Page 1

The energy you need

Installation instructions

Envirosorb₃

GB

Page 2

Contents

Contents

1 Safety .................................................................... 3

1.1 Action-related warnings ......................................... 3

1.2 Required personnel qualifications ......................... 3

1.3 General safety information .................................... 3

1.4 Regulations (directives, laws, standards).............. 4

1.5 CE label ................................................................. 4

1.6 Approvals............................................................... 4

1.7 Local regulations.................................................... 5

1.8 Regulations............................................................ 5

1.9 Other regulations ................................................... 5

1.10 Intended use .......................................................... 5

2 Notes on the documentation .............................. 7

2.1 Observing other applicable documents ................. 7

2.2 Storing documents................................................. 7

2.3 Applicability of the instructions .............................. 7

3 System overview.................................................. 7

3.1 Safety devices ....................................................... 7

3.2 Functionality........................................................... 7

3.3 Permitted hydraulic configurations ........................ 8

3.4 System diagram (Envirosorb35)............................ 8

3.5 System diagram (Envirosorb38, Envirosorb311,

Envirosorb315) ...................................................... 9

4 Overview of the equipment................................. 9

4.1 Type designation and serial number ..................... 9

4.2 Information on the identification plate.................... 9

5 Assembly and installation ................................ 10

5.1 Preparing for fitting and installation ..................... 10

5.2 Carrying out the installation ................................. 14

5.3 Hydraulics installation.......................................... 15

5.4 Carrying out the electrical installation.................. 17

5.5 Connection diagrams........................................... 19

6 Start-up ............................................................... 21

6.1 Run the start-up................................................... 21

6.2 Filling the heating circuit ...................................... 21

6.3 Treating the heating water................................... 21

6.4 Filling the heating installation .............................. 22

6.5 Activating the heat pump ..................................... 22

6.6 Checking the product's operation ........................ 22

6.7 Operating noises.................................................. 23

6.8 Adjusting the heating circuit................................. 23

6.9 Installing the side cladding .................................. 24

6.10 Instructing the operator........................................ 24

7 Maintenance....................................................... 24

7.1 Observing maintenance intervals ........................ 24

7.2 Preparing for maintenance .................................. 24

7.3 Instructions before carrying out maintenance

work ..................................................................... 25

7.4 Yearly maintenance............................................. 25

7.5 Cleaning the product............................................ 25

7.6 Draining the product ............................................ 26

7.7 Checking the product's status codes ................... 26

7.8 Checking the electrical installation ...................... 26

7.9 Start-up following maintenance ........................... 26

8 Troubleshooting ................................................ 26

8.1 Troubleshooting................................................... 26

8.2 Fault codes .......................................................... 26

9 Decommissioning.............................................. 27

9.1 Temporary decommissioning .............................. 27

9.2 Permanently decommissioning............................ 27

10 Customer service............................................... 27

11 Disposal.............................................................. 27

11.1 Recycling and disposal ........................................ 27

11.2 Arranging disposal of coolant .............................. 27

Appendix ............................................................................28

A Heat pump schematic........................................ 28

A.1 Heat pump schematic drawing (Envirosorb

3

5).......................................................................... 28

A.2 Heat pump schematic drawing (Envirosorb

3

8).......................................................................... 29

A.3 Heat pump schematic drawing (Envirosorb

3

11)........................................................................ 30

A.4 Heat pump schematic drawing (Envirosorb

3

15)........................................................................ 31

B Heat pump setting parameters......................... 31

C Technical data.................................................... 32

D Status codes ...................................................... 34

E Overview of fault codes .................................... 36

Index ...................................................................................39

2 Installation instructions Envirosorb₃ 0020154078_03

Page 3

Safety 1

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Required personnel qualifications

▶ Secure against being switched back on

again.

▶ Wait for at least 3 minutes until the con-

densers have discharged.

▶ Check that there is no voltage.

▶ Cover or insulate adjacent live parts.

1.3.3 Risk of death due to lack of safety devices

A lack of safety devices (e.g. expansion relief valve, expansion vessel) may lead to potentially fatal scalding and other injuries, e.g.

due to explosions. The schematic drawings

included in this document do not show all

safety devices required for correct installation.

▶ Install the necessary safety devices in the

system.

▶ Inform the operator about the function and

position of the safety devices.

▶ Observe the applicable national and inter-

national laws, standards and guidelines.

Improper work carried out on the product

may cause material damage to the complete

installation and, as a consequence, may even

cause personal injury.

▶ You should therefore only work on the

product if you are an authorised competent

person.

1.3 General safety information

1.3.1 Danger caused by improper operation

Improper operation may present a danger to

you and others, and cause material damage.

▶ Carefully read the enclosed instructions

and all other applicable documents, particularly the "Safety" section and the warnings.

1.3.2 Risk of death from electric shock

There is a risk of death from electric shock if

you touch live components.

1.3.4 Risk of being scalded by hot drinking water

There is a risk of scalding at the hot water

draw-off points if the hot water temperatures

are greater than 50 °C. Young children and

elderly persons are particularly at risk, even

at lower temperatures.

▶ Select the temperature so that nobody is at

risk.

1.3.5 Risk of injury or material damage due to incorrect handling of the product

Using the fins on the front side of the product

as conductors may lead to injuries (due to

falling) or to material damage.

▶ Do not use the fins as conductors.

1.3.6 Risk of material damage due to additional elements in the heating water

Before commencing work on the product:

▶ Disconnect the product from the power

supply (electrical partition with a contact

opening of at least 3 mm, e.g. fuse or

power switch).

Unsuitable frost and corrosion protection

agents may damage seals and other components of the heating circuit and may therefore also lead to leaks in the water outlet.

▶ Only add approved frost and corrosion

protection agents to the heating water.

0020154078_03 Envirosorb₃ Installation instructions 3

Page 4

1 Safety

1.3.7 Risk of material damage caused by using an unsuitable tool

▶ Use the correct tool to tighten or loosen

screw connections.

1.3.8 Avoid environmental damage caused by escaping coolant

The heat pump contains R410A coolant.

The coolant must not be allowed to escape

into the atmosphere. R410A is a fluorinated

greenhouse gas covered by the Kyoto Protocol, with a GWP of 1725 (GWP = Global

Warming Potential). If it escapes into the atmosphere, its impact is 1725 times stronger

than the natural greenhouse gas CO2.

Before the heat pump is disposed of, the

coolant it contains must be completely

drained into a suitable vessel so that it

can then be recycled or disposed of in

accordance with the regulations.

▶ Ensure that only officially certified com-

petent persons with appropriate protective

equipment carry out maintenance work on

the coolant circuit or access it.

▶ Arrange for the coolant contained in the

product to be recycled or disposed of by

accredited specialists in accordance with

regulations.

▶ Only use coolant R410A.

▶ Only use a suitable R410A tool for the

filling, pressure measurement, vacuum

generation and discharge.

▶ Solder the lines using shielding gas. Check

the lines for leak-tightness using nitrogen.

▶ In the event of a repair or maintenance

work, fill the coolant circuit with liquid

coolant.

▶ If the coolant circuit is not leak-tight, check

which component must be repaired or replaced.

▶ Lower the negative pressure in the coolant

circuit to max. 10 mbar (1000 Pa).

▶ When filling the coolant circuit, observe the

values in the "Technical data" section.

1.4 Regulations (directives, laws, standards)

As part of the installation, commissioning and

operation of the heat pump and the DHW

storage you must take into account the current versions of the following regulations or

standards, along with any local directives or

guidelines that may apply.

– Electricity at work act.

– Health and safety at work act.

– Relevant Utility supplier’s regulations.

– Water regulations and by-laws.

– Environment agency and local council re-

quirements regarding bore holes, water

courses, or noise levels.

– Gas safety installation and use regulations

concerning any associated gas fired heat

source used within the heating system.

– Building regulations part “L” and directives

concerning energy saving.

– Building regulations such as G3 covering

Hygiene and L8 Legieonella.

– COSHH regulations.

– Other relevant bodies such as HETAS and

OFTEC.

– BS7671 requirements for electrical installa-

tions.

1.5 CE label

The CE label shows that the products comply

with the basic requirements of the applicable

directives as stated on the identification plate.

The declaration of conformity can be viewed

at the manufacturer's site.

1.6 Approvals

This product has been fully tested in accordance with:

– BS EN 14511:2011

4 Installation instructions Envirosorb₃ 0020154078_03

Page 5

Safety 1

1.7 Local regulations

Benchmark places responsibilities on both

manufacturers and installers. The purpose is

to ensure that customers are provided with

the correct equipment for their needs, that it

is installed, commissioned and serviced in

accordance with the manufacturer’s instructions by a competent person approved at the

time by the Health and Safety Executive and

that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be

provided to the customer for future reference.

Installers are required to carry out installation,

commissioning and servicing work in accordance with the Benchmark Code of Practice

which is available from the Heating and Hotwater Industry Council who manage and promote the Scheme.

standards and provisions in eff ect at the

time.

1.8.3 Reminder of existing regulatory acts

– EC regulation No. 20372000 from the 29th

of June 2000 This European regulation repeals regulation No. 3093/94 and presents

the elimination schedules of CFC and

HCFC. It also deals with the collection of

refrigerants, system leaks, particularly systems containing more than 3 kg of CFC

or HCFC, as well as the minimum level of

qualifi cation required by the technicians.

– EC regulation No. 0842/2006 from the 17th

of May 2006 regarding the containment,

use, collection and disposal of the fl uorinated greenhouse gases, the labelling and

elimination of the products and equipment

containing these gases, the restriction of

use and banning of certain products from

the market, as well as the training and certifi cation of personnel and companies operating in the activities targeted by this regulation: refrigeration, air-conditioning, heat

pumps and fi re protection systems containing greenhouse gases.

Visit www.centralheating.co.uk for more information.

Planning consent and Building works notification should be submitted either to Building

Control or to a Competent Person Provider.

1.8 Regulations

1.8.1 Statutory requirements

Where no British Standards exists, materials

and equipment should be fi t for their purpose

and of suitable quality and workmanship.

The installation of this appliance must be carried out by a competent person in accordance the rules in force in the countries of destination.

Manufacturer’s instructions must not be taken

as overriding statutory requirements.

1.8.2 Standards

On installing and commissioning the appliance you must adhere to the technical rules,

1.9 Other regulations

1.9.1 Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at

Work Act 1974, we are required to provide information on substances hazardous to health.

The adhesives and sealants used in this appliance are cured and give no known hazard

in this state.

The refrigerant used in this appliance is

R410a the use of which is strictly controlled

by F Gas regulation EN842/2006.

1.10 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The heat pump is an air/water monoblock

system and uses the energy from the outside

air to supply heat to the building.

The heat pumps are intended exclusively for

domestic use as heat generators for closed

0020154078_03 Envirosorb₃ Installation instructions 5

Page 6

1 Safety

heating and hot water central heating systems and for hot water generation.

Intended use includes the following:

– observance of accompanying operating,

installation and servicing instructions for

the product and any other system components

– installing and fitting the product in accord-

ance with the product and system approval

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document, shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

6 Installation instructions Envirosorb₃ 0020154078_03

Page 7

Notes on the documentation 2

1

2

3

4

5

6

1

2

3

4

5

6

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

2.3 Applicability of the instructions

These instructions apply to units with the following type designations and article numbers only:

Type designation Art. no.

