Page 1

www.glow-worm.co.uk

Installation and Servicing

High Efficiency

Condensing System

Boilers

Ultracom

30sxi

G.C. No. 41-019-08

18sxi

G.C. No. 41-019-07

Page 2

2

Guarantee Registration

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances are manufactured to the very highest standard so we are pleased to offer

our customers a Comprehensive Guarantee.

This product is guaranteed for 24 months from the date of installation or 30 months from the date

of manufacture, whichever is the shorter, for parts and labour.

The second year of the parts guarantee, from the beginning of the 13th month onwards after

installation or manufacture, is conditional upon the boiler having been serviced by a competent

person approved at the time by the Health and Safety Executive,

in accordance with the manufacturer’s recommendations. We strongly recommend regular

servicing of your gas appliance, but where the condition is not met, any chargeable spare parts or

components issued within the applicable guarantee period still benet from a 12 month warranty

from the date of issue by the manufacturer.

We recommend you complete and return as soon as possible your guarantee registration card.

If your guarantee registration card is missing you can obtain a copy or record your registration by

telephoning the Glow-worm Customer Service number 01773 828100.

Customer Service:

01773 828100

Technical Helpline:

01773 828300

General and Sales enquiries:

Tel. 01773 824639

Fax: 01773 820569

To register your Glow-worm appliance call:

0800 0732142

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided

with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future

reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of

Practice which is available from the Heating and Hotwater Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

Page 3

3

CONTENTS DESCRIPTION SECTION PAGE

Warnings 4

Important Information 4

Statutory Requirements 5

Boiler Design 6

Safety Devices 6

Servicing, Maintenance and Spare Parts 6

Boiler Specication 1 7

Boiler Dimensions &

Hydraulic Schematic 2 8

Boiler Location, Clearances

and Ventilation 3 9

Flue Options and Terminal Clearances 4 10

Water System 5 12

Installation Preparation 6 14

Boiler Fixing 7 15

Gas/Water Connection 8 16

Safety Discharge Valve and

Condensate Connections 9 17

Flue Length Preparation and Installation 10 19

Electrical Connection 11 35

Commissioning 12 37

Servicing 13 41

Fault Finding 14 45

Replacement of Parts 15 52

Spare Parts 16 60

Manual Handling 17 62

Declaration of Conformity - 63

INTRODUCTION

INSTALLATION

MAINTENANCE

These instructions consist of, Installation, Servicing, Fault Finding, Replacement of Parts

and Spares. The instructions are an integral part of the appliance and must, to comply

with the current issue of the Gas Safety (Installation and Use) Regulations, be handed to

the user on completion of the installation.

Page 4

4

WARNINGS

Gas Leak or Fault

Turn off the gas emergency control valve immediately. Eliminate all sources of ignition, i.e.smoking, blowlamps,

hot air guns etc. Do not operate electrical lights or switches either on or off. Open all doors and windows,

ventilate the area.

Metal Parts

This boiler contains metal parts (components) and care should be taken when handling and cleaning,

with particular regard to edges.

Sealed Components

Under no circumstances must the user interfere with or adjust sealed parts.

Important Information

Gas Category

This boiler is for use only on G20 natural gas, but may be

converted for use on G31 gas (Propane L.P.G.).

Gas Safety (Installation and Use) Regulations

In your own interests and that of safety, it is the Law that

ALL gas appliances are installed by a competent person

approved at the time by the Health and Safety Executive in

accordance with the current issue of these regulations.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act

1974, we are required to provide information on substances

hazardous to health.

The adhesives and sealants used in this appliance are cured

and give no known hazard in this state.

Insulation Pads

These can cause irritation to skin, eyes and the respiratory

tract.

If you have a history of skin complaint you may be susceptible

to irritation. High dust levels are usual only if the material is

broken.

Normal handling should not cause discomfort, but follow

normal good hygiene and wash your hands before eating,

drinking or going to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the

skin seek medical attention.

Manual Handling

With regards to the “Manual Handling Operations, 1992

Regulations”, the appliance exceeds the recommended

weight for a one man lift, refer to section 17 for more

information.

The handling of the boiler may involve lifting, pushing and

pulling, the use of a sack truck may be required.

The following handling techniques and precautions should be

considered:

- Grip the boiler at its base

- Be physically capable

- Use safety clothing where appropriate, e.g. gloves, safety

footwear.

Ensure safe lifting techniques are used

- Keep back straight.

- Avoid twisting at the waist.

- Avoid upper body/top heavy bending.

- Always grip using the palm of the hand.

- Use designated hand holds.

- Keep load as close to body as possible.

- Always use assistance if required.

Electrical Supply

The boiler MUST be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

External wiring must be correctly earthed, polarised and in

accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The boiler MUST be connected to a permanent 230V ac,

50Hz supply.

Connection of the whole electrical system of the boiler,

including any heating controls, to the electrical supply MUST

be through one common isolator and must be fused 3 Amp

maximum.

Isolation should be by a double pole switched fused spur box,

with a minimum gap of 3mm for both poles. The fused spur

box should be readily accessible and preferably adjacent to

the appliance. It should be identied as to its use.

Alternatively connection can be made through an unswitched

shuttered socket and 3A fused 3-pin plug both to the current

issue of BS 1363, provided they are not used in a room

containing a bath or shower.

Wiring to the boiler must be PVC 85

O

C insulated cable, not

less than 0.75mm2 (24/0.20mm).

Testing and Certification

This boiler is tested and certicated for safety and

performance. It is, therefore, important that no alteration is

made to the boiler, without permission, in writing, by Glowworm.

Any alteration not approved by Glow-worm, could invalidate

the certication, boiler warranty and may also infringe the

current issue of the statutory requirements.

Page 5

5

Statutory Requirements

CE Mark

This boiler meets the requirements of Statutory Instrument,

No. 3083 The Boiler (Efciency) Regulations, and therefore is

deemed to meet the requirements of Directive 92/42/EEC on

the efciency requirements for new hot water boilers red with

liquid or gaseous fuels.

Type test for purposes of Regulation 5 certied by: Notied

body 0087.

Product/production certied by: Notied body 0086.

The CE mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the laws

of the Member States relating to appliances burning gaseous

fuels.

2. Directive 73/23/EEC on the harmonisation of the Laws of

the Member States relating to electrical equipment designed

for use within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of

the Member States relating to electromagnetic compatibility.

IMPORTANT

Where no British Standards exists, materials and equipment

should be t for their purpose and of suitable quality and

workmanship.

The installation of this boiler must be carried out by a

competent person approved at the time by the Health and

Safety Executive and in accordance the rules in force in the

countries of destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

Statutory Requirements

In GB, the installation of the boiler must comply with the

requirements of the current issue of BS6798 and be carried

out by a competent person approved at the time by the

Health and Safety Executive and as described in the following

regulations:

The manufacturer’s instructions supplied.

The Gas Safety (Installation and Use) Regulations.

The appropriate Buildings Regulations either The Building

Regulations, The Building Regulations (Scotland),The

Building Regulations (Northern Ireland).

The Water Supply (water fittings) Regulations 1999 and water

byelaws 2000, Scotland.

The Health and Safety at Work Act, Control of Substances

Hazardous to Health (COSHH).

The Current I.E.E. Wiring Regulations.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a competent

person approved at the time by the Health and Safety

Executive and installed in accordance with the current edition

of I.S.813 “Domestic Gas Installations”, the current Building

Regulations and reference should be made to the current

ETCI rules for Electrical Installation.

GB: the following Codes of Practice apply:

BS4814, BS6798, BS5440 Part 1 and 2, BS5546 Part 1,

BS5449, BS6891, BS6700, BS7074 Part 1 and 2, BS7593,

BS7671.

IE: I.S.813, BS5546, BS 5449, BS 7074, BS 7593.

NOTE: For further information, see the current issue of the

Building Regulations, approved document L1 ( in the UK) and

the following current issues of:

1) Central heating system specication (CheSS)

and

2) Controls for domestic central heating system and hot water.

BRECSU.

Gas Supply

The gas installation must be in accordance with the relevant

standards.

In GB, this is BS6891.

In IE, this is the current edition of I.S.813 “Domestic Gas

Installations”.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg)

at the boiler.

On completion, test the gas installation for tightness using the

pressure drop method and suitable leak detection uid, purge

in accordance with the above standard.

Domestic Hot Water

All domestic hot water circuits, connections, ttings must be

in accordance with the relevant standards and water supply

regulations.

GB: Guidance G17 to G24 and recommendation R17 to R24

of the Water Regulations Guide.

IE: The current edition of I.S.813 “Domestic Gas Installations”.

Heating System

In GB, it is necessary to comply with the Water Supply (Water

Fittings) Regulations 1999 (for Scotland, the Water Byelaws

2000, Scotland).

To comply with the Water regulations your attention is drawn

to: The Water Regulations guide published by the Water

Regulations Advisory Service (WRAS) gives full details of the

requirements.

In IE, the requirements given in the current edition of I.S.813

“Domestic Gas Installations” and the current Building

Regulations must be followed.

Page 6

6

Boiler Design

Boiler Design

This boiler is designed to provide central heating from a

sealed water system with a fully indirect cylinder, pumped

circulation. The pump, expansion vessel and associated

safety devices are all tted within the boiler. The integral

programmer is designed for both simple operation and

maximum control. Once the controls are set the boiler will

operate automatically.

