Page 1

AG3000T

USER MANUAL

AG3000T AG3000T-LS

User Manual: AG3000T

Version: 1.0

Issue Date: May 2016

AG3000T (print & apply system) with optional label unwinder

Page 2

Contents

1. Introduction ................................................................................................................................................4

1.1 Overview ...................................................................................................................................................4

1.2 Applicator Specifications Summarized .....................................................................................................4

3. Basic Safety Precautions .............................................................................................................................5

3.1 Coverage .............................................................................................................................................5

3.2 Following the instructions in this operating manual ..........................................................................5

3.3 Possible device handling risks .............................................................................................................5

3.4 Environmental conditions of the device operation ............................................................................5

3.5 Occupational health and safety rules .................................................................................................6

3.6 Safety instructions ..............................................................................................................................6

3.7 Never: .................................................................................................................................................7

3.8 Applied harmonized standards and the safe use of electrical appliances ..........................................7

3.9 The possible risks of electric shocks if working with the applicator ...................................................8

3.10 Configuring the pneumatic unit, safety ..............................................................................................8

4. Contents of delivery - what’s in the box? ...................................................................................................9

4.1 Standard configuration with 170 mm effective stroke .......................................................................9

3.2 Checking the box contents (AG-3000-110060 / AG-3000-110100) ..........................................................9

3.2.1 Box 1: Printer + Accessories ..............................................................................................................9

3.2.2 Box 2: Applicator components ....................................................................................................... 11

5. Assembling the system ............................................................................................................................ 13

5.1 Required Tools ................................................................................................................................. 13

5.2 Assembling the stand ...................................................................................................................... 13

5.3 Installing the internal rewinder in the printer ................................................................................. 17

5.4 Installing the applicator interface .................................................................................................... 19

5.5 Integrating the printer and applicator unit ..................................................................................... 21

6. Operating your AG3000T(-LS) .................................................................................................................. 26

6.1 Print & apply cycle: the basics ......................................................................................................... 26

6.2 Printer configuration for applicator use ........................................................................................... 26

6.2.1 Power on the printer ................................................................................................................... 26

5.2.2 Firmware ......................................................................................................................................... 27

5.2.3 Setting the printer in applicator mode ........................................................................................... 27

5.2.4 Formatting the applicator interface (!) ........................................................................................... 29

5.2.5 Smart backfeed ............................................................................................................................... 29

5.2.6 Create a label and load media ........................................................................................................ 29

6.3 Putting the applicator into service .................................................................................................. 29

6.3.1 Air supply ..................................................................................................................................... 29

2

Page 3

5.3.2 Checking the mechanical settings (!) .............................................................................................. 29

5.3.3 Run a test cycle ............................................................................................................................... 31

5.3.4 The “START” menu ......................................................................................................................... 31

5.3.5 The “SERVIS1” menu ....................................................................................................................... 33

5.3.6 The “MANUAL” menu ..................................................................................................................... 33

5.3.7 The “LANGUAGE” menu ................................................................................................................. 34

6. Mechanical and pneumatic adjustments ................................................................................................. 35

6.1 Manual menu ................................................................................................................................... 35

6.2 Applicator head alignment ............................................................................................................... 35

6.2.1 Height adjustment .......................................................................................................................... 37

6.2.2 Horizontal adjustment after vertical adjustment ........................................................................... 37

6.2.3 Horizontal adjustment without vertical adjustment ...................................................................... 37

6.3 Air settings i: blowing ...................................................................................................................... 38

6.4 Air settings ii: vacuum ...................................................................................................................... 39

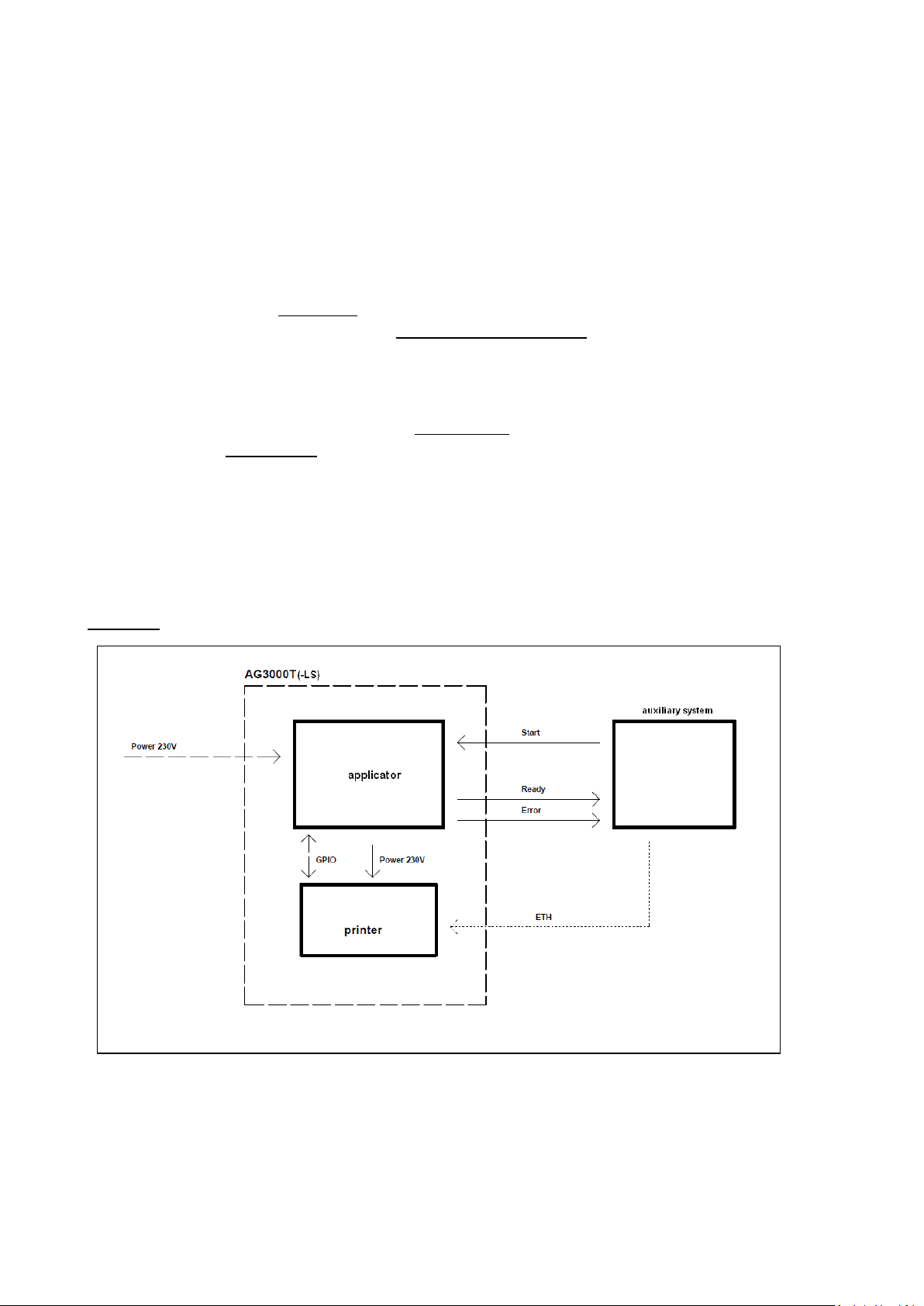

7 Connecting to auxiliary systems .............................................................................................................. 40

7.1 Introduction..................................................................................................................................... 40

7.2 Triggering devices – input signals .................................................................................................... 41

7.3 Outgoing signals ............................................................................................................................... 41

8 Options .................................................................................................................................................... 42

9 Maintenance ............................................................................................................................................ 42

