Page 1

rok założenia

1992

OPERATING AND ASSEMBLY MANUAL

ELECTRIC TANKLESS WATER HEATER

FOR CENTRAL HEATING SYSTEMS

(Electric water boiler)

TYPE EKW -

AsDC-W

- AsDC-W

-

AsZN-W

-

AsB II

- AsD-W

AsZN-W

AsB II

GoldLine

AsD-W

Intelligent AntiStop system

ZŁOTY CERTYFIKAT

PRZEDSIĘBIORSTWO

ZŁOTY CERTYFIKAT

GRAND PRIX

EKO-BUD '97

FAIR PLAY

2001-2009

2001

2010

GoldLine

Page 2

2

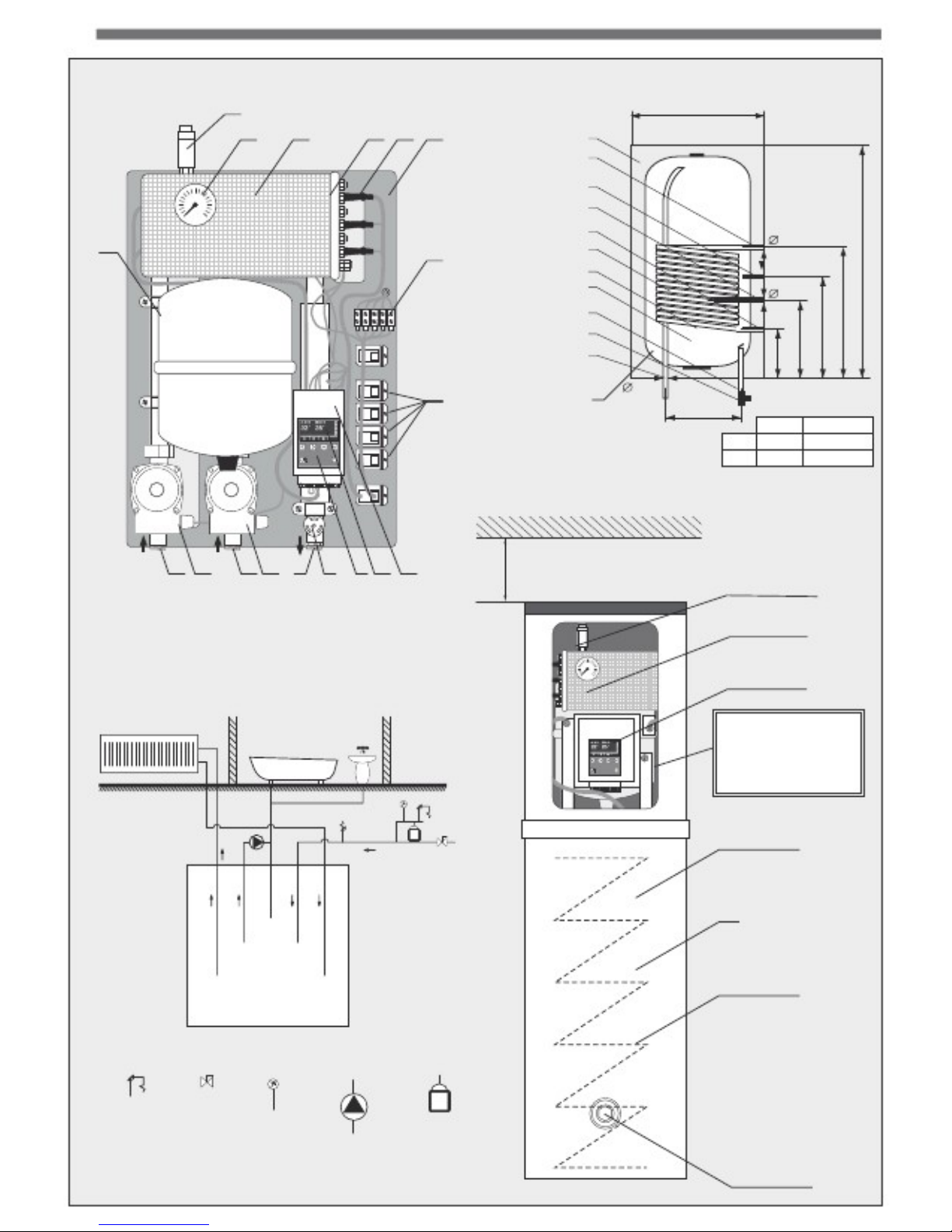

Bolier EKW AsD

-

W

10

15

8

7 9 2

Insulation (polistyren)

CH hot water inflow

Circulation

Sensor cover

CH water outflow

Tank diagram

460 mm

18

11

Spiral coil

Thermostat sensor cover

Magnesium anode.

Cold water inflow

3/4"

L

400 mm

1/2"

325 mm

12

20

c

11:53:3312 05 2011 czw

c

123456

1/2"

100 mm

L

80 l 830 mm

100 l

975 mm

Net weight

50 kg 53 kg

ESC ON OFF

Boiler

EKW AsDC

-

W

RETURN RETURN SUPPLY

54 cm

14 17

21 19 13 16 5 4 3

Min

. Premises height

2,1m

(required while installation)

VENT

MANOMETER 4 BAR

Boiler

EKW AsDC

-

W

With build-in HUW tank

- exemplary application

c 11:5

3:3312 05 2011 czw c 123456

CONTROL PANEL

ESC ON OFF

INSIDE BOILER

:

- CH PUMP

- HUW PUMP

- 8l CH MEMBRANE VESSEL

- 2X ONE-WAY VALVE

100l HUW TANK

20

circulation

HUW

outflow

CH.

Cold water

outflow

CH

COIL 29 kW

Safety

valve

Ball

valve

manomet

e

r

circulation

pump

membrane

vessel

MAGNESIUM ANODE

200 mm

Safety valve)

