Golden Technologies HMI 575, HMI 1200 TV, HMI 1200 User Manual

GOLDEN SCAN 3

ENGLISH

HMI 575

HMI 1200

HMI 1200 TV

®

1

ENGLISH

• Installation

Make sure all the parts for fixing the projector are in a good state of repair.

Make sure the point of anchorage is stable before positioning the projector.

The safety rope, properly hooked onto the fitting and secured to the framework, must

be installed so that, if the primary support system fails, the fitting falls as little as

possible. If the safety rope gets used, it needs to be replaced with a genuine spare.

SAFETY INFORMATION

1

INSTRUCTIONS MANUAL

Carefully read this instructions manual in its entirety and keep it safe for future

reference.

It is essential to know the information and comply with the instructions given

in this manual in order to ensure the fitting is installed, used and serviced

correctly and safely.

CLAY PAKY S.p.A. disclaims all liability for damage to the fitting or to other

property or persons deriving from installation, use and maintenance that have

not been carried out in conformity with this instructions manual, which must

always accompany the fitting.

CLAY PAKY S.p.A. reserves the right to modify the characteristics stated in

this instructions manual at any time and without prior notice.

Congratulations on choosing a Clay Paky product! We thank you for your

custom. Please note that this product, as all the others in the rich Clay Paky

range, has been designed and made with total quality to ensure excellent

performance and best meet your expectations and requirements.

• Maximum ambient temperature

For the fitting to operate well and reliably, the ambient temperature should not

exceed 35°C (95°F).

• IP20 protection rating

The fitting is protected against penetration by solid bodies of over 12mm (0.5”) in

diameter (first digit 2), but not against dripping water, rain, splashes or jets of water

(second digit 0).

• Protection against electrical shock

This fitting is classified in accordance with the type of protection against electrical

shock, in Class I. It must therefore be connected to a power supply system with

efficient earthing.

It is however recommended to protect the supply lines of the projectors from indirect

contact and/or shorting to earth by using appropriately sized residual current

devices.

• Connecting to the supply mains

Connection to the electricity mains must be carried out by a qualified electrical

installer.

Check that the mains frequency and voltage correspond to the frequency and

voltage stated on the electrical data label for which the projector is designed.

This label also gives the input power. Refer to this to evaluate the maximum number

of fittings to connect to the electricity supply in order to avoid overloading.

• Maintenance

Before starting any maintenance work or cleaning the projector, cut off power from

the mains supply.

After switching off, do not remove any parts of the fitting for 10 minutes.

After this time the likelihood of the lamp exploding is virtually null. If it is necessary to

replace the lamp, wait for another 15 minutes to avoid getting burnt.

The fitting is designed to hold in any splinters produced by a lamp exploding.

The lenses must be fitted and, if visibly damaged, they have to be replaced with

genuine spares.

• Temperature of the external surface

The maximum temperature that can be reached on the external surface of the fitting,

in a thermally steady state, is 90°C (194°F).

• Lamp

The projector mounts a high-pressure lamp that needs an external igniter.

This igniter is fitted onto the projector.

- Carefully read the "operating instructions" provided by the lamp manufacturer.

- Immediately replace the lamp if damaged or deformed by heat.

It is permissible to mount the fitting on normally flammable surfaces.

The products referred to in this manual conform to the

European Community Directives to which they are subject:

• Low Voltage 73/23

• Electromagnetic Compatibility 89/336

HMI 1200

• Minimum distance from target objects

The projector must be positioned in such a way

that objects struck by the beam are separated

from the lens at least by the distance indicated

on the lamp change label against the symbol

shown alongside.

• Minimum distance of flammable materials

The projector must be positioned so that any flammable materials are at least

0,1 meter (4”) for HMI 1200 and 0,07 meter (3”) for HMI 575 from every point on the

surface of the fitting.

