Page 1

User Manual

C-650Plus II

© Godex Europe GmbH – Arnzhäuschen 36 – 42929 Wermelskirchen - Germany

Page 2

User Manual

i

User Information according to European Directive

2002/95/EC and 2003/108/EC

This unit must be recycled or discarded according to applicable local and national regulations.

The symbol shown above, applied to the product or on its packing, indicates that, at end of life, the product is

not to be thrown away, or disposed as unsorted municipal waste, but separately collected.

Godex encourages owners of information technology (IT) equipment to responsibly recycle their equipment

when it is no longer needed.

Customer that needs to dispose this equipment must contact the produce and follow the collection

framework available locally for the return, recycling and recovery of WEEE.

Customer participation to the separate collection is important to minimize any potential effects on the

environment and human health, due to the potential presence of hazardous substances in the equipment,

and aids the reuse and recycle of the materials by which the equipment is made.

Uncorrect disposal of the product by the customer will be punished according to the local regulations and

Laws.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

This manual refers to various company and products by their trade names.

In most of the cases, these designations are claimed as trademarks or

registered tramarkers by their respective companies.

Copyright 2012 GODEX

Page 3

User Manual

i

Godex Product Information

Thanks for choosing the Godex FPB-650PII printer.

Your printer is a reliable working equipment that will be very useful in your daily job.

Our printers have been designed to be compact and respectful of the work environment. They offer a wide

range of features and multiple functions that confirm the high technological level reached by Godex printers.

To maintain these printing performances unchanged in the long run, Godex has developed its own specific

branded consumables for each printer type that assure an excellent operation with high printing quality level

reliability.

Godex recommends to use only its original Godex branded consumables with original packaging (identified

by its holographic label). In this way, a proper use of the printer at quality level stated in the product

characteristics can be assured. All typical usage problems related to not certified consumables may be

avoided, such as an overall quality print level degradation and, often, the reduction of the product life due to

the fact that the proper working conditions for the print heads and other printer parts are not assured.

Moreover, Godex does not only certify its consumables in terms of working conditions but also carefully

controls their compliance with the international standard rules concerning:

no cancerous materials;

no flammability of the plastic materials;

other standards

Godex advises the customers not to use products for which the compliance to this safety rules are not

warranted. Finally seek your dealer or contact a GODEX office and be sure that are provided you the original

Godex branded consumables.

FCC Notes

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one

or more of the following measures:

o Reorient or relocate the receiving antenna.

o Increase the separation between the equipment and the receiver.

o Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected

o Consult the dealer or an experienced technician for help.

A shielded Centronics IEEE1284 compliant bi-directional parallel cable, maximum length 3 meters (10 feet),

and a shielded RS-232 serial cable, maximum length 15 meters (50 feet), are necessary for this device to

meet the requirements of a Class B digital device pursuant to part 15 of the FCC rules.

The above specified cables are readily available as Personal Computer or Peripheral accessories from

multiple retail outlets. Please consult your dealer for details concerning such cables and also for information

about FCC rules for digital devices.

Changes or modifications to the device covered by this manual, which are not expressly approved by the

party responsible for compliance, could void the user’s authority under the FCC rules to operate the

equipment.

Page 4

User Manual

ii

Canadian D.O.C. Radio Interference Regulation

This digital apparatus complies with the Canadian ICES-003 Class B limits for radio

frequency emissions.

Cet appareil numérique est conforme aux limites de Classe B de la norme NMB-003 du

Canada.

EEC Regulations

This equipment conforms to the essential requirements of EU Directives 2006/95/EC, 2004/108/EC.

Per the applicable requirements of EU Directive 2006/42/EC (“machines”) sound pressure of this product

(measured according to EN27779) does not exceed 70 dBA.

This product is also compliant to the EU directive 2002/95/EC (RoHS) and 2002/96/EC (WEEE).

Page 5

User Manual

iii

Table of Contents

User Information according to European

Directive 2002/95/EC and 2003/108/EC i

Godex Product Information i Offset Adjustments 27

FCC Notes i Reading the Preprinted Setup Forms 28

Canadian D.O.C. Printer Setup Flow Chart 29

Radio Interference Regulation ii Printer Setup through USB and RS232/C

EEC Regulations ii Ports 30

Table of Contents iii Godex CDC RS-232 Emulation Driver

Printer Presentation 1 Installation 30

Unpacking the Printer 1 FBP-650PII Setup Utility Installation 32

Printer Parts 2 Remote Setup 32

Front View 2 Read NVM 33

Rear View 3 Troubleshooting 35

Inside View 3 Paper Problems 35

Printer Installation 4 Paper Jams 35

Installing the Power Cable 4 Paper Damaged after printing 36

Installing the Ribbon Cartridge 5 Hexadecimal Dump 36

Paper Handling 9 Error Handling 37

Loading Paper 9 Recoverable Errors 37

The Operator Panel 10 Not-Recoverable Errors 38

Function Keys 10 Ribbon Cartridge Problems 39

Leds 11 Paper Specifications 40

LCD display messages 11 Cut Sheets 40

Software Driver Selection 12 Technical Specifications 41

Connection to the Host 13 Serial Interface Connection 42

Setting the Interface Parameters 14

Parallel Interface 14

Serial Interface 14

USB Interface 14

Printer Setup 15

Entering the Printer Setup Mode 15

Printing the Self Test Page 16

Printing the Printer Setup Forms 18

Filling the Printer Setup Forms 21

Setup Parameters 21

Page 6

User Manual

1

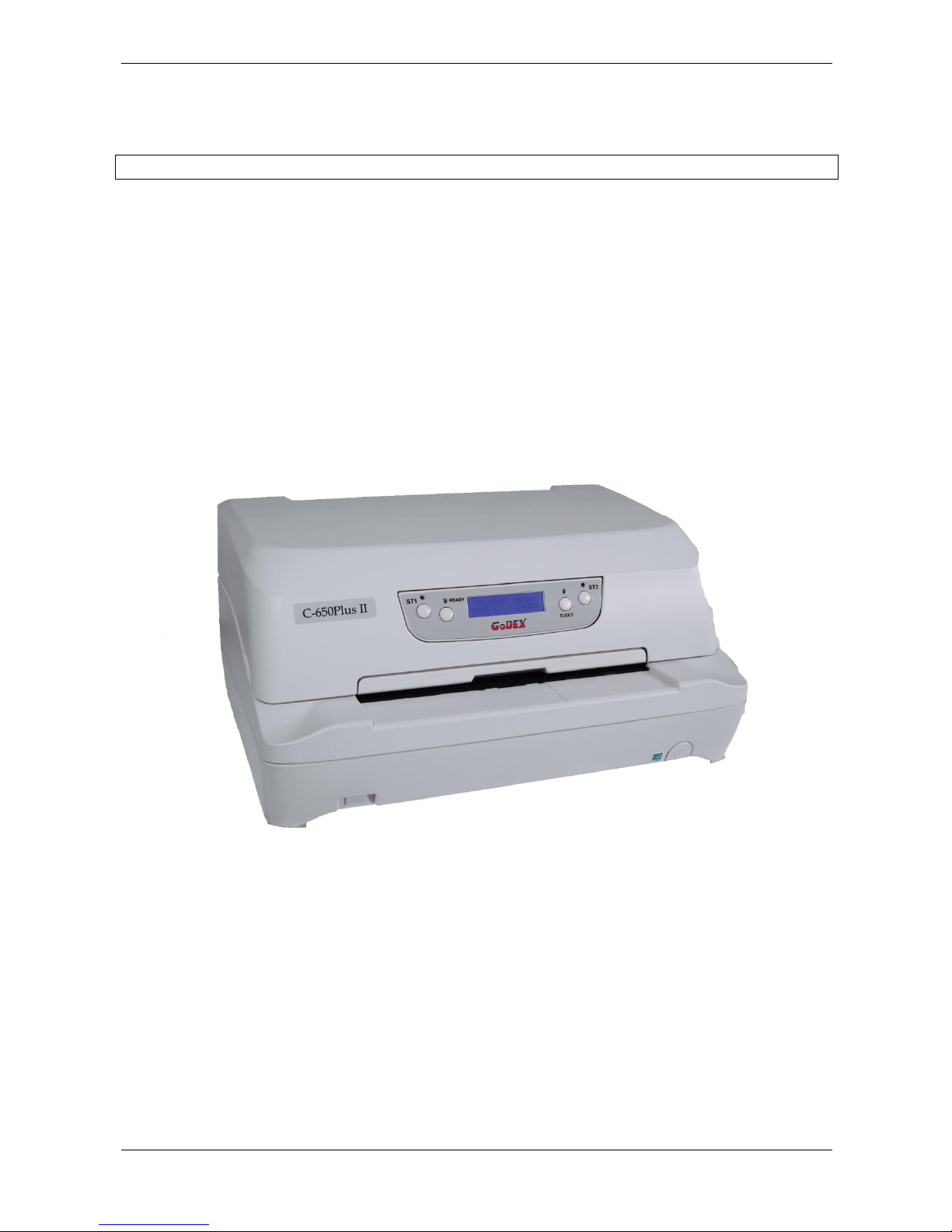

Printer Presentation

This dot-matrix printer is a multi-purpose printer for front office applications. Its compact structure is designed

for integration in an ergonomic environment. The printer provides a high level of reliability, form-handling

accuracy and data integrity.

