Page 1

Operation Manual, Parts Directory, and Price List

BB60, BB84, BB108, ND52, ND72, ND92,

BB60BW, BR, WR, BB84BW, BR, WR, BB108BW, BR, WR,

ND52BW, BR, WR, ND72BW, BR, WR, ND92BW, BR, WR

2008 EnErgy Star Compliant SElf-ContainEd

BB and nd CoolErS

BB and nd two ZonE CoolErS

Rev. 12-15-10

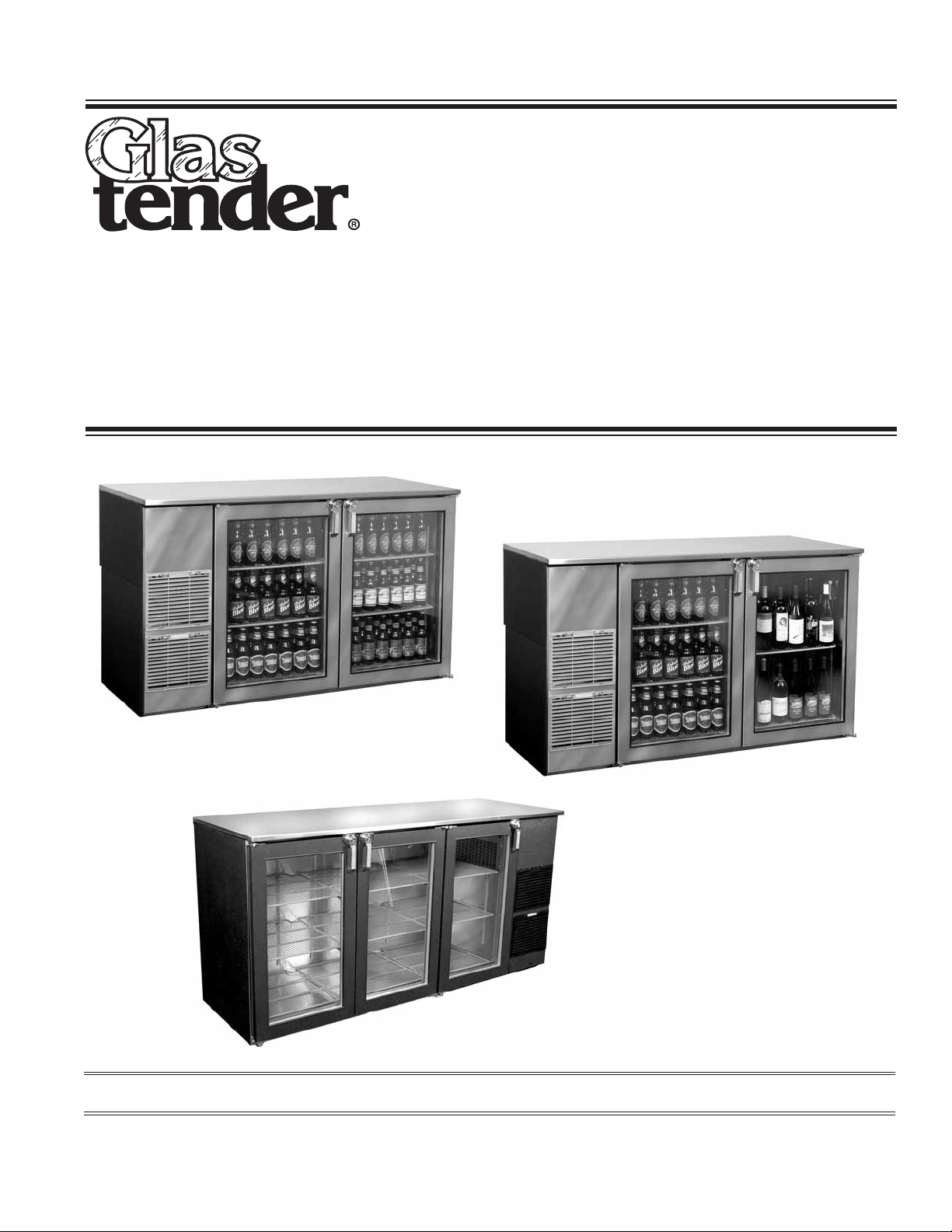

BB60-L1-XSH(LR)

BB60BR-L1-XS(LR)

ND72-R1-GS(LRL)

Glastender, Inc. · North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 989.752.4444 · www.glastender.com

© 2009 Glastender, Inc.

