Page 1

Rev. A, 06.2011

User Manual

BZB-2U

Page 2

1

1. ABOUT THE BZB PRINTER ....................................................... 2

1-1. Introduction ........................................................................................... 2

1-2. About the BZB labeling Software .......................................................... 2

1-3. About the BZB Windows drivers ............................................................ 2

1-4. Contents of the BZB Package ............................................................... 3

1-5. BZB Printer Parts .................................................................................. 3

2. SETTING UP THE BZB-2U PRINTER ........................................ 5

2-1. Connecting the Printer to a Power Outlet. ............................................. 5

2-2. Connecting the Printer to a PC .............................................................. 5

2-3. Loading the BZB Printer with Labels ..................................................... 5

2-4. Testing the BZB printer ......................................................................... 6

3. MAINTENANCE AND ADJUSTMENTS ...................................... 7

3-1. How to remove the BZB top cover ........................................................ 7

3-2. How to clean the BZB printer head ....................................................... 7

3-3. How to clear a label jam in the BZB Printer ........................................... 7

3-4. Label gap sensor adjustment for the BZB printer .................................. 8

APPENDIX A. TROUBLESHOOTING ............................................ 9

APPENDIX B. BZB-2U TECHNICAL SPECIFICATION ................ 11

APPENDIX C. USB PORT SPECIFICATION ................................ 13

Page 3

2

1. About the BZB Printer

1-1. Introduction

The BZB-2U label printer r will enable you to automate a lot of tasks currently handwritten saving

time and giving a more professional image. It is the easiest way to produce high quality labels for

a wide variety of applications, the printer works with direct thermal labels eliminating the need for

costly ink, toner and ribbons.

With the power full BZB software provided with every printer you can easily produce the

following:

Address Labels Barcode Labels Diskette Labels

File Labels Shelf Labels Shipping Labels

….. and many more.

1-2. About the BZB labeling Software

Every BZB label printer is supplied with fully featured labeling software for Windows XP, Vista,

Windows 7, Server 2003, 2008. Features include the following:

Windows software

Easy to use no programming experience required

True WYSIWYG (What you see is what you get)

Sequential Numbering

Bar codes supported: EAN 8 (add on 2 of 5), EAN13 (add on 2 of 5),

Code 39, Code93, Codabar, Code 128, EAN 128, UPC A, UPC E

Interleaved 2 of 5.

2 Dimensional Bar Codes supported: PDF 417, Maxicode.

Variable data, Prompt at print time

Import information from a Database using ODBC link

Adjust print darkness from the software.

1-3. About the BZB Windows drivers

A complete set of windows drivers for Windows XP, Vista, Windows 7, Server 2003, 2008.

The BZB drives will help you to print from your existing Windows applications.

Page 4

3

1-4. Contents of the BZB Package

Fig. 1.4.1

Please check the contents of the packet as attached.

1-5. BZB Printer Parts

Using the following diagram to familiarize yourself with the features and components of the

BZB-2U printer (see figure 1.5.1).

Fig. 1.5.1

Item

Parts Description

1.

Front cover Protect the printer head of the unit.

2.

Label tear line Sharp edge is used to tear off printed label

3.

Power light Indicate whether the power is on or off.

4 Feed button Manually feed labels or adjust label position.

5 Rear cover Protect the roller and labels.

6 Lock switch Lock the rear cover.

7 Printer mechanism The engine of the printer.

Page 5

4

Item

Parts Description

8 Label guide Label guide

9 Label spindle hole To locate the label roller in position

10 Stands for big roll of label The big label roll holder stands

11

USB port The printer port connector

12

Power jack Connect the power cord to the unit

13

Power switch Turn printer power on/off

14 Print head release level To release label or adjust the label position.

Page 6

5

2. Setting up the BZB-2U Printer

2-1. Connecting the Printer to a Power Outlet.