Its main features are:

o Printing on a wide range of paper media: different types of cut sheets and multi-parts.

o High print pressure for multi-parts documents

o High print quality supplied by a 24 wire print head

o High reliability paper handling

The straight paper path allows the printing on particular documents such as envelopes and multipart

forms.

o Automatic paper thickness adjustment

The print head detects the paper thickness for correct printing on any type of document. This printer

can print also on documents with a variable thickness.

o Easy paper handling

The operator places the paper on the front table and the printer loads it without any other user

intervention. The paper ejection towards the front or the rear of the printer allows an easy access to

the printed document.

o Automatic document alignment feature

The printer checks automatically the alignment of the top margin of the document and adjusts it, if

necessary. The printout is therefore performed correctly independently from the paper loading

position.

o Standard parallel, serial and USB interface with automatic switch-over function.

o Easy printer setup through an optically managed menu.

o Supported emulations: Epson 570, IBM Proprinter XL24E, XL24E AGM, IBM 2390+, 4722, 9068 and

Olivetti PR40+, PR2, 2845.

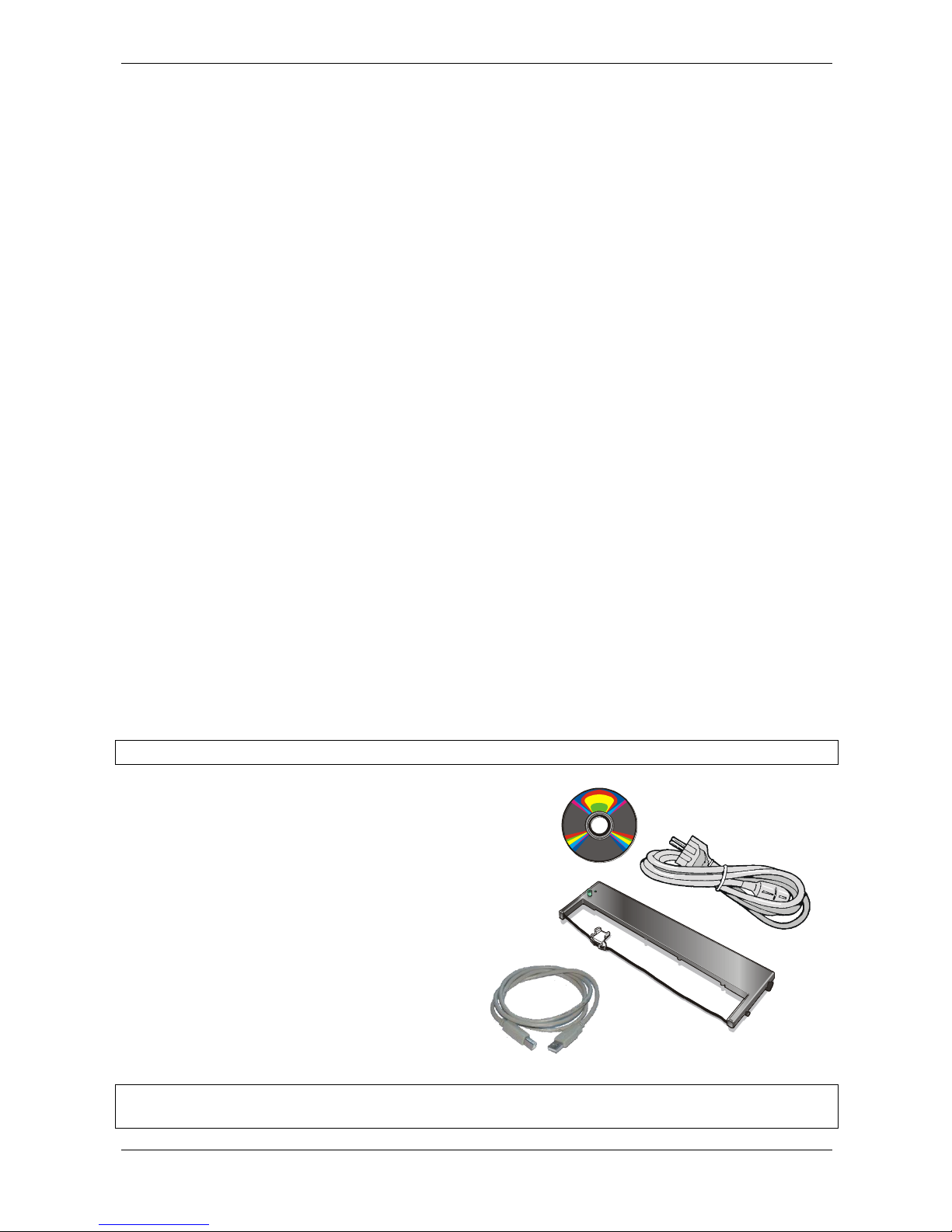

Unpacking the Printer

Together with the printer the following items are included in the shipment box:

Notify any damage to your supplier.

o Ribbon Cartridge

o Power Cable

o CD-ROM with printer documentation and drivers.

o Quick Reference Guide

o USB Cable

Always keep the packing material in a safe place as you must repack the printer into

it, when you need to move it.

Page 7

User Manual

2

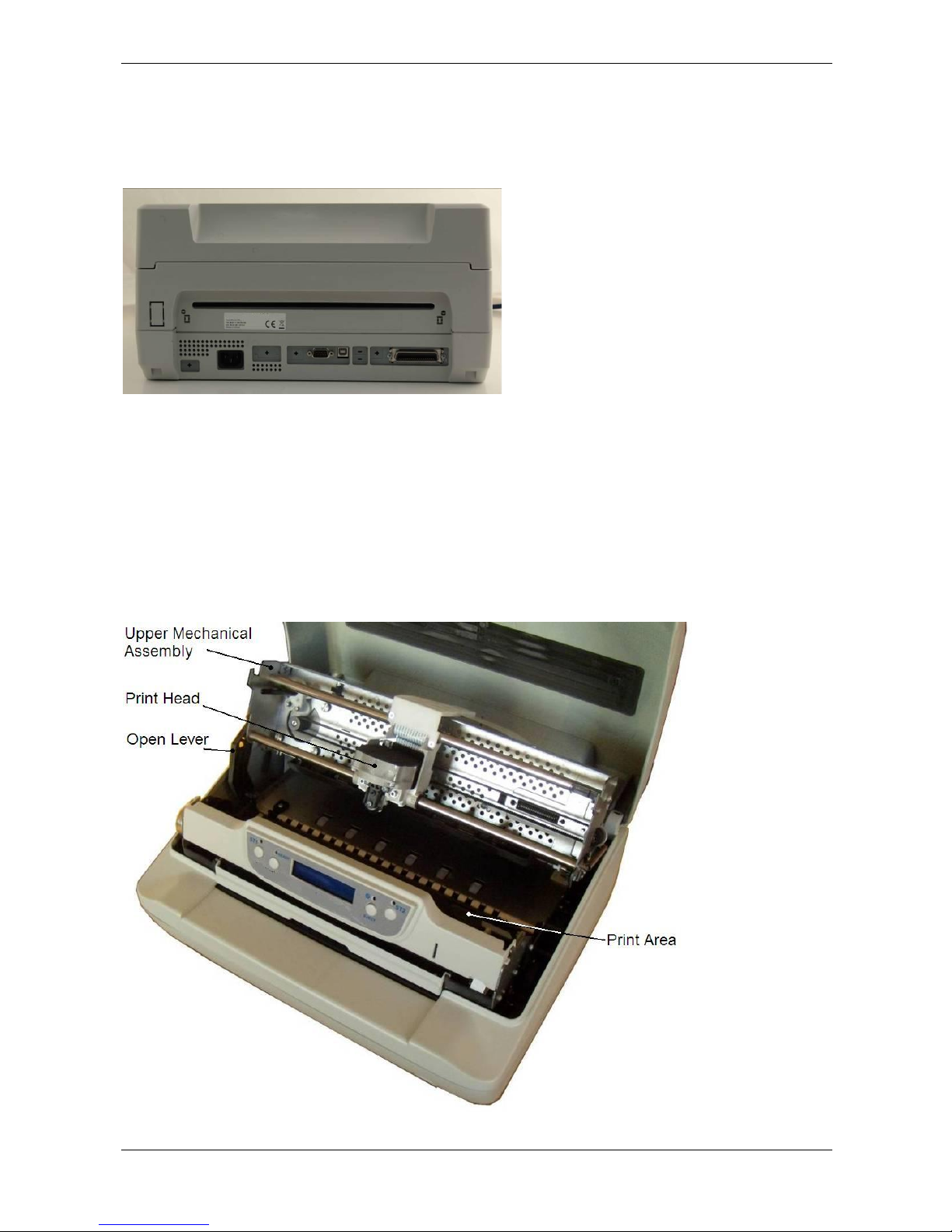

Printer Parts

Never remove any printer part unless it is expressly indicated in this manual.