HUW outflow

600 mm

Page 3

3

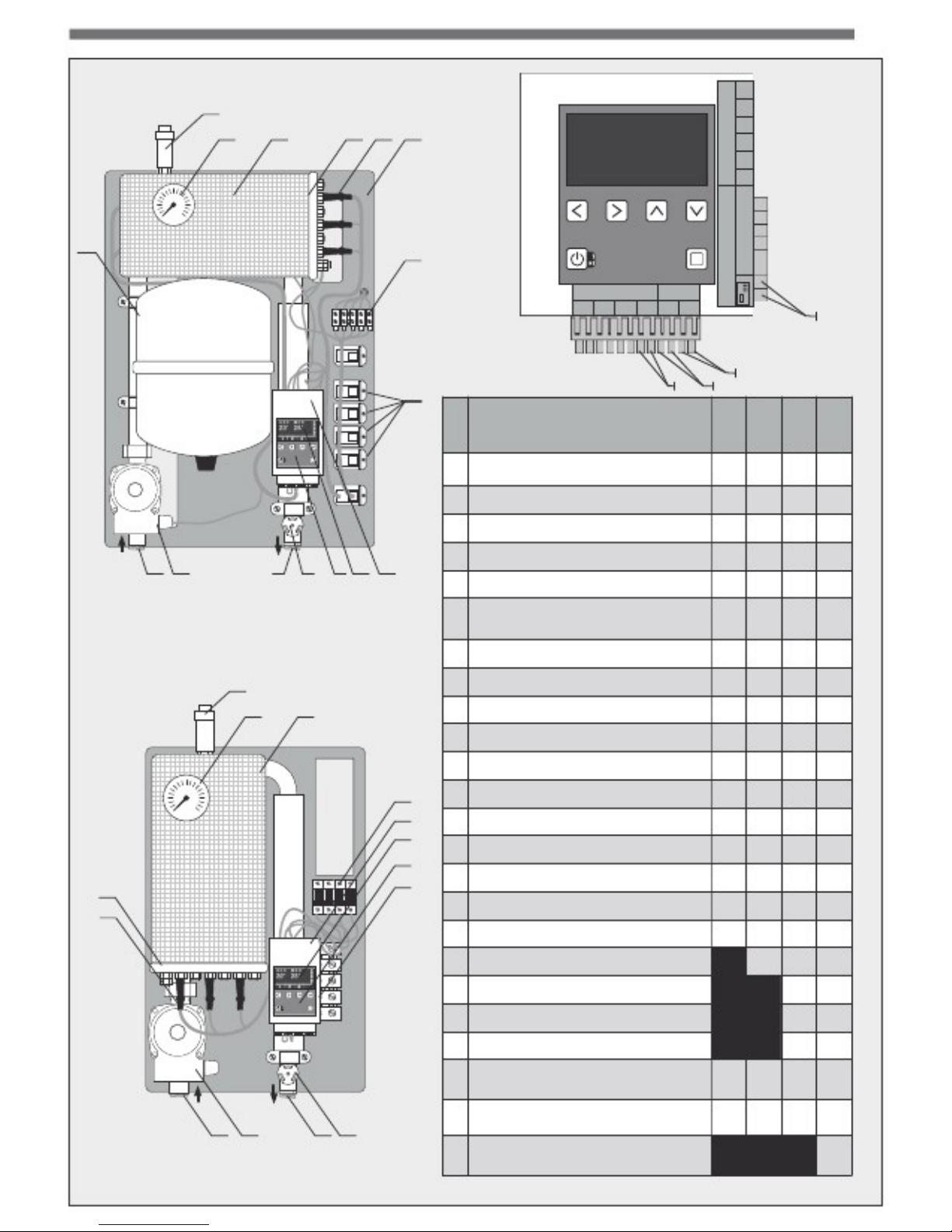

RELAYS

ESC

ON OFF

10

15

8

7 9 2

18

11

SENSORS

SENSORS

ELTERM

BODY. BAL. CH. HUW. ROOM. WEA..

EXTERNAL

REGULATORS

ATTENTION

THERMOREGULATOR

0 V!

6

5

4

3

2

1

Boiler

EKW AsZN

-

W

6

c

11:53:3312 05 2011 czw

c

123456

BOILER

EQUIPMENT

1

2 3 External casing

Mounting plate

Automatics mounting brackets

LCD display

Control panel

Room thermostat connection strip

Boiler body (tank)

Boiler insulation

Heating unit

ESC ON OFF

y

y y y y y y y y y y y y y y y y n

n

n

n

y

y

n

RETURN SUPPLY

4

16 5 4 3

14 17

13

5 6

Boiler

EKW AsB II

10

15

8

7 8 9 10

3/8”

automatic vent

11 Terminal strip

11

3

4

5

7

9

12

12

Relays

13

Feed stub pipe

3/4",

AsB II 1" 14

Return stub pipe

3/4",

AsB II 1" 15 Manomet

e

r 4 bar

16

Safety valve

3 bar 17 CH pump

(up to 48kW)

c

11:53:3312 05 2011 czw

c

123456

18 8 l membrane vessel

19 HUW pump

20 100l tank 21

Return stub pipe

¾’’