Envirosorb35 0010014421

Envirosorb38 0010011967

Envirosorb311 0010011968

Envirosorb315 0010014422

The seventh to sixteenth digits of the serial number on the

identification plate form the article number.

protection agent should be added to the heating water as

the heating water temperature may fall below the freezing point in the event of a power cut, which poses a risk

of frost to the heating installation.

Note

Operating the heat pump outside the application

limits results in the heat pump being switched off

by the internal control and safety devices.

3.2 Functionality

The product comprises the following circuits:

– The coolant circuit releases heat into the heating circuit

by means of evaporation, compression, condensation

and expansion

– The heating circuit

3.2.1 Heating mode

3 System overview

3.1 Safety devices

– The product can work at the following outside temperat-

ures:

Envirosorb

5

Heating mode −15 … 28 ℃ −20 … 28 ℃

Cylinder charging mode −15 … 46 ℃ −20 … 46 ℃

– If the product's coolant circuit pressure exceeds the max-

imum pressure of 4.15 MPa (41.5 bar), the high-pressure pressure switch switches the product off. Following a waiting period, the product attempts to start once

more. After three failed start attempts in succession, a

fault message is displayed.

– If the product is switched off, the crankcase housing

heating is switched on when the compressor outlet temperature reaches 7 °C in order to prevent possible damage caused by switching it back on.

– If the compressor inlet temperature and the compressor

outlet temperature are below 1 °C, the compressor does

not start up.

– A temperature sensor on the compressor outlet limits the

product's operation if the measured temperature exceeds

the maximum permissible temperature. The maximum

permissible temperature depends on the evaporation and

condensation temperature.

– The product measures the flow rate of the connected

heating circuit when starting up the product.

– If the heating circuit temperature falls below 3 °C, the

product's frost protection function is automatically activated as the heating pump is started. In addition, frost

Envirosorb

3

8,

Envirosorb

11,

Envirosorb

15

3

1 Evaporator

2 4-way valve

3

3 Fan

3

4 Compressor

5 Electronic expansion valve

6 Plate heat exchanger

3.2.2 Thawing

1 Evaporator

2 4-way valve

3 Fan

4 Compressor

5 Electronic expansion valve

6 Plate heat exchanger

3.2.3 Application limits

Operation of the pump outside the application limits results in

the heat pump being switched off by the internal control and

safety devices.

0020154078_03 Envirosorb₃ Installation instructions 7

Page 8

3 System overview

60

50

70

40

30

20

10

0

-20 -10 0 10 20 30 40 50

[-15;22]

[-15;45]

[46;22]

[46;58]

[35;60]

[28;60]

[2;60]

[-10;55]

1

2

[28;22]

[35;22]

A

B

60

50

70

40

30

20

10

0

-20 -10 0 10 20 30 40 50

[-20;22]

[-20;43]

[46;22]

[46;58]

[35;63]

[28;63]

[2;63]

[-10;55]

1

2

[28;22]

[35;22]

A

B

e

1 3 12161719

24

1521

14

11

4

23

20222

5 13 8 9

6

7

10

A

B

18

3.2.3.1 Application limits in heating mode (Envirosorb35)

1 Heating mode application

limits

2 Hot water generation

application limits

A Water temperature

B Air temperature

3.2.3.2 Application limits in heating mode

(Envirosorb38, Envirosorb311, Envirosorb

15)

3.3.2 Indirect connection to a heating installation via a hydraulic module

3.4 System diagram (Envirosorb35)

3

1 Heating mode application

limits

2 Hot water generation

application limits

3.3 Permitted hydraulic configurations

3.3.1 Direct connection to a heating installation

8 Installation instructions Envirosorb₃ 0020154078_03

A Water temperature

B Air temperature

1 Fan

2 Air inlet temperature

sensor

3 Ribbed pipe heat ex-

changer

4 Temperature sensor of

the ribbed pipe heat exchanger

5 4-way valve

6 Return heating circuit

temperature sensor

7 High-efficiency pump with

flow rate sensor

8 Purging valve

9 Flow heating circuit tem-

perature sensor

10 Drain valve

11 Plate heat exchanger

12 Temperature sensor after

the plate heat exchanger

13 Service valve for the high-

14 High-pressure pressure

switch in the coolant circuit

15 High-pressure sensor in

the coolant circuit

16 Compressor outlet temper-

ature sensor

17 Rotary piston compressor

18 Filter

19 Liquid separator

20 Electronic expansion valve

21 Compressor inlet temper-

ature sensor

22 Service valve for the low-

pressure range of the

coolant circuit

23 Filter

24 Fluid collector

A Heating return

B Heating flow

pressure range of the

coolant circuit

Page 9

Overview of the equipment 4

e

1 3 12161719

25

23

1521

14

11

4

24

20222

5 13 8 9

6

7

10

A

B

18

1

1

3.5 System diagram (Envirosorb38, Envirosorb311, Envirosorb315)

1 Fan

2 Air inlet temperature

sensor

3 Ribbed pipe heat ex-

changer

4 Temperature sensor of

the ribbed pipe heat exchanger

5 4-way valve

6 Return heating circuit

temperature sensor

7 High-efficiency pump with

flow sensor

8 Purging valve

9 Flow heating circuit tem-

perature sensor

10 Drain valve

11 Plate heat exchanger

12 Temperature sensor after

the plate heat exchanger

13 Service valve for the high-

pressure range of the

coolant circuit

14 High-pressure pressure

switch in the coolant circuit

15 High-pressure sensor in

the coolant circuit

16 Compressor outlet temper-

ature sensor

17 Rotary piston compressor

18 Filter

19 Liquid separator

20 Electronic expansion valve

21 Compressor inlet temper-

ature sensor

22 Service valve for the low-

pressure range of the

coolant circuit

23 Flow rate limiter (cooling

mode) on Genia Air 8/1

only

24 Filter

25 Gas buffer

A Heating return

B Heating flow

4 Overview of the equipment

4.1 Type designation and serial number

The type designation and serial number are on the identification plate (1).

4.2 Information on the identification plate

Information on the identification plate

Serial no. Unique unit identification number

P max Maximum rated power

I Max. operating current

I max Maximum start-up current

R410A Coolant type and fill quantity

PSR_LP

PSR_HP

PSHmin

PSHmax

COP (Ax/Wxx) Output figure (coefficient of

(Ax/Wxx)

Volt Compressor, pump and control-

Hz Power frequency

IP Protection class

Meaning

Min. and max. operating pressure in the coolant circuit

Minimum and maximum operating pressure in the heating circuit

performance) at an air inlet

temperature of xx °C and a

heating flow temperature of

xx °C

Heating output at an air inlet

temperature of xx °C and a

heating flow temperature of

xx °C

ler mains voltage

0020154078_03 Envirosorb₃ Installation instructions 9

Page 10

5 Assembly and installation

13mm

1

2

3

4

B

A

D

E

C

5 Assembly and installation

5.1 Preparing for fitting and installation

5.1.1 Delivery, transport and positioning

5.1.1.1 Transporting the product

▶ During transport, do not tilt the heat pump

by any more than the maximum angle of

45°.

1. Use the transportation belt to carry the product to the

final installation site.

2. Only lift the product from the back and side where the

hydraulic connections are located.

3. When transporting the product using a hand truck, secure the product using a belt.

4. In order to avoid scratches and damage, protect the

sides of the product that come into contact with the

hand truck.

5.1.1.2 Unpacking the product

Warning.

Risk of injury from lifting a heavy weight.

Lifting weights that are too heavy may cause

injury to the spine, for example.

▶ When transporting the product, two

people should lift it.

▶ Observe the product weight stated in the

technical data.

▶ When transporting heavy loads, observe

the applicable directives and regulations.

1. Remove the accessory (2).

2. Remove the documentation supplied (1).

3. Remove the transport belt (4).

4. Carefully remove the packaging and padding without

damaging the product (3).

5. Remove the screws from the pallet at the front and rear

of the product.

Caution.

Risk of material damage due to incorrect

transportation.

Regardless of the mode of transport, the heat

pump must never be tilted by more than 45°.

Otherwise, this may lead to malfunctions in

the coolant circuit during subsequent operation. In the worst case scenario, this may lead

to a fault in the whole system.

10 Installation instructions Envirosorb₃ 0020154078_03

Page 11

5.1.1.3 Checking the scope of delivery

120

120

740

980

360

800*

386

11

Envirosorb 5

3

162

162

778

1103

415

942*

437

11

Envirosorb 8

3

Envirosorb 11

3

▶ Check the contents of the packaging units

Quantity

1 Condensate discharge

1 Bag with seals

4 Vibration-isolating feet

1 Purge hose

5.1.2 Complying with clearances and installation

5.1.2.1 Unit dimensions and connection

Description

clearances

dimensions

Assembly and installation 5

* Size increases by 45 mm

when using the vibration

dampers supplied.

* Size increases by 45 mm

when using the vibration

dampers supplied.

0020154078_03 Envirosorb₃ Installation instructions 11

Page 12

5 Assembly and installation

162

162

778

1103

415

1340*

437

11

Envirosorb 15

3

C

B

D

A

A

E

5.1.2.2 Installation clearance

* Size increases by 45 mm

when using the vibration

dampers supplied.

Clearance For heating mode

A > 250 mm

B > 1000 mm

C > 120 mm*

D > 600 mm

E > 300 mm

*Caution: If the minimum clearances are not maintained, the

output of the product may be affected.

▶ To guarantee sufficient air flow and to facilitate mainten-

ance work, observe the minimum clearances that are

specified above.

▶ Ensure that there is sufficient room to install the hydraulic

lines.

▶ If the product is to be installed in areas where heavy

snow falls, ensure that the snow does not accumulate

around the product and that the minimum clearances

specified above are observed. If you cannot ensure this,

install an additional heat generator in the heating circuit.

12 Installation instructions Envirosorb₃ 0020154078_03

Page 13

5.1.2.3 Selecting the installation site

dB(A)

dB(A)

▶ Observe all valid regulations.

▶ Install the product outside the building.

▶ Do not install the product:

– Near a heat source,

– Near flammable materials,

– Near ventilation openings for adjacent buildings,

– Under deciduous trees.

▶ Note the following points when installing the product:

– Prevailing winds,

– The visual impression on the environment

▶ Avoid places where strong winds blow on the product's

air outlet.

▶ Point the fan away from nearby windows. Install noise

protection if necessary.

▶ Install the product on one of the following supports:

– Concrete slab,

– Steel T-beam,

– Concrete block,

– Elevating socket (accessory),

– Wall bracket (permitted accessory for Envirosorb35,

Envirosorb38 and Envirosorb311).

▶ Do not expose the product to dusty or corrosive air (e.g.

near unsecured streets).

▶ Do not install the product near ventilation shafts.

▶ Prepare the routing for the electrical lines.

Assembly and installation 5

▶ Note any noise emissions from the fan and compressor.

0020154078_03 Envirosorb₃ Installation instructions 13

Page 14

5 Assembly and installation

>100mm

B

A

A

C

5.1.2.4 Installing the heat pump

1. Note the safety information in this manual and in the

operating instructions before installing the product.

2. Install the product on steel beams, concrete blocks or

using a wall holder (accessory).

3. Ensure that no water collects under the product.

4. In order to avoid ice formation, ensure that the ground

in front of the product can absorb water well.