Condensate Drain

A plastic drain pipe must be tted to allow discharge of

condensate to a drain.

Electrical Supply Failure

The boiler will not work without an electrical supply.

Normal operation of the boiler should resume when the

electrical supply is restored.

Reset any external controls, to resume normal operation of

the central heating.

If the boiler does not resume normal operation press the reset

button. If the boiler does not resume normal operation after

this call your Installation/Servicing company or Glow-worm

service.

Overheating Safety

The boiler software is designed to recognise the potential for

an overheat lockout and will shutdown before this happens.

To restart the boiler, press the reset button on the controls

fascia.

If the boiler fails to resume normal operation and all external

controls are calling for heat, then call your Installation/

Servicing company or Glow-worm service.

Safety Discharge Valve

A safety discharge valve and discharge pipe are tted to

the boiler. This valve must not be touched. Should there

be any discharge from the pipe, isolate the boiler electrical

supply and call your installer or Glow-worm’s own service

organisation using the telephone number on the inside front

cover of this booklet.

Safety Devices

Frost protection

The appliance has a built in frost protection device that

protects the boiler from freezing. With the gas and electric

supplies ON and irrespective of any room thermostat setting,

the frost protection device will operate the pump when the

temperature of the boiler water falls below 8

O

C.

A timer is used so that the temperature can be checked

periodically. After 10 minutes the pump will be stopped if the

temperature is higher than 10

O

C or has already reached 35OC.

The burner will activate if the boiler temperature does not

reach 10

O

C after 30 minutes or at any time if the temperature

drops to 5OC.

The burner will switch off when the temperature reaches

35

O

C.

Condensate Drain Blockage

As a safety feature the boiler will stop working if the

condensate drain becomes blocked. During freezing

conditions this may be due to the forming of ice in the

condense drain external to the house. Release an ice

blockage by the use of warm cloths on the pipe, the boiler

should then restart.

Condensate should, if possible, be discharged into the internal

household draining system. If this is not practical, discharge

can be made externally into the household drainage system or

a purpose designed soak away, see section 9 for more details.

Pluming from flue terminal

Like all condensing boilers this appliance will produce a plume

of condensation from the ue terminal in cool weather. This is

due to the high efciency and hence low ue gas temperature

of the boiler.

This is normal and not an indication of a fault.

Servicing, Maintenance and Spare Parts

Servicing and Maintenance

To ensure the continued efcient and safe operation of the

boiler it is recommended that it is checked and serviced as

necessary at regular intervals. The frequency of servicing will

depend upon the particular installation conditions and usage.

If this appliance is installed in a rented property there is a duty

of care imposed on the owner of the property by the current

issue of the Gas Safety (Installation and Use) Regulations,

Section 35.

Servicing/maintenance should be carried out by a competent

person approved at the time by the Health and Safety

Executive in accordance with the rules in force in the countries

of destination.

To obtain service, please call your installer or Glow-worm’s

own service organisation using the telephone number on the

inside front cover of this literature.

Spare Parts

Remember, when replacing a part on this appliance, use

only spare parts that you can be assured conform to the

safety and performance specication that we require. Do not

use reconditioned or copy parts that have not been clearly

authorised by Glow-worm.

If a part is required contact Glow-worm’s own service

organisation.

Please quote the name of the boiler this information will be on

the name badge on the front of the appliance.

If in doubt seek advice from the local gas company or Glowworm’s own service organisation using the telephone number

on the inside front cover of this booklet.

Page 7

7

1 Boiler Specication

13498

Table 1. Flow Rate

MODEL MINIMUM FLOW RATE

18sxi 774 litres/hr.

30sxi 1289 litres/hr.

This is equal to 20

o

C differential at maximum heat input.

BOILER SPECIFICATION 18sxi 30sxi

Lift weight 36kg (80Ib) 39kg (86Ib)

Total weight (installed) 41kg (90Ib) 44.5kg (98Ib)

Gas connection 15mm copper 15mm copper

Heating flow & return connection Ø O.D. 22mm. copper 22mm. copper

Condensate connection Ø I.D. 21.5mm. plastic 21.5mm. plastic

Safety valve 3 bar (43/5Ibf/in

2

) 3 bar (43/5Ibf/in2)

Safety valve discharge 15mm. copper 15mm. copper

Expansion vessel capacity 8 litres (1.76 gallons) 8 litres (1.76 gallons)

Expansion vessel charge pressure 0.5bar (7,3Ibf/in

2

) 0.5bar (7,3Ibf/in2)

Electrical supply 230V~50Hz fused 3A 230V~50Hz fused 3A

Electrical rating 180W fused 3A 180W fused 3A

EN60529 IP clasification IPX4D IPX4D

Internal fuse rating on main PCB 2A 2A

Gas supply (governed meter only) II

2H3P

G20 natural gas II

2H3P

G20 natural gas

Inlet gas working pressure 20mbar 20mbar

Burner % CO

2

case on 9.3 nominal 9.3 nominal

Burner % CO

2

case off 9.1 nominal 9.1 nominal

2.0 m

3

/h 3.0 m3/h

71 ft

3

/h 107 ft3/h

0.53 m

3

/h 0.53 m3/h

18.7 ft

3

/h 18.7 ft3/h

Flue type C

13, C33, C43, C53 C13, C33, C43, C53

NOx Class 5 Class 5

Heat output condensing mode 20.02kW 30.58kW

Heat input Nett Q = kW max. 18.9 min. 5 max. 28.6 min. 5.3

Heat output P = kW max. 18.57 min. 4.95 max. 28.17 min. 5.25

SEDBUK rating Band A 90.4% Band A 90.6%

Approximate max. gas rate

after 10 mins. from cold

Approximate min. gas rate

after 10 mins. from cold

Page 8

8

2 Boiler Dimensions and Hydraulic Schematic

13482

Diagram 2.2

Diagram 2.1

13642

2.1 Boiler Dimensions & Hydraulic Schematic

All dimensions are given in millimetres (except as noted).

The general arrangement of the boiler is shown in diagram

2.1. and the hydraulic and gas schematic, diagram 2.2.

The data label is positioned on the front of the inner casing

panel.

Page 9

9

3 Boiler Location, Clearances and Ventilation

3.1 Location

This boiler is not suitable for outdoor installation.

This boiler may be installed in any room, although particular

attention is drawn to the installation of a boiler in a room

containing a bath or shower where reference must be made to

the relevant requirements.

This boiler is suitable for installation in bathroom zones 2 and

3.

In GB, this is the current I.E.E. WIRING REGULATIONS and

BUILDING REGULATIONS.

In IE, reference should be made to the current edition of

I.S.813 “Domestic Gas Installations” and the current ETCI

rules.

3.2 Clearances

The boiler should be positioned so that at least the minimum

operational and servicing clearances are provided, see

diagram 3.1.

Additional clearances may be benecial around the boiler for

installation and servicing.

For ue installations where external access is not practicable,

consideration should be given for the space required to insert

the ue internally, which may necessitate clearance larger

than those specied in diagram 3.1.

3.3 Timber Frame Buildings

If the boiler is to be installed in a timber frame building it

should be tted in accordance with the Institute of Gas

Engineers document IGE/UP/7/1998. If in doubt seek advice

from local gas undertaking or Glow-worm.

3.4 Combustible Material

The boiler and ue are suitable for installation onto and

through combustible materials provided that:-

1) Minimum 5mm clearance is maintained around the

circumference of the ue (air intake).

2) The combustible surface and xings are suitable for

supporting the load.

3) The minimum clearances from the boiler case are

maintained.

3.5 Room Ventilation

The boiler is room sealed so a permanent air vent is not

required.

3.6 Cupboard or Compartment Ventilation

Due to the high efciency and hence low casing temperature

of this boiler, cupboard or compartment ventilation is not

necessary.

Leave existing air vents.

Diagram 3.1

13208

Page 10

10

4 Flue Options and Terminal Clearances

Diagram 4.1

Top horizontal telescopic ue (Ø60/100)

Part No. A2043600 - Section 10, page 19

Top horizontal standard ue (Ø60/100)

Part No. A2043400 - Section 10, page 23

Twin Flue

Twin Flue Adapter, concentric ue (Ø80)

Part No. A2011000 - Section 10, page 31

Plume Management Kit

basic set, white, concentric

ue (Ø60/100) - Part No.

A2044100 for use with Part

No. A2043400 and Part No.

A2043600 - Section 10,

page 34

Vertical Flue

Vertical Flue Adapter, concentric ue (Ø60/100)

Part. No. A2024600 - Section 10, page 28

Vertical ue terminal kit, concentric ue (Ø60/100)

Part. No. 2000460480 - Section 10, page 27

Multiple Boiler Chimney Flue

Vertical concentric stack ue

suitable for use with:-

Top horizontal telescopic ue,

Top standard horizontal ue,

Twin Flue, as specied by the

manufacturer.