HUW 22 “Room” sensor terminal strip

23 „Floor” sensor terminal strip

24 HUW sensor terminal strip

ESC ON OFF

RETURN

SUPPLY

14 17

13 16 6

EKW

EKW EKW

AsZN . AsDC AsD

-W -W -W

12

24 22 23

EKW

AsBII

y y y y y y y y y y y y y y y y y y

n

n

n

y

y

n y y y y y y y y y y y y y y y y y y

y

y

y

y

y

n y y y y y y y y y y y y y y y y y y

y

y

y

y

y

y

Page 4

4

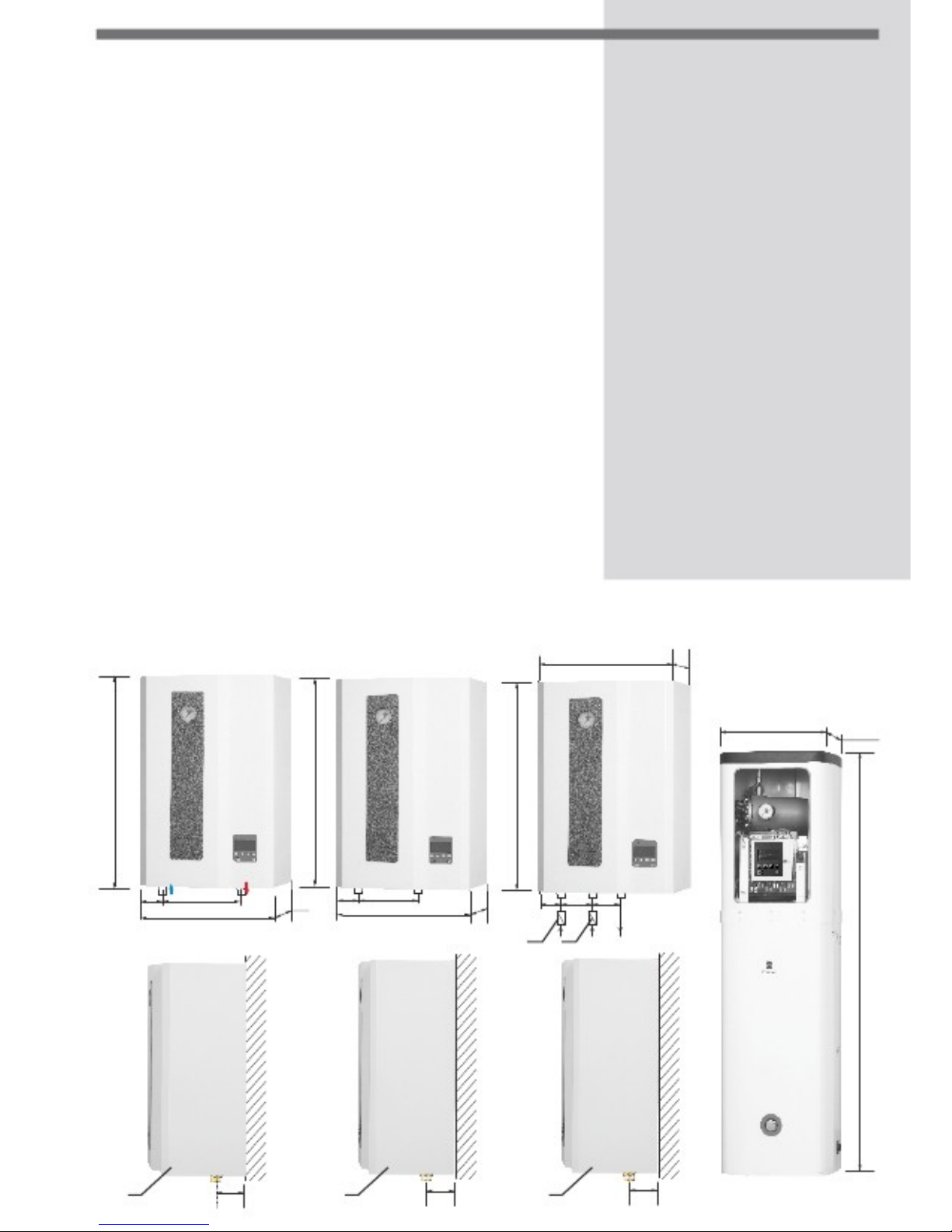

Thank you for placing trust in our company and for purchasing our product

. OPERATING AND ASSEMBLY MANUAL

- ELECTRIC TANKLESS WATER HEATER

FOR CENTRAL HEATING SYSTEMS

TYPE EKW AsZN-W, AsD-W AsDC-W, ASB II (Electric water boiler)

APPLICATION

All of the GoldLine (EKW AsZN-W, EKW AsD-W, EKW AsDC-W, EKW AsBII

) boilers are

designed to provide heating to small and medium sized locations equipped with

either open or closed low temperature (T<100°C) central heating water systems.

Boilers

EKW:

AsZN

-

W, AsD

-

W, AsDC

-

W in closed central heating system:

Boilers are designed for autonomous operation in both open and closed central

heating systems. Those boiler types come with a safety unit, 8l membrane vessel

and CH pump (*HUW pump in AsD-W and AsDC-W as well).

AsB

II 27 ÷ 48 kW

in closed central heating system

:

In closed heating system CH installation needs to be equipped in membrane vessel.

The membrane vessel is not supplied with the boiler.

AsB II

54 ÷ 144 kW

in closed central heating system

:

In closed heating system CH installation needs to be equipped in membrane vessel

and CH pump. The membrane vessel and CH pump are not supplied with the boiler.

TABLE OF CONTENTS

BOILER DESIGN

. . . .

. . . . .

.

. . .

. . . . .

2 HYDRAULIC AND

ELECTRICAL ASSEMBLY . .. . . . . . . . . 5

BOILER START

-UP

. . . . .

.

. . . . . ..

. . 7 SETTINGS

. . . . . . . .

. . . . . . . . . . .

. . . 8 REFERENCE DIAGRAMS

. . . . . . .

. . 17 DECLARATIONS OF CONFORMITY.

