Page 1

Hepworth Heating Ltd.,

Nottingham Road, Belper, Derbyshire. DE56 1JT

General/Sales enquiries:

Tel: (01773) 824141 Fax: (01773) 820569

One Contact Local Service

Customer Services:

Tel: (01773) 828100

Fax: (01773) 828070

221917C.06.02

All replacement parts

All labour charges

All call-out charges

Guarantee Registration

Miami GF

Radiant Convector Gas Fire

This is a Cat I2H Appliance

Reference in these instructions to British Standards and Statutory

Regulations/Requirements apply only to the United Kingdom.

For Ireland the rules in force must be used.

The instructions consist of three parts, User, Installation and Servicing Instructions, which includes the Guarantee Registration

Card. The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety

(Installation and Use) Regulations, be handed to the user on completion of the installation.

To be left with the user

❏

✔

❏

✔

❏

✔

Instructions for Use

Installation and Servicing

G.C. No. 32- 047- 05

REGISTER YOUR GLOW-WORM APPLIANCE

FOR 1ST YEAR GUARANTEE PROTECTION

CALL 0208 247 9857

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased to offer our customers'

a Comprehensive First Year Guarantee.

In the center pages are to be found your Guarantee Registration Card, which we recommend you complete and

return as soon as possible.

If this card is missing you can obtain a copy or record your registration by telephoning the Heatcall Customer

Service number 01773 828100.

Our Guarantee gives you peace of mind plus valuable protection against breakdown by covering the cost of:

9418

Page 2

2

221917C

CONTENTS DESCRIPTION SECTION PAGE No.

Certification

This fire is certificated to the current issue of BS6332 part 2, invoking the current issue of BS5258 part 5 for safety and performance.

It is, therefore, important that no alteration is made to the fire, without permission, in writing, from Hepworth Heating Ltd.

Any alteration that is not approved by Hepworth Heating Ltd., could invalidate the certification, the warranty and could infringe the

statutory requirements.

CE Mark

The CE mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the Laws of the Member States relating to appliances burning gaseous fuels.

2. Directive 89/336/EEC on the harmonization of the Laws of the Member States relating to electromagnetic compatibility.

INFORMATION FOR THE INSTALLER AND SERVICE ENGINEER.

Under Section 6 of the Health and Safety at Work Act 1974, we are required to provide information on substances hazardous to health.

The Adhesives and sealants used in this appliance are cured and give no known hazard in this state.

RADIANTS

After handling wash hands thoroughly.

INSULATION PADS/CERAMIC FIBRE, GLASSYARN, MINERAL WOOL

These can cause irritation to skin, eyes and the respiratory tract.

If you have a history of skin complaint you may be susceptible to irritation. High dust levels are usual only if the material is broken.

Normal handling should not cause discomfort, but follow normal good hygiene and wash your hands before eating, drinking or going

to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the skin seek medical attention.

Safety 3

Operating your Fire 4

Cleaning 5

Replacing Radiants 5

Maintenace 5

Installation Requirements 1 6

Pre-Installation Preparation 2 9

Closure Plate Installation 3 10

Appliance Installation 4 11

Control & Pressure Checks 5 12

Outer Case Fitting 6 12

Spillage Check 7 13

Final Review 8 13

Servicing & Parts Replacement 9 14

Fault Finding 10 16

INSTRUCTIONS

FOR USE

INSTALLATION

INSTRUCTIONS

SERVICING

INSTRUCTIONS

Important Information

SERVICING

REMEMBER, When replacing a part on this appliance, use only spare parts that you can be assured conform to the safety and

performance specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised by Hepworth

Heating Ltd.

Page 3

3

221917C

Instructions for Use

IF YOU SMELL GAS

DON’T SMOKE

EXTINGUISH ALL NAKED FLAMES

DON’T TURN ELECTRICAL SWITCHES ON OR OFF

TURN OFF THE GAS SUPPLY AT THE METER

OPEN DOORS AND WINDOWS TO GET RID OF THE GAS

IMMEDIATELY CALL THE GAS EMERGENCY SERVICE - SEE YOUR LOCAL TELEPHONE

DIRECTORY

For your Safety

Have the fire installed by a competent person. In the United

Kingdom, installation must be in accordance with the latest

edition of the Gas Safety (installation & use) Regulations. In the

Republic of Ireland, installation must be in accordance with all

national and local regulations in force.

Have the chimney swept prior to installation if it was previously

used for solid fuel.

Have the fire installed in accordance with the installation

instructions

Allow a minimum clearance of 110mm from the top of the

appliance case to the underside of any shelf whether it is made

from combustible or non-combustible materials. This clearance

is necessary to allow the case to be lifted off for servicing and

also allows sufficient access to operate the control knob. For a

shelf made from wood or other combustible materials deeper

than 150mm add 12.5mm to this clearance for every 25mm of

shelf depth over 150mm. Please bear this in mind if ever you

add a shelf.

Provide a suitable guard which complies with BS 6539 or 6778

for the protection of young children, the elderly and the infirm.

Such a guard is also recommended for the protection of pet

animals. (Although this fire conforms to all the applicable

standards, it is a heating appliance and certain parts of its

surface will become hot.)

Note: The guard supplied with the fire acts as a fireguard

conforming to BS1945:1971 and satisfies the Heating Appliance

(Fireguard) (Safety) Regulations 1991.

Always wait three minutes before attempting to relight if the fire

is switched off or the flames are extinguished for any reason.

(Your fire is fitted with a safety device which will automatically

shut off the gas supply to the fire if, for any reason, the flames

go out.)

Get advice about the suitability of any wall covering near your

fire. Soft wall coverings (e.g. embossed vinyl, etc.) which have

a raised pattern, are easily affected by heat. They may, therefore,

scorch or become discoloured when close to a heating appliance.

Please bear this in mind whenever you are considering

redecorating.

Provide a minimum clearance of 12mm between the outer case

sides and any corner wall or other surface which projects

beyond the front of the fire. Please bear this in mind if ever you

are considering altering the room.

Never hang clothing, towels or any other fabrics over the fire.

Never fill in the space behind the case.

Never use the fire without the dress guard being in position.

Never attempt to clean or service the fire off until it has been

switched off and allowed to cool completely.