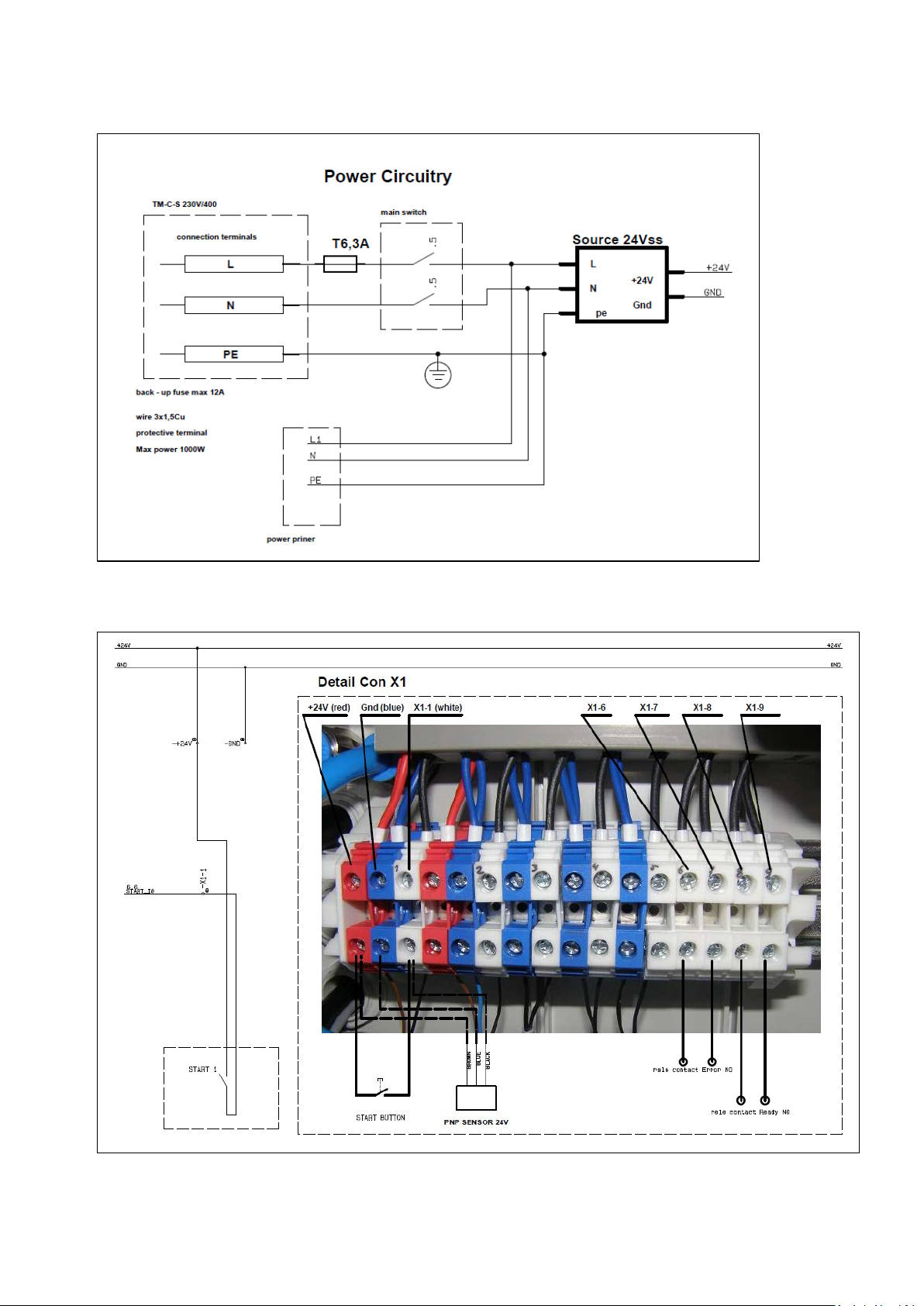

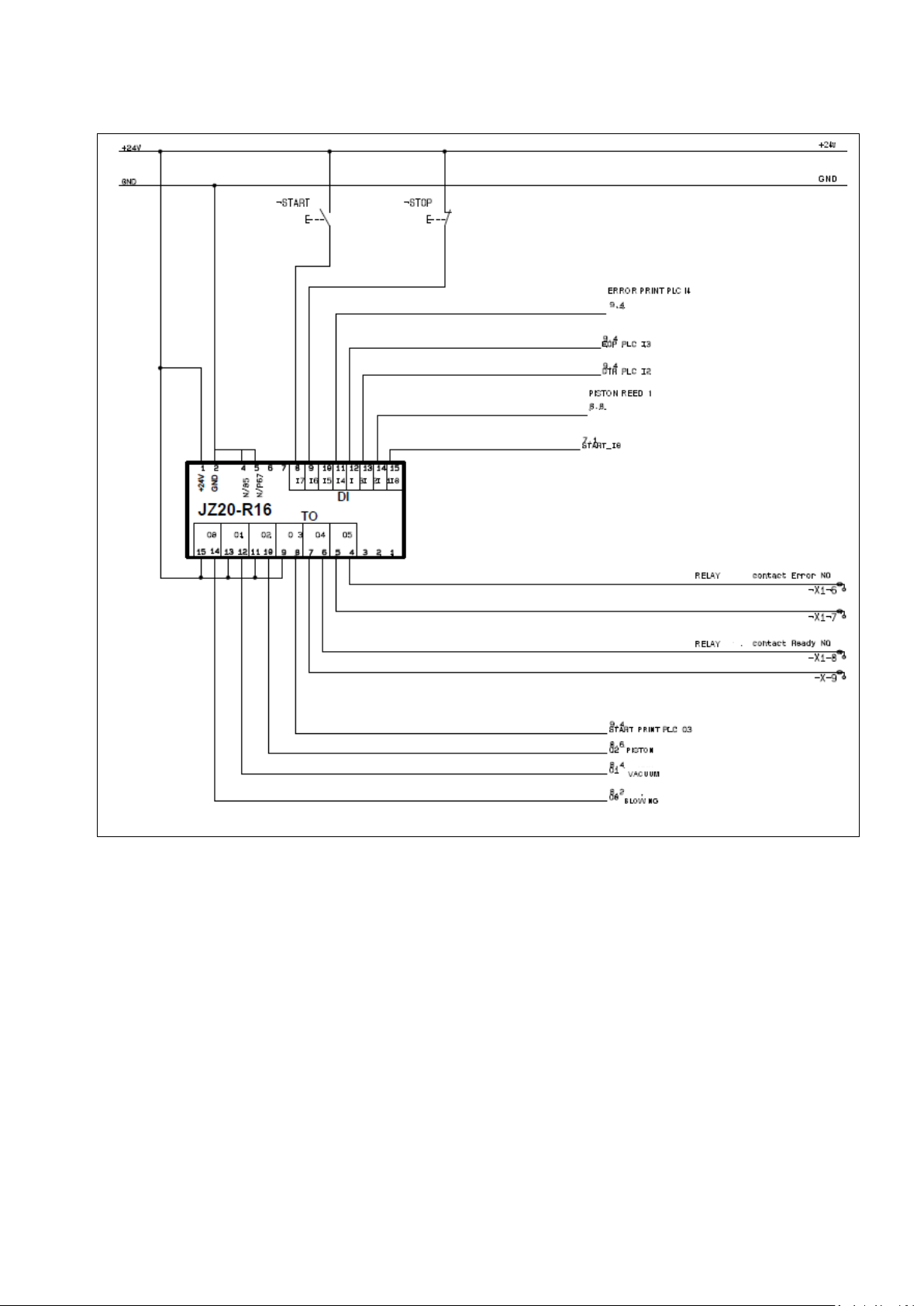

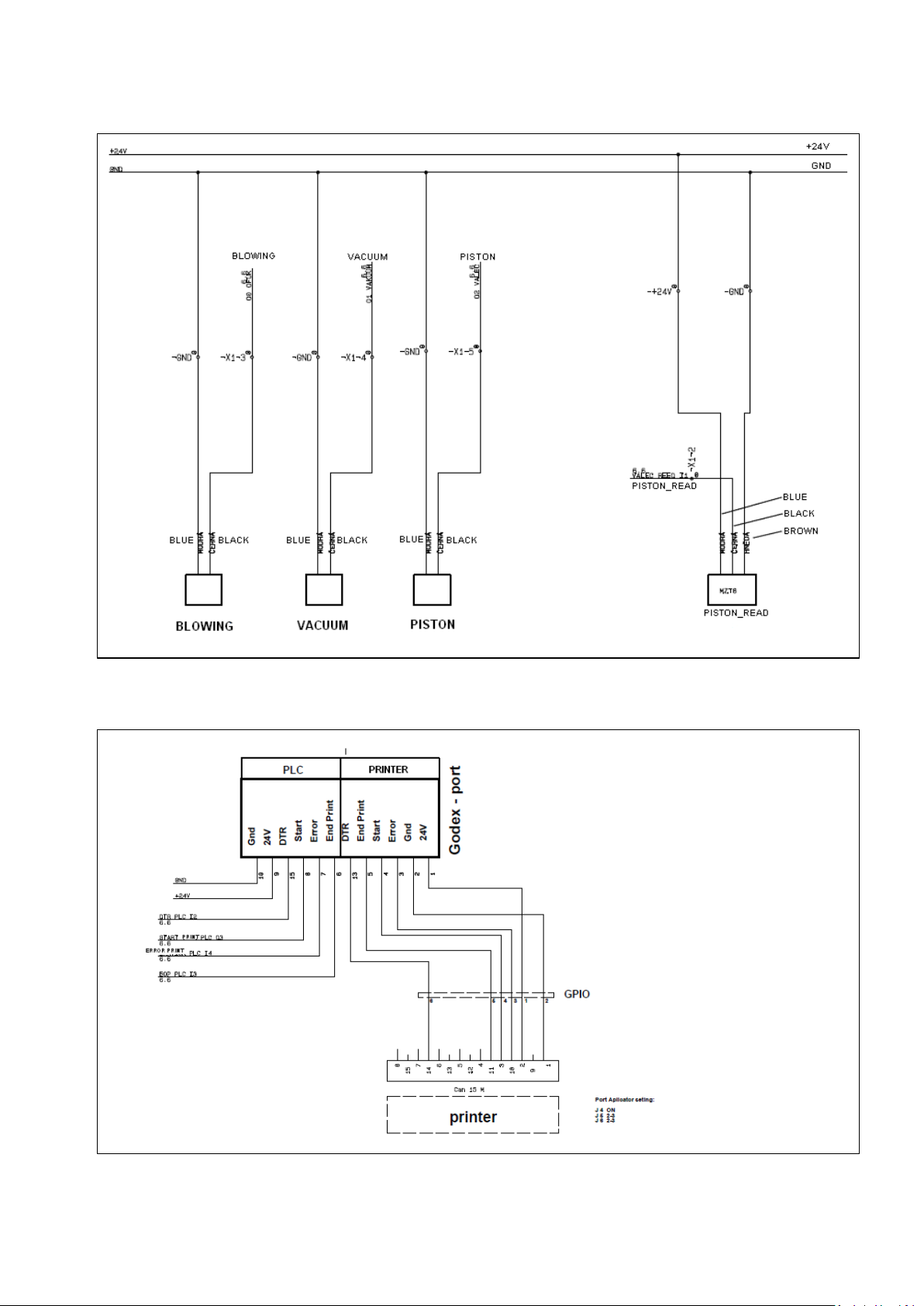

10 Wire diagrams ...................................................................................................................................... 43

10.1 Power and signals schematic ............................................................................................................ 43

10.2 Control unit picture .......................................................................................................................... 43

10.3 Power circuits ................................................................................................................................... 44

10.4 Connector rack - detailed view ......................................................................................................... 44

10.5 Connector rack diagram ................................................................................................................... 41

10.6 Electro-pneumatic diagram ............................................................................................................. 42

10.6 PLC / Printer applicator port diagram ....................................................................................... 42

3

Page 4

1. Introduction

Item no:

AG-3000-110060 / AG-3000-110100

AG-3000-22L060 / AG-3000-22L100

1.1 Overview

Godex AG3000 print & apply systems match ZX1000i printers, either with 203, 300 or 600dpi print

resolution, with high end, air-driven tamp applicators with the purpose of print and apply labels

on demand.

AG3000 print & apply systems are available as easy to install, ready-to-use solutions, but you can

also configure your own customized systems by combining the components in a different way. The

AG3000 enables you to attach unique information to each single product coming down the

production- or packaging line. The systems come with standard applicator heads of either 60mm

x 60mm or 100mm x 100mm. With optional heads they can handle any label size from 20mm x

20mm up to 100mm x 200mm. Tamp applicators are typically used to label non-moving items on

intermittent conveyor systems, in robotized processes, and in manual workflows. With roll-on and

blow-on heads, available on request, they will also label moving items accurately. The AG3000T

delivers an effective stroke of 170mm (total stroke 300mm) and the AG3000T-LS of 370mm (total

stroke 500mm). Various options are available to tune the AG3000T/AG3000-LS to your particular

needs.

