Page 1

Operation Manual & Parts List

A Family Company Manufacturing In The USA Since 1969

BLC-1/3-E, BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2, BLC-3/4, BLC-3/4-2

Remote DRaft BeeR Line ChiLLeRs

BLC-1/3-E

BLC-1/3-2

BLC-3/4-2

Glastender, Inc. · 5400 North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 989.752.4444 · www.glastender.com

© 2008 Glastender, Inc. Rev. 01-09-18

Page 2

inDex

Beer Line Chiller Specifications ............................................................................... 2

Inspection Upon Arrival ........................................................................................... 3

Set-Up Remote Glycol Line Chiller ......................................................................... 3

Electrical Hook-Up ................................................................................................... 3

Glycol Line Connection ............................................................................................ 3

Glycol Filling ............................................................................................................ 4

Unit Start-Up ............................................................................................................. 4

System Start-Up ........................................................................................................ 4

Electronic Temperature Control Programming ........................................................ 5

Cold Control Adjustment .......................................................................................... 5

Digital Controller Operation ..................................................................................... 6

Wiring Diagrams .................................................................................................... 7-8

BLC-1/3-E ....................................................................................................... 7

BLC-1/3, BLC-1/3-2 ....................................................................................... 7

BLC-1/2, BLC-1/2-2 ...................................................................................... 8

BLC-3/4, BLC-3/4-2 ....................................................................................... 8

Typical Installation Detail ......................................................................................... 9

Remote Installation Directions ............................................................................... 10

Remote Control Panel Installation Detail ............................................................... 11

Remote Control Panel Installation Photo ............................................................... 12

Remote Beer Line Chiller Accessories ................................................................... 12

Replacement Parts ..............................................................................................13-17

BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2 ...........................................13-14

BLC-3/4, BLC-3/4-2 ................................................................................15-16

Electrical Components ................................................................................... 16

BLC-1/3-E ..................................................................................................... 17

Terms and Conditions ............................................................................................. 18

Warranty .................................................................................................................. 19

Trouble Shooting .................................................................................................... 20

Installation Notes .................................................................................................... 20

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

1

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 3

BLC speCifiCations

1/3 HP Beer Line Chiller

Model: BLC-1/3-E

stanDaRD featuRes:

• Glycol connections with flared fittings for easy service access

• Durable black vinyl-clad exterior with 16 gauge galvanized steel base

• Stainless steel, CFC-free, foamed-in-place insulated glycol bath

• High efficiency heat exchanger minimizes glycol bath size to one gallon

• Front located glycol filling port

BLC-1/3-E

1/3, 1/2, and 3/4 HP Beer Line Chillers with Remote Installable Control Panel

Models: BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2, BLC-3/4, BLC-3/4-2

stanDaRD featuRes:

• Control panel is removable and includes wall bracket for remote installation

• Glycol connections with flared fittings for easy service access

• Durable black vinyl-clad exterior with 16 gauge galvanized steel base

• Stainless steel, CFC-free, foamed-in-place insulated glycol bath

• High efficiency heat exchanger minimizes glycol bath size to one gallon

• Front located glycol filling port

• Digital temperature control with LCD display

BLC-1/3-2

• Over-sized condenser coil for maximum efficiency

• Clear glycol bath cover for easy visual inspection

• Available with two recirculating pumps (designated by “-2” suffix in model number)

Dimensional and Specication Information

Model No. BLC-1/3-E BLC-1/3 BLC-1/3-2 BLC-1/2 BLC-1/2-2 BLC-3/4 BLC-3/4-2

Dimensions† Length 27" 27" 27" 27" 27" 27" 27"

Width 21-1/4" 25-5/8" 25-5/8" 25-5/8" 25-5/8" 25-5/8" 25-5/8"

Height 14-3/4" 16" 16" 16" 16" 16" 16"

† Note: A minimum six inch clearance should be allowed around the entire unit for proper air ow.

Additional clearance should be considered above and in front of the unit for service access.

Electrical Voltage 120V 120V 120V 120V 120V 230V 230V

Frequency

Phase 1ø 1ø 1ø 1ø 1ø 1ø 1ø

FLA 13 13 18.6 13.5 19.5 10.1 12.9

Dedicated

Circuit

Electrical

Connection

Refrigerant R134a R134a R134a R134a R134a R134A R134A

Refrigerant Charge 14 oz. 26 oz. 26 oz. 30 oz. 30 oz. 35 oz. 35 oz.

Compressor 1/3 HP 1/3 HP 1/3 HP 1/2 HP 1/2 HP 3/4 HP 3/4 HP

Capacities*

Max Distance to Taps 125 ft. 125 ft. 125 ft. 250 ft. 250 ft. 400 ft. 400 ft.

Circulating Pumps 60 gph 60 gph 60 gph 60 gph 60 gph 60 gph 60 gph

Glycol Bath Capacity .94 gal .94 gal .94 gal .94 gal .94 gal .94 gal .94 gal.

