Page 1

Pallet Truck with Scale

Instruction Manual

globalindustrial.com

11 Harbor Park Drive Port Washington, NY 11050

globalindustrial.com

Page 2

Table of Contents

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Guide For Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . .4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Weighing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Battery Power Data and Replacement . . . . . . . . . . . . . .6

Pump and Axle Components Diagram . . . . . . . . . . . . . .7

Pump and Axle Components Parts List . . . . . . . . . . . . .8

Handle/Control Lever Diagram . . . . . . . . . . . . . . . . .9

Frame, Wheel and Display Components

Diagram and Parts List . . . . . . . . . . . . . . . . . . . . . . . .10

Assembly List, Charging,

Weighing Unit Troubleshooting . . . . . . . . . . . . . . . .11

globalindustrial.com 11 globalindustrial.com

9. CHARGING

A battery charger, sold as an accessory, for the hand pallet truck with scale allows

recharging. When the “low battery” indicator is displayed, the battery needs to be

charged. First turn off the indicator, and then insert the charging plug from the jack

of indicator case (F308) to one side, and connect the other side to AC power supply.

The charger will begin to charge. There are two LBD’s on the charger. The red LBD is

the pilot lamp for power signal and the green one is pilot lamp of charging signal.

These will continuously signal while the battery charges. When the battery is fully

charged, the green LBD light will go out. The charger will self-stop when battery is

fully charged.

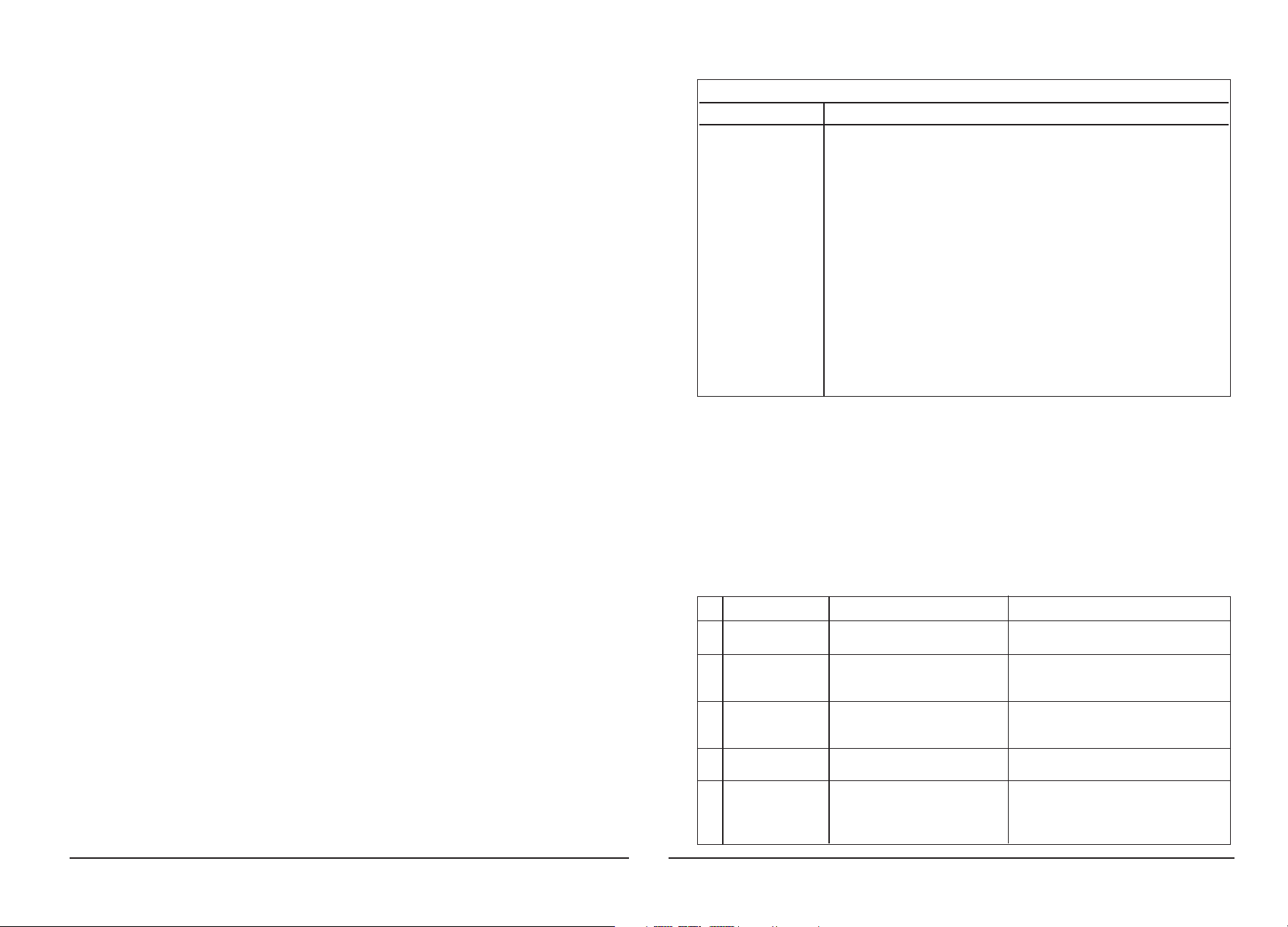

No. Problem Cause Solution

1 Data drift • Fastener or end of a thread in • Check the connection in junction box

junction box is loose or off. after confirming safe.

