Page 1

Instruction Manual

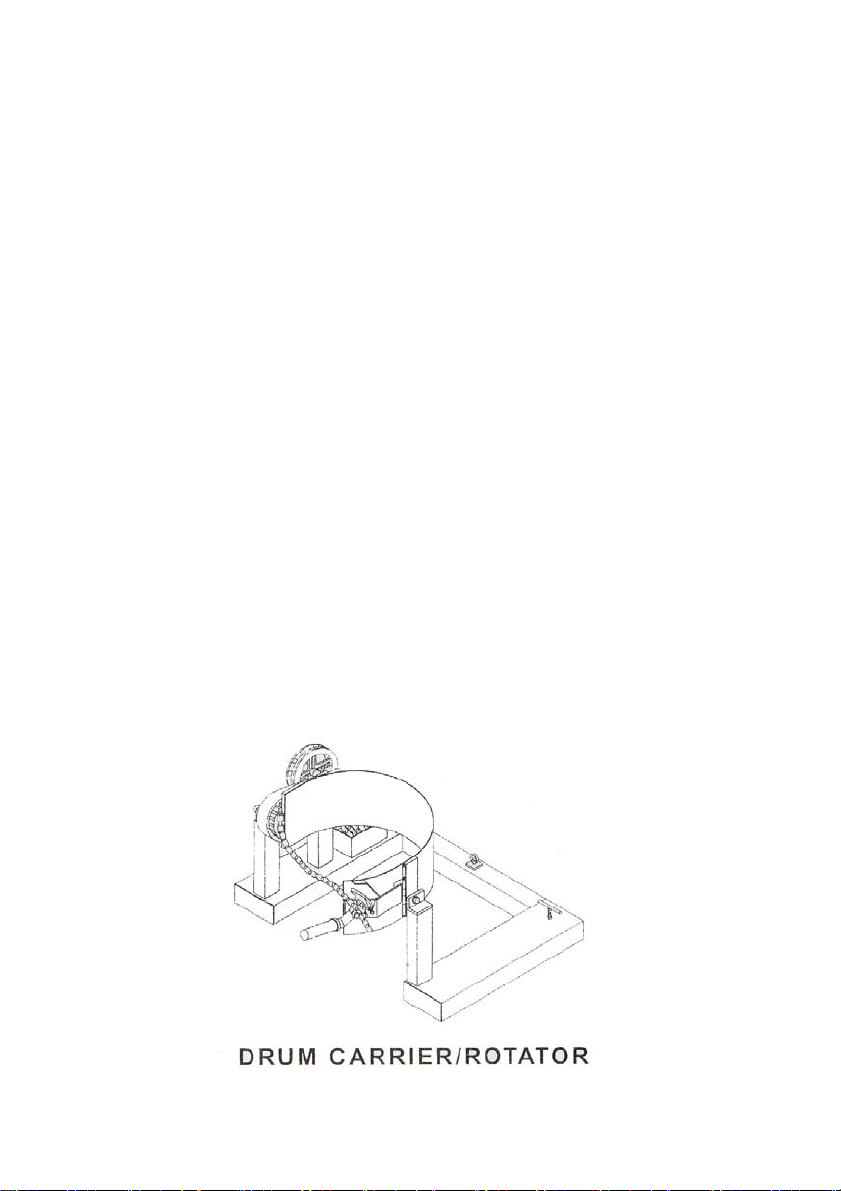

HK285

Note: The Owner/Operator must read carefully and

understand all the information presented here

before operation.

Page 2

Contents

Warnings and Safety Instructions …………………………………………1

Receiving Instructions…………………………………………………………2

Warranty …………………………………………………………………… 2

Operating Instructions …………………………………………………………3

Warning Label Identification ………………………………………………… 4

Periodic Maintenance Instructions ………………………………………… 4

Parts List ………………………………………………………………………5

Location of Center of Gravity ………………………………………………9

Page 3

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

~ Never operate drum carrier/rotator unless you are watching it.

~ Never use the drum carrier/rotator if the cradle is in need of repairs or

in the case of a malfunction.

~ Do not stand below any part of a raised drum carrier/rotator or drum.

~ Never exceed the maximum loading capacity of the drum

carrier/rotator as described below:

Model HK285A: 800 pounds for FULL drum, or 500 pounds for

HALF-FULL drum.

Model HK285B: 1500 pounds for FULL drum, or 900 pounds for

HALF-FULL drum.

~ Always load drum at the center of the cradle,

~ Consult factory for uneven loading.

~ When elevation is not required, always transport the drum in the

lowered position.

~ Always transport drum only in vertical position when fork truck is

moving.

~ Do not allow drum to impact on floor, ground, or dumping station etc.,

or there may be damage to the unit.

~ Remove drum before working on unit.

~ Consult factory if adding or performing any modification to the original

equipment.

~ Use only maintenance parts supplied or approved by the

manufacturer.

~ Make sure all operator safety labels are in place (p.2).

Page 4

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to shipment.