Shipping Weight LBS (kg) 128 (58.1) 150 (68.0) 163 (73.9) 153 (69.4) 166 (75.3) 175 (79.5) 193 (87.7)

60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

20A 20A 30A 20A 30A 20A 20A

Cord & Plug Cord & Plug

2,175 BTU/hr 2,175 BTU/hr 2,175 BTU/hr 3,300 BTU/hr 3,300 BTU/hr 6,375 BTU/hr 6,375 BTU/hr

* Note: Rated capacities assume maximum operating ambient temperature of 80°F.

Hard Wire

Cord & Plug

Hard Wire Cord & Plug Cord & Plug

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

2

Page 4

inspeCtion anD set-up

1. inspeCtion upon aRRivaL:

Immediately upon arrival, a visual inspection of the carton should be made to determine if there is evidence of damage

in shipment. Following uncrating, make an inspection for any signs of external damage.

2. set-up of Remote GLyCoL Line ChiLLeR:

Once the survey of the location has been completed to determine the positioning of the remote glycol line chiller and the

connecting draft beer dispensing stations (refer to the specification sheet to be certain that the trunk line will be within

the recommended distance), make the necessary provisions to locate the unit and provide for the electrical services.

The ideal set-up is to mount the glycol line chiller on a proper machine stand that is easily accessible for routine main-

tenance and service.

In less-than-ideal circumstances, it may be necessary to locate the unit on top of the walk-in cooler or on the floor.

NOTE: Do not locate the glycol chiller in the walk-in cooler, as the cold ambient temperature will reduce the

cooling performance of the unit.

NOTE: A minimum of six inches of clearance should be allowed around the entire unit for proper performance.

Additional clearance should be considered for above the unit and in front of the unit for serviceability.

NOTE: When installed above walk-in cooler, ensure air flow is sufficient to maintain 80°F or lower ambient

temperature to maintain rated cooling capacity.

If the unit is located on the floor:

• Ensure the cabinet is sealed to the floor with NSF listed silicon RTV sealant applied around the entire bottom edge

of the cabinet.

• An optional 4" leg set is available as an accessory.

3. eLeCtRiCaL hook-up:

Models BLC-1/3, BLC-1/3-E, BLC-1/2, BLC-3/4, & BLC-3/4-2 are supplied with a 20 Amp grounded cord and plug

that connects at the rear of the unit. Models BLC-1/3-2 & BLC-1/2-2 ship as hard wire units and are supplied with a 30

Amp grounded cord only (no plug) that connects at the rear of the unit. A corresponding 20 Amp or 30 Amp grounded

receptacle or junction box, depending on the line chiller model used, must be installed within reach of the unit.

4. GLyCoL Line ConneCtion:

Typically, glycol recirculating lines are used to transport the glycol in the line chiller to and from the walk-in cooler to be

connected to the glycol lines in the beer line set.

Recirculating Return

Connect your glycol recirculating

line from the beer line set to the

Line Chiller 3/8" barb fitting.

Recirculating Outlet

Connect your glycol recirculating

line from the beer line set to the

Line Chiller 3/8" barb fitting.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

3

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 5

GLyCoL fiLLinG anD staRt-up

5. GLyCoL fiLLinG:

The glycol bath capacity is 1 gallon (US). Glycol supplied by Glastender, Inc. may be diluted to a ratio of (1) part

glycol to (2) parts water for freeze protection down to 0ºF (-18ºC) or a ratio of (1) part glycol and (3) parts water

for freeze protection down to 10ºF (-12ºC). These mix ratios are recommended, since the refrigeration system is not

capable of lowering the temperature of the glycol bath below 15ºF (-9.4ºC)

For glycol not supplied by Glastender, Inc. please consult the glycol manufacturer’s recommended mixing ratio for

the desired operating temperature.

NOTE: Do not place full strength glycol (undiluted) in the bath, as it will reduce the efficiency of the refrig-

eration system and may result in damage to the recirculation pump due to increased viscosity of cold

glycol.

NOTE: Select and use only a propylene glycol product that meets FDA (Food and Drug Administration) regu-

lations as a food grade product. Any substitution of food grade glycol with automotive anti-freeze or

other products will expose people to hazardous chemicals.

Fill the bath with glycol mixture by removing the black plug in the top of the glycol back and placing a funnel in the

fill hole. Pour in the glycol mixture until the level is 2-1/2" from the top.

6. unit staRt-up:

• Connect unit to appropriate electrical circuit. For more information refer to Step 3, Electrical Hook Up.

• Model BLC-1/3-E has one power switch that operates the compressor unit and recirculating pump.

• Models BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2, BLC-3/4, and BLC-3/4-2 have a condensing unit power switch.

There are separate power switches to operate the recirculating pumps. The condensing unit power switch will not

operate the compressor unless a pump switch is in the on position.

• Check all glycol circuit line connections for leaks.

• As you are priming the BLC-1/3, BLC-1/2, or BLC-3/4 lines, continue to add the glycol mixture to keep the bath

level 2-1/2" from the top.

7. system staRt-up:

It is a good practice to operate the glycol recirculation system for sixty (60) minutes before running beer through to

the remote dispensing station(s). This enables the glycol circuit to be checked for leaks. Also, recirculating cold glycol

through the lines enables the temperature inside the trunk line to stabilize before beer is introduced.

Once the refrigeration unit and the glycol recirculating pump have operated for sixty (60) minutes or more, the beer

product can be connected and drawn through the trunk line.

