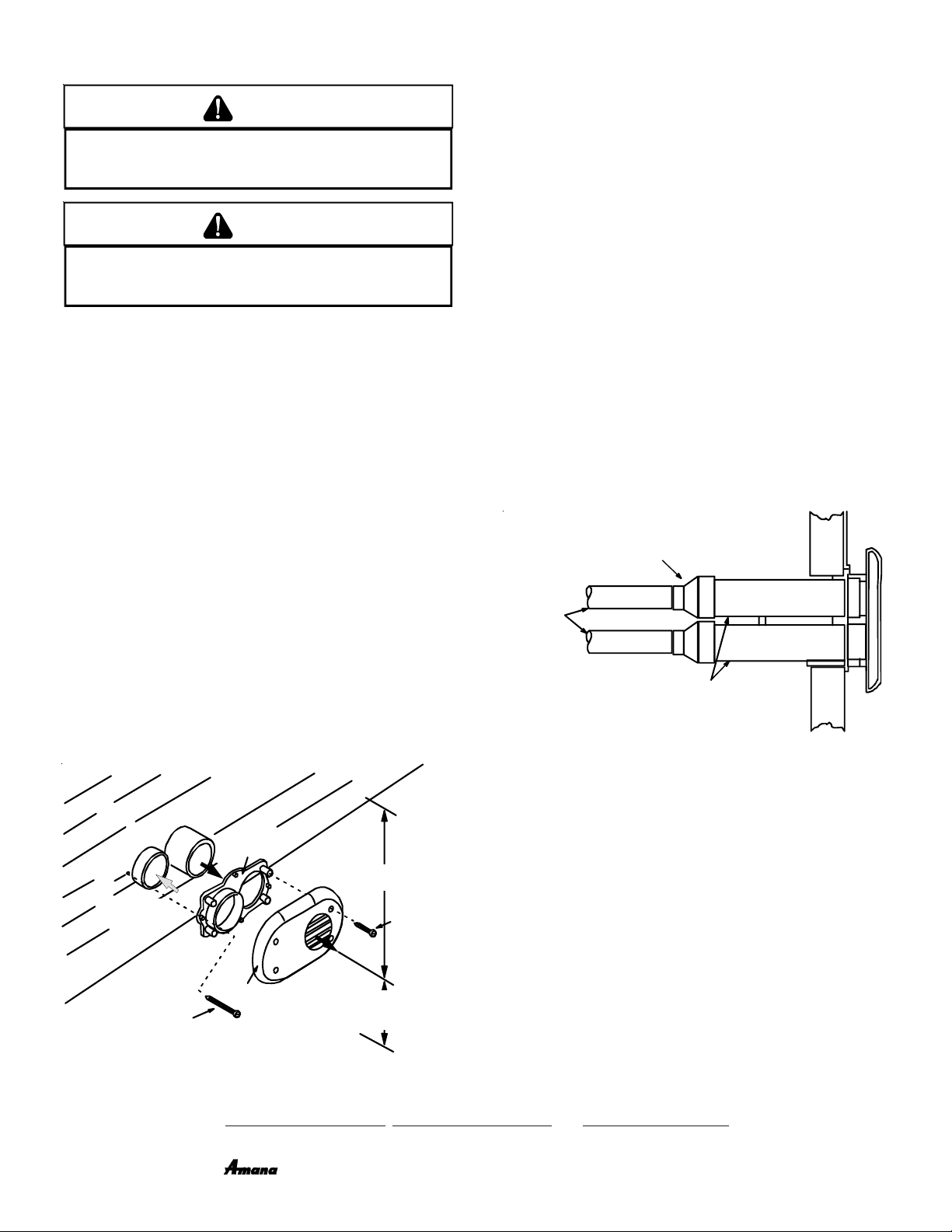

5. Insert the four plastic screw anchors into the screw holes and

mount the vent terminal base to the wall using the four 2” long

screws provided.

6. Assemble the vent terminal cap to the vent terminal base, using

four 1” long screws provided.

7. Install 3” diameter vent and air intake pipes into the back side of

the openings in the vent terminal base.

8. Seal all gaps between the pipes and wall.

9. Using RTV silicone sealant, seal the vent pipe to the vent cap.

This will allow the terminal to be disassembled later if necessary

for cleaning. DO NOT use PVC solvent cement to seal this connection.

1. Determine the best location for the vent terminal. In addition to

all applicable codes, consider the following when determining

the location:

a. The vent terminal should be located so as to minimize the

total length and number of elbows in the piping. Consult the

furnace installation instructions for the pipe lengths and number of elbows allowed.

b. T erminal should be positioned where vent vapors will not dam-

age plants, shrubs, air conditioning equipment or building materials.

c. Terminal should be located where it will not be affected by

wind gusts, snow, airborne leaves or other debris, and where

it will not allow recirculation of flue gases.

d. Terminal should be located where it will not be damaged or

exposed to foreign objects such as stones, balls, etc.

e. T erminal should be located where vent vapors are not objec-

tionable.

2. Using the vent terminal base as a template, locate the pipe holes

and the four mounting screw holes on the wall.

3. Cut two 3 7/8” diameter holes for the vent and intake pipes.

4. Drill four 3/16” diameter holes for inserting the plastic screw anchors into the wall.

NOTE: T o downsize the piping to 2” diameter, use a field-supplied

reducing coupling.

10. Operate the furnace for 15 minutes to ensure that it is working

properly and that all piping joints are sealed to prevent the escape of combustion products into the home.

1 1. For installations where two or more furnaces are to be vented

using this kit, ensure a minimum clearance of 1” between the

vent terminal caps. To prevent condensate freezing problems,

do not install multiple vent kits above one another .

Field-Supplied

Reducing Couplings,

if required

2" or 3" Pipe

Seal all holes thr ough

wall with sealant

3" Pip e

Vent

Base

Minimum 12"

to overh ang

Combustion

Air

2" Screw s x 4

Vent Cap

Vent

Minimum 12" clearance

above highest snow

level or grade

1" Screws x 4

Goodman Manufacturing Company , L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.daikincomfort.com, www.goodmanmfg.com and www.amana-hac.com

© 2005, 2013 Goodman Manufacturing Company , L.P.

is a trademark of Maytag Corporation and is used under license. All rights reserved.

Loading...

Loading...