Gold Medal 2620DT, 2630DT, 2631DT, 2621DT, 2631D User Manual

...

Karmel King

- Digital

Instruction Manual

Model No. 2620D, 2621D, 2630D, 2631D

2620DT, 2621DT, 2630DT, 2631DT

10700 Medallion Drive, Cincinnati, Ohio 45241-4807 USA

© 2017 Gold Medal Products Co.

Part No. 110023

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

DANGER

DANGER

WARNING

WARNING

WARNING

WARNING

Digital 2620DT, 2621DT, 2630DT, 2631DT

SAFETY PRECAUTIONS

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury, or death. Any alterations to this equipment

will void the warranty and may cause a dangerous condition. This appliance

is not intended to be operated by means of an external timer or separate

remote-control system. NEVER make alterations to this equipment. Read the

Installation, Operating, and Maintenance Instructions thoroughly before

installing, servicing, or operating this equipment.

008_051514

014_020416

To avoid burns, DO NOT touch the kettle or any heated surface.

DO NOT place or leave objects in contact with heated surfaces.

013_092414

ALWAYS wear safety glasses when servicing this equipment.

010_010914

No user serviceable parts inside. Refer servicing to qualified service

personnel.

011_051514

Read and understand operator’s manual and all other safety instructions

before using this equipment. To order copies of the operator’s manual go to

gmpopcorn.com or write to Gold Medal Products Co., 10700 Medallion Drive,

Cincinnati, OH 45241 USA 1-(800)-543-0862

022_060215

Page 2

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

WARNING

WARNING

Digital 2620DT, 2621DT, 2630DT, 2631DT

SAFETY PRECAUTIONS (continued)

DO NOT allow direct contact of this equipment by the public when used in

food service locations. Only personnel trained and experienced in the

equipment operation may operate this equipment.

Carefully read all instructions before operation.

This machine is NOT to be operated by minors.

Note: Improvements are always being made to Gold Medal’s equipment. This information

may not be the latest available for your purposes. It is critical that you call Gold Medal’s

Technical Service Department at 1-800-543-0862 for any questions about your

machine operations, replacement parts, or any service questions. (Gold Medal

Products Co. does not assume any liability for injury due to careless handling and/or

reckless operation of this equipment.) General images may be used in manual for

reference only.