• Check the system for leaks.

• Thoroughly insulate all line joints in the trunk line and dispensing station(s).

It is recommended that the glycol lines be insulated inside the walk-in cooler to prevent excessive ice build up. Insulate

the glycol lines all the way up to the sealed chaseway as it exits the walk-in cooler.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

4

Page 6

tempeRatuRe ContRoL

8. eLeCtRoniC tempeRatuRe ContRoL pRoGRamminG

BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2, BLC-3/4, BLC-3/4-2 (note: this ContRoL

useD on units pRioR to 11/21/2013 sn134147623x):

The unit is shipped from the factory set at 26°F, differential set at 5, in C1, cooling mode. If reprogramming or adjusting is necessary follow these steps:

Step 1 Press the SET key to start programming.

Use the up or down arrow to toggle between and select F for degrees Fahrenheit or C for degrees Celsius.

Step 2 Press the SET key again to access the setpoint.

To achieve the desired temperature, press the UP key to increase or the DOWN key to decrease the setpoint.

Step 3 Press the SET key again to access the differential.

To achieve the desired differential, press the UP key to increase or the DOWN key to decrease the setting.

Step 4 Press the SET key again to access the mode.

Use the up or down arrow to toggle between and select C1, cooling or H1, heating mode.

Step 5 Press the SET key again to complete programming.

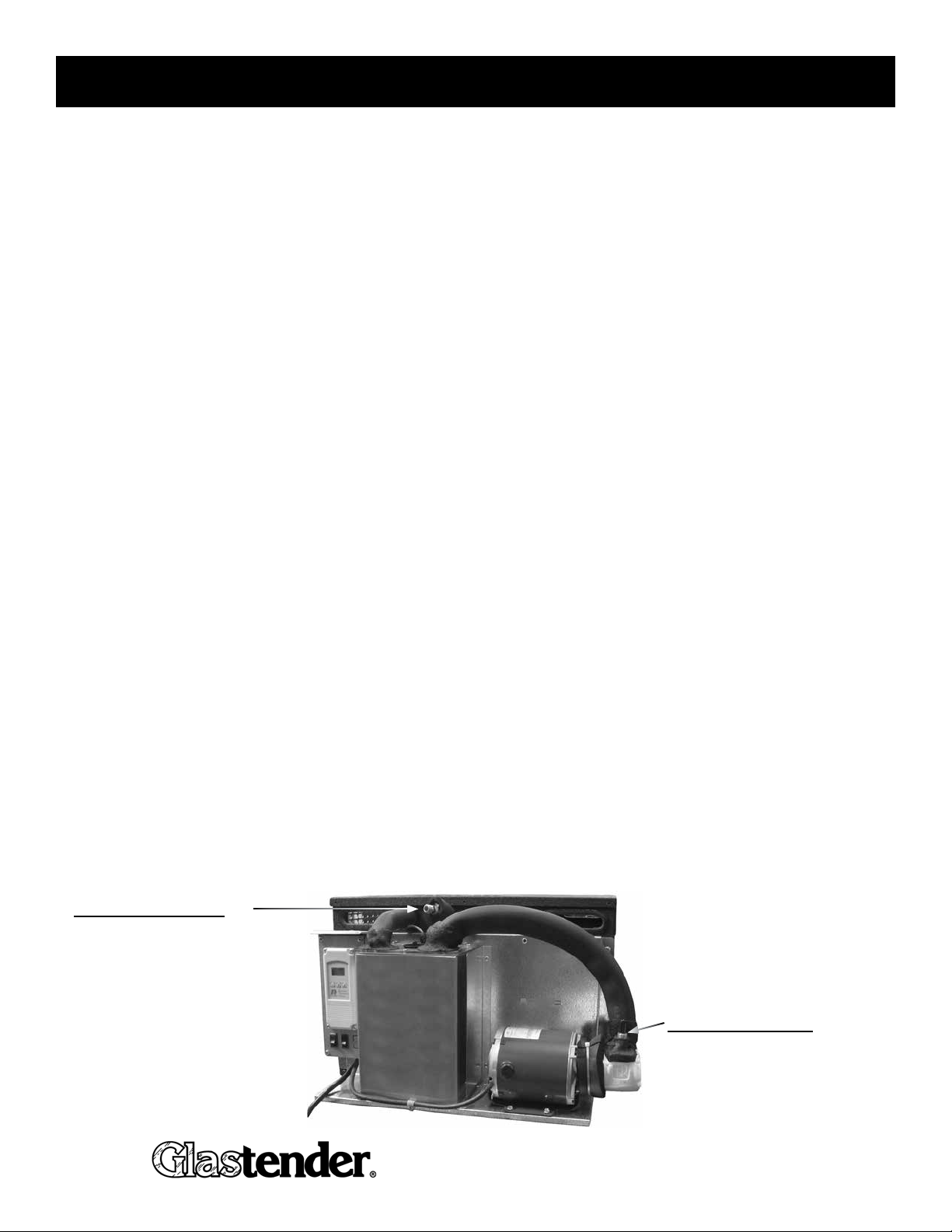

CoLD ContRoL aDjustment, BLC-1/3-e

The unit is shipped from the factory set at 26°F, differential set at 5. To decrease the temperature turn the adjusting knob

clockwise. To increase the temperature turn the adjusting knob counter clockwise.