Front View

Page 8

User Manual

3

Rear view

Inside view

Inside View

Page 9

User Manual

4

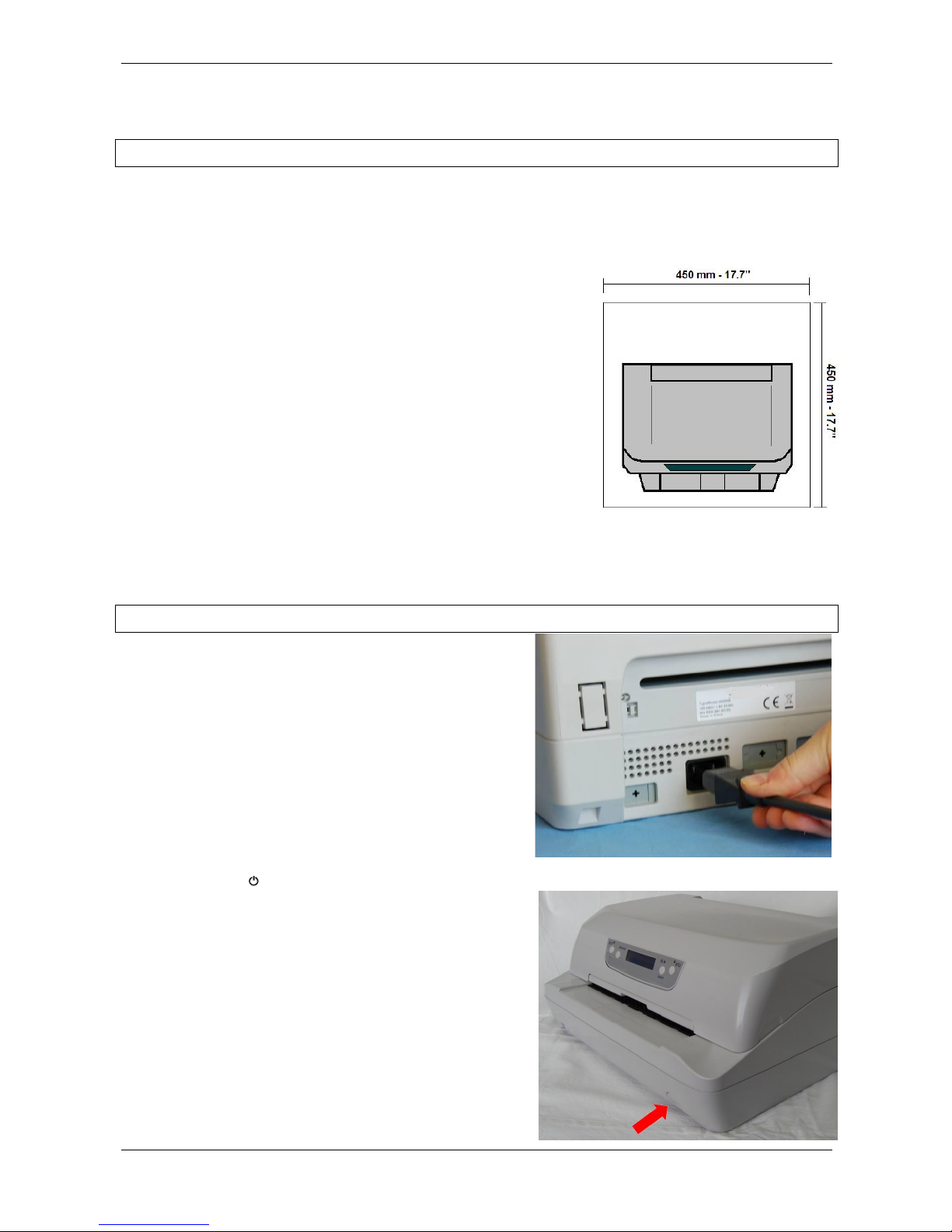

Printer Installation

Choosing a Suitable Location

Consider the following points when you choose the location for your printer:

The distance between the printer and the host computer must not exceed the length of the interface cable;

The location must be sturdy, horizontal and stable;

Your printer must not be exposed to direct sunlight, extreme heat, cold, dust or humidity;

When printing on standard paper formats, the paper comes out

partially on the rear side of the printer. Make sure that behind the

printer there is sufficient clearance to correctly move the paper.

Installing the Power Cable

1. Find the power cable connector on the rear side of the printer.

Always use a grounded outlet

2. Insert the power cable into the connector

on the printer and the other end into a

convenient mains outlet.

3. Press the key on the right side of the

printer front to power the printer on.

Page 10

User Manual

5

Installing the Ribbon Cartridge

In order to avoid damaging the print head or mechanical gearings, this printer

accepts only original Godex ribbon cartridges.

Therefore, if you install a not original cartridge, the printer may not work.

1. Remove the cartridge from its bag.

2. Unhook the green ribbon mask from the cartridge pins.

3. Open the printer cover.

The print head will automatically move in the middle

of the printer.

Page 11

User Manual

6

4. Open the upper mechanical frame.

Locate the open green lever in the left

side of the printer.

5. Unhook the green lever with the left hand

towards the rear of the printer in the open

position.

6. Then rise up the lever to its maximum

position in order to completely open

the head assembly.

7. Check for the “click” which means the

correct open lever position, showed in the inset

picture.

Page 12

User Manual

7

8. The printer is now ready to install the

ribbon cartridge.

9. Turn the tension knob in the direction

of the arrow to tighten the ribbon.

10. Insert the upper cartridge pins onto the

corresponding grooves on both sides of the upper

mechanical frame.

11. Then push the lower cartridge pins into

the corresponding lower grooves on both

sides of the upper mechanical frame until it clicks

into place.

Page 13

User Manual

8

12. Insert the green plastic ribbon mask onto the print

head. Pay attention to match the two pins (2) on both

sides of the green ribbon mask with the grooves (1)

on both sides of the print head.

13. Push the green ribbon mask up until it clicks into

place.

14. Turn the tension knob in the direction of the arrow to

tighten the ribbon

15. Carefully pull down the green lever following the step 3, 4, and 5 in reverse order in order to securely

close the Upper Mechanical Frame.

If you do not LOCK the Upper Mechanical Frame, the printer does not print correctly.

16. Close the printer cover.

Remark

The printer detects the Ribbon Genuine type and the amount of printed characters and stops in error if

appearing.

See “Error Message” later in this manual.

Page 14

User Manual

9

Paper Handling

This printer is designed for versatile and reliable paper handling. The flat-bed mechanism allows the handling

of special documents, such as multiple invoices, postcards, labels and tickets.

The print head detects the paper edges automatically, the sheet can therefore be inserted in any position

within the detection area according to the rules described in the following paragraph.

The paper alignment sensors determine the alignment of the upper paper margin, adjusting it if necessary.

Loading Paper

The inserted documents must not have folds, tears, pins, clips, staples or any foreign material.

If you insert damaged documents or paper with foreign material, you

can seriously damage the printer.

Fold

Clip

Pin

Tear

Staple

Foreign

material

Page 15

User Manual

10

The Operator Panel

The operator panel is located in the middle of the printer cover and is composed of function keys and leds

with which you can easily check the printer status and select the functions.