012_010914

007_010914

Page 3

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

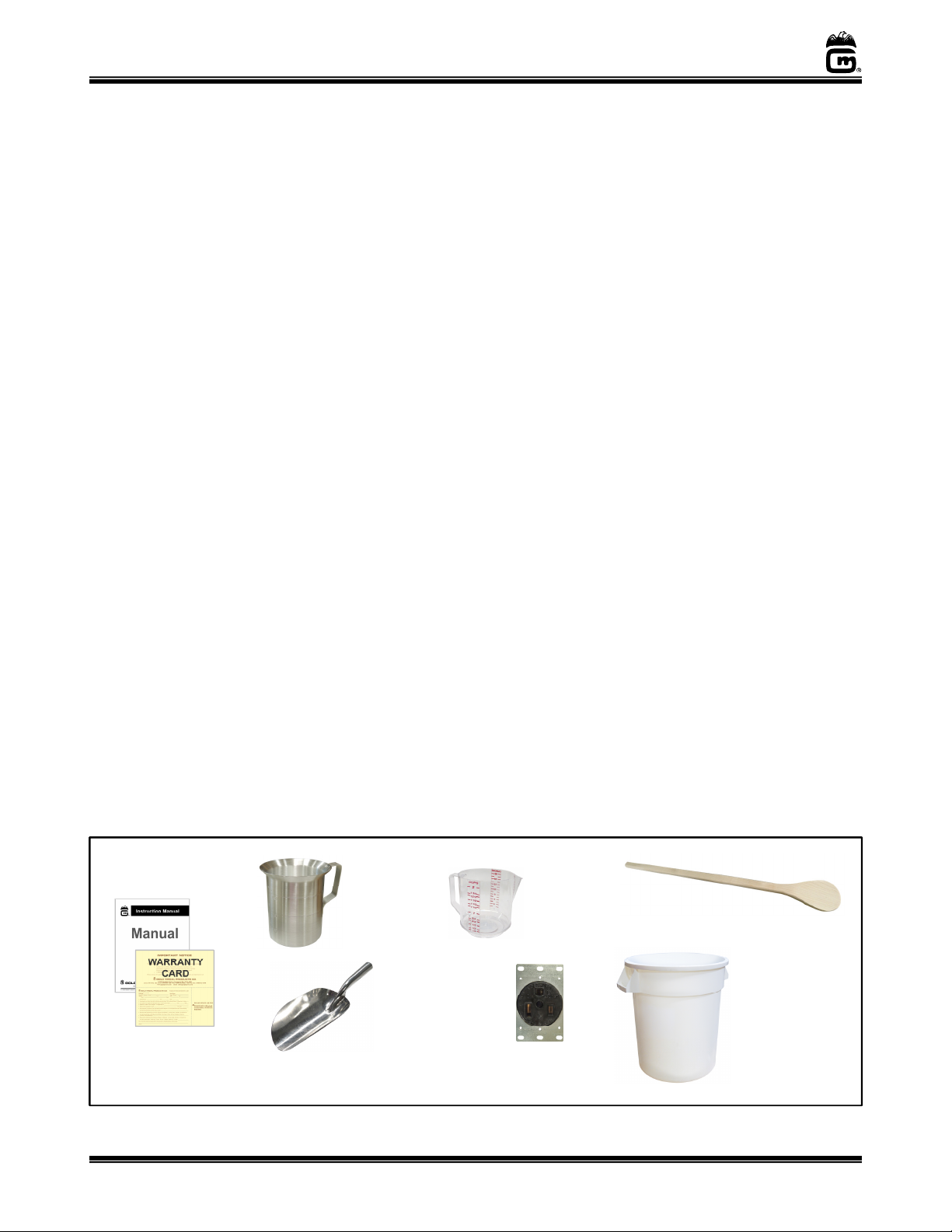

2

Cup

Aluminum

Scoop

8 Cup

20 Gallon

Wooden Paddle

50A Receptacle

Instruction

Registration

Digital 2620DT, 2621DT, 2630DT, 2631DT

INSTALLATION INSTRUCTIONS

Inspection of Shipment

After unpacking, check thoroughly for any damage which may have occurred in transit. Claims

should be filed immediately with the transportation company. The warranty does not cover

damage that occurs in transit, or damage caused by abuse, or consequential damage due to the

operation of this machine, since it is beyond our control (reference warranty in back of manual).

Manual

Read and understand the operator’s manual and all other safety instructions before using this

equipment. To order copies of the operator’s manual go to gmpopcorn.com or write to Gold

Medal Products Co., 10700 Medallion Drive, Cincinnati, OH 45241 USA 1-(800)-543-0862.

Model Description

The Digital Mark 20 Corn Treat Unit has a 20 gallon capacity and is available with either right

hand or left hand dump capability (see below for unit description). For electrical specifications,

refer to the Electrical Requirements section of this manual.

240 Volt Corn Treat Units

2620D: Mark 20 with Digital Heat Control, Right Hand Dump

2620DT: Mark 20 with Digital Heat Control, Right Hand Dump, and Dual Timer

2621D: Mark 20 with Digital Heat Control, Left Hand Dump

2621DT: Mark 20 with Digital Heat Control, Left Hand Dump, and Dual Timer

208 Volt Corn Treat Units

2630D: Mark 20 with Digital Heat Control, Right Hand Dump

2630DT: Mark 20 with Digital Heat Control, Right Hand Dump, and Dual Timer

2631D: Mark 20 with Digital Heat Control and Left Hand Dump

2631DT: Mark 20 with Digital Heat Control, Left Hand Dump, and Dual Timer

Items Included with this Unit

Manual

Measure

(PN 69826)

Measure

(PN 62807)

(PN 2093)