Adjusting Knob

Scale

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

5

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 7

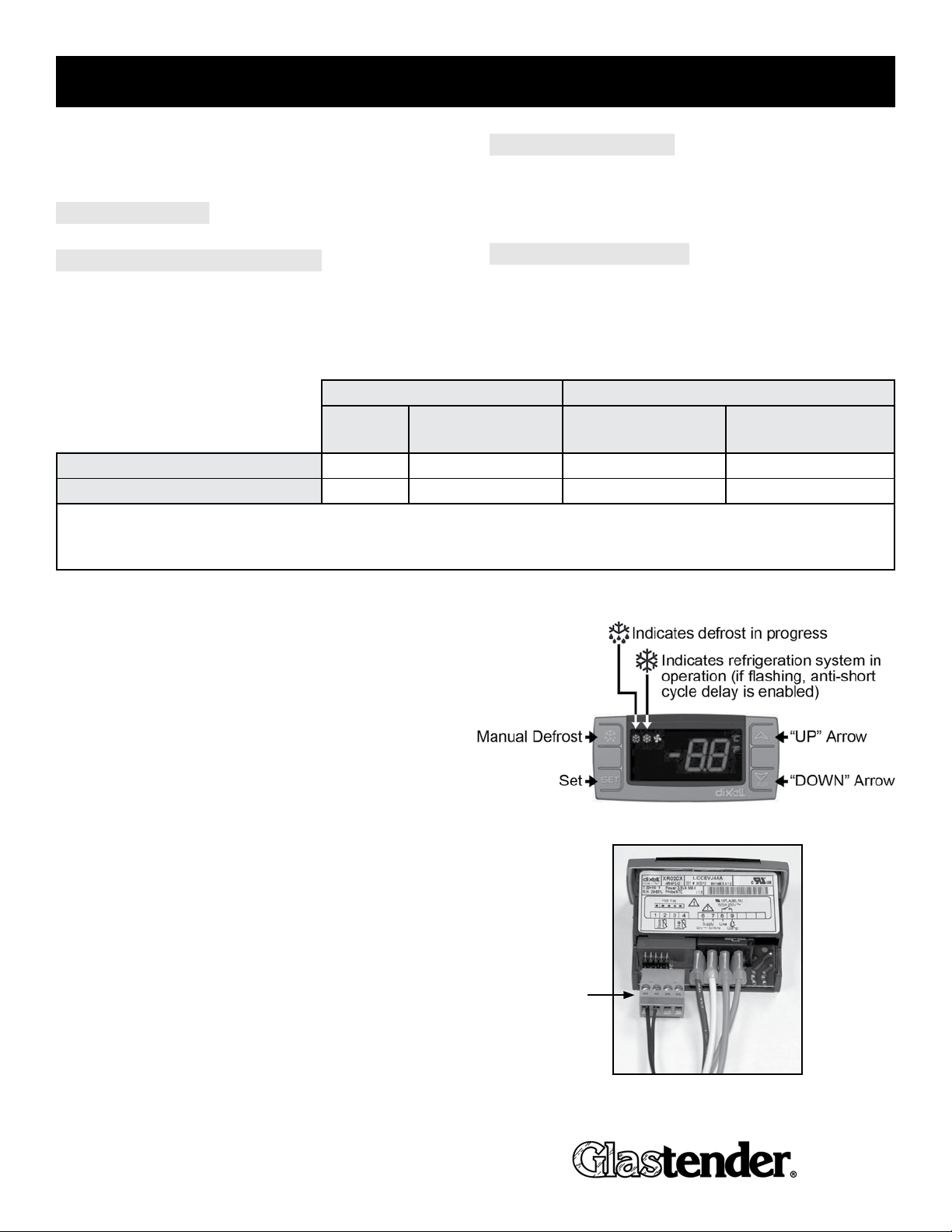

DiGitaL ContRoLLeR opeRation

The operating temperature range is preset at the

factory according to the table below and can be

adjusted up or down within the limits shown.

To see the set point - push and immediately release

the SET button. The set point will be displayed.

To return to normal visualization - Push and

immediately release the SET button or wait ve

seconds.

To change the set point - push and hold the SET

button for more than two seconds. When the º F

display begins ashing, push the up arrow or down

arrow buttons to adjust the set point to the desired

value.

To save the new set point and return to the temperature display mode - push and release the SET

button or wait ten seconds.

Factory Settings Range of Adjustment

Set Point Operating

Range†

Minimum Set

Point

Standard Cooler Setting

BLC

28º F 28º F to 33º F 27º F 32º F

† Adjusting the factory set point will also adjust the operating range by the same amount

Maximum Set

Point

The thermostat controller does not have an “OFF”

function. To turn chiller off, the unit must be

unplugged or power to the electrical branch circuit

has to be turned off via a circuit breaker or switch.

The thermostat control probe wire connector may

become disconnected when the electrical compartment

cover and/or grill are removed. This will result in

thermostat P1 code. While the P1 code is ashing the

compressor will cycle 5 minutes on and 5 minutes off

and may cause icing of the evaporator coil. Service

calls to reconnect the probe wiring are not covered by

factory warranty.