Ridge Tile Terminal

Part No. A2043800 Section 10, page 29

Page 11

11

HORIZONTAL FLUES

A DIRECTLY BELOW AN OPENING, AIR BRICK,

OPENING WINDOWS 300

B ABOVE AN OPENING, AIR BRICK,

OPENING WINDOWS 300

C HORIZONTALLY TO AN OPENING,

AIR BRICK, OPENING WINDOWS 300

D BELOW GUTTER, DRAIN/SOIL PIPE 25

E BELOW EAVES 25

F BELOW A BALCONY OR CAR PORT 25

G FROM VERTICAL DRAIN PIPES AND

SOIL PIPES 25

H FROM INTERNAL/EXTERNAL CORNERS 25

H

* TO A BOUNDARY ALONGSIDE THE

TERMINAL 300

I ABOVE ADJACENT GROUND OR

BALCONY LEVEL 300

J

* FROM SURFACE OR A BOUNDARY

FACING THE TERMINAL 600

K FACING TERMINALS 1200

L FROM OPENING (DOOR/WINDOW)

IN CAR PORT INTO DWELLING 1200

M VERTICAL FROM A TERMINAL 1500

N HORIZONTALLY FROM A TERMINAL 300

VERTICAL FLUES

P FROM ANOTHER TERMINAL 600

Q ABOVE ROOF LEVEL 300

R FROM ADJACENT OPENING WINDOW 1000

S FROM ADJACENT WALL TO FLUE 300

Diagram 4.2

4 Flue Options and Terminal Clearances

Diagram 4.3

15583

4.1 Flue Options

There are various ue options to choose from as illustrated in

diagram 4.1. The ue lengths and installation are described in

section 10.

4.2 Flue Terminal Position

In GB the minimum acceptable siting dimensions for the

terminal from obstructions, other terminals and ventilation

openings are shown in diagram 4.2. In IE the minimum

distances for ue terminal positioning must be those detailed

in I.S.813 “Domestic Gas Installations”.

The terminal must be exposed to the external air, allowing free

passage of air across it at all times.

Being a condensing boiler some pluming may occur from

the ue outlet. This should be taken into consideration when

selecting the position for the terminal.

Carports or similar extensions of a roof only, or a roof and

one wall, require special consideration with respect to any

openings, doors, vents or windows under the roof. Care is

required to protect the roof if made of plastic sheeting. If

the carport comprises of a roof and two or more walls, seek

advice from the local gas supply company before installing the

boiler.

H* and J* See diagram 4.2 . These dimensions comply with

the building regulations, but they may need to be increased to

avoid wall staining and nuisance from pluming depending on

site conditions.

NOTE: If the flue terminal is positioned near a light source

insects may enter the flue system. Where safe and practical

to do so advise the homeowner to check the flue outlet and

clear visible insects from the terminal end.

4.3 Terminal Guard

A terminal guard is required if persons could come into contact

with the terminal or the terminal could be subject to damage.

If a terminal guard is required, it must be positioned to provide

minimum of 50mm clearance from any part of the terminal and

be central over the terminal.

The guard should be similar to that shown in diagram 4.3.

A suitable guard is manufactured by: -

Tower Flue Components

Morley Rd.

Tonbridge

Kent TN9 1RA.

Size: 280mm x 165mm. Part No. CGDK3

Page 12

12

5 Water System

5.1 General

This boiler is designed for use as part of a sealed water

central heating system with fully pumped circulation. The

pump, expansion vessel and associated safety devices are all

tted within the boiler.

An options board accessory is available to link the internal

programmer with a Honeywell S or Y plan system.

5.2 Safety Valve

The safety valve is an integral part of the boiler and it cannot

be adjusted. The pipe from the safety discharge valve must

not discharge above an entrance, window or any type of

public access area.

5.3 Expansion Vessel

The boiler has an integral expansion vessel with a capacity of

8 litres (1.76 gallons), with a charge pressure of 0.5bar.

NOTE: The expansion vessel volume depends on the total

water system volume and the initial system design pressure.

In GB, Guidance on vessel sizing is also given in the current

issue of BS5449 and BS7074 Part 1.

In IE, current edition of I.S.813 “Domestic Gas Installations”.

5.4 Flow Rate

If it is necessary to alter the ow rate, the system can be

tted with a lockable balancing valve in the main ow or

return pipes shown as valve “A” in diagram 5.1. The ow rate

through the boiler must not be allowed to fall below that given

in section 1 - Specication Table.

5.5 Bypass

The boiler is tted with an automatic bypass which can be

adjusted to suit your system requirements.

Ensure that under no circumstances does the ow rate drop

below the gure specied, refer to section 1 - Specication

Table.

5.6 Filling the Sealed System

Provision for lling the system at low level must be made, see

diagram 5.2. There must be no permanent connection to the

mains water supply, even through a non-return valve.

NOTE: It is important that ttings used for connection

to potable water comply with the water undertakings

requirements.

5.7 Draining Points

Draining taps must be provided at all the low points of the

system, which will allow the entire system to be drained.

Draining taps shall be to the current issue of BS2879.

Drain points for the appliance are provided at the positions

shown in diagram 8.1.

5.8 Domestic Hot Water Cylinder

SINGLE FEED INDIRECT CYLINDERS ARE NOT SUITABLE

AND SHOULD NOT BE USED. The domestic hot water

cylinder must be of the double feed indirect coil type. It must

be suitable for working at a gauge pressure of 0.35bar above

the safety valve setting.

13486

5.9 Water Treatment

Existing system- It is ESSENTIAL that prior to installing the

new boiler the system is thoroughly ushed.

New system- For optimum performance after installation, the

boiler and its associated central heating system should also

be ushed.

Flushing should be carried out in accordance with BS7593:

2006 using a cleanser such as Sentinel X300 or X400, Fernox

Restorer or Salamander corrosion guard cleaner.

IMPORTANT: Ensure all cleanser is removed from the whole

system before adding an inhibitor.

For long-term corrosion protection, after ushing, an inhibitor

suitable for stainless steel exchangers should be used, refer

to the current issue of BS 5449 and BS 7593 on the use of

inhibitors in central heating systems. Examples are Sentinel

X100 Fernox Protector or Salamander corrosion guard

inhibitor.

Diagram 5.1

Page 13

13

5 Water System

13801

Diagram 5.2

Page 14

14

Diagram 6.1

13647

6.1 Appliance Pack

Please check the contents of packs as shown in diagram 6.1.

The packs are located in the top polystyrene packing.

Remove the carton sleeve and top pack then lift the boiler and

its polystyrene base support out of the lower pack.

6.2 Site Requirements

The boiler mounting wall should be suitable for the weight of

the appliance and be true and at.

NOTE: Due to the varied site conditions we do not supply

xings and advise that the installer should supply those which

are suitable.

6 Installation Preparation

6.3 Wall Template

Take the wall template from the document pack located within

the top polystyrene packing and place in the desired position

on the wall, giving due consideration to the required boiler

clearances, see section 3, and the ue you are tting.

Mark the position of the ue centre, if tting a side ue, extend

the ue centre line into the corner then 176mm along the

adjacent wall, see diagram 6.2.

For extended side ues, the ue hole centre should be

determined by extending the dashed inclined line on the

template to the side wall. This dashed line is drawn at 44mm/

metre (2.5°) rise from the boiler. Where this line reaches the

side wall, a horizontal line should be marked. The vertical

centre line of the ue should then be marked at 156mm from

the back wall.

To allow for the ue passing through the wall at this angle

a 125mm hole should be drilled irrespective of internal or

external installation.

Remove the wall template whilst drilling the ue hole.

B - Union Nut and Sealing Washer

A - Central Heating x 2

B - Gas

A - Large Sealing Washers

C - Gas

C - Saftey Discharge

Electrical

Cartridge

Gas and Water Isolating Valves

0020036801

Pipe Pack 0020029672

Loose Items Pack

(discard addtional items

within this pack)

A

A

A

C

B

B

Documentation Pack

(not illustrated)

Wall Template, User Instructions,

Installation and Servicing Instructions.

Hanging Bracket

C

Retaining Screws

Stored in cartridge

Base Coverplate

Page 15

15

Diagram 7.1

13490

6 Installation Preparation

7.1 Hanging Bracket Fixing

The Wall Hanging Bracket is supplied in the main boiler

packaging at the rear of the boiler.

Reposition the wall template over the ue hole and mark

the position of the xing holes for the hanging bracket, see

diagram 7.1.

Drill xing holes and insert suitable wall plugs.

Diagram 7.2

13479

7.2 Boiler Hanging

IMPORTANT: With regards to the Manual Handling

Operations, 1992 Regulations, the following lift operation

exceeds the recommended weight for a one man lift, refer to

section 17 Manual Handling.

Lifting the boiler into position, lean the top of the boiler slightly

to the wall and position just above the hanging bracket. Lower

the boiler slowly and engage onto the hanging bracket, see

diagram 7.2.

7 Boiler Fixing

13853

Diagram 6.2

6.4 Flue Hole Cutting

External access ue installation can use a 105mm diameter

core drill.

Internal access only ue installation will need a 125mm

diameter core drill.

NOTE: The ue is designed with an internal fall of 44mm/

metre (2.5°), therefore the hole can be drilled horizontally.

If ue extension pipes are to be used then a core drill size of

125mm is required. This will allow the extension pieces to

slope at 44mm/metre (2.5°) towards the boiler.

Page 16

16

8 Gas / Water Connection

8.1 Systems Connection

Remove the protective caps from the boiler connections.

NOTE: The appliance may contain a small amount of water,

place a water container beneath the boiler connections.

Assemble and secure the pre formed copper tails to their

respective isolation valves making sure of their correct

orientation, see diagram 8.1.

Fit the isolation valves/copper tails with seals to the appliance

as shown in diagram 8.1

There are ats on the body of the valves for locating a

spanner to aid tightening to copper tails.

NOTE: Make sure that the test and drain points are

accessible, refer diagram 8.1.

