GLEM GAS AL8516MI, AL6613GI, AP9620GI, AP9622GI, AP9616GI User Manual

...

instructions booklet

NOTICE D’UTILISATION

English - EN

We would like to thank you for purchasing one of our products, we are confident it will fulfil your needs. We would also like to invite you to read this booklet carefully and keep it safe, as it contains important information and useful tips for your new cooker optimal use, in complete safety.

This appliance is in conformity in force:

-2006/95/CE Low Voltage (Directive)

-2004/108/CE Electromagnetic Compatibility (Directive)

-2009/142 Gas Appliance (Directive)

-1935/2004/CE Materials intended to come into contact with food (Regulation)

-2002/95/CE Restriction of the use of certain hazardous substances in electrical and electronic equipment (Directive)

-2002/40/CE Energy labelling of household electric ovens (Directive)

TABLE OF CONTENTS

03 General warnings

04 Your product

05Use

Hob Oven

Programmers and minute minders Cooking suggestions

08 Cleaning

09Maintenance

10Instructions for the installer

Product handling Installation

Adaptation to the different types of gas

14 Technical assistance

14 Product and packaging disposal

14 Technical data

16 Cooking and grilling tables

2

GENERAL WARNINGS

This appliance is only designed and built for household use. Any other use, such as heating, for example, is considered improper, and therefore highly dangerous.

Keep children away with under the age of 8 years, if not under the constant supervision of an adult.

Children and people with reduced physical, mental or sensory abilities and/or with lack of adequate knowledge of the use and dangers that the equipment can entail, are forbidden to use this appliance unless they are under the constant supervision of a responsible adult.

Children must not play with or near the appliance, whether it is in operation or not. Please do not allow children to clean the appliance.

If the appliance has a fault and/or is not working properly, please close the gas line, disconnect the appliance from the power mains, and do not attempt to service it by yourself. Contact your nearest authorized assistancecentredirectly(seethe"technicalassistance"sectionherein).

The surface temperatures of every part must strictly comply with the regulations in force. This does not mean that some metal parts will not burn during or after its use. Accordingly, please use with due care.

The cooker cannot be installed without feet;

The Company will not be held liable in case of failure to observe the information provided herein.

The Company reserves the right to change product specifications maintaining safety and functionality.

3

CAUTION

Some parts of the cooker are protected by a special film. Take it out before operating the appliance and use lukewarm soapy water to remove any sticky residue.

Some parts of the cooker are protected by a special film. Take it out before operating the appliance and use lukewarm soapy water to remove any sticky residue.

Preventing accidents in the home

Preventing accidents in the home

Do not leave the appliance unattended when cooking with fats or oil: it may cause a fire. Do not leave objects near the cooking surfaces.

If glass ceramic hobs crack, turn the appliance off to prevent possible electric shock.

NEVER try to put out a flame/fire with water; rather, turn the appliance off and cover the flame with a lid or flame-proof blanket.  Prevent pots from protruding from the hob edges during use.It is also advisable to use containers with an intact,flat base.

Prevent pots from protruding from the hob edges during use.It is also advisable to use containers with an intact,flat base.

During use the appliance overheats. Children must be kept away from the appliance. Be careful to avoid touching the heating elements inside the oven.

During use the appliance overheats. Children must be kept away from the appliance. Be careful to avoid touching the heating elements inside the oven.

The accessible parts can be hot when the grill is used, therefore children must be kept away.

The accessible parts can be hot when the grill is used, therefore children must be kept away.

Do not use jets of steam to clean the appliance. Steam could reach the electrical parts, damaging them and causing short circuits. Do not use cleaning products that contain chlorine, ammonia or bleach on parts made of steel or superficially treated with metal finishes (for example anodizing, nickel plating, chrome plating).

Do not use jets of steam to clean the appliance. Steam could reach the electrical parts, damaging them and causing short circuits. Do not use cleaning products that contain chlorine, ammonia or bleach on parts made of steel or superficially treated with metal finishes (for example anodizing, nickel plating, chrome plating).

It is essential that all installation,adjustment and technical maintenance operations are carried out by qualified personnel only. The appliance must be installed in compliance with the regulations in force in the country of use.

It is essential that all installation,adjustment and technical maintenance operations are carried out by qualified personnel only. The appliance must be installed in compliance with the regulations in force in the country of use.

Prior to every maintenance operation it is necessary to unplug the appliance from the power socket and wait for it to cool down completely.

Prior to every maintenance operation it is necessary to unplug the appliance from the power socket and wait for it to cool down completely.

Toprevent accidental tipping of the appliance to installa stabilizingdevice,as shown on page 11 in the installation section.

Toprevent accidental tipping of the appliance to installa stabilizingdevice,as shown on page 11 in the installation section.

Theapplianceisdesignedtooperatewithdifferenttypesofgas;eachtypeofgasrequiresspecificinjectorsandadjustments.

To make any change, it is always necessary to disconnect the appliance from the power mains, and temporarily cut off the gas supply from the mains.

If your cooker has a glass lid, make sure it is lifted open before turning on the burners, during use and the subsequent cooling phase. Failure to do so may cause breakage of the glass.

If your cooker has a glass lid, make sure it is lifted open before turning on the burners, during use and the subsequent cooling phase. Failure to do so may cause breakage of the glass.

Do not use abrasive products or sharp metal spatulas to clean the oven door glass as this may scratch the surface, causing the glass to shatter.

Do not use abrasive products or sharp metal spatulas to clean the oven door glass as this may scratch the surface, causing the glass to shatter.

Removeanyliquidsthatmayhaveoverflownontothelidbeforeopeningit.Letthesurfaceofthehobcooldownbeforeclosingthelid.

Removeanyliquidsthatmayhaveoverflownontothelidbeforeopeningit.Letthesurfaceofthehobcooldownbeforeclosingthelid.

The first time you use the oven, take out all of the accessories and supplied materials placed inside of it, turn it on and let it run idle for at least one hour at the highest temperature, with the door closed (but not using the grill). Then, switch it off, open the oven door and ventilate the room. Any odour you can smell is from the evaporation of the sealing and protective substances inside the oven.

The first time you use the oven, take out all of the accessories and supplied materials placed inside of it, turn it on and let it run idle for at least one hour at the highest temperature, with the door closed (but not using the grill). Then, switch it off, open the oven door and ventilate the room. Any odour you can smell is from the evaporation of the sealing and protective substances inside the oven.

The appliance is not conceived to operate with an external timer or remote control system.

The appliance is not conceived to operate with an external timer or remote control system.

The use of a gas appliance produces heat and moisture in the room where it has been installed. Please ensure good ventilation of the room keeping open the orifices of natural ventilation or installing a mechanical ventilation device (extraction hood with exhaust duct).

The use of a gas appliance produces heat and moisture in the room where it has been installed. Please ensure good ventilation of the room keeping open the orifices of natural ventilation or installing a mechanical ventilation device (extraction hood with exhaust duct).

During cooking do not cover the bottom of the oven or hob with aluminum foil.

During cooking do not cover the bottom of the oven or hob with aluminum foil.

4

YOUR PRODUCT

Given the wide range of products available on the market, this booklet contains information about several models, and it is therefore possible that not all of the information contained herein refers to your appliance or its accessories.We are nevertheless at your disposition for any clarification you may require.

