Page 1

Gas Built-in Hob

1 BURNER GAS HOB (GL301N)

2 BURNER GAS HOB (GL2N, GL302N)

3 BURNER GAS HOB (GL3N, GL603N, GL3SS)

4 BURNER GAS HOB (GL4N, GL4SS)

4 BURNER GAS HOB (GL704N)

INSTALLATION INSTRUCTIONS (FOR FITTERS ONLY)

&

USER AND OPERATOR INSTRUCTIONS

Installation must be in accordance with manufacturer’s instruction, relevant Gas

Fitting Regulations or AS5601 – “Gas Installation” regulations.

These instructions should be read carefully prior to initial use and retained in a safe

place in order that full advantage can be taken of the features of your HOB COOKER.

REMINDER:

ANY SERVICING AND INSTALLATION OF THE HOTPLATE

MUST BE CARRIED OUT BY AN AUTHORIZED PERSON.

ANY QUERIES SHOULD BE FORWARDED TO:

MANUFACTURER: A’VARD INDUSTRIES P/L.

ADDRESS: 58-60 Quantum Close, South Dandenong, Victoria 3175, Australia.

TEL: 61 3 9799 9660

FAX: 61 3 9799 9662

WEBSITE: www.goldlinecorp.com.au

Goldline N12- manual-ULPG Jan 2012

1

Page 2

Goldline N12- manual-ULPG Jan 2012

2

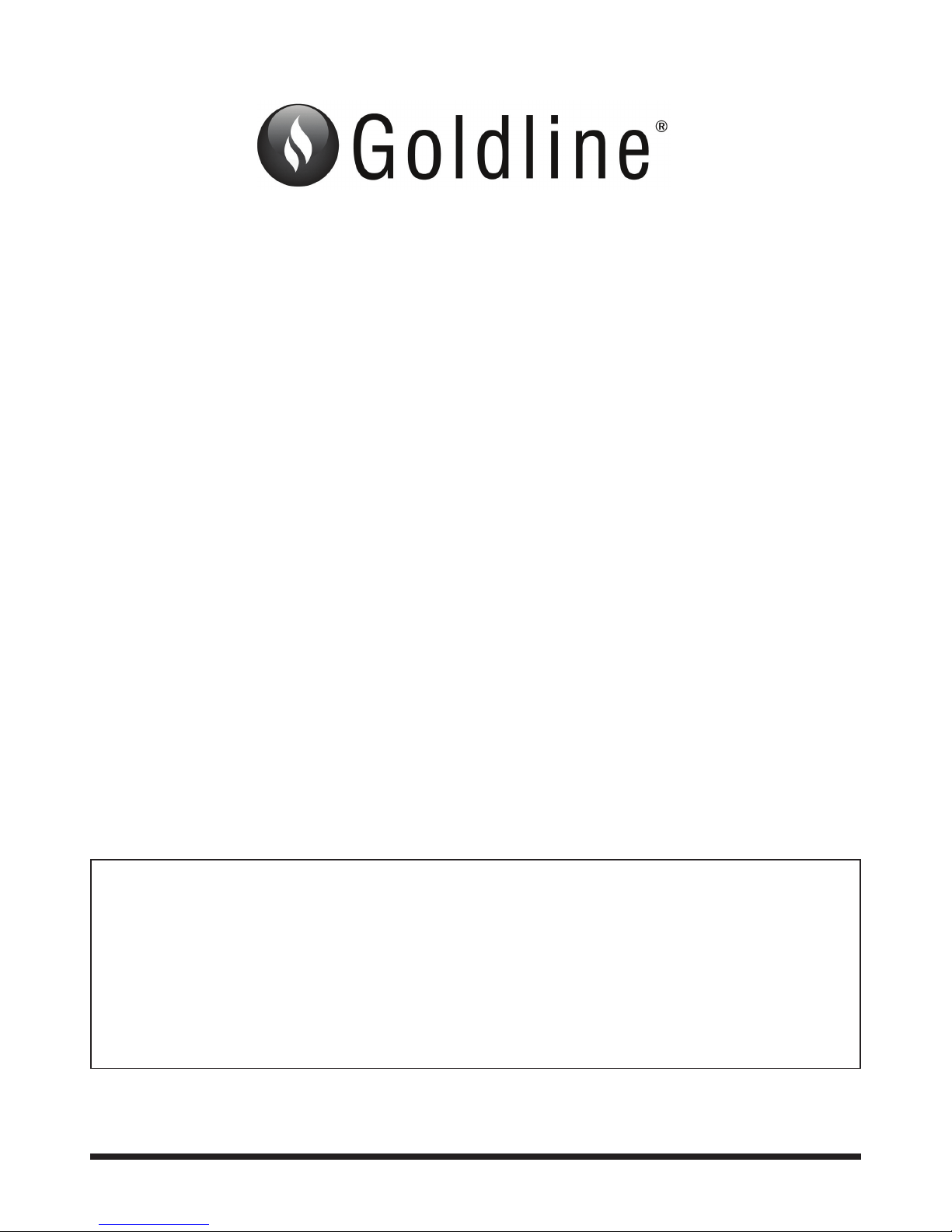

Model GL301N/GL301ND

Diagram A

Tray Dimensions (in mm)

Diagram B

Cut-Out (in mm)

Model GL302N/GL302ND

Diagram A

Tray Dimensions (in mm)

Diagram B

Cut-Out (in mm)

Model GL2N/GL2ND

Diagram A

Tray Dimensions (in mm)

Diagram B

Cut-Out (in mm)

Model GL3N/GL3SS

Diagram A

Tray Dimensions (in mm)

Diagram B

Cut-Out (in mm)