Warranty Card

(PN 2071)

2 included with unit

Page 4

Measure

(PN 48886) for

popped corn

(PN 89830)

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

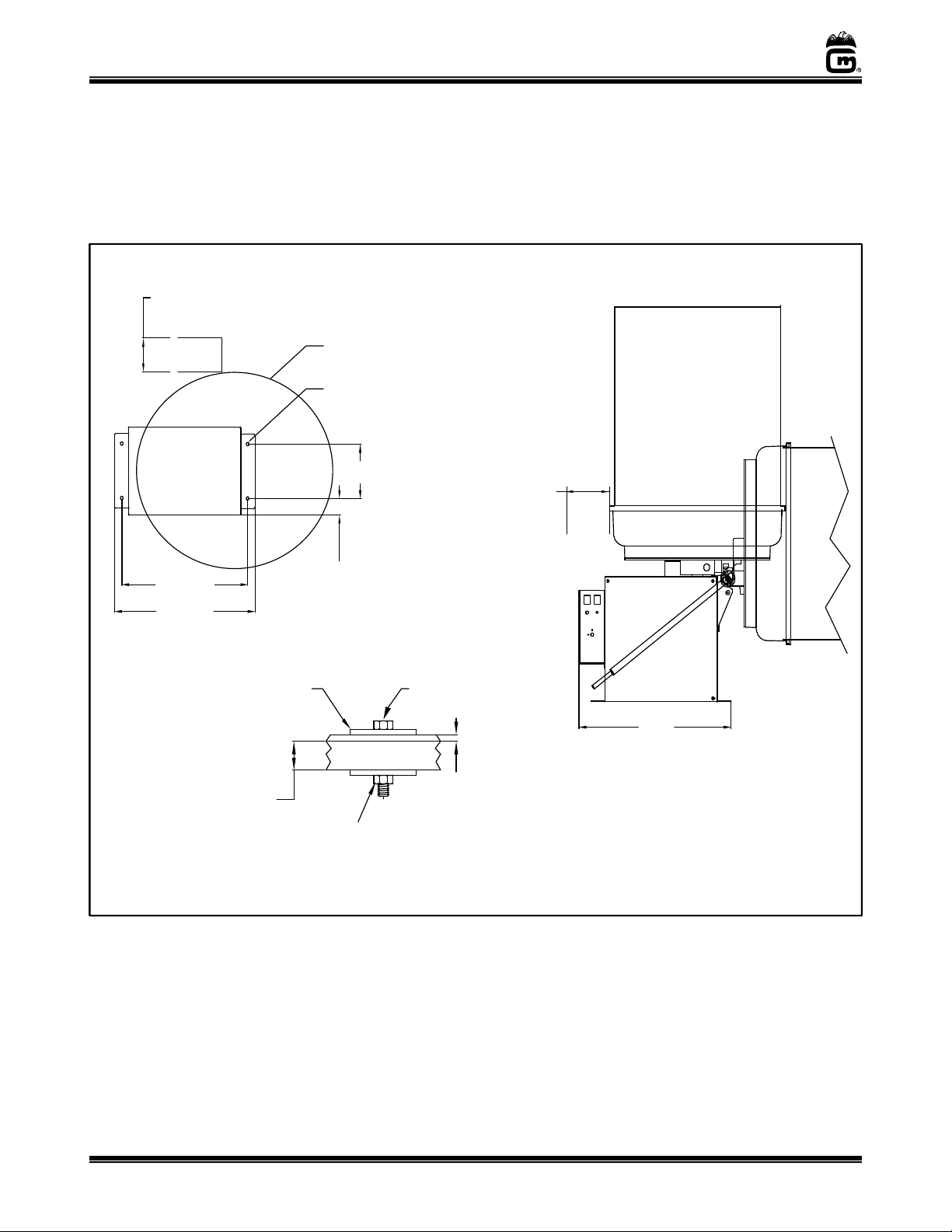

Counter Mounting Requirements

3” Minimum Clearance

24” Dia.