Your cooker consists of the following main parts:

•hob: flat top part where the pan supports (supports for the pots),the gas burners,electric plates or the glass-ceramic areas,depending on the size and model of your cooker are locatedV.

•control panel: cooker control devices zone (i.e.knobs and switches).

•oven door

How to IDENTIFY the symbols on the control panel

Symbol Meaning

Burner / front left area

Burner / rear left area

Central burner

Burner / front right area

Burner / rear right area

Burner / left area

Oven temperature control (°C)

Timer / minute minder

Symbol Meaning

Multi-function electric oven features

Oven thermostat

Gas oven burner

Grill burner

Light button

Ignition button (spark)

Ventilated gas button (MultiChef)

These two pilot lights indicate that the electric oven is on and/or that the oven is heating up

USE

HOB

USING THE HOB

If your cooker has a glass lid, make sure it is lifted open before turning on the

burners,during use and the subsequent cooling phase.Failure to do so may cause the breakage of the glass.

burners,during use and the subsequent cooling phase.Failure to do so may cause the breakage of the glass.

Turning on the gas burner

Place a lit match near the burner (or a spark or a flame generator),press and turn the corresponding knob counter-clockwise to the MAX position. The hob can be equipped with electrical ignition activated through a separate button or by pressing the knob.

The hob can be equipped with electrical ignition activated through a separate button or by pressing the knob.

When it is lit,hold the knob down for approximately 10 seconds,then release it and adjust flame intensity,being careful to position the knob in the area between maximum and minimum (included) and never between maximum and zero to prevent turning it off unexpectedly.

The burner may go out when you release the knob: this means that the thermocouple is not hot enough. If it does not ignite within 15 seconds, wait 1 minute before trying again.

If your model does not have a gas safety valve (copper-coloured thermocouple near the burner),please check that,at regular intervals,the flame does not go out due to possible liquid overflowing from the pots during cooking.

USE OF ELECTRIC PLATES

The electrical plates are switched on by turning the knob clockwise, at a value between 0 and 4. The higher the number, the greater the applied electrical power.

By turning a plate on for the first time or after a long period of inactivity,it is advisable to make it run idle without cooking on it,on the“minimum heating”position (position1)foratleast15minutes,soastoeliminateanyhumiditythattheinsulationmayhaveabsorbed.Tooptimizetheuseofelectricplates,useflat-bottomed pots and avoid using pots with diameters smaller than the plates.

USING GLASS-CERAMIC HOBS (Highlight)

Please refer to the booklet supplied with the appliance.

Preventing home accidents

Do not leave the appliance unattended when cooking with fats or oil: it may cause a fire.

Do not leave objects near the cooking surfaces.

If glass ceramic hobs crack,turn the appliance off to prevent possible electric shock.

Practical tips FOR USING THE HOB

For best use of the burners with minimum gas consumption, it is advisable to use flat-bottomed pots with lids, and a suitable size for the burner.The table below provides the pot diameters for each burner, from the smallest to the largest.

5

Type (burner size in cm) |

Pot size (cm) |

Auxiliary burner (A) Ø 5 |

Ø 10 - 14** |

|

|

Semi-rapid Burner (S) Ø 7.5 |

Ø 16 - 20 |

|

|

Rapid Burner (R) Ø 10 |

Ø 20 - 24 |

|

|

Triple Crown Burner (TC) Ø 13 |

Ø 24 - 28 |

|

|

Fish Burner (FB) 6x23,5 |

max 14x35 |

|

|

** The reduction grill ,FOR models that include it, must only be used for the auxiliary burner when cooking with pots with a diameter less than 12 cm.

Type (screen-printing area size in cm) |

Pot size (cm) |

Electrical plate Ø 14.5 |

Ø ≥ 14.5 |

|

|

Electrical plate Ø 18 |

Ø ≥ 18 |

|

|

Glass-ceramic area (highlight) Ø 14.5 |

Ø ≥ 14.5 |

|

|

Extendible glass-ceramic area (highlight) Ø 12 - 21 |

Ø ≥ 12 - 21 |

|

|

Glass-ceramic area (highlight) Ø 21 |

Ø ≥ 21 |

|

|

Extendible glass-ceramic area (highlight) Ø 17 - 26.5 |

Ø ≥ 17 - 26,5 |

|

|

Oven

Turning the OVEN on

The first time you use the oven, take out all of the accessories and supplied materials placed inside it, turn it on and let it run idle for at least one hour at the highest temperature,with the door closed (but not using the grill).Then,switch it off,open the oven door and ventilate the room.Any odour you can smell is from the evaporation of the sealing and protective substances inside the oven.

COOKER WITH GAS OVEN AND ELECTRIC GRILL

The gas oven is equipped with a heating element (oven burner) located under the base of the oven and with a top heating element (grill).Some models also have a rear fan, which can be switched on and off with a key, and is used to evenly distribute heat during use. To check the oven, it is necessary to use a knob and 1

or 2 keys ( /

/  ).

).

The oven burner must always be lit with the oven door fully open and the cavity empty.Press and turn the oven knob counter-clockwise to the MAX position. Holdingtheknobdown,bringalitmatch(orasparkoraflamegenerator)closetotheholeonthebaseoftheoven.Keeptheknobpresseddownforapproximately 10 seconds,then release it and adjust to the required temperature.Close the oven door and wait few minutes to preheat the cavity before cooking foods.

Some models also have a rear fan which is used to evenly distribute heat during oven use.

If you need to carry out cooking with forced air, insert its control.

If the burner does not ignite within 15 seconds, wait 1 minute before trying again.

Insome modelsthe burnercanbeequippedwith ignitionactivatedwitha separatebuttonorby pressingthe knobitself.whenitislit,keep holdingtheknob down for approximately 15 seconds. The burner may go out when you release the knob: this means that the thermocouple is not hot enough. wait at least 1 minute and repeat the operation holding the knob down longer.

ELECTRIC GRILL

The Grill feature is switched on and off from its key. In cookers with an accessory to protect the knobs (glazed black knob protection) grilling must be done with the oven door partially open. before starting the grill, assemble the knob protection on the slots located on both sides of the frontal part, between the control panel and the oven itself.If your cooker does not have this accessory, it means that grilling must be done with the door closed.

COOKER WITH GAS OVEN AND GAS GRILL

This type of cooker has a burner located under the base of the oven and a grill burner on the ceiling of the oven.

Generally only one knob is used to control the oven

Some models have two separate knobs

, one for each burner, allowing the two burners inside the oven to be used at the same time. This particular option, traditionally offered in certain markets,is useful for cooking large quantities of food and for bringing the oven to the required temperature quickly.

, one for each burner, allowing the two burners inside the oven to be used at the same time. This particular option, traditionally offered in certain markets,is useful for cooking large quantities of food and for bringing the oven to the required temperature quickly.

GAS OVEN

The oven burner must always be lit with the oven door fully open and the cavity empty. Press and turn the oven knob counter-clockwise to the MAX position. Holdingtheknobdown,bringalitmatch(orasparkoraflamegenerator)closetotheholeonthebaseoftheoven.Keeptheknobpresseddownforapproximately 10 seconds,then release it and adjust to the required temperature.Close the oven door and wait few minutes to preheat the cavity,after that put foods inside the oven on the desired level.

