Page 1

User's manual Manual del usuario Manuel de l'utilisateur

Customer Service

Servicio de atención al Cliente

US: 1-800-645-2986

Manual Chain Hoist

Models: 241638, 241639, 241640, 241641, 241642, 241643, 241644, 241645

Capacity - 0.5, 1, 1.5, 2, 3, 5, 10, 20 Tonne

Read this manual thoroughly prior to

installation, operation or maintenance.

Keep these instructions in a safe

location for future reference. For

questions, visit globalindustrial.com

or contact Customer Service at 1-800645-2982.

US: 1-800-645-2986

Service à la clientèle

Canada: 888-645-2986

Table of Contents

1. TECHNICAL DATA.....................................................................................2

2. APPLICATION..............................................................................................2

3. SAFETY INSTRUCTION............................................................................2

4. OPERATION INSTRUCTION......................................................................3

5. INSPECTION & MAINTENANCE...............................................................4

6. EXPLODED VIEW & PARTS LIST..............................................................5

1

012921

Page 2

User's Manual

Manual Chain Hoist

THANK YOU VERY MUCH FOR SELECTING OUR MANUAL HOIST!

This instruction manual describes the correct operating method to ensure prolonged service life. Please read

and completely understand this manual before operating the Manual Hoist. Always keep this manual at an

appropriate place. If the manual or warning decal is missing, please contact your vendor.

NOTE: All information reported herein is based on the data available at the time of printing. The factory

reserves the right to modify its own products at any time without notice or incurring in any sanction. Please

verify with the factory for possible updates.