Plumb the system pipe work to the copper tails.

NOTE: Do not subject the isolation valves to heat.

Flush out the heating system before connecting to the boiler,

refer to section 5.9.

The whole of the gas installation, including the meter, should

be inspected, tested for tightness and purged in accordance

with the current issue of BS6891 and in IE the current edition

of I.S.813 “Domestic Gas Installations”.

Diagram 8.1

13477

OLIVE

PIPE

PIPE

OLIVE

NUT

WASHER

WASHER

WATER

ISOLATION

VALVE (2 OFF)

GAS

ISOLATION

VALVE

DRAIN

POINT

DRAIN

POINT

Page 17

17

SAFETY

DISCHARGE

VALVE

VIEW ON UNDERSIDE OF BOILER

UNION NUT

AND SEAL

9 Safety Discharge Valve and Condensate Connections

Diagram 9.1

13491

9.1 Safety Discharge Valve

Take the safety discharge pipe, supplied in the pipe pack and

the union nut and seal, supplied in the loose items pack and

t as shown in diagram 9.1.

This must be extended, using not less than 15mm o.d. pipe,

to discharge, in a visible position, outside the building, facing

downwards, preferably over a drain.

The pipe must have a continuous fall and be routed to a

position so that any discharge of water, possibly boiling,

or steam cannot create any danger to persons, damage to

property or external electrical components and wiring.

To ease future servicing it is advisable to use a compression

type tting to extend the safety discharge valve tube.

9.2 Condensate Trap and Siphonic Drain

Connection

The condensate drain connection is behind the pump at the

rear of the boiler, see diagram 9.2. A exible condensate

outlet pipe is tted and should be used to couple the

condensate trap and siphonic drain to a 22mm to 25mm O.D.

non corrosive plastic pipe (overow pipe), see diagram 9.2.

IMPORTANT: Please remove the bung from the exible pipe

before tting to a drain outlet pipe.

NOTE: the pipe should have a fall of a least 2.5

o

44mm/metre

away from the boiler.

Condensate should, if possible be discharged into the

household internal drainage system. If this is not practicable,

discharge can be allowed into the external household drains

or a purpose designed soak away, refer to diagram 9.3.

It is recommended that any external condensate drain pipe is

protected and also preferably of 32mm diameter, to prevent

freezing in adverse weather conditions.

The condensate is discharged periodically in ‘slugs’ by

siphonic action.

It is not necessary to provide air breaks or extra traps in the

discharge pipe as there is already a 75mm high trap inside

the boiler. Fitting an extra trap may cause the boiler siphon to

work incorrectly.

Refer to BS5546 or BS6798 for advice on disposal of boiler

condensate.

Diagram 9.2

13492

FLEXIBLE

CONDENSATE

OUTLET PIPE

CONDENSATE

TRAP AND

SYPHONIC DRAIN

VIEW ON UNDERSIDE OF BOILER

FLEXIBLE

CONDENSATE

OUTLET PIPE

Page 18

18

9 Safety Discharge Valve and Condensate Connections

Diagram 9.3

13000

Page 19

19

10.1 Flue Length

The maximum permissible horizontal ue length is 10 metres

plus the ue terminal assembly, this can be achieved by use

of the accessories, see diagram 10.3.

However should an additional 90o or 2 x 45o elbows be used

then the length MUST be reduced by 1metre.

The diagram 10.1 shows the length achievable by using the

kit A2043600.

When extension pipes are used the ue system must be

designed to have a continuous fall to the boiler of at least 2.5o

44mm/metre to allow condensate to run back into the boiler

and out via the condensate drain.

The ue can be installed from inside the building, when

access to the outside wall face is not practicable.

10 Telescopic Flue - Length, Preparation and Installation

Horizontal Telescopic Flue - Rear

Diagram 10.1

13558

13559

Ultracom

18sxi

Ultracom

30sxi

Exhaust mass rate (g/s)

At Min Thermal

Load (40C°/30°C)

2.30 2.45

At Max Thermal

Load (80C°/60°C)

8.75 13.25

Exhaust temperature (ºC)

At Min Thermal

Load (40C°/30°C)

56.0 44.0

At Max Thermal

Load (80C°/60°C)

69.0 57.0

Horizontal Telescopic Flue - Side

Multiple Boiler Chimney Flue Length

The ue length must be calculated and installed according to

the relevant standards EN 13384-1 and 2 (C43 flue systems

only) with reference to the table below and the manufacturers

instructions supplied.

The appliance maximum ue length must be included when

calculating the overall design of the ue system.

Page 20

20

14826

Diagram 10.3

10 Telescopic Flue - Length, Preparation and Installation

Diagram 10.2

15418

Page 21

21

10.2 Horizontal Telescopic Flue - A2043600

Refer to diagram 10.2 for kit contents.

10.3 REAR Flue

If a wall thickness is between 203mm min. to 413mm max.

then the ue can be used without extensions.

With the ue elbow temporarily tted, measure the distance

from the outside wall to the butt joint, see diagram 10.4. If

the measurement ‘Y’ exceeds 525mm, then the appropriate

length of extension pipe is required.

If the dimension is less than 315mm DO NOT cut the ue, it

can project to a maximum of 600mm, see diagram 10.5. If

this is not desirable then a Standard ue MUST be used and

cut to length.

10.4 SIDE Flue

With the ue elbow temporarily tted, measure the distance

from the outside wall to the butt joint, see diagram 10.6. If

the measurement ‘Y’ exceeds 525mm, then the appropriate

length of extension pipe is required.

If the dimension is less than 315mm DO NOT cut the ue, it

can project to a maximum of 600mm, refer to diagram 10.5, if

this is not desirable then a Standard ue MUST be used, and

cut to length.

Diagram 10.4

13223

Diagram 10.5

12979

10 Telescopic Flue - Length, Preparation and Installation

Diagram 10.6

13224

Page 22

22

Diagram 10.7

12929

Diagram 10.8

12977

Diagram 10.9

13254

10 Telescopic Flue - Length, Preparation and Installation

10.5 Flue Fitting

IMPORTANT:-

The ue seals are sensitive to mineral oil based lubricants. Do

not grease the seals. If the seals do need to be lubricated

use only water.

During the installation of the ue system, ensure that debris

such as mortar, lings or swarf are cleared from the ue

system before completion.

Inspect the ue pipes before tting and do not install damaged

or dented ue components.

When assembling the ue system, ensure that the inner

seals are not damaged, do not install a ue component with a

damaged seal.

When tting ue elbows ensure that they are tted at the

correct angle to avoid strain, this will ensure that the seal ts

correctly preventing leakage.

With the air duct seams aligned and the ue set to the

required length ‘Y’, mark the securing hole position in the air

duct. Drill a 3mm diameter hole at this position, take care not

to pierce the inner ue duct. Secure with screw provided and

tape the joint, see diagram 10.7.

Fit the sealing collar onto the locating ring on the ue terminal,

see diagram 10.8.

With the ue elbow removed, push the ue assembly into

the wall, externally or internally, until the end of the assembly

protrudes a short way from the inside face of the wall. This

will enable the internal trim ring (if required) to be positioned

and allow the ue assembly to be drawn back up to the ue

elbow.

Secure the ue elbow in position on top of the boiler with four

screws supplied.

Draw the ue assembly from wall and engage the ue duct

into the elbow and butt t between the air duct and ue elbow.

Fit the securing collar into position.

Ensuring correct alignment of the ue, mark through two of

the pre drilled holes in the securing collar. Remove securing

collar and drill two 3mm diameter holes one in the elbow and

one in the air duct, take care not to pierce the inner ue duct.

Fit the securing collar and secure with screws provided, see

diagram 10.9.

Slide the internal trim ring back against the wall, securing in

place with a small amount of sealant if required.

Insert the ue duct into the air duct terminal assembly,

remembering to engage the catch within the terminal.

Check that the outer rubber sealing collar makes an

effective seal against the wall face.

Page 23

23

13561

Standard Horizontal Flue

10.6 Flue Length

The maximum permissible horizontal ue length is 10 metres

plus the ue terminal assembly, this can be achieved by use

of the accessories, see diagram 10.12.

However should additional 87.5o or 2 x 45o elbows be used

then the length MUST be reduced by 1metre.

The diagram 10.10 shows the length achievable by using the

kit A2043400.

When extension pipes are used the ue system must be

designed to have a continuous fall to the boiler of at least 2.5o

44mm/metre to allow condensate to run back into the boiler

and out via the condensate drain.

The ue can be installed from inside the building, when

access to the outside wall face is not practicable.

Multiple Boiler Chimney Flue Length

The ue length must be calculated and installed according to

the relevant standards EN 13384-1 and 2 (C43 flue systems

only) with reference to the table below and the manufacturers

instructions supplied.

The appliance maximum ue length must be included when

calculating the overall design of the ue system. NOTE: The

horizontal ue terminal must be removed, see diagram 10.11.

10 Standard Flue - Length, Preparation and Installation

Diagram 10.10

220

170

505mm

55mm

13560

MODEL 18sxi 30sxi

Exhaust mass rate (g/s)

At Min Thermal

Load (40C°/30°C)

2.30 2.45

At Max Thermal

Load (80C°/60°C)

8.75 13.25

Exhaust temperature (ºC)

At Min Thermal

Load (40C°/30°C)

56.0 44.0

At Max Thermal

Load (80C°/60°C)

69.0 57.0

Page 24

24

Diagram 10.11

13222

10 Standard Flue - Length, Preparation and Installation

Diagram 10.12

15418

Page 25

25

10.7 Standard Horizontal Flue - A2043400

Refer to diagram 10.11 for kit contents.