18

DIMENSIONS

: EKW AsB II

EKW AsZN

-

W EKW AsD

-

W

410

270

EKW AsDC

-

W

455mm 455mm

680

680

680

POWRÓT ZASILANIE

50

235

410

270

50

225

55

410

270

120 105

21 21

1

55

1

50

1

50

1560mm

Page 5

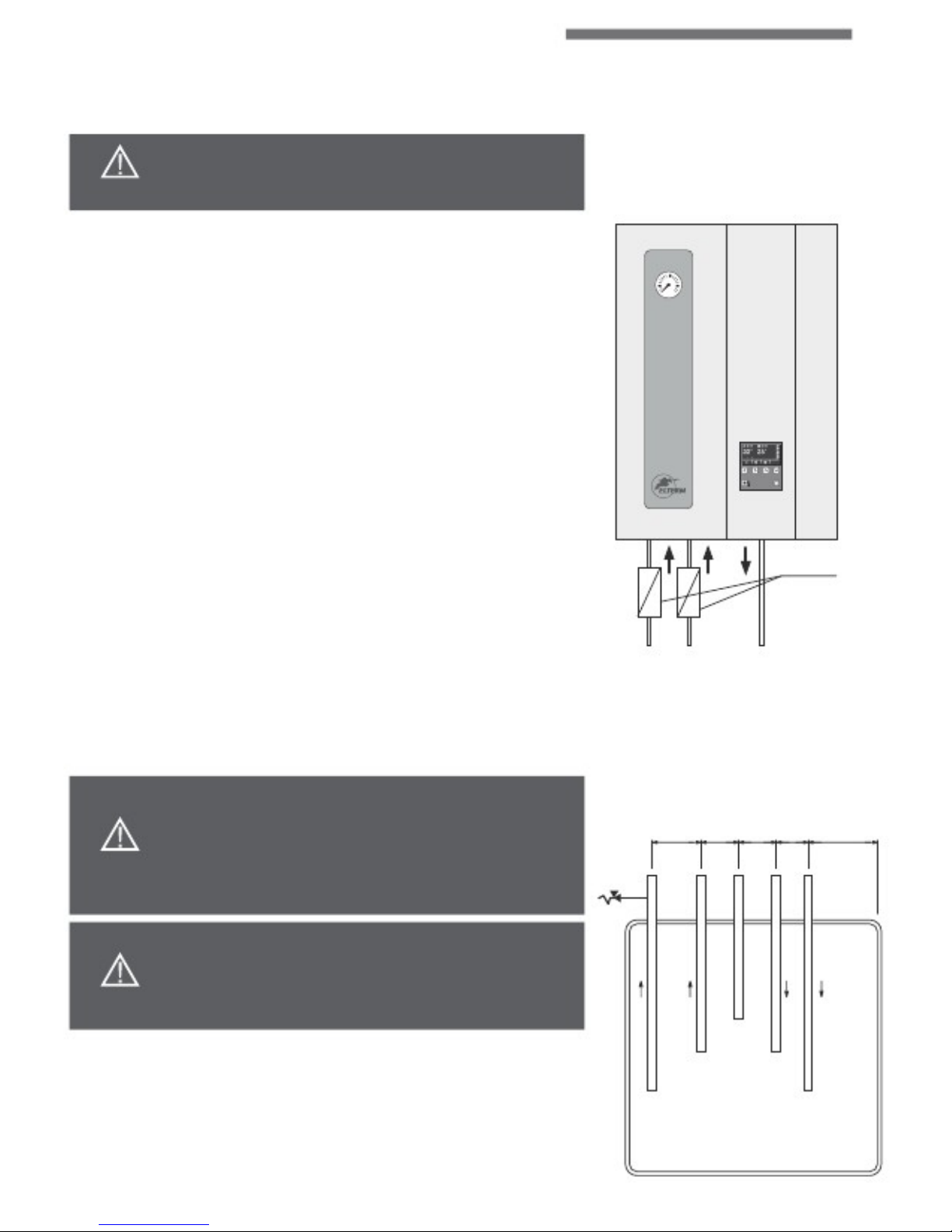

H

YDRAULIC

AND

ELE

CTRIC ASSEMBLY

HYDRAULIC ASSEMBLY

Please familiarize yourself with

the electrical and hydraulic diagram

, as

well as technical data prior to assembly. Details on www.elterm.pl

Boilers

EKW

AsZN

-W,

AsD-W, AsB II

are hanging vertical devices and should be

hung on bolts. First, remove the cuboidal casing (unscrew the sheet metal screw

at the bottom of the boiler).

HUW tank (supplied with AsD

-

W boiler) should as well be hung on bolts

. Boiler

EKW

AsDC

-W

is a standalone device

.

HUW tank is build

-

in into boiler.

I –

HYDRAULIC ASSEMBLY

A –AsZN

-W (¾” male thread half union for CH pump

– supplied with boiler

)

1. Feed stub pipe ¾” male thread – on the boiler’s right side (no. 13)

2. Return stub pipe ¾” female thread – on the boiler’s left side (no. 14)

B –

AsB II 27 ÷ 48

(

1”

male thread half union for CH pump

– supplied with boiler

)

1. Feed stub pipe 1” male thread – on the boiler’s right side (no. 13)

2. Return stub pipe 1” male thread – on the boiler’s left side (no. 14)

C – AsB II 54 ÷ 144

1.

Feed stub pipe

1” male thread

– on the boiler’s right side (n

o. 13)

2. Return stub pipe 1” male thread – on the boiler’s left side (no. 14)

D –AsD-W (¾” male thread half union

s for CH

and HUW

pump

s – supplied with boiler)

1. Feed stub pipe ¾” male thread – on the boiler’s right side (no. 13)

2. Return stub pipe ¾” male thread – on the boiler’s left side (no. 14)

3. Return stub pipe for HUW ¾” male thread – in the middle (no. 21)

5

EKW AsD

-W

BOILER

c

11:53:3312 05 2011 czw

c

123456

ESC ON OFF

ONE-WAY

VALVES

CH HUW SUPPLY

RETURN

E –EKW AsDC

-

W All male threads

¾”

(top view

)

80 60 60 50 120

ATTENTION

!

Concerns AsD

-W

only One-way valves are mandatory while assembly

AsD-W boiler

.

Lack of

such valves on CH and HUW return causes inappropriate boiler and

pump operation as well as loss of guarantee.

One-way valves are not supplied with

boiler.

ATTENTION!

Concerns AsDC

-

W only

One-way valves for CH and HUW are factory assembled.

Safety valve is not included.

circulation

The boiler has to be connected to the central heating system

using the

¾” or

1”

pipe

unions according to the direction of water flow (arrows on boiler).

Connection to be

made in accordance with PN-91/B-02413 (open central heating systems) or

PN-91/B-02414 (closed central heating systems.). T

he central heating system has to be

flushed prior to start-up. If installed outside Poland, the boiler ought to be co

nnected in

accordance

with the applicable regulations valid in the country where the boiler is

installed

.

CH

HUW water

inflow

cold water

inflow

CH

Page 6

6

ELECTRIC ASSEMBLY

BOILER START

-

UP

Connection to the electrical system needs to be done in accordance with the regulations applicable

in

the

country where the given boiler is installed, and therefore must be done by qualified electrician (electrical

company installing the boiler puts a relevant stamp on the guarantee card). Heaters with powers from 4

to

24 kW are designed by an alternating current, 3-phase (400V3N~50Hz). 4, 6 and 9 kW

versions are also

available in 1-phase (230V1N~50Hz). In case 400V work is essential one should protrude bridge out of L1 L2 L3

clamp bar. Boilers AsZN-W, AsD-W and AsDC-W are equipped in TLZ terminal strip.

AsB II boiler is equipped

in switch disconnector. For this terminal strip one should connect power supply in accordance to L1 L2 L3

N PE

description. The technical data table (page 7) provides information on the cross-

section of the power cord to

be used for boiler connection and the applicable power (A) of the main fuses protecting the boiler.

Boiler

EKW

should be connected to the electric installation by a device enabling full power disconnection

. It is also

required to use residual current device (in case house installation lacks such).

A –

Connection strip

1 –

HUW measuring sensor

– concerns AsD-W boiler (no. 24)

0

VOLT !!!

ESC

ON

OFF

RELAYS

Sensors

ELTERM

Body. BALL. CH. HUW. ROOM WEATH

EKW

BOILER START

-

UP

2 –

room sensor

ELTERM (

optional

)

– clamps (no. 22)

3 –

„weather” sensor

(no. 23) 4 –

external room temperature controller

,

recommended

ELTERM’s „ThermLine RT” (no. 6)

Sensors

EXTERNAL

REGULATORS

6

5

4

3

2

1

THERMOSTATE

6

B –

„weather

” sensor connection

Weather sensor

no. 25

we do connect to boiler using 2

-

strand wire.

We connect it to the boiler by no. 23 strip, on weather sensor by no.

25A strip – connection order is irrelevant (2-strand wire is not

included to the boiler).

23 22 24

25 A

- weather

sensor

26 A

- room

sensor

C –

room sensor connection

(op

tional

)

Weather sensor no. 2

6 we do connect to boiler using 2

-

strand wire.

We connect it to the boiler by no.

22 strip, on weather sensor by no.

26A strip – connection order is irrelevant (2-strand wire is not

included to the boiler).

ATTENTION

:

Room and weather sensors are universal and exchangeable. One should remember about proper connection according

to points B and C above.