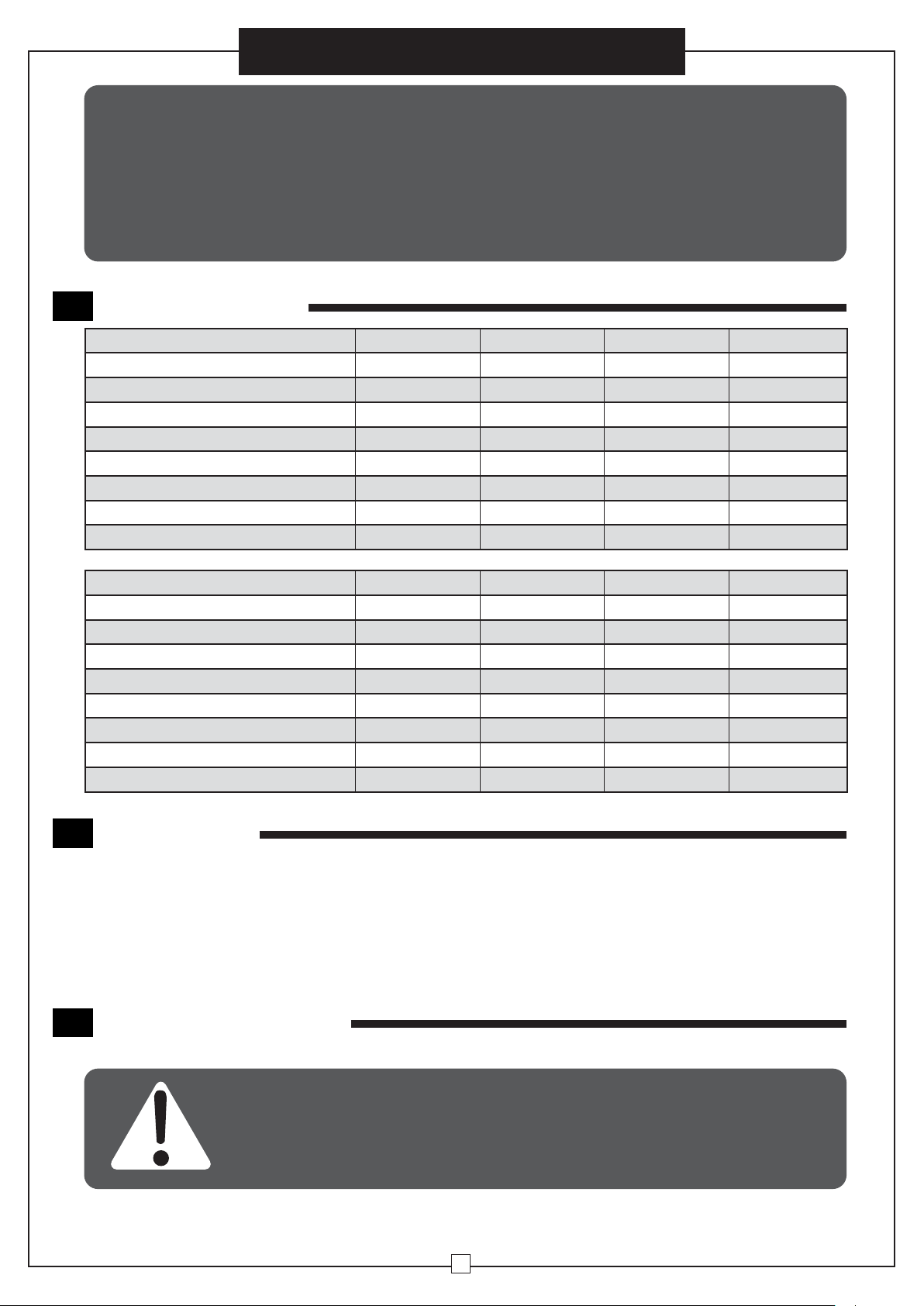

TECHNICAL DATA

1

Model

Lifting Capacity (tonne)

Standard Lift (m)

Testing Load (KN)

Head Room (mm)

Effort Force to Max. Load (N)

No. of Falls of Load Chain

Diameter of load Chain (mm)

Net Weight (kg)

Model

Lifting Capacity (tonne)

Standard Lift (m)

Testing Load (KN)

Head Room (mm)

Effort Force to Max. Load (N)

No. of Falls of Load Chain

Diameter of load Chain (mm)

Net Weight (kg)

241638 241642 241639 241643

1.0

3.0

12.5

300

310

1 1

Ø6 Ø6 Ø6

10

241640 241644 241641 241645

3

3.0

37.5

470

360

2 2

Ø8 Ø10 Ø10

21.7

1.0

12.5

300

310

14.9

3 5

6.0

37.5 62.5 62.5

470 600 600

360 400 400

Ø8

32.8

2.0

3.0 6.0

37.5

380

320

2

Ø6

13.5 21

3.0

2 2

35 50.6

2.0

6.0

37.5

380

320

6.0

2

5

APPLICATION

2

HCB Series Manual Hoist is a portable lifting device easily operated by hand chain. It is suitable for use in

factories, mines, farms, construction sites, wharves, docks and warehouses for installation of equipment, as

well as for loading and unloading goods. It is specially advantageous for lifting work in open air grounds and

places where no power supply is available.

The chain block can be attached to a trolley of any type as traveling chain block. It is suitable to monorail

overhead conveying system, hand traveling crane and jib crane.

SAFETY INSTRUCTION

3

WARNING Be sure each person reads and understands this manual before operating

or maintaining the hoist. The manual hoist must be properly operated and maintained

at all times. Do not operate this hoist with any power devices. The hoist is design for

manual operation.

2

Page 3

Manual Chain Hoist

• Do not exceed the rated load limit. Overloading may

cause hoist failure.

• Do not use power devices to operate the hoist, it is

designed for manual operation only.

• Do not attempt to repair the chain. Replace it with

new steel welded chain of the same size and strength.

• Lubricate the chain with good quality light oil or

chain oil before use.

• Do not lubricate the internal braking surfaces. The

brake must be kept dry.

• Make sure the load chain has no twists in the chain

sprocket, guide, and the vertical hanging length. If

there is a twist, disassemble and thread the chain

through the guide and chain sprocket.

• Make sure the load chain is attached to the loose

end pin before each use.

• Stand in the same plane or at the same angle as the

wheel when pulling the hand chain. Do not pull at an

oblique angle. Keep safe footing at all times.