4 Holes for

6 31/64

”

1 63/64”

17

3/8”

19

3/8”

2” Dia. X 1/8” Thick

3/4” Minimum

5/16

-18

3/16” Minimum

6” Recommended

21”

5/16

-18

Digital 2620DT, 2621DT, 2630DT, 2631DT

Setup

1. Remove all packaging and tape, and accessories before starting operation.

2. This unit must be properly fastened to a sturdy counter, see illustration below for counter

mounting requirements.

Between Kettle and Wall

5/16” Dia. Bolts

Fender Washer

for Wood or

Wood Plastic

Products

Grade 5 Nut

Minimum Clearance

Between Wall and

Control Box for

Service.

Grade 5 Bolt

Thickness for

Stainless Steel

Over Wood

Page 5

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

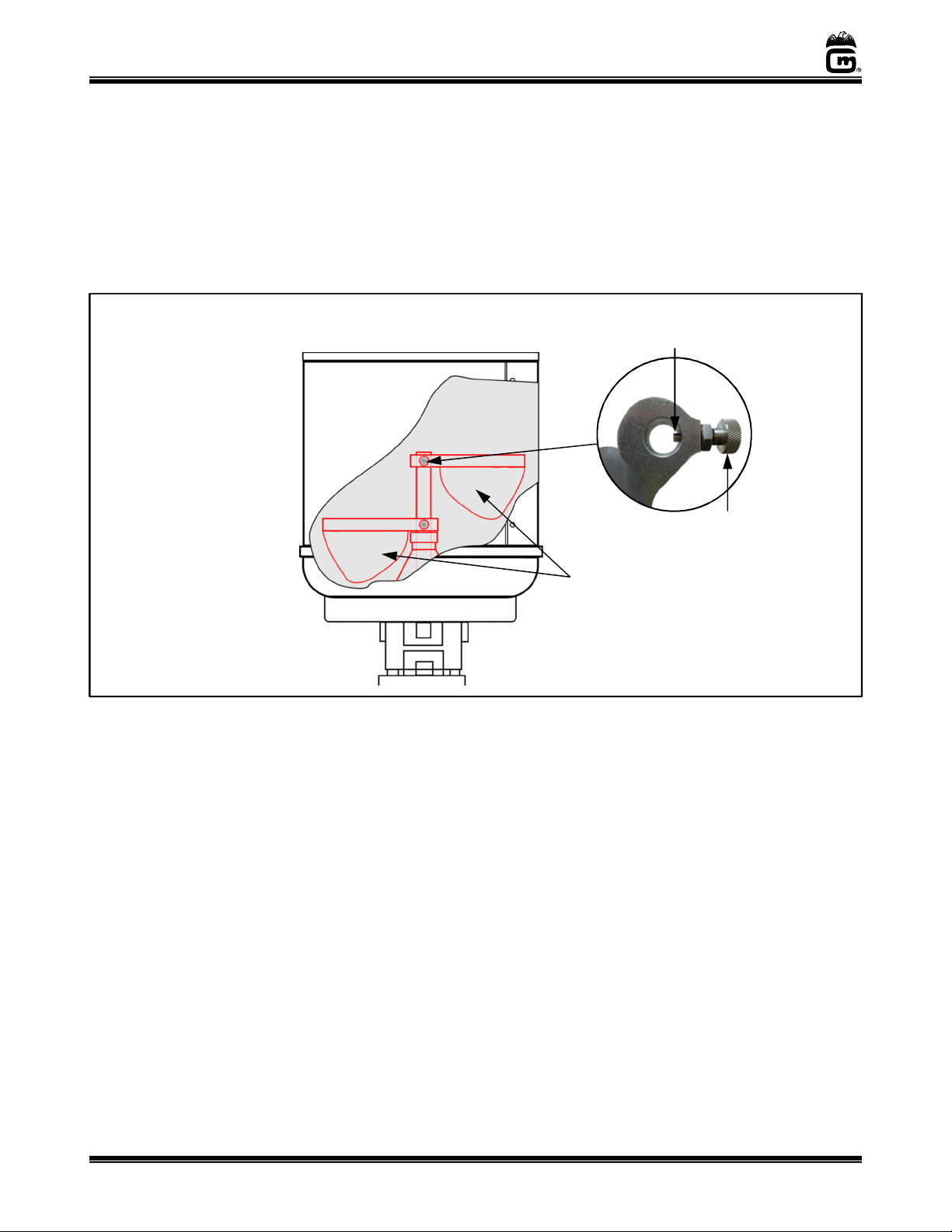

Paddles shown in

Plunger

(Be sure plunger is

Knurled Knob

Digital 2620DT, 2621DT, 2630DT, 2631DT

3. Prior to operation, rotate the top paddle from the shipping position into the mixing

position and fix into place with the plunger provided. Pull knurled knob of plunger, to free

plunger from shaft (see illustration below).

Once the paddle is positioned, make sure the plunger is securely set into the holes

provided in the shaft.

4. After setup, the unit should be cleaned prior to use (see Care and Cleaning section of this

manual).

Paddle Assembly

securely set into hole in shaft.)

of Plunger

Correct Mixing Position

Page 6

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

DANGER

CAUTION

Digital 2620DT, 2621DT, 2630DT, 2631DT

Electrical Requirements

The following power supply must be provided:

2620D, 2620DT, 2621D, 2621DT: 240 V~, 6768 W, 60 Hz

2 wire plus ground, single phase. The machine is rated for 28.2 amps. A wall receptacle is

supplied with the machine. This receptacle will accept the attachment plug on the

machine and must be used.

2630D, 2630DT, 2631D, 2631DT: 208 V~, 6594 W, 60 Hz

2 wire plus ground, single phase. The machine is rated for 31.7 amps. A wall receptacle is

supplied with the machine. This receptacle will accept the attachment plug on the

machine and must be used.

Machine must be properly grounded to prevent electrical shock to personnel.

Failure to do so could result in serious injury, or death.