10.8 REAR Flue

With the ue elbow temporarily tted, measure the distance

from the outside wall to the butt joint, see diagram 10.13. If

the measurement ‘Y’ exceeds 665mm, then the appropriate

length of extension pipe is required. The minimum dimension

is 187mm to suit a 75mm min wall thickness. The ue can

project to a maximum of 600mm, if this is desirable, refer to

diagram 10.14.

10.9 SIDE Flue

With the ue elbow temporarily tted, measure the distance

from the outside wall to the butt joint, see diagram 10.15. If

the measurement ‘Y’ exceeds 665mm, then the appropriate

length of extension pipe is required. The minimum dimension

for Lhd is 254 and Rhd 226 to suit a minimum wall thickness

of 75mm. The ue can project to a maximum of 600mm, if

this is desirable, refer to diagram 10.14.

13224

Diagram 10.15

Left Hand illustrated

Diagram 10.13

13223

Diagram 10.14

12979

10 Standard Flue - Length, Preparation and Installation

Page 26

26

Diagram 10.16

12847

Diagram 10.17

13254

10 Standard Flue - Length, Preparation and Installation

10.10 Flue Fitting

IMPORTANT:-

The flue seals are sensitive to mineral oil based lubricants.

Do not grease the seals. If the seals do need to be

lubricated use only water.

During the installation of the flue system, ensure that debris

such as mortar, filings or swarf are cleared from the flue

system before completion.

Long lengths of flues must be secured to the walls or ceilings

they run against. Use at least one fixing bracket for every flue

extension that is used.

After cutting inner flue tubes ensure that you de-burr and

chamfer the male tube end to prevent damage.

Inspect the flue pipes before fitting and do not install

damaged or dented flue components.

When assembling the flue system, ensure that the inner

seals are not damaged, do not install a flue component with a

damaged seal.

When fitting flue elbows ensure that they are fitted at the

correct angle to avoid strain, this will ensure that the seal fits

correctly preventing leakage.

Remove the ue elbow.

Separate the ue duct from the terminal by twisting to release

the terminal catch, then pull out of the retaining seal, refer to

diagram 10.16.

The ue duct cutting length (L + 11mm.) is shown in diagram

10.16.

The air duct should be cut at the opposite end to the terminal

The plastic ue duct MUST be cut at the opposite end to the

terminal catch.

The plastic ue duct extensions MUST be cut at the opposite

end to seal.

Insert the ue duct into the air duct terminal assembly,

remembering to engage the catch within the terminal.

Fit the sealing collar behind the locating lugs on the ue

terminal, see diagram 10.17.

Push the ue assembly into the wall, externally or internally,

initially until the end of the assembly protrudes a short way

from the inside face of the wall. This will enable the internal

trim ring (if required) to be positioned and allow the ue

assembly to be drawn back into the ue elbow.

Secure the ue elbow in position on top of the boiler with four

torque headed screws supplied.

Draw the ue assembly from wall and engage the ue duct

into the elbow and butt t between the air duct and ue elbow.

Fit the securing collar into position.

Ensuring correct alignment of the flue, mark through two of

the pre drilled holes in the securing collar.

Remove securing collar and drill two 3mm diameter holes one

in the elbow and one in the air duct, take care not to pierce the

inner ue duct. Fit the securing collar and secure with screws

provided, see diagram 10.17.

Slide the internal trim ring back against the wall, securing in

place with a small amount of sealant if required.

NOTE: If the air and ue ducts have been correctly cut to the

instructions the sealing collar should t ush with the outside

wall.

Page 27

27

Diagram 10.18

14851

10 Vertical Flue - Length, Preparation and Installation

10.11 Vertical flue

The vertical ue system is available as an option where the

boiler position does not permit the use of the top horizontal

ue system.

The system is made up from accessories. The accessories

include terminal assembly, bends 45º and 87.5º, ue

extensions, xing bracket and appropriate weather collar, see

diagram 10.19.

The maximum permitted straight ue length is 10 metres

plus the terminal. for each 87.5

o

or 2x45o bends tted, the

maximum length must be reduced by 1 metre, see diagram

10.18.

NOTE: 2x45º bends can replace 1x87.5º bend if necessary.

When using 87.5º bends any horizontal extension pipe should

be inclined by a minimum of 44mm/metre (2.5°) towards

the boiler to facilitate condense removal, see (a) in diagram

10.18.

Alternatively use 45º bends to avoid horizontal runs, see (b) in

diagram10.18.

The terminal siting should be as shown in diagram 4.2.

Measure the distance of ue length required for the

installation.

The ue must be designed with a continuous fall towards the

boiler.

Page 28

28

10 Vertical - Flue Length, Preparation and Installation

14849

Diagram 10.19

Flue Installation

IMPORTANT:-

The flue seals are sensitive to mineral oil based lubricants.

Do not grease the seals. If the seals do need to be

lubricated use only water.

During the installation of the flue system, ensure that debris

such as mortar, filings or swarf are cleared from the flue

system before completion.

Long lengths of flues must be secured to the walls or ceilings

they run against. Use at least one fixing bracket for every flue

extension that is used.

After cutting inner flue tubes ensure that you de-burr and

chamfer the male tube end to prevent damage.

Inspect the flue pipes before fitting and do not install

damaged or dented flue components.

When assembling the flue system, ensure that the inner

seals are not damaged, do not install a flue component with a

damaged seal.

When fitting flue elbows ensure that they are fitted at the

correct angle to avoid strain, this will ensure that the seal fits

correctly preventing leakage.

Refer to diagram 10.21 and secure the ue adapter in position

on top of the boiler with four screws supplied, making sure

the nib ts into the locating slot in the boiler casing to ensure

correct orientation.

Secure the rst extension pipe to the ue adapter with the

securing collar supplied by positioning the collar centrally over

the joint, then tighten the two screws on the securing collar,

see diagram 10.22.

Fit more extension pipes as required using the collar and

screws supplied with each extension pipe. To t position the

collar centrally over the joint, tighten the two screws on the

securing collar. Using the holes provided in the securing

collar drill and insert the two self tapping screws supplied, see

diagram 10.23.

Project the rise of the ue pipe to roof level and cut a 150mm

hole in the roof.

Flue Terminal Installation

(a) Pitched Roof

Fit the required pitched roof weather collar over the 150mm

hole in the roof. Make good the tiling or slating around the

collar incorporating the ashing of the weather collar. Position

the angle cap over the weather collar in the correct orientation

to attain the correct angle for your roof.

(b) Flat Roof

Fit the aluminium weather collar over the 150mm hole in the

roof ensuring a weather tight seal.

From above carefully place the ue terminal through the

weather collar.

Flue Terminal to Boiler Connection

Should the clearances above the boiler to roof not allow for

extensions, it is permitted to cut the ue terminal ensuring the

relationship of ue and air duct lengths are retained.

Page 29

29

10 Vertical - Flue Length, Preparation and Installation

14853

Diagram 10.20

Ridge Tile Terminal

A ridge tile terminal is available - part no. A2043800, see

diagram 10.20.

The installation of a ridge tile will be required.

A suitable ridge tile is manufactured by: -

Aspect East Anglia Limited

The Old Mill

East Harling

NORWICH

NR16 2QW

Website: www.aspectroong.co.uk

Contact: Chris Haythorpe

General Manager - Tile Division

Tel: 01953 717777 Fax: 01953 717164

Page 30

30

10 Vertical Flue - Length, Preparation and Installation

Diagram 10.21

13243

Diagram 10.22

13242

Diagram 10.23

12982

Completion of Installation

With the ue terminal positioned in the roof the length of the

nal pipe can be determined. If a telescopic length cannot

be used, then a standard ue length can be cut to make the

correct length. Cut the ue to the desired length measuring

from the ‘O’ ring end and discard the plain end of the tube.

The cuts must be square and made free of burrs to allow

correct assembly.

NOTE: The ue pipe is 10mm longer than the air pipe, see

diagram 10.24.

Carefully push the terminal assembly upwards to allow room

for tting the nal ue piece. Fit a xing bracket to the terminal

assembly. Pull the terminal assembly down and join to the ue

system. Ensure that the terminal is making a weather tight

seal on the weather collar. Secure the xing bracket tted to

the terminal to the roong struts or a purpose made batton.

Diagram 10.24

12983

Page 31

31

10 Twin Flue - Length, Preparation and Installation

Diagram 10.25

15406

Secure long flue lengths (horizontal &

vertical) to walls or ceiling at every joint or

on straight flue runs at every joint and

every metre flue run.

Page 32

32

10 Twin Flue - Length, Preparation and Installation

10.12 Twin flue

The twin ue system is available as an option when the top

horizontal or vertical ue system is not appropriate.

The system can provide an independent horizontal air inlet

and ue outlet, horizontal air inlet and vertical ue outlet or

vertical air inlet and ue outlet via a concentric terminal.

The system is made up from accessories, see diagram 10.26.

NOTE: The air and ue outlets do not have to be equal

lengths. 2x45° bends can replace 1x90° bend if necessary.

The maximum permitted combined (air inlet + ue outlet) ue

length is 40 metres plus terminal assemblies, for each 90°

or

45° x 2 bends tted, the maximum length must be reduced by

1 metre, see diagram 10.25.