Never use the fire with damaged radiants

SAFETY

Page 4

4

221917C

Instructions for Use

OPERATING YOUR FIRE

Please Note

When operating your fire for the first time, some vapours may

be given off which may cause a slight odour and could possibly

set off any smoke alarms in the immediate vicinity. These

vapours are quite normal with new appliances. They are totally

harmless and will disappear after a few hours use.

The Oxysafe flame sensing & flue blockage

safety system.

For your safety, this appliance is fitted with a flue blockage

safety device which will shut down the appliance in the event of

abnormal flue conditions. This device is NOT a substitute for

an independently mounted Carbon Monoxide detector.

The device will also automatically shut off the gas supply to the

fire if the pilot flame goes out due to lack of oxygen or for any

other reason.

If this device starts to repeatedly shut off the gas, get expert

advice.

This device incorporates a probe which senses that the heat

from the pilot flame is correct. If this probe is cool, the device

will prevent any gas flow unless the control knob is held down

at the ignition position.

If, for any reason, the flames go out when the fire is hot or if the

fire is turned off when hot, always wait at least three minutes

before attempting to relight.

To light the fire

The control is shown in diagram 2.

Depress the control knob and turn anticlockwise towards the 1/

IGN position. A spark should be generated at the pilot while

turning. The spark should ignite the pilot. The pilot flame can be

seen through the opening immediately below the centre radiant

- See diagram 3.

If the pilot does not light, turn the knob back to OFF and try

again.

In the unlikely event of failure of the ignition mechanism the pilot

can be lit with a long match or taper - See next page.

When the pilot has lit keep the knob depressed for about ten

seconds to allow the flame sensing probe to warm up.

Diagram 1

Diagram 2

Diagram 3

The control knob can then be set to your preferred heat level.

The settings are:

Knob Radiants Condition

Position

2 Centre radiant on low. Outer radiants off.

3 Centre radiant fully on. Outer radiants off.

4 Centre radiant fully on. Outer radiants on low.

5 All radiants fully on.

9421

9402

SEE SAFETY INSTRUCTIONS

12mm MINIMUM

EITHER SIDE

686mm

203mm

625mm

9424

Page 5

5

221917C

Diagram 4

LOCATION PINS

1678

0723

Diagram 5

Diagram 6

To exchange a radiant first ensure the fire is cold and

remove dressguard.

Lift up the radiant at the bottom and withdraw forward.

Instructions for Use

To Turn the Fire Off

Partially depress the knob and turn clockwise to off.

Wait at least three minutes before attempting to relight.

Lighting with a match or taper

Depress the control knob and turn anticlockwise towards the 1/

IGN position.

While keeping the knob depressed,light the pilot by inserting a

long match or taper into the pilot viewing opening, see diagram

3.

When the pilot is alight, keep the knob depressed for about ten

seconds to allow the flame sensing probe to warm up before

setting to your preferred heat level.

For your own convenience, have the heater serviced as soon as

possible.

CLEANING

Turn the fire off and allow it to cool before attempting any

cleaning.

Normally the fire will only need dusting. The bright metal trims

may be cleaned with a damp cloth and dried with a soft duster.

The wood case can be polished with furniture polish from time

to time.

Obstinate marks can be removed from the guard and trims

using soapy water. Never use abrasive cleaners.

The radiants can be cleaned with a soft brush - see the next

section for how to remove the radiants.

REPLACING RADIANTS

Make sure that the fire is cold

Remove the dress guard by holding the outer edge and flexing

the centre outwards to release the upper and lower locating

pins. See diagram 4.

Lift up the centre radiant from the bottom and withdraw forwards.

Move the other radiants to the centre and remove in a similar

way. See diagram 5.

To replace, insert the top of the radiant first then the bottom.

Lower into position. The back of the radiant should rest against

the rear ribs of the metal fire box and the bottom front edge of

the radiant should be behind the metal retaining bar. See

diagram 6.

It will be found easier to replace the radiants at the centre and

move them left or right.

Replace the dress guard.

We suggest that the position of the radiants is changed from

time to time to equalise any colour change caused during use.

MAINTENANCE

Regular maintenance

In order to achieve and maintain high levels of personal safety

and performance efficiency, it is essential that the opening at

the back of the fire and the flue are kept clear of any form of

obstruction. It is possible that deposits of mortar or soot could

fall and accumulate causing the flue to be blocked or restricted

and so preventing proper clearance of dangerous exhaust

fumes.

In the United Kingdom it is the law that a landlord must have any

gas appliance, flue and pipework which is situated in a tenant’s

premises checked for safety at least every twelve months by a

competent person (In the U.K, a CORGI registered installer).

We recommend that all gas appliances and their flues, wherever

situated, are checked annually.

Servicing

Use only genuine Glow-worm parts. Buy them from a recognised

supplier.

For all service enquiries please quote that the appliance is a

Glow-worm Miami GF, GC No. 32-047-05.

Radiants to touch

rear rib

9426

Page 6

6

221917C

1 Installation Requirements

Diagram 1.1

This appliance does not contain any component manufactured

from asbestos or asbestos related products.

The appliance data label is on the inner face of the back panel

at the lower left hand side. It is visible when the outer case is

removed.

1.1 Data

Gas Natural (G20)

Inlet Pressure 20mbar

Gross Heat Input

Max. 5.01kW (17,220Btu/h)

Min. 1.13kW (3,880Btu/h)

Max. Output 3.58kW (12,215Btu/hr)

*

Burner Test

Pressure (Cold) 17.95

+0.75mbar (7.2+0.3in w.g.)

Gas Connection 8mm pipe

Burner Injector

Upper

(Centre Radiant) Bray Cat. 28 Size 120

Lower

(Outer Radiants) Bray Cat. 28 Size 250B

Pilot & Atmosphere

Sensing Device OP9093

Ignition Piezo-electric integral with gas tap

Aeration Non-adjustable

Total Weight 17.1Kg

* As tested in accordance with BSI Document No. 98/708846.

1.2 Statutory Requirements

The installation must be in accordance with these instructions.