2 Indicator does • Battery voltage is low. • Charge battery.

not turn on. • Battery life is complete. • Replace rechargeable battery.

• Charging jack is damaged. • Replace charging jack.

3 Battery does • Battery is damaged. • Replace rechargeable battery.

not charge • Charger is damaged. • Check charger output voltage (17V~18V),

unbalanced loads. replace charger.

4 Scale displays EEE • Load is present on the fork. • Move the load and then turn on scale.

when turned on. • Check and replace parts.

5 Scale displays -EEE • Connection between sensor • Check the connection between sensor

when turned on. and junction box is loose or and junction box.

disconnected. • Replace sensor

• Sensor is damaged.

10. WEIGHING UNIT TROUBLESHOOTING

Assembly list

Assembly Description

AH Pump unit

B Lowering valve assembly

CH Lowering screw assembly

D Hydraulic valve assembly

E Handle seat assembly

F2 Polyurethane steering wheel assembly

G Handle assembly

H1B Polyurethane load roller assembly (tandem type)

H2B Polyurethane load roller assembly (single type)

I2 Tandem polyurethane load roller system assembly

L Rhombus plate assembly

M Spring cover assembly

N Pump piston assembly

W Safety valve assembly

SH *Seal kit

Page 3

globalindustrial.com 3 globalindustrial.com 10

Thank you for purchasing this pallet truck with scale. For safe and correct

operation, please carefully read this instruction manual before use.

NOTE: All of the information reported herein is based on data available at the

moment of printing. The factory reserves the right to modify its own products at any

moment without notice and incurring in any sanction. It is suggested to always verify

possible updates.

1. General Specifications

2. Attach Handle To Pump Unit

2.1 Loosen the setting screw (140) on the crank link (139H).

2.2 Remove three screws (H109) and three spring washers (H110) from the base (103).

2.3 Place the handle (H101) on the base (103), please note: Feed the rod and chain

(H107) through the center of the base (103) and axle (109).

2.4 Insert three screws (H109) with spring washers (H110) into the base (103). Then

tighten them securely.

2.5 Raise the crank link (139H) and put the pin on rod and chain (H107) into the

groove of crank link (139H).

3. Adjust Release Device

On the handle of the pallet truck, you will find the control lever (H106), which can be

set in three positions (See Fig. 1, page 6):

Lower= to lower the forks; Neutral= to move the load; Ascend= to raise the forks.

After assembling the handle, you can adjust the three positions.

3.1 First tighten the setting screw (140) on the crank link (139H) until the Lower

position function works.

3.2 If the forks elevate while pumping in the Neutral position, turn the setting screw

(140) clockwise until pumping the handle does not raise the forks and the Neutral

position functions correctly.

3.3 If the forks descend while pumping in the Neutral position, turn the setting screw

(140) counter-clockwise until the forks do not lower.

3.4 If the forks do not descend when the control lever (H106) is in the LOWER

position, turn the setting screw (140) clockwise until raising the control lever (H106)

lowers the forks. Then check the Neutral position as per item 3.2 and 3.3.

3.5 If the forks do not elevate while pumping in the Ascend position, turn the setting

screw (140) counter-clockwise until the forks elevate while pumping in the Ascend

position. Then check the Neutral and Lower position as per item 3.2, 3.3 and 3.4.

Weighing

Fork Size

Net

Model Capacity Accuracy Length Width Over Forks Fork Width Weight

HPW20S 2000kg

+

1

0

/00 1150mm 555mm 180mm 136kg

HPW20L 2000kg

+

1

0

/00 1150mm 690mm 180mm 143kg

–

–

Parts No. Description Qty. Parts No. Description Qty.