Some models also have a rear fan which is used to evenly distribute heat during oven use.

If you need to carry out cooking with forced air, insert its control.

GAS GRILL (oven door closed)

Thegrillburnermustalwaysbelitwiththeovendoorfullyopenandthecavityempty.Pressandturntheovenknobcounter-clockwisetotheMAXposition.Holding the knob down, bring a lit match (or a spark or a flamegenerator) close to the hole on the base of the oven. Keep the knob pressed down for approximately 10 seconds, then release it and adjust to the required temperature. Close the oven door and wait few minutes to preheat the cavity, after that put foods inside the oven on the desired level.

Some models also have a rear fan which is used to evenly distribute heat during oven use.

If you need to carry out cooking with forced air, insert its control.

GAS OVENWHIT GAS GRILL (oven door closed)

The oven burner must always be lit with the oven door fully open and the cavity empty. Press and turn the oven knob counter-clockwise to the MAX position. Holdingtheknobdown,bringalitmatch(orasparkoraflamegenerator)closetotheholeonthebaseoftheoven.Keeptheknobpresseddownforapproximately 10 seconds,then release it and adjust to the required temperature.Close the oven door and wait few minutes to preheat the cavity,after that put foods inside the oven on the desired level and ignite the gas grill.

Some models also have a rear fan which is used to evenly distribute heat during oven use.

If you need to carry out cooking with forced air, insert its control.

6

Cooker with electric oven

There are two types of electric ovens in our range: static (no fan) and multifunction. Static ovens only have one control knob which manages the features and internal temperature, while multifunction ovens have two knobs: one to select the features and another to manage the temperature.

Electric oven with 1 knob (static - no fan) to control the oven

Turn the knob  clockwise and set the required temperature.Both lights on the control panel will turn on,indicating that the oven is on and is heating up.When it reaches the required temperature,the light indicator will switch off.

clockwise and set the required temperature.Both lights on the control panel will turn on,indicating that the oven is on and is heating up.When it reaches the required temperature,the light indicator will switch off.

In these models the Grill is switched on by turning the knob clockwise by three clicks.The grill (heating element) must be used with the oven door partially open. In these cases it is essential that you apply a device to protect the knobs (glazed black knob protection) which is part of the standard supply of the the cooker (it will be inside the oven).With the door open,the device must be inserted into the slots on both side of the front of the oven,between the control panel and the oven itself.

Attention: when the grill is in use,the accessible parts may reach high temperatures.

Multifunction oven

Multifunction electric ovens are controlled by a feature selector (knob) associated to a thermostat that allows you to choose the required temperature.Depending on the oven model,it will have various cooking features (see the cooking features table to identify symbol and use).

Select the desired feature and temperature. If the cooker does not have any knob protection, this means that grilling is carried out with the door closed and it is not possible to set temperatures above 200°C.

For immediate access to the cooking features in ovens with a programmer (manual, analogue or electronic), always make sure the programmer / timer is in “manual”mode .

.

Turnspit

The turnspit can be switched on from a manual key

or in automatic by selecting the corresponding symbol  .

.

Put the food on the turnspit so that it can be supported by the two forks; balance the weight in the centre to avoid unnecessary strain

on the turnspit motor as it rotates.

Light

The light inside the oven can be switched on and off by the relative key, or by turning the oven knob  .

.

Cross flow cooling fan

The cross flow cooling allows the surface temperatures of the cooker to decrease thanks to the forced air recirculation between the oven door,the control panel and the oven cavity under the hob.The cross flow fan,located between the hob and the ceiling of the oven,automatically starts up a few minutes after the oven is switched on, and a device keeps it running even when the oven is switched off, until the outside of the oven cools down.

PRH FEATURE (if applicable)

This feature pre-heats the oven quickly, allowing you to reach the ideal temperature to start cooking.To enable it (in models without the digital timer/prog and mechanical cooking-end timer) turn the oven knob to the PRH feature to turn it on; the two Leds light uo (PRH-°C) and when the pre-heating cycle is finished they will go off. It is now possible to put the food in the oven and select the desired cooking feature.

Bottom compartment (under the oven door)

Some models have a bottom compartment where the cooker's metal accessories can be stored when not in use.

Do not place flammable material,paper,rags,plastic bags etc...inside this compartment.

Programmers and minute minders

Minute minder

The minute minder is switched on by turning the knob clockwise to the end of its run,in order to load the mechanism,then counter-clockwise to set the required time. The time is expressed in minutes, a bell will let you know when the previously-set minutes are up.

Cooking-end mechanical timer (only in models with an electric oven)

This mechanical timer, in addition to sounding the bell, also acts as a switch, by switching off the power. It is different from the minute minder because the ring nut around the knob (washer),in addition to indicating the minutes,also has the symbol of a hand.To set it,turn the knob to the end of its run,in order to load the mechanism,then turn it in the opposite direction to set the required time.If you wish to turn the oven on without setting any time,position the knob on the 'hand' symbol in the manual position.

3 keys of the digital timer (fig.3 - page 8)

•Set the time: press the timer on/off button (bell) immediately followed by the + or – key to adjust the time. Once it has been set, the time will automatically be set after 10 sec.

•Use the timer:to set the cooking time,press the + or – key until you reach the required amount of time (between 1 and 99 minutes).When the timer is on,it will appear on the screen.When the time is up,the timer will start ringing.To turn it off,press the timer on/off key (bell).

•Changing the volume of the timer: set the timer at 1 minute and when you hear the bell, press the - key to change the volume.

toucH Programmer (fig.4 - page 8)

The touch programmer can work in 3 modes:

-minute MINDER: once the time is set the timer will start counting down until it is up, and a bell will ring.

-AUTOMATIC END-COOKING:when the time is up,the oven will switch off and a bell will ring (only in models with electric ovens).

-DELAYED START: by setting the cooking time and the switch off time, the oven will start and stop automatically.

•Keyboard freeze:the programmer is equipped with automatic keyboard freeze after 7 seconds of inactivity.To unfreeze it,press any key for 2 seconds.

•Set theprogrammer time:holdthe+and-keys downatthe sametimeuntilthecentral cursor betweenthehour andminutesstartsflashing.Thenpress +or - to

7

set the time.Once you have reached the time you need to set,do not press any other key,and after a few seconds a beep will confirm the set time.

•Setting the count down (minute minder feature): the minute minder operates separately from the oven, and can be used for all cooking features. Hold the

"Menu" key down until the screen changes.

Release the key and adjust the time (minutes) by using the + and - keys. Once you reach the required time, release the key and wait for the confirmation beep.

A bell icon will appear on the screen. At the end of the minutes, the bell will ring. Press any key to turn it off. To remove the bell icon from the screen, press the "Menu" key.

To check the remaining amount of time (before it expires), hold the "Menu" key down.To delete the set amount of time, press the "Menu" key until the screen changes,and then press the + and - keys at the same time.The set amount of times will thus be deleted.

•SettingAuto Power Off (only for electric ovens):turn the oven on by adjusting features and temperatures.Hold the "Menu" key down until the screen changes, then press it again.The letters "DUR" (for 'duration') will appear on the screen.Press the + and - keys to adjust the cooking time.Wait for the confirmation beep without touching any keys. When the set amount of time is over, the oven will switch off and the beeping sound will be set off. Press any key to turn it off.