Page 2

tErmS and ConditionS

priCES:

All prices are LIST. Applicable taxes will be added.

QuotationS:

Unless otherwise stated, quotations are effective for 30 days only.

dElivEry:

The majority of equipment is manufactured to order and typically ships

within three to six weeks after complete order information is received by

the factory. In-stock equipment typically ships within two to three days

of the factory receiving complete order information.

aCCEptanCE:

All orders are subject to acceptance by Glastender, Inc.’s headquarters in

Saginaw, Michigan. Possession of the Product Directory and Price List

is not an offer to sell.

ShipmEntS:

F.O.B. factory in Saginaw, Michigan. Freight terms are Third Party or

Collect if shipped directly to you. Prepay and Add to Invoice freight

terms are available upon request. The approximate shipping weights of

all products are listed with the prices. Partial shipments will be made

unless otherwise specified by the customer. Surface freight classifications are:

Glasswashers, Line Chillers - Class 92.5

Cocktail Stations, Underbar Equipment - Class 85

Bar Die/Underbar Equipment – Class 125

Refrigeration Equipment, 48” long or smaller - Class 100

Refrigeration Equipment, greater than 48” long - Class 110

All small items are evaluated to see the most cost effective means for

shipment. Many small items ship via UPS or FedEx; however, when

dimensional weight is excessive DB Schenker, UPS Supply Chain, or

even common LTL carriers are the most cost effective choice. Spare

parts orders received before 1:00 PM EST can usually be shipped the

same day.

The order department is happy to assist with routing or shipping questions.

paymEnt tErmS:

Cash should be included with all orders unless credit terms have been

arranged. To establish credit, banking and trade references are required.

A convenient credit application is available upon request. Payment via

credit card is not our normal means of receiving payment. Visa and

MasterCard will be accepted, but must be charged at the time of shipment. In addition, a payment via credit card for orders totaling more than

$500 will incur a 3% convenience fee on the total transaction amount.

rEturnS:

Items specified as “Manufactured to Order” are NOT returnable.

A Return Material Authorization (RMA) number must be issued by the

factory in advance for any items that are returnable. The RMA number

MUST be noted on the outside of the returned package. Returns must be

received within 90 days of the RMA issue date. Shipping charges must

be prepaid. A minimum 20% restocking charge will be applied to all

authorized returns if received in new, unused condition in the original

packaging.

The above conditions apply to spare part returns, except spare part

returns must be received within 30 days of original shipment for electronic or electrical parts or within 90 days for all other parts.

loSS or damagE:

For customer routed shipments, Glastender, Inc. is not responsible for

any loss, damage, or delay of merchandise during shipment. Such transit

claims must be filed with the carrier. Merchandise must be examined on

arrival. If shortages occur, Glastender, Inc. must be notified in writing

within five (5) days of delivery to honor any shortage claim. Glastender

will assume responsibility for freight claims on Prepay and Add shipments but the customer must inspect freight and note any damage upon

receipt. Failure to do so may result in losses at the customer’s expense.

CuStom ordErS:

Custom orders must be paid in advance and are not subject to cancellation.

laminatES:

Some products include common, readily available plastic laminates of

the customer’s selection. There may be an additional charge if uncommon varieties are ordered.

05/18/10

CoolEr SErial numBEr information

This manual is specic to 2008 Energy Star compliant self-contained BB60, BB84, BB108,

ND52, ND72, and ND92 coolers beginning with the serial numbers and dates listed below in

addition to all BB and ND Two Zone Coolers.