1.2 Applicator Specifications Summarized

Type:

Std. head size: 60mm x 60mm / 100mm x 100mm

Opt. head sizes: 20mm x 20mm up to 110mm x 200mm

Stroke 300mm 500mm

Effective Stroke 170mm 370mm

(The effective stroke equals the maximum allowed height difference between the products in

one production batch)

Label sizes min 20mm x 20mm, max 100 x 200mm

Label roll diameter 200mm standard inside the printer

Performance up to 30 labels/min of 100mm x 100mm at an effective stroke of 170mm

up to 60 labels/min of 20mm x 20mm at an effective stroke of 10mm

Compatible printers ZX1200i (203dpi) / ZX1300i (300dpi) / ZX1600i (600dpi)

)*: the process speed depends on variables such as label size, the type and source of the data

processed, stroke length (product height), required product contact time and conveyor speed.

AG3000

60mm x 60mm / 100mm x 100mm

20mm x 20mm up to 110mm x 200mm

280mm optional with external holder

AG3000-LS

4

Page 5

Basic Safety Precautions

Coverage

Safety rules and instructions either written or referred to in this manual apply to the installation, the

usage and the maintenance of both the applicator- and the printer components within AG3000

systems. They do however not replace any safety instruction published in separate Godex

ZX1(X)00i user- and service manuals, and must be considered complementary to those instead.

Therefore, personnel working with AG3000 systems must be familiar with the safety instructions

stated in the applicable Godex printer manuals as well.

Following the instructions in this operating

manual

A thorough knowledge of basic safety instructions and safety regulations is an essential

prerequisite for using this device in accordance with safety requirements, while ensuring its faultfree operation. This operating manual, and in particular the safety instructions contained herein,

must be adhered to by any personnel using the device. All relevant standards and regulations

pertaining to the prevention of accidents and injuries relevant to the device installation site must

also be adhered to.

Possible device han dling risks

The device was manufactured in accordance with relevant technical requirements and

internationally recognized safety and technical standards. However, situations might still arise

during the use of the device that could pose a risk to the health and/or lives of operators and/or

third parties, or cause damage to the device and/or other property.

The device may only be used:

• In accordance with the purpose for which it was manufactured

• If it is free of any defects in terms of safety and technical requirements.

Any defects that could potentially compromise safety must be rectified immediately.

Environmental conditions of the device

operation

• Operation ambient temperature within the range of 5 °C to 40 °C (41 °F to 104 °F)

• Storage and transport temperature: -20 °C to 55 °C (-4 °F to 131 °F); the device can withstand

temperatures of up to 64 °C (149 °F) for a period of up to 24 hours

• Operation ambient non-condensing relative air humidity within the range of 20% to 85% RH

5

Page 6

• Storage ambient non-condensing relative air humidity within the range of 20% to 85% RH

Occupational health and safety rules

The device contains moving parts that can pose a risk to the operator unless the safety rules are

adhered to. In order to prevent a potential injury, read the following safety rules carefully:

• Only persons trained in operating the device and acquainted with associated risks should be

authorized to enter the space where the device is installed.

• A safe distance from the application plate must be maintained when the device is being

connected to a source of compressed air and/or when it is being switched on or off, as the

device may begin to move unexpectedly.

• Crumpled and/or detached labels may only be removed when pressurized air is not being

supplied to the device or if the device has moved into an error mode.

• An error or pause mode must be invoked before print material is replaced in the device.

Safety instructions

• When working with the device the operator must adhere to all relevant generally binding

safety regulations as specified in the labor code of his/her country and in other legal safety

regulations that may apply.

• The device’s keeper must ensure the performance of regular maintenance. Routine

maintenance must be carried out by properly trained and authorized personnel. Failure to do so

could result in device failure or injury and may breach health and safety laws.

• The device may only be operated by properly trained and authorized personnel.

• The device may only be used for those purposes for which it is technically fit in accordance with

the terms and conditions specified by the manufacturer, while the structure, design and technical

condition must comply with the relevant safety regulations.

• The device’s operator must perform a visual inspection of the device regularly, along with

regular basic maintenance and servicing.

• Should there be a discovery of any defect and/or damage that might compromise operating

safety and/or the operation of the printer that cannot be rectified on the spot, the device must

not be brought into operation / must be switched off immediately, and the defect must be

reported to the device’s keeper and other relevant persons.

• The legibility of safety signs, symbols and notices on the device must be maintained at all times.

In the event of damage and/or illegibility, any such signs must be restored by the device’s keeper

to their original condition.

6

Page 7

Never:

• Connect the device to a source of electric power if any of the protective parts (electric

component covers, safety labelling and/or safety elements of the device) have been removed

and/or damaged.

• Modify the mechanical design and/or electrical circuitry of the device in any way.

• Perform any maintenance tasks before the device has been secured in its off state and the

device has been disconnected from the main power.

Applied harmonized standards and the safe

use of electrical appliances

• AG3000 Print & Apply systems are class I electrical devices in terms of the necessary protection

against electric shock in accordance with harmonized standard EN 61140, ed. 2 and hence also

meet generally acknowledged standards such as, but non only CE, meaning that all non-live

conductive parts are mutually conductively connected and are further connected to the

protective earth conductor of the printer’s power supply. Other harmonized standards that have

been applied, are EN 60439-3, applicable to low-voltage switch gear and EN ISO 12100 regarding

the safety of machinery.

• Connection to the power network supply must be made in compliance with the

requirements specified in regulations and technical standards valid and applicable in the

country of operation.

• Any work on the device may only be performed by persons who are duly qualified according to

the legislative code of the country where the device is installed (1) and who has been

acquainted to the necessary extent with the device (2).

• The keeper of the device is obliged to secure the performance of inspections of the electrical

device in prescribed intervals and to do so in accordance with the legislation regarding such

inspections applicable in the country of operation.

• The device may not be dismantled.

• If shielded data cables are used with the device, they must comply with international standards

governing devices producing electromagnetic radiation. The utilised data cables must be

completely shielded. The use of shielded data cables is necessary in order to prevent the

production and/or reception of electromagnetic noise. Using non-shielded data cables may

result in electromagnetic radiation exceeding permitted limits.

7

Page 8

The possible risks of electric sh o c ks i f working

with the applicator

Despite the application device being manufactured in accordance with relevant technical

regulations pertaining to safety, its technical design cannot preclude all risks that may occur,

especially in the event of careless or negligent behavior during use of the device. The device must

be used with full awareness of the following risks of electric shock:

• Resulting from direct or indirect contact with parts designed to conduct electric current (live

parts), direct or indirect contact during the removal of electric equipment covers, or direct or

indirect contact in the event of damage caused to insulating parts of a movable power cord;

• Caused by damaged parts of electrical equipment;

• Resulting from a failure to observe instructions regarding equipment connected to the power

mains.

Configuring the pneumatic unit, safety

Excessive operating pressure may cause:

• Injury by crushing;

• Mechanical damage to parts of the labelling machine.

The equipment manufacturer configures the pneumatic unit of the labelling machine in a manner

that ensures all pneumatically controlled parts of the device (e.g. the piston) can be stopped by

hand without the use of excessive force (max. 150N)

The customer shall bear responsibility for any adjustments that are not made by the equipment

manufacturer prior to delivery.

8

Page 9

Contents of delivery - what’s in the box?

Standard configuration with 170 mm effective

stroke

Most likely you ordered a standard configuration with a 203dpi printer 170mm effective stroke: the

AG-3000- 110060 or AG-3000-110100 (the only difference between those two is the size of the

applicator heads included: 60mm x 60mm versus 100mm x 100mm). Therefore, and because the

installation and operation of most configurations are identical, we will use this standard

configuration to guide you through the installation and make you familiar with the usage of the

AG3000 print & apply solution. Further in this manual you find an option list.

3.2 Checking the box contents (AG-3000-110060 / AG-3000-110100)

You have received two boxes. Please check whether their content has arrived undamaged. §

3.2.1 and 3.2.2 will help you to check whether nothing is missing. Please inform your supplier

immediately if anything seems to be wrong.

3.2.1 Box 1: Printer + Accessories

If you have received the printer parts for your AG3000 directly from a Godex subsidiary the printer

box contains the printer components described below here. In case you have purchased the

printer and options through a Godex distributor or dealer you may receive them in separate

boxes. In that case it is also possible the internal rewinder and applicator interface have been preinstalled.

• 1x GoDEX ZX1200i 203dpi printer (optional: ZX1300i dpi printer, ZX1600i 600dpi printer)

9

Page 10

• 1x GoDEX ZX1(X)00i applicator interface, item no. GP-031-Z2i003-001:

• 1x GoDEX ZX1(X00i) peeler/rewinder unit, item no. GP-031-Z21005-000

10

Page 11

3.2.2 Box 2: Applicator components

A- Parts to build heavy duty floor stand item AG-2000-123322

B-From left to right:

Positioner (AG-2000-110110) (AG-2000-110108)

700mm tube (AG-2000-110112)

90° clamp for use with positioner (AG-110106)

C- Applicator machine clamp

D- Control Unit

11

Page 12

E- AG3000T applicator base plate, piston, mounting material, applicator head.

(Item AG-3000-110060, AG-3000-110100, AG-3000-22L060, or AG-3000-22L100)

12

Page 13

Assembling the system

Required Tools

• Hex wrenches 4, 5, 6, 8

• Socket wrench 15

• Screwdriver set

• Phillips head screwdriver set

Assembling the stand

Please preview all steps and parts described below here before you start assembling. It will help you

to anticipate on every step to come.

Picture 1 – 3: mount the four round feet to the corners of the 2 longer alloy profiles (check also pic.

4 + 5!):

Pic. 1 Pic. 2 Pic. 3

Picture 4: mount the feet on the faces which do not have screw holes

Picture 5: let the narrow ends of the screw holes face each other on the inside whilst mounting the

feet.