470

475

Page 3

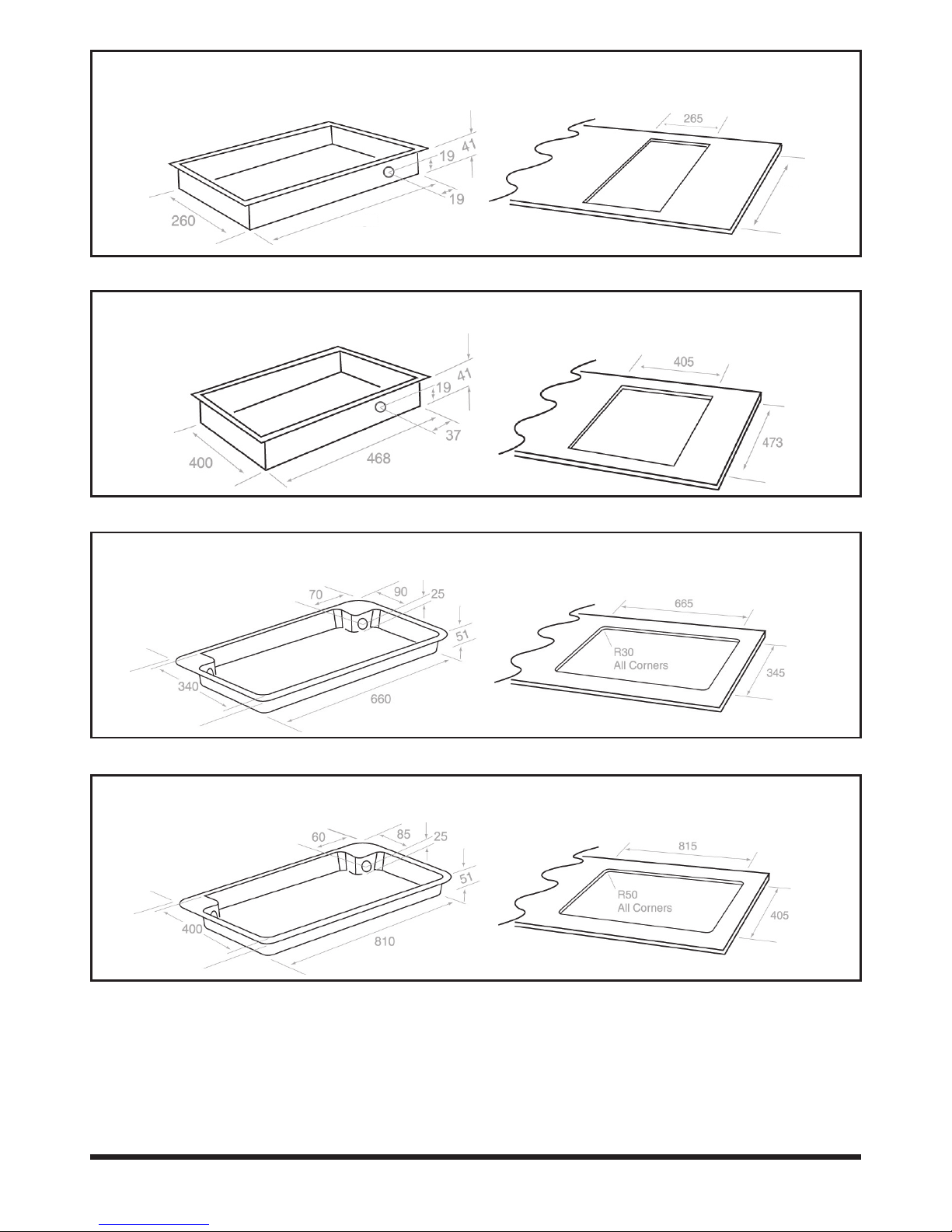

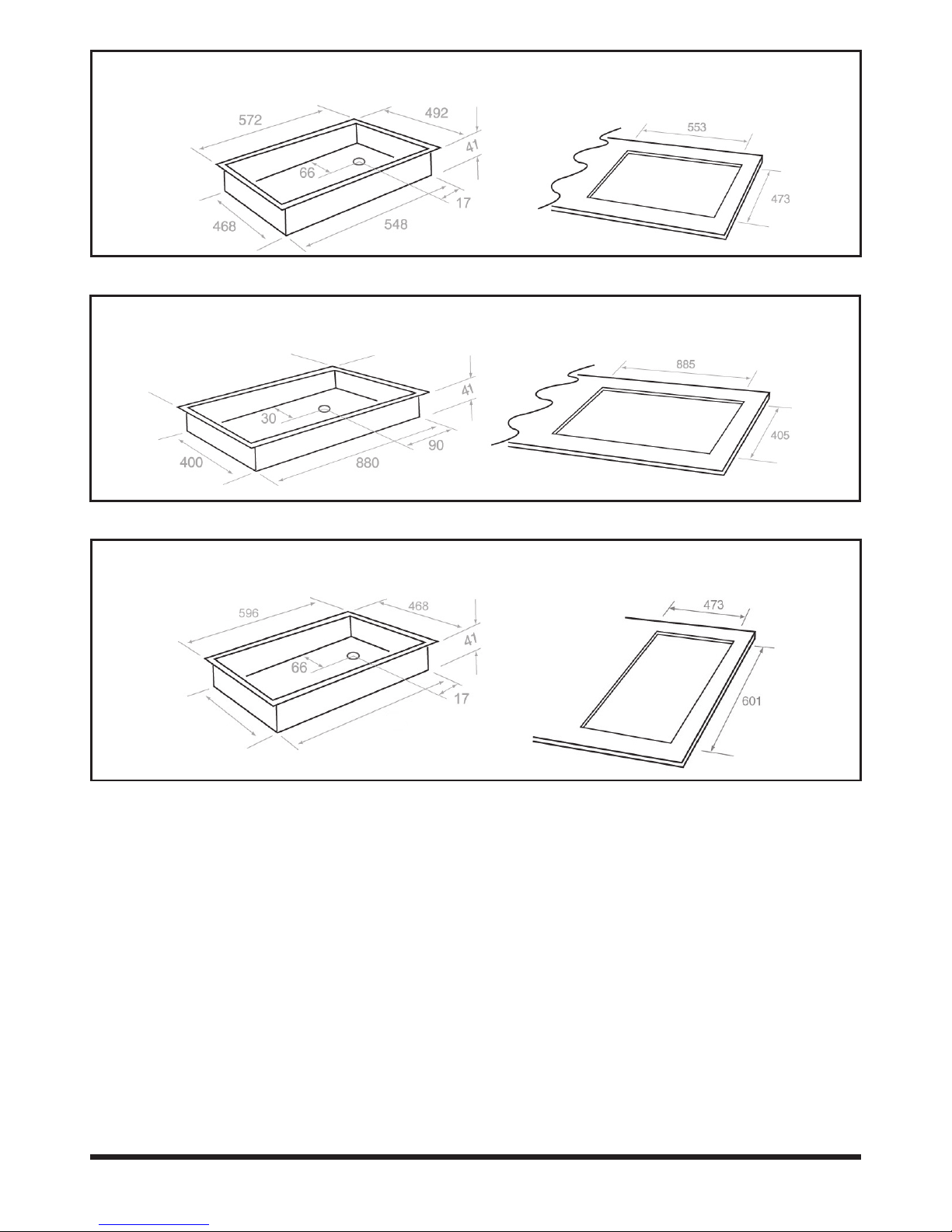

Model GL603N/GL603ND

Diagram A

Tray Dimensions (in mm)

Diagram B

Cut-Out (in mm)

Model GL4N/GL4SS

Diagram A

Tray Dimensions (in mm)

Diagram B

Cut-Out (in mm)

Model GL704N

Diagram A

Tray Dimensions (in mm)

Diagram B

Cut-Out (in mm)

Goldline N12- manual-ULPG Jan 2012

3

Page 4

Goldline N12- manual-ULPG Jan 2012

4

INSTALLATION INSTRUCTIONS

DATA PLATE DETAILS:

The data plate is located on the tray oor.

CHECK THAT THE DATA PLATE SHOWS THAT THE APPLIANCE IS SUITABLE FOR THE

AVAILABLE GAS SUPPLY. IMPORANT: VERIFY GAS TYPE WITH LOCAL GAS NETWORK

OPERATOR BEFORE CONNECTION OF THIS APPLIANCE.

1. Room Ventilation

This cooktop must be installed in a room that has permanent ventilation to effect

the correct operation of the appliances and also to provide adequate ventilation.