For the user’s protection, in the United Kingdom it is the law that

all gas appliances are installed by competent persons in

accordance with the current edition of the Gas Safety (Installation

and Use) Regulations. Failure to install the appliance correctly

could lead to prosecution. The Council for the Registration of

Gas Installers (CORGI) requires its members to work to

recognised standards.

In the United Kingdom the installation must also be in accordance

with:

• All the relevant parts of local regulations.

• All relevant codes of practice.

• The relevant parts of the current editions of the following British

Standards:-

BS 715, BS 1251, BS 1289 Part 1, BS EN 1806,

BS 4543 Part 2, BS 5440 Parts 1 and 2, BS 5871 Part 1,

BS 6461 Part 1, BS 6891.

• In England and Wales, the current edition of the Building

Regulations issued by the Department of the Environment and

the Welsh Office.

• In Scotland, the current edition of the Building Standards

(Scotland) Regulations issued by the Scottish Executive.

• In Northern Ireland, the current edition of the Building regulations

(Northern Ireland) issued by the Department of the Environment

for Northern Ireland.

• In the republic of Ireland the installation must also conform to

the relevant parts of:

• The current edition of IS 813

• All relevant national and local rules in force.

DIMENSIONS & CLEARANCES

SEE SECTION 1.10.

12mm MINIMUM

EITHER SIDE

686mm

203mm

625mm

9424

Page 7

7

221917C

1 Installation Requirements

Diagram 1.2

Diagram 1.3

1.3 Fire Location

• If the fireplace opening is an underfloor draught type, it must

be sealed to stop any draughts.

• The flue spigot and any spigot extension must be capable of

passing through the closure plate by at least 25mm with a

minimum clearance of 50mm between its open end and the

nearest obstruction. See diagram 1.2

• There must also be a minimum clearance of 165mm between

the back of the closure plate and the back of the catchment

space. See diagram 1.2.

• The catchment space below the flue spigot must extend at

least 250mm downwards measured from the bottom of the flue

spigot. See diagram 1.2.

• The front of the fireplace should be flat over an area sufficient

to ensure a good seal with the closure plate. The flat surface

should extend for a height equal to that of the closure plate plus

20mm and a for a width equal to that of the closure plate plus

40mm.

• If the fire is to be fitted against walls with combustible cladding,

the cladding must be removed from the area shown in diagram

1.3.

• In the United Kingdom, as supplied, this appliance can be

installed in the following situations:-

1.4 Conventional Fireplace

The fireplace opening must be within the following dimensions:

Width Max. 440mm

Min. 305mm

Height Max. 610mm

*

Min. 525mm

* Though the total height of the closure plate will accommodate

a maximum opening height of 650mm, heights above 610mm

will leave the closure plate and sealing tape visible above the

appliance.

• The appliance must be mounted on a non-combustible hearth

(N.B. conglomerate marble hearths are considered as noncombustible). The hearth must be at least 880mm wide x

300mm deep. The hearth material must be at least 12mm thick.

The periphery of the hearth (or fender) should be at least 50mm

above floor level to discourage the placing of carpets or rugs

over it.

• The appliance can be fitted to a purpose made proprietary

class “O” 150°C surround.

1.5 Wall Mounted

The wall opening must be within the following dimensions:

Width Max. 440mm

Min. 305mm

Height Max. 610mm

*

Min. 350mm

* Though the total height of the closure plate will accommodate

a maximum opening height of 650mm, heights above 610mm

will leave the closure plate and sealing tape visible above the

appliance.

• The bottom of the appliance must be at least 50mm above the

finished floor covering. See diagram 1.1. This requires the top

of the opening to be at least 575mm above the finished floor

covering. Any opening visible below the appliance may be

closed in but the depth of the catchment space within the wall

opening must be as shown in diagram 1.2.

FIREPLACE CATCHMENT SPACE

AREA TO BE FREE OF

COMBUSTIBLE CLADDING

9427

9425

NOT LESS THAN

165mm

NOT LESS THAN

250mm

NOT LESS THAN

50mm

520mm

615mm

Page 8

8

221917C

1.6 Precast Flues

• The appliance can be installed to a fireplace that has a properly

constructed precast concrete or clay flue block system

conforming to BS1289 or BS EN 1806. The appliance is suitable

for installations conforming to older versions of BS1289 as well

as the current standards. The flue blocks must have a minimum

width not less than 63mm and a cross-sectional area not less

than 13,000mm

2

.

Older editions of BS1289 required a cross-

sectional area of 13,000mm

2

. The current revision of the standard

requires 16,500mm

2

. This appliance is suitable in both cases.

• The chimney should be one or two storeys high but not less

than 3m vertical height and be correctly terminated. No mortar

fangs between the blocks should be extruded into the flueway.

If raking blocks are used, they must be fitted in accordance with

the manufacturer’s instructions. Mortar must not be allowed to

drop down and accumulate in the raked positions.

• The fireplace opening must be within the following dimensions:

Width Max. 440mm

Min. 305mm

Height Max. 610mm

1

Min. 610mm

2

1

Though the total height of the closure plate will accommodate

a maximum opening height of 650mm, heights above 610mm

will leave the closure plate and sealing tape visible above the

appliance.

2

Any opening visible below the appliance may be closed in.

1.7 Metal Flue Box

• The appliance can be installed to a metal flue box conforming

to BS715 Section 6 (For gas fires to BS5258:Part5) having a

minimum internal depth of 165mm.

• The opening must be within the following dimensions:

Width Max. 440mm

Min. 380mm

Height Max. 610mm

*

Min. 525mm

* Though the total height of the closure plate will accommodate

a maximum opening height of 650mm, heights above 610mm

will leave the closure plate and sealing tape visible above the

appliance.

1.8 Flue Requirements

The following flues are suitable:

• 225mm x 225mm conventional brick flue.

If a flue liner is used, it must be a minimum of 125mm diameter.

The liner must be sealed to the surrounding area above the

fireplace opening and to the top of the chimney. An approved

terminal must be fitted.

• A properly constructed precast flue conforming to B.S 1289 or

BS EN 1806.

• A flue pipe with a minimum diameter of 127mm. See B.S 6461

Part 1 for suitable materials. Metal flue pipes must comply with

B.S 715. See section 2.9.4 of this guide for flue box opening

sizes.