Pic. 4 Pic. 5

13

Page 14

Picture 6: the height of each foot is adjustable to level the stand on uneven surfaces

Picture 7: close the ends of the alloy profiles with the black plastic covers

Pic. 6 Pic. 7

Picture 8: place the shorter alloy leg (the one with holes on two faces) between the longer

legs. Make sure the wider ends of the screw holes are on the same side as the feet.

Picture 9 - 10: firmly connect the three legs

Pic. 8 Pic. 9

Pic. 10

14

Page 15

Picture 11 - 13: take the remaining profile (pic. 11) and mount it firmly onto the central leg:

Pic. 11 Pic. 12 Pic. 13

Picture 14 - 16: mount the adapter plate and clamp on the top of the vertical profile.

Pic. 14 Pic. 15 Pic. 16

Picture 17-18: insert the 700mm tube into the floor stand:

Pic. 17 Pic. 18

i: now first see the appendix “AG3000 OPTIONS” plier in case you also received the

demonstration / exhibition kit AG-3000-EXHKIT.

15

Page 16

Picture 19-20: mount clamp 110106 onto the slide inside positioner 110110 and then mount the

positioner on the upper end of the 700mm tube:

POSITIONER

AG-2000-110110

CLAMP

AG-2000-110106

Pic. 19 Pic. 20

Picture 21: at a later stage the end of the horizontal positioner must be inserted in- and firmly

attached to clamp 110108, which is pre-mounted on the applicator unit:

Pic. 21

16

Page 17

Picture 1:

Picture 2:

Installing the internal rewinder in the printer

Step 1. Open the main printer cover

Step 2. Remove the three screws holding the left side

cover

Step 3. Remove the lower front cover

Step 4. Remove the plug from the center plate

(The rewinder bearings will be inserted here)

Step 5. Remove the left cover

Picture 3:

Step 6. Insert the first bearing from the right side

Picture 4:

17

Page 18

Picture 4:

Step 7. Insert the second bearing from the left sight

Picture 5:

Step 8. SKIP this step! Not relevant for applicator use.

Step 9. SKIP this step! Not relevant for applicator use.

Step 10. Install the diverter pulley

Picture 6:

Step 11. Insert the rewinder shaft into the bearings

Step 12. Install the “rewinder full” sensor

Step 13. Plug in the sensor connector

Step 14. Remove the motor.

Step 15. Install the 22T cogwheel and its retaining ring.

Step16. Install the motor and the rewinder drive belt

Step 17. Install this gear set

Step 18. Install this gear set

Step 19. Install the clutch

i: The default torque setting of the clutch suits the AG3000 requirements. Please check the

printer service manual in case the torque needs to be adjusted at some point.

i: GO TO § 4.4 (APPLICATOR INTERFACE INSTALLATION) BEFORE RE-INSTALLING THE PRINTER

COVER!

18

Page 19

Installing the applicator interface

The GoDEX ZX1X00i applicator interface can be used with both 24V and 5V peripheral systems,

both in terms of power supply and in- and outgoing signals. Hence, the correct voltage levels of

the in- and outgoing signals must be configured before installation in the printer. Even in case the

interface board has been pre-configured you must verify the setup is correct. You may need to

(re)configure the board to be compatible with the AG3000. The AG3000 requires the 24Volt

configuration. A wrong configuration may damage your equipment!

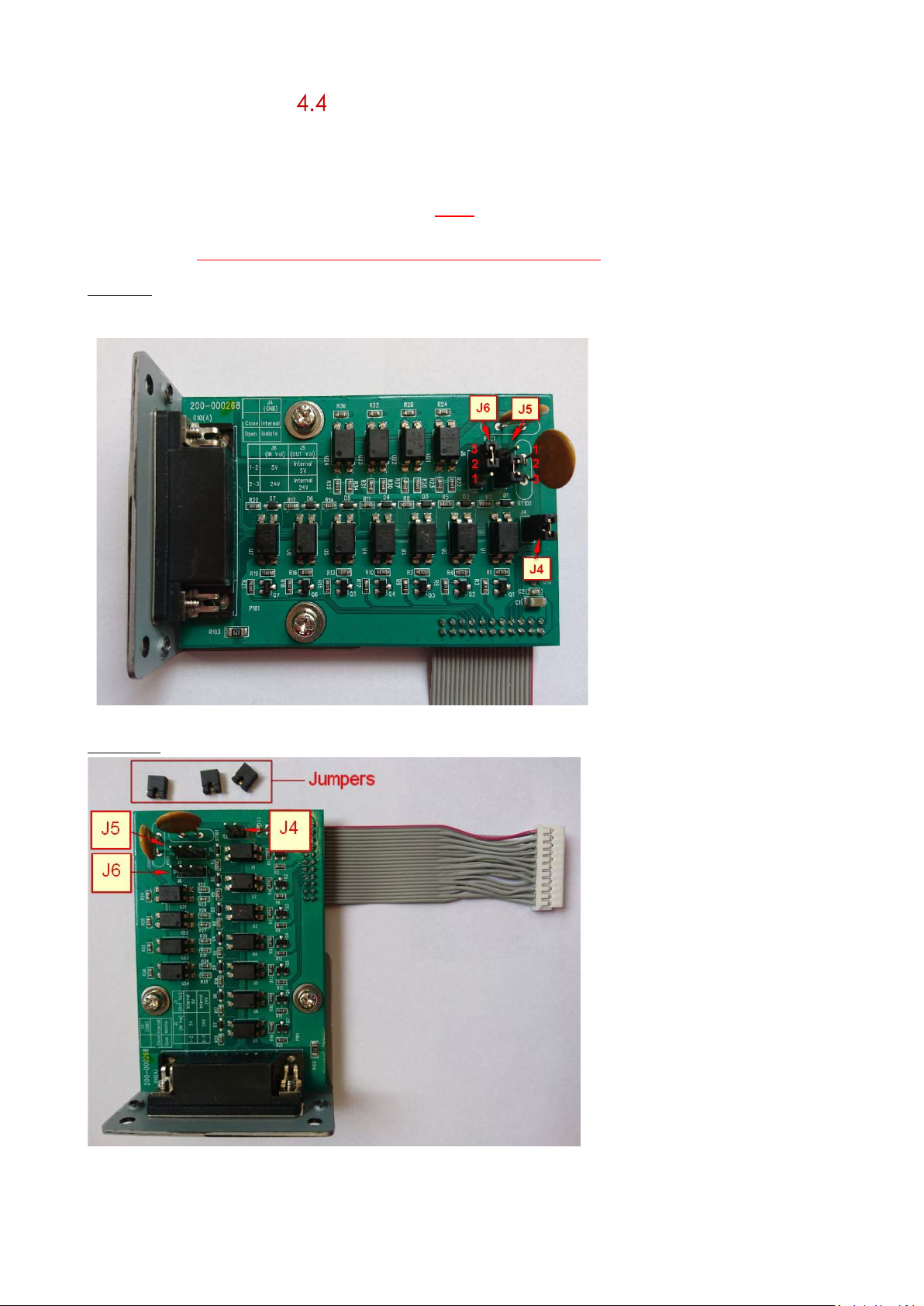

Picture 1: check whether the configuration of the applicator interface board is set correctly for use

with the AG3000 applicator series. Adjust it if necessary. Picture 1 shows the correct configuration.

A. The two pins on J4

must be connected.

B. Pin 2 and 3 on J5

must be connected.

C. Pin 2 and 3 on J6

must be connected.

Pic. 1

Picture 2: the applicator interface board with the three loose jumpers and mainboard flat cable.

Pic. 2

19

Page 20

Picture 3 and 4: remove this cover on the back of the printer

Pic. 3 Pic. 4

Picture 5 and 6: connect the applicator interface to the socket on the mainboard:

Pic. 5 Pic. 6

20

Page 21

Picture 7 + 8: place the external connector in the slot and tighten the screws from

outside

Pic. 7 Pic. 8

Picture 9 - 11: remount the left printer cover:

21

Page 22

Integrating the printer and applicator unit

After installing the internal rewinder and applicator interface it is time to mount the printer on the

applicator. You do this by following the steps showed in the following pictures.