(8’ 2’’)

2.5 m

HMI 575

(5’ 11’’)

1.8 m

• Preparing the warning label

Find the warning label (19) on the re-lamping cover (18) and, if necessary, replace it

with one of the optional multilingual labels (16) located in the projector lamp

compartment. For the instructions on opening the projector, read paragraph

4 MAINTENANCE.

CAUTION: Read carefully and meticulously apply the information and

instructions given on this label. In addition, check it is never removed as it

contains important safety information.

• Fitting the lamp

Refer to the instructions for opening the projector and changing the lamp in

paragraph 4 MAINTENANCE.

2

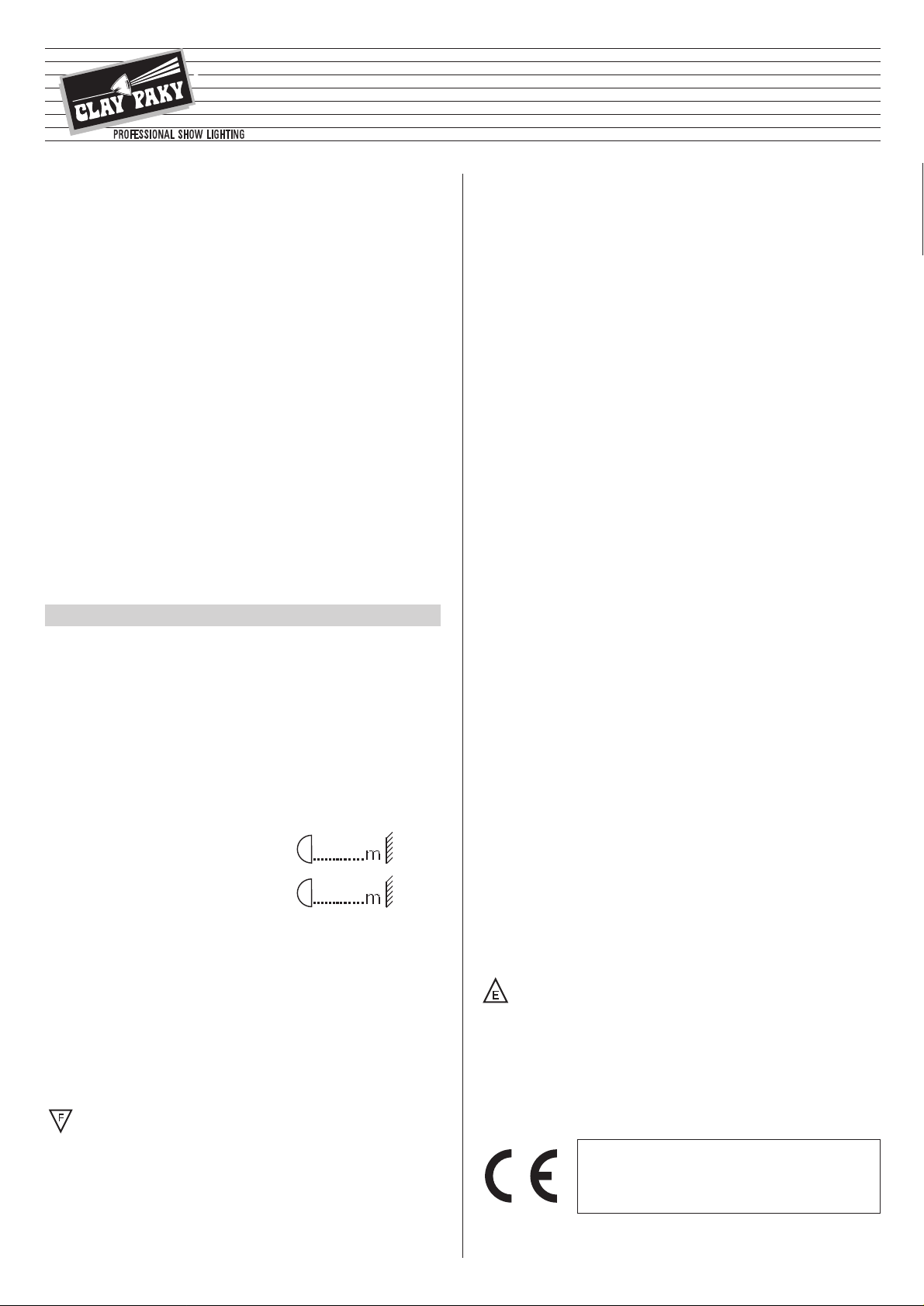

• Packing contents

Besides the projector, the packing also contains the following accessories:

- This instructions manual

code 099406 (1).