Page 7

BOILER START

-

UP

Elements

1 –LCD screen

2 – HUW signal icon

3 – HUW pump active icon

4 – HUW program active icon

5 – CH signal icon

6 – CH pump active icon

7 – CH program active icon

8 – current HUW temperature

9 – current CH temperature

10 – time

11 – data

12 – CH and HUW temperature setting icon

13 – floor heating icon

14 – room temperature icon (optional)

15 – weekday

16 – relays status

17 – function buttons

18 –ON/OFF + back button

19 – green diode – boiler turned on

20 – red diode – boiler turned off

21 – CHOOSE button

7

2 8 10

11

3 4 1 5 6 7 9 15

c

11:53:33

12 05 2011 THU

c

1

2

3

4

5

6

16 12

ESC

ON

14

OFF

18 13

20 19 17 21

TECHNICAL DATA

Power

4 kW 4 kW 6 kW 6 kW 9 kW 9 kW 12 kW

15 kW

18 kW

21 kW

24 kW

Manual power

distribution

100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% 100%

- 67% -

33% Modulation of Power Safety fuses (A)

Power cord Heated area Alternative

power supply (mm²) (m²) heating (m²)

by 1/3 by 1/3 by 1/3 by 1/3 by 1/6 by 1/6 by 1/6 by 1/6 by 1/6 by 1/6 by 1/6 1

phase

3

phase

s 1

phase

3

phase

s 1

phase

3

phase

s 3

phase

3

phase

s 3

phase

3

phase

s 3

phase

1 x 20

3 x 6 1 x 32

3 x 10

1 x 40

3 x 16

3 x 20

3 x 25

3 x 32

3 x 40

3 x 40

3 x 2,5

5 x 1,5

3 x 4 5 x 2,5

3 x 10

5 x 2,5

5 x 4 5 x 4 5 x 6 5 x 6 5 x 10

~ 50 ~ 50 ~ 70 ~ 70 ~ 110 ~ 110 ~ 150 ~ 180 ~ 220 ~ 260 ~ 300 ~ 70 ~ 70 ~ 100 ~ 100 ~ 150 ~ 150 ~ 210 ~ 250 ~ 310 ~ 360 ~ 400 5x35 5x50

5x50

5x50

5x70

5x95

5x120

AsB II boiler Manual power Power

Safety Power cord Heated area

(kW) distribution (V) fuses (A) (mm²) (m²)

EKW 27 9 ÷ 18 ÷ 27 400 3 x 50 5 x 16 220 - 380

EKW 30 10 ÷20 ÷30 400 3 x 50 5 x 16 240 – 400

EKW 33 11 ÷22 ÷33 400 3 x 50 5 x 16 260 – 450

EKW 36 12 ÷ 24 ÷36 400 3 x 63 5 x 16 280 – 480

EKW 39 13 ÷ 26 ÷39 400 3 x 63 5 x 16 290 – 500

EKW 42 14 ÷ 28 ÷42 400 3 x 80 5 x 25 300 – 520

EKW 45 15 ÷ 30 ÷45 400 3 x 80 5 x 25 320 – 570

EKW 48 16 ÷ 32 ÷48 400 3 x 80 5 x 25 340 – 600

AsB II boiler

Power

Safety Power cord

(V) fuses (A) (mm²)

EKW 54

EKW 60

EKW 66

EKW 72

EKW 96

EKW 120

EKW 144

400 400

400

400

400

400

400

3x100A

3x100 A

3x125 A

3x125 A

3x160 A

3x200 A

3x240 A

* Exact section should be matched by qualified electrician

**

Exact heated area depends on multiple factors

Page 8

8

3

SETTINGS

SETTINGS

ATTENTION

!!!! Boiler connected to the installation according to

point II ELECTRICAL

ASSEMBLY. CH (HUW) pump should be turned on for III speed. Valves on

radiators should be completely open while start-up.

1.

Red diode on

– no. 20,

boiler stand

-by –

boiler turned on

. 2.

For 5 s.

Press button:

Green diode no.

19

turns on.

JEZYK

POLSKI

ENGLISH

OK

JEZYK

POLSKI

ENGLISH

OK

LANGUAGE

LANGUAGE

3.

Choose language

POLSKI / ANGIELSKI (ENGLISH).

– choose

ENGLISH

– back to POLISH

– OK.

Confirm language selection.

4. On

LCD –

sign „

venting

+

progress bar”. One cannot skip this part. CH

(optionally HUW) pump turns on –

there is no possibility to disconnect

heaters. Those 5 minutes should be sufficient to vent

whole system

including boiler and pump. In case however another venting

is essential

please repeat previous step.

5. On

LCD –

information according to

description on page 7.

4

Venting

5

c

11:53:33

12 05 2011 THU

c

1

2

3

4

5

6

1

I –

INITIAL SETTINGS

:

1

CH and HUW

(concerns AsD-W and AsDC-W boilers only)

temp. setting

– press

1 time

,

enter function

: HUW

CH – go to CH setting

– get back to HUW setting

50 50

HUW

.

CH

50

50

CONTROL PANEL

ESC

ON

CH and HUW temperatures are set in the same way.

OFF

Page 9

SETTING

- press another time, below sign appears

: HUW

CH - decrease CH or HUW temp.

- in

crease CH or HUW temp.

- „

BACK

” (

given

parameters are

set

)

Multiple press enables getting back to main menu

9

HUW

50°C

50°C

DEFAULT: 50

CH

2

„Weather curve” setting

- press

1 time

,

enter the „weather curve” setting

- choose curve from

0 to 10

DEFAULT: 50

2

Weather curves operate for outside temperatures lower than

15°C.

To

make them work properly one should set CH temperature, e.g. 30°C and

choose curve number (1 – 10). Zero – no weather correction.

Meaning of values

:

Boiler keeps fixed CH temperature – the one we have previously chosen.

This temperature is then increased by weather correction value, i.e.

boiler’s temperature = set temperature + weather correction; where

correction factor depends on our choice.

For each grade below

15°C,

weather correction equals:

for 1 for 2 for 3 for 4 for 5 for 6 for 7 for 8 for 9 for 10

Examples

Weather curve set at

5,

boiler CH temperature:

30°C.

For outside temperature

higher than 15°C boiler will keep 30°C. For external temperature equal 5°C,

correction will estimate 10 x 0,5 = 5°C, thus boiler will maintain 35°C. For external

temperature equal - 5°C numbers will be: 20 x 0,5 = 10°C, boiler temp.: 40°C.

c

11:53:33

12 05 2011 THU

c

1

2

3

4

5

6

c

k:0

50 (+0 ) c

1

2

3

4

5

6

0,1°C

0,2°C

0,3°C

0,4°C

0,5°C

0,6°C

0,7°C

0,8°C

0,9°C

1,0°C

Boiler temp

80 70 60 50

40 30 K-=1 External temp.