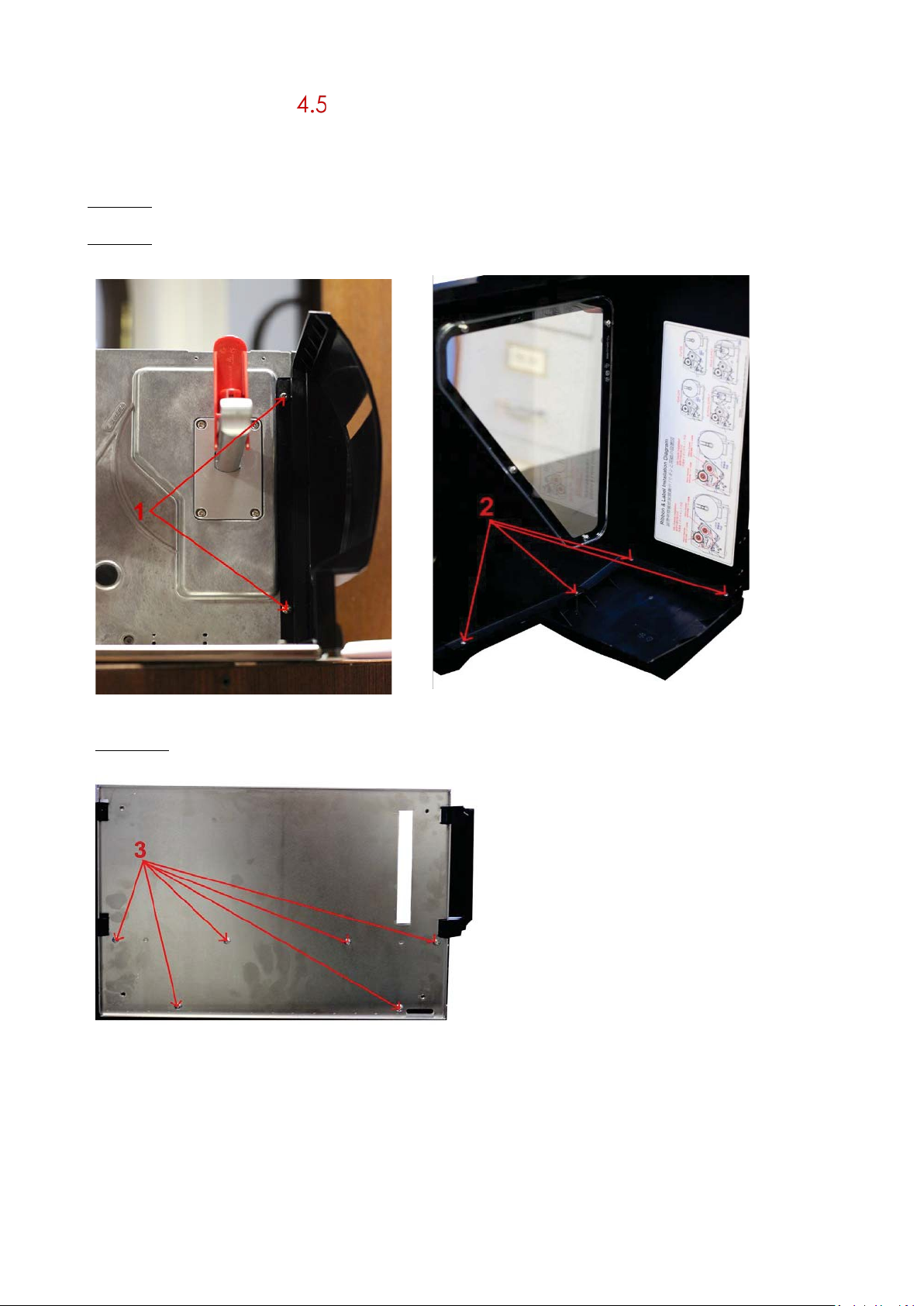

Picture 1: unscrew the screws indicated with “1” and remove the printer’s back cover

Picture 2: unscrew the screws indicated with “2” and remove the printer’s front cover

Pic. 1 Pic. 2

Picture 3: unscrew the screws indicated with “3” and remove the bottom plate from the printer.

Pic. 3

21

Page 23

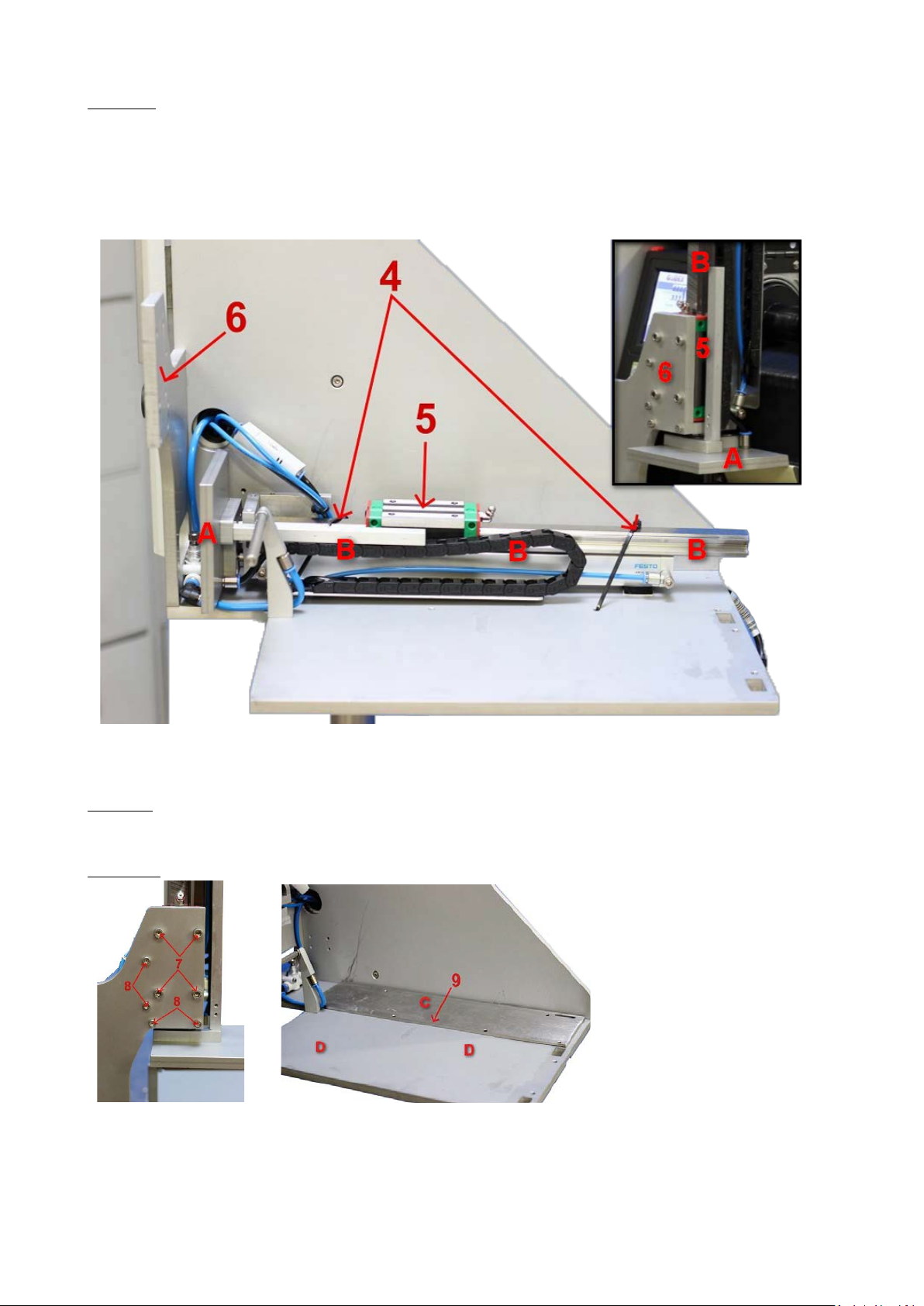

Picture 4:

• Remove the tie wraps (4)

• Move the slide (5) as far as possible towards the applicator head (A)

• Lift up the piston (B) including the slide and tubes and place the slide (5) against surface “6”

Pic. 4

Picture 5: mount the slider to the bracket with 4 bolts M5x16 and tighten properly (step 7) mount

the pneumatic cylinder bracket with 4 bolts M4x16 and tighten properly (step 8)

Picture 6: place adapter plate “C” onto the applicator main frame “D” (step 9)

Pic. 5 Pic. 6

22

Page 24

Picture 7: place the prepared printer onto adapter plate “C” and main frame “D”

Pic. 7

Picture 8: mount the printer E on main frame D with 6x M4x16 and tighten properly (step 10)

Pic. 8

23

Page 25

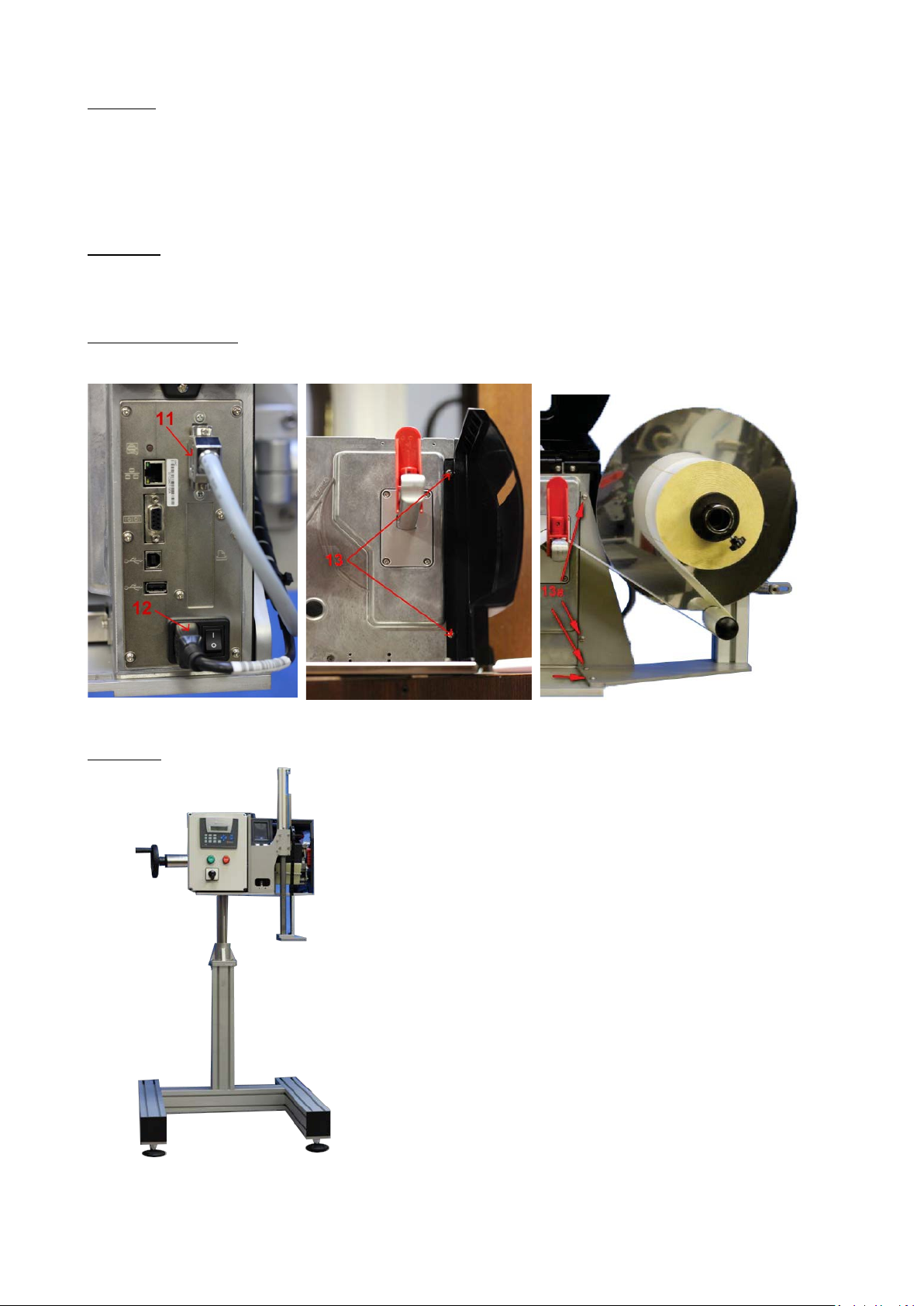

Picture 9:

• Connect the I/O interface cable coming from the control box to the printer’s

applicator port (step 11)

• Connect the power cable coming from the control box to the

printer (step 12)

Picture 10:

• Remount the rear printer cover (step 13 - not applicable if you install the optional

label unwind stand)

Picture 11 (optional):

• Mount the optional label unwind stand (step 13a)

Pic. 9 Pic. 10 Pic. 11

Picture 12: your AG3000 system should look like this now and is ready

Pic. 12

24

Page 26

Operating your AG3000T(-LS)

Print & apply cycle: the basics

The labelling cycle is initiated by the START signal, given by the applicator control box. The cycle

can only begin if the buffer memory of the printer is provided with data, the printer READY signal

to the applicator is on and the applicator operating status is RUN. Once the START signal is given,

the control unit instructs the printer to print a label, while simultaneously the blow valve (OFUK) is

opened. The lower blow nozzle ensures the secure detachment of the label from the carrier tape

and its transfer onto the application head using suction. The label is secured in place on the

application head by a vacuum. Subsequently the piston rod lowers the application plate onto the

product to apply the label, before the application plate is returned to its upper standby position,

thus completing the application cycle.