-

2 spacers code

167002/001 (2).

- 1 right bracket support plate

code 167003/001 (3).

- 1 left bracket support plate

code 167003/002 (4).

- 2 eyebolts M8x20mm

code 167004/001 (5).

-

2 nuts M8

code 020106/006 (6).

- 2 knobs code 020502 (7).

- 2 plane washers ø10,5mm

code 020210/004 (8).

-

1 bracket

code 101011/001 (9).

- 4 bracket bushings

code 101014/001 (10).

- 4 countersunk washers

code 080606/001 (11).

- 4 countersunk head

screws M8x20mm

code 020005/001 (12).

- 1 Allen wrench 5 mm

code 050001 (13).

- 4 handles

code 082017/001 (14)

(only for TV version).

- 8 screws TCEI M8x20

code 020002/029 (15).

- Multilingual label (16) with

safety information code 081948/003

(located in the projector lampholder compartment).

- 1 safety ropes code 105041/001 (17).

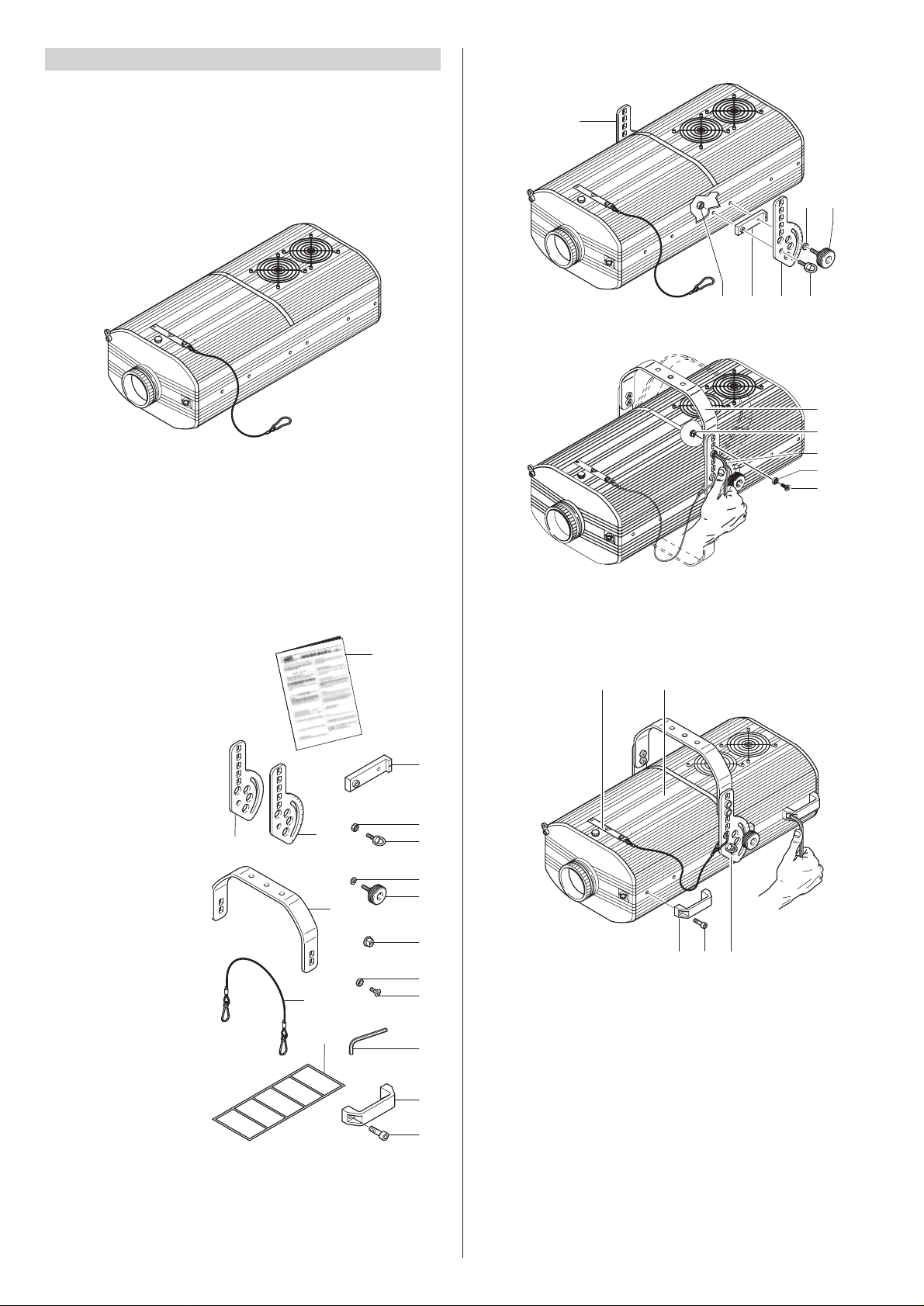

• Fitting the bracket

• Fitting the handles (only for TV version)

2

13

14

15

12

1

4

3

5

6

7

8

9

10

11

17

16

7

6 2 4 5

8

3

12

11

9

10

13

1514 4

19 18

UNPACKING AND PREPARING

2

• Unpacking

Open the box from the top, take all the accessories out of the box and remove the

polystyrene containing structures.

Open the plastic bag, remove the projector from the box frame and position it on a

horizontal top where access is easy to carry out the following preliminary work.

3

5

17

5

17

• Installing the projector

The projector can be installed on the ceiling or on a wall through the holes in the

bracket. It is recommended to use 2 screws ø12mm with nut and spring washer

.

CAUTION: Check the plates (3 and 4) are correctly secured to the sides of the

fitting; If the plates has been removed, to carry out non-routine maintenance

work, reposition them, following the relevant instructions and checking the

threads in the projector sides hold properly.