• The flue must conform to BS 5440: Part 1 in design and

installation.

• The flue, measured from the bottom of the fireplace opening

to the bottom of the terminal, shall be not less than 3m in actual

vertical height. When calculated in accordance with BS 5440:

Part 1 Annex A, the minimum equivalent height of the flue shall

be 2.0m of 125mm dia. flue pipe.

The flue must be clear of any obstruction and its base must be

clear of debris.

The flue must be completely sealed so that combustion products

do not come into contact with combustible materials outside the

chimney.

The flue must serve only one fireplace.

Proprietary terminals must comply with BS 715 or BS 1289. Any

terminal or termination must be positioned in accordance with

BS 5440 Part 1 to ensure that the products of combustion can

be safely dispersed into the outside atmosphere. Where the

appliance is connected to an unlined brick chimney it is generally

unnecessary for the chimney pot to be replaced or for a terminal

to be fitted unless the flue has a diameter smaller than 170mm.

If the appliance is intended to be installed to a chimney which

was previously used for solid fuel, the flue must be swept clean

prior to installation. All flues should be inspected for soundness

and freedom from blockages.

Any chimney dampers or restrictors should be removed. If

removal is not possible they must be fixed in the open position.

1.9 Ventilation

In the United Kingdom (GB) special ventilation bricks or vents

are not normally required in the room for this appliance.

In the Republic of Ireland (IE), permanent ventilation must

comply with the regulations currently in force.

An extractor fan may only be used in the same room as this

appliance, or in any area from which ventilation for the appliance

is taken, if it does not affect the safe performance of the

appliance. Note the spillage test requirements detailed further

on in this manual. If the fan is likely to affect the appliance, the

appliance must not be installed unless the fan is permanently

disconnected.

1.10 Appliance Clearances

Note that soft wall coverings (e.g. embossed vinyl, etc.) are

easily affected by heat. They may scorch or become discoloured

when close to a heating appliance. Please bear this in mind

when installing.

The minimum allowable distance from the outside of the

appliance case to a corner wall or other combustible surface

which projects beyond the front of the appliance is 12mm at

either side. See diagram 1.1.

Allow a minimum clearance of 110mm from the top surface of

the appliance case to the underside of any shelf whether it is

made from combustible or non-combustible materials. This

clearance is necessary to allow the case to be lifted off for

servicing and also allows the owner sufficient access to operate

the control knob.

A shelf made from wood or other combustible materials

deeper than 150mm must have a minimum clearance of

110mm + 12.5mm for every 25mm depth over 150mm. See

diagram 1.1.

The space between the fireplace front face and the back of the

outer case must not be filled in.

1.10 Room Restrictions

The appliance must not be installed in any room, which contains

a bath, or shower or where steam is regularly present.

1 Installation Requirements

Page 9

9

221917C

2 Pre-installation Preparation

Diagram 2.1

2.1 Unpacking

This appliance is supplied completely assembled except for:-

• 3 radiants which are in a cardboard pack inside the firebox.

• The closure plate

• Literature pack

• An olive & olive nut for gas line connection

Remove all the items carefully to prevent damage. Some items

may be contained in the packaging fitments -Examine the

packaging carefully before discarding. Check that all the items

are present and undamaged.

2.2 Fireplace Flue Pull

Close all doors and windows in the room in which the appliance

is to be installed. After confirming with a match that smoke is

drawn into the flue, light a 13 gram smoke pellet and check that

there is a definite flow through the flue. Verify outside that the

smoke exits from one terminal only and that the termination is

suitable. Observe, where possible, upstairs rooms and loft

spaces for signs of escaping smoke indicating a defective flue.

If there is not a definite flow warm the flue for a few minutes and

repeat the smoke pellet test. If there is still no definite flow the

flue may need remedial work - Do not fit the appliance until

there is a definite flow through the flue.