NOTE: When using 90° bends any horizontal run should be

inclined by a minimum of 44mm/metre (2.5°) towards the

boiler to facilitate condense removal.

Alternatively use 45° bends to avoid horizontal runs in the ue

pipe.

Multiple Boiler Chimney Flue Length

The ue length must be calculated and installed according to

the relevant standards EN 13384-1 and 2 (C43 flue systems

only) with reference to the table below and the manufacturers

instructions supplied.

The appliance maximum ue length must be included when

calculating the overall design of the ue system.

Terminal Position

The clearances for a ue outlet are given in the "Flue Location

and Ventilation" section.

In addition the horizontal air inlet must not be closer than 300

mm from a ue outlet on the same wall or 1200mm from an

opposing ue outlet.

Diagram 10.26

14869

MODEL 18sxi 30sxi

Exhaust mass rate (g/s)

At Min Thermal

Load (40C°/30°C)

2.30 2.45

At Max Thermal

Load (80C°/60°C)

8.75 13.25

Exhaust temperature (ºC)

At Min Thermal

Load (40C°/30°C)

56.0 44.0

At Max Thermal

Load (80C°/60°C)

69.0 57.0

Page 33

33

10 Twin Flue - Length, Preparation and Installation

Diagram 10.27

13240

Installation Details

The parts available for a twin ue system installation are

shown in diagram 10.26.

Boiler Connection

IMPORTANT: The ue seals are sensitive to mineral oil based

lubricants. Do not grease the seals. If the seals do need to

be lubricated use only water.

Push the twin ue adaptor onto the outlet of the boiler with

the air inlet to the left hand side, see diagram 10.27. Secure

the adaptor to the top panel with the screws provided. Care

should be taken when inserting the screw through the hole in

adaptor top.

Air and Flue Pipe Installation

The air and ue pipes can now be built up from the boiler.

The ue must be designed with a continuous fall towards the

boiler. If using the horizontal ue pipe or 90° bends the pipe

must be inclined at 44mm/metre (2.5°)

minimum, see diagram

10.25.

Alternatively if space allows, use 45° bends in place of 90º

bends.

To avoid rain ingress to the air Inlet terminal, it is good

practice to aim the inlet downwards by approx 2° as rain can

damage the boiler. The Flue outlet pipe must always run at

44mm/metre (2.5°) back to the boiler.

IMPORTANT:-

Long lengths of ues must be secured to the wall or ceiling it

runs against. Use at least one xing bracket on each ue joint

used or on straight ue runs every joint and for every metre

ue run.

Provision must be made in concealed boxing or ductwork that

the ue joints can be inspected during annual servicing.

The ue seals are sensitive to mineral oil based lubricants. Do

not grease the seals. If the seals do need to be lubricated

use only water.

Do not use the ue pipe to attach other pipes or equipment. If

visible, advise the householder not to hang or clip items to ue

pipes.

Do not stress the ue connections during the installation, this

can damage the ue seals.

Horizontal Terminal Installation

NOTE: The air inlet terminal and the ue outlet terminals

must never be installed on the opposite sides of a property.

Termination must only be on the same wall or adjacent walls.

When installed close together separated vertically, the air

inlet must be tted below the ue outlet terminal (see diagram

10.25).

The air terminal must not terminate less than 20mm from an

adjacent wall or structure and the ue outlet terminal less than

100mm from any adjacent wall or structure.

With due consideration to terminal clearances mentioned in

Section 4.2 drill the one or two holes as required with a 90mm

core drill.

Push the horizontal terminal through the wall allowing approx.

100mm to protrude outside.

Push a grey rubber wall seal onto either side of the wall

ensuring that both wall seals are pushed up to the wall

surface, see examples (b) and (c) diagram 10.25.

Vertical Terminal Installation

With due consideration to terminal clearances mentioned in

Section 4.2, project the rise of the ue pipe to roof level and

cut 150mm hole in the roof.

(a) Pitched Roof

Fit the required pitched roof weather collar over the 150mm

hole in the roof. Make good the tiling or slating around the

collar incorporating the ashing of the weather collar. Position

the angle cap over the weather collar in the correct orientation

to attain the correct angle for your roof. One way round gives

a pitch of 25°-38° and the other gives 37°- 50°.

(b) Flat Roof

Fit the aluminium weather collar over the 150mm hole in the

roof ensuring a weather tight seal.

Horizontal Pipes-Completion of Installation

Having built the pipe(s) from the boiler to the terminal(s), the

length of the nal pipe piece can be determined. Cut pipes at

the opposite end to the ‘O’ ring seal making square and free

from burrs. Push the horizontal terminal through the wall to

engage the nal pipe piece and pull back ensuring the grey

wall seals are fully pulled up to the outside and inside wall

faces.

Vertical Pipes-Completion of Installation

Refer to diagram 10.25.

For installation of (a), attach the twin pipe to concentric

ue adaptor, part number A2011600, to the base of vertical

terminal assembly. For installation of (b), attach the single

pipe to concentric adaptor, part number A2011500, to the base

of vertical terminal assembly.

With the vertical terminal assembly positioned in the roof,

the length of the nal pipe can be determined. Cut the ue

to the desired length measuring from the ‘O’ ring seal end

and discard the plain end of the tube. The cut end should

be square and free from burrs. Carefully push the terminal

assembly upwards to allow room for tting the nal ue

piece(s). Fit a 100mm xing bracket to the terminal assembly

Part No 2000460486. Pull the terminal assembly down and

join to the ue system. Ensure that the terminal is making a

weather tight seal on the weather collar. Secure the xing

bracket tted to the terminal to the roong struts or a purpose

made batton.

Page 34

34

10 Plume Management Kit

10.13 Plume Management Kit

The Plume Management Kit: Part No. A2044100 (white) or

A2044000 (black) can be used to overcome many site issues.

The Plume Management Kit will t to the Top Horizontal

Telescopic, Rear Horizontal Telescopic and Standard

Horizontal Flue. This enables the ue products to exhaust

further away from the boiler, thereby reducing the impact of

pluming.

NOTE: The ue air inlet can be sited closer to doors, opening

windows and air bricks, than stated in section 4.2, see

diagram 10.27.

The maximum length of the Plume Management Kit must NOT

exceed 6m with a horizontal concentric ue length of 2m max.

For each 90

o

bend or 2 x 45o bends the maximum length of the

Plume Management Kit must be reduced by 1m.

For more information contact Glow-worm, refer to page 2.

The Plume Management Kit is supplied with installation

instructions.

Refer to BS5546 or BS6798 for advice on disposal of boiler

condensate.

Diagram 10.27

150mm.

MIN.

12997

10 Deector Flue Terminal Kit

Diagram 10.28

14465

10.14 Deector Flue Terminal Kit

The terminal kit ts onto the telescopic and standard

horizontal ue, see diagram 4.1 for kit contents.

The kit is also supplied with installation instructions.

NOTE: The deector ue terminal kit can be tted after the

boiler and ue have been installed.

The deector part of the deector ue terminal can be rotated

45º to allow pluming away from openings, people, cars,

windows etc., see diagram 10.28.

Should the deflector terminal be positioned under a soffit

or horizontal surface, it is allowed to project the flue

600mm from the wall, to allow the discharge of flue gases

produced into free air.

IMPORTANT: Do not t the deector ue terminal with the

deector positioned downwards.

Page 35

35

11 Electrical Connection

WARNING: This appliance must be earthed.

● This appliance must be wired in accordance with these

instructions. Any fault arising from incorrect wiring cannot be put

right under the terms of the Glow-worm guarantee.

● All system components must be of an approved type.

Electrical components have been tested to meet the equivalent

requirements of the BEAB.

● Do not interrupt the mains supply with a time switch or

programmer.

● Connection of the whole electrical system and any heating

system controls to the electrical supply must be through a

common isolator.

● Isolation should preferably be by a double pole switched fused

spur box having a minimum contact separation of 3mm on each

pole. The fused spur box should be readily accessible and

preferably adjacent to the boiler. It should be identied as to its

use.

● A fused three pin plug and shuttered socket outlet may be used

instead of a fused spur box provided that it is not used in a room

containing a xed bath or shower.

● The boiler is suitable for installation in bathroom zones 2 and 3.

11.1 Electrical Wiring

If you are tting the Glow-worm Options Board Kit, please refer to

the instructions supplied with the kit for the system wiring.