To remove the bell icon from the screen,press the "Menu" key.To check the remaining amount of time (before it is over) hold the "Menu" key down.To delete the set amount of time,press the "Menu" key until the screen changes,and then press the + and - keys at the same time.Accordingly,the set amount of times will be deleted. At the end of cooking, remember to place the knob back to the "0" position.

•Setting delayed start (only for electric ovens): hold the “Menu” key down until the screen changes, then press it again.The letters ''DUR'' (for 'duration') will appearonthescreen.Pressthe+and-keystoadjustthecookingtime.Thenpressthe"Menu"keyonceandthelettersENDwillappearonthescreen,indicating the menu to set the switch-off time.Press the + and - keys to adjust the switch-off time.Then select the cooking feature and required temperature.Obviously the oven will not start up immediately. Once the set amount of time has passed, the oven will switch off and the beep sound will start. Press any key to turn it off. To remove the bell icon from the screen, press the "Menu" key.

•Setting the volume: press + and - at the same time, followed by “Menu”, to enter the tone setting mode and press the – key repeatedly to change the tone of the alarm.Once you have selected the tone,the timer will memorize your selection until you wish to change it again.

Practical tips when using the programmer: please consider the amount of time for heating the oven when the cooking time is being set. Please switch the oven off at the end of the cooking cycles.

Analogue clock with hands (fig.5)

• Setting the time:pull the rod (F) and turn clockwise until you have set the current time.When it is set,put the rod back in its initial position.

• Setting the cooking time:turn the rod (without pulling it) (F) clockwise and set the required minutes on the clock disk set at“9”(E).

The maximum amount of time is 3 hours. When the time is over, a bell will ring. It will turn off automatically after three minutes. If you wish to turn it off manually, turn the rod clockwise until you see E, 0 or a crossed-out bell on the disk and in the E box.

• Setting the manual feature:Turn the rod clockwise to position I or to exclude the minute minder.

to exclude the minute minder.

Inside racks (fig.6,6a,6b)

Theovenhas4internallevelsfortherackpositioning(blackrectangularbakingrackorchrome-platedrack),whereyoucanplacethevariousdishestobecooked.

It is advisable to consult the cooking table in the following pages to use the best position and achieve the best cooking results.

Caution! The stop grid device requires the bracket to be inserted in the right position to work properly (fig.6-6a-6b).

Caution! The stop grid device requires the bracket to be inserted in the right position to work properly (fig.6-6a-6b).

fig.3 |

fig.4 |

fig.5 |

fig.6 |

fig.6a |

fig.6b |

|

A |

|

|

|

|

- |

+ |

|

|

|

|

COOKING TIPS |

|

|

|

|

|

Cooking features |

|

|

|

|

|

oven light |

|

|

FAN ASSISTED |

GRILL + FAN |

|

It lights up the inside of the oven. It is useful to check |

|

The heat of the top and bottom heating elements, |

The grill combined with the fan spreads heat evenly. It |

||

the food cooking degree. |

|

|

combined with that of the fan, allows excellent distribution |

is ideal for medium/thick meat, making it crisp on the |

|

|

|

|

of the heat, making it possible to cook several dishes. |

outside and soft inside. |

|

PIZZA |

|

|

CIRCULAR ELEMENT + FAN |

MAXI GRILL + FAN |

|

the pizza programme allows you to cook pizza as in a |

|

The fan makes hot air circulate inside the oven, |

Excellent to grill meat or fish. |

|

|

wood-burning oven. |

|

|

allowing even cooking on three levels, without |

|

|

|

|

|

transmitting odour. |

|

|

TRADITIONAL COOKING |

|

|

PRE HEATING |

GAS BURNER |

|

The heat is produced by the heating elements in |

|

This feature reduces the oven heating time, bringing the |

Traditional gas cooking. Ideal for cooking that requires |

||

the upper and lower parts of the oven Excellent for |

|

temperature to 200°C in just a short time. |

"humid" heat, such as meat and roasts. |

||

pastries and traditional recipes. |

|

|

|

|

|

UPPER ELEMENT |

|

|

DEFROST |

TURNSPIT |

|

This feature allows direct cooking, excellent for lightly |

|

The fan operates without heating elements. This |

Ideal for cooking game and roasts on a skewer It can |

||

browning. |

|

|

ensures optimal rapid defrost in just a few minutes. |

be used with static or ventilated grill features. |

|

BOTTOM ELEMENT |

|

|

GRILL |

GAS GRILL |

|

The bottom heating element is on. Excellent for slow |

|

This is used to brown the food top. Excellent for |

Suitable for grilling meat and browning. Ideal in |

||

cooking, leavening and keeping food warm. |

|

cooking meat arranged in thin layers. |

combination with the turnspit for cooking game. |

||

BOTTOM + FAN |

|

|

MAXI GRILL |

GAS BURNER + FAN |

|

The heat from the bottom heating element is ventilated |

|

The grill combined with the ceiling heating element |

The heat produced by the burner is ventilated, |

||

(recommended to finish cooking and sterilizing). |

|

makes it possible to grill larger surfaces. |

ensuring an even temperature and the possibility of |

||

|

|

|

|

cooking several dishes at the same time. |

|

8

CLEANING

It is necessary to periodically clean the oven thoroughly to avoid the formation of grease, which over time can produce smoke, unpleasant odour and malfunctions. Below is a list of our tips concerning the various parts of your cooker.

WARNING

Do not use jets of steam to clean the appliance.

Steam could reach the electrical parts, damaging them and causing short circuits.

Do not use cleaning products that contain chlorine, ammonia or bleach on parts made of steel or superficially treated with metal finishes (for example anodizing, nickel-plating, chrome-plating).

USING THE HOB

It is advisable to clean the hob daily after every use,once it has cooled down,using specific products for steel,or a normal degreaser for coloured cookers.

Be careful to remove all cooking residues. We strictly advise you against using abrasive or chlorine-based products.

CLEANING THE PAN SUPPORTS

The pan supports must be cleaned on a regular basis with warm water and non-abrasive detergent, being careful to remove all incrustations.

Cleaning the burner black caps and flame spreaders

The burner caps and flame spreaders can be taken off to make it easier to clean the hob.Wash them with hot water and non-abrasive detergent, making sure they are thoroughly dry before being re-installed.

Cleaning the burner black caps and flame spreaders

The burner caps and flame spreaders can be taken off to make it easier to clean the hob.Wash them with hot water and non-abrasive detergent, making sure they are thoroughly dry before being re-installed.

Cleaning the SPARK PLUGS and thermocouples

To avoid malfunctions, check and keep the hob spark plugs and thermocouples clean. Remove any cooking residues by wiping them gently with a damp cloth.

Cleaning the oven

For a good preservation of the oven it must be cleaned regularly after it has cooled down.

•Remove all removable parts.

•Clean the oven grids with hot water and non-abrasive detergents, rinse and dry.

•to make cleaning easier, it is possible to take the door and/or the glass off (refer to the maintenance paragraph).

•At the end of these operations,to dry the damp parts thoroughly. It is advisable to turn the oven on for a maximum of 15/20 minutes after the use of specific cleaning products, in order to eliminate any residues from the inside of the oven.