This airow must exceed 20m³ via permanent vented openings in the walls of the

room and these must have a section of 100cm² minimum. They must be constructed

in a manner so as to avoid any possible blockages. The airow can also be drawn

indirectly from an adjacent room provided it complies with any local regulations to

vent any fumes outdoors.

Not for use in Marine craft, caravans or Mobile homes unless

tted with safety device.

2. Before installing the appliance check that the location provides the required

clearances from combustible materials and if necessary provide protection to adjacent

surfaces as required by the regulations. Make provision for the gas supply to be

connected in the position shown in Diagram A.

3. Cut the opening in the bench top to the dimensions shown in diagram B.

4. Remove the hotplate from the carton.

Refer – Gas tting manual.

Position of gas inlet: See diagram on page 2. Depth from top of glass to bottom of tray:

70mm excluding regulator

5. Install the hotplate in the cut-out (see diagram B on page 2).

Note:

If clearance between side and rear walls and periphery of the burner is less than 250mm,

the walls must be protected with a non-combustible material. The protection must extend

a minimum distance of 450mm above the burner. Horizontal surfaces less than 750mm

vertically above the hotplate must also be protected.

6. Ensure that gas and electrical outlet are accessible with the appliance installed.

The gas connection to the regulator is 1/2” BSP. Please ensure gas supply line to

the appliance is of adequate length to allow sufcient withdrawal of appliance for

service or disconnection. The connection must be annealed copper pipe or exible

hose (if permissible by local authority).

7. In the event that exible hose is being used:

- The exible hose must be certied to AS/NZS1869 - class B or class D.