DO NOT immerse any part of this equipment in water.

DO NOT use excessive water when cleaning.

Keep cord and plug off the ground and away from moisture.

Always unplug the equipment before cleaning or servicing.

Make sure all machine switches are in the OFF position before plugging the

equipment into the receptacle.

008_051514

A certified electrician must furnish sufficient power for proper machine operation and install any

supplied receptacle. We recommend this equipment be on a dedicated and protected circuit.

Failure to wire properly will void the warranty and may result in damage to the machine. It is Gold

Medal Products Co.’s recommendation that this machine be plugged directly into a wall outlet. The

use of extension cords is not recommended due to safety concerns, and may cause sacrificed

and/or reduced performance. Make sure cord is located to prevent a trip hazard or unit upset.

Before You Plug In Machine

1. Make sure all machine switches are OFF before plugging equipment into receptacle.

2. Make sure wall outlet can accept the grounded plugs (where applicable) on the power

supply cord.

3. The wall outlet must have the proper polarity. If in doubt, have a competent

electrician inspect the outlet and correct if necessary.

4. DO NOT use a grounded to un-grounded receptacle adapter (where applicable).

5. Install unit in a level position.

If the supply cord is damaged, it must be replaced by Gold Medal Products Co.,

its service agent or similarly qualified persons in order to avoid a hazard.

Page 7

gmpopcorn.com

039_080614

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

Kettle Dump

2 Position

Bracket

Control Panel View

Heat/Motor

Motor Only

Digital Heat

Control

15 Amp

Hole Plug

Digital 2620DT, 2621DT, 2630DT, 2631DT

OPERATING INSTRUCTIONS

Controls and Their Functions

HEAT/MOTOR SWITCH

Two position, ON/OFF lighted rocker switch – provides power to the heating elements in

the bottom of the kettle, and powers the agitator motor to turn for 30 seconds of every

minute. The green switch light ON indicates there is power to these features.

Note: It is normal for the motor to stop for 30 seconds of every minute (when the Motor

Only Switch is OFF).