However, it is possible that the unit may incur damage during transit. If

damage is noticed when unloading, make a note of it on the BILL OF

LADING. Remove all packing and strapping material, then inspect the

unit again for damage.

IF DAMAGE IS EVIDENT, FILE A CLAIM WITH THE CARRIER

IMMEDIATELY!

WARRANTY

This product is warranted for 90 DAYS from date of purchase to be

free of manufacturing defects in material and workmanship.

The manufacturer's obligation hereunder is limited to repairing such

products during' the warranty period, provided the product is sent

prepaid back to the factory.

This warranty does not cover normal wear of parts or damage

resulting from any of the following: negligent use or misuse of the

product, use or application contrary to installation instructions, or

disassembly, repair or alteration by any person prior to authorization

from a factory representative.

Page 5

Safety Instructions For The Operator

1.) Please read all instructions THOROUGHLY before attempting to

operate your new Drum Carrier/Rotator.

2.) HK285A has a MAXIMUM CAPACITY RATING of 800 pounds

for FULL drum, and 500 pounds for FULL drum. HK285B has a

MAXIMUM CAPACITY RATING of 1500 pounds for FULL drum, and

900 pounds for HALF-FULL drum. Both models are intended for lifting,

moving, and pouring drums of size and type noted above. DO NOT

exceed these ratings as the unsafe condition that may result could

cause damage or excessive wear, or make the unit awkward to handle.

3.) When operating, loading, unloading, or maintaining your drum

carrier/rotator, always use care and good judgment, have good footing

and a firm hold. Keep hands and loose clothing etc., away from all

moving parts. Never allow anyone to be below any part of a raised Drum

Carrier/Rotator or drum. Read operating instructions before operation.

Operating Instructions

1.) Adjust the forks so that the inside width between the forks is 24

1/2" minimum. One fork must be locked to bed plate.

2.) Drive the truck forward to slip forks into fork sleeves. Attach

safety chain to mast to secure drum carrier/rotator to forks.

3.) Open carrier cradle full width and hook cradle chain on stud.

4.) Drive truck with forks near- floor level to position carrier cradle

around drum. Lock drum in place by clinching chain with ratchet

tightener.

5.) Remove control chain from box and place end of loop near

operator's seat.

6.) Raise forks and transport drum in VERTICAL position.

7.) TO POUR DRUM: Pull on chain, rotating drum to angle required

for emptying. For best control of drum pouring angle, pay out one side of

the loop while pulling in the other.

Page 6

8.) After emptying, rot ate drum back to vertical position and drive the

truck to deliver drum.

Periodic Maintenance Instructions

1.) Lubricate gear-train once a month with a good grade lube. There

are three grease fittings on the gear block for HK285A and four grease

fittings for HK285B and one grease fitting in the idler bearing block.

2.) Oil cradle hinges, ratchet, pawl, chain and other moving parts

periodically.

3.) Periodically inspect all moving parts, framework, and contact

areas for signs of wear, fatigue or loosening. Tighten, adjust or replace

parts as necessary to prevent failure and maintain proper functions.

Page 7

HK285A

Page 8

No. Description Qty No. Description Qty

1

Rubber bushing

2

Handle

3

Retaining ring

4

Hex bolt

5

Spring

6

Ratchet

7

Left clamping ring

8

Spring

9

Bolt

10

Nut

11

Washer

12

Spring pin

13

Grip

14

Strapping chain

15

Nut

16

Big gear

17

Hex screw

18

Ring

19

Hex bolt

20

Base frame

1 21

1 22

1 23

1 24

1 25

1 26

1 27

1 28

1 29

1 30

1 31

1 32

1 33

1 34

1 35

1 36

4 37

1 38

1 39

Bushing.

Aligning ring

Screw

Aligning ring

Bushing

Chain rack

Chain wheel

Chain cover

Hand chain

Spring pin

Ring

Big chain wheel

Roller chain

Chain rod

Key

Gear axes

Screw

T-bolts

Galvanized hand

chain (option)

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

Page 9

HK285B

Page 10

No. Description Qty No. Description Qty

1 Rubber bushing

2 Handle

3 Retaining ring

4 Hex bolt

5 Spring

6 Ratchet

7 Left clamping ring

8 Nut

9 Washer

10 Spring pin

11 Spring

12 Bolt

13 Grip

14 Nut

15 Strapping chain

16 Nut

17 Right clamping ring

18 Hex bolt

19 Ring

20 Key

21 Big gear & shaft

22 Ring

23 Key

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

25 Bushing

26 Pin

27 Double roller chain

28 Double big chain wheel

29 Chain over

30 Bushing

31 Double small chain wheel

32 Aligning ring

33 Bushing

34 Chain rack

35 Chain wheel

36 Hand chain

37 Chain over

38 Roller chain

39 Bushing

40 Ping

41 Big chain wheel

42 Gear axes

43 Key

44 Screw

45 T-bolts

46 Bushing

47

Galvanized hand chain

(option)

1

3

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

24 Base frame unit. 1

Page 11

Loading...

Loading...