5.1.2.5 Preparing the condensate discharge

5.2 Carrying out the installation

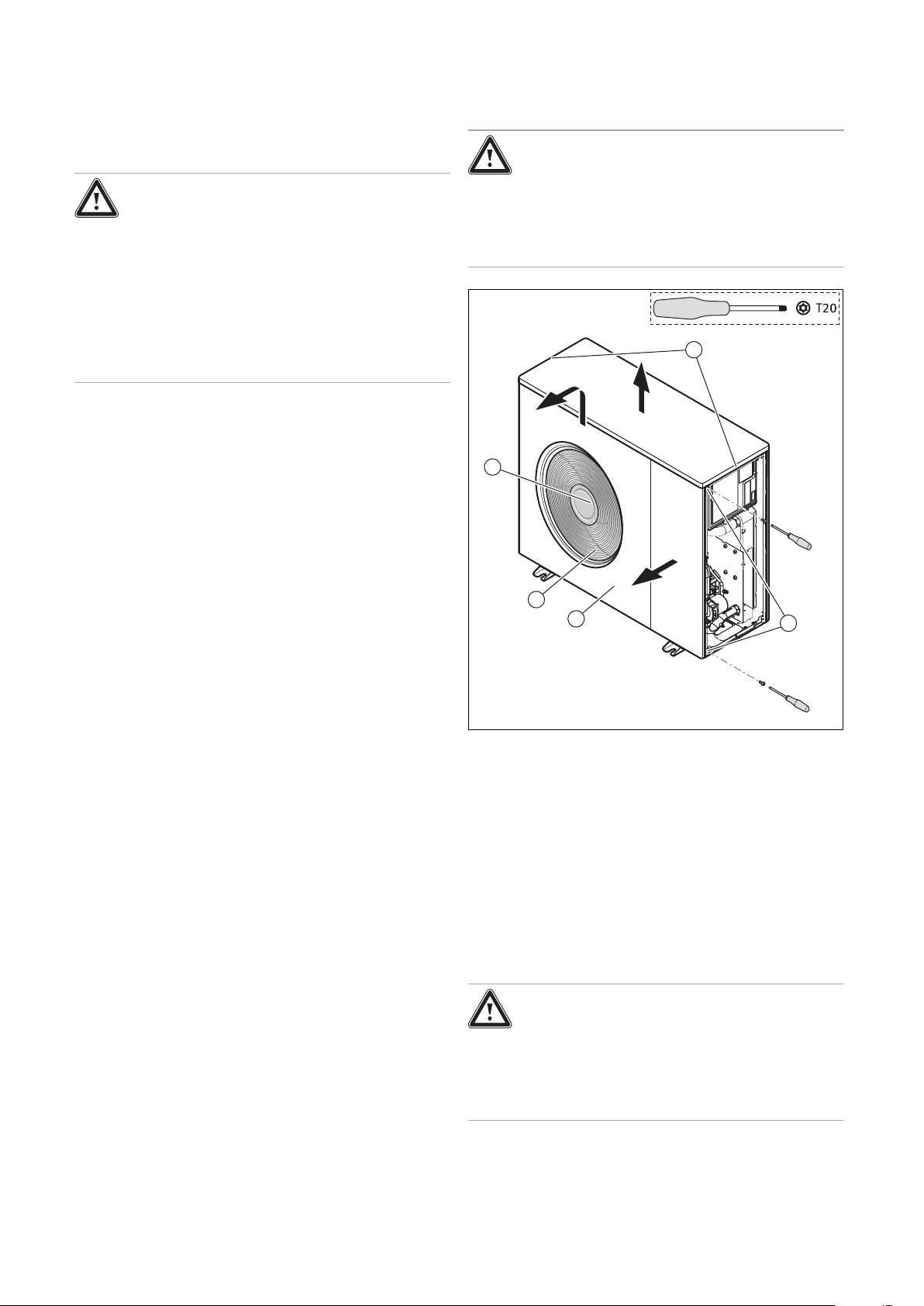

5.2.1 Removing the side casing

Danger!

Risk of injury due to frozen condensate.

Frozen condensate on paths may cause falls.

▶ Ensure that condensate does not dis-

charge onto paths and that ice cannot

build up there.

The condensate is discharged centrally underneath the

product.

▶ Prepare the condensate discharge using a drain line or in

a gravel bed.

1. Remove both screws (A).

2. Pull the side casing downwards and then forwards.

Note

Note that the required tool is not included in

the scope of delivery.

5.2.2 Aligning the product

1. Only use bolts of a specific length.

14 Installation instructions Envirosorb₃ 0020154078_03

Page 15

Assembly and installation 5

0.75 m min.

1

4

5

6

7

3

2

– Maximum length: ≤ 8 mm

2. Align the product horizontally so that condensate can

flow.

Note

The product must be installed with the vibration-isolating feet supplied. The product

is lifted by the vibration-isolating feet, which

simplifies the condensate-discharge process

and reduces vibrations.

3. Screw in the vibration-damping feet using the concrete

foundation.

Note

The concrete foundation must not be joined

to the house foundations.

5.3 Hydraulics installation

In heating installations that are equipped primarily with thermostatic or electrically controlled valves, a constant and sufficient flow through the heat pump must be ensured. Irrespective of which heating installation is selected, the minimum volume of circulating heating water (40% of the nominal flow, see the technical data table) must be guaranteed.

5.3.1 Carrying out the hydraulics installation

Caution.

Risk of damage caused by residue in the

heating flow and return.

Residue from the pipelines, such as welding

beads, scale, hemp, putty, rust and coarse

dirt, may be deposited in the product and

cause malfunctions.

1. Insulate the lines (including those running below

ground) with UV-resistant and high-temperature-resistant insulation between the product and the heating

installation.

2. In order to avoid transferring vibrations to the surrounding buildings, use flexible connection pipes on the

product that have a length of at least 0.75 m.

3. When the product is not installed at the highest point in

the heating circuit, install additional purging valves in

suitable places.

4. Install the following accessories in the heating return.

Installation without decoupling hydraulic module

– Drain cock

– Air separator (if required)

– Dirt filter

– An expansion vessel suitable for the complete hydraulic

installation

– Expansion relief valve 0.3 MPa (3 bar)

– Pressure gauge (recommended)

Maximum length of the

heating circuit

When using a hydraulic

module without an expansion

vessel

Note

If you use glycol, you must collect it at the

expansion relief valve to prevent environmental pollution.

DN 26 DN 28

50 m 30 m

▶ Flush the heating installation thoroughly

before connecting the product in order to

remove any possible residue.

Caution.

Risk of material damage due to corrosion.

If plastic pipes that are not diffusion-tight are

used in the heating circuit, this may lead to

corrosion and deposits in the heating circuit

and in the product.

▶ Do not treat the water with corrosion pro-

tection agents if plastic pipes that are not

diffusion-tight are used.

Danger!

Risk of material damage caused by sol-

dering work.

Carrying out soldering work on lines that

have already been installed may damage the

seals.

▶ Solder the lines before installing the

product.

1 Connection hose in the

heating flow to the building

(on-site)

2 O-ring seal

3 Covering cap

4 Heating flow connection

(diameter 1 1/4") to the

building

5. Remove the covering caps (3) from the product's hydraulic connections.

6. Install a dirt filter in the heating circuit return between

two stop valves so that the filter can be cleaned regularly.

5 Heating return connection

(diameter 1 1/4") to the

heat pump

6 Connection hose in the

heating return to the heat

pump (on-site)

7 Insulation (on-site)

0020154078_03 Envirosorb₃ Installation instructions 15

Page 16

5 Assembly and installation

B

A

365

Ø25

1

2

3

4

5

7. Install a flexible connection pipe (1) and (6) (to be

provided on-site) with an O-ring and a stop valve to

each of the connections for the heat pump heating flow

and return.

8. Check the connections for tightness.

5.3.2 Connecting the swimming pool (optional)

Danger!

Risk of material damage due to a direct

connection to a swimming pool.

If the product is directly connected to a swimming pool, damage may be caused by corrosion.

▶ Do not connect the heat pump heating

circuit directly to a swimming pool.

▶ If you want to connect a swimming pool to the heating

circuit, note the components (expansion vessels, etc.)

that are required for the installation.

5.3.3 Connecting the condensate drain pipework

Note

Observe all valid national regulations and rules.

1 Condensate drain pipe

2 Adaptor

3 Cable tie

1. Observe the various installation dimensions for the

products.

Product Dimension Value

– Envirosorb35 A 70.0 mm

– Envirosorb38

– Envirosorb311

– Envirosorb315

2. Pull the heating wire in the condensate pan until the

elbow (4).

3. Connect the elbow (4) and adaptor (2) to the seal (5)

and secure them both using a cable tie (3).

4. Connect a condensate drain pipe to the elbow.

5. Install the heating wire in the condensate drain pipe (1)

in order to prevent the condensate from freezing in the

line.

6. Connect the adaptor (2) with the product's floor plate

and secure it with a 1/4 rotation.

4 Elbow

5 Seal

B 490.0 mm

A 102.5 mm

B 550.0 mm

16 Installation instructions Envirosorb₃ 0020154078_03

Page 17

Assembly and installation 5

30 mm max.

1

2

X4

X9

EBUS

X7

FLOOR H

X2

21

2

1

7. Make sure that the condensate drain pipe ends in a

gravel bed.

Note

The condensate drain pipe must not be

longer than 365 mm, otherwise it may freeze

over.

8. Route the condensate drain pipework with a downward

gradient.

5.4 Carrying out the electrical installation

1 Connecting wires 2 Insulation

Danger!

Risk of death from electric shock as a res-

ult of an improper electrical connection!

An improper electrical connection may negatively affect the operational safety of the

product and result in material damage or personal injury.

▶ The electrical installation must be carried

out by a suitably qualified competent person who is responsible for complying with

the existing standards and directives.

1. Only strip a maximum of 3 cm from the outer sheathing

of the flexible lines.

2. Secure the conductors in the connection terminals.

5.4.1 Establishing the power supply

The external mains connection cable must be earthed and

connected with the correct polarity and in accordance with

the valid regulations.

▶ Check that the mains connection cable is connected cor-

rectly.

The cables that connect the product to the fuse box must:

– Be suitable for fixed installation,

– Be weatherproof,

– Be equipped with a wire cross-section that is necessary

for the product performance.

▶ Connect the product using a fixed connection and a parti-

tion with a contact opening of at least 3 mm (e.g. fuses or

power switches).

In order to meet the overvoltage category II requirements,

further fuse protection may be required.

To meet the overvoltage category III conditions, the partitions must ensure a complete separation of the power supply.

5.4.2 Standard tariff

5.4.2.1 230 V connection

1 Mains connection terminal

in the product

2 Partition

Caution.

Risk of material damage due to high con-

nected voltage.

At mains voltages greater than 253 V, electronic components may be damaged.

▶ Ensure that the rated voltage of the mains

is 230 V.

▶ Connect the mains connection cable to the product's

power supply connection.

Envirosorb

5

Power supply 1/N/PE

230 V

50 Hz

Fuse 16 A -

type C

or D

Recommended

cable dimension

3G x

2.5 mm²

▶ To ensure that people are safe, install a separate 30 mA

residual-current-operated circuit-breaker for the heat

pump.

▶ Guide the mains connection cable through the product's

cable duct (PEG screwed connection).