• Do not lift loads over people. Do not allow anyone

to walk under the load. Warn personnel before lifting a

load.

• Do not use the hoist to lift people.

• Avoid off-center loading. Balance the weight evenly.

• Pull the hand chain steadily and smoothly to prevent

jerking or tangling.

• Seat the load firmly in the hook. Do not try to lift with

the tip of the hook.

• Do not wrap the chain around the load. Balance the

load weight evenly.

• Pull the lever handle steadily and smoothly to

prevent jerking or tangling.

• Raise the load only enough to clear the support

surface. Check for any malfunction or obstructions

before continuing the lift.

• If the chain jams or the lever handle cannot be pulled

any further, stop, inspect and correct the problem.

Do not try to force the hoist.

• Do not leave the load suspended in the air.

• Do not lower the load beyond the usable chain

length. Pulling the chain tight against the chain

sprocket will cause damage.

• Do not allow the load to contact the hoist. This will

block the swivel and may cause damage, twisted

chains, or a jammed wheel.

• Perform periodic inspection and maintenance.

Replace all damaged or malfunctioning parts.

• Test the hoist function thoroughly in both with

load or without load situation, before returning it to

normal operation.

• Do not touch the selector switch when the hoist is in

operation.

• Always lift./lower the load vertically.

OPERATION INSTRUCTION

4

4.1 To lift the load.

Pull the hand chain in a clockwise direction, rotating the

hand wheel in a clockwise direction. Pulling the hand chain

clockwise presses the friction plates and the ratchet disc

tightly against the brake seat, turning the drive shaft. The drive

shaft turns the spline gear, which transfers the rotation to the

disc gears, rotating the chain sprocket and smoothly moving

the load chain and hook upward.

4.2 Stopping the pull.

Stop the load movement and actuates the brake. The singleaction friction plates and ratchet disc press against the brake

seat, and pawl seats into the ratchet disc teeth.

Loose End Pin

Hand Chain

Load Chain

To lower hook

pull down on this

side of hand chain

Hand Chain

Load Chain

To raise hook

pull down on this

side of hand chain

4.3 To lower the load.

Pull the hand chain in a counterclockwise direction, rotating

the hand wheel releases the ratchet disc from the pawl,

allowing the friction plates and ratchet disc to separate from

the brake seat. The drive shaft turns the chain sprocket to

move the load hook downward.

3

Page 4

Manual Chain Hoist

5

INSPECTION & MAINTENANCE

5.1 Daily Maintenance

Hooks

1. Carefully inspect the hooks, and block attachments to the

hoist wheel and load chain.

2. Measure the hook throat openings. Replace if they are

stretched beyond the allowed maximum.

3. Inspect the hooks for distortion and stress cracks.

4. Make sure the hooks hang straight with a free swivel.

5. Inspect the hook latches for proper operation and

engagement. Do not use damaged or bent latches.

6. Replace all stretched, bent, or damaged parts. Lubricate the

attachments.

Chain

1. Examine the chain for adequate lubricant, excessive wear, foreign material, or twists before each use.

2. If the chain is twisted, rethread it through the sprocket and guides.

3. Lubricate the chain daily.

Brake

1. Check the brake operation for possible slippage before each use.

2. Keep the brakes dry. Do not allow oil or lubricant on the brake surfaces.

3. Repair or replace any damaged parts or worn friction discs.

Hoist

1. Inspect the chain sprocket and chain guides. Make sure the chain aligns properly.

2. Set the selector switch to neutral and pull the chain to make sure the chain and chain sprocket turn freely in both directions.

3. Lubricate the chain sprocket and guide rollers.

Opening

5.2 Annual Maintenance

WARNING To avoid injury or damage, allow only certified technicians to

disassemble and reassemble the hoist

Hooks

1. Carefully inspect the hooks, and block attachments to the hoist wheel and load chain.

2. Measure the hook throat openings. Replace if they are stretched beyond the allowed maximum.

3. Inspect the hooks for distortion and stress cracks.

4. Make sure the hooks hang straight with a free swivel.

5. Inspect the hook latches for proper operation and engagement. Do not use damaged or bent latches.

6. Replace all stretched, bent, or damaged parts. Lubricate the attachments.

Load Chain

1. Clean the chain with a neutral solvent and allow slack in the chain. Inspect the chain, link by link for nicks, gouges, or excessive

wear.