MOTOR ONLY SWITCH

Two position, ON/OFF lighted rocker switch – provides power to the agitator motor to

run continuously.

Note: The main function of this switch is for mixing the product/popcorn at the

end of the cooking cycle with the kettle in the tilt position, and it is used for

“cleaning mode”.

15 AMP FUSE

The 15 AMP Fuse protects the Motor and Heat Control from an overload condition.

KETTLE DUMP HANDLE

The Kettle Dump Handle tilts the kettle from the upright cook position to the mix position

or the dump position. The 2 position bracket holds the handle in the tilted position.

Switch

Switch

Fuse

Handle

Page 8

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

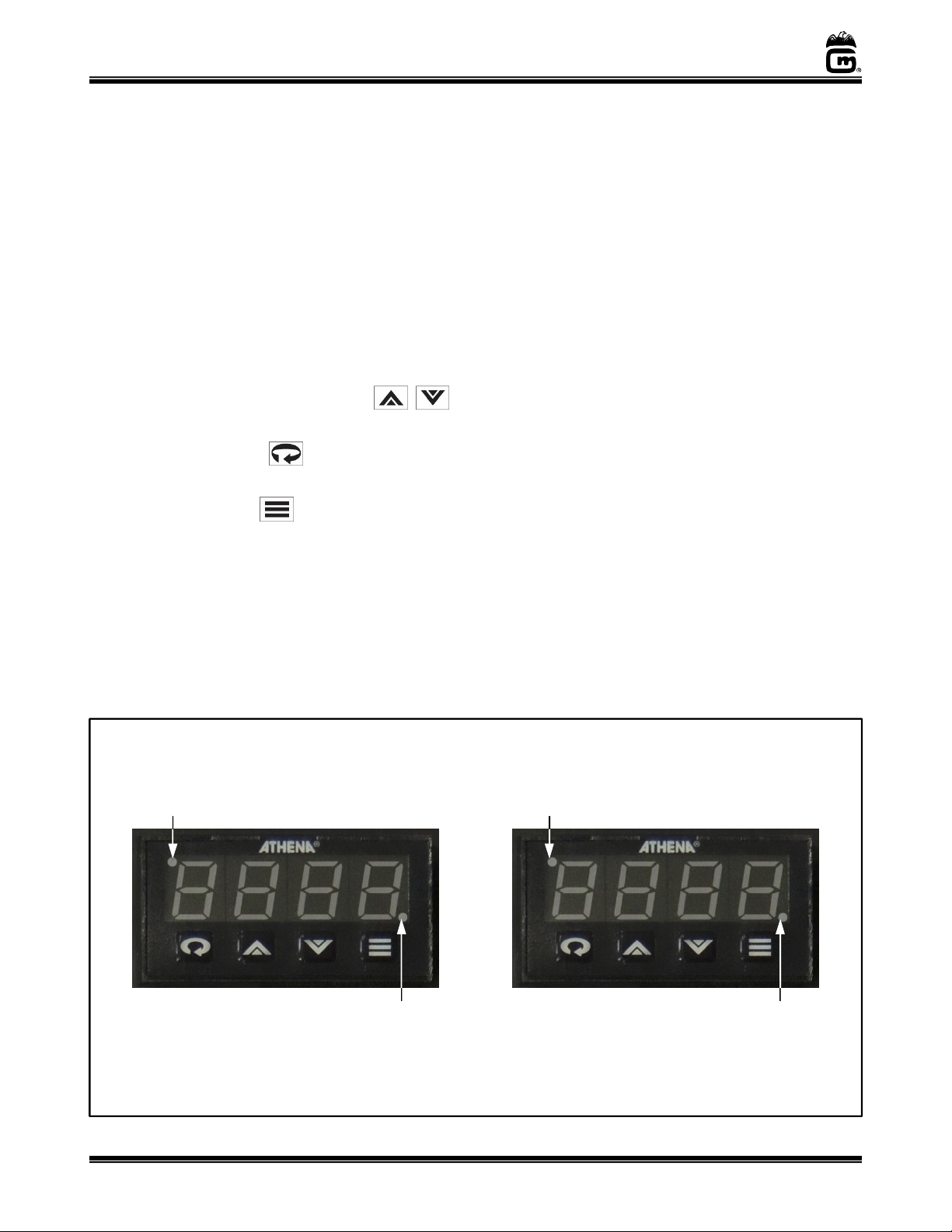

Heat Indicator Light (D Models)