20 10 0

-

10 -20 -30 K=5 K=10 Curves

1, 5, 10

for CH temp.

30°C

Page 10

10

3.

Room temperature setting on boiler (optional)

- press

1 time

,

enter the function

:

Room temperature

setting on boiler

- decrease CH or HUW temp.

(from

5° to

29°C)

- in

crease CH or HUW temp.

(from 6° to 30°C)

- „

BACK

” (

given temperatures are

set

)

Multiple press enables getting back to main menu

SETTINGS

ad. 3

c

11:53:33

12 05 2011 THU

c

1

2

3

4

5

6

c

k:19 c

25 c

1

2

3

4

5

6

I –

SETTINGS F

RO

M MENU

:

A.

SETTINGS

: 1. 2. 3. 4. 5. 6. 7. 8. 9. POWER

. . . . . . . . . . . . . . . . . . . 100 / 67 / 33%

SECTIONS

. . . . . . . . . . . . . . . . . . . .

CH and HUW

DATE

& TIME

. . . . . . . . . . . . . . . .

current

PID-P . . . . . . . . . . . . . . . . . . . 1

– 2 – 3 – 4 –

5 CH HISTERESE

. . . . . . . . . . . . 1

– 2 – 3 – 4 – 5 – 6

°C

HUW HISTERESE

. . . . . . . . . . . 1

– 2 – 3 – 4- 5 – 6

°C

DEF. SETTINGS

CONTROL

S ROOM

(OP

TIONAL

) . . . . . .

.

9 program

s CONTROL

s HUW

(OPTIONAL

) . . . . . . . . 9 program

s

ad. A1

SETTINGS

ENERGY CONSUM.

VENTING

POWER

SECTIONS

DATE & TIME

PID-P

CH HISTERESE

66

1

2

B.

ENERGY

CONSUMPTION

C.

VENTING

(CH and HUW

) Ad. A1. „

SETTINGS

–

POWER

”

EKW boiler

- press

1 time

,

SETTINGS sign appears

- press

2 times

,

POWER sign appears

- press another time

,

below sign appears

POWER

- decrease boiler power to

67%

or 33% - increase boiler power to

67%

or 100%

- „

BACK

” (

given

parameters are

set

)

Multiple press enables getting back to main menu

POWER

DEFAULT: 100

100%

POWER

DEFAULT: 100

Page 11

SETTING

ad. A2

11

SETTINGS

ENERGY CONSUM.

VENTING

Ad. A2.

„SETTING

S – SECTIONS ”

active

CH and HUW

. - press 1 time, SETTING sign appears

- press 2 times, SECTIONS sign appears

- (

to enter SECTION area press one time

button:

Another press shows below screen:

HUW

CH ON ON )

HUW

CH ON ON

- press

1 time

,

enter CH function

If we would like to turn off HUW, do not

press this function

- press another time

,

below

screen

appears

HUW

CH

(when we turn off CH function)

(when we turn off HUW function.)

ON ON

HUW

CH

ON

ON

- OFF –

section inactive

- ON –

section active

- „

BACK

” (

given

parameters are

set

)

Multiple press enables getting back to main menu

CH CH

ad. A3

Ad. A3.

„

SETTINGS

–

DATE & TIME

” - press

1 time

,

SETTING sign appears

- press

2 times

,

DATE

& TIME sign appears

(to enter press twice button on the right )

- press another time

,

below screen appears

Date, time and weekday

- change parameter

- change parameter’s value

- „BACK” (

given

parameters

are set

)

Multiple press enables getting back to main menu

SETTINGS

ENERGY CONSUM.

VENTING

POWER

SECTIONS

DATE & TIME

PID-P

CH HISTERESE

66

1

2

FRI

Page 12

12

Ad. A4.

„

SETTINGS

–

PID-P” –

proportional integral derivative controller

- press

1 time

,

SETTINGS sign appears

- press

2 times

, PID

-P

sign appears

(to enter press three times button on the right

- change parameter

- change parameter’s value

ATTENTION

:

In case boiler needs long time to achieve set temperature - set 4 or 5

In case boiler reaches set temperature to quickly – set 1 or 2

)

SETTINGS

ad. A4

SETTINGS

ENERGY CONSUM.

VENTING

- press another time

, PID

-P

function is visible

POWER

SECTIONS

DATE & TIME

PID-P

CH HISTERESE

66

1

2

- „

BACK

” (

given

parameters are

set

)

Multiple press enables getting back to main menu

PID-P

DEFAULT: 2

ad. A5

Ad. A5.

„

SETTINGS

–

CH H

I

STERES

E

” - p

ress 1

time

,

SETTING sign appears

- press

2 times

,

CH H

I

STERES

E sign appears

(to enter press four times button on the right)

- press another time

,

below screen is visible

CH H

I

STERES

E - decrease h

i

steres

e 1 – 2 – 3 – 4 - 5 - in

crease h

i

steres

e 2 – 3 – 4 – 5 – 6 - „BACK” (

given

parameters are

set

)

Multiple press enables getting back to main menu

SETTINGS

ENERGY CONSUM.

VENTING

6

POWER

SECTIONS

DATE & TIME

PID-P

CH HISTERESE

66

1

2

CH

HISTERESE

DEFAULT: 4

Page 13

SETTINGS

ad. A6

13

SETTINGS

ENERGY CONSUM.

VENTING

Ad. A6. „

SETTINGS

–

HUW

H

ISTERESE

” - press

1 time

,

SETTINGS sign appears

- press

2 times

,

HUW H

I

STERES

E sign appears

(to enter press five times button on the right)

- press another time

,

below screen is visible

HUW H

I

STERES

E - decrease h

i

steres

e 1 – 2 – 3 – 4 - 5 - in

crease h

i

steres

e 1 - 2 – 3 – 4 – 5 –

6 (

recommended

6) - „

BACK

” (

given

parameters are

set

)

Multiple press enables getting back to main menu

.

6

SECTIONS

DATE & TIME

PID-P

CH HISTERESE

HUW HISTERESE

1

2

4

HUW

HISTERESE

DEFAULT: 4

Ad. A7. „

SETTINGS

–

DEF. SETTINGS

” - press

1 time

,

SETTINGS sign appears

- press

2 time

,

DEF. SETTINGS sign appears

(to enter press six times button on the right

- press another time, below screen is visible

DEF. SETTINGS

- NO

- resigning from

default

settings

- YES - OK - approving

default

settings

- activating

default

settings

- HUW temperature

. . . . . . . . . 50°C

- CH temperature

. . . . . . . . . . . 50°C

- Bioler power

. . . . . . . . . .. . . . . 100%

- HUW sections

. . . . . . . . . . . . . . ON

- CH sections

. . . . . . . . . . . . . . . .