INSTALLATION AND FINE-TUNING

3

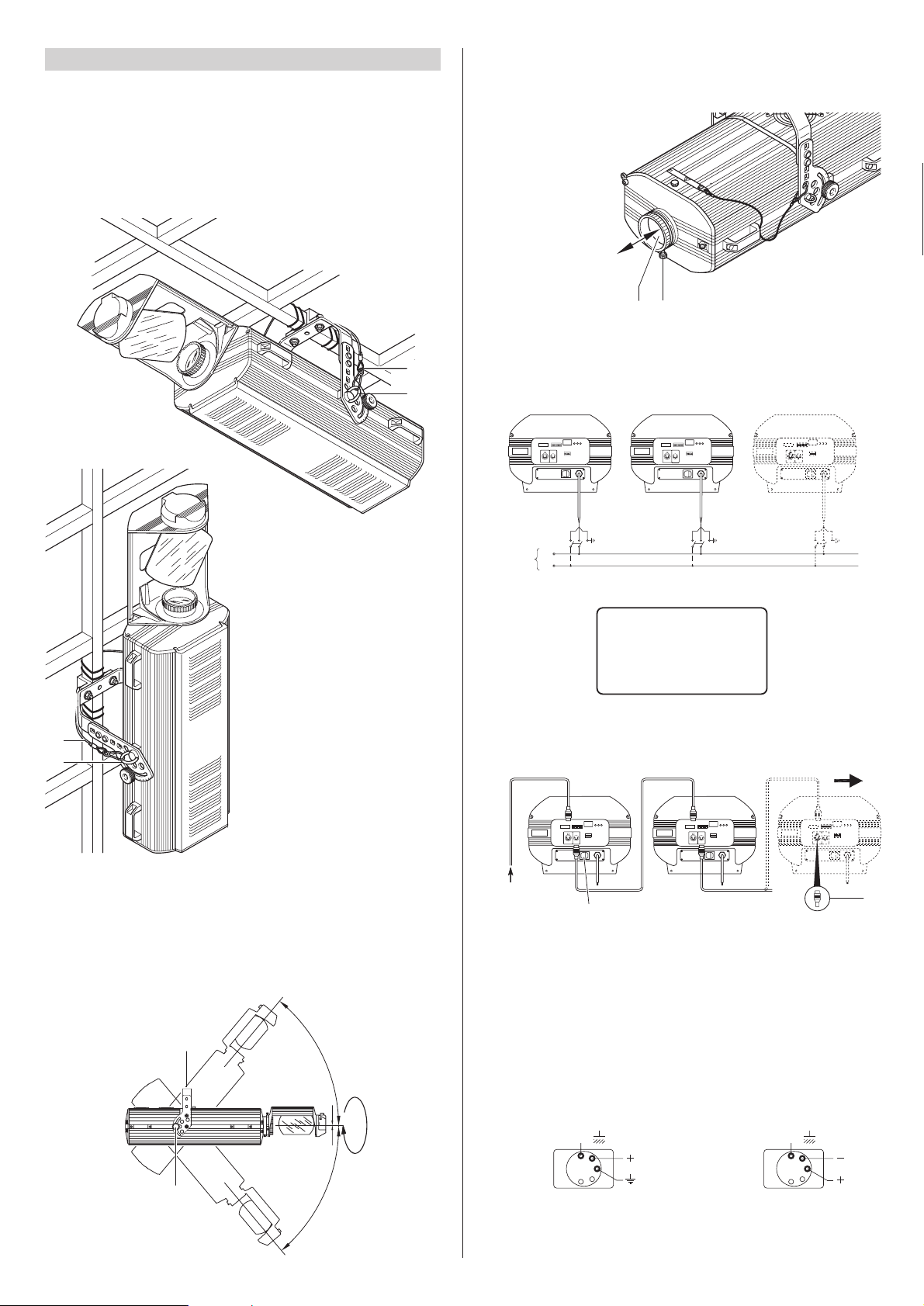

• Adjusting the projector position

180

°

50°

50

°

7

9

GOLDEN SCAN 3

• Adjusting the lens

Slightly unscrew the knob (20) and move the lens (21) until the projected image is

perfectly focused, then tighten the knob (20).

20

21

• Mains power connection

It is advisable to connect each projector via its own switch so as to be able to switch

it on and off individually from a distance.

N

L

Mains

BROWN =

BLUE =

YELLOW =

GREEN =

L

N

=

• Connecting the control signals RS 232/423 (PMX) - DMX 512.

The connection between projector and control unit and between different projectors

must be made with a cable conforming to the EIA RS-485 specifications: bipolar

braided, shielded, 120Ω characteristic impedance, 22-24 AWG, low capacity.

IMPORTANT: Do not use microphone cable or any other cable whose specifications

are different to the ones stated above.

The terminations need to be made with male/female connectors type XLR with

5 pins.

If using the DMX signal it is necessary to insert a terminal plug (22) on the last fitting

with a resistance of 120Ω (minimum 1/4 W) between terminals 2 and 3.

The terminal is not needed if using the RS232/423 (PMX) signal.

• Securing the safety ropes

Except for when the projector is standing on the floor, it is compulsory to fit the

safety rope (17). These need to be secured to the projector framework and then

hooked onto the eyebolts (5) screwed into the sides of the projector

IMPORTANT: The wires must make no contact with each other or with the metal

casing of the connectors. The casing needs to be connected to the braid of the

shield and to pin 1 of the connectors.

SIGNAL

SCREEN

SIGNAL

54

3

2

1

DMX

512

SIGNAL

SCREEN

SIGNAL

RS232/423

(PMX)

1

2

3

4

5

10

10

10

22

23

RS 232/423(PMX)

DMX 512

ENGLISH

Loading...

Loading...