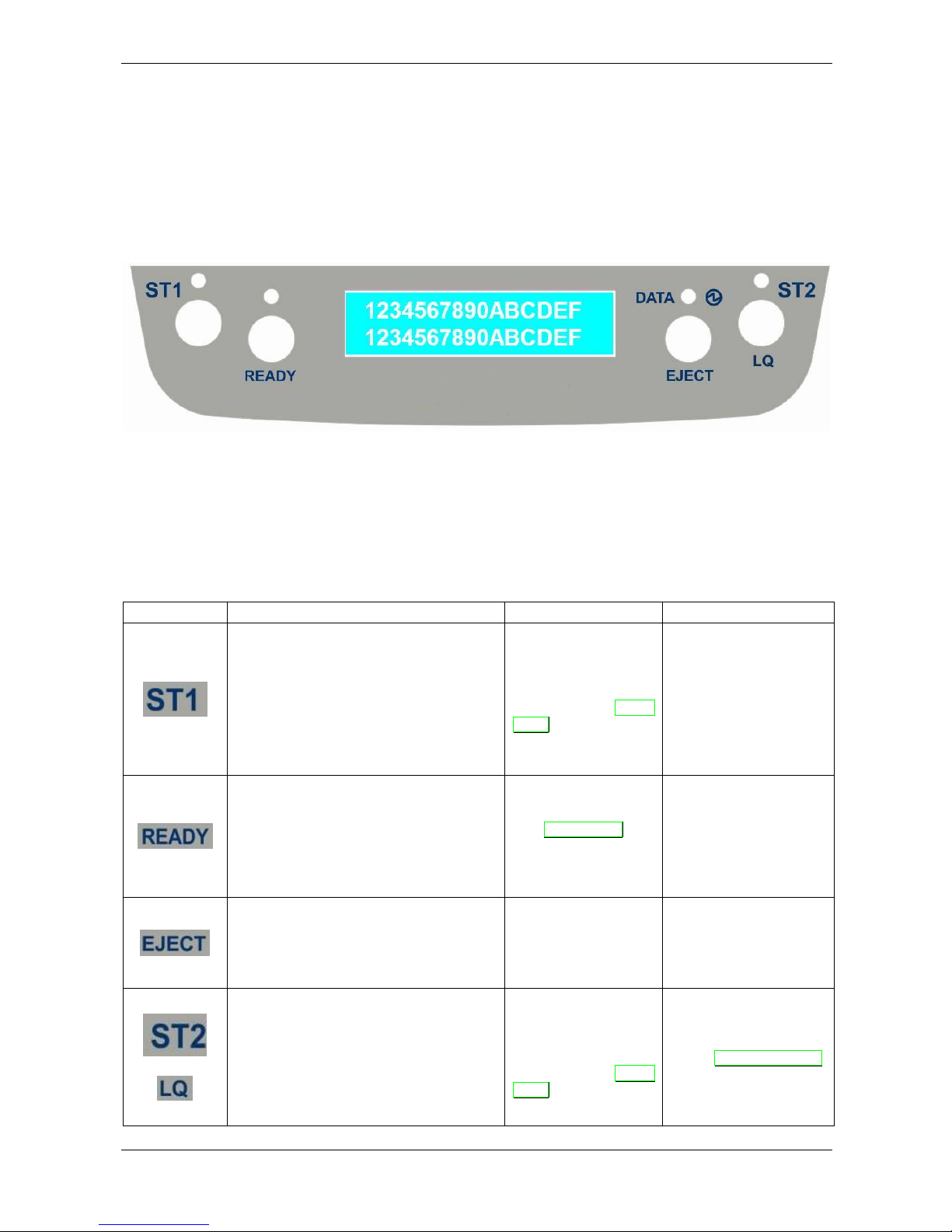

Function Keys

KEY

NORMAL MODE

SETUP MODE

SPECIAL MODE

When using the IBM 4722, IBM 9068 and

the Olivetti protocols in two operators

(“booking”) mode, the application software

determines the function of this key.

When the Printer is in

the Printer Setup mode,

pressing this key the

operator selects the

Configuration Page to

be printed. See “Printer

Setup” later in this

manual.

When pressed while

powering the printer on

with READY key selects

the T&D mode

(diagnostic).

When pressed while

powering the printer on

with cover open enters in

firmware upgrading

procedure.

Toggles the printer between Ready (on-line)

and Local (off-line) status.

If pressed in the Printer

Setup mode, the printer

prints the Self Test Page.

See “Printer Setup” later

in this manual.

When pressed while

powering the printer on,

selects the Printer Setup

Mode.

When pressed while

powering the printer on

with ST1 key select the

T&D mode (diagnostic).

Pressing this key, when the printer is offline,

or when the printer is online and no print

data are in the buffer, the printer ejects the

paper, if inserted (EJECT function). In the

Olivetti protocols, the EJECT function may

be performed only if the printer is offline.

When using the IBM 4722, IBM 9068 and

the Olivetti protocols in two operators

(“booking”) mode, the application software

determines the function of this key.

When the printer is offline or when the

printer is online and no print data are in the

buffer, pressing this key, the printer toggles

between Letter Quality and Draft printing mode

(no Olivetti)

When the Printer is in

the Printer Setup mode,

pressing this key the

Setup Page selected

with the ST1 key will be

printed. See “Printer

Setup” later in this

manual.

When pressed while

powering the printer on,

selects the HEX_DUMP

mode.

See “Hexdump Mode”

later in this manual.

Page 16

User Manual

11

Leds

LED

NORMAL MODE

SETUP MODE

SPECIAL MODE

Lit if paper presence, Unlit without paper

(no Olivetti).

When using the IBM 4722, IBM 9068 and

the Olivetti protocols in two operators

(“booking”) mode, the ST1 led is under

software control.

If the printer is in Setup

Mode, this led indicates

which setup page is

selected for printing. See

“Printer Setup” later in this

manual.

Blinks, together with the

ST2 led, if a printer error

occurs. See “Error

Message” later in this

manual.

Lit, when the printer is ready (on line).

Unlit, when the printer is in local (off line).

If the printer is in Setup

Mode, this led indicates

which setup page is

selected for printing. See

“Printer Setup” later in this

manual.

On, if the printer is powered on without

data.

Off, if the printer is powered off.

Blinks if the printer has data traffic or data

in the buffer.

Blinks if the printer is in

Setup Mode. See “Printer

Setup” later in this

manual.

Lit when the Letter Quality print mode is

selected. Unlit when the Draft printmode is

selected.

When using the IBM 4722, IBM 9068 and

the Olivetti protocols in two operators

(“booking”) mode, the S2 led is under

software control.

If the printer is in Setup

Mode, this led indicates

which setup page is

selected for printing. See

“Printer Setup” later in this

manual.

Blinks, together with the

ST1 led, if a printer error

occurs. See “Error

Message” later in this

manual.

LCD display messages

Upper line message

Lower line message

Indication

STARTING UP

The printer initialization phase is starting-up.

..INIT..

The printer initialization phase is ended

FPB-650PII Rel. xxx

The printer firmware release message

PRINTER READY

PROG1 DRAFT

The printer is in normal ready status showing the current Program and the current Font.

PRINTER READY

HEX-DUMP MODE

The printer is in normal ready status in hex dump mode.

PRINTER OFF-LINE

PUSH ON LINE

The printer is in off-line status.

PAUSE ON PRINT

PUSH ON LINE

The printer is going in off-line status while data are in the buffer and ready to be printed.

WAITING MEDIA

INSERT MEDIA

Data are sent to the printer, the printer is waiting for the insertion of the paper.

PRINTER BUSY

EPSON PARALLEL

The printer is currently printing showing the used Emulation and interface

SET UP

The printer is in Set Up status and is waiting for a blank sheet to be loaded

See “Printer Setup” later in this manual.

SETUP PAG=CONF

ST1=PAG ST2=PRT

The printer is waiting for a Set Up operation selection.

See “Printer Setup” later in this manual.

NVM CHANGED

The firmware of the printer has been updated and the NVM values have been resored to

the default parameters.

Page 17

User Manual

12

Software Driver Installation

At this point it is necessary to configure your printer for your application package.

The installation procedures depend upon the host environment.

The printer is Plug&Play, therefore when it is connected to a computer under Windows O.S., it automatically

discovers the new hardware and it looks in the systems the proper drivers.

For this purpose, together with the printer you receive a CD-ROM containing the printer drivers for the

Windows environment. This printer supports the Plug&Play facility in the 2000 / XP / Vista (32 or 64 bits) /

Win 7 (32 or 64 bits).

If you want to install the printer in the Windows environment, insert the CD-ROM and follow the given

instructions.

Page 18

User Manual

13

Connection to the Host

This printer can be connected to the host by means of the following available interface ports:

1. Parallel standard Centronics or bi-directional IEEE 1284 type interface

2. Serial RS-232/C interface

3. USB 2.0 full speed interface

Proceed as follows:

Make sure that both the host and the printer are turned off.

Identify the connector for the interface you want to plug and firmly insert the cable into it.

Fix the cable by means of the corresponding hooks or screws. on either side of the connector.

Parallel Interface Connection Serial Interface Connection

USB Interface Connection

Page 19

User Manual

14

Setting the Interface Parameters

Parallel Interface

The parameters set for the parallel interface mainly match of the most common environments and the printer

can be used immediately after connection to the host.

In case you need to modify the standard parameters see “Printer Setup” later in this section.

Serial Interface

Because of the great variety of the possible connection configurations, when you use the serial interface you

will need to set the parameters accordingly.

To assure a correct functioning of the printer connected through the serial interface, the transmission

parameters set for the printer must match the values set for the host.

In case you need to modify the standard parameters see “Printer Setup” later in this section.