Envirosorb

3

8

1/N/PE

230 V

50 Hz

16 A type C

or D

3G x

2.5 mm²

Envirosorb

3

11

1/N/PE

230 V

50 Hz

20 A type C

or D

3G x

2.5 mm²

Envirosorb

3

15

1/N/PE

230 V

50 Hz

20 A type C

or D

3G x

2.5 mm²

3

0020154078_03 Envirosorb₃ Installation instructions 17

Page 18

5 Assembly and installation

X4

X9

EBUS

X7

FLOOR H

3

1

2

123456789101112131415

16

1

2

3

4

ØA

ØA

1

2

5.4.3 Laying the 24 V cabling

1 eBUS connection in the

heat pump (observe the

polarity)

2 Limit thermostat connec-

tion (underfloor protective

circuit)

3 eBUS connection in the

heat pump control module

1. Feed the cable through the cable duct.

Envirosorb35

Envirosorb38

Envirosorb311

Envirosorb315

Recommended eBUS cable dimension

Recommended cable dimension for

eBUS + limit thermostat

2 x 0.75 mm²

4 x 0.75 mm²

2. Connect the eBUS cable to the system controller.

3. If you install a limit thermostat (e.g. 50 °C) in the heating circuit flow, remove the bridge from terminal (2) and

connect the limit thermostat to this terminal.

5.4.4 Installing the cable duct

Caution.

Risk of malfunction due to incorrect rout-

ing of the supply lines.

If you route the supply lines for the power

supply and the eBUS line through the same

cable duct, the signal will be disrupted.

1 eBUS line and limit ther-

mostat line cable duct

2 Power supply cable duct

1. Measure the diameter of the cable.

2. Drill a hole the same size as the cable diameter in the

cable duct.

3. Route the cable through the cable duct.

4. Tighten the cable duct with two open-end spanners.

▶ Route the supply lines for the power sup-

ply and the eBUS line through various

cable ducts in the product.

18 Installation instructions Envirosorb₃ 0020154078_03

Page 19

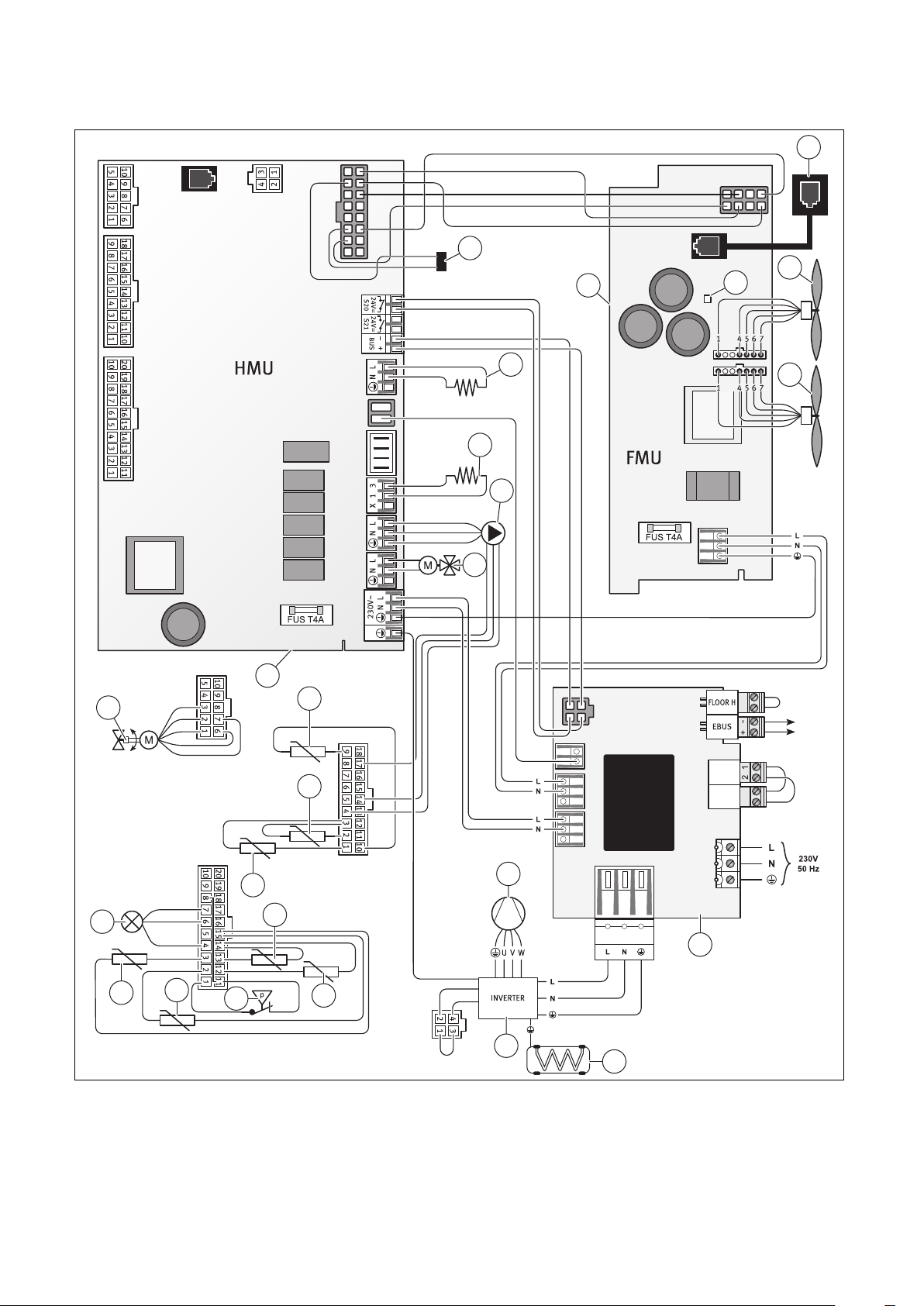

5.5 Connection diagrams

X8

X1

X6

X4

X7

X60DA

X14

X700

X16

X11

F1

X1

X15

X13

X26

X23

X21

X22

X30 X25

X24

X25

X5

X10CA

X9

X2

RL1

X3

15

16

17

12

18

19

20

21

22

23

24

25

11

9

8

7

6

5

4

3

1

2

13

14

10

5.5.1 Connection diagram

Assembly and installation 5

1 Temperature sensor of the ribbed pipe heat exchanger

2 Temperature sensor after the plate heat exchanger

3 Coolant circuit pressure switch

4 Compressor inlet temperature sensor

5 Compressor outlet temperature sensor

0020154078_03 Envirosorb₃ Installation instructions 19

6 Coolant circuit temperature sensor

7 Heat pump heating flow temperature sensor

8 Heat pump heating return temperature sensor

9 Air inlet temperature sensor

10 Electronic expansion valve

Page 20

5 Assembly and installation

11 Main PCB

12 Coding resistance

13 Diagnosis software connection

14 Fan 1

15 Fan 2 (with 15 kW only)

16 Fan PCB

17 Crankcase heating

18 Drain pan electrical heating rod

19 LED status display

20 Heating circuit high-efficiency pump with flow sensor

21 4-way valve

22 PCB installation

23 Rotary piston compressor

24 Inverter box

25 Temperature sensor for ribbed pipe heat exchanger

20 Installation instructions Envirosorb₃ 0020154078_03

Page 21

Start-up 6

A

B

10mm

2

1

3

4

6 Start-up

6.1 Run the start-up

1. Before starting up the product, read through the operating instructions.

2. Check that the electrical partition is installed.

3. Check that the hydraulic and electric connections are

correctly designed.

4. Check that a dirt filter is installed in the heat pump return.

5. Check whether an expansion relief valve, an expansion

vessel and a pressure gauge are installed.

6. Check the leak-tightness of the connections.

7. Open all the heating circuit valves.

6.2 Filling the heating circuit

Note

We recommend using ethylene glycol with corrosion-inhibiting additives.

If no frost protection has been poured in, the

product will not be protected in the event of a

power cut when there is frost.

▶ To purge the heating circuit, open the purging valve by a

1/4 rotation (B) using an open-end spanner.

▶ Increase the operating pressure in the heat pump heat-

ing circuit.

– Operating pressure: 0.15 … 0.2 MPa (1.50

… 2.0 bar)

Note

The pressure level may fall in the first month

following start-up. It may also vary depending

on the outside temperature.

Conditions: If you are using glycol

▶ The glycol must not escape into the outflow or the envir-

onment.

▶ Prepare a mixture with suitable glycol (max. 50% ethyl-

ene glycol) in order to protect the heat pump against

frost according to the regional minimum temperatures.

Note

If no frost protection has been poured in, the

product will not be protected in the event of a

power cut when there is frost.

Conditions: SW10 open-end spanner

1 Heating circuit purging

valve

2 Open-end spanner (on-

site)

3 Hose

4 Collecting container (on-

site)

▶ To purge the heating circuit during the filling procedure,

use a filling pump.

▶ Connect one end of the hose (3) to the drain valve.

▶ When purging, insert the other end of the hose (3) into

the mixing container (4).

▶ Open the filling valve using an open-end spanner (2).

▶ Use a frost protection tester to ensure the correct

dosage.

6.3 Treating the heating water

Caution.

Risk of material damage if the heating

water is treated with unsuitable frost and

corrosion protection agents.

Frost and corrosion protection agents may

cause changes in the seals, noises during

heating and may lead to further damage.

▶ Do not use any unsuitable frost and corro-

sion protection agents.

Mixing additives with the heating water may result in material

damage. However, no incompatibility with the units has been

detected to date with proper use of the following products.

▶ When using additives, follow the manufacturer's instruc-

tions without exception.

Note

Glow worm accepts no liability with respect to

the compatibility of any additive in the rest of

the heating system or its effectiveness.

Additives for cleaning measures (subsequent

flushing required)

– Fernox F3

– Sentinel X 300

– Sentinel X 400

Additives intended to remain permanently in the

system

– Fernox F1

0020154078_03 Envirosorb₃ Installation instructions 21

Page 22

6 Start-up

– Fernox F2

– Sentinel X 100

– Sentinel X 200

Additives for frost protection intended to remain

permanently in the system

– Fernox HP 15 or HP15c

– Sentinel X 500

▶ Inform the operator about the measures required if you

have used these additives.

▶ Inform the operator about the measures required for frost

protection.

Permissible water hardness

Note

Contact the local water supply company for further

information on water quality.

▶ Observe all applicable national regulations and technical

standards when treating the filling and supplementary

water.

Provided the national regulations and technical standards

do not stipulate more stringent requirements, the following

applies:

You must treat the heating water in the following cases:

– If the entire filling and supplementary water volume dur-

ing the operating life of the system exceeds three times

the nominal volume of the heating installation,

– If the limit values shown in the following tables are not

observed.

Total heating

output

kW

< 50

> 50 to 200 2 (200) 1,5 (150) 0,02 (2,0)

1) Of the specific system volume (nominal capacity in

litres/heating output; on systems with more than one boiler, the

lowest individual heating output must be set). These values only

apply up to three times the system volume for filling and supplementary water. If three times the system volume is exceeded,

the water must be treated in accordance with the specifications

from the VDI (softening, desalting, hardness stabilisation or

blowing down). This is exactly the same as if the limit values in

the table were exceeded

2) On systems with circulation water heaters and for systems

with electric heating elements

Permissible salt content

Heating water characteristics

Electrical conductivity

at 25 °C

Appearance —

Total hardness at smallest boiler heating

1)

surface

20 l/kW

mol/m³ (mg/l

CaCO₃)

No requirement

< 32)(3002))

Unit Low-salt Saline

μS/cm < 100 100 … 1,500

> 20 l/kW

< 50 l/kW

mol/m³ (mg/l

CaCO₃)

2 (200) 0,02 (2,0)

Free of sedimentary materials

> 50 l/kW

mol/m³ (mg/l

CaCO₃)

Heating water characteristics

pH value at 25 °C —

Oxygen mg/l < 0.1 < 0.02

Unit Low-salt Saline

8,2 … 10,01)8,2 … 10,0

1)

6.4 Filling the heating installation

Caution.