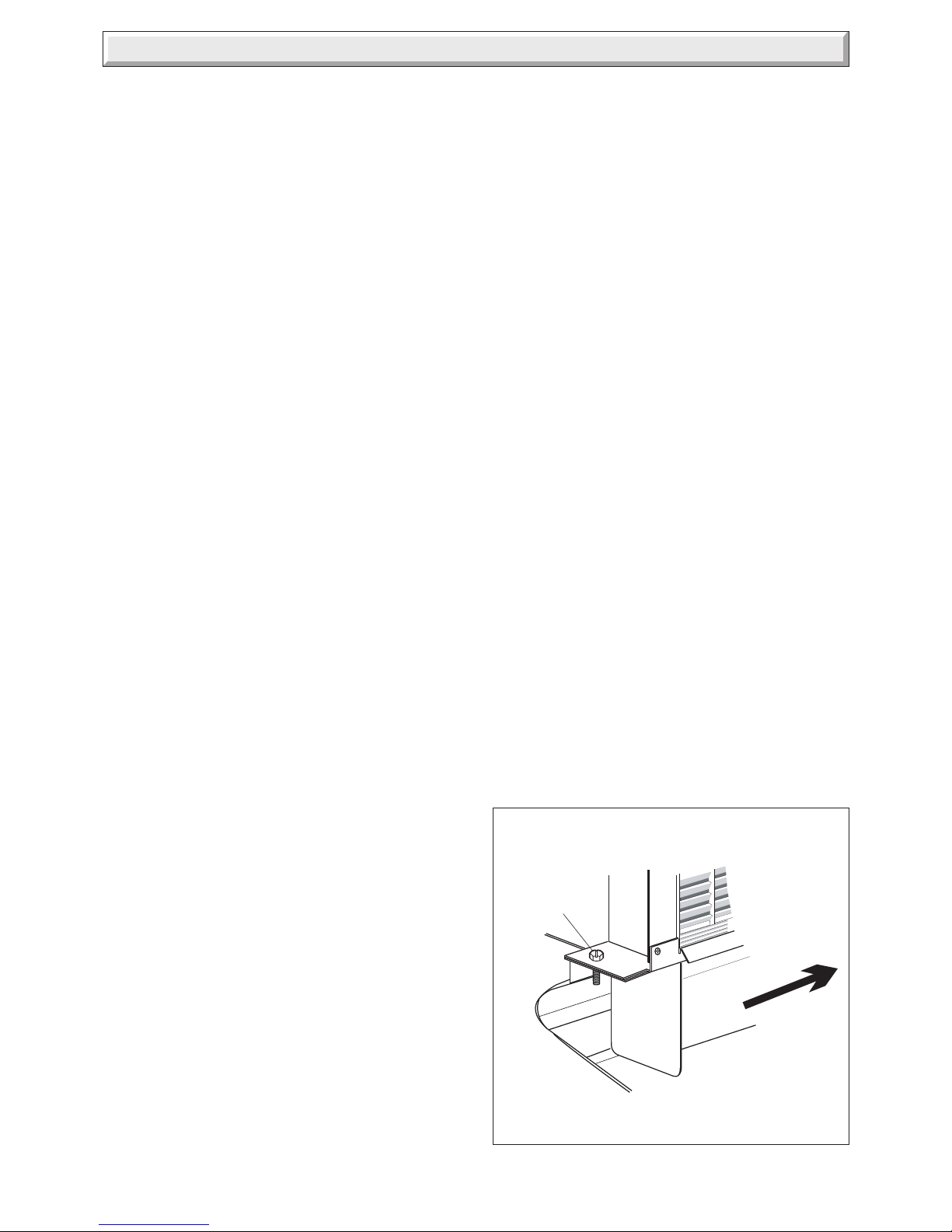

2.3 Appliance Preparation

Stand the fire upright.

Remove the two transit screws from the top of the back panel,

see diagram 2.1

Remove the control knob by pulling clear of the gas tap spindle.

Remove the two case retaining screws located at the front of the

case near the bottom. See diagram 2.2.

Lift the case up and forward to clear the rear top location and

store in a safe place.

Remove the radiant pack.

Remove any protective film from all the bright trims.

2.4 Check ignition spark

Before attempting to install, it is worth checking that the piezo

electric spark ignition system operates satisfactorily.

To initiate the spark, temporarily refit the control knob to the

spindle. Depress the knob and while keeping it depressed, turn

to the 1/IGN position. A spark should track from the electrode pin

to the thermocouple tip. If there is no spark or incorrect tracking,

check the spark gap between the electrode wire and

thermocouple tip. See diagram 2.3.

If the spark gap is correct but there is no spark check the ignition

wiring.

If the fire is fitted to a recessed fireplace, an extension flue spigot

up to a maximum total length of 125mm may be used. The

extension must be a tight fit over the flue spigot and be secured

by two self tapping screws. Note the minimum clearance required

as shown in diagram 1.2.

Diagram 2.2

CASE ATTCHMENT SCREWS

PILOT SPARK GAP

9464

9421

TRUE GAP

3.0mm - 5.0mm

Diagram 2.2

9421

TRANSIT

SCREW

(2off)

Page 10

10

221917C

3 Closure Plate Installation

Diagram 3.1

Diagram 3.2

Diagram 3.3

3.1 Closure Plate Details

The closure plate details are shown in diagram 3.1.

The closure plate has an opening at the bottom for a central gas

feed pipe. The gap between the pipe and this opening should be

sealed with tape after connection. If a central feed pipe is not

required the opening should be completely sealed with tape.

3.2 Hearth mounting

See diagram 3.2.

The closure plate must be fitted and sealed to the hearth and

fireplace opening using a suitable heat resistant material. If

necessary cut the closure plate but make sure that it overlaps

the fireplace opening sufficiently to allow satisfactory sealing.

Make sure that the rectangular air relief openings are fully within

the fireplace opening.

3.3 Wall mounting

See diagram 3.3.

The closure plate must be fitted and sealed to the hearth and

fireplace opening using a suitable heat resistant material. If

necessary cut the closure plate but make sure that it overlaps

the fireplace opening sufficiently to allow satisfactory sealing.

Make sure that the rectangular air relief openings are fully within

the fireplace opening.

The bottom of the appliance must be at least 50mm above any

carpet or other floor covering. To achieve this, the bottom of the

flue spigot opening must be at least 495mm above the finished

floor covering.

3.4 Flue Pull Check

Check the flue pull with closure plate fitted by applying a lighted

match or smoke match to the flue spigot opening in the closure

plate and observe the smoke. If there is a definite flow continue

with the installation. If not check the fitting of the closure plate.

The fireplace flue pull check described in section 2.2 should

have confirmed that the fireplace itself is satisfactory.

CLOSURE PLATE

CLOSURE PLATE FOR

HEARTH MOUNTING

CLOSURE PLATE FOR

WALL MOUNTING

10172

10173

10174

225mm

460mm

660mm

425mm

475mm

30mm

FLUE

SPIGOT

OPENING

2 AIR RELIEF

OPENINGS

DO NOT COVER

OR CUT AWAY

OPENING OR CENTRE PIPE.

SEAL OPENING IF NOT USED.

SEAL ALL ROUND

WITH TAPE

KEEP AIR RELIEF

OPENINGS CLEAR

SEAL CENTRAL

FEED PIPE

OPENING

SEAL ALL

ROUND

WITH TAPE

KEEP AIR

RELIEF

OPENINGS

CLEAR

SEAL

CENTRAL

FEED PIPE

OPENING

495mm MIN.

TO BOTTOM

OF FLUE

SPIGOT

OPENING

50mm

TOP OF FINISHED

FLOOR COVERING

Page 11

11

221917C

Diagram 4.2

Diagram 4.1

WALL FIXING HOLES

4 Appliance Installation

4.1 Hearth Mounting

Place the fire centrally on the hearth making sure that the spigot

lines up with the spigot hole in the closure plate. Gently slide the

appliance into place. The spigot must enter the closure plate to

a depth of at least 25mm.

Level the fire by loosening the lock nuts and turning the levelling

screws in the feet up or down as required while they bear on the

hearth. When the fire is level and square to the wall, retighten

the lock nuts.

Mark the fixing holes by marking the wall through the holes in the

back panel. Remove the fire, drill and plug the holes using no.

10 wall plugs.

Place the fire in position and secure with four no. 10 x 2in.

woodscrews.

4.2 Wall Mounting

The fixing hole positions in relation to the flue spigot opening are

shown in diagram 4.1. Mark these positions on the wall. The

positions can alternatively be marked by placing the fire in

position and marking the wall through the holes in the back

panel.