USB Interface

Once the Godex FPB-650PII driver has been correctly installed, printer can be immediately used with USB

port.

For a complete description of the printer setup procedure see the paragraph “Printer Setup” later in this

manual.

Page 20

User Manual

15

Printer Setup

The Printer Setup is used to configure the printer parameters and to print a Self Test page, to check the

settings and the printer installation, and to perform the Print Offset Tuning.

The default configuration of this printer matches most of the commonly used environments, but it may be

necessary to change some printer parameters.

With this printer you print the forms for the setup, you fill them in, and then you insert them back into the

printer for reading.

Once the printer reads the form, the new values are set.

The following is the complete description of the Setup Procedure.

Entering the Printer Setup Mode

To enter the Printer Setup Mode press and hold the READY key pressed for at least 1 second while

powering the printer on. The printer enters the Setup Mode.

The leds ST1, ST2 and READY are unlit, the DATA led is flashing.

You can now:

Print the Self Test. See “Printing the Self Test” later in this manual.

Print one of the Printer Setup Forms (Configuration Menu or Program1 – Program2 – Program 3 - Program4

Menu) or the Offset Tuning Form. See “Printing the Printer Setup Forms” later in this manual.

Insert a filled-in Printer Setup Form to set the corresponding Setup values.

Page 21

User Manual

16

Printing the Test Page

The Self Test page is useful to test, if the printer has been correctly installed, and allows to see the current

parameter settings.

1. With the printer in the Setup Mode, insert a single sheet in A4 or Letter format.

2. The printer loads the sheet and stops.

3. Press the READY key again.

The printer prints the Self-Test page. Check that the printout is correct. The following printout example shows

the Printer Setup default values.

Once the self-test is finished, the printer remains in Setup Mode.

Page 22

User Manual

17

Page 23

User Manual

18

Printing the Printer Setup Forms

If you already have the preprinted forms for the printer setup, go to “Filling in the Printer Setup Forms” later in

this manual.

1. With the printer in Setup Mode, insert a blank sheet in A4 or Letter format.

2. The printer loads the sheet and stops.

3. If you press the ST1 key, the three leds change and you can select the Setup Page you want to print

as follows:

= unlit = lit = flashing

SETUP STATUS

Configuration Page

Program 1 – Setup Page

Program 2 – Setup Page

Program 3 – Setup Page

Program 4 – Setup Page

Offset Tuning Set Up Page

Pressing the ST2 key, the printer prints the selected Setup Page, showed in next pages.

Only the Program 1 Setup Page printout is reported because the other are exactly the same except for the

marker.

The printer setup forms contain all printer parameters and the values that can be set. The current value is

indicated by an asterisk (*).

For a detailed description of the parameters and the settings see “Setup Parameters” later in this manual.

Each Setup form is identified by a marker in the upper left corner of the page as follows:

Configuration Setup

( ) FPB-650PII

Program 1

( ) FPB-650PII

Program 2

( ) FPB-650PII

Program 3

( ) FPB-650PII

Program 4

( ) FPB-650PII

Offset Tuning Setup

( ) FPB-650PII

In this line an empty marker ( ) is printed within the printer model and the Code Version to be used for the

white calibration check.

Remark: do not fill this empty marker

For the printer with operator panel with LCD, the SETUP operation are directly displayed on the LCD jointly

with the above described leds combination.

Page 24

User Manual

19

Page 25

User Manual

20

Page 26

User Manual

21

Filling in the Printer Setup Forms

To change the values of the parameters, fill in the marker ( ) beside the value you want to set with a black or

blue ball-point pen or a fiber-pen.

Do not use pencils.

AUTOFEED SIGNAL ( ) ( )

disabled * enabled

SLCT-IN SIGNAL ( ) ( )

disabled * enabled

BUFFER CONTROL ( ) ( ) ( )

DTR XON/XOFF* XON/XOFF +

If more than one value is set for a parameter, the printer ignores these parameters and maintains the

currently set value.

Do not fill in the marker beside the title of the preprinted form, otherwise the printer will not be able to read

that page.

For a detailed description of the parameters and values contained in the Configuration and Program1,

Program2, Program3 and Program4 Menus, see “Setup Parameters” later in this manual.

For a detailed description of the Offset Tuning procedure, see “Offset Adjustment” later in this manual.

Setup Parameters

The following is a listing of the setup parameters.

Configuration Setup ( ) FBP-650PII : Code Version xxxx

Setup Parameter

Values

Description

RESTORE TO MFG

No*

all

config

prog. 1, prog. 2

prog. 3, prog. 4

The selected values are not set to factory

defaults.

The values set in all printer setups are reset to

factory defaults.

The values set in the configuration setup are

reset to factory default values

PROGRAM

prog. 1, prog. 2

prog. 3, prog. 4

on interface(*)

Defines the default Program Setup. Selecting

prog.1, prog. 2, progr 3 or progr.4 the setup

parameters set in the corresponding

Program Setup are set. Selecting on interface

the printer matches the Program 1 settings with

the data arriving on the Centronics interface, the

Program 2 settings with the data it receives from

the serial interface, Program 3 settings with the

data from USB interface and Program 4 setting for

any other optional interface.

When changing from one interface to the other,

the default values are set for the corresponding

Program Setup.

ERROR BUZZER

Disable, enable*

Enables or disables the buzzer in case of an

error.

JOB BUZZER

no beep*,

1 beep, continuous

Selects the behavior of the buzzer when a new

print job starts: no signal (no beep), one beep (1

beep) or a continuous signal (continuous).

Page 27

User Manual

22

Setup Parameter

Values

Description

INTERFACE TYPE

parallel, serial, opt, usb,

automatic*

Selects the interface type. In case of printer with

optional interface ports are installed, they are

listed to be selected. Choosing ‘automatic’ the

interface type is selected between all the

available interface ports depending on data

coming from host.

IBM FINANCIAL

No*

honorCTS, ignoreCTS

Disables the Financial protocol if IBM 4722 or

IBM 9068 emulation is selected

Enables the IBM FINANCIAL for the IBM 4722

and 9068 protocols. Considers (handles) or

ignores the CTS signal received from host for

the control of the data stream from host

INPUT BUFFER

1 Kb, 8 Kb*, 16 Kb, 32

Kb, 64 Kb

Selects the buffer size.

When the 'financial' interface is selected, this

setting is ignored.

IGNORE PE

Enabled, disable*

Selects whether the printer signals the paper

empty condition (disabled) or not (enabled) on the

busy line.

AUTOFEED SIGNAL

Disable*, enabled

The parallel interface uses (enabled) or does

not use (disabled) the AUTOFEED signal.

SLCT-IN SIGNAL

Disable*, enabled

The parallel interface uses (enabled) or does not

use (disabled) the SELECT-IN signal.

BUFFER CONTROL

DTR+SRTS*, SRTS,

XON/XOFF, ETX/ACK,

XON/XOFF+DTR+SRTS

Selection of the buffer protocol. When the

'financial' interface is selected, this setting is

ignored.

ROBUST XON

Enabled*, disabled

Perform the Robust XON (enabled) or not

(disabled).

WORD LENGTH

7 bit, 8 bit*

Sets the number of the data bits. When the

'financial' interface is selected, this value is

always set to 8 bits.

BAUD RATE

1200, 2400, 4800,

9600*, 19200, 38400

bps

Sets the data transfer rate.

PARITY BIT

even, odd, space, mark,

none*

Selects the parity control for the data.

STOP BIT

1*,2

Selects the number of stop bit.

USB MODE

2.0*, 1.1

Select the USB specification level

COPIES

no, yes*

Selects the printing on normal paper (no) or on

multicopy format paper (yes)

LOW NOISE

No*, yes

Disables/enables the low noise function

SAFE BOTTOM EDGE

no, yes*

Distance from the bottom of the last printer line .

Yes = 5,8 mm from bottom edge

no = 1,5 mm from bottom edge

GET EDGE QUOTE

0/4”, 1/4”*, 2/4”, 3/4”,

4/4”, 5/4”, 6/4”, 7/4

Sets the position in which the left paper edge is

checked. If set to 0, the check is performed at

the first line. The other values correspond to the

physical distance from the first line.

PASSBOOK TYPE

Setup

sw control*

Fixed thick*

Vertical

Horizontal

Enables the setting made in the current

PASSBOOK TYPE section and the specific

Escape command is not actives.

Enables the specific ESCape command.

Printing a document with fixed thickness.

Printing of passbooks with vertical binding .

Printing of passbooks with horizontal binding

Page 28

User Manual

23

Setup Parameter

Values

Description

PROTOCOL

EPSON 570*, IBM X24E*

X24E AGM, IBM 2390,

OLI. PR40+, OLI. PR2*,

OLI. PR2845, IBM 4722, IBM

9068, HPR 4915

Defines the printer protocol.