•Do not use abrasive detergents or metal scrapers to clean the oven door glass as this may scratch the surface of the glass, causing its breakage.

MAINTENANCE

WARNING

Prior to every maintenance operation it is necessary to unplug the appliance from the power socket and wait for it to cool down completely.

changing the oven lamp inside the oven (fig. 7 - page 10)

Unscrew the protective protruding cap inside the oven (A). Unscrew and change the bulb (B) with a new one with the same power and resistance to high temperatures (300°C). Put the cap back in place by screwing it in clockwise.

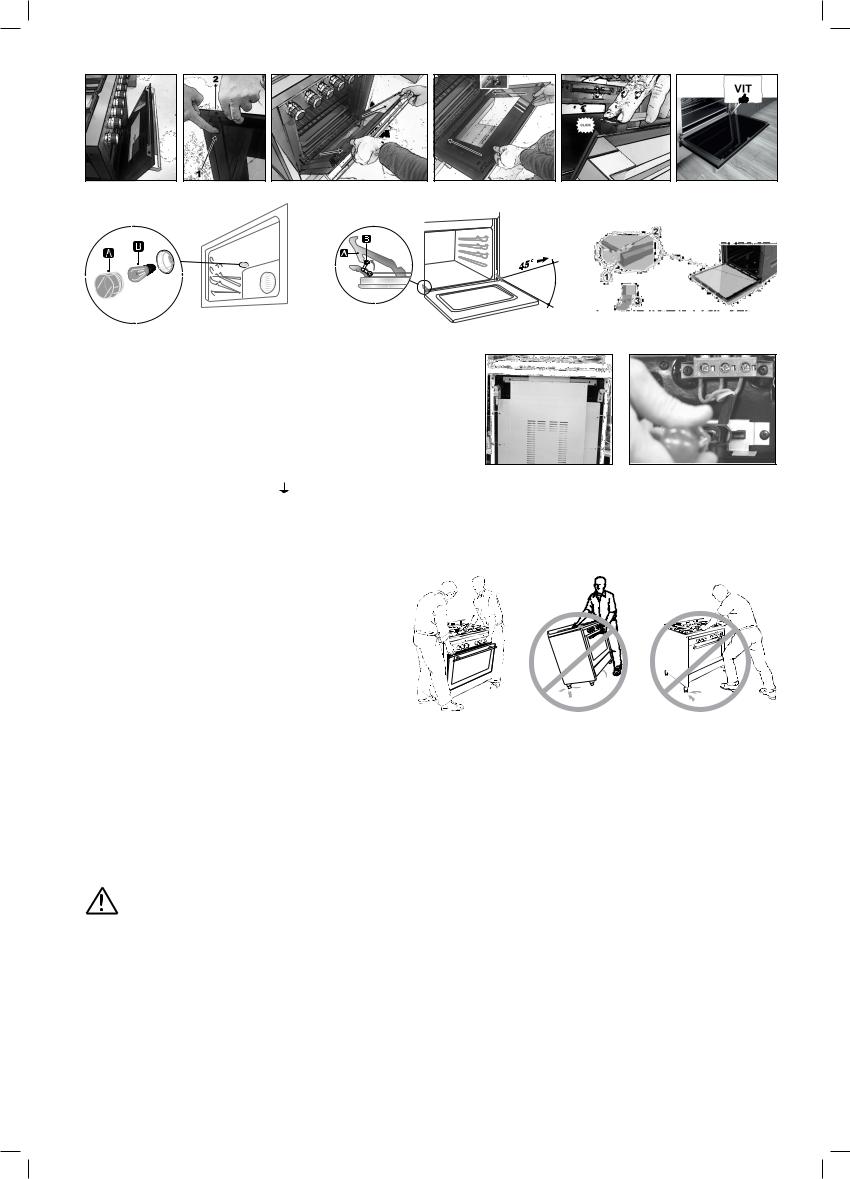

Oven door removal

Door with traditional hinge (fig. 8 - page 10)

•Lift levers B and hold the door by its two sides with both hands, near hinges A.

•Lift the door upwards at an angle of approx.45° and carefully pull it out.To re-assemble it,fit the hinges into the relative grooves,then let the door slide downwards, and release levers B.

Door with compact hinge (fig. 9 - page 10)

•Lift levers “2” up to the ledge with hinges “1” and hold the door by its two sides with both hands, near the hinges.

•Lift the door upwards at an angle of approx. 45° and carefully pull it out.

•To re-assemble it,fit hinge“2”into the relative grooves,then let the door slide downwards,making sure it stays blocked in the grooves“3”,then release levers “1”.

Removing the glass from the oven door (only in applicable models)

This operation can only be carried out when the appliance is cold.

To take the glass out from the oven door, you must do the following:

•Open the door slightly.

•Press the black keys located on the side supports of the door at the same time, and slide them upwards.

•Remove the top profile of the door.

•Take the glass out by pulling it towards you.

To re-install the glass, follow these steps in reverse order being careful to align the glass with the side supports and making sure that the letters VIT are in the bottom right corner marked by the arrow. Lastly, put the top profile back in place on the door.

9

fig.7 |

fig.8 |

fig.9 |

Changing the power cable (this operation must be carried out exclusively |

|

|

|

by qualified personnel) |

|

|

|

Disconnect the appliance from the power mains and take the rear panel off |

|

|

|

the cooker to have access to the terminal board (fig. 10). Loosen the clamping |

|

|

|

screws of the cable retainer and the screws on the terminal board that hold down |

|

|

|

the three cable conductors (fig.11). |

|

|

|

the instructions listed below: |

|

|

|

• Blue cable for Neutral on clamp N; |

|

|

|

• Brown cable for Phase on clamp L; |

fig.10 |

fig.11 |

|

• Yellow-Green cable for earth on clamp. |

|||

|

|

Attach the cable to the corresponding cable clamp (brown terminal board) and re-assemble the rear panel of the cooker.

If the power cord is damaged,contact immediately the after sales service which will replace it.

INSTRUCTIONSFORTHEINSTALLER

Product handling

The product must be handled by two people.

Do not lift the cooker by the oven door handle, rather, open the door and hold the cooker by the top of the internal cavity.

Do not drag or make the cooker slide.

INSTALLATION

VENTILATION OF THE ROOMS (fig.12 - page 11)

This appliance can only be installed and made to operate in permanently ventilated rooms, in accordance with national legislation in force.

It is essential that the amount of air required for gas combustion can flow through the room where the appliance is installed.

In particular, the air flow required for the correct combustion must not be lower than 2 m3/h for every kW of the appliance's rated power. (Refer to the technical data plate attached to the appliance,applied inside the door under the oven door or on the rear of the appliance).

The air must be drawn directly from the outside through permanent openings or ventilation ducts.

COMBUSTION GAS EXHAUST (fig.13 - page 11)

WARNING

It is essential that all operations relative to installation,regulation and technical maintenance are carried out exclusively by qualified personnel. The appliance must be installed in compliance with regulations in the country of use.

This appliance is not connected to an exhaust device for the combustion products. The appliance must convey the combustion products out into the atmosphere through a specific hood connected to a stack,flue or directly outdoors.