Data exchange may take place between the printer and auxiliary systems via one or more of the

available interfaces on the printer (USB, LAN, SERIAL, USB Host as well as optional WIFI and BT). No

data are sent to the printer via the applicator control unit.

Printer configuration for applicator use

5.2.1 Power on the printer

1) Properly ins er t the applicator control box’s power cable into a 240V AC socket

2) Switch on the main switch on the control box (Pic. 1) .

3) Switch on the main switch on the back of the printer Pic. 2).

4) Push the power button beneath the printer display (Pic.

Pic. 1 Pic. 2 Pic. 3

26

Page 27

5.2.2 Firmware

The recommended fir m ware version for applicato r usage is V2.Y06 (April 2016). Please

always verify with your supplier or directly with GoDEX whether updates have been

released. The current s u pportive display firmware is 2.003 (April 2016).

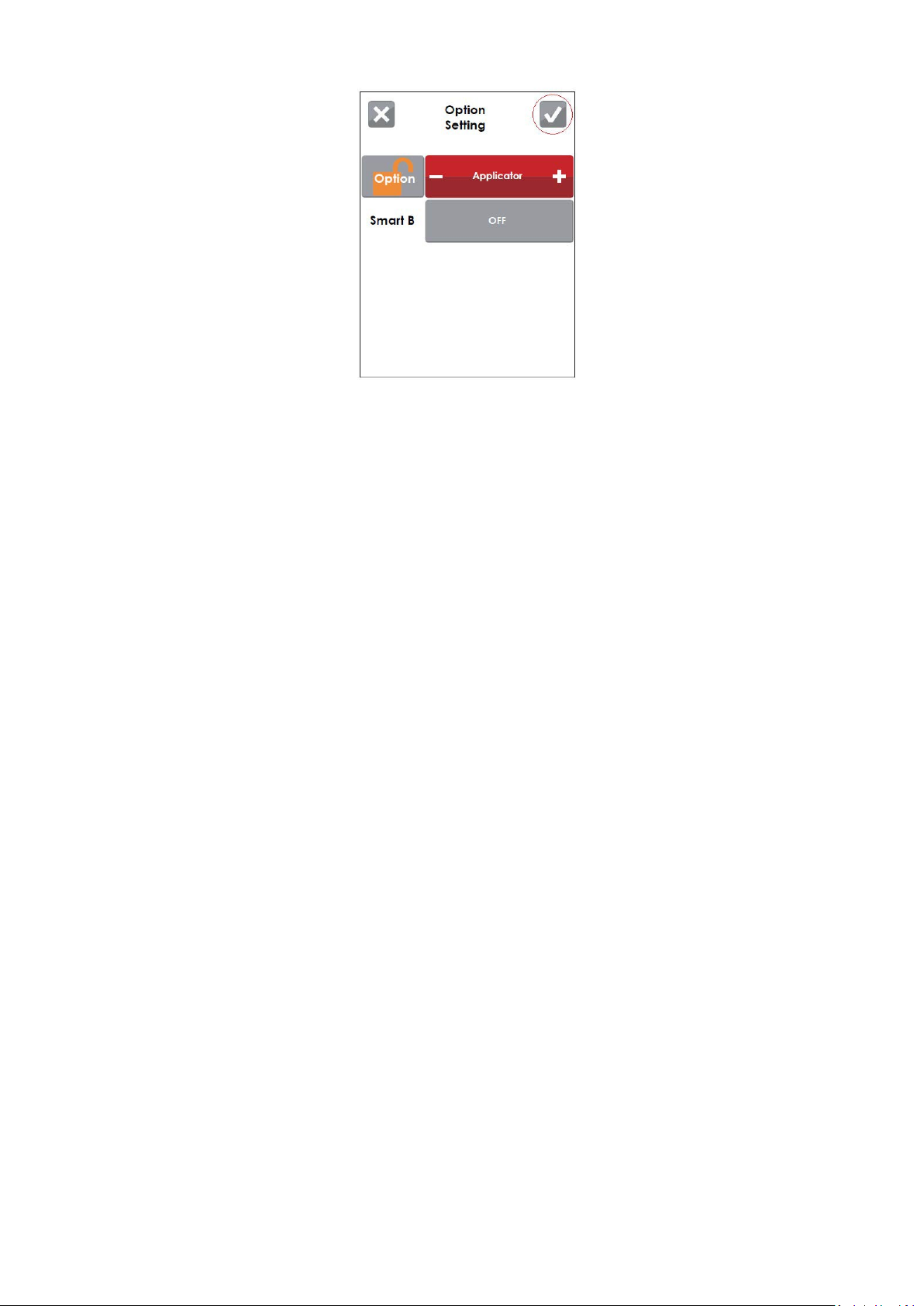

5.2.3 Setting the printer in applicator mode

Set and lock the applicator mode in the printer menu to enable correct and reliable

communication between the applicator control unit and the printer. The procedure is as follows:

Pic. 1: select "main"

setting"

Pic. 2: select "devices"

Pic. 3: select "option

Pic. 4: select "+". "None"

will change to "Applicator"

Pic. 5: select "option" to lock

the printer in applicator

mode

Pic. 6: select "check box" to

confirm the option settings

and leave the option menu

27

Page 28

Pic. 7: select the icon shown

below) to return to main menu

Pic. 8: Back on main menu

28

Page 29

5.2.4 Formatting the applicator interface (!)

It is necessary to format the applicator interface by sending the command ^XSET,APPLICATOR,0,1

to the printer. For more details, please see the printer manual.

5.2.5 Smart backfeed

The smart backfeed function is currently (April 2016) not supported in applicator mode.

5.2.6 Create a label and load media

Now create a label and store it on the printer. Always select the applicator mode in either the

software or the driver you are using. Load the printer with suitable media and TTR if applicable. The

printer is ready to go now. For more information regarding creating labels and handling the ZX

printer, please see the printer manual.

Putting the applicator into service

5.3.1 Air supply

Connect the AG3000 to a pressed air supply. The required pressure is at least 4,5bar. The system’s

air intake valve protects the applicator against too high pressure. You insert the end of an 8mm air

hose into the quick coupler on the backside of the control box:

Picture 1: AG3000 air intake coupler

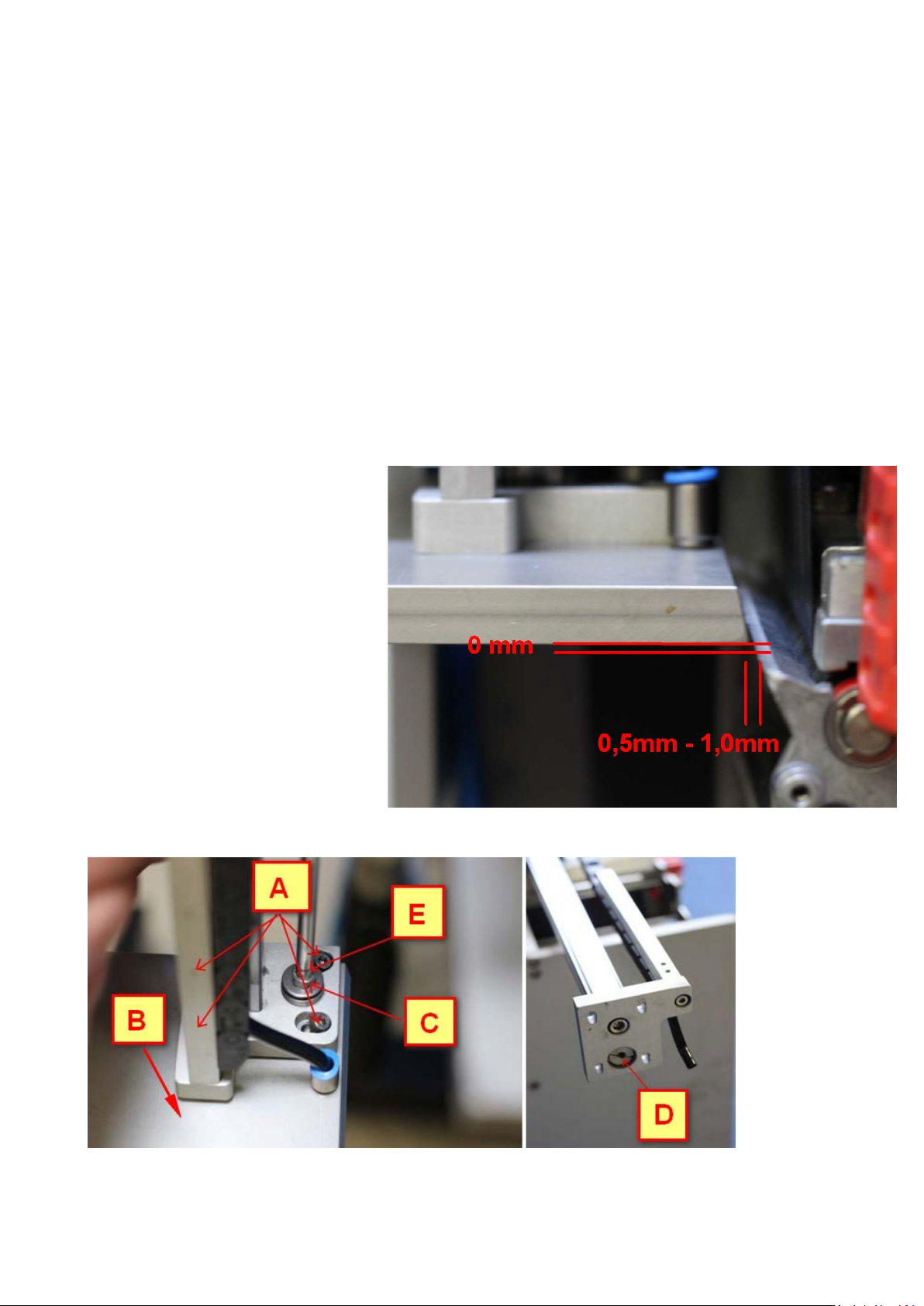

5.3.2 Checking the mechanical settings (!)

Basically no adjustment of the mechanical parts is needed. During its production the applicator