Drill and plug the holes using no. 10 wall plugs.

Place the fire in position and secure with four no. 10 x 2in.

woodscrews.

4.3 Gas Supply Connection

8mm rigid tubing must be used to connect the gas supply to the

appliance.

An olive and nut are provided for connection to the “T” connector

on the appliance. The connector can be rotated to allow

connection from either side or the rear. The connector includes

a valve for isolating the gas supply.

The closure plate has a cut-out for rear connection. Seal the gap

between the cut-out and the supply pipe.

Pressure check the installation pipework for gas soundness. In

the United Kingdom check in accordance with the current

edition of BS6891. In the Republic of Ireland check in accordance

with the rules in force.

4.4 Radiants Installation

Fit the radiants ensuring that they rest against the horizontal ribs

in the rear panel and that their bottom front edges are just

behind the retaining channel at the front of the radiant box.

4.5 Flue Restrictor Adjustment

See diagram 4.2.

The appliance has an integral adjustable flue draught restrictor.

This is supplied set in the fully open (unrestricted) position and

in most cases no adjustment should be necessary. It can be

reset to a fully restricted position if the flue draught is excessive.

The restrictor must remain in its fully open position if the

flue has an equivalent height of 4m or less (as calculated in

accordance with BS5440: Part 1 Appendix A) or where a

pre-cast flue is used.

To close the restrictor:

1. Loosen the screw situated behind the cut-out in the black

upper heat shield. Do not fully remove the screw.

2. Push the restrictor firmly down as far as it will go.The top

of the slot in the restrictor bracket should touch the screw.

3. Fully tighten the screw.

There may be certain exceptional circumstances where closing

the restrictor causes the fire to fail the spillage test (See section

7). In such cases the restrictor will have to be reopened.

FLUE RESTRICTOR ADJUSTMENT

FIRE C

L

9410

9411

495mm MIN.

315mm

65mm

SLIDE

DOWN

TO

RESTRICT

FLUE

TOP OF FLOOR COVERING

4 FIXING HOLE

POSITIONS

540mm

FLUE SPIGOT OPENING

Page 12

12

221917C

5 Control & Pressure Checks

5.1 Check Control Settings

If closed, open the isolating valve at the inlet elbow.

To check the control positions temporarily place the outer case

loosely over the engine. Fit the control knob over the gas tap

spindle.

Depress the control knob and turn anticlockwise partially towards

the 1/IGN position until some resistance is felt.

Keep depressed at this position for a few seconds to purge air

from the system then, while keeping it depressed, turn fully to

the 1/IGN position. A spark should be generated at the pilot

while turning. The spark should ignite the pilot.

When pilot ignition has been achieved, keep the control knob

depressed for approximately ten seconds to allow the

thermocouple probe to warm up and then release it. If the pilot

does not remain alight, ensure that the air has been purged, that

the pilot orifice is clear and that the thermocouple connections

are sound. Replace the pilot unit if necessary (see servicing

section of this manual).

Check all the control settings. These are:-

Knob Radiants Condition

Position

2 Centre radiant on low. Outer radiants off.

3 Centre radiant fully on. Outer radiants off.

4 Centre radiant fully on. Outer radiants on low.

5 All radiants fully on.

5.2 Flame Supervision & Spillage Monitoring

System

The pilot unit incorporates a system which will automatically

shut off the gas supply if the pilot flame goes out or if there is

insufficient oxygen due to spillage or lack of ventilation.

Check that the system operates properly as follows;

Light the appliance. Set at position 5 and leave for one minute.

Turn back to “OFF” to extinguish the pilot. Note the time when

the pilot goes out.

6.1 Outer Case Fitting

Remove the protective wood transit strips (secured with panel

pins) from the bottom of the wooden case sides.

Place the case over the engine. Make sure that the channel

near the top of the rear of the outer case locates fully into the

wings of the engine back panel. See diagram 6.1.

Fit the control knob firmly on to the control spindle.

Refit the two case retaining screws at the front of the case near

the bottom.

Listen for a snap sound at the gas tap. Note the time when the

sound is heard. This sound is caused by an electromagnetic

valve shutting off the gas supply through the tap. The valve is

located in the body of the tap. The valve should operate within

60 seconds of the pilot going out.

If the valve does not operate within this time limit do not allow

the appliance to be used until the fault has been corrected.

This monitoring system must not be adjusted, bypassed or

put out of operation.

This monitoring system, or any of its parts, must only be

exchanged using Glow-worm authorised parts.

5.3 Check Reference Pressure

The appliance is pre-set to give the correct heat input at the inlet

pressure shown in section 1 of this manual. No adjustment is

necessary.

Detach the control knob from the spindle. Remove the outer

case.

Check the burner pressure by fitting a pressure gauge at the test

point. The test point is on the gas tap. Check the pressure with

the appliance alight and set at maximum output (Control position

5).

After checking, turn off the appliance. Remove the pressure

gauge and replace the test point sealing screw. Relight the

appliance. Turn to the maximum output position and test around

the sealing screw for gas soundness with a suitable leak

detection fluid.

If all the above checks are satisfactory, continue with the

installation. If not, check the control and ignition circuitry and

components as described in the servicing section of this manual.

6 Outer Case Fitting

Diagram 6.1

9415

CASE TOP LOCATION

OUTER CASE

CHANNEL

BACK PANEL

WING

Page 13

13

221917C

7 Spillage Check

Diagram 7.1

SPILLAGE CHECK

7.1 Spillage Check

A spillage test must be made before the installed appliance

is left with the customer.

Close all doors and windows in the room containing the fire.

Light the appliance and set the control knob to the maximum

position (Position 5).

Leave the appliance on for five minutes.

Place a smoke match tube (with lighted match) horizontally

underneath the radiant box but touching the top lip of the box.

The tube should be between the two vertical inner ribs of the

centre radiant. The tip of the match should project between

2mm and 5mm beyond the lowest edge of the radiant box lip.

See diagram 7.1.

The installation is satisfactory if the smoke is drawn into the

appliance.

If the smoke is not drawn into the appliance, leave the appliance

alight at the maximum setting for a further ten minutes and then

repeat the test.