Buzzer Indicator Light (

D Models

)

Heat Indicator Light (DT Models)

sounds (signaling

Buzzer Indicator Ligh

t (DT Models

)

Dual Timer Control (DT Models)

Digital 2620DT, 2621DT, 2630DT, 2631DT

DIGITAL HEAT CONTROL

The Digital Heat Control adjusts the Set Point Temperature of the unit. The machine comes

from the factory preset to achieve a Product Cook Temperature of 280°F. See Digital Heat

Control Adjustment/Calibration section for adjusting the Product Cook Temperature.

D Models: The sound of the buzzer signals kettle heat shut-off. The buzzer will continue

to sound until the unit is turned off or until the unit temperature falls below set point.

DT Models: Dual Timer units. The pre-alarm sounds the buzzer 40°F before Set Point

Temperature; alerting operator that flavor can be added to the mix (the kettle will

continue to heat the mixture). The second buzzer sounds kettle heat shutoff at a Product

Cook Temperature of 280°F. Each buzzer only sounds for 10-15 seconds.

Buttons/Indicator Light Descriptions

UP Button / DOWN Button

– adjusts the Set point Temperature UP or DN

when in programming mode.

Access Button

– accesses programming mode to change Set Point Temperature, see

Heat Control Adjustment section.

Mode Button

– exits programming mode and locks in adjustments, see Digital Heat

Control Adjustment section.

Digital Display – display shows temperature of the kettle; this is not the same as the product

temperature. (Reference the Digital Heat Control Adjustment/Calibration section.)

Heat Indicator Light – light is ON when the unit is heating. See image below for D Model

and DT Model indicator descriptions.

Buzzer Indicator Light – See image below for D Model and DT Model indicator light

description.

Light is ON when the unit is heating. It goes

OFF when the buzzer sounds (signaling heat

shut-off).

Light is ON when the unit is heating. It stays

on until the second buzzer

heat shut-off).

Light comes ON when the buzzer

sounds (signaling heat shut-off).

Digital Heat Control (D Models)

Page 9

Light is ON until the first buzzer sounds

(pre-alarm), and then the light goes OFF.

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

Digital 2620DT, 2621DT, 2630DT, 2631DT

Digital Heat Control Adjustment/Calibration

Product Cook Temperature is the actual temperature of the PRODUCT (Caramel Corn Mix); this

is measured with an accurate candy thermometer. Infrared temperature readers are NOT

recommended.

Set Point Temperature is the temperature setting of the KETTLE; this is the temperature

needed to get the Carmel Corn Mix up to the finished Product Cook Temperature of 280°F. The

digital display shows the kettle temperature, NOT the product temperature.

Note: The Set Point Temperature will be higher than the product temperature.

Refer to the candy thermometer for accurate product temperature.

Digital Heat Control Adjustment

The machine comes from the factory preset to achieve a Product Cook Temperature of 280°F.

Small adjustments may need to be made for mix used or cooking conditions. If the product is

ready, either before or after the buzzer sounds, then follow the steps listed to increase or

decrease the Set Point Temperature of the kettle:

Note: D Models - The sound of the buzzer signals kettle heat shut-off.

DT Models – The sound of the second buzzer signals kettle heat shut-off.

1. To change the Set Point Temperature, press the key. The display shows SP

followed by a temperature number flashing. Use the arrow keys to set the desired

temperature.

2. Once the temperature is set, press the key to lock in the new temperature.

Digital Heat Control Calibration (Performed at the Factory)

This unit has been calibrated at the factory. Other than small adjustments made for mix used or

cooking conditions (see above Digital Heat Control Adjustment), the unit is ready for use and

should not need calibration.