NOTE: For the IBM 4722 and 9068 protocols, if

the software driver uses the controlled link of

the IBM financial driver, set the IBM FINANCIAL

item in the Configuration Menu.

The default value is EPSON 570 for Program1,

IBM X24E for Program 3, OLI. Pr2 for Program

2 and 4.

FONT

Draft*, Courier, OCR-B,

Gothic, Prestige, Present,

OCR-A, Script, Boldface

Selects the font.

QUALITY MODE

LQ*, NLQ

Select the level of quality font.

DRAFT MODE

DRAFT*, HSD, VHSD

Select the level of draft font.

DOWNLINE LOADING

disabled, enabled*

Disable or enable the font downloading

HORIZONTAL PITCH

10 cpi*, 12 cpi, 15 cpi,

16.6 cpi, 17.1 cpi, 20 cpi

Selects the character spacing in characters per

inch (cpi).

VERTICAL PITCH

5 lpi, 6 lpi*, 8 lpi

Selects the line spacing in lines per inch (lpi).

LOCK

no lock*, font, hor. pitch,

font+hor.pitch

The following selections made in the printer setup

may be locked: font, horizontal pitch (hor.pitch), or

both the font and horizontal pitch (font+hor. pitch).

The locked settings cannot be changed via

software commands.

FORM LENGTH

# lines, A4*, letter, A5, legal

Sets the page length in number of lines or

standard formats A4, Letter, A5 or Legal. If you

select # lines, you must indicate the number of

lines you want to set in the scheme below this

selection. The values range between 0 and 255.

To set the values combine the numbers

considering that the first line corresponds to the

hundreds, the second line to the tens and the third

line to the units. See the example below.

Example:

How to set the form length to 82 lines:

FORM LENGTH

█ #lines

( )A4

( )Letter

( )A5

( )Legal

100x

( )0

( )1

( )2 10x

( )0

( )1

( )2

( )3

( )4

( )5

( )6

( )7

█ 8

( )9

1x

( )0

( )1

█ 2

( )3

( )4

( )5

( )6

( )7

( )8

( )9

Setup Parameter

Values

Description

LEFT MARGIN

10 x

1 x

Sets the left margin in number of columns. The values range

between 0 and 90. To set the values combine the numbers

considering that the first line corresponds to the tens, the

second line to the units. See the example below.

Page 29

User Manual

24

Example:

How to set the Left Margin to 20.

LEFT MARGIN

10x

( )0

( )1

█2

( )3

( )4

( )5

( )6

( )7

( )8

( )9

1x

█0

( )1

( )

( )3

( )4

( )5

( )6

( )7

( )8

( )9

Setup Parameter

Values

Description

RIGHT MARGIN

100 x

10 x

1 x

Sets the right margin in number of columns. The values

range between 0 and 190. The physical position of margin

depends on the current character spacing. To set the values

combine the numbers considering that the first line

corresponds to the hundreds, the second line to the tens

and the third line to the units. See the example below:

Example:

How to set the Right Margin to 101.

RIGHT MARGIN

100x

( )0

█1

10x

█0

( )1

█2

( )3

( )4

( )5

( )6

( )7

( )8

( )9

1x

( )0

█1

( )

( )3

( )4

( )5

( )6

( )7

( )8

( )9

Setup Parameter

Values

Description

TOP MARGIN

10 x

1 x

Sets the top margin in number of lines. The values range

between 0 and 90. To set the values combine the numbers

considering that the first line corresponds to the tens, the

second line to the units. See the example below.

Example:

How to set the Top Margin to 15.

TOP MARGIN

10x

( )0

█1

( )2

( )3

( )4

( )5

( )6

( )7

( )8

( )9

1x

( )0

( )1

( )

( )3

( )4

█5

( )6

( )7

( )8

( )9

Setup Parameter

Values

Description

BOTTOM MARGIN

10 x

1 x

Sets the bottom margin in number of lines. The values range

between 0 and 90. To set the values combine the numbers

considering that the first line corresponds to the tens, the

second line to the units. See the example below.

Example:

How to set the bottom margin to 34 lines:

BOTTOM MARGIN

10x

( )0

( )1

( )2

█3

( )4

( )5

( )6

( )7

( )8

( )9

1x

( )0

( )1

( )

( )3

█4

( )5

( )6

( )7

( )8

( )9

Setup Parameter

Values

Description

IBM C-SET

IBM set 1*, IBM set 2

Selects the IBM character set.

IBM COMPRESS

17.1 cpi*, 20 cpi

Selects the pitch for the compressed

mode printing in IBM emulation.

EPSON C-SET

Italic, graphic*

Selects italic or graphic Epson character

set.

NATION C-SET

USA*, FRANCE, GERMANY,

ENGLAND, DENMARK1,

SWEDEN, ITALY, SPAIN1,

JAPAN, NORWAY, DENMARK2,

SPAIN2, LATIN A1

Selects the national character sets.

Page 30

User Manual

25

Setup Parameter

Values

Description

CODE PAGE

CP437*, CP437G, 96GREEK,

CP850, CP851, CP852, CP853,

CP855, CP857, CP858, CP860,

CP862, CP863, CP864, CP865,

CP866, CP867, CP876, CP877,

CP1098, CP1250, CP1251,

CP1252, CP1257, GOST, TASS,

MAZOWIA, CP437SL, UKRAIN,

KOI8-U, 8859/1, 8859/2, 8859/3,

8859/4, 8859/5, 8859/6, 8859/7,

8859/8, 8859/9, 8859/15,

ROMAN-8, ID 12, CP874, ID 14,

ID 17, SANYO, KU, PHILIP

Selects the code page for both the IBM

and the EPSON emulations.

OLIVETTI C-SET

CODE PAGE, INTERN.*,

GERMANY, PORTUGAL,

SPAIN1, DEN/NORW, FRANCE,

ITALY, SWE/FIN, SWISS,

G. BRITAIN, USA ASCII,

GREECE, ISRAEL, SPAIN 2,

JUGOSLAVIA, TCV 370,

CANADA, SDC, TURKEY, CIBC,

PC-DEN/NORW, PC-DEN OPE,

PC-210, PC-220, OLI-UNIX

Selects the character sets for the

OLIVETTI protocol.

Selecting CODE PAGE, it is possible to

select one of the above Code Pages to

be used with the OLIVETTI protocol.

OLIVETTI COMPRES

17.1 cpi*, 16.6 cpi

Selects the compressed pitch in

OLIVETTI protocol.

VERT. RESOLUTION

1/216 inch, 1/240 inch*

Sets the vertical character resolution.

Setting used for the OLIVETTI

protocols.

CUT SHEET EJECT

on front*, on rear

Selects whether the cut sheet loaded

into the printer is ejected towards the

front or the rear of the printer.

PRINT DIRECTION

unidir., bidir., sw control*

Selects the printing direction of the print

head: unidirectional (unidir.),

bidirectional (bidir.) or selected via

software (sw control).

LINE MODE

LF=LF, CR=CR*

CR=LF+CR

LF=LF+CR

LF&CR=LF+CR

If the printer receives a LF code (LF), it

only performs a line feed. If the printer

receives a CR code (CR), it only

performs a carriage return.

If the printer receives a CR code (CR), it

performs a carriage return followed by a

line feed. If the printer receives a LF

code (LF), it performs a line feed.

If the printer receives a LF code (LF), it

performs a line feed followed by a

carriage return. If the printer receives a

CR code (CR), it only performs a

carriage return.

If the printer receives a LF code (LF) or

a CR code (CR), it performs both a line

feed and a carriage return.

WRAP MODE

truncate, autowrap*

The data exceeding the line length are

truncated (truncate) or printed on the

following line (autowrap).

REFERENCE EDGE

Left*, right

Document reference on left or right, for

software compatibility.

Page 31

User Manual

26

Setup Parameter

Values

Description

SLASHED ZERO

No*, yes

Selects the printing character for zero,

with a slash (yes) or without (no).

EJECT ON FF

no, yes*

Performs a form feed according to the

selected page format (no) or ejects a

cut sheet loaded into the printer (yes).

RESET WITH EJECT

no, yes*

When the printer receives a reset

command, if this item is set to yes the

paper inserted in the printer is ejected.

If the item is set to no the printer

performs only the reset command.

CUT SHEET EJECT

On front*, on rear

Selects wheter the cut sheet loaded into

the printer is ejected toward the front or

the rear of the printer.

Page 32

User Manual

27

Offset Adjustments

For a precise adjustment of the position of the printed characters on a preprinted form, the printer allows to

easily adjust the first line and the first printing column as follows:

1. When the printer is in Setup Mode, insert a blank sheet into the printer press the ST1 key until the

leds are in the configuration showed in previous SETUP STATUS table.