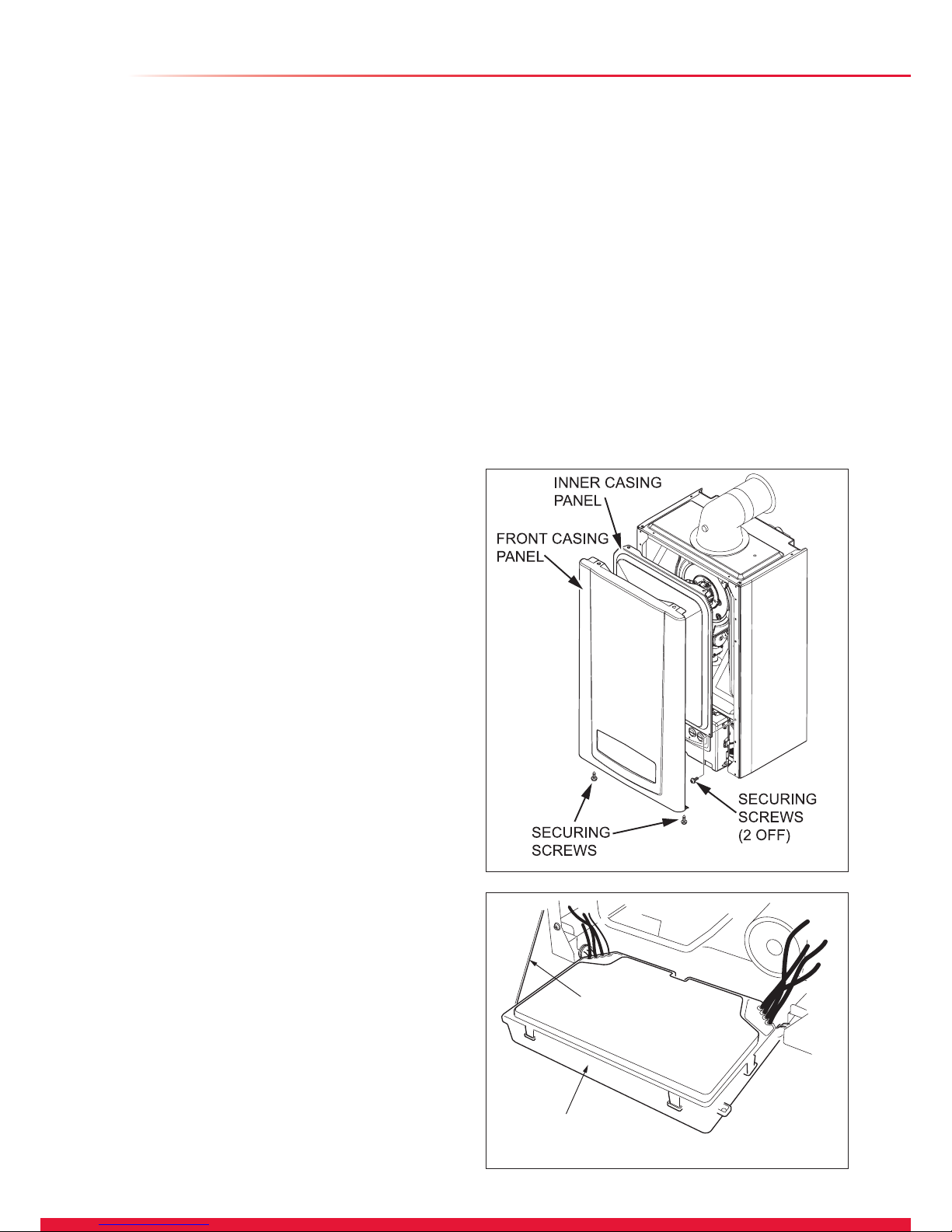

Remove the electrical cartridge from the ttings pack.

Remove the securing screw to open the cartridge.

NOTE: There are two screws supplied loose in the electrical

cartridge, these will be required to secure the cartridge into the

electrical interface housing.

Slacken the screws of the cable strain relief in the electrical

cartridge, see diagram 11.1.

Route the mains supply and system cables through the strain

relief and connect to the relevant plug, refer to the appropriate

sections 11.2 or 11.3 .

13302

Diagram 11.1

Diagram 11.3

13369

Diagram 11.2

13368

Page 36

36

11 Electrical Connection

Diagram 11.4

13488

11.2 System Controls 24V

WARNING: UNDER NO CIRCUMSTANCES MUST

ANY MAINS VOLTAGE BE APPLIED TO ANY OF THE

TERMINALS ON THE 24V CONNECTION PLUG.

Connect the mains supply and system heating controls e.g.

room thermostat as diagram 11.2. External controls should be

tted in accordance with the rules in force.

11.3 Mains Voltage System Controls

WARNING: UNDER NO CIRCUMSTANCES MUST

ANY MAINS VOLTAGE BE APPLIED TO ANY OF THE

TERMINALS ON THE 24V CONNECTION PLUG.

Connect mains supply and system controls as diagram 11.3.

External controls should be tted in accordance with the rules

in force.

11.4 Electrical Cartridge Securing

Fit electrical cartridge into the interface housing on completion

of the wiring, see diagram 11.4.

Secure with the two cartridge retaining screws provided in the

cartridge body.

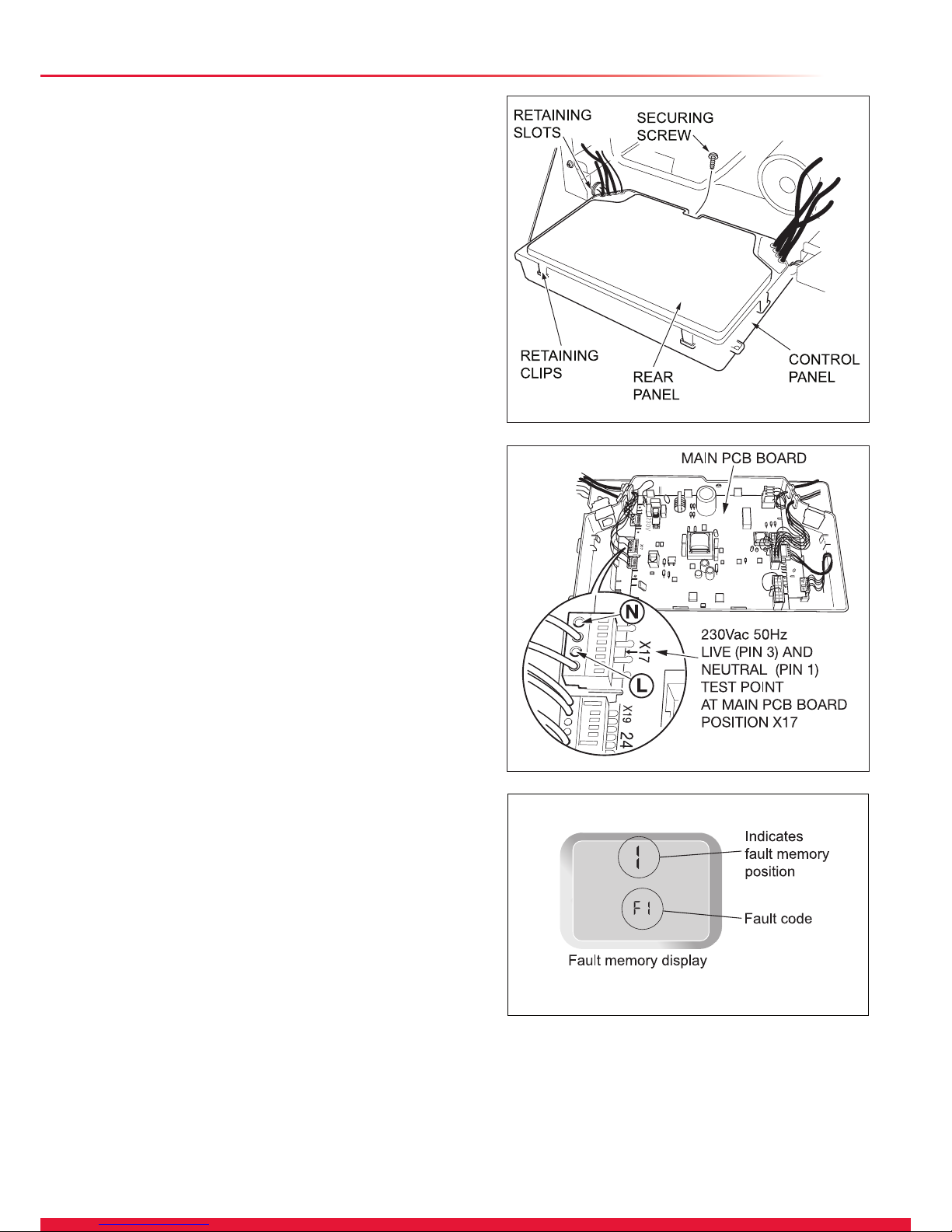

11.5 Electrical Connections - Testing

Carry out preliminary electrical system checks as below:

1. Test insulation resistance to earth of mains cables.

2. Test the earth continuity and short circuit of cables.

3. Test the polarity of the mains.

NOTE: If you require to test the appliance refer to section 14.

IMPORTANT: At the time of commissioning, complete all

relevant sections of the Benchmark Checklist located in the

centre pages of this document.

12.1 Preliminaries - All Systems

The commissioning should be carried out by a competent

person approved at the time by the Health and Safety

Executive and in accordance with the current issue of

BS6798.

DO NOT operate the boiler without water.

Make sure that the system has been thoroughly ushed

out with cold water and that all cleanser, if used, has been

removed.

Isolate the boiler from the mains electrical supply.

Test for gas tightness and purge air from the gas supply.

IMPORTANT: Before starting the boiler check that all ue

connections are secure and sealed correctly.

12 Commissioning

12.2 Filling the Heating Circuit

With the gas isolation valve closed and with no demand from

any external controls switch on the power supply to the boiler.