- The gas connection point must be between 800 to 850mm above the oor and in the

region outside the width of the appliance to a distance of 250mm.

Page 5

Goldline N12- manual-ULPG Jan 2012

5

- Please ensure that the exible hose shall not kink, in permanent deformation

position, exposed to exceeding heat (more than what is certied) or subject to

abrasion.

- Please ensure the hose assembly is restrained from accidental contact with the ue

outlet of an under bench oven.

- To inspect and replace the hose regularly.

- The length of the exible hose must be kept to a minimum.

8. Use a spanner at the at area provided to hold the regulator rmly, when making

the join. Refer diagram below.

Pressure test point:

- This is provided in the gas regulator.

- Remove the screw; connect the hose from the pressure gauge.

- Turn on the gas to the large burner and manually light the burner.

- The pressure is shown on the data plate.

- To increase the pressure, loosen locking nut and turn clockwise.

- Disconnect gauge and replace test point screw.

10. Test the appliance:

- Depress each control knob and turn to full ame setting.

- The burner will ignite. Adjust control knob to desired setting. Normally, no adjustment

should be necessary.

Note:

The cook top must be installed with provision to allow the gas to be turned off and

disconnected for servicing and removal of the appliance as required from gas supply.

WARNING!

HOSE ASSEMBLY MUST BE RESTRAINED TO PREVENT ACCIDENTAL

CONTACT WITH THE FLUE OF AN UNDERBENCH OVEN.

9. Once they are tightened

securely, turn the gas on and

check for leaks using a soap

solution and brush around all

joints and connections.

Pressure test point for LP and ULP gas only.

Use the regulator provided for town and natural gas.

Page 6

Goldline N12- manual-ULPG Jan 2012

6

- If any problem occurs, refer to the servicing instruction of the faultnding chart.

11. Please make sure that gas supply connection is easily accessible for servicing or

other purpose.

12. Stick the second data label (which is provided in the box) at a place, which is

noticeable, e.g.: inside the cabinet door or the sidewall.

13. Instruct the user to keep the user instruction manual.

If any of the above procedures do not produce satisfactory results, the agent’s service

department should be consulted for more specialize assistance.

14. Please note that the cooktop is tted with the ame failure device that cuts off the

gas supply when burner ame extinguishes suddenly or abnormally in order to avoid

gas leakage.

CONVERSION TO UNIVERSAL LPG FROM OTHER TYPE OF GAS

1. Install the correct injector size for the boiler and wok venturi system.

(refer the injector size table)

2. Adjust the bypass screw for each burner approximately by half a turn

from fully

3. Replace the boiler ring to the type that does not have any inner

portholes.

WARNING:

- DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

- SOME PROPELLANT GASES CAN BREAK DOWN WHEN HEATED AND PRODUCE CORROSIVE

VAPOURS, WHICH WILL ATTACK SOME MATERIALS.

- ARTICLES, WHICH ARE MADE OF FLAMMABLE MATER SHOULD NOT BE STORED IN DRAWERS

OR CUPBOARDS IMMEDIATELY BELOW THIS APPLIANCE.

- THE SILICONE RUBBER GASKET SHOULD NOT BE REMOVED UNDER ANY CIRCUMSTANCES. IN

THE EVENT THAT ANY PROTECTIVE RUBBER GASKET IS DROPPED OFF OR DAMAGED, THE

CONSUMER SHOULD CEASE FORTHWITH THE USE OF THE UNIT UNTIL IT IS DULY RECTIFIED.

- DO NOT STORE ARTICLES WITHIN 50MM OF THE BOTTOM OF THE HOTPLATE CASING.

- DO NOT TOUCH SPARK IGNITOR WHILE LIGHTING THE BURNER.

- WHEN THE APPLIANCE IS INSTALLED IN A MARINE CRAFT OR IN A CARAVAN, IT SHALL NOT BE

USED AS A SPACE HEATER.

- DO NOT MODIFY THIS APPLIANCE.

WARNING!