1. Plug the power cord into a power outlet.

2. Plug the AC adapter cable into the power jack at the rear of the BZB printer

3. Turn the BZB printer on by pressing the power switch.

4. The LED on the printer will turn red.

5. Proceed to 2-2 Loading your BZB printer with Labels.

2-2. Connecting the Printer to a PC

1. Be sure the printer is powered off.

2. Plug the power adapter into the printer power jack.

3. Connect the printer to the parallel interface on the PC (with the cable provided)

4. Power on. The LED light will be red (no label) or green.

2-3. Loading the BZB Printer with Labels

Loading small-size label roll

1. Press the two lock switches (part 6) and lift up a little to open the rear cover. Then insert a

small-size label roll onto the core shaft (see figure 2.3.1).

Fig. 2.3.1

2. Place the roll into the groove.

3. Insert the edge of labels into the label guide, until the edge is blocked by the printhead.

4. Press feed button to drive the label (under the printhead) into the printer.

Page 7

6

Loading large-size label roll

1. Power on.

2. Press the two lock switches (part 6) and lift up a little to open the rear cover. (See figure

2.3.1)

3. Remove the label roll stands. Vertically place the two stands along the left and right sides

of the rear cover.

4. Place the large-size label roll on the stands (see figure 2.3.3).

5. Insert the edge of labels into the label guide, until0l the edge is blocked by the printhead.

6. Press feed button to drive the label (under the printhead) into the printer.

Fig. 2.3.3

2-4. Testing the BZB printer

The self-test function helps you check if the printer works normally.

To start the self-test function, please follow these steps.

1. Load the label. (As described in 2-3)

2. Power the printer OFF and wait for 2 seconds).

3. Hold down the feed key and power the printer ON.

4. Release the feed key and wait for few seconds. The printer will print a self-test page.

Note: To disable the self-test, please power OFF the printer at least 2 seconds,

then power ON again.

Page 8

7

3. Maintenance and Adjustments

3-1. How to remove the BZB top cover

1. Face the front side of the printer. Place

your thumbs on the top cover and the

other fingers on the left and right sides

of the printer.

2. Gently press down the top cover with

your thumbs, and pull it toward you to

remove the top cover. (See figure 3.1.1

& 3.1.2)

Fig. 3.1.1 Fig. 3.1.2

3-2. How to clean the BZB printer head

1. Remove the top cover.

2. Press your pointing finger on “A”, move out the

two plastic fasteners from the retainer, and you

can take out the retainer and the print head

unit. (see figure 3.2.1)

3. Use soft cloth soaked in isopropyl alcohol, to

rub off caught labels and cleans the surface.

Reinstall the fasteners and retainer.