Probe wire

connector

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

6

Page 8

BLC-1/3-e WiRinG DiaGRam

BLC-1/3, BLC-1/3-2 WiRinG DiaGRam

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

7

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 9

BLC-1/2, BLC-1/2-2 WiRinG DiaGRam

BLC-3/4, BLC-3/4-2 WiRinG DiaGRam

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

8

Page 10

typiCaL instaLLation DetaiL

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

9

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 11

Remote ContRoL paneL instaLLation DetaiL

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

10

Page 12

instRuCtions foR ContRoL paneL Remote instaLLation

The Glastender exclusive, patent pending beer line chiller design houses the heat exchanger inside the condensing unit

compartment. For models BLC-1/3, BLC-1/3-2, BLC1/2, BLC-1/2-2, BLC-3/4, and BLC-3/4-2, this unique feature allows

the control panel with glycol bath and recirculating pump(s) to be easily installed separately from the condensing unit in a

more conveniently accessible location.

Remove cabinet top and vented

side to get at the power cord.

Disconnect 33" power cord.

Remove control panel installed

with four screws from cabinet. NOTE: Wall rack will be

found behind control panel.

Remove control cover to get

at the power cord. Disconnect

33" power cord.

Mount wall rack for control

panel at new site.

Disconnect glycol line from

heat exchanger.

Clip control panel onto wall

mounting plate. Secure against

wall through four corner holes.

Disconnect glycol line from

bath.

Install power line between

condensing unit and control

panel.

Install and insulate glycol line

from heat exchanger to bath

11

Connect glycol recirculating

line from pump outlet 3/8"

barb fitting to the beer line set.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Connect glycol recirculating

line from beer line set to the

return 3/8" barb fitting.

Page 13

Remote ContRoL paneL instaLLation photo

The Glastender exclusive, patent pending beer line

chiller design houses the heat exchanger inside the

condensing unit compartment. This unique feature

allows the control panel with glycol bath and recirculating pump(s) to be easily installed separately

from the condensing unit in a more conveniently

accessible location. Simply remove the control

panel from the condensing unit cabinet and mount

it in the desired location. Only glycol and electrical lines need to be run between the control panel

and the condensing unit cabinet.

Electrical connection between condensing

unit & control panel by local electrician

Glycol line from heat exchanger to bath

Digital temperature control with LCD display

Power cord for unit

Condensing unit &

heat exchanger cabinet

Glycol return from

beer tower to heat

exchanger

Glycol line from

pump to beer tower

Glycol line from bath

to pump

Recirculating pump

1 gallon glycol bath

Photo shows BLC-1/3 in an installation setting with the control panel installed remotely from the condensing unit cabinet.

Remote BeeR Line ChiLLeR aCCessoRies

All Glastender line chillers may be placed on 6" legs that are adjustable up to 7". The leg set includes 16 gauge galvanized steel that are

mounted to the base plate of the unit.

A line chiller stand is 26-1/2" wide by 39" high by 24" deep and comes

with adjustable feet for leveling. The bottom shelf is at the 8" high

level. The top shelf has holes that correspond to the line chiller mounting holes, so the line chiller can be bolted to the shelf. One size stand

is used for all line chiller models.

A line chiller wall rack is a shelf that is mounted to a structural wall.

The shelf has holes that correspond to the line chiller mounting holes,

so the line chiller can be bolted to the shelf. One size rack is used for

all line chiller models.

stands

Wall Racks

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

12

Page 14

BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2 RepLaCement paRts

3

7

4

5

13

6

1

12

16

17

11

2

10

9

15

8

14

13

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 15

BLC-1/3, BLC-1/3-2, BLC-1/2, BLC-1/2-2 RepLaCement paRts

paRt no. DesCRiption pRiCe

1. 06001439 Compressor, 1/3 HP, R134a, 120V $435.00

09000481 Start capacitor for 1/3 HP R134a compressor (prior to 11/06/13 - SN 134147373) 10.00

06009616 Start capacitor for 1/3 HP R134a compressor

(starting with and after 11/06/13 - SN 134147373)

09000479 Relay for 1/3 HP R134a compressor (prior to 11/06/13 - SN 134147373) 20.00

06009614 Relay for 1/3 HP R134a compressor (starting with and after 11/06/13 - SN 134147373) 31.00

09000480 Overload protector for 1/3 HP R134a compressor (prior to 11/06/13 - SN 134147373) 11.50

06009615 Overload protector for 1/3 HP R134a compressor

(starting with and after 11/06/13 - SN 134147373)

09000334 Compressor, 1/2 HP, R134a, 120V 720.00

09000650 Start capacitor for 1/2 HP R134a compressor 19.00

09000652 Relay for 1/2 HP R134a compressor 30.50

09000651 Overload protector for 1/2 HP R134a compressor 22.00

2. 09000526 Condenser coil, 12.00″ x 13.50″ 270.00

3. 08000085 Motor, condenser fan 135.00

4. 09000528 Fan blade, 10″ 30 degree S condenser 17.00

5. 06001385 Filter dryer, 1/4″ x 1/4″ 20.00

6. 07000953 Accumulator, suction line 30.00

7. 09000523 Evaporator, at plate housing assembly 515.00

8. 09000331 Pump, glycol, 60 GPH, brass 225.00

9. 09000340 Pump motor, 1/3 HP, 120V 350.00

10. 06001595 Insulation, Fluid-O-Tech pump, 2 piece set 9.00

11. 06001412 Rocker switch 5.00

12. 09000616 Electronic temperature control (prior to 11/21/13 - SN 134147623) 190.00