Intenseorprolongeduseoftheappliancemayrequiresupplementaryventilation,forexample,theopeningofawindow,ormoreeffectiveventilationbyincreasing the level of mechanical ventilation, when applicable.

INSTALLATION (fig.14 - page 11)

The appliance is class 1 and class 2.1 (see reference figure below). It can be free-standing or recessed (installed between other elements) in observance of the following minimum distances: 750 mm between the hob and any horizontal element above it (cabinets, for example); this space can be reduced to 650 mm if the above element is an extraction hood; 150 mm between the side of the appliance and elements that are taller than the appliance. It can be installed alongside walls that are higher then the work surface, at a minimum distance of 150 mm from the side of the appliance.

If it is installed between elements,it is necessary that the furniture of these elements be resistant to temperatures of up to 90 °C.

10

Appliances with a cylinder cabinet and electric oven can only be installed as free-standing

|

|

|

|

|

|

|

|

|

|

|

|

fig.12 |

|

|

|

|

fig.13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

ventilation opening for air flow required for correct combustion

min. 150 mm |

.min |

|

mm 750 |

||

|

enlarged hole to allow |

direct exhaust out-take to the |

exhaust out-take through the flue |

adequate air flow from the adjacent room |

outdoors |

installed for the cooker only |

fig.14 |

|

|

.min |

min. 150 mm |

.min |

|

mm 750 |

mm 750 |

||

|

Recessed appliance

(Class 2 sub-class 1)

Recessed appliance

(Class 2 sub-class 1)

Free-standing appliance installation (Class 1)

STABILITY DEVICE (only if required by regulation in the country of use and provided as a kit together with the cooker)

WARNING

To prevent accidental tipping of the appliance,it is necessary to install this stabilizing device as shown in the pictures below.

1.Children should not play or sit, on the open oven door.

2.Do not lean or sit, on the appliance’s open door. The excessive load may compromise the stability.

3.Do not place hot pans with sharp bottom, on the internal glass.

For models with a width of 50,60,70,80,90,100 cm it is necessary to install rear safety devices,as an absolute guarantee against the appliance tipping forwards, even when bearing heavy loads on the open oven door.

•There is a rear cover panel installed on the rear of the cooker. Measure distance H from the highest point of the panel to the floor (A).

•Use the value of the H measurement to draw reference marks where the holes for the plugs will need to be drilled on the wall where the cooker will be installed (B).

•Also mark the centre distance of the cooker on the wall at the same previously measured H height (C).

•It is now possible to install the two brackets at a distance of 400 mm from each other (200 mm from the centre distance) and position the cooker against the wall under the two brackets (D).

|

|

|

|

|

|

|

|

|

|

|

400 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CENTRE DISTANCE OF COOKER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BRACKET 1 |

|

|

|

|

|

|

|

|

|

|

|

|

BRACKET 2 |

||||

|

|

H |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

H |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200 mm 200 mm |

|

|

|

|

A |

|

|

B |

C |

|

|

D |

|||

If your cooker has a 90x60,80x50 cylinder cabinet,or 80x50 cabinet,it is necessary to assemble the brackets at the distance given in the pictures below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CENTRE DISTANCE OF COOKER |

|

|

|

CENTRE DISTANCE OF COOKER |

|

|

|

|

|

CENTRE DISTANCE OF COOKER |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

BRACKET 1 |

|

|

|

|||||||

BRACKET 1 |

|

|

|

BRACKET 1 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

BRACKET 2 |

|

|

BRACKET 2 |

|

|

|

|

BRACKET 2 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

H |

|

|

|

H |

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

200 mm 315/320 mm |

|

|

|

|

|

200 mm 310 mm |

|

|

|

|

|

|

280 mm |

|

|

|

|

|

Cooker with 90 x 60 cylinder cabinet |

|

|

|

|

|

Cooker with 80 x 50 cylinder cabinet |

|

|

|

|

|

|

Cooker with 80 x 50 cabinet |

|

|

|

LEVELLING

Once the supplied feet are fitted and screwed in,if necessary,level the appliance by turning them.This will avoid any possible oscillation.

11

CONNECTION

GAS CONNECTION

While the connection to the gas mains or gas cylinder can be made with various types of tubes (flexible rubber or steel),it is nevertheless necessary to carry out this operation in accordance with regulations and amendments in force, once it has been ascertained that the appliance is properly adjusted to the type of gas it will be supplied with (see technical plate inside the bottom door or on the rear of the cooker).

CONNECTION WITH FLEXIBLE METAL TUBE (fig.15)

The connection is made using a tube that is compliant with national regulation, connected to the appliance threaded fitting, through the use of a sealing joint (gasket).The maximum extension of the tube must not exceed 2 metres in length.

CONNECTION WITH FLEXIBLE RUBBER TUBE

•This type of connection is not authorized when the appliance is recessed (class 2/1 appliance) and the tube can not be inspected for its entire length.Connect the tube connection to the threaded fitting through the use of a sealing joint (washer).

Depending on the type of gas being used, the tubes will have different diameters:

•G30 (GPL) gas tube (fig.16) to be applied to tube connections with an 8 mm diameter;

•G20 (METHANE) gas tube (fig.17) to be applied to tube connections with a 12 mm diameter.

Fasten the two ends of the tube with the required tube clamps according to national regulations.

The tube must be replaced by the terms of the date printed on it and must not exceed the maximum length of 1.5 metres.

•The tube must not come into contact with: sharp objects, corners and with the cooker rear panel (see picture A); it must not be strained or twisted; no point of the tube must exceed a temperature of 50°C.

fig. A |

fig. B |

fig. C |

If the gas pipe is damaged, do not attempt to repair it by yourself but replace it with a new one before using the appliance.

GAS CONNECTION TO THE CYLINDER

With models with a cylinder cabinet it is possible to house cylinders with up to 15 kg of butane, that are compliant with national regulations.

The cylinder must be equipped with a pressure reducer,compliant with national regulations.

The connection to the cylinder must be set up in compliance with installation standards pursuant to national regulations.

The flexible tube used for the connection must have an internal diameter of 8 mm,it must be compliant with standards and must be replaced before its expiration date.It must be fitted to the tube connection on the cooker and the pressure reducer using regulation tube clamps.

During the operations to connect the cylinder, it is necessary to follow the instructions below:

•the gas connecting tube must not exceed 1 meter in length;

•the pressure reducer fitting must face the door of the cylinder cabinet;

•therouteoftheflexibletubemustnottouchanyhotsurfacesofthecooker(theleftinsidewallofthecylindercabinet,therearofthecookerandcabinetceiling) and IT MUST follow the route provided by the relative clamps;

•the cylinder must be set up so that it is not touching the wall adjacent to the oven.

Whenever you finish cooking,it is advisable to close the cylinder valve.

CONNECTION WITH RIGID COPPER PIPE (fig.18)

Connect the rigid part to the threaded fitting located on the rear side of the appliance,through a regulation sealing joint.

SEAL CHECK

Following installation, make sure the fittings are firmly connected. Never use a flame to check the seal on the gas circuits, always use a soapy solution.