If the smoke is still not drawn into the appliance, inspect the

sealing of the closure plate.

If the sealing is satisfactory but the appliance is installed with the

flue restrictor in the closed position (see section 4.5), reopen the

restrictor, reseal the appliance and retest.

If smoke is still not drawn into the appliance Disconnect the

appliance and seek expert advice.

If the above test is satisfactory, open all internal connecting

doors, hatches, etc. in the room. Keep all doors and windows

that open to the outside of the building closed. recheck for

spillage as above.

If an extractor fan is installed in the same room as the appliance

or a connecting room, check that spillage does not occur with

the fan operating and all doors and other openings between the

fan and the appliance open.

If the test is satisfactory continue with the installation.

If the test is not satisfactory Disconnect the appliance and

advise the customer of the cause of failure.

8.1 Final Review

Make sure that the radiants and dress guard are securely in

position.

Recheck the operation of the fire at all control positions.

Visually inspect the appliance. Clean off any marks incurred

during installation.

Advise the customer how to operate the fire.

Explain to the customer that the appliance has a flame failure

and spillage monitoring system. Point out the explanation of this

system shown in the Instructions for use. Advise that if the fire

goes out for any reason, wait at least three minutes before

relighting. Stress that if the monitoring system repeatedly shuts

off the fire, the appliance should be switched off and a specialist

should be consulted.

Advise that the dressguard can be removed to replace the

radiants.

Advise that the fire may give off a slight odour while new. This

is quite normal and it will disappear after a short period of use.

Advise that any cleaning must only be carried out when the fire

is off and cold.

Advise the customer that they should read the Instructions for

use before operating the fire.

Advise the user that the appliance can be lit with a match if

necessary by inserting it through the central opening at the

bottom of the radiant box.

Recommend that the appliance should be serviced and the

chimney inspected by a competent person (In the UK a CORGI

registered person) at least annually.

If the appliance is in premises in the United Kingdom occupied

by a tenant, point out that by law a landlord must have any gas

appliance, flue and pipework which is situated in a tenant’s

premises checked for safety at least every 12 months.

Mention that the radiants may become brown with use, that this

is quite normal and has no adverse effect.

Hand these instructions to the customer.

8 Final Review

9416

SMOKE MATCH TO BE

BETWEEN INNER RIBS

OF CENTRE RADIANT

2mm - 5mm INSIDE

RADIANT BOX LIP

Page 14

14

221917C

Diagram 9.1

9 Servicing & Parts Replacement

REMEMBER, When replacing a part on this appliance, use only

spare parts that you can be assured conform to the safety and

performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised

by Hepworth Heating Ltd.

Always turn off the gas supply before commencing any

servicing (The appliance inlet “T” connector incorporates

an isolating valve).

It is recommended that, at least once a year, the appliance

is disconnected and the catchment space behind the closure

plate checked and cleared of any debris. The closure plate

must be resealed to the wall after checking.

Check that soot or debris is not impairing the electrode spark or

pilot burner.

Check that soot or debris is not blocking any of the holes in the

main burner.

Always test for gas soundness and spillage after servicing

the appliance.

9.1 To Replace Radiant(s)

Remove the dress guard by holding its outer edges and flexing

the centre outwards to release the upper and lower locating

pins.

Remove the old radiant(s) Fit the new radiant(s) ensuring that

they rest against the horizontal ribs in the rear panel and that

their bottom front edges are just behind the retaining channel at

the front of the radiant box.

Replace in the reverse order.

9.2 To Remove the Outer Case

Remove the control knob by pulling clear of the gas tap spindle.

Remove the two case retaining screws located at the front of the

case near the bottom.

Lift the case up and forward to clear the rear top location.

Replace in the reverse order. Make sure that the channel near

the top of the rear of the outer case locates fully into the wings

of the engine back panel. See diagram 6.1 in the installation

section.

Make sure that the radiants are not dislodged when refitting the

case.

9.3 To Replace the Pilot Unit

Remove the outer case as section 9.2 above.

Disconnect the thermocouple connection at the bottom of the

gas tap.

Disconnect the pilot pipe from the gas tap. It is the upper

connection at the right side of the tap.

Remove the first screw securing the dust cage to the pilot unit

& burner bracket. Carefully remove the dust cage and place

aside. Remove the second screw securing the pilot unit to the

burner bracket.

Disconnect the electrode lead from below the pilot electrode.

Carefully remove the pilot unit together with the pilot pipe then

disconnect the pipe from the pilot unit.

Replace in the reverse order.

Note:

1 The pilot unit must be replaced as a whole assembly. Its

individual components are not separately replaceable.

2. Once removed, ensure that the dust cage is cleaned

before refitting. Make sure that it locates squarely onto the

pilot unit without any gaps between the cage edges and

the pilot unit.

9.4 To Remove the Piezo Generator

Remove the outer case as section 9.2.

Disconnect the electrode lead from below the pilot electrode.

Disconnect the control spindle & adapter from the gas tap by

removing the split pin. Lift the adapter clear of the gas tap

spindle.

Remove the circlip holding the piezo generator to the tap.

Replace in the reverse order. Make sure that the control knob

with spindle is correctly turned to agree with the gas tap position

before refitting the split pin.

9.5 To Remove The Complete Burner Module,

Pipes and Pilot

Remove the outer case as section 9.2

Support the inlet isolating elbow to avoid straining the pipework

and disconnect the appliance from the elbow.

Disconnect the control spindle & adapter from the gas tap by

removing the split pin. Lift the adapter clear of the gas tap

spindle.

Detach the left end of the burner module from the radiant box by

removing one screw. See diagram 9.1.

Carefully slide the burner module to the right to free it from the

right side of the radiant box. See diagram 9.1.

Remove the pipes, gas tap or injectors as required.

Replace in the reverse order.

Take care when replacing the injectors. The injectors have

ceramic tips at each end. It is important not to allow jointing

compound to get on either end of the injectors.

Make sure that the control knob with spindle is correctly turned

to agree with the gas tap position before refitting the split pin.

BURNER MODULE REMOVAL

9417

1

REMOVE

SCREW

2

SLIDE BURNER UNIT

TO RIGHT

Page 15

15

221917C

9.6 To Grease the Gas Tap

Remove the burner module as section 9.5.