09000728 Dixell control (starting with and after 11/21/13 - SN 134147623) 165.00

06003951 Probe, Dixell control 30.00

13. 09000527 Capillary tubing, precut .049 at 65″, BLC-1/3, BLC-1/3-2 20.00

09000625 Capillary tubing, pre-cut .049 at 42″, BLC-1/3, BLC-1/2-2 20.00

14. 08000724 Expansion valve (starting with and after 11/06/13 - SN 134147373) 100.00

15. 09000496 Top, compressor, black vinyl, at plate chiller 35.00

16. 09000498 Front, compressor, moly, at plate chiller 35.00

09000500 Back, compressor, black vinyl, at plate chiller 35.00

17. 09000502 Side, compressor, black vinyl, at plate chiller 27.00

09000522 Side, coil, black vinyl, at plate chiller 15.00

35.00

20.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

14

Page 16

BLC-3/4 & BLC-3/4-2 RepLaCement paRts

3

2

7

6 13

5

41

15

16

17

8

14

12

11

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

15

10

9

Page 17

BLC-3/4 & BLC-3/4-2 RepLaCement paRts

paRt no. DesCRiption pRiCe

1. 09000335 Compressor, 3/4 HP, R-134a, 120V 60hz $930.00

09000668 Start capacitor for 3/4 HP 220V compressor 31.00

09000670 Relay for 3/4 HP 220V compressor 35.00

09000671 Overload protector for 3/4 HP 220V compressor 13.00

2. 09000640 Condenser coil, 15 x 13 x 4 370.00

3. 08000085 Motor, 16 watt Condenser Fan 135.00

4. 09000528 Fan Blade, 10″ 17.00

5. 09000285 Filter Dryer, 1/4″ x 1/4″ 20.00

6. 09000286 Accumulator 126.00

7. 09000523 Evaporator, at plate housing assembly 500.00

8. 09000331 Pump, glycol, 60 GPH, brass 225.00

9. 09000342 Pump motor 1/3hp, 220V 396.80

10. 06001595 Insulation, Fluid-O-Tech Pump, 2 piece set 9.00

11. 06001412 Rocker Switch 5.00

12. 09000616 Electronic Temperature Control (prior to 11/21/13 - SN 134147623) 190.00

09000674 Thermostat, LED display, range 28-34°F, BLC, 220V 200.00

06003951 Probe, Dixell Control 30.00

13. 09000649 Capillary tubing, set of 2, 60″ x .049″ ID 20.00

14. 09000724 Expansion valve (prior to 11/6/13 - SN 134147373) 100.00

15. 09000496 Top, compressor, black vinyl, at plate chiller 35.00

16. 09000498 Front, compressor, moly, at plate chiller 35.00

17. 09000502 Side, compressor, black vinyl, at plate chiller 27.00

09000500 Back, compressor, black vinyl, at plate chiller 35.00

eLeCtRiCaL Components

paRt no. DesCRiption pRiCe

06006121 Replacement powercord assembly, includes (06001572 06009527) $40.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

16

Page 18

BLC-1/3-e RepLaCement paRts

paRt no. DesCRiption pRiCe

1. 06001439 Compressor, 1/3 HP, R-134a, 120V $435.00

09000481 Start capacitor for 1/3 HP R-134a compressor, prior to 11/06/13 SN134147373 10.00

06009616 Start capacitor for 1/3 HP R-134a compressor, after 11/06/13 SN134147373 20.00

09000479 Relay for 1/3 HP R-134a compressor, prior to 11/06/13 SN134147373 20.00

06009614 Relay for 1/3 HP R-134a compressor, after 11/06/13 SN134147373 31.00

09000480 Overload protector for 1/3 HP R-134a compressor, prior to 11/06/13 SN134147373 11.50

06009615 Overload protector for 1/3 HP R-134a compressor, after 11/06/13 SN134147373 20.00

2. 09000292 Condenser coil 170.00

3. 09000336 9W condenser fan motor 85.00

4. 09000300 Fan blade 40 series 15.00

5. 06001385 Filter dryer, 1/4" x 1/4" 20.00

6. 07000953 Accumulator, suction line 30.00

7. 09000523 Evaporator, at plate housing assembly 515.00

8. 09000331 Pump, glycol, 60 GPH, brass 225.00

9. 09000340 Pump motor, 1/3HP, 120v 350.00

10. 06001595 Insulation, Fluid-O-Tech pump, 2 piece set 9.00

11. 06001412 Rocker switch 5.00

12. 09000303 Thermostat, adjustable 160.00

13. 09000527 Capillary tubing pre-cut .049 at 65" 20.00

14. 09000499 Top, compressor, moly, at plate chiller, BLC-1/3-E 35.00

15. 09000531 Front, compressor, moly, at plate chiller 35.00

09000503 Back, compressor, moly, at plate chiller 35.00

16. 09000505 Side, compressor, black vinyl, at plate chiller 20.00

09000510 Side, coil, black vinyl, at plate chiller 12.00

17

2

3

12

7

13

14

11

15

4

1

16

8

6

5

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

10

9

Page 19

teRms anD ConDitions

pRiCes:

All prices are LIST. Applicable taxes will be added.