NOT FOR USE IN MARINE CRAFT, CARAVANS OR MOBILE HOMES

UNLESS FITTED WITH SAFETY DEVICE.

Page 7

Goldline N12- manual-ULPG Jan 2012

7

SERVICING INSTRUCTIONS

MINOR ADJUSTMENT

Access to By Pass Screw

- Light the burner and turn to

minimum setting (marked small

ame).

- The ame should be stable on

minimum setting and should not

extinguish when passing from

maximum setting to low setting.

- If adjustment is necessary, remove

the control knob by pulling upward.

The bypass screw is accessible

via the control knob spindle. Turn

the bypass screw anti-clockwise to

increase the turn-down rate

Access to manifold, gas taps and burner

assembly

- Remove glass hob and control knobs.

- To remove gas cocks. Unscrew the locking nut

(between cock and burner). Remove screws, the

cock can now be removed from the manifold.

If access to the barrel is required, remove two

screws, which retain spindle to body. If lubricating

the mechanism use Regosine Moly LM or other

approved grease.

To replace electrode

- Remove screw from the clamp holding the

electrode and thermocouple and note the

adjustment setting height of each. Replace electrode

and then t clamp and screw.

FAULT ISOLATION CHART

FAULT CAUSES REMEDY

Burner will not light

1. Air in gas line

2. Blockage in line

3. Ignition not sparking

4. Flame failure device faulty

5. Check the battery

(applicable to DC version)

1. Purge gas line

2. Trace back and clear

3. Check lead and electrode

4. Replace thermocouple and test

5. Replace the battery

Burner lights back to

injector

1. Excessive lint up burner

mixing tube

2. Excessive gas pressure

1. Remove and clean burner

2. Check gas regulator pressure.

Adjust if necessary.

Burner has explosive

ignition

1. Excessive gas pressure 1. Check gas regulator pressure.

Adjust if necessary.

Ignitor not sparking

1. Electrode gap

2. Ignition connection

1. Check gap, adjust if not

between 4-5mm

2. Check connection to ignitor,

replace if faulty.

If any problem cannot be rectied please contact the agent in your state or the gas supply authority service department

or contact the product manufacturer.

WARNING!

DANGER 220 VOLTS 50Hz.

DISCONNET POWER BEFORE SERVICING UNIT

DO NOT MODIFY THIS APPLIANCE

Page 8

Goldline N12- manual-ULPG Jan 2012

8

OPERATING INSTRUCTIONS

The hob cooker is unique in its burner design and layout. It is tted with the ultra hi-speed

burners and one boiling burner. Whilst all three burners perform as general utility burner the

two outside burners are specically designed for wok cooking. They deliver up to one and

a half times the ame heat and spread compared to normal hi-speed burners. All burners

retain normal simmer cooking facilities. The widely spaced positioning of the burners allows

for the use of large woks.

IGNITION

This hotplate is equipped with electronic ignition to each of the three burners and is

operated by depressing the individual control knob and turning it a quarter turn anticlockwise.

MANUAL IGNITION

If there is no power to the appliance or your are is experiencing a power black-out, simple

strike a match or spark igniter next to the required burner and follow the instruction above.

Note: the ame safety system is independent of power and will still operate without a power source.

Should your cooktop fail to ignite after manual procedure has been followed then check to

see that the gas supply to appliance has not been shut off.

CONTROLS

The Hobcooker has the control knobs, which are situated, at the front of the glass plate. An

indicator motif advises which knob controls each burner. The ‘full-on’ and pre-set ‘simmer’

positions are indicated by a large and small ame graphic on the glass plate next to each

individual control knob.

BURNER OPERATION

1. Depress the required control knob anti-clockwise to the FULL-ON position.

2. When the burner has ignited, adjust the control knob to the required setting. Flame

adjustment is achieved by rotating the control knob further in an anti-clockwise fashion

BATTERY REPLACEMENT (applicable to battery ignition model)

1. Open the battery holder cover ap

2. Remove old battery

3. Replace with new 1.5 Volt “D” size battery noting correct polarity

4. Close cover ap

Page 9

Goldline N12- manual-ULPG Jan 2012

9

CLEANING

- Allow the hob cooker to cool before attempting to dismantle or clean it. The glass

plate is best cleaned with a cloth, using warm soapy water. Use of abrasive powders

and pastes should be avoided as far as possible, but when necessary use only a mild

abrasive. For removal of hardened grease, very ne steel wool, wetted and liberally

soaped, can be used.

