Global Industrial 168032, 168033, 168034, 168035, 168036 User Manual

...

OPERATION INSTRUCTIONS

Parts List

Hand Pallet Truck

Note: Owner and operator MUST read and understand these

operating instructions before using this pallet truck.

ATTENTION:

1. The waste packages should be sorted and put into solid dustbins according to the materials

and be collected disposal by local special environment protection bureau. To avoid pollution, it’s

forbidden to throw away the wastes randomly.

2. To avoid leaking during the use of the products, the user should prepare some absorbable

materials (scraps of wooden or dry duster cloth) to absorb the leaking oil in time. To avoid

second pollution to the environment, the used absorbable materials should be handed in to

special departments in terms of local authorities.

1

Thank you for choosing our pallet trucks. For your safety and correct operation, please carefully

read the manual before use.

NOTE:

factory reserves the right to modify its own products at any time without notice or liability in any

sanctions. Please verify with the factory for possible updates and changes .

All of the information reported herein is based on data available at the time of printing. The

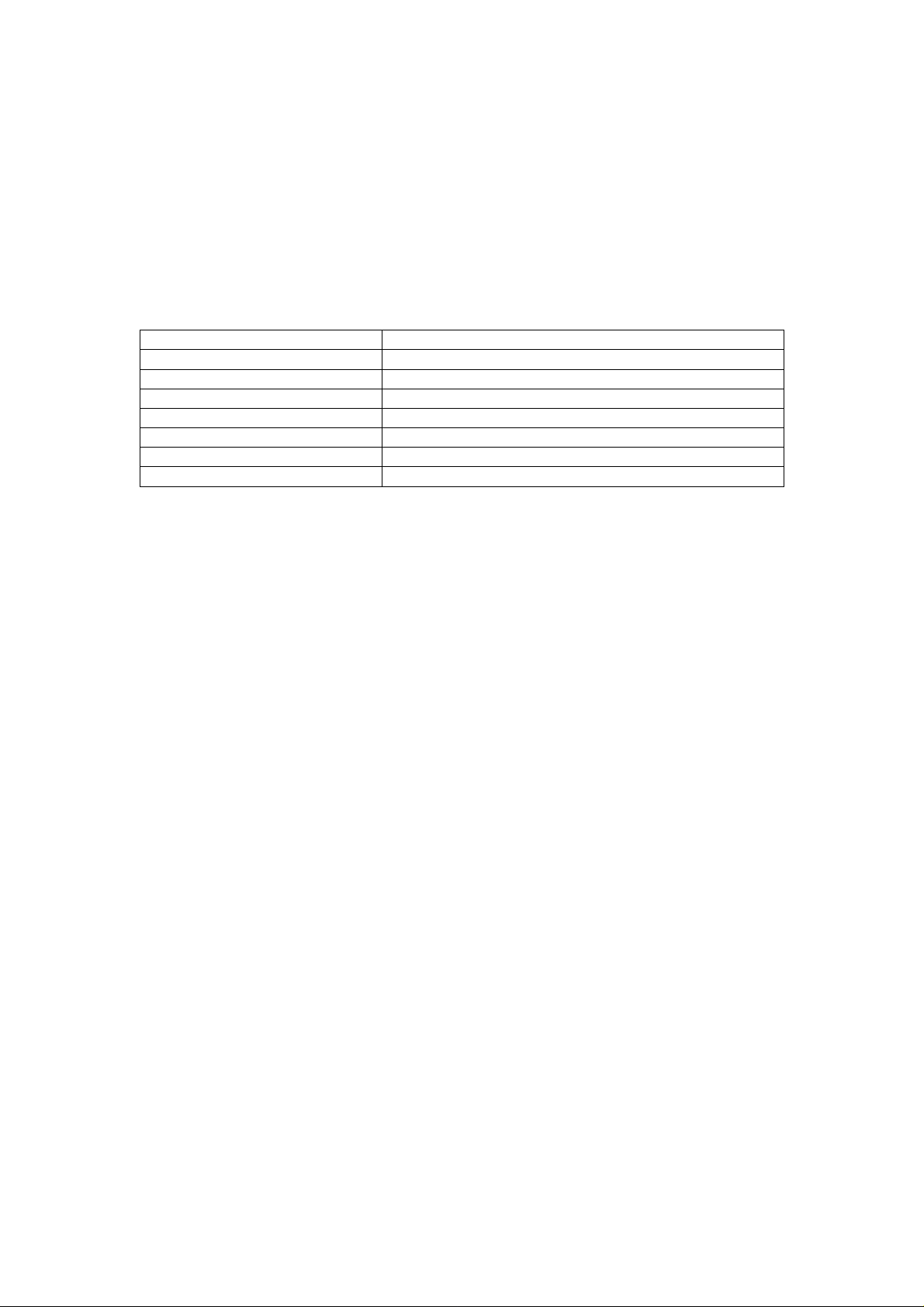

1. GENERAL SPECIFICATIONS

Capacity (kg) 2000

Maximum Fork Height (mm)

Minimum Fork Height (mm)

Fork Length (mm) 1150

Width Overall Forks (mm) 450 / 520 / 550 / 685

Individual Fork Width (mm) 160

Load Wheel Diameter (mm) Ø 80x70(or Ø 74x70) Nylon, Polyurethane

Steering Wheel Diameter (mm)

Special fork lengths are available in 800, 900, 950, 1000, 1220, 1500, 2000 mm.

Materials and specifications are subject to change without notice.

2. ATTACHING HANDLE TO PUMP UNIT

2.1 Remove 3 bolts (D611) from the handle bracket (D151).

2.2 Set handle (D610A, D610B or D610AS) on the bracket (D151), notice to allow the chain (D612)

and the adjusting bolts (D614) assembly to pass through the hole in the center of the bracket (D151)

and shaft (D153).

2.3 Insert the 3 bolts (D611) through the handle into the bracket (D151), then tighten them securely.

2.4 Raise the lever plat (D132) and insert the adjusting bolt (D614) into the front slot, keeping the

adjusting nut (D615) on the under side of the lever plat (D132).

200(or190)

85(or75)

Ø 200(or Ø 180) Nylon, Polyurethane, Rubber

3. ADJUSTING RELEASE DEVICE

On the draw-bar of this pallet truck, you can find the control handle (D608 or D608S) which can be

adjusted in three positions :

Raise - handle down

Drive - handle in center position

Lower - handle up, the lever moves back the drive position when released.

If however they have been changed, you can adjust according to the following steps:

3.1 If the forks elevate while pumping in the DRIVE position, turn the adjusting nut (D615) on the

adjusting bolt (D614) or adjusting screw (D133) clockwise until pumping action does not raise the

forks and the DRIVE position functions properly.

3.2 If the forks descend while pumping in the DRIVE position, turn the nut (D615) or adjusting screw

(D133) counter-clockwise until the forks do not lower.

3.3 If the forks do not descent when the control handle (D608 or D608S) is in the LOWER position,

turn the nut (D615) or adjusting screw(D133) clockwise until raising the control handle(D608 or

D608S) lowers the forks. Then check the DRIVE position according to item 3.1 and 3.2 to be sure

2

Loading...

Loading...