2. Press ST2 key, the following sheet will be printed:

3. Fill in the marker corresponding to the value you want to set .

Page 33

User Manual

28

The Vertical Offset Tuning values correspond to 1/60 inches and set the vertical offset of the first print line

starting from the default standard position at 1 mm from the upper paper margin.

The Horizontal Offset Tuning values correspond to 1/60 inches and set the horizontal offset of the first print

line starting from the default standard position at 3 mm from the left paper margin.

If you need to change the default position of the first print line the vertical offset can be set in the Vertical

Position Offset lines and/or the horizontal offset in the Vertical Position Offset lines.

Both these values correspond to 1/10 inch values.

1 mm

3 mm

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Vertical Offset Tuning

Vertical Offset Tuning

VERT. DEF. POS

HORIZ

DEF.

POS

Horizontal Offset Tuning

= FIRST PRINT POSITION

Reading the Preprinted Setup Forms

When the Printer Setup Forms have been filled in, insert them back into the printer, when the printer is in

Setup Mode.

The printer is able to recognize the Setup Forms by means of the markers on these pages. The printer reads

the values marked for the various parameters and configures the printer accordingly.

The settings are confirmed by a # symbol printed on the left of the corresponding marker.

The following page shows the printer setup flow-chart.

For further details concerning the parameters that can be set in the Configuration Setup, Program 1, Program

2, Program 3 and Program 2, see “Setup Parameters” before in this manual.

For further details on how to adjust the offset with this printer, see “Offset Adjustments” before in this manual.

Page 34

User Manual

29

Printer Setup Flow Chart

+

Printer OFF

Printer Ready

Setup Mode

# Parameters are set

Self

Test

(●)

Page 35

User Manual

30

Printer Setup through USB and RS232/C Ports

The printer Setup parameters can be changed through normal Setup as described in previous chapter or

through USB or Serial 232/C port.

For this purpose is necessary install the ”Godex CDC RS-232 Emulation” driver creating a virtual serial port

and the “FPB-650PII Setup” software, Windows based utility able to configures the printer through USB

(directly) or RS232/C Serial connection (directly or via a serial/USB adapter).

This chapter described how to install the driver and the utility.

This utility can be used also for the Firmware downloading, but this features is not covered with this manual

Godex CDC RS-232 Emulation Driver installation

If the printer is connected through the USB interface and the Setup mode is running, the Windows gives a

message for “founds a new hardware, Godex CDC RS-232 Emulation”.

Follow the steps displayed in the below masks in order to correctly install the driver.

The information file for the driver is : Godex-CDC.inf

Page 36

User Manual

31

If the installation is positively ended, in the Windows hardware resources a new COMn port will be found.

Page 37

User Manual

32

FBP-650PII Setup utility installation

Once the Godex CDC RS-232 Emulation driver has been installed, found the Setup.exe file and double click

on it.

Follow the steps displayed in the below masks in order to correctly install the utility.

The utility will ask where install the program and choose the program group.

If the installation is positively ended, in the program pop-up window, the FBP-650PII Setup icon will appear.

Double click on it and the FBP-650PII Setup utility will be run.

See next chapter for details.

Remote Setup

When this utility is running, the following home mask will be displayed.

In the left top side, under Option, there is the choice of the FPB-650PII Program Setup selection.

In the right to side there are the following selection window:

1) port selection choice COMn (*)

The following action keys:

2) NVM choices for Read, Write, Send Setup, Restore MFG and Exit from Setup for Setup Parameters

3) Refresh List Interfaces

4) Load FW

5) Other selection keys are currently disables (Reboot and USB ID).

Page 38

User Manual

33

Note (*)

The first available port number used by the Setup utility is taken from the system registry and can be different

from the one displayed.

When the Read/Write/Restore MFG action will be run, the following message will be displayed by the

operator panel LCD :

REMOTE SETUP

FROM: USB

REMOTE SETUP

FROM: SERIAL

Read NVM

In the left part are displayed the current Setup parameters when the Read NVM selection are done.

The parametes are read from the selected port.

Through the vertical cursor it is possible to change each of them for all the Setup selection pages

(Configuration, Program 1 to 4, Offset Tuning) and write using the selected port.

Page 39

User Manual

34

Write NVM

After reading the configuration, it is possible to do all the possible changes simply select the new values.

When all modification are done, the new configuration can be stored in the printer NVM pressing the Write

NVM action key.

The utility will show the “save as name” mask.

The new configuration can be saved in a specific file and path (default name is wnvm.dmp and default path

is where the FBP-650PII Setup utility is stored) to be used for future configuration with a simply copy file

action.

After that the printer will reboot.

The configuration file.dmp can be simply used to duplicate the same configuration on more printers.

FPB-650PII unit has to be powered on in normal mode, connected to the PC through any active interface

(Centronics or Serial port) and prompt:

copy file.dmp lpt1: /b command from a DOS shell,

After that the printer will reboot.

Send Setup

When Send Setup action key is activated, the host will displayed the stored configuration files.dmp; select

one and then click on open to immediate send it to the printer.

After that the printer will reboot.

Restore MFG

If the restore of the manufacturing values must be done, press the proper key: all the parameters will

be set immediately to the default values.

After that the printer will reboot.

Page 40

User Manual

35

Troubleshooting

Paper Problems

The straight paper path of this printer is designed for trouble-free handling of a great variety of documents.

Paper Jam

In case a paper jam condition occurs, proceed as follows:

1. Open the printer cover. And rise the upper mechanical frame as explained in the chapter: Installing

the Ribbon Cartridge, page 5.

2. Remove the jammed paper, pulling it towards the front of the printer.

3. To have an even better access to the paper path,

unlock and rotate down the Operator Panel Group

Page 41

User Manual

36

4. In case it is not possible to remove the jammed

paper because you cannot reach it with your

hand or it is embedded so that you cannot move

it, rotate the paper belt to free the paper.

5. Carefully pull down the green lever following the step 3, 4, and 5 in reverse order in order to securely

close the Upper Mechanical Frame.If you do not close the Upper Mechanical Frame, the printer does

not print correctly.

6. Close the printer cover.

Paper Damaged after Printing

If the paper is damaged after printing, it probably does not correspond to the specifications given in this

manual or was not loaded according to the indications given.

Verify that the paper corresponds to the specifications (see “Paper Specifications” later in this manual) and

has been loaded according to the indications given (see “Paper Handling” before in this manual).

Hexadecimal Dump

The hexadecimal dump function is activated when the ST2 key is press at power-on.

The printer enters in this functions and remains until it is powered-off.

The hexedecimal-dump shows all the characters sent by the host to the printer, even the not-printable ones

as well as escape commands or line terminator.

Page 42

User Manual

37

Error Handling

There are two types of error:

o Recoverable errors

o Not-recoverable errors

Recoverable errors

When an error of this kind occurs:

1. The printer is disabled with the ST1 and ST2 led flashing and the printer sounds a beeps.

2. With operator panel with display, the following messages will be displayed; the first line indicates the

error, while the second line gives more details concerning the error conditions.

Press always the READY key to reset the error condition

Recoverable error message description

Upper line message

Lower line message

Indication

Solution

RIBBON BROKEN

REPLACE RIBBON

The ribbon cartridge installed

is not genuine or it is wrongly

installed.

Verify if the ribbon cartridge is a Godex

genuine one.

Check that the ribbon is correctly inserted

See “Installing the Ribbon Cartridge”.

RIBBON NEAR END

The ribbon cartridge installed

is near its end of life (500.000

characters to be printed)

Prepare a new Godex genuine ribbon

cartridge.

See “Installing the Ribbon Cartridge”.

RIBBON EXHAUST.

REPLACE RIBBON

The ribbon cartridge installed

has reached the 105% of the

its nominal life.

Install a new Godex genuine ribbon

cartridge.

See “Installing the Ribbon Cartridge”.

CARRIAGE ERROR

The carriage movement has

been stopped during printing

causing print integrity.

Check for carriage free movement.

PAPER JAM

REMOVE PAPER

A paper jam error condition

occurs in the paper path.

Check the paper path and remove the

jammed paper.

RS232 FAILURE

DATA LOST

A buffer overflow condition

occurred for the serial

interface.

Check the RS232 parameters.

Check the interface cable.

RS232 FAILURE

DSR SIGNAL FLT

The DSR signal is not

connected to the printer and

is not ready for data transfer.

Check the interface cable connection.

RS232 FAILURE

GENERIC ERROR

A generic error on the serial

interface.

Check the RS232 parameters.

Check the interface cable.

Check the interface cable connection.

Page 43

User Manual

38

Not-Recoverable errors

When an error of this kind occurs:

1. The printer is halted with all the four leds flashing.

2. With operator panel with display, the following messages will be displayed; the first line indicates the

error, while the second line gives more details concerning the error conditions.

Power-off and Power-on the printer.

It the problem remains contact the service.