Quotations:

Unless otherwise stated, quotations are effective for 30 days only.

aCCeptanCe:

All orders are subject to acceptance by Glastender, Inc.’s headquarters in

Saginaw, Michigan. Possession of the Product Directory and Price List

is not an offer to sell.

shipments:

F.O.B. factory in Saginaw, Michigan. Freight terms are Third Party or

Collect if shipped directly to you. Prepay and Add to Invoice freight

terms are available upon request. The approximate shipping weights of

all products are listed with the prices. Partial shipments will be made

unless otherwise specified by the customer. Surface freight classifications are:

• GT-24/GT-30/GW24 Glasswashers - Class 175

• GT-18 Glasswashers - Class 250

• All Underbar Equipment - Class 175

• Bar Die Orders – Class 250

• Portable Bars - Class 175

• Remote refrigerators (i.e., no compressor) or dry storage back bar

equipment - Class 175

• Self-contained refrigeration equipment - Class 150

• Ice Display Units (IDU and GDU) - Class 85

• Lighted Liquor Displays - Class 85

• Beer line chillers and beer towers (beverage dispensing equipment)

- Class 92.5

• Bottle Disintegration System - Class 150

• Ice Cream Freezers - Class 77.5

DeLiveRy:

The majority of equipment is manufactured to order and typically ships

within three to six weeks after complete order information is received by

the factory. In-stock equipment typically ships within two to three days

of the factory receiving complete order information.

RetuRns:

Items specified as “Manufactured to Order” are NOT returnable.

A Return Authorization number must be issued by the factory in

advance for any items that are returnable. The number MUST be noted

on the outside of the returned package. Returns must be received within

90 days of the issue date. Shipping charges must be prepaid. A minimum 20% restocking charge will be applied to all authorized returns if

received in new, unused condition in the original packaging.

The above conditions apply to spare part returns, except spare part

returns must be received within 30 days of original shipment for electronic or electrical parts or within 90 days for all other parts.

Loss oR DamaGe:

For customer routed shipments, Glastender, Inc. is not responsible for

any loss, damage, or delay of merchandise during shipment. Such transit

claims must be filed with the carrier. Merchandise must be examined on

arrival. If shortages occur, Glastender, Inc. must be notified in writing

within five (5) days of delivery to honor any shortage claim. Glastender

will assume responsibility for freight claims on Prepay and Add shipments but the customer must inspect freight and note any damage upon

receipt. Failure to do so may result in losses at the customer’s expense.

Custom oRDeRs:

Custom orders must be paid in advance and are not subject to cancellation.

All small items are evaluated to see the most cost effective means for

shipment. Many small items ship via UPS or FedEx; however, when

dimensional weight is excessive, LTL carriers are the most cost effective

choice. Spare parts orders received before 1:00 PM EST can usually be

shipped the same day.

The order department is happy to assist with routing or shipping questions.

payment teRms:

Cash should be included with all orders unless credit terms have been

arranged. To establish credit, banking and trade references are required.

A convenient credit application is available upon request. Payment via

credit card is not our normal means of receiving payment. Visa and

MasterCard will be accepted, but must be charged at the time of shipment. In addition, a payment via credit card for orders totaling more than

$500 will incur a 3% convenience fee on the total transaction amount.

Laminates:

Some products include common, readily available plastic laminates of

the customer’s selection. There may be an additional charge if uncommon varieties are ordered.

12/14/17

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

18

Page 20

WaRRanty statement

APPLICABLE TO ALL PRODUCTS SOLD WITHIN THE UNITED STATES AND CANADA

Glastender, Inc. warrants all products to be free of defects in material and workmanship. One-year labor and parts warranty applies to

all glasswashers, self-contained refrigeration models, and BDS model

bottle disintegration units. In established areas, a start up is included

with GT-24 and GT-30 model glasswashers. Warranty is effective for

one year from the date of installation or up to 18 months from date of

factory shipment, whichever occurs sooner. Glastender, Inc. will replace

any part or assembly found defective under normal use and service.

For warranty labor claims beyond 15 months from the date of factory

shipment, proof of date of installation or occupancy must be provided.

Authorization for labor must be obtained from Glastender within the

warranty period and prior to the service being performed.

Labor warranty applies to the United States and Canada only.

Remote refrigeration models and beer line chillers include a one-year

parts warranty only. There is no labor warranty on these products.

Field replacement parts not covered under the original warranty include

a 90-day part warranty from the date of installation.

FOUR YEAR ADDITIONAL COMPRESSOR WARRANTY:

Glastender will warrant to the original user the compressor for all selfcontained refrigeration models for an additional four years following the

regular one-year warranty period. This plan applies to the compressor

only.