BB60R 134121363F 02/26/09

BB60L 134121425F 03/03/09

BB84R 134121457F 03/04/09

BB84L 134121456F 03/04/09

BB108R 134121452F 03/04/09

BB108L 134121226F 02/17/09

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

1

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

ND52R 134121519F 03/09/09

ND52L 134121559F 03/11/09

ND72R 134121906F 04/08/09

ND72L 134121475F 03/11/09

ND92R 134121126F 02/09/09

ND92L 134122745F 06/10/09

Page 3

indEx

SErviCE and partS

Terms and Conditions................................................. 1

Warranty ....................................................................11

CoolEr SErial numBEr information ............................ 1

digital ControllEr opEration ..................................... 2

inStallation

Introduction ................................................................ 3

Utility Requirements and Connections ...................... 3

Uncrating and Start-Up Instructions .......................... 3

Operation .................................................................... 3

Cleaning Instructions .................................................. 4

Sealing Vertical Door Cooler to Floor Instructions ... 4

Cooler Installation Checklist ...................................... 5

Beer Tower Installation .............................................. 5

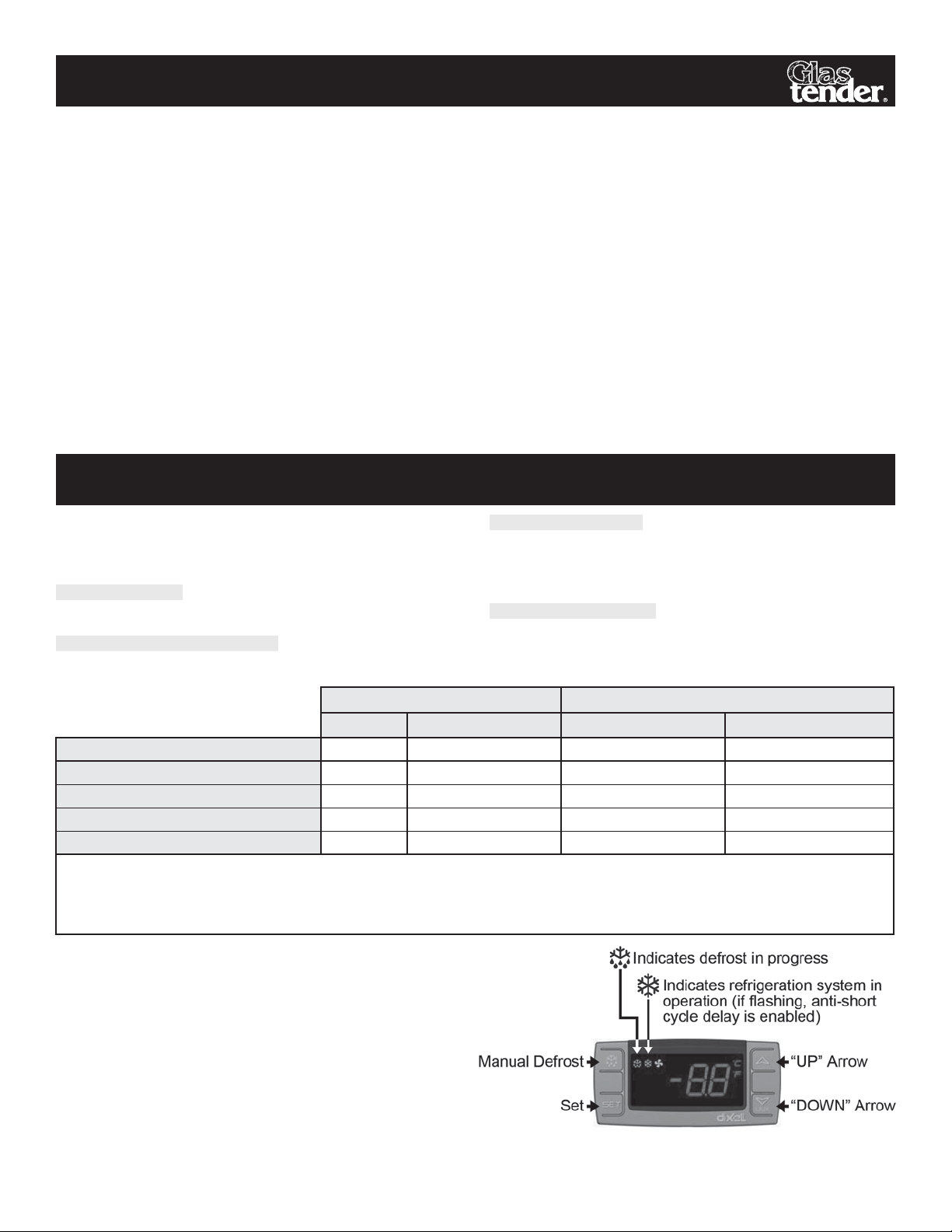

digital ControllEr opEration

The operating temperature range is preset at the factory

according to the table below and can be adjusted up or down

within the limits shown.

To see the set point - push and immediately release the SET

button. The set point will be displayed.

To return to normal visualization - Push and immediately

release the SET button or wait ve seconds.

SpECifiCationS

Electrical and Refrigeration Specifications ................ 6

Wiring Diagrams ........................................................ 6

rEplaCEmEnt partS

Compressor and Condenser Related Parts ................. 7

Evaporator and Related Parts ..................................... 8

Shelving, Racks and Related Parts ............................. 8

Doors and Related Parts ........................................ 9-10

Refrigeration Compartment Covers ........................... 9

220 Volt Electrical Parts ........................................... 10

Electrical Components ............................................. 10

To change the set point - push and hold the SET button for

more than two seconds. When the º F display begins ashing,

push the up arrow or down arrow buttons to adjust the set point

to the desired value.

To save the new set point and return to the temperature