ELECTRICAL CONNECTION

Install a plug on the cable,suitable for the load stated on the specifications plate on the appliance (located inside the door under the over door,or on the rear of the cooker).The electrical connection must have an efficient earthing connection.The yellow-green conductor for the power cable must not have any switches

fig.15 |

|

|

fig.16 |

|

fig.17 |

fig.18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12

set up along it. When there is a direct connection to the mains, it is necessary to set up a omnipolar switch between the appliance and the mains with a minimum opening between the contacts of 3 mm,sized for the load and compliant with national standards in force (the earth wire must not have any switches set up along it).The power cable must be positioned so that it does not exceed the ambient temperature by 50°C at any point.

The manufacturing company will not be held liable in cases of failure to observe the electrical regulations in force, and if the connection has not been set up by qualified personnel.

ADAPTATION TO THE DIFFERENT TYPES OF GAS

WARNING

The appliance is designed to operate with different types of gas; each type of gas requires specific injectors and adjustments. To make any variations it is always necessary to cut the appliance off from the power mains and temporarily cut off the gas supply from the mains.

CHANGING HOB BURNER INJECTORS (fig.19)

Manually remove the burners (no other disassembly operation is required) and using a suitable socket wrench,unscrew the injectors and replace them with the ones suitable for the type of gas,as listed in the technical data table and in the data plate on the cooker (see figure at the top of page 12).

REGULATING THE MINIMUM FLOW LEVEL OF GAS TO THE HOB BURNERS (fig.20)

The regulation of the minimum flow rate of gas to the burners is carried out in factory.When an injector is changed to adapt it to the type of gas available, or following particular pressure conditions of the mains, it may be necessary to regulate the minimum again. Ignite the burner and let it operate on maximum capacityforapproximately10minutes.Rotatetheknobtotheminimumposition.Removetheknobbypullingitoffthevalverod.Withasmallflatheadscrewdriver adjust the minimum by turning the by-pass screw clockwise to decrease the flame or counter-clockwise to increase the flame. When using valve cocks the adjustment screw (by-pass) is located on the body of the cock.When using valves other than valve cocks,the adjustment screw is situated inside the valve body. After any injectors replacement or adjustment operation always make sure that the flame is blue,steady and quiet and produces no detachment from the burner and will not cause backfire between the passage from maximum to minimum.

CHANGING BURNER INJECTORS INSIDE THE OVEN (fig.21)

Take the burners out by removing the clamping screws and using a suitable wrench to unscrew the injectors and replace them with the ones that are suitable for the type of gas, as listed in the technical data table.

REGULATING PRIMARY BURNER AIR INSIDE THE OVEN (only applicable to models with tube burners)

Somemodelshaveametalcollar(fixedwithscrew)locatedontheendoftheburnertoadjusttheairopening(byincreasingordecreasingtheamountofair)based on the result you wish to obtain.After any injector adjustment operation always make sure that the flame is blue,steady and quiet and produces no detachment from the back burner and will not cause backfire between the passage from maximum to minimum.

REGULATING THE MINIMUM FLOW RATE OF GAS TO THE OVEN AND GRILL BURNERS (fig.22)

Turn the burner on and position the knob on the maximum temperature. Let the oven heat up for at least 30 minutes. Rotate the knob to the minimum position.

Pull the knob out of the thermostat rod and with a small flat head screwdriver adjust the minimum by turning the by-pass screw clockwise to decrease the flame or counter-clockwise to increase the flame.The flame should be short and steady; no air drafts or the closing of the door have to cause the extinguishing of the flame or its return.The adjusting screw (by-pass) is usually located on the body of the thermostat.When using valve cocks the adjustment screw (by-pass) is situated on the body of the cock (fig.23). When using valves other than valve cocks, the adjustment screw is situated inside the valve body.

After any action to change or adjust parts of the appliance, it is necessary to carefully re-assemble all affected parts to restore the original features. Any adaptations made for a different type of gas must be completed by changing the tube connection. In this case, also check the circuit seal with a soapy solution, and never with the use of a flame.Lastly,replace the old calibration label with a new one (included) for the new type of gas being used.

Your product is now correctly installed.Please remove all information labels and materials (located inside the oven) before turning it on.

fig.19 |

fig.20 |

fig.21 |

fig.22 |

13

TECHNICAL ASSISTANCE

To find an authorized service center near you, contact your dealer.We recommend having the information available on your technical data plate.

PRODUCT AND PACKAGING DISPOSAL

The packaging used on our products can be recycled, therefore we ask you not to dispose of the packaging or parts of it as household waste, and to dispose of it in the best way possible to reduce the effect on the environment.

If you are purchasing our appliance to replace an old one,it is necessary to contact your locally authorized company for the collection of decommissioned appliances.This will allow the recyclable materials to be re-used and avoid polluting the environment.

The crossed-out bin symbol printed on the appliance indicates that at the end of its service life the appliance must be collected separately from other waste. Accordingly, at the end of its service life, the user must hand the appliance over to suitable electric and electronic waste collection centres, or deliver it to the dealer when purchasing a new, similar appliance, on a one for one basis. The suitable dismantling of the decommissioned appliance and sending of its parts to recycling, ecologically compatible treatment and disposal,contributes to avoidingpossible negative effectson the environmentand human healthand promote the re-useof thematerials that comprise the appliance.The unlawful disposal of the product by the user will result in administrative sanctions.

* In reference conditions, gas temperature 15°C, atmospheric pressure 1013.25 mbar

TECHNICAL DATA

|

|

|

INJECTOR |

|

POWER (kW) |

RECOMMENDED |

||

BURNER TYPE |

|

PRESSURE |

GAS |

POT |

||||

GAS TYPE |

MARKING |

|||||||

(sizes mm) |

(mbar) |

CONSUMPTION* |

|

|

DIAMETER** |

|||

|

(1/100 mm) |

|

|

|||||

|

|

|

|

MAX. |

MIN. |

(cm) |

||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MINI AUXILIARY |

LPG |

30 |

46 |

58 g/h |

|

|

12÷14 |

|

|

|

|

|

0,800 |

0,300 |

6 with reduction |

||

Ø 39 |

|

|

|

|

||||

natural gas |

20 |

68 |

95 dm3/h |

|

|

grill |

||

|

|

|

||||||

|

|

|

|

|

|

|

|

|

AUXILIARY |

LPG |

28..30/37 |

52 |

73 g/h |

|

|

12÷14 |

|

|

|

|

|

1,000 |

0,300 |

6 with reduction |

||

Ø 55 |

|

|

|

|

||||

natural gas |

20 |

72 |

95 dm3/h |

|

|

grill |

||

|

|

|

||||||

|

|

|

|

|

|

|

|

|

SEMIRAPID |

LPG |

28..30/37 |

68 |

127 g/h |

|

|

|

|

|

|

|

|

1,750 |

0,440 |

16÷20 |

||

Ø 75 |

natural gas |

20 |

98 |

167 dm3/h |

||||

|

|

|

||||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

RAPID |

LPG |

28..30/37 |

88 |

218 g/h |

|

|

|

|

|

|

|

|

3,000 |

0,750 |

20÷24 |

||

Ø 100 |

natural gas |

20 |

116 |

286 dm3/h |

||||

|

|

|

||||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

ULTRARAPID |

LPG |

28..30/37 |

91 |

240 g/h |

|

|

|

|

|

|

|

|

3,300 |

1,500 |

22÷26 |

||

Ø 120 |

natural gas |

20 |

124 |

314 dm3/h |

||||

|

|

|

||||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

FISH BURNER |

LPG |

28..30/37 |

88 |

211 g/h |

|

|

Max |

|

|

|

|

|

2,900 |

1,500 |

|||

60x235 |

natural gas |

20 |

120 |

276 dm3/h |

14÷35 |

|||

|

|

|||||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

TRIPLE |

LPG |

28..30/37 |

96 |

262 g/h |

|

|

|

|

|

|

|

|

3,600 |

1,500 |

24÷28 |

||

Ø 130 |

natural gas |

20 |

135 |

343 dm3/h |

||||

|

|

|

||||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

TRIPLE |

LPG |

28..30/37 |

98 |

277g/h |

|

|

|

|

|

|

|

|

3,800 |

1,500 |

24÷28 |

||

Ø 130 |

natural gas |

20 |

137 |

363 dm3/h |

||||

|

|

|

||||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

* In reference conditions, gas temperature 15°C, atmospheric pressure 1013.25 mbar. ** In compliance with burners and pots specifications.