- Caustic solutions, washing soda, aerosol spray cleaners, bleach and some biological

cleaners are detrimental to some surface nishes and care must be taken not to

apply them to the burner bodies and caps.

- Do not wash burner caps in a dishwasher.

- For ease of cleaning, remove spillage from the bowls as soon as possible. Control

knobs may be pulled off for cleaning beneath them, but take care not to allow water to

enter the holes in the glass plate.

- When re-assembling the spillage bowl always ensure that it is correctly located over

the spark electrode. Care should be taken to keep the electrode clean and avoid

damage to the porcelain insulator when removing the spillage bowl during cleaning.

- It is recommended that the appliance should be clean as describe above daily for

optimal performance and longer life expectancy.

- Wash spill bowl regularly and clean dirt and grease in a weekly basis.

- Inspect exible hose connection regularly for sign of frying or damage once at

least a year.

- Check the burner port regularly for blockage especially if there is occurrence of

spillage and clean them if necessary.

MAINTENANCE SCHEDULE

- It is recommended that to have the units serviced by an authorized person at least

once a year.

Page 10

Goldline N12- manual-ULPG Jan 2012

10

HINTS ON THE USE OF THE HOTPLATE

Utensils should always be placed centrally on the pan supports and over the burners.

Flames which extend beyond the bottom of utensils are wasteful and can damage or

overheat handles. Large diameter utensils (greater than 200mm in diameter) must not be

allowed to protrude beyond the perimeter of the hotplate, as this could cause overheating or

damage to the adjacent bench.

SAFETY HINTS.

Always turn panhandles to the side or back of the hotplate – not out into the kitchen where

they can easily be knocked. Do not wear loose tting garments while the burners are in

operation, due to the possibility of fabric ignition, which may result in personal injury.

MINOR TROUBLE SHOOTING.

Symptoms Please check the following:

NO IGNITION

1. Check if anything is obstructing the electrode metal tip.

2. If 240 AC: check if appliance is connected to electrical supply.

3. If 1.5V battery: check and replace battery if required.

NO GAS Check that the gas is turned on at the main meter.

BURNER FLAME NOT

BURNING EVENLY

Check the burner head is sitting evenly and that the slots in the

burner head are not obstructed. In the event that you are not

satised with the hotplate, the distributor in your State should be

consulted.

Note:

Should you still experience difculties with your Goldline cook top please contact the manufacturer at the address and

phone number provided in this manual.

Do not place anything, e.g. ame tamer, asbestos mat, between pan

and pan support as serious damage to the appliances may result.

Do not remove the pan support and enclose the burner with a wok

stand as this will concentrate the ame and deect the heat onto the

hotplate.

Do not use large pots or heavy weights which can bend the pan support

or deect the ame onto the hotplate.

Locate pan centrally over burner so that it is stable and does not

overhang the appliance.

Use only wok support supplied or recommended by the manufacturer of

the appliance.

Page 11

Goldline N12- manual-ULPG Jan 2012

11

RECOGNISING ABNORMAL OPERATION

Should you notice any of these symptoms,

- ame light back

- ame lift off from the burner ports

- popping or minor explosions sound

- appreciable yellow tipping ame

- objectionable odour

Turn off the unit immediately. Stop using the unit.

Call authorized person or contact the manufacturer.

WARNING

This Gas Hob can be supplied in either of two Models

220 VOLTS 50 HZ or 1.5v D.C. Battery pack.

Check the data label afxed to your unit to ensure the correct model has been supplied.

IMPORTANT:

ANY SERVICING TO THIS APPLIANCE MUST BE CARRIED

OUT BY AN AUTHORIZED PERSON.