F301 Signal wire 1 F325 Bolt 8

F302 Screw 4 F326A Load cell 4

F303 Cover plate 1 F327S Frame(555mm) 1

F304 Screw 8 F327L Frame(690mm) 1

F305A Analog junction box 1 F328 Pull rod 2

F306 Rubber 1 F101 Torsion tube assembly 1

F307 Rubber 1 F102 Bushing 4

F308 Indicator case 1 F103 Hexagon socket screw 1

F309 Knurled screw 2 F104 Spring pin 1

F310 Indicator 1 F105 Torsion tube shaft 1

F311 Bolt 1 F112 Spring pin 8/4*

F312 Washer 1 F113 H-link 2

F313 Washer 5 F114 Load roller axle 4

F314 Spring washer 5 F115 Bearing 8/4*

F315 Nut 1 F116B Poly load roller, tandem type 4

F316 Bolt 4 F117B Poly load roller, single type 2

F317 Wire clip 2 F118 Axle 2

F318 Screw 4 F119 Roller 2

F319 Fix screw 4 F120 Wheel frame 2

F320S Cover plate assembly (555mm) 1 F121 H-link axle 2

F320L Cover plate assembly (690mm) 1 F122 Pull rod axle 2

F321 Convex spherical washer 4 F123 Nut 2

F322 Concave spherical washer 4 F124 Spring washer 2

F323 Nut 4 F126 Eccentric pin 2

*Note: Quantity for tandem roller is 8, for single roller is 4

Frame, Wheel

and Display

Components

Page 4

globalindustrial.com 9 4

4. MAINTENANCE

4.1 OIL

Please check the oil level every six months. The volume of oil is about 10 oz. Use the

hydraulic oil type according to temperature scale below.

4.2 HOW TO EXPEL AIR FROM THE PUMP UNIT

Air may come into the hydraulic pump while transporting scale with pump in

upright position. This can cause forks to not elevate while pumping in the

ASCEND position. The air can be removed in the following way: Put the control

lever (H106) to the LOWER position, and then move the handle (H1501) up and

down several times.

4.3 DAILY CHECK AND MAINTENANCE

Daily check of the pallet truck can limit wear as much as possible. Give special

attention to the wheels (127, F116 or F117), the axles (F114, F118, F121, F122),

the handle (H101), the forks (F110) and lift and lower control. The forks should

be unloaded and lowered in the lowest position when the job is over.

4.4 LUBRICATION

Use motor oil or grease to lubricate all moveable parts.

5. GUIDE FOR SAFE OPERATION

For safe operation of the truck, please read all warning signs and instructions

here and on the truck before using this truck.

5.1 Do not operate the pallet truck unless you are familiar with it and have been

trained or authorized to do so.

5.2 Do not operate the truck unless you have checked its condition. Give special

attention to the wheels, the handle assembly, the forks, lift and the lower control.

5.3 Do not use the truck on sloping ground.

5.4 Never place any part of your body in the lifting mechanism or under the forks

or load. Do not carry passengers.

5.5 The operator should wear gloves and safety shoes for protection.

5.6 Do not handle unstable or loosely stacked loads.

5.7 Do not overload the truck.

5.8 Do not subject to unbalanced loads, either side to side or along the length of

the frame (refer to Fig. 2, page 6).

5.9 The capacity of the truck assumes an evenly distributed load with the center

of the load being at the halfway point of the length of the forks.

5.10 Make sure the length of the forks matches the length of the pallet.

5.11 Lower the forks to the lowest height when the truck is not being used.

5.12 At other specific conditions or places, the operator should be careful to

operate the pallet truck.

Temperature Oil

23°F-113°F L-HM68 Hydraulic oil (equivalent to ISO VG68

5°F-23°F L-HM46 Hydraulic oil (equivalent to ISO VG46)

Parts No. Description Qty. Parts No. Description Qty.

H101 Handle 1 H107 Rod and chain 1

H102 Spring pin 1 H108 Rubber cushion 1

H103 Spring leaf 1 H109 Screw 3

H104 Spring pin 2 H110 Spring washer 3

H105 Spring pin 1 H111 Nylon roller 1

H106 Control lever 1 H112 Spring pin 1

globalindustrial.com

Handle Components

Page 5

globalindustrial.com 5 globalindustrial.com 8

Parts No. Description Qty. Parts No. Description Qty.