Remove the circlip holding the piezo generator to the tap.

Remove the two screws from the head of the tap.

Remove the spindle and spring from the tap.

Note the position of the slot in the plug. Mark this position on the

tap body.

Rotate the plug and pull it out of the tap.

Clean and grease the plug lightly with a suitable grease. Do not

apply excessive grease. Particularly, make sure that the gas

ports are not restricted by grease.

Push the plug back into the tap body. Line up the slot in the plug

with the mark previously made on the tap body.

Reassemble in the reverse order making sure that the

components are correctly engaged. Check the operation of the

tap and piezo. Make sure that the control knob with spindle is

correctly turned to agree with the gas tap position before

refitting the split pin.

9 Servicing & Parts Replacement

KEY DESCRIPTION No. OFF PART No.

A Gas Tap & Spark Generator 1 462500

B Spark Generator 1 462501

C Upper injector Bray Cat. 28 Size 120 1 462502

D Lower injector Bray Cat. 28 Size 250B 1 462503

E Pilot Unit 1 462504

F Control Knob 1 462506

G Radiant 3 462507

H Dress Guard 1 427504

J Dust cage 1 427509

9423

9466

A

H

F

G

E

C

D

J

B

Page 16

16

221917C

Because of our constant endeavour for improvement details may vary slightly from those in the instructions.

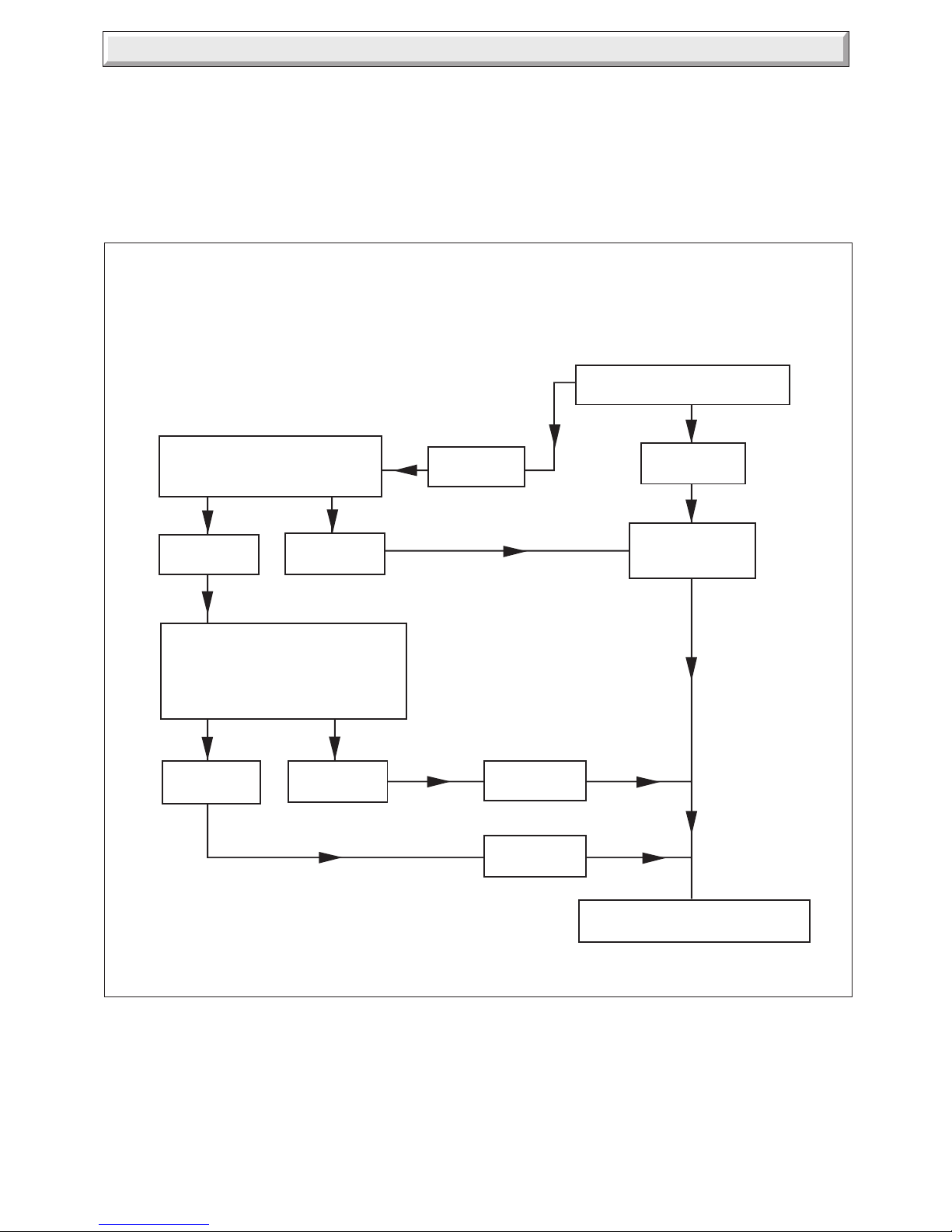

10 Fault Finding

10.1 Ignition Fault Finding

Refer to diagram 10.1.

10.2 Flue Blockage Safety Device

If the device operates it indicates there could be a problem with

the chimney. First make sure air vents are free of obstructions,

by carrying out spillage checks as section 7.1.

Diagram 10.1

IGNITION FAULT FINDING

9467

Disconnect ignition lead from

electrode and place within 4mm of

burner. Operate igniter

No spark

Spark across

gap

Remove ignition lead from piezo unit

and place screwdriver between

applaince chassis and piezo tag,

leaving a 4mm gap between blade

and tag. Operate igniter

No spark

Spark

No spark

Renew ignition

lead

Renew piezo

unit

Reassemble ignition system and

check ignition is satisfactory

Renew Flue

Blockage

Safety Device

Spark

no ignition

Turn on tap to operate igniter and

observe spark

If burner will not light, check the electrode lead connections are satisfactory

and that the burner ports are clean.

Check the electrode gap is correct.

If ignition is still unsatisfactory carry out the following procedure.

Loading...

Loading...