POWER OF HEATING ELEMENTS

COOK-TOP

|

Diameter |

Power |

|

Diameter |

Power |

|

(mm) |

(Watts) |

|

(mm) |

(Watts) |

|

|

|

|

|

|

|

|

|

|

|

|

Electric plate Normal |

145 |

1000 |

Circular High-Light |

145 |

1200 |

|

|

|

|

|

|

Electric plate Normal |

145 |

1500 |

Circular High-Light |

180 |

1800 |

|

|

|

|

|

|

Electric plate Rapid |

180 |

2000 |

Circular High-Light |

210 |

2200 |

|

|

|

|

|

|

|

|

|

Extensible High-Light |

120/210 |

700/2100 |

|

|

|

|

|

|

|

|

|

Extensible High-Light |

170/265 |

1400/2200 |

|

|

|

|

|

|

14

|

|

|

|

|

|

OVEN |

|

|

|

|

|

|

Storage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Compartment |

|

|

|

|

|

|

|

Bottom |

|

|

|

|

|

|

Double-Grill |

|

Circular |

|

|

|

|||

oven capacity |

|

|

Top Element |

Grill Element |

|

|

Element |

|

|

|

|

||||||

|

Element |

|

Element |

|

Element |

|

|

|

|

|

|||||||

(Liters) |

|

|

|

(Watts) |

(Watts) |

|

|

(Watts) |

|

|

|

|

|||||

|

(Watts) |

|

|

(Watts) |

|

(Watts) |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

123 |

|

1500 |

|

|

|

950 |

2000 |

|

2950 |

/ |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

111 |

|

1500 |

|

|

|

950 |

1500 |

|

2450 |

2400 |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

105 |

|

1500 |

|

|

|

950 |

2000 |

|

2950 |

/ |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

95 |

|

1500 |

|

|

|

950 |

1500 |

|

2450 |

2400 |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90 |

|

1500 |

|

|

|

950 |

2000 |

|

2950 |

/ |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80 |

|

1500 |

|

|

|

950 |

1500 |

|

2450 |

2400 |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

67 |

|

1400 |

|

|

|

850 |

1400 |

|

2250 |

/ |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

61 |

|

1400 |

|

|

|

850 |

1400 |

|

2250 |

2200 |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

61 Double Oven |

|

1100 |

|

|

|

700 |

1400 |

|

2100 |

2200 |

500 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

58 |

|

1100 |

|

|

|

650 |

1350 |

|

2000 |

/ |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

51 |

|

1100 |

|

|

|

650 |

1350 |

|

2000 |

2200 |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

47 |

|

900 |

|

|

|

600 |

1350 |

|

1950 |

/ |

/ |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

37 Double Oven |

|

800 |

|

|

|

500 |

1200 |

|

1700 |

/ |

500 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TECHNICAL DATA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PRESSURE |

|

INJECTOR |

GAS |

POWER (kW) |

||

VOLUME OVEN / BURNER |

|

|

|

|

|

GAS TYPE |

|

|

MARKING |

|

|

||||||

|

|

|

|

|

|

(mbar) |

|

CONSUMPTION* |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

(1/100 mm) |

MAX. |

MIN. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oven burner |

|

|

|

|

|

|

|

|

LPG |

|

28..30/37 |

|

62 |

|

145 g/h |

|

|

Volume cavity: 37 – 41 l (dm3) |

|

|

|

|

|

|

|

|

|

|

|

|

2,000 |

0,700 |

|||

Small oven/double oven cooker |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Cooker dimensions (WxD): 90x60 or 100x60 |

|

|

|

|

natural gas |

|

20 |

|

108 |

|

190 dm3/h |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oven burner |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Volume cavity: 45 – 70 l (dm3) |

|

|

|

|

|

LPG |

|

28..30/37 |

|

79 |

|

193 g/h |

|

|

|||

Single oven cooker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooker dimensions (WxD): 50x50, 60x50, 70x50, 60x60, |

|

|

|

|

|

|

|

|

|

2,650 |

1,000 |

||||||

|

|

|

|

|

|

|

|

|

|||||||||

Bottle compartment 80x50, Bottle compartment 90x60 |

|

|

natural gas |

|

20 |

|

122 |

|

252 dm3/h |

|

|

||||||

Big oven/double oven cooker |

|

|

|

|

|

|

|

|

|

|

|||||||

Cooker dimensions (WxD): 90x60 or 100x60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oven burner |

|

|

|

|

|

|

|

|

LPG |

|

28..30/37 |

|

93 |

|

276 g/h |

|

|

Volume cavity: 74 – 109 l (dm3) |

|

|

|

|

|

|

|

|

|

|

|

|

3,800 |

1,000 |

|||

Single oven cooker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooker dimensions (WxD): 80x50 or 80x60 |

|

|

|

|

|

natural gas |

|

20 |

|

145 |

|

362 dm3/h |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oven burner |

|

|

|

|

|

|

|

|

LPG |

|

28..30/37 |

|

100 |

|

305 g/h |

|

|

Volume cavity: 102 – 126 l (dm3) |

|

|

|

|

|

|

|

|

|

|

|

|

4,200 |

1,000 |

|||

Single oven cooker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooker dimensions (WxD): 90x60 or 100x60 |

|

|

|

|

natural gas |

|

20 |

|

150 |

|

400 dm3/h |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Grill burner |

|

|

|

|

|

|

|

|

LPG |

|

28..30/37 |

|

60 |

|

116 g/h |

|

|

Volume cavity: 37 – 41 l (dm3) |

|

|

|

|

|

|

|

|

|

|

|

|

1,600 |

|

|||

Small oven/double oven cooker |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Cooker dimensions (WxD): 90x60 o 100x60 |

|

|

|

|

|

natural gas |

|

20 |

|

101 |

|

152 dm3/h |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Grill burner |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Volume cavity: 45 – 70 l (dm3) |

|

|

|

|

|

LPG |

|

28..30/37 |

|

65 |

|

145 g/h |

|

|

|||

Single oven cooker |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooker dimensions (WxD): 50x50, 60x50, 70x50, 60x60, |

|

|

|

|

|

|

|

|

|

2,000 |

|

||||||

|

|

|

|

|

|

|

|

|