A completed warranty claim form MUST accompany all returned defective parts or assemblies. Upon request, a defective part or assembly must

be returned to Glastender, Inc., Saginaw, Michigan, with all transportation and delivery charges prepaid. Warranty repairs or replacements

will be shipped FOB factory in Saginaw, Michigan. Reimbursement for

applicable freight charges covers ground service only.

Glastender provides in-warranty repairs during a service company’s

regular working days and hours. There is no provision for payment

of a premium rate during “overtime” hours. When warranty service is

requested during other than normal working hours, the end user will be

charged the premium portion of the overtime rate.

The warranty covers substantiated travel expenses for up to 2 hours /

100 miles round trip up to a maximum of $150. Any additional costs

due to installations that require extra work, time, or travel to gain access

for service are the sole responsibility of the equipment purchaser. Any

exceptions to these travel and access limitations must be pre-approved

by a factory representative.

The warranty does not cover door gaskets, chemical tubing, pump

squeeze tubing, and/or any equipment subjected to accidents, freight

damage, alterations from the original design, improper power and/or

plumbing hookups, improper chemical use, general misuse, or lack

of routine required maintenance as determined by Glastender, Inc.

Installation, normal control adjustments, general maintenance, correcting an installation error, or service calls that reveal the unit is functioning normally will not be reimbursed under warranty.

Condenser coils on self-contained refrigeration products must be

cleaned regularly. Failure to provide adequate air flow to a refrigeration

unit will void the warranty.

Glastender shall not be liable for loss of use, revenue, or profit, or for

any other indirect, incidental, special, or consequential damage including, but not limited to, product spoilage or loss.

This warranty is conditioned upon Glastender receiving notice of any

defect subject to this warranty within sixty (60) days of its discovery

by the end user or dealer. All products are warranted only for the initial

place of installation. Removal of a product automatically terminates

this warranty.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

19

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

SECOND YEAR EXTENDED PARTS & LABOR WARRANTY:

Glastender’s one-year parts and labor warranty on self-contained refrigeration units, excluding beer line chillers, can be extended to two years

with the purchase of a two year parts and labor warranty. Specify part

number EWR2 ($150 net price) when ordering.

EXPORT WARRANTY - One year parts only.

EXCLUSION OF WARRANTIES

EXCEPT AS PROVIDED ABOVE, GLASTENDER MAKES

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

OR NON-INFRINGEMENT.

LIMITATION OF REMEDIES AND DAMAGES

If Buyer makes a valid and timely claim as outlined above, Glastender’s

liability and Buyer’s remedies under this agreement will be limited solely

to labor charges authorized and/or replacement or credit, at Glastender’s

option, with respect to Products returned at Buyer’s expense within thirty (30) days after warranty repair. GLASTENDER’S LIABILITY WILL

IN NO EVENT BE GREATER IN AMOUNT THAN THE PURCHASE

PRICE OF THE RETURNED PRODUCTS. GLASTENDER

WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCE FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING,

BUT NOT LIMITED TO, LABOR COSTS EXCEPT AS COVERED

UNDER OUR WARRANTY, LOST PROFITS OR THE LOSS OF

PERISHABLE PRODUCTS RESULTING FROM THE USE OF OR

INABILITY TO USE OUR PRODUCTS OR FROM OUR PRODUCTS’

INCORPORATION INTO OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT. NEITHER PARTY WILL HAVE ANY

NEGLIGENCE OR OTHER TORT LIABILITY TO THE OTHER, OR

TO ANY THIRD PARTY, ARISING FROM ANY BREACH OF THIS

AGREEMENT.

GOVERNING LAW - JURISDICTION

The terms and conditions of an order are to be governed and construed

according to the laws of the State of Michigan, without regard to conflict

of laws principles. Buyer hereby consents to the jurisdiction and venue

of the courts located in Saginaw County, Michigan.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Warranty Administrator.

04-19-17

IMPORTANT!!

Attention Service Companies

Please review the important warranty information on this page. If you

believe a service call should be covered by the factory, please call

the factory for authorization between 8AM and 5PM EST, Monday

through Friday.

Page 21

tRouBLe shootinG

Complaints of warm beer...

• Check the temperature of walk-in beer cooler.

• Check the glycol bath temperature.

• Check that recirculating pump is operating.

Refrigeration Compressor Will Not Run...

• Check that the unit is getting electrical power.

• Check that cold control is working.

• Check that all wiring connections are secure.

Refrigeration Compressor Runs But Stops...

• Check for dirt build-up on condenser coil surface.

• Check that there is no obstruction of air flow into the cabinet.

• Ensure that enough voltage is supplied to the unit.

Refrigeration Compressor Runs But Not Cooling...

• Check for refrigerant leaks.

Noisy or Hot Recirculating Pump...

• Ensure that glycol bath is not frozen.

• Ensure that the glycol solution has been properly diluted.

• Check motor and pump coupling for wear.

Recirculation Pump Not Working...

• Ensure that pump and motor coupling has not worn free.

• Check power supply to the motor.

• Replace worn pump.

instaLLation notes

Installation Notes

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Original System Installer

Company: _____________________________________________

Address: _____________________________________________

_____________________________________________

City, State, Zip: _____________________________________________

Phone Number: _____________________________________________

Fax Number: _____________________________________________

Contact: _____________________________________________

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

20

Loading...

Loading...