Risk of material damage due to heating

water that is extremely calciferous or corrosive or contaminated by chemicals.

Unsuitable tap water damages the seals

and diaphragms, blocks components in the

product and heating installation through

which the water flows and causes noise.

▶ Only fill the heating installation with suit-

able heating water.

Note

If a heat exchanger module is used, the heating

circuit must be topped up with heating water.

Conditions: System separation with a heat exchanger module

▶ Connect the filling cock with the heating water supply

using a cold water valve where possible.

▶ Open all radiator valves (thermostatic radiator valves) of

the heating installation.

▶ Open the cold water valve.

▶ Slowly open the filling cock.

▶ Fill it with water until the required filling pressure is

reached.

▶ Close the cold water valve.

▶ Purge all radiators.

▶ Then check the filling pressure on the display.

▶ Top up with more water if necessary.

▶ Close the filling cock.

6.5 Activating the heat pump

1. Ensure the maximum flow temperature setting matches

the heating installation.

2. To fully activate the heating installation, observe the

installation instructions for the system controller.

3. Switch on the line protection switch in the fuse box

which is connected to the heat pump.

6.6 Checking the product's operation

1. Ensure that the external control equipment (thermostats, external sensors, etc.) are sending a heating

demand to the heat pump. When configuring several

areas, test heating circuit by heating circuit and ensure

that the appropriate heating circuit gets warmer.

2. Ensure that all heating circuit thermostatic radiator

valves are open.

3. If necessary, balance the heat generator.

22 Installation instructions Envirosorb₃ 0020154078_03

Page 23

Start-up 6

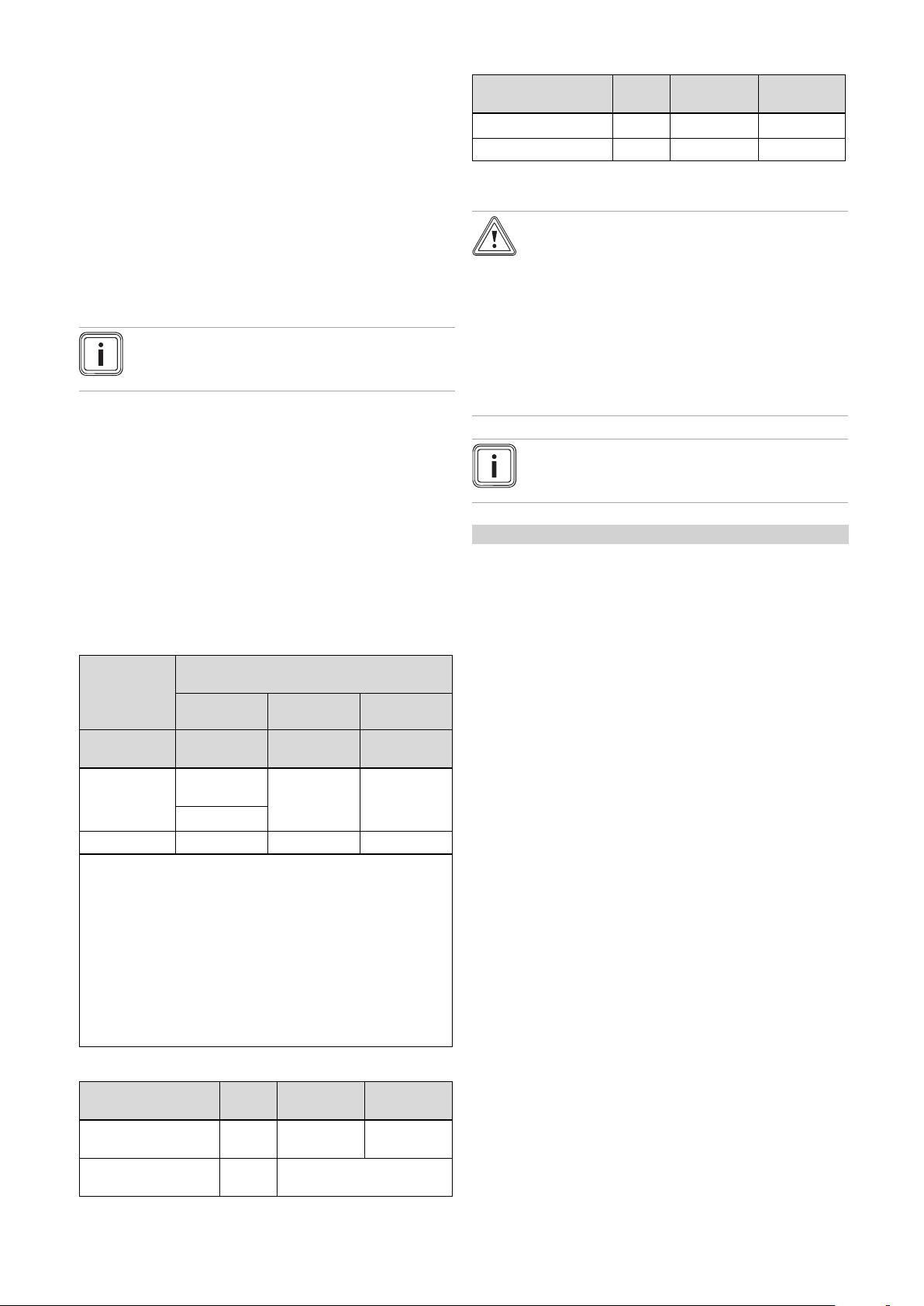

"Hhmmm..." (*)

"Ttsheeh...!"

"Eeee..."

“Clink!"

"Chug, chug,

chug,..."

"Whirr..." (*)

1

2

3

4

5

6

A

B

0

10

20

30

40

50

60

70

80

5000 1000 1500 2000

C

100

200

300

400

500

600

700

800

90 900

2500

3

2

1

4

6.7 Operating noises

– Operating pressure: 0.15 … 0.2 MPa (1.50

… 2.0 bar)

▶ Open the service valves on the back of the product.

▶ Remove the hose and the mixing container.

6.8.1.1 Available pressure in the heat pump heating circuit

1 Envirosorb35 (water tem-

perature 20 °C)

2 Envirosorb38 (water tem-

perature 20 °C)

3 Envirosorb311 (water

temperature 20 °C)

4 Envirosorb315 (water

temperature 20 °C)

A Remaining feed head

(kPa)

B Flow rate (l/h)

C Remaining feed head

[mbar]

* Permanent operating

noises

The noises listed do not constitute a fault with the heat

pump.

In various operating modes, the noises come from the heat

pump (Start, Thawing, Stop).

6.8 Adjusting the heating circuit

6.8.1 Purging the heating circuit

Conditions: SW14 open-end spanner

▶ Connect one end of the hose to the purging valve.

▶ In order to collect the residual glycol when purging the

heating circuit, insert the other end of the hose into the

mixing container.

▶ Close the stop valves on the back of the product.

▶ Increase the pressure in the heating circuit.

▶ Open the purging valve with an open-end spanner.

▶ Open the lower stop valve on the back of the product.

▶ If liquid escapes from the pipe, close the purging valve.

▶ Check the pressure in the heating circuit. If necessary,

increase it.

0020154078_03 Envirosorb₃ Installation instructions 23

6.8.2 Adjusting the heating circuit flow rate

Caution.

Risk of material damage due to frost

If the minimum flow rate is too low, the heat

exchanger may become damaged by frost.

▶ Operate the product with a sufficient flow

rate (see table).

The product is designed for operation between the minimum

flow rate and maximum flow rate, as specified in the table. If

the product is operated with the minimum flow rate, this results in a loss of energy and efficiency. The heating comfort is

still guaranteed but the energy savings are reduced.

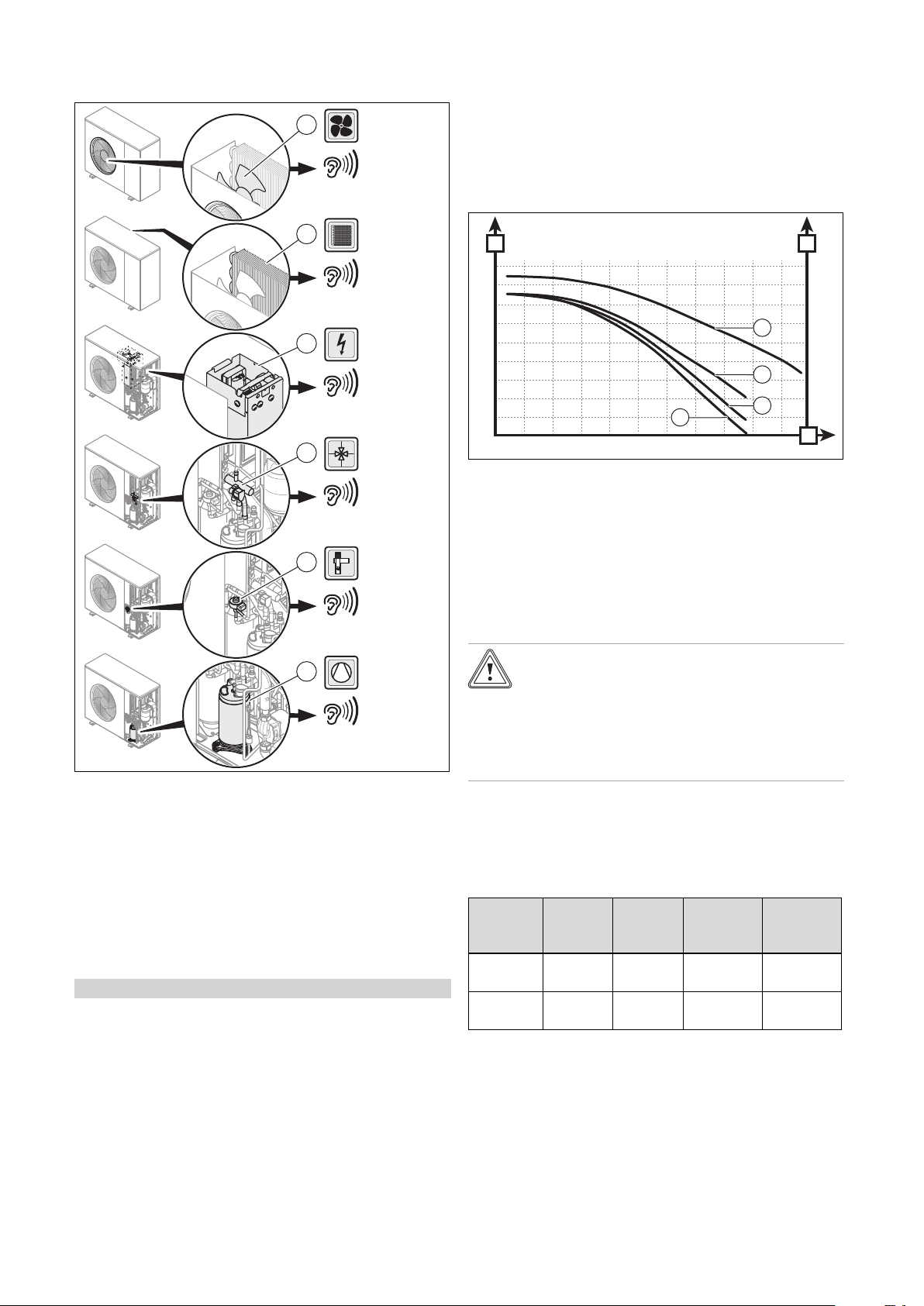

Envirosorb

5

Minimum

flow rate

Maximum

flow rate

380 l/h 380 l/h 540 l/h 1,200 l/h

860 l/h 1,400 l/h 1,900 l/h 2,590 l/h

You can read the flow rate directly from the controller. Depending on the type of liquid in the heating circuit, the flow

rate displayed on the controller may be exaggerated.