has been tuned to be a perfect fit with the printer, out-of-the-box. But due to transportation and

re-assemblage certain elements might require fine-tuning after all. Therefore, it is a must to check

the correct position and - functioning of the crucial before putting the AG3000 into operation.

29

Page 30

Please perform the following procedure:

Picture 1 & 2: Check the alignment of the application head (A) and the printer peeler edge (B).

• The horizontal distance between applicator head and peeler edge (1) must be 0,5mm to 1mm.

• The applicator head and the peeler edge must be aligned perfectly parallel to each other

• The bottom of the applicator head should be the same height (2) as the upper end of the peeler

edge.

• If the height has been set correctly the label will slightly bend down to move forward under the

head (3)

Picture 1

Picture 2

30

Page 31

5.3.3 Run a test cycle

After verifying the applicator and printer have been aligned properly (see § 5.3.2) and after the

printer has received the print data (see § 5.2.6) you can run a test cycle. The system must be in

“START” menu to do so.

Option 1: Enter key

1) At start-up the applicator display will show “STOP”

2) Push the START-button on the control unit to bring the system in “RUN READY”” mode

3) Select the “ENTER” key underneath the control box display to trigger one cycle

i: if the display will show “only “RUN” instead of “RUN READY” the applicator head is not in its start

position

Option 2: Triggering device

1) At start-up the applicator display will show “STOP”

2) Push the START-button on the control unit to bring the system in “RUN READY” mode

3) Activate the triggering device (e.g. switch, sensor, external PLC) in case you already

connected one.

i: if the display only shows “RUN” instead of “RUN READY” the applicator head is not in its start

position

Observe the way the labels travel from the print head onto the applicator head and then

towards the product. If the label is transported correctly no mechanical adjustment is needed.

Also in the course of long-term operation no adjustments are anticipated because the label

position is determined by the alignment of printer and applicator, which again is fixed.

How to proceed now:

1) Most probably your test results are positive which means your system is now READY TO USE. Go to

§ 5.3.4.

2) In case the label does not travel correctly or a cycle won’t start, it may be necessary to adjust

one or more of the stop positions of individual pneumatic parts. Also in that case we recommend

to first read § 5.3.4 - § 5.3.7. In case you prefer to adjust the mechanics first, please go to §6.

5.3.4 The “START” menu

Image 1: the system will start up in the „START“ menu, displaying either „STOP“ and „ERROR PRINT“

(in case the printer is not ready yet) or only „STOP“ (as soon as the printer is in „READY“ mode).

LCD display

STOP

Numeric keypad

“DOWN” arrow

ERROR PRINT

ENTER button

31

Page 32

Image 2: By pushing the START-button on the control unit you will bring the applicator from “STOP”

/

into “RUN” mode if:

• There does not occur an error in the applicator

• There does not occur an error in

the printer the screen will display

“RUN” and “READY”

!! In case only “RUN” is indicated you

cannot start a cycle. It means the

applicator head is not in its uppermost

position (start position). Check the

pneumatic cylinder in this case. Maybe

there is no air, or the sensor position is not

correct. The LED on the sensor must be

on!!

i: as soon as “RUN READY” is displayed

you can run a test cycle

Image 3: the display will show “ERROR”:

• In case an application cycle cannot

be completed after a predetermined

length of time (time out function)

Image 4: the display will show “ERROR PRINT”:

• In case the printer ran out of media

• In case the printer ran out of ink ribbon

• In case the print head is open

• In case no print file ready in printer buffer

ERROR

RUN READY

RUN

ERROR PRINT

i: the control box can also deliver error

signals to auxiliary systems. See § 7.1 - §

7.3.

Image 5: by selecting the DOWN-arrow

you will enter the “SERVIS1” menu.

32

Page 33

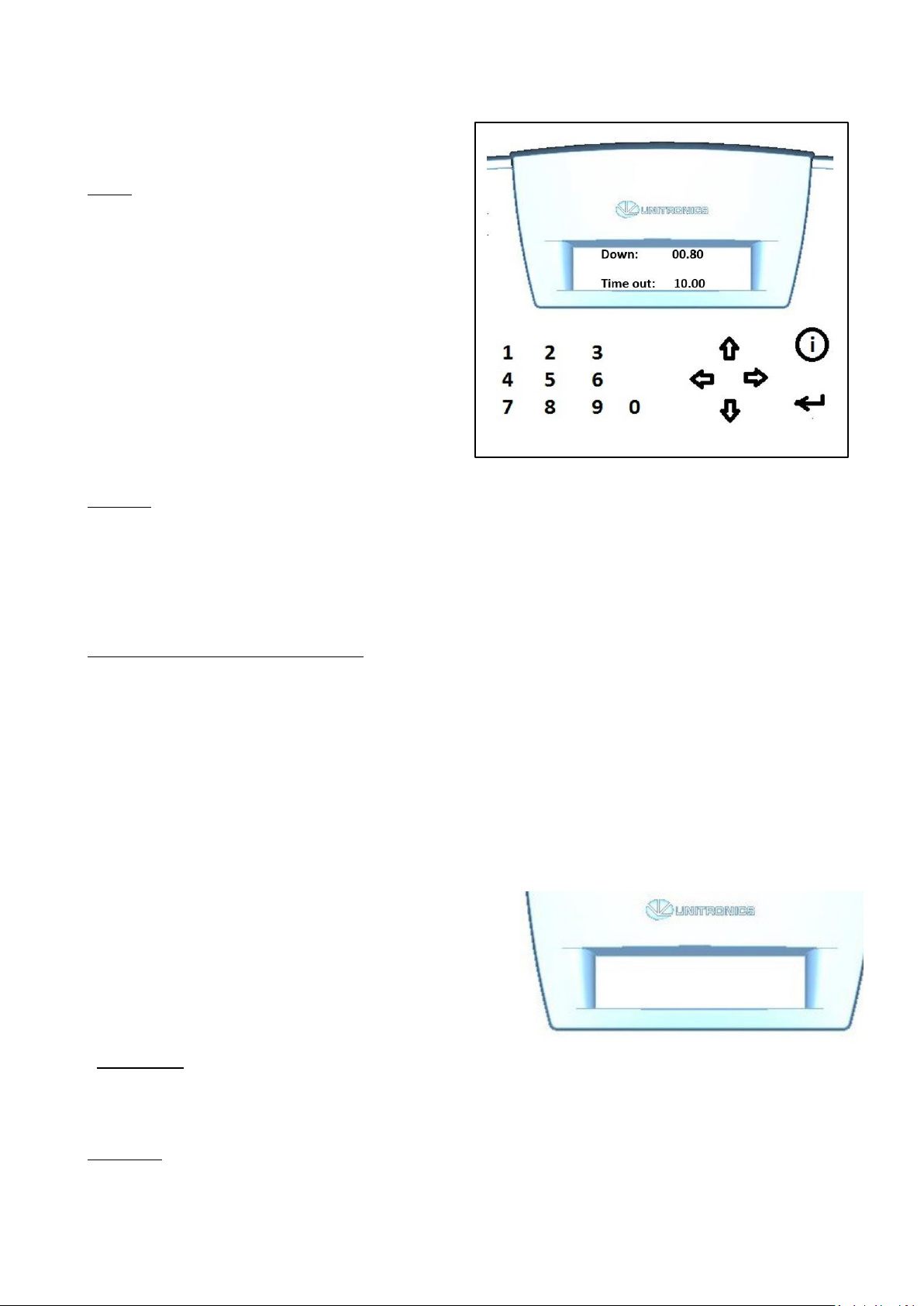

5.3.5 The “SERVIS1” menu

Image 1: in this menu you set 2 key

parameters.

Down

The time in seconds during which the applicator

head travels and remains down before returning

to its starting position.

In workflows in which objects of various sizes

are handled simultaneously this value must be

adjusted to the objects that require the

longest travelling time.

In case all objects require the same travelling

time the distance to the applicator base plate

can be minimized and with it the travelling

time. This ensures the highest possible system

speed.

Time out

This value in seconds determines the maximum duration of one application cycle. If a cycle has

not been completed within this length of time the system will go into error mode.

This function will stop the system if an error occurs after the initialization of an application cycle

and the cycle cannot be completed. Possible examples are the applicator head being

obstructed and lack of feedback from the printer.

Selecting and setting the parameters

1) The „DOWN“ value will be blinking automatically. Either change and confirm or only confirm

the pre-selected value with the „enter“ key. The cursor will jump to the „TIME OUT“ value.

2) Change and confirm or only confirm the pre-selected „TIME OUT“ value with „enter“. Exit menu

“SERVIS1”

Push the “START” button to return to the “START” menu Select the DOWN-arrow to go to the

“MANUAL menu

5.3.6 The “MANUAL” menu

Image 1: this menu is used to test individual

stages of the print&apply process. Can only

be used with the system in “STOP” mode. It is

not possible to test a full cycle in this menu.