The boiler should be in “OFF” mode, this will be indicated

on the user interface display, refer to diagram 12.2. If not,

press the “Mode” button repeatedly until the “OFF” symbol is

displayed, then continue as follows:

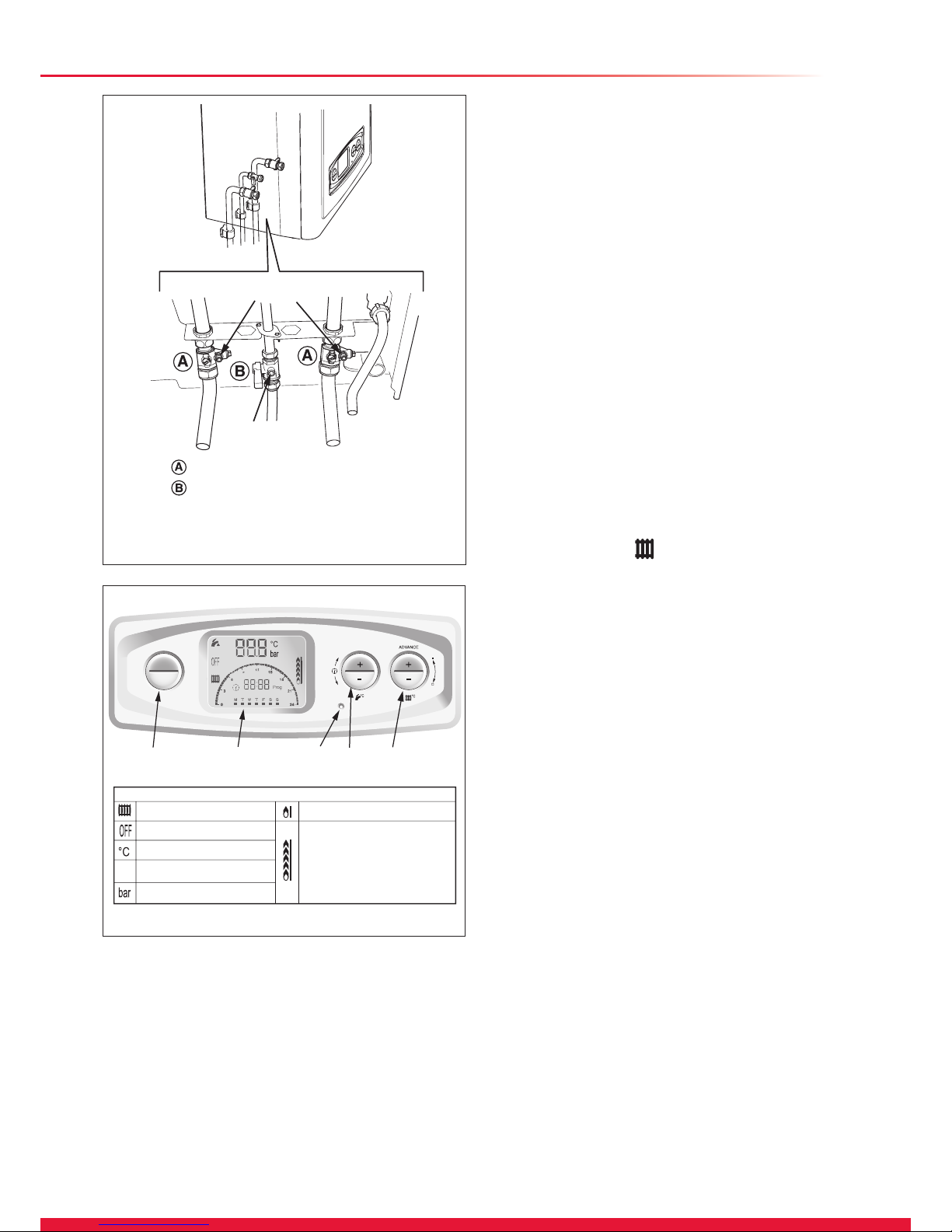

1. Open the Central Heating Flow and Return isolating

valves marked ‘A’ using a screwdriver or a 4mm allen

key - slot in line with the axis of the valve (shown closed

in diagram).

2. Fill the heating system to a pressure of 1.0bar. The

system pressure will be displayed on the user interface.

3. Vent all air from the system - repeat as necessary

until the system is full and all the air has been vented.

Page 37

37

12 Commissioning

Diagram 12.1

13476

Diagram 12.2

MODE

PROG

Ext

Ext

SYMBOLS DISPLA YED ON THE LCD AND DESCRIPTIONS

Max burner display

Min burner display

Temperature

Appliance OFF

Central Heating Function

LCD

DISPLAY

RESET

BUTTON

NOT

USED

CH TEMPERATURE

ADJUSTMENT

TOGGLE BUTTON

MODE and PROG

Glow-worm control (Optional)

Ext

System pressure - not applicable

13473

CENTRAL HEATING ISOLATION VALVES

GAS SERVICE ISOLATION VALVE

ALL SHOWN CLOSED

DRAIN POINTS

UNDERSIDE VIEW OF BOILER

PRESSURE

TEST POINT

12.3 Gas Supply

The gas valve is factory set for natural gas (G20) and should

need no adjustment. Turn on the gas supply at the isolation

valve, see diagram 12.1. Check the supply pressure at the

pressure test point is 20mbar.

12.4 Initial Lighting

NOTE: The combustion for this appliance has been checked,

adjusted and preset at the factory for operation on natural gas

(G20) as dened on the appliance data label.

Do not adjust the Gas/Air ratio valve.

No measurement of the combustion is necessary, having

checked :

● the appliance has been installed in accordance with the

instructions.

● the integrity of the ue system and ue seals.

● the integrity of the appliance combustion circuit and

relevant seals.

● that all internal/external controls are calling for heat.

● the gas service isolation valve, diagram 12.1, is open.

As an option, a chargeable boiler only commissioning service

can be provided by Glow-worm Service by calling telephone

No. 01773 828100.

LPG Conversion: See section 12.9.

NOTE: If you have tted a Glow-worm Options Board Kit,

please refer to the instructions supplied with the kit for

completion of commissioning.

Do not operate the boiler without water.

Refer to diagram 12.2

1. With no demand from any external controls, switch on the

electrical supply to the boiler.

Open the gas service isolation valve, see diagram 12.1.

2. Select your required function by pressing “ Mode “, scroll

through your options and select one of the following:-

Central heating.

Boiler functions ALL switched off. “OFF”

3. Turn ON your external controls and select the room

temperature required.

The boiler will operate automatically.

NOTE: The display will indicate the Heating system water

temperature or a fault code if in a fault condition.

12.5 Check the Gas Inlet Pressure and

Gas Rate

The supply from the governed meter must be of adequate

size to provide a steady inlet working pressure of 20mbar (8in

wg) at the boiler. On completion, test the gas installation for

tightness using the pressure drop method and suitable leak

detection uid, purge as necessary.

NOTE: Due to the modulating operation of the boiler and

the need to check the gas inlet pressure and measure the

gas rate at maximum rate, it will be necessary to force it to

maximum.

Press the “reset” button on the controls fascia, release

and immediately press and hold in the “+” button. After

approximately 5 seconds “Hi” will be displayed. Pressing

the mode button when “Hi” is selected will force the boiler

to maximum rate, the display will ash between “Hi” and the

“default display” this will indicate the boiler has been forced to

maximum.

Operational Gas Inlet Pressure

With ALL other gas appliances operating, check the

operational supply pressure at the gas service isolation valve

test point, see diagram 12.1.

The nominal supply pressure for Natural Gas (G20) is 20mbar.

The nominal supply pressure for LPG (G31) is 37mbar.

Turn the taps and appliances off, then disconnect the pressure

gauge.

Page 38

38

12 Commissioning

13234

Diagram 12.3

Additionally the safe nominal maximum heat input of the

appliance can be achieved at an inlet pressure down to

15mbar.

NOTE: The BURNER PRESSURE cannot be measured and

is not used to measure the gas rate.

Gas Rate

Make sure that ALL other gas burning appliances and pilot

lights are off.

Check the gas rate using the gas meter test dial and stop

watch, at least 10 minutes after the burner has lit, see table

below for approximate rates.

In communal or LPG installations where the gas rate cannot

be measured it is acceptable to measure the combustion rate

as described in the servicing section.

On completion, press the “mode” and “+” buttons

simultaneously, this will reset the boiler.

12.6 Heating Systems

Ensure that the external controls are calling for heat.

Fully open all radiator valves, ow control valve, if tted, see

diagram 5.1.

Switch on the appliance and ensure that the central heating is

calling for heat.

Balance the radiators as required and if tted adjust valve to

give the required system differential. Turn off all radiators that

can be shut off by the user and check to see if less than the

maximum differential allowed of 20

o

C can be achieved across

ow and return.

NOTE: Should the system require that the appliance has to

be adjusted, the front will need to be removed, as described

in the servicing section 13, and the control box lowered into its

service position.

The appliance pump has two speeds and can be adjusted

depending on the requirements of the system.

The appliance has an inbuilt automatic adjustable bypass

valve. The pressure can be adjusted between approx 1.5

and 3.5mH

2O but is factory pre-set to approx 2.5mH2O.

The pressure changes by approx 0.1mH

2O for each full turn

of the bypass screw, see diagram 12.3. Turning clockwise

increases the pressure and turning anti-clockwise decreases

the pressure.

Allow the system to reach maximum temperature then switch

off the boiler by isolating from the electrical supply.

Drain the entire system rapidly whilst hot, using the drain taps

at all the low points of the system. Fill and vent the system as

described previously.

Lock or remove the handle from control valve, if tted.

Adjust the boiler temperature controls and any system

controls to their required settings.

13866

sxi

sxi

0.53

0.53

18.7

18.7

2.0