Fig. 3.2.1

3-3. How to clear a label jam in the BZB Printer

1. Power off the printer.

2. Remove the top cover and back cover.

3. Remove label roll.

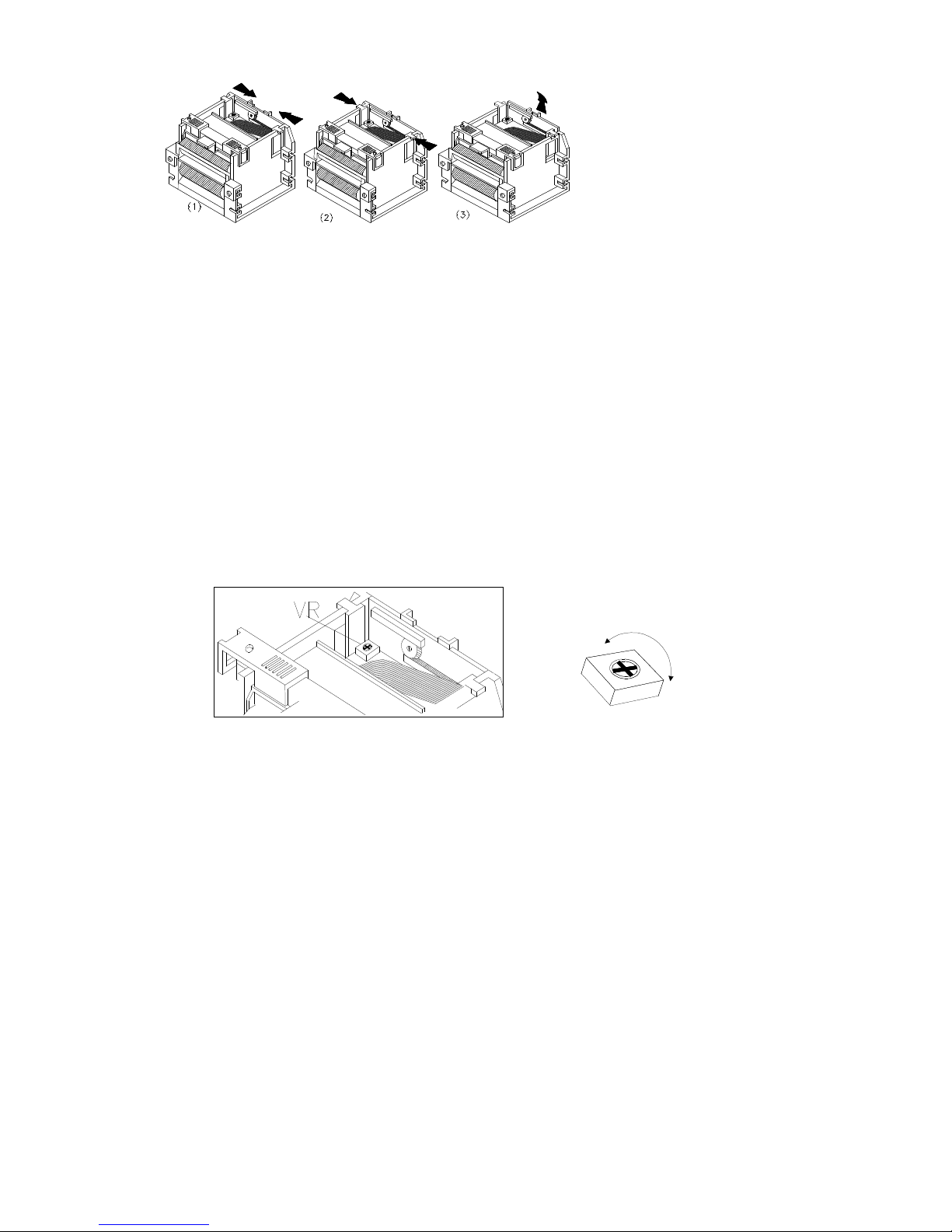

4. Close the two label guides the way as figure 3.3.1(1).

5. Make apart the two retaining clips from the assembly, by gently pressing the clips the

direction as figure 3.3.1(2), and afterward by lifting them a little.

6. Lift the guide board the direction as figure 3.3.1(3).

7. Clean, with alcoholic cloth, the label jam on the bottom of the assembly.

8. Reassemble the printer

Page 9

8

Fig. 3.3.1

3-4. Label gap sensor adjustment for the BZB printer

Due to different quality labels available it may be necessary to make an adjustment to the label

gap sensor for detecting the label gap

Any adjustment must be made in well light room.

1. Remove top cover.

2. The top view shows the circuit board as indicated on figure 3.4.1.The Variable Resistor (VR)

can be adjusted the ways either counter-clockwise for lower transmit power (less sensitivity)

or clockwise for higher transmit power (higher sensitivity). Each slight adjustment of the

VR has to be verified by pressing the feed button at least 7 times.

less

sensitivity

higher

sensitivity

Fig. 3.4.1

Thermal Labels

1. Remove the label from the backing paper. Load the backing paper under the sensor.

2. Slowly adjust the Variable resistor and press the label feed switch successively (at least 7

times), until the LED light turns red.

3. Put the label with backing paper under the sensor, and then press feed button a few times.

If the LED light turns green, you have finished the adjustment. If the LED light is red, repeat

step 2 and 3 until the LED light turns green.