SAFETY WARNING WHEN OPERATING WITH LP GAS:

WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT OR IN CARAVANS, IT SHALL

NOT BE USED AS A SPACE HEATER.

SPARE PARTS SERVICE CONTACT NUMBERS:

For spare part and technical support enquires please call

MANUFACTURER: A’VARD INDUSTRIES P/L.

ADDRESS: 58-60 Quantum Close, South Dandenong, Victoria 3175, Australia.

TEL: 61 3 9799 9660

FAX: 61 3 9799 9662

WEBSITE: www.goldlinecorp.com.au

e-mail: info@goldlinecorp.com.au

Page 12

Items Unit

Ignition - -

Type Reference D/A

Top plate material -

Glass Colour -

Glass Shape -

Nos. of hob -

Gas Type -

Heat input for burner kW

Left

(Mj/hr) Centre

Right

Flame failure device -

Gas pressure kPa

Gas inlet connection -

Tray depth mm

Side clearance from the periphery of

mm

each burner to any combustable surfa

ce

Clearance from base tray of cooker to

mm

its non-combustable material underneath

Dimension

Base tray WxD mm

Glass top WxDxH mm

Cut-out WxD mm

Net weight kg

Model number

GL2N

DC 1.5V 220V/240V

Battery 50Hz

D

8mm toughened

Australian Glass

Black/White

Curved

2

HKTown Gas

5.2 (18.72)

-

5.2 (18.72)

Yes

1

Screw-1/2 inch BSP

51

150

50

660 x 340

750 x 450 x 8

665 x 345

13

GL301N

DC 1.5V 220V/240V

Battery 50Hz

D

8mm toughened

Australian Glass

Black/White

Rectangular

1

NG LPG

-

4.2 (15.0)

Yes

1

Screw-1/2 inch BSP

43

150

50

260 x 470

300 x 500 x 8

265 x 475

9.5

GL302N

DC 1.5V 220V/240V

Battery 50Hz

D

8mm toughened

Australian Glass

Black/White

Rectangular

2

NG LPG

2.3 (8.0)

-

4.2 (15.0)

Yes

1

Screw-1/2 inch BSP

43

150

50

400 x 468

465 x 500 x 8

405 x 473

11.5

GL3N

DC 1.5V 220V/240V

Battery 50Hz

D

8mm toughened

Australian Glass

Black/White

Curved

3

HKTown Gas

5.2 (18.72)

2.7 (9.72)

5.2 (18.72)

Yes

1

Screw-1/2 inch BSP

51

150

50

810 x 400

860 x 460 x 8

815 x 405

16.5

GL603N

DC 1.5V 220V/240V

Battery 50Hz

D

8mm toughened

Australian Glass

Black/White

Rectagular

3

HKTown Gas

2.5 (9.0) x 2

-

5.2 (18.72)

Yes

1

Screw-1/2 inch BSP

40

150

50

550 x 470

640 x 500 x 8

555 x 475

13.8

GL4N / GL4SS

DC 1.5V 220V/240V

Battery 50Hz

D

8mm toughened glass

or Stainless steel .

Black , White or Stainless steel

Rectagular

4

NG LPG

2.5 (9.0) x 2

-

5.2 (18.72) x 2

Yes

1

Screw-1/2 inch BSP

40

150

50

880 x 400

930 x 450 x 8

885 x 405

18

SPECIFICATION TABLE

Design and specification may change due to product improvement. No prior notice will be given. If there are any

queries, please feel free to contact our service center.

Please refer to the English version of this manual as the standards.

GL704N

DC 1.5V 220V/240V

Battery 50Hz

D

8mm toughened

Australian Glass

Black/White

Rectagular

4

NG LPG

2.5 (9.0) x 2

1.7 x1

5.2 (18.72) x 1

Yes

1

Screw-1/2 inch BSP

40

150

50

596 x 468

640 x 520 x 8

601 x 473

18

Loading...

Loading...