ON - PID-5 . . . . . . . . . . . . . . . . . . . . . . 3

- CH h

i

steres

e

. . . . . .. . . . . . . . . . 6

- HUW h

i

steres

e . . . . . . . . . . . . . 7

- „

BACK

” (

given

parameters are

set

)

Multiple press e

nables getting back to main menu

)

ad. A5

SETTINGS

ENERGY CONSUM.

VENTING

DATE & TIME

PID-P

CH HISTERESE

HUW HISTERESE

DEF. SETTINGS

1

2

4

DEF. SETTINGS

NO

YES

OK

DEF. SETTINGS

NO

YES

OK

Page 14

14 SETTINGS

WEEKLY PROGRAMMING ON BOILER

+ HUW TIME PROGRAMMING (OPTIO

NAL)

- are not a standard boiler equipment

Weekly programming on boiler, as well as HUW time programming

enables setting and maintaining

given temperature

at any defined time periods with minute accuracy. Limpid menu and illuminated

display makes the whole setting process easy. All previously selected parameters are memorized in

non-volatile boiler memory. Electronic processor can steer up to 9 programs, eac

h enables setting

requested temperature in any given time period.

1.

In case of two temperature ranges overlapping, the one with higher, more comfort temperature is

chosen.

2.

In case of a program overlapping with INITIAL SETTINGS (p

t.

I ad.1),

boiler wi

ll heat according to

chosen program variant.

Variant

I

II III IV V VI VII M

O TU WE TH FR MO MO M

O M

O M

O TU TU WE WE TU WE WE TH TH TH FR FR S

A S

A SU S

A TH FR FR WEEKDAY PROGRAMING

SA SU

SU SU SU

All days active

4

days active

3

days active

1 day active

(free choice

) Workdays active

Weekend

active

6

days active

1.

2.

3.

4.

5.

6.

7.

MO TU WE TH FR SA SU

–

weekdays

START – turn the program on

STOP – turn the program off

TEMP – settings from 20°C to 70°C

AKTYWNY – YES/NO

PROGRAM NO. – 1 to 9

FUNCTION BUTTONS

1

2

3

4

5

TU WE

START:

STOP:

TEMP:

ACTIVE:

TH FR SA SU

08:03

16:00 NR.

25 c

YES

6

ESC

ON

OFF

7

Page 15

SETTINGS

ad. A8

15

SETTINGS

ENERGY CONSUM.

VENTING

Ad. A8. „

SETTINGS

–PROGRAMS

ROOM

” (

OPTIONAL

) - press

1 time

,

SETTINGS sign appe

ars - press

2 time

,

PROGRAMS

ROOM

sign appears

(to enter press seven times button on the right)

- press another time

,

settings menu is visible

- change parameter

- change parameter’

s value

- „

BACK

” (

given

parameters are

set

)

Multiple press enables getting back to main menu

PID-P

CH HISTERESE

HUW HISTERESE

DEF. SETTINGS

PROGRAMS ROOM

1

2

4

TU WE

START:

STOP:

TEMP:

ACTIVE:

TU WE

START:

STOP:

TEMP:

ACTIVE:

ad. A8

TH FR SA SU

08:03

16:00 NR

25 C

YES

TH FR SA SU

08:03

16:00 NR

25 C

YES

Ad. A9.

„

SETTINGS

–PROGRAMS

HUW

” (

OPTIONAL

) - press

1 time

,

SETTINGS sign appears

- p

ress 2

time

,

PROGRAMS

HUW

sign appears

(to enter press seven times button on the right

)

SETTINGS

ENERGY CONSUM.

VENTING

- press another time, settings menu is visible

- change parameter

- change parameter’s value

- „BACK” (

given

parameters are

set

)

Multiple press enables getting back to main menu

CH HISTERESE

HUW HISTERESE

DEF. SETTINGS

PROGRAMS ROOM

PROGRAMS HUW

2

4

TU WE

START:

STOP:

TEMP:

ACTIVE:

TU WE

START:

STOP:

TEMP:

ACTIVE:

TH FR SA SU

08:03

16:00 NR

25 C

YES

tak

TH FR SA SU

08:03

16:00 NR

25 C

YES

tak

Page 16

16

ACTIVE

/ NONACTIVE PROGRAM

Each program can be temporarily deactivated

.

One should then turn in PROGRAMS ROOM or PROGRAMS HUW:

A

CTIVE

: N

O In case

we want to turn the program on

: ACTIVE: YES

SETTINGS

TU WE

START:

STOP:

TEMP:

ACTIVE:

TU WE

START:

STOP:

TEMP:

ACTIVE

:

TH FR SA SU

08:03

1 6 :00 NR

25 C

NO

TH FR SA SU

08:03

1 6 :00 NR

25 C

YES

Ad. A9.

„

ENERGY

CONSUMPTION

” - press

1 time

,

SETTINGS sign appears

- press

1 time

,

go to ENERGY

CONSUM.

- press 1 time, counters appear

- RST –

reset erasable counter

RESETABLE COUNTER

:

consumed energy in

kWh (

since

measurement start for max 24h). After 24h counter stops

autamatically.

LAST

24H:

counter shows actual energ

y consumption for the

last 24h – update every 20 min.

- „

BACK

” (

given

parameters are

set

)

Multiple press enables getting back to main menu

ad. A9

SETTINGS

ENERGY CONSUM.

VENTING

RES. COUNTER:

LAST 24h:

RST

Ad. A10. „

VENTING

”

1.

Function enables additional system

venti

ng without turning boiler off.

Proper system

vent

ing guarantees its proper operation, as well as preven

ts whole

installation from too quick wear.

2.

Additional possibility to check whether CH and HUW pumps operate properly.

ad. A10

SETTINGS

ENERGY USAGE

VENTING

- press

1 time

,

SETTINGS appear

- press

2 times

,

go to

VENT

ING function

Page 17

SETTINGS

- press

1 time

,

below screen appears

: HUW

CH

(

turn on HUW bleeding)

17

ON ON

HUW

CH

OFF

OFF

- press

1 time

–

go to HUW function:

OFF - press

1 time

–

turn on HUW bleeding:

ON Same method applies to CH installation

- After proper

vent

ing process, one should turn function off

: HUW

CH OFF OFF

HUW

HUW

- „

BACK” (

given

parameters are

set

)

Multiple press enables getting back to main menu

REFERENCE DIAGRAMS

Exemplary application of

AsZN

-W

boiler

(Max. Operation temperature 40°C)

AsZN-W boiler in floor heating instalation

AsZN-W as an independent heat source

AsDC-W boiler

With build-in HUW tank – exemplary diagram

AsZN-W boiler with HUW tank

- heating large quantities of water in short time

circulation

HUW

outflow

CH

Cold water

inflow.