Example: If you use a 30% mixture of propylene glycol and

the liquid temperature is 5 °C, you must subtract 400 l/h from

the value shown on the display.

▶ Use the following table to compare the various exaggera-

tion flow rate values depending on liquid type.

– Applies for: Envirosorb35,

3

Envirosorb

8

3

Envirosorb

11

3

Envirosorb

15

3

Page 24

7 Maintenance

C

C

B

A

Envirosorb38,

Envirosorb311

Flow rate increase (l/h) Temper-

ature

5 °C

Water 0 0 0

60% alcohol 0 0 0

Liquid

type

30% propylene

glycol

50% propylene

glycol

30% ethylene

glycol

50% ethylene

glycol

400 240 120

650 500 400

120 0 0

400 140 50

– Applies for: Envirosorb315

Flow rate increase (l/h) Temper-

ature

5 °C

Water 0 0 0

60% alcohol 0 0 0

Liquid

type

30% propylene

glycol

50% propylene

glycol

30% ethylene

glycol

50% ethylene

glycol

600 440 280

1050 740 580

520 350 300

880 680 540

Note

Insufficient purging may lead to deviations in the

flow rate.

Temperature

15 °C

Temperature

15 °C

6.9 Installing the side cladding

Temperature

25 °C

Temperature

25 °C

▶ Install the side cladding.

6.10 Instructing the operator

1. Explain the how the system operates to the operator.

2. Draw particular attention to the safety information,

which the operator must follow.

3. Make the operator aware of the need for regular maintenance (maintenance contract).

4. Explain to the operator how to check the system's water

volume/filling pressure.

7 Maintenance

▶ If you cannot reach the minimum flow rate, install an ad-

ditional pump.

▶ If you cannot reach the recommended flow rate, adjust

the heating circuit pressure on the controller and, if necessary, use a bypass valve (item 50).

7.1 Observing maintenance intervals

1. Only carry out maintenance work if you are a competent

person.

2. Carry out annual maintenance.

7.2 Preparing for maintenance

7.2.1 Procuring spare parts

The original components of the product were also certified

as part of the CE declaration of conformity. Information about

available original spare parts is available by contacting the

contact address provided on the reverse of this document.

▶ If you require spare parts for maintenance or repair work,

use only original spare parts.

24 Installation instructions Envirosorb₃ 0020154078_03

Page 25

Maintenance 7

3

4

5

3.

6.

5.

1

2

7.3 Instructions before carrying out maintenance work

Observe the basic safety rules before carrying out maintenance work or installing spare parts.

Danger!

Risk of injury due to unauthorised access

to the coolant circuit.

Escaping coolant may cause freezing if the

exit point is touched.

▶ Only carry out work on the coolant circuit if

you have been trained to do so and if you

have the required protective clothing.

▶ Avoid skin and eye contact with the

coolant.

▶ Switch the system off.

▶ Disconnect the system from the power supply.

▶ Where necessary, disconnect the heating circuit from the

product by using the stop valves.

▶ If you have to replace parts on the heating circuit, you

must first drain the product.

▶ When working on the product, protect all electric com-

ponents from spray water.

7.5 Cleaning the product

7.5.1 Cleaning the front

Warning.

Risk of injury due to sharp-edged casing.

The product's casing sections have sharp

edges.

▶ Wear gloves when installing or dismant-

ling the product's casing sections.

7.4 Yearly maintenance

▶ Check that the safety devices are functioning properly.

▶ Check the heating circuit's fill pressure.

▶ Ensure that there are no traces of rust or oil on the

coolant circuit components.

▶ Ensure that the product components are neither worn nor

defective.

▶ Check that all wires sit securely in the connectors.

▶ Check the product's earthing.

▶ Check the heating pump's flow temperature and the set-

tings.

▶ Remove any dust from the electronics box and the in-

verter box.

▶ Clean the ribbed pipe heat exchanger and ensure that air

circulates between the fins and around the product.

▶ Check that the fan rotates freely.

▶ Check that condensate can escape freely from the heat

pump by removing the adaptor underneath the heat

pump.

▶ Clean the product as described in the operating instruc-

tions.

▶ Check that the vibration dampers are correctly seated on

the coolant lines.

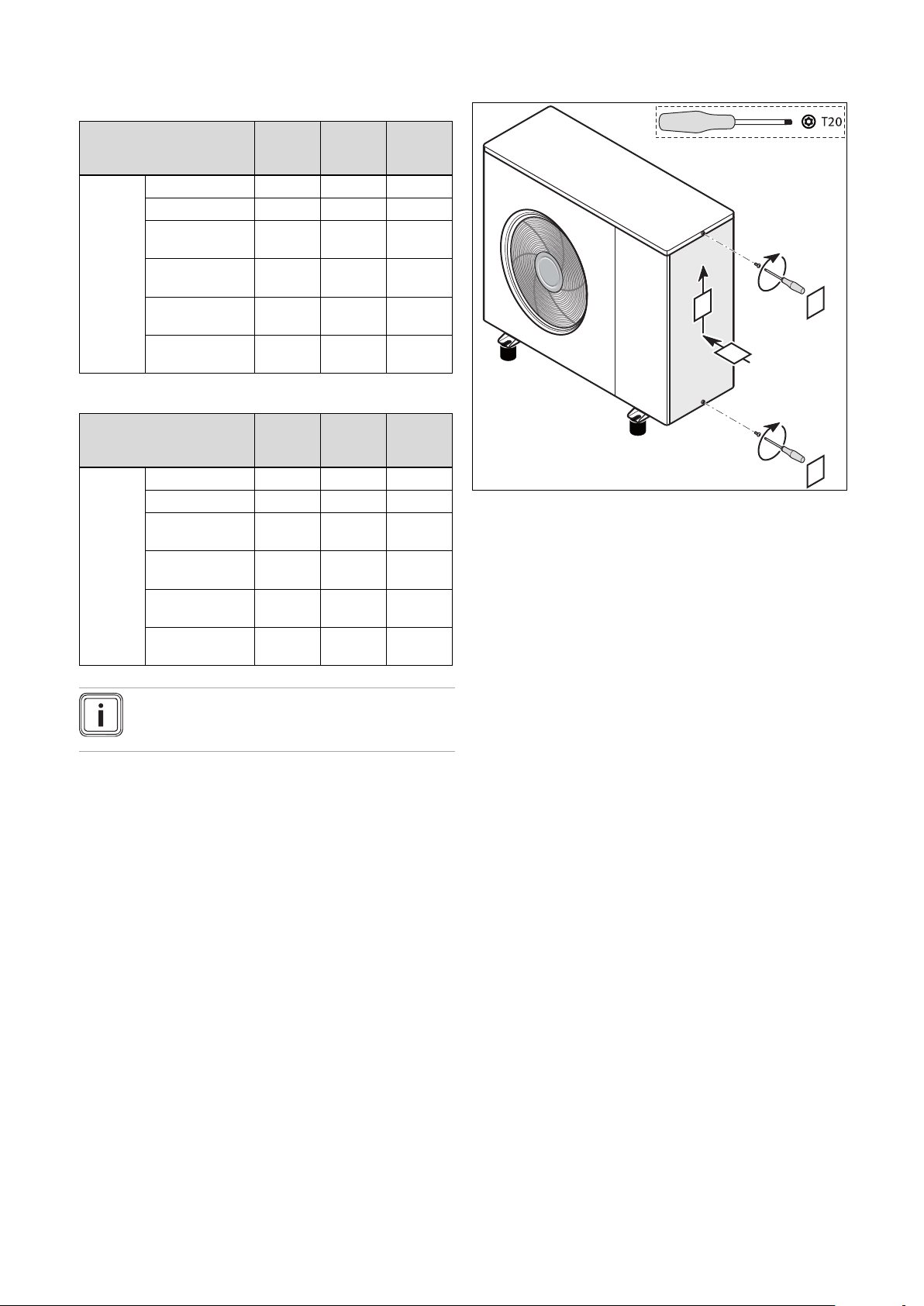

1. Remove the side casing. (→ Page 14)

2. Remove both screws (1).

3. Lift off the cover.

4. Remove both screws (2) on the right front casing.

5. Remove the right front casing.

6. Lift the louvred grill (3) upwards.

7. Remover the fan grill casing (4).

8. Remove the nut (5) from the fan.

9. Remove the fan.

10. Clean the product and the ribbed pipe heat exchanger.

7.5.2 Cleaning the back

Warning.

Risk of injury due to sharp-edged casing.

The product's casing sections have sharp

edges.

▶ Wear gloves when installing or dismant-

ling the product's casing sections.

0020154078_03 Envirosorb₃ Installation instructions 25

Page 26

8 Troubleshooting

1

2

3

10mm

2

1

Note

If necessary, you can drain the heating

installation using this drain cock by opening

the stop valves on the back of the heat

pump.

7.7 Checking the product's status codes

You can check the product's status codes at any time to see

which operating condition the heat pump is in. These codes

can be read on the system's control module.

The status codes are described in the table in the appendix.

7.8 Checking the electrical installation

▶ Check the electrical installation and take all relevant dir-

ectives into account.

Checking the cable

If the product's mains power cable is damaged, then, in order

to avoid danger, only the manufacturer, the Customer Service team or a similarly qualified person should replace the

mains power cable.

▶ To replace the mains power cable, see Carrying out the

electrical installation (→ Page 17).

1. Remove the side casing. (→ Page 14)

2. Remove both screws (1).

3. Lift off the cover.

4. Remove the four screws (2) and remove the mesh (3).

5. Clean the product.

7.6 Draining the product

Conditions: SW10 open-end spanner

▶ Disconnect the product from the power supply.

1 Heating circuit drain cock 2 Drain hose

1. Close the stop valves on the back of the heat pump.

2. To drain the heating circuit, connect a hose to the drain

cock or place a vessel underneath the drain cock.

3. Open the drain cock with an open-end spanner.

7.9 Start-up following maintenance

1. After the maintenance work has been completed, start

up the product – see Start-up (→ Page 21).

2. If you have carried out work on load-bearing parts,

check that they are securely fitted.

3. When you have completed work on the product, carry

out an operational and safety test.

8 Troubleshooting

8.1 Troubleshooting

You should carry out the following tests before introducing

additional steps:

▶ Make absolutely sure that the power supply was not cut

and that the product is correctly connected.

▶ Ensure that the service valves are open.

▶ Check that all external controllers are correctly connec-

ted.

8.2 Fault codes

The fault codes are described in a table in the Appendix.

Fault codes (→ Page 36)

In the event of a fault, a fault code number is shown in the

controller's display.

▶ Carry out all necessary repairs.

▶ Switch the product on/off using the partition.