Page 10

9

Appendix A. Troubleshooting

Problems Recommended Solution

Power switch already turned on but the

LED does not light.

Check Power connector.

Printing stops and LED goes red.

Probably software setting or programming

problem.

Check to use the correct paper

Probably label jam, remove the stuck label

Printer is working but nothing is printed

on label.

Check the label is facing up and the paper you

use is thermal paper.

Check to choose the correct printer driver.

Make sure to choose the correct model of

printer on platen.

Label is stuck

Remove the stuck label and use soft cloth

soaked with alcohol to clean the adhesive glue.

Only part of the label got printed

Label is stuck on print head.

Probably software problem

Margins are not set properly

Printer head is not fixed in proper position,

re-positing printer head screws or clipper

Difficult to load label roll

Check if the label stuck on printer.

Remove the stuck label.

Make sure the width and thickness of label is

within the specification.

When printing out, some dots missing

Clean printer head with alcohol. (If the label

glue is attached to printer head, please apply

alcohol to printer head; wipe with soft cloth

softly.)

Replace printer head for possible damage.

Printing is not in the correct position

Check the Label Transmit Sensor, it may be

covered with dust.

Check with your label supplier; make sure they

have used the recommended backing material.

Adjust the label transmit sensor if you are an

experienced printer user.

Check the label guide, it may not be in the

proper position.

Page 11

10

Label printing jumps to next label

Check if the label height setting is the same as

actual label height.

Check the Label Transmit sensor, it may be

covered with dust.

Printing is not very clear

Check the printer darkness setting.

If any problems occur that are not described here, please contact your dealer.

Page 12

11

Appendix B. BZB-2U Technical Specification

Printer Specifications:

Model

BZB-2U

Print Method

Direct Thermal

Resolution

203 dpi (8 dots/mm)

Print Speed

Max. 2 ips (50.8 mm/s)

Print Width

2.12” (54 mm)

Controller

8-bit MCU, 64KB Flash, 32KB SRAM

Sensor Type

Fixed center alignment GAP label sensor

Media

Width: 1” (25.4 mm) Min. – 2.36” (60 mm) Max.

Thickness: 0.003” (0.06 mm) Min. -0.008” (0.2 mm) Max.

Label roll outer diameter: Max. 4” (101.6 mm) / 10" (254 mm)

Core diameter: 1” (25.4mm)

Barcodes

1-D barcodes supported:

EAN8 (add on 2 of 5), EAN13 (add on 2 of 5), Code 39, Code 93,

Codbar, Code 128, EAN128, UPCA, UPC E interleaved 2 of 5, Postnet

code & Royal Mail code supported

2-D barcodes supports:

PDF417, Maxicode

Print Language

EZPL-1, GODEX Line mode command

Software

BZB Application Software, compatible to Microsoft® 32-bit Windows XP,

Vista, Windows 7, Server 2003, 2008

Driver

Compatible to Microsoft® 32-bit Windows XP, Vista, Windows 7, Server

2003, 2008

Interface

USB Device 2.0 Full Speed B-Type outlet

Control Panel

One dual Color LED: Green light indicates the printer is working fine; Red

light indicates the printer is in Error status

Control key: FEED

Dimension

Depth: 5" (127 mm)

Height: 8.46” (215 mm)

Width: 5.67” (144 mm)

Weight

< 2.61 lbs (1.2 Kg)

Power Supply

60W switching power adaptor, I/P: AC100~240V 50/60Hz, O/P:

DC19V/3.15A peak 5A

Certifications

CE (EMC), RoHS

Page 13

12

Environment

Storage temperature : -4 to 122 (℉ -20 to 50 ) ℃

Operation temperature : 40 to 104 (5 to 40 ) ℉ ℃

Storage humidity : 10 to 90% non-condensing Operation humidity : 30 to

85% non-condensing

* Specifications are subject to change without notice

Page 14

13

Appendix C. USB Port Specification

Connector type : Type B

Pin No. 1 2 3 4

Function VBUS D- D+ GND

Loading...

Loading...