CH

safety

valve

ball

valve

manomet

e

r

circulation

pump

membrane

vessel

Page 18

D

ECLARATION

OF CONFORMIT

Y

DECLARATION OF CONFORMITY

EC No. 1/2011

ELTERM M.M. KASZUBA SP.J. 86

-

200 CHEŁMNO UL.

PRZEMYSŁOWA 5

We herewith declare, under our sole responsibility, that the following products:

Tankless water

heater for central heating systems (electric central heating water boiler)

TYPE:

• EKW4As, EKW6As, EKW9As (~230V,50Hz, max power 4kW, 6kW, 9kW),

18

•

EKW4As, EKW6As, EKW9As, EKW12As, EKW15As, EKW18As, EKW21As, EKW24As, EKW27As, EKW30As, EKW33As,

EKW36As, EKW39As, EKW42As, EKW45As, EKW48As (3N~400V,50Hz, max power 4kW, 6kW, 9kW, 12kW, 15kW,

18kW, 21kW, 24kW, 27kW, 30kW, 33kW, 36kW, 39kW, 42kW, 45kW, 48kW)

• EKW-AsBII (3N~400V,50Hz, combined max power 54- 960kW, boilers’ cascade, each up to 48kW)

Models: AsPC, AsP, AsBN, AsZN, AsD, AsBI, AsZN-W, AsD-W, AsDC-W, AsBII

manufactured at the Elterm production plant,

are in conformity with the applicable provisions of the following EC Directives:

Directive no.

73/23/EWG

as amended

Title:

: Low Voltage Directive

(LVD) Electromagnetic Compatibility Directive

(EMC)

Directive on the restriction of the use of

certain hazardous substances in electrical and

electronic equipment (RoHS)

Directive on waste electrical and electronic equipment

(WEEE)

; GIOŚ reg. no.

: E0001767

89/336/EWG

as amended

Nr 2002/95/WE

as amended

Nr 2002/96/WE

as amended

and that the standards hereinafter referred to have been duly applied and observed. The last two digits of the year of the CE

marking application: 08. The harmonized standards applicable to the product to which this declaration of conformity pertains:

Number: PN-EN 60335

-

1 Issue

: Title

: :94+A11:95+A1:96+A12:96+A13:98+A14:98+A2:2000

Safety of household and similar elec

tr

ical appliances

+A15:2000+A16:2001:2004/A1:2005/A12:2006(U)

Particular requirements for tankless water heaters

Int

erference emission for household appliances

Interference immunity

Harmonic current emissions

Limitations of voltage fluctuations

Electromagnetic fields

- methods for evaluation

And measurement

:2002+A1

:1999+A1:2004

:2004 PN-EN 60335

-2-

35

:1998+A1:2000:2005/A1:2007(U)

PN-EN 55014

-

1 PN-EN 55014

-

2 PN-EN 61000

-3-

2 PN-EN 61000

-3-

11

:2000 PN-EN 50366

:2004+A1:2006(U)

Other documents or information required by the EC Directives:

Report n

o.

:

B-47/03

CLBT/ZR/67/2003

456/BS/EMC/04

BE/39/2006

BEM-66/07

B-71/07

Date:

24.06.2003

09.07.2003

27.04.2004

27.01.2006

17.10.2007

17.10.2007

Laborator

y

:

KEWA - ECO, Bydgoszcz

GP -

CLBT, Warszawa

PREDOM

- OBR, Warszawa

Laboratorium Elektrotechniczne PCBC S.A.

Laboratorium Badawcze Maszyn i Urządzeń J.N.B. EUROVITA Sp. z o.o.

Laboratorium Badawcze Maszyn i Urządzeń J.N.B. EUROVITA Sp. z o.o.

Maciej Kaszuba

Chełmno, 2011.05.07

Page 19

WE ALSO RECOMMEND

:

HYDRAULIC BALANCERS

SHE, SHE

-

SP, SHE

-

OC

from 25 to 420 kW

LEATHERETTE

COAT

PUR FOAM

0,025W/mK

HYDRAULIC BALANCERS

SHE-ELTERM

HYDRAULIC BALANCERS

SHE-SP ELTERM

WITH AIR SEPARATOR

HYDRAULIC BALANCERS

SHE-OC ELTERM INSULATED

PUMP MODULES WITH MIX SYSTEM

Boiler's pump module with mix system

ADVANTAGES

: - Boiler's return protection (against dew

effect)

- Required along with new solid fuel CH

boilers installation (guarantee terms)

- Pump work regulation according to

temperature differences (supply vs.

return) - (turns pump off when low

supply temp. occurs)

- In case there is no separate safety

pipe in CH, boiler will not be cut

off from open system vessel (as it

happens in case of 3- and 4-way

valves)

Floor heating's pump module with mix system

-

Floor area

- up to 120m²

,

- Possibility to link up two separate funnels

- Regulation from 2° to 50°C

Details on

www.elterm.pl

Page 20

Reccomended room temperature controllers:

ThermLine RT

Room temperature controllers

ThermLine RT

Pump temperature controllers

ThermLine PT

ThermLine RT

–

R (

air temp.

)

ThermLine RT–F (floor temp.)

ThermLine RT–RF (air-floor temp.)

ThermLine RT–RW (wireless air temp.)

ThermLine PT

-

P2

ThermLine PT-P3

ThermLine PT-P4

controlls CH or HUW pump

controlls HUW pump

controlls CH and HUW pump

Advantages of RT controller:

• Programming with accuracy of 1 min.

• 9 independent programs

• Actual temperature setting

• Accurate hysteresis - from +/- 0,1°C to +/- 1°C

• Removable steering panel (safe installation)

• Build-in installator mode

• 16A relay

• Non-volatile memory

Advantages of PT controller:

• LED display

• Intelligent Anti Stop system

• Anti-freeze

• Simple handling

Electric towel rails and bathroom hea

ters

ECO 70 ÷ 110 W

and ECOTERM 320 ÷ 800 W with stepless power regulation

Full offer on www.elterm.pl

rok założenia

1992

ELTERM M.M. Kaszuba SP.J.:86-200 Chełmno, ul. Przemysłowa 5, POLSKA,

tel. (0048) 56/686 93 05, 692 06 06, biuro@elterm.pl • www.elterm.pl

Loading...

Loading...