101 Steel ball 1 136 Pressure regulating screw 1

102 Rod 1 137 O-ring 1

103 Base 1 138 Screw 1

104 Steel roller 1 139H Crank link 1

105 Bushing 1 140H Setting screw 1

106 Pin 1 141 Nut 1

107 Shaft 1 142 Parallel pin 1

108 Retaining ring 2 143 Retaining cover 1

109 Axle 1 144 Spring cover 1

110 Screw 1 145 Spring 1

111 Washer 1 146 Pump rod 1

112 Spring 1 147 Dust proof ring 1

113 Pressure rod 1 148 Pump cylinder 1

114 Steel ball 1 149 Seal ring 1

115 Pressure valve body 1 150 Nylon bushing 1

116 Split ring 1 151 Red copper washer 1

117 O-ring 2 152 Retaining ring 1

118 Washer 2 153 Rhombus plate 1

119 Steel needle 1 154 Pin 2

120 Bushing 2 155 Dowel pin 2

121 Pin 2 156 Dust proof ring 1

122H Pump body 1 157 O-ring 1

123 Dust cover 1 157-1 O-ring 1

124 Bearing 1 158H O-ring 1

125 Steering wheel axle 1 159H Cylinder 1

126 Bearing 4 160H Seal ring 1

127A Steering wheel, Nylon 2 161H O-ring 1

127B Steering wheel, Polyurethane 2 162H Filler plug 1

127C Steering wheel, Poly/Nylon 2 163H Reservoir cover 1

127D Steering wheel, Rubber 2 164H Screw 2

128 Retaining ring 2 165H Reservoir 1

129 Steel ball 1 166 Retainer 3

130 Discharge valve body 1 167 Retainer 1

131 Spring 1 168 Retainer 1

132 O-ring 1 169 O-ring 1

133 Discharge valve shaft 1 170 Retainer 1

134 Valve tape core 1 171 Dust cover 2

135 Spring 1

No. Problem Cause Solution

1 Forks do not rise • Not enough hydraulic oil • Add filtered oil.

to max. height.

2 Forks do not • There is no hydraulic oil. • Add more filtered oil.

lift up. • The oil has impurities. • Change the oil.

• Discharge valve is out of place. • Adjust the setting screw. (140)

• Air is present in the hydraulic oil. (See item 3.5)

• Remove unwanted air (See item 4.2)

3 Forks do • The rod (102) and the cylinder • Replace the rod (102) or cylinder (159H).

not descend (159H) are deformed due to • Repair or replace component.

unbalanced loads. • Remove the rust on the rod (102).

• The forks were kept at upright • Keep forks in lowest position when

position for long period of time not in use.

with rod (102) bare and are rusted • Adjust setting screw (140) (See item 3.4)

4 Leaks • Seals are worn out or damaged. • Replace seals.

• Parts may be cracked or worn • Check and replace parts.

5 Forks descend • Impurities in the oil can cause • Replace with filtered oil.

without the the discharge valve (B) to not • Remove the air (See item 4.2)

discharge valve close tightly. • Replace seals.

working • Air in the oil • Adjust setting screw (140) (See item 3.3)

• Seals worn or damaged

• Discharge valve (B) is out of place.

6 Scale is not • Dirt on load cells • Clean load cells.

weighing properly

*Note: Do not attempt to repair the pallet truck unless trained or authorized to do so.

6. TROUBLESHOOTING

7. WEIGHING OPERATION

7.1 Preparation:

Put the control lever in the LOWER position and lower the truck to lowest position.

7.2 Press the “Print” key until the backlight is on. After the indicator self checks,

it displays “0kg”.

7.3 Weighing method for gross weight:

Place forks under pallet and check if load is balanced. Put the control lever in the

ASCEND position; pump the handle to lift forks until the pallet leaves ground

position. The stable reading of the indictor is the gross weight of the goods

(total weight of the pallet and the goods).

7.4 Net weight weighing method:

To weigh the goods packed in the same type standard pallet, please

operate as follows:

7.4.1 Weigh single standard pallet, for example: weight of pallet: 40kg.

7.4.2 Press the “TARE” key, the indicator will display “0kg”.7.4.3

Remove the pallet from the forks, then the indicator displays “-40kg”.

7.4.4 Weigh the palletized goods according the method of 7.3; the stable reading of

the indicator is the net weight of the goods.

Page 6

globalindustrial.com 7 globalindustrial.com 6

7.5 Switch between kilogram and pound.

When the reading of indicator is in kilogram units, press the “FUNCTION” key, the

unit reading switches to lis. Press the “FUNCTION” key again, the unit reading returns

to kilograms.

7.6 Turn off the Indicator

When the indicator is on, press the “PRINT” key until the indicator display “OFF”.

Loosen the key to turn off the indicator.

8. BATTERY POWER DATA AND REPLACEMENT

The HAWK indicator on scale pallet truck uses six “D” size batteries for DC power. You

are recommended to use alkaline batteries. Rechargeable batteries can also be used.

Change the batteries when the illuminated cursor displays the “Low battery” icon on

the keyboard indicator.

How to change batteries:

8.1 Loosen the knurled screw (F309) on the two sides of the indicator case (F308), turn

over the baffle of indicator case.

8.2 Open the battery cover plate on the rear of indicator (F310), insert six “D” size

batteries into the battery holder according to the direction marked on the holder.

Then re-install the battery cover plate.

8.3 Screw the knurled screw to fix the baffle of indicator case.

Fig. 1

Fig. 2A B

(2-1)

Pump and Axle

Components

Loading...

Loading...