2. Pull the chain taut and measure throughout its length with a gauge, to identify twisted, bent or stretched links.

3. If any links are damaged, bent, stretched, or worn, replace the entire load chain with the same strength and type. DO NOT repair

the chain. The links are welded hardened steel and should not be individually repaired.

4. To replace the chain, thread the new chain through the chain sprocket and guide rollers, and attach to the loose end pin.

5. Lubricate the load chain thoroughly. Make sure the lubricant reaches the load bearing surfaces of the chain.

Hand Chain

1. Clean the hand chain and inspect for damage in the same manner as the load chain. Measure and gauge the total length to check

for stretched or bent links.

2. Cut damaged links from the chain. Purchase new unwelded connecting links. Do not use a cut chain link as a connector.

3. Connect the two end links with the new connector link, and close. If a connector link is opened and closed more than two times,

do not use it. Discard and use a new link.

Brake

1.

Inspect the brake components for glazing, wear, or lubricant on the friction discs. Check for scoring on the ratchet disc and brake seat.

2. Clean all brake parts with a neutral solvent. Make sure no lubricant is on any brake part. Keep the brake surfaces dry.

3. When replacing worn friction plates, discard to prevent re-use.

4

Page 5

Manual Chain Hoist

Ratchet and pawls

1. Inspect the ratchet teeth, pawls, pawl tips, and pawl studs. Check the springs for stretching, breaking, or corrosion.

2. Make sure the pawls move freely on the pawl studs. Lubricate the studs with WD-40

3. Look for signs of wear, or loose, broken, or missing parts. Replace and lubricate.

Chain sprocket and gears

1. Inspect the drive shaft, chain sprocket, gears, and roller bearings. Check for wear on all components.

2. Lubricate all threads, the chain sprocket, chain guides, gear train and all friction points.

3.

Use heavy grease at the gear train rotation points and rollers, to hold the parts while reassembling, and synchronize the gear timing.

4. Align the teeth of the two disk gears, the drive shaft and the splined gear, making sure the timing marks “0” of the disk gears are aligned

as shown.

5. After aligning the marks, place the end plate over the gear train and attach to the side plate.

Align

Timing

Marks "0"

CAUTION ! After internal maintenance and reassembly, test the hoist in load

and no-load conditions before returning to operation

6

EXPLODED VIEW & PARTS LIST

No. Description Qty. No. Description Qty.

1

Hand Wheel Cover 1

2

Hand Chain 1

3

Hand Wheel 1

4

Ratchet Disk 1

5

Friction Plate 2

6

Stripper 1

7

Brake Seat 1

8

Side Plate A 1

9

Bearing Race 2

10

Bearing Inner Ring 2

11

Chain Sprocket 1

12

Cylindrical Rollers A 60

13

Load Chain 1

14

Guide Roller 1

15

Pin 1

16

Stay A 1

17

Stay B 2

18

Splined Gear 1

19

Side Plate B 1

20

Disk Gear A Comb. 1

21

Cylindrical Roller B 48

22

Snap Ring 1

23

Driving Shaft 1

24

Gear Case 1

25

Disk Gear B Comb. 1

26

Sheet Cover 1

27

Label Set 1

28

Pawl Pin 1

29

Pawl Spring 1

30

Pawl 1

31

Snap Ring 2

32

Chain Pin 1

33

Latch Clamp 2

34

Bottom Hook Block 1

35

Hook 2

36

Top Hook Holder 1

37

Pinion Shaft 1

38

Slotted Nut 1

39

Split Pin 1

40

Headless Rivet 1

41

Spring 1

42

Stripper Pin 1

43

Spring Washer 1

44

Hex Nut 1

45

Hex Nut 1

46

Spring Washer 1

5

Loading...

Loading...