26 Installation instructions Envirosorb₃ 0020154078_03

Page 27

9 Decommissioning

9.1 Temporary decommissioning

1. Switch the product off.

2. Disconnect the product from the power supply.

9.2 Permanently decommissioning

1. Switch the product off.

2. Disconnect the product from the power supply.

3. Drain the product. (→ Page 26)

4. Dispose of or recycle the product and its components.

10 Customer service

For contact details for our customer service department, you

can write to the address that is provided on the back page,

or you can visit www.glow-worm.co.uk.

11 Disposal

Decommissioning 9

11.1 Recycling and disposal

▶ The competent person who installed your product is re-

sponsible for the disposal of the packaging.

If the product or any batteries that it contains are

marked with this symbol, they contain substances hazardous

to human health and to the environment.

▶ In this case, do not dispose of the product and any bat-

teries that it contains with your normal household waste.

▶ Instead, bring the product and any batteries to a collec-

tion centre for batteries and electrical or electronic appliances.

11.2 Arranging disposal of coolant

Warning.

Risk of damage to the environment.

This heat pump contains R 410 A coolant.

The coolant must not be allowed to escape

into the atmosphere. R 410 A is a fluorinated

greenhouse gas covered by the Kyoto Protocol, with a GWP of 1725 (GWP = Global

Warming Potential).

▶ Before the product is disposed of, have

the coolant which it contains completely

drained into a suitable vessel so that it

can then be recycled or disposed of in

accordance with regulations.

The competent person who installed the heat pump must

dispose of the coolant.

Personnel who are approved for energy recovery must have

the relevant certification that corresponds to the valid regulations.

0020154078_03 Envirosorb₃ Installation instructions 27

Page 28

Appendix

PZHH

-

TI

-

TCE

TI

-

TI

-

PT

-

TI

-

TI

-

TI

-

TI

-

7

9

8

23

22

18

15

16

17

14

12

6

1

4

5

13

19

21

24

10

25

11

20+

2

3

Appendix

A Heat pump schematic

A.1 Heat pump schematic drawing (Envirosorb35)

1 Flow heating circuit temperature sensor

2 Return heating circuit temperature sensor

3 High-efficiency pump with flow sensor

4 Expansion vessel

5 Drain valve

6 Purging valve

7 Fan

8 Air inlet temperature sensor

9 Ribbed pipe heat exchanger

10 Temperature sensor of the ribbed pipe heat exchanger

11 4-way valve

12 Plate heat exchanger

13 Temperature sensor after the plate heat exchanger

14 Service valve for the high-pressure range of the coolant

circuit

15 High-pressure pressure switch in the coolant circuit

16 High-pressure sensor in the coolant circuit

17 Compressor outlet temperature sensor

18 Rotary piston compressor

19 Filter

20 Liquid separator

21 Electronic expansion valve

22 Compressor inlet temperature sensor

23 Service valve for the low-pressure range of the coolant

circuit

24 Filter

25 Fluid collector

28 Installation instructions Envirosorb₃ 0020154078_03

Page 29

A.2 Heat pump schematic drawing (Envirosorb38)

PZHH

-

TI

-

TCE

TI

-

TI

-

PT

-

TI

-

TI

-

TI

-

TI

-

7

9

8

23

22

18

15

16

17

14

12

6

1

4

5

13

19

21

24

10

25

11

20+

2

26

3

Appendix

1 Flow heating circuit temperature sensor

2 Return heating circuit temperature sensor

3 High-efficiency pump with flow sensor

4 Expansion vessel

5 Drain valve

6 Purging valve

7 Fan

8 Air inlet temperature sensor

9 Ribbed pipe heat exchanger

10 Temperature sensor of the ribbed pipe heat exchanger

11 4-way valve

12 Plate heat exchanger

13 Temperature sensor after the plate heat exchanger

14 Service valve for the high-pressure range of the coolant

circuit

15 High-pressure pressure switch in the coolant circuit

16 High-pressure sensor in the coolant circuit

17 Compressor outlet temperature sensor

18 Rotary piston compressor

19 Filter

20 Liquid separator

21 Electronic expansion valve

22 Compressor inlet temperature sensor

23 Service valve for the low-pressure range of the coolant

circuit

24 Filter

25 Gas buffer

26 Flow rate limiter (cooling mode)

0020154078_03 Envirosorb₃ Installation instructions 29

Page 30

Appendix

PZHH

-

TI

-

TCE

TI

-

TI

-

PT

-

TI

-

TI

-

TI

-

TI

-

7

9

8

23

22

18

15

16

17

14

12

6

1

4

5

13

19

21

24

10

25

11

20+

2

3

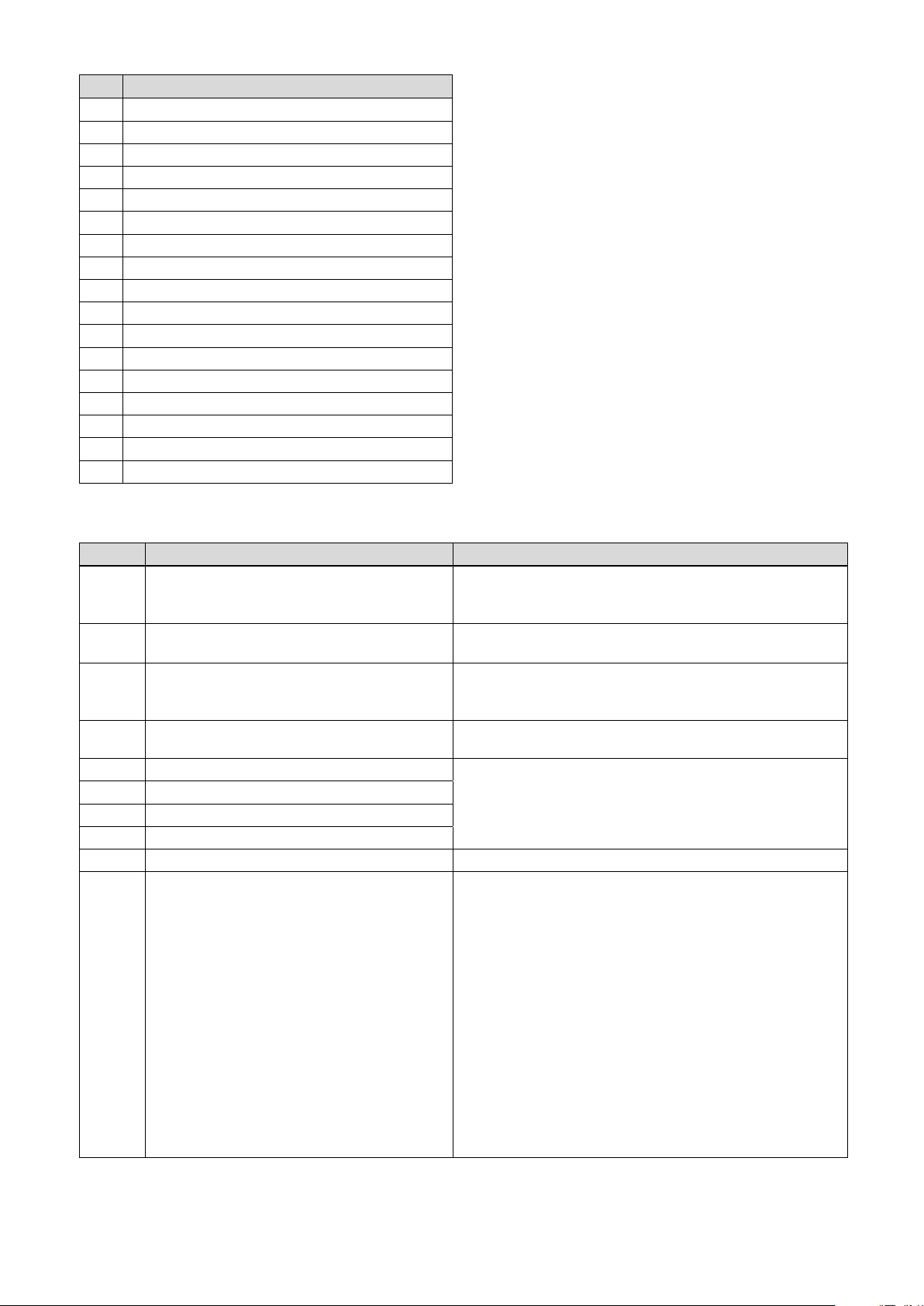

A.3 Heat pump schematic drawing (Envirosorb311)