To reset the Digital Heat Control back to factory settings follow the procedure shown below.

Note: For calibration purposes only, corn oil is used to determine the Digital Heat Control

temperature setting which will produce an accurate finished product temperature

of 280°F.

1. Start with a clean unit, which is cool before attempting to calibrate.

2. Fill the mixing bowl with a one inch depth of corn oil.

3. Turn the Heat/Motor Switch ON.

4. Use an accurate candy thermometer to measure the temperature of the oil in the

mixing bowl. (Infrared temperature readers are NOT recommended.)

Page 10

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

Digital 2620DT, 2621DT, 2630DT, 2631DT

5. Set the digital control set point temperature to 400°F.

6. Turn the Motor Only Switch ON to stir the oil while it heats.

7. When the oil reaches 335°F, note the temperature displayed on the digital control and

make that the Set Point Temperature.

Note: The Set Point Temperature will be higher than the product temperature.

Refer to the candy thermometer for accurate product temperature.

8. Allow oil to cool below 300°F, then repeat Step 5 to check the buzzer sounds at 335°F.

9. The unit is now calibrated for the heat control buzzer to sound at a finished product

temperature of 280°F.

Caution: Allow hot oil to cool below 140°F before attempting to drain.

Page 11

gmpopcorn.com

Karmel King Model No. 2620D, 2621D, 2630D, 2631D

Digital 2620DT, 2621DT, 2630DT, 2631DT

Making Carmel Corn

Instructions for Making Carmel Corn (Mark 20)

Always remember, leave the lid on the kettle during the first part of the batch. Once steam starts

to “roll-up” from underneath the lid, then carefully remove lid for remainder of the cooking cycle.

CAUTION: Beware of rising steam; keep face and hands clear of rising steam.

1. Turn Heat/Motor Switch ON (DO NOT turn on the Motor Only Switch).

2. Add (4) 22 ounce packages of Gold Medal Caramel Corn Mix (Item No. 2094), 16 cups of

granulated sugar (brown or white), and 32-48 ounces of water (add water last).

Note: When using Gold Medal “One Step” Carmel Corn Mix, DO NOT add granulated

sugar.

3. Turn Motor Only Switch ON and mix for approximately one minute, then turn Motor

Only Switch OFF. (With the Heat/Motor Switch ON, the motor will run for 30 seconds of

every minute.)

4. Add 4 sticks (16 ounces) of coconut oil or vegetable oil. Put on the lid.

Note: Once steam starts to “roll-up” from underneath the lid, then carefully remove

the lid for the remainder of the cooking cycle.

5. Allow mix to cook until the buzzer sounds at 280°F product temperature.

Dual Timer Units: When the first buzzer sounds, add flavor mixture (if desired), the

unit will continue to heat until the second buzzer sounds at 280°F product temperature.

Note: Product temperature is measured with an accurate candy thermometer.

(Reference the Heat Control Adjustment section.)

6. Turn Heat/Motor Switch OFF.

7. Turn Motor Only Switch ON.

8. Add 20 gallons of pre-popped corn.

9. Allow corn to mix for approximately 10 seconds with the kettle in the upright position.

10. Move kettle to the mix position and spray 20-30 “squirts” of GOLD Medal Free-N-Easy

(Item No. 2250) for proper corn separation, and mix popcorn until thoroughly coated.

11. Dump the caramel corn into the cooling pan, and mix/separate the caramel corn using

two popcorn scoops.

12. After dumping caramel corn, turn Motor Only Switch OFF.

13. Allow the finished product to cool before packaging.

During normal operation, sugar build-up will occur in the kettle. The build-up must be removed

by steaming out the kettle every 3-4 batches, and especially before the machine is turned off for

the day. If making single batches, with the unit turned off between batches, the kettle must be

steamed out after each batch has been completed. Follow the Proper Kettle Cleaning Procedure

in the Care and Cleaning section of this manual.

Page 12

gmpopcorn.com

Loading...

Loading...