Not-Recoverable error messages description

Upper line message

Lower line message

Indication

Solution

ENGINE FAULT

The software of the printer

detects an engine failure

during the initialization phase.

The problem may depends by the home

carriage or paper sensor initialization errors.

Check for paper inside the paper path.

Check for the carriage free movement.

SOFTWARE FAULT

**SUPERVISOR**

The software of the printer

detects a failure during the

displayed phase.

The problem may depends by an internal

software routine error.

SOFTWARE FAULT

**PARSER**

The software of the printer

detects a failure during the

displayed phase.

The problem may depends by an internal

software routine error.

SOFTWARE FAULT

*PRINT MANAGER*

The software of the printer

detects a failure during the

displayed phase.

The problem may depends by an internal

software routine error.

SOFTWARE FAULT

**ENGINE**

The software of the printer

detects a failure during the

displayed phase.

The problem may depends by an internal

software routine error.

Page 44

User Manual

39

Ribbon Cartridge Problems

The following table is useful to identify and solve print quality problems.

Problem

Cause

Solution

Fading print

The ribbon is not fed

Check that the ribbon is correctly inserted (see

“Installing the Ribbon Cartridge”.

Turn the ribbon tension knob to verify, that the

ribbon is not blocked.

If the problem is not solved, change the ribbon

cartridge.

The ribbon is used up or torn

Change the ribbon cartridge.

NOTE:

Godex FPB-650PII printer can signal with a

specific display message or by means of a blinking

led configuration when original Godex ribbon near

to be replace

(“Installing the Ribbon Cartridge”.

The printer does not

print

The ribbon cartridge is not an

original Godex cartridge or it is

an exhausted cartridge.

The printer checks the inserted cartridge, to avoid

damaging the print head assembly due to incorrect

ribbon feeding.

Insert or replace with an original Godex ribbon

cartridge.

Page 45

User Manual

40

Paper Specifications

The documents must all guarantee the following characteristics:

o Use paper matching the indicated characteristics.

o They must have well defined top and left edges, with a square angle tolerance of 0.1° on all edges.

o The radius on a corner of the form must be within 9.5 mm from the left or right edge.

o The form to be printed must not contain foreign material.

o Form opacity must be at least 75%. Forms with a lower opacity may cause feed errors.

o Never print on documents with metallic or hard plastic fasteners or staples, they may damage the

printer.

o To get the maximum print contrast you should print on white or light colored paper. You may

overstrike to improve the low contrasting paper.

o It is preferable to use single and multiple documents with the fibre running in the insertion direction of

the printing unit.

o Recycled paper is permitted on principle.

o It is preferable to print on multiple forms with a narrow glue strip or top-gluing. The gluing must not

cause waving in the set of forms.

Cuts Sheets

Insertion direction

Print Area

A

B

C

C

D

E

Dimensions

Maximum

Minimum

A

Form width

244 mm (9,606 in.)

65 mm (2,559 in.)

B

Form length

470 mm (18,50 in.)

65 mm (2.559 in.)

C

Distance between dot position and left or

right paper edge

-

3.0 mm (0,1181 in.)

D

Distance between top of the first printed

line and top margin of the document

-

1 mm (0.0394 in.)

E

Distance between the lower margin and

the lower part of the last printed line

-

5.8 mm (0..2283 in.)

Reduced to 1.5 mm (0.0591 in.) with

item SAFE BOTTOM EDGE = no

Weight (original)

200 g/m2

40 g/m2

Weight

(original + 1 to 6 copies)

1st 75 g/m

2

other 75 g/m

2

carbon 35 g/m

2

1st 55 g/m

2

other 45 g/m

2

carbon 14 g/m2

Thickness

Single form media up to 0,65 mm (0.0256 in.)

Multi form media up to 0.65 mm (0.0256 in.).

Overall thicker than 0,35 mm (0.0138 in.) may cause print quality

degradation in last copy.

Page 46

User Manual

41

Technical Specifications

Printing Technology

24 pin serial dot matrix printer (needle diameter 0,25 mm)

Printing Speed

(@10 cpi)

HSD 520 cps

Draft 400 cps

NLQ 200 cps

LQ 133 cps

Line Length

94 columns @10 cpi – 112 columns @ 12 cpi – 141 columns @ 15 cpi

Paper Handling

Single Sheet, envelopes, labels, (paper weight from 40gr/m2 to 200 gr/m2)

Cut Sheet max thickness: up to 0.65mm

Single Sheet Width: 64 – 244 mm Single sheet Length: 65 – 470 mm

Copies

1 + 6

Special Functions

Automatic Gap Adjustment (AGA), Auto Alignment, Auto Border Recognition,

Optical Mark reading, Horizontal and Vertical, Automatic Set-up (automatic

recognition of marked values)

Graphic resolution

(dpi)

60, 120, 180, 240, 360 (horizontal)

72, 90, 180, 216, 360 (vertical)

Vartical spacing

6-8-12- lines/inch, 3-4-6-8-12-lines/30mm, n/60, n/72, n/180, n/216, n/360 per inch

Barcodes

UPC/A, UPC/E, EAN8, EAN13, Code 39, Code 128, Postnet, Codabar, ADD-ON 2,

ADD-ON 5, Code 11, Code 93, BCD, MSI, 2/5 Interleaved,

2/5 Matrix, 2/5 Industrial

Character set

(IBM and Epson)

PC standard set (CS1-CS2) - 13 National Epson sets - CP437 (USA) - CP437G

(Greek) - CP437 Slavic - CP850 (Multilanguage) –

CP851 (Greek) – CP852 (Latin 2) - CP853 (Turkish) - CP855 (Russian) - CP857

(Turkish) - CP 858 (Euro) - CP860 (Portuguese) - CP862 (Hebrew) - CP863

(French/Canadian) - CP864 (Arabic) - CP865 (Norwegian) –

CP866 (Cyrillic) - CP867 (Turkish) – CP876 (OCRA) - CP877 (OCRB) – CP1098

(Farsi Arabic) - CP1250 (Central Europe) – CP1251 (Cyrillic) – CP1252 (Windows

Latin1 Ansi) – Gost - Tass – Mazowia –

ISO 8859/1/2/3/4/5/6/7/8/9/15 - 96GREEK- Ukrainian - ID 12 - ID 14 - ID 17 -

Roman-8 – Sanyo – Ku – Philip

Character set

(Olivetti)

CS000 – CS010 International, CS020 Germany, CS030 Portugal,

CS040 Spain1, CS050 Denmark/Norway, CS060 France, CS070 Italy, CS080

Sweden/Finland, CS090 Switzerland, CS100 Great Britain,

CS110 USA ASCII, CS140 Greece, CS150 Israel, CS170 Spain 2,

CS200 Jugoslavia, CS410 Olivetti TCV 370, CS510 SDC, CS520 Turkey, CS540

CIBC, CS680 OLI-UNIX, CS701 PC-220 Spain2,

CS711 PC-Denmark/Norway, CS712 PC-Denmark OPE,

CS771 PC-210 Greek

Resident Fonts

Draft, Courier, Gothic, Prestige, Presentor, Script, OCR-A, OCR-B, Boldface

Resident Emulations

IBM ® Personal Printer 2390+, Proprinter XL24E, Proprinter XL24AGM, IBM ®

4722, Epson ® LQ2550/LQ1170 and Olivetti ® PR40 PLUS/PR2/PR2845, IBM

9068, HPR 4915

Interfaces

Parallel IEEE 1284 bidirectional, Serial RS232C, USB 2.0 Full Speed Automatic

Interface Switching

Optional: 2nd RS232, Ethernet 10/100 LAN, 2nd USB 2.0 High Speed, up to 3 USB

ports Hub/Hosts for external devices

Input Buffer up to 64 Kbytes

Plug&Play – Drivers Windows 2000, XP, VISTA (32/64 bits), Windows 7 (32/64 bits)

Reliability

> 10.000 hours MTBF (mean time between failure)

Print Head Life

>400 Million characters or > Billion strokes/wire

Consumables

Type: black ribbon cartridge Life: > 10 Million characters

Noise Level<54 dbA

<54 dbA

Power Supply

Universal from 100 to 230 V Frequency: 50 / 60 Hz

Power consumption:

45 W max. (printing DIN letter) - < 3 W (standby – 0 W (switched off)

Physical Dimensions

& Weight

8 Kg (9.2 Kg packed)

Page 47

User Manual

42

Serial Interface Connection

RTS

DCD

Femaleconnector

5

9

4

8

3

7

2

6

1

Soldersid

e

vie

w

GND

Toprinter

CTS

ToPCIBM

compatibl

e

CTS

DSR

DSR

DTR

R

X

DTR

Soldersid

e

vie

w

DCD

T

X

RTS

GND

R

I

Female

connector

5

9

4

8

3

7

2

6

1RI

R

X

T

X

Page 48

Loading...

Loading...