MANUAL

1 x 2 x 3 x 4 x

Options are selected on the numeric keypad.

Select “1” to check the airflow through the

little tube underneath the print head. This

airflow blows the label towards the applicator

head.

Select “2” to check whether the applicator head vacuum works well.

33

Page 34

Select “3” to check whether the cylinder receives enough air pressure to go down and up.

Select “4” to check printer output (the printer will print one label if the input buffer is loaded)

You exit this menu with either the LEFT arrow (back to the SERVIS1 menu), the DOWN arrow

(further to the language settings) or the START button (back to the START menu).

5.3.7 The “LANGUAGE” menu

Image 1: in this menu you can select

any language included in the

AG3000 firmware.

1) You access this menu from the

MANUAL menu by selecting the

DOWN arrow key.

2) Use the arrow RIGHT key to select a

language

3) Leave this menu by selecting the

arrow LEFT key (back to the

MANUAL menu) or the START button

(back to the START menu).

CHOOSE LANGUAGE

EN

34

Page 35

6. Mechanical and pneumatic adjustments

6.1 Manual menu

You must first open the “MANUAL” menu to adjust mechanical settings on the applicator:

• Bring the device in stop mode

• Press the “DOWN” arrow whilst the device is in “STOP” mode to open the “SERVIS 1

menu”, confirm the preselected settings with “ENTER” and select the “DOWN” key again.

6.2 Applicator head alignment

It is required to align the applicator head in case:

• In start position its bottom is higher than the upper end of the peeler edge

• In start position its bottom is lower than the upper end of the peeler edge

• The distance between the head and the peeler edge is less than 0,5mm

• The distance between the head and the peeler is more than 1,0mm

• The head and the peeler edge are

not parallel Picture 1: correct

Alignment.

Picutres 2 & 3: re-align the applicator

head

35

Page 36

Pictures 2.

Picture 3

36

Page 37

6.2.1 Height adjustment

1) Note the distance in mm the applicator head start position is too low or too high

2) Bring the applicator head in its lowest possible position by selecting “3” on the keypad

3) Remove screws (A) and remove the applicator head (B)

4) Loosen locknut (C) against nut (D)

5) Hold piston rod (E) and rotate nut (D) to move the applicator head bracket in the desired

direction 6/ tighten locknut (C) with the applicator bracket in the new position

7) Remount the applicator head but only loosely tighten the screws (A). You must still be able to

move the applicator head. Move the head as far as possible in the direction of arrow “F” (away

from the printer).

8) Bring the piston back in its upper position by selecting “3” on the keypad again

9) Check whether the vertical position (start position) is correct now. If not please repeat the

procedure until the vertical position is correct.

CONTINUE NOW WITH § 6.2.2

6.2.2 Horizontal adjustment after vertical adjustment

After adjusting the vertical start position of the applicator head it is always necessary to also set

the horizontal position again. You do so as follows:

1) Slide the applicator head towards the printer until it is 0,5mm – 1,0mm from the peeler edge

2) Make sure the peeler edge and applicator head are placed perfectly parallel to each other

3) Select key “3” on the keypad to bring the applicator head in its lowest position

4) Tighten the screws (A)

5) Select key “3” again to bring the applicator head back in start position

6) Verify whether the horizontal position is correct. If not repeat the procedure until all corrected.

7) Leave the MANUAL menu by activating the START button and run a test cycle

6.2.3 Horizontal adjustment without vertical adjustment

In case the original starting height of the applicator head is correct but you need to change the

horizontal position of the head, you proceed as follows:

1) Measure where and to what extend the distance between applicator head and peeler edge

must be corrected

2) Bring the applicator head in its lowest possible position by selecting “3” on the keypad

3) Loosen the screws (A on picture 2 on the previous page) and move the applicator head (B,

same picture) into the desired horizontal position

4) Tighten the screws (A)

5) Bring the applicator back in start position with key “3” on the key pad

6) Verify whether the horizontal position is correct now. If not repeat the procedure until all correct.

7) Leave the MANUAL menu by activating the START button and run a test cycle

37

Page 38

6.3 Air settings i: blowing

In case the label is not transferred to the applicator head properly and tends to fall down there

may be too little air flowing through the nozzles underneath the labels or the direction of the airflow

is faulty. In case labels seem to be blown away from the area beneath the applicator head the

airflow may be too strong. The following pictures and descriptions help you eliminate such errors.

Picture 1: correct direction of airflow

In case the airflow is not directed as depicted on pic. 1 you loosen locker “A” shown on picture 2,

turn the blow tube with in such way that the nozzles point in the right direction and fasten locker

“A” again.

Picture 2: Changing the direction of the airflow

Given the applicator head position and airflow direction are correct but labels still tend to drop

before being attached to the applicator head, the amount of air flowing through the nozzles is

probably too low. You can increase the airflow by further opening throttle valve “B” on picture 3.

And opposite: in case labels seem to be blown away before the applicator head “catches” them,

you reduce the airflow with the same valve “B” shown on picture 3.

Picture 3: Valve to set the airflow through the label blow-on nozzles

38

Page 39

6.4 Air settings ii: vacuum

The applicator creates a vacuum which sucks the label towards the bottom of the applicator head

during its transfer from the printer to the applicator and which keeps it there whilst travelling

towards the product. To properly distribute the sucking power, the applicator head contains

grooves over all of its surface.

• The label width and the applicator head width must be equal!

• The length of the applicator head should be equal to or bigger than the length of the label!

• The vacuum cannot be regulated

Picture 1: Grooved applicator head

Pic. 1

39

Page 40

7 Connecting to auxiliary systems

7.1 Introduction

The AG3000 applicator can be integrated in any hard- and software environment as long as the

GoDEX ZX1X00i printer is compatible with that environment as well. However, the communication

lines between the printer and any auxiliary system and between the applicator and such system are

fully separated. Also the kind of information which is exchanged differs:

1) The printer will receive print data (content and settings) from the system through one or more of

its interfaces and can send certain status and error data via the same interfaces. The

communication can take place in various printer languages, the commands being generated by

drivers, label software or the auxiliary system itself. See the printer documentation for detailed

information.

2) The applicator control unit will receive start signals from the auxiliary system and can report

certain status and error signals to that system

A schematic depiction of an AG3000 integrated in a higher control system (e.g. an ERP system) is

given in picture1. The chosen Ethernet is just a random example of how data can be exchanged

between printer and such auxiliary system.

We will explain now how to connect the AG3000 control unit to the most common kinds of these

auxiliary systems, starting with the auxiliary system as a triggering device.

Picture 1: communication between printer, applicator and system

Pic. 1

40

Page 41

7.2 Triggering devices – input signals

The triggering device can be a manual start button, a sensor on a conveyor line, a switch which

is automatically activated when a product is placed onto it, an external PLC built in a robot, a PLC

ultimately controlled by an ERP system, et cetera.

Picture 1: incoming start impulses & outgoing signals

Pic. 1

• Connect +24V red (leftmost) and X1-1 and include a switch or relay in this circuit. This can be

done with any kind of switch or relay. By closing this circuit, you trigger the applicator to start a

print & apply cycle. If the AG3000 is controlled by an external system (e.g. an intermittent

product forwarding system) a controller in that system can close this circuit and trigger the

applicator.

• In case a PNP sensor is used you connect the sensor wires as follows: BROWN to +24V (leftmost

connector), BLUE to Ground (second connector from the left), BLACK to X1-1

7.3 Outgoing signals

X1-6/X1-7 and X1-8/X1-9 form relay controlled switches.

In case of an application time out or printer error, switch X1-6/X1-7 will be closed (ON). If the

AG3000T is ready for the next print & apply cycle switch X1-8/X1-9 will be closed (ON). See both

picture 1 on this page and picture 1 on the previous page for a visualization.

Hence, by creating an electrical circuit over X1-6/X1-7 which is connected to a controller (e.g. a

PLC) on the side of the auxiliary system, that system will know when there is an error and can be

programmed to react in any desirable way (e.g. stop forwarding products, start a warning light).

Hence, by creating an electrical circuit over X1-8/X1-9 which is connected to a controller (e.g. a

PLC) on the sid e of the auxiliary system, that system will know the next product can be labeled.

Such system can be programmed to react in any desirable way (e.g. placing the next product

under the applicator).

41

Page 42

8 Options

Item Number

Description

Lead Time

Integration

AG-3000-HEA060

applicator head 60mm x 60mm

stock item

n.a.

AG-3000-HEA100

applicator head 60mm x 60mm

stock item

n.a.

AG-3000-HEADIV

custom size Applicator Head min. 20x20 max 100x200

2 weeks

low

AG-3000-HEATOU

Applicator Head with Touch Sensor, Suspension,

3 weeks

medium

AG-3000-HEAROL

Applicator Head with Roll-On Unit

stock item

high

AG-3000-HEABLO

Applicator Head with Blow-On Unit, Appr. Sensor,

on request

high

AG-3000-

AG3000 Label Unwinder O/D max 280mm, 40mm

stock item

n.a.

AG-3000-

AG3000 Label Unwinder Core Adapter 76mm

stock item

n.a.

AG-3000-EXHKIT

Set of product table, switch & cable, tubes,

mounting materials

stock item

low

The following AG3000 options are available to suit particular applications. Please be aware

though, that not all are stock items and in some cases a successful implementation may require a

significant amount of experience with the installation of print & apply systems. Therefore, we

mention for each option the complexity of its integration.

Contact us or your GoDEX equipment supplier for more detailed information regarding the options

listed here and in case you are not sure the AG3000T(-LS) is the right solution for your application.

9 Maintenance

AG3000T(-LS) systems require hardly any maintenance, which goes for both the printer and the

applicator components. For applicator maintenance instructions please see the “AG3000

Maintenance & Options Guide” and for printer maintenance instructions the “ZX1200i Service

Manual”. Both are made available to authorized GoDEX dealers.

42

Page 43

10 Wire diagrams

10.1 Power and signals schematic

10.2 Control unit picture

43

Page 44

10.3 Power circuits

10.4 Con ne ct or ra c k - detailed view

44

Page 45

10.5 Connector rack diagram

41

Page 46

10.6 Electro-pneumatic diagram

10.6 PLC / P rinter applicator port diagram

42

Loading...

Loading...