1 Flow heating circuit temperature sensor

2 Return heating circuit temperature sensor

3 High-efficiency pump with flow sensor

4 Expansion vessel

5 Drain valve

6 Purging valve

7 Fan

8 Air inlet temperature sensor

9 Ribbed pipe heat exchanger

10 Temperature sensor of the ribbed pipe heat exchanger

11 4-way valve

12 Plate heat exchanger

13 Temperature sensor after the plate heat exchanger

14 Service valve for the high-pressure range of the coolant

circuit

15 High-pressure pressure switch in the coolant circuit

16 High-pressure sensor in the coolant circuit

17 Compressor outlet temperature sensor

18 Rotary piston compressor

19 Filter

20 Liquid separator

21 Electronic expansion valve

22 Compressor inlet temperature sensor

23 Service valve for the low-pressure range of the coolant

circuit

24 Filter

25 Gas buffer

30 Installation instructions Envirosorb₃ 0020154078_03

Page 31

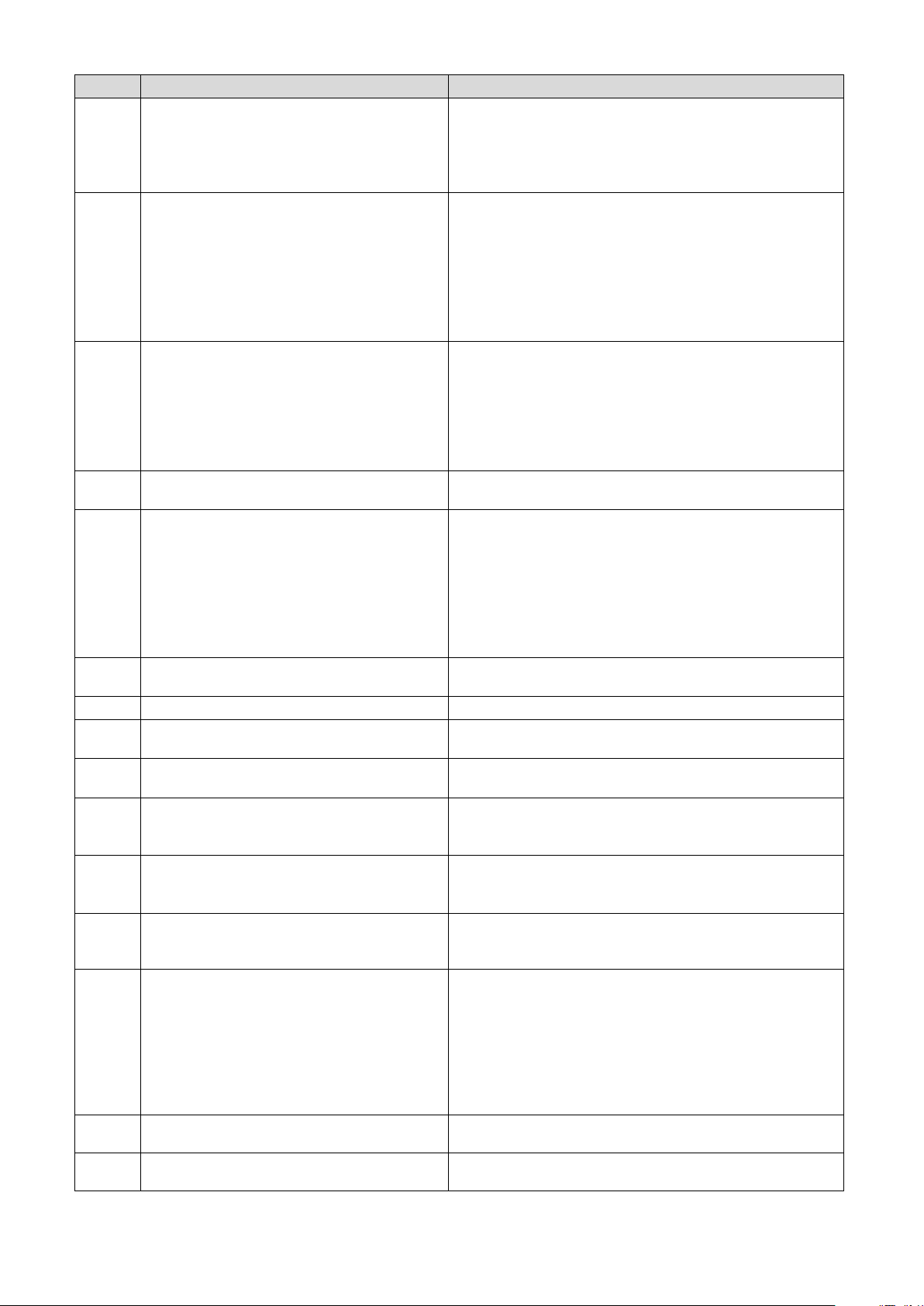

A.4 Heat pump schematic drawing (Envirosorb315)

PZHH

-

TI

-

TCE

TI

-

TI

-

PT

-

TI

-

TI

-

TI

-

TI

-

7

9

8

23

22

18

15

16

17

14

12

6

1

3

4

5

13

19

21

24

10

25

11

20+

2

Appendix

1 Flow heating circuit temperature sensor

2 Return heating circuit temperature sensor

3 High-efficiency pump with flow sensor

4 Expansion vessel

5 Drain valve

6 Purging valve

7 Fan

8 Air inlet temperature sensor

9 Ribbed pipe heat exchanger

10 Temperature sensor of the ribbed pipe heat exchanger

11 4-way valve

12 Plate heat exchanger

13 Temperature sensor after the plate heat exchanger

B Heat pump setting parameters

Note

If repairs are carried out on the heat pump electronics (e.g. replacing the PCB), you must reset the parameters.

14 Service valve for the high-pressure range of the coolant

circuit

15 High-pressure pressure switch in the coolant circuit

16 High-pressure sensor in the coolant circuit

17 Compressor outlet temperature sensor

18 Rotary piston compressor

19 Filter

20 Liquid separator

21 Electronic expansion valve

22 Compressor inlet temperature sensor

23 Service valve for the low-pressure range of the coolant

circuit

24 Filter

25 Gas buffer

0020154078_03 Envirosorb₃ Installation instructions 31

Page 32

Appendix

Parameter Explanation Default

setting

Language Select the required language here. 02 English 01 Deutsch

Contact

details

Max. remaining heating

circuit feed

head

Max. remaining hot water

feed head

As a competent person, you can enter your telephone number here. The end customer can read this number in the

menu → Information.

Limiting the remaining heating circuit feed head. If the value

is reduced, the pump speed is reduced as far as necessary

in order to prevent the remaining feed head from being

exceeded.

Limiting the remaining hot water circuit feed head. If the

value is reduced, the pump speed is reduced as far as necessary in order to prevent the remaining feed head from

being exceeded.

Maximum

value

Maximum

value

Adjustment

range

02 English

03 Français

04 Italiano

05 Dansk

07 Castellano

08 Türkçe

09 Magyar

11 Українська

15 Svenska

16 Norsk

18 Čeština

19 Hrvatski

20 Slovenčina

22 Slovenščina

≥ 100 mbar

≥ 100 mbar

Own setting

C Technical data

Note

The following performance data is only applicable to new products with clean heat exchangers.

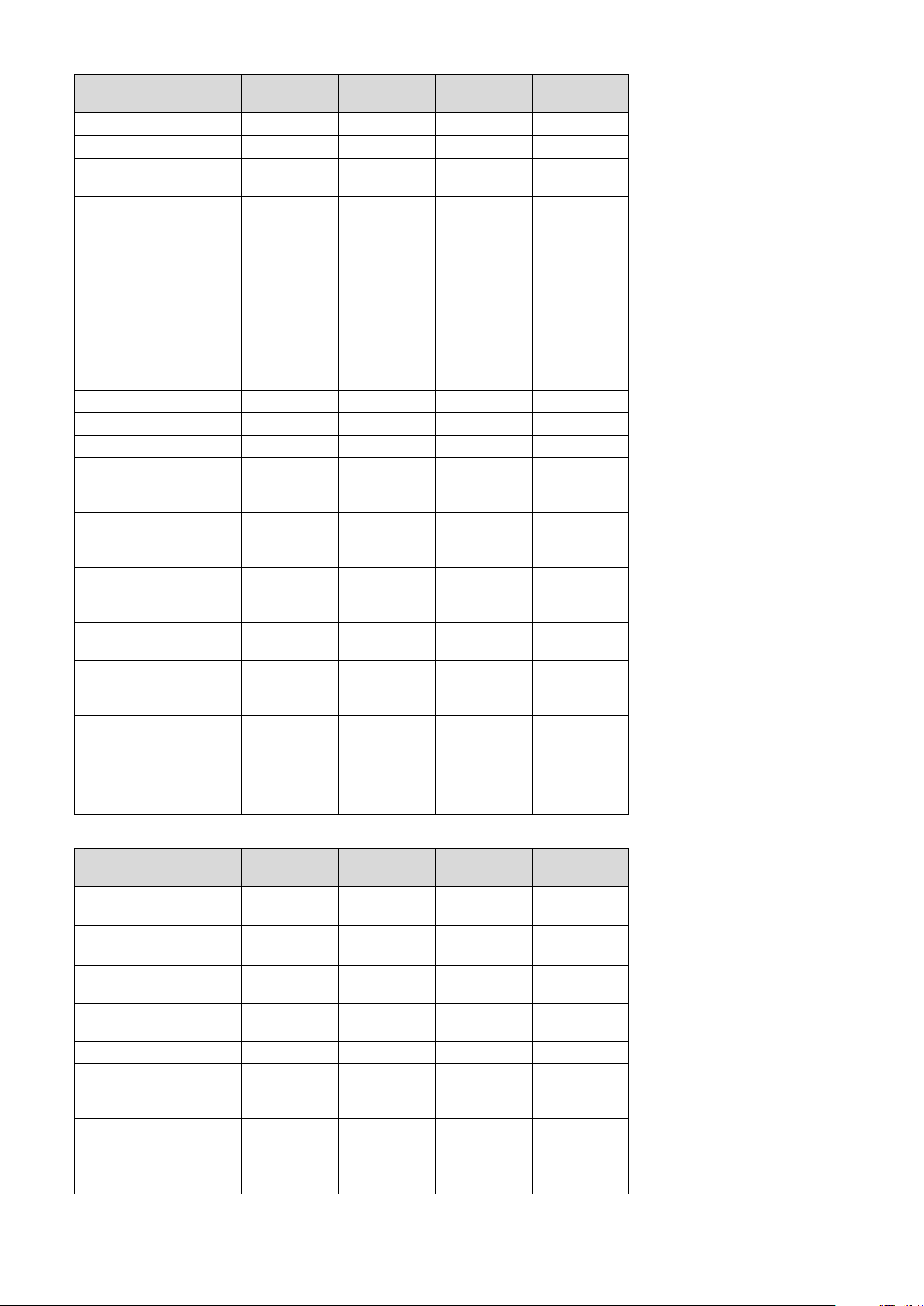

Technical data – General

Heat pump type

Flow/return heating connections, boiler side

Product dimensions,

width

Product dimensions,

height

Product dimensions,

depth

Net weight

Hydraulic lines material

Hydraulic connections

material

Hydraulic seals material

Plate heat exchanger material

Pump casing material

Pollution rating

Envirosorb35 Envirosorb38 Envirosorb

11-1 ph

Monoblock

air/water heat

pump

1 1/4" 1 1/4" 1 1/4" 1 1/4"

980 mm 1,103 mm 1,103 mm 1,103 mm

800 mm 942 mm 942 mm 1,340 mm

360 mm 415 mm 415 mm 415 mm

90 kg 106 kg 126 kg 165 kg

Copper Copper Copper Copper

Brass Brass Brass Brass

EPDM EPDM EPDM EPDM

AISI 304

stainless steel

Painted cast

iron

2 2 2 2

Monoblock

air/water heat

pump

AISI 304

stainless steel

Painted cast

iron

Monoblock

air/water heat

pump

AISI 304

stainless steel

Painted cast

iron

Envirosorb

3

Monoblock

air/water heat

stainless steel

Painted cast

15-1 ph

AISI 304

3

pump

iron

32 Installation instructions Envirosorb₃ 0020154078_03

Page 33

Appendix

Electric connection

Fuse type

Inverter controller fuse

Level of protection

Maximum start-up current

Maximum current consumption

Pump power consumption

Fan power consumption

Electrical classification

Overvoltage category

Fan rotational speed

Sound power level for

A7W35 according to EN

12102 and EN ISO 9614-1

Sound power level for

A7W45 according to EN

12102 and EN ISO 9614-1

Sound power level for

A7W55 according to EN

12102 and EN ISO 9614-1

Maximum cylinder temperature

Minimum air temperature

(heating and cylinder

charging)

Maximum air temperature

(heating)

Maximum air temperature

(hot water generation)

Max. air flow

Envirosorb35 Envirosorb38 Envirosorb

11-1 ph

3

Envirosorb

15-1 ph

230 V/50 Hz 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz

T4A T4A T4A T4A

HRC 20 A 550VHRC 20 A 550VHRC 32 A 550VHRC 32 A 550

V

IP 25 IP 25 IP 25 IP 25

16 A 16 A 20 A 25 A

16 A 16 A 20 A 25 A

15 … 70 W 15 … 70 W 15 … 70 W 6 … 87 W

15 … 42 W 15 … 42 W 15 … 76 W 15 … 76 W

Note

2 x

I I I I

II II II II

550 rpm 550 rpm 675 rpm 600 rpm

58 dB(A) 60 dB(A) 65 dB(A) 65 dB(A)

59 dB(A) 60 dB(A) 65 dB(A) 65 dB(A)

61 dB(A) 61 dB(A) 66 dB(A) 66 dB(A)

60 ℃ 63 ℃ 63 ℃ 63 ℃

−15 ℃ −20 ℃ −20 ℃ −20 ℃

28 ℃ 28 ℃ 28 ℃ 28 ℃

46 ℃ 46 ℃ 46 ℃ 46 ℃

2,000 m³/h 2,700 m³/h 3,400 m³/h 5,500 m³/h

3

Technical data – Heating circuit

Envirosorb35 Envirosorb38 Envirosorb

11-1 ph

Minimum operating pressure

Maximum operating pressure

Heating circuit water con-

0.1 MPa

(1.0 bar)

0.3 MPa