display mode - push and release the SET button or wait ten

seconds.

Factory Settings Range of Adjustment

Set Point Operating Range† Minimum Set Point Maximum Set Point

Standard Cooler Setting

Two Zone Cooler Settings*

B = Beer

W = White Wine

R = Red Wine

34º F 34º F to 39º F 33º F 35º F

34º F 34º F to 39º F 33º F 35º F

50º F 50º F to 55º F 45º F 55º F

60º F 60º F to 65º F 55º F 65º F

† Adjusting the factory set point will also adjust the operating range by the same amount

* To determine a Two Zone Cooler refrigeration conguration, refer to the 2 digits immediately preceding the rst hyphen of the

model number found on the cooler data tag. These 2 digits will always be BW (Beer/White Wine), BR (Beer/Red Wine), or WR

(White Wine/Red Wine). Example: MODEL: BB60BR-L1-XS(LR).

The refrigerator is programmed to automatically defrost four

times daily for approximately twenty minutes. During defrost,

the fan inside the cooler will remain on and the refrigeration

system will turn off. To initiate defrost manually, push and

hold the DEFROST button for more than two seconds.

The thermostat controller does not have an “OFF” function.

To turn refrigerator off, the unit must be unplugged or power

to the electrical branch circuit has to be turned off via a circuit

breaker or switch.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

2

Page 4

inStallation

introduCtion

This manual describes the operational features of self-contained BB60, BB84, BB108, ND52, ND72, and ND92

coolers and two zone coolers. Please review this information before attempting installation and operation.

Long term, trouble-free service will follow if good housekeeping and maintenance procedures are followed.

Thank you for selecting Glastender, Inc. products.

utility rEQuirEmEntS and ConnECtionS

• Electrical: 115 Volt AC, 1 Phase, 60 Hz. A separate 15 Amp circuit is recommended. A 6-foot grounded

cord and plug is included with self-contained models.

• Plumbing: Automatic condensate evaporator is included. No drain connection required.

unCrating and Start-up inStruCtionS

All models are shipped in one carton. These steps should be followed:

1. If legs or casters are included, bolt them to the base with the bolts provided.

2. Unwrap power cord from base if included.

3. Position unit and level and/or seal as required (see page 4 and 5).

4. All units intended for draft beer must be plumbed to an external drain. On self-contained models with

draft beer and a factory installed finished top, the beer tower drain pan is plumbed through the cabinet

and stubs out in the 3" space below the compressor compartment. Connection to an external drain must

be made from that point.

5. Place shelves in desired location.

6. Plug into 115 volt AC outlet.

7. Load with bottles or cans and allow time for products to cool.

8. Your Glastender equipment is now ready for use.

opEration

The operating temperature range is 34°F (1°C) to 40°F (5°C).

Self-contained models include an automatic defrost system. The refrigerator will defrost four times daily for

approximately 20 minutes. During the defrost, the fan inside the cooler will remain on and the refrigeration

system will turn off.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

3

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 5

inStallation

COOLER DOOR

COOLER CABINET

1" BASE

BEAD SEALANT

FLOOR

MAGNETIC GASKET

ClEaning inStruCtionS

Cleaning is essential to sustaining the integrity of your equipment and preventing corrosion.

ESTIMATED CLEANING TIME: 5 to 10 minutes per unit daily, 45 minutes quarterly

FREQUENCY: Daily cleaning of exterior & door gaskets. Quarterly cleaning of interior, including shelves.

PROCEDURE:

1. A non-chlorine based cleaner or mild detergent and warm water applied with a soft cloth or sponge to all

contact surfaces.

2. Immediately rinse off cleaning agent(s), using clean warm water, clean soft cloth or sponge.

3. Dry with a soft clean cloth, removing standing water as soon as possible.

NOTES:

1. Never use hydrochloric acid, wire brushes, steel wool, scrapers, or chlorine based cleaners on stainless steel

surfaces, since they will break down the passivity layer and allow corrosion to occur.

®

2. On stainless steel surfaces, you may use a soft bristle brush or Scotch-Brite

Always scrub with the direction of the grain. Follow with a thorough cleaning as described above.

3. Deposits from food preparation must be properly removed. Even hard water deposits will rust stainless steel,

if not removed.

4. Repeated cleaning may dry up black-vinyl-clad steel (exterior) surfaces of the cooler. Armor All® or similar

product can bring back the shine. Apply the product to a cloth and then rub into the surface, rather than spraying it directly onto the black-vinyl-clad surface.

5. The cooler door gaskets are most often overlooked when cleaning. Failure to clean them regularly will lead to

premature failure, since alcohol and moisture build-up breaks down the gasket material.

pad for more stubborn stains.

SEaling vErtiCal door CoolEr to floor

To comply with NSF & health codes, the cooler base must be sealed to the floor using NSF listed sealant. Place

a bead of sealant along outer edges of the base and remove excess with disposable towel. The floor sealing

procedure does not apply to models that include legs or casters.

Side View of Cabinet

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

4

Page 6

inStallation

attEntion inStallEr: WARNING!!

Failure to level this cooler WILL VOID THE FACTORY WARRANTY. Doors will not close properly causing

damage to hinges, handles, and/or gaskets which will adversely affect the refrigeration systems.

Cooler with 6" legs

CoolEr inStallation ChECkliSt

Is the unit evenly and solidly supported, either upon legs, or flat on the base; check for high spots?

Cooler without legs

If the unit was designed for legs, are they attached?

Is the unit level at the base, from end to end?

Do the doors open and close freely, without touching any other part of the unit in travel?

Are there open holes to the outside of the cabinet which are not plugged or insulated?

Are there obstructions of any kind to air flow into or out of the condensing unit?

Is product tubing or are other lines installed in such a manner to not allow shelf access?

SpECial inStruCtionS for BEEr towEr inStallation

Before you begin:

1. Disassemble the tower into three parts, stiffener, skin, and top plate, by

unscrewing the top two screws.

2. Mount the column stiffener with the provided four 1/4"-20x1-1/2" bolts.

3. Install insulation provided into the bottom of the column stiffener.

4. Place the column skin over the stiffener. Run the beer lines through the

hole at the same time.

5. Install insulation provided into the top of the tower assembly.

6. Mount the column top plate to the column stiffener with the two #10-32x1/2" phillips at head s/s machine

screws provided.

7. Apply a bead of silicone sealant around the perimeter of the column. Use your nger to smooth out the bead.

8. Wash tapping device and faucet with detergent and water. Flush beer tapping device and faucet lines.

top plate

stiffener

skin

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

5

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 7

ElECtriCal and rEfrigEration SpECifiCationS

BB60, nd52 modElS

ElECtriCal rEfrigErant prESSurE p.S.i.g

115V, 1 phase, 60 Hz, 6.5 full load amps, 1/4 HP typE R134a, ChargE 16.0 oz. high 186, low 88

BB84, BB108, nd72, nd92 modElS

ElECtriCal rEfrigErant prESSurE p.S.i.g

115V, 1 phase, 60 Hz, 6.5 full load amps, 1/4 HP typE R134a, ChargE 16.0 oz. high 331, low 174

BB and nd two ZonE modElS

ElECtriCal rEfrigErant prESSurE p.S.i.g.

120V, 1 phase, 60 Hz, 6.5 full load amps, 1/3 HP typE R134a, ChargE 16.0 oz. high 350, low 88

wiring diagram

SelfContained

Unit

Overload

S

Start Relay

Compressor

Blue

Green

Blue

C

R

Start Capacitor

Cond Fan

White

Evap Fan Switch

Evap Fan

Fans Per

Unit Varies

White

Evaporator

White

White

Power Supply

120VAC 60HZ 1PH

Optional

230VAC 50/60HZ 1 PH

Blue

Black

Green

White

Blue

Transformer

120/240VAC 50/60HZ

Blue

White

Orange

12 VDC

Orange

White

+

-

Blue

Mate

N' Lock

Lights

Lights Per

Unit Varies

Wiring For

Optional Packages

Temp Probe

Digital Controller

Self Contained

Units Only

123

4 6

Optional Beer Tower

Blower Package

Blowers per

unit varies

Supply

9

8

7

Orange

Orange

White

Blue

Mate

N' Lock

Optional Wine

Chiller Package

Blower Motors

Wine Chiller

Controller

123

Temp Probe

Blue

White

Controller supply wires

will be jumpered to the

main controller by

matching numbers

Supply

4 6

9

8

7

Red

Red

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

6

Page 8

ComprESSor and CondEnSEr rElatEd partS

part no. dESCription priCE

1. 11000084 1/4 HP Tecumseh compressor, R134a $390.00

2. 06001382 Start capacitor for 1/4 HP Tecumseh R134a compressor 15.00

3. 04000243 Relay for 1/4 HP Tecumseh R134a compressor 18.00

4. 06001303 Overload protector for 1/4 HP Tecumseh R134a compressor 10.00

5. 06001445 Condenser fan motor 35.00

6. 06001395 Fan blade, 5 blade, white 5.00

7. 06004180 Bracket, fan, evaporator 14.00

8. 06001393 Condenser coil 230.00

9. 06006088 Fan shroud, condenser 20.00

10. 06001385 Filter dryer, 1/4" x 1/4" 20.00

11. 06000846 Drain pan, condensing unit, endwall cooler 9.00

12. 07000234 Wicking material 24.00

13. 06001350 Tubing, drain, clear plastic, per foot, 3/4" ID 3.50

14. 06000845 Base, condensing unit 22.00

15. 06003950 Thermostat, switch, digital temperature, LED display 165.00

06003951 Probe, PVC 5' cable, for use with digital temperature switch 06003950 30.00

16. 06001313 Condensing unit power cord 20.00

06006096 Expansion valve, 1/8 ton, 134a, cooler/slide top 115.00

1

3

13

4

6

2

5

16

15

11

8

9

10

14

7

12

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

7

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 9

EvaporatorS and rElatEd partS

part no. dESCription priCE

06001383 Evaporator fan guard 12.00

06004394 Evaporator fan motor 30.00

06001395 Fan blade, 5 blade, white 5.00

06004180 Bracket, fan evaporator 14.00

06004231 Coil, evaporator 200.00

06004417 Drain pan, evaporator, right 48.00

06004418 Drain pan, evaporator, left 48.00

06007317 Assembly, shroud, evaporator, 2-fan, e/s 150.00

06003950 Thermostat, switch, digital temp, LED display 165.00

06006108 LED light strip 25.00

06006109 Power supply for LED light strip 55.00

06001412 Switch 5.00

06000888 Electrical Outlet, black (Triboro with no ground) 7.50

06001409 Receptacle, snap in with ground 5.00

06001553 Thermometer 6.00

06003951 Digital temperature probe 30.00

ShElving, raCkS and rElatEd partS

part no. dESCription priCE

06004398 Shelf for ND72 middle 77.00

06004389 Shelf (fits end doors) 77.00

06004396 Shelf for middle door 77.00

06004397 Shelf for ND models (end doors) 77.00

06006013 Shelf divider 18.00

06001557 Pilaster 3.00

06001574 Thumbscrew, stainless steel, for pilaster 2.00

06001565 Clip, for pilaster, stainless steel 2.00

00000018 Nut, acorn, 8/32" natural nylon 1.00

06001579 ABS Scuff Channel with mounting screws 26.00

06001580 ABS Scuff Channel (ND models) with mounting screws 26.00

. 06006264 Wine rack shelf for BB, stainless steel with slots for 7 bottles 126.00

06006265 Wine rack shelf for ND, stainless steel with slots for 5 bottles 126.00

06006236 Keg rack (ND end) 195.00

06006235 Keg rack (BB middle) 195.00

06006234 Keg rack (BB ends, ND middle) 195.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

8

Page 10

doorS and rElatEd partS

part no. dESCription priCE

06001462 Door handle, stainless 60.00

06001653 Door handle, brass 110.00

06001536 Door lock, stainless 36.00

06004009 Key, #806, for stainless cooler door lock (06001536) 4.00

06001535 Door lock, brass 43.00

06004010 Key, #606, for brass cooler door lock (06001535) 4.00

06001677 Plug for door handle, stainless 1.00

06001678 Plug for door handle, brass 1.00

00000200 Screws for top of handle, stainless (set of 2), 10/32 x 1" PFH Machine Screw 1.00

00000016 Screws for top of handle, brass (set of 2), 10/32 x 5/8" PFH Machine Screw 1.00

00000046 Screw for bottom of handle, stainless, and screws for old style brackets .50

00000043 Screw for bottom of handle, black .50

06006207 Hinge set and brackets, 180º swing, left (complete with screws) 35.00

06006208 Hinge set and brackets, 180º swing, right (complete with screws) 35.00

06001322 Lock bracket 10.00

06006596 Hinge set & brackets for wood doors, 180º swing, left (complete with screws) 45.00

06006597 Hinge set & brackets for wood doors, 180º swing, right (complete with screws) 45.00

06006269 Lock bracket for raised wood panel doors 10.00

06004390 Gasket, door, Energy Star cooler, gray, 22½" x 32" OD 45.00

06006178 Gasket, door, Narrow Door Energy Star, gray, 18½" x 32" OD 45.00

00000067 Screw for door hinges (4 required) .50 ea.

00000041 Bolts for brackets (6 required) .50 ea.

06001485 Plastic washer for hinge 1.00

06001569 Bushing for hinge (gray) 1.00

06007095 Standard laminated door trim rail kit 35.00

06007096 Laminated door trim rail kit, for narrow doors 35.00

rEplaCEmEnt doorS for BB60, BB84, and BB108 modElS

part no. dESCription priCE

06006250 Black vinyl clad door 308.00

06006251 Unlaminated door 308.00

06006252 Laminated door 428.00

06006253 Stainless door 358.00

06006254 Stainless Steel Glass Door 648.00

06006255 Black Vinyl Clad Glass Door 598.00

06006256 Laminated Glass Door 718.00

rEplaCEmEnt doorS for nd52, nd72, and nd92 modElS

06006260 Black vinyl clad door, narrow 308.00

06006261 Unlaminated door, narrow 308.00

06006262 Laminated door, narrow 428.00

06006263 Stainless door, narrow 358.00

06006257 Stainless Steel Glass Door 648.00

06006258 Black Vinyl Clad Glass Door 598.00

06006259 Laminated Glass Door 718.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

9

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 11

rEfrigEration CompartmEnt CovErS

part no. dESCription priCE

06007628 Grill, black vinyl clad, BB & ND w/digital control, 12”, replacement kit 120.00

06007629 Grill, stainless, BB & ND w/digital control, 12”, replacement kit 140.00

06007630 Grill, unlaminated, BB & ND w/digital control, 12”, replacement kit 140.00

06001360 Grill insert, refrigeration compartment cover, polypropylene, black 25.00

06001361 Grill insert, refrigeration compartment cover, polypropylene, gray 25.00

06001546 Filter, refrigeration compartment grill insert 5.00

06001848 Laminated compressor compartment trim rail kit, for BB and ND models 39.00

06001555 Rubber Bumper 2.15

220 volt ElECtriCal partS

part no. dESCription priCE

06006103 Compressor, 1/4 HP, 134a, 220VAC, 60Hz, AEA4430YXD $665.00

06006175 Compressor relay 15.00

06006176 Compressor overload 14.00

06006174 Compressor capacitor 15.00

06006101 Motor, evaporator fan, 220 volt, 1000 rpm (SA 145-232) 30.00

06001448 Motor, fan, 220 volt 1300RPM 50.00

06004232 Digital controller (220V version 06004232 - TS2-020) 200.00

ElECtriCal ComponEntS

part no. dESCription priCE

06006121 Replacement powercord assembly, includes (06001572 06001314) $40.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

10

Page 12

warranty StatEmEnt

APPLICABLE TO ALL PRODUCTS SOLD WITHIN THE UNITED STATES AND CANADA

LABOR: Glastender, Inc. warrants all products to be free of defects

in material and workmanship. In established areas, a start-up and a

90-day labor warranty are included with glasswasher models GT-24

and GT-30. The GT-18 series glasswashers include a 90-day labor

warranty. Self-contained refrigeration models, except beer line chillers, include a 1-year labor warranty, for the duration of one year from

date of installation or up to 18 months from date of factory shipment,

whichever occurs sooner. For warranty labor claims beyond 15 months

from the date of factory shipment, proof of date of installation or occupancy must be provided. Authorization for labor must be obtained from

Glastender within the warranty period and prior to the service being performed. Labor warranty applies to the United States and Canada only.

PARTS: Within one year from date of installation or 18 months from

date of factory shipment, whichever occurs sooner, Glastender, Inc.

will replace any part or assembly found defective under normal use and

service. Field replacement parts include a warranty of 90 days from date

of installation.

FOUR YEAR ADDITIONAL COMPRESSOR WARRANTY: Glastender

will warrant to the original user the compressor for all self-contained

refrigeration models for an additional four years following the regular

one-year warranty period. This plan applies to the compressor only.

A warranty claim form MUST accompany all returned defective

parts or assemblies. This form MUST be completed in full. Failure

to do so may result in delay or denial of credit. Any defective part or

assembly must be returned to Glastender, Inc., Saginaw, Michigan,

with all transportation and delivery charges prepaid. Warranty repairs

or replacements will be shipped FOB factory in Saginaw, Michigan.

Reimbursement for applicable freight charges covers ground service only.

Glastender provides in-warranty repairs during a service company’s

regular working days and hours. There is no provision for payment

of a premium rate during “overtime” hours. When warranty service is

requested during other than normal working hours, the end user will be

charged the premium portion of the overtime rate.

The warranty does not cover equipment subjected to accidents, freight

damage, alterations from the original design, improper power and/or

plumbing hookups, improper chemical use, general misuse, or lack

of routine required maintenance as determined by Glastender, Inc.

Installation, normal control adjustments, general maintenance, correcting an installation error, or service calls that reveal the unit is functioning normally will not be reimbursed under warranty.

Condenser coils on self-contained refrigeration products must be

cleaned regularly. Failure to provide adequate air flow to a refrigeration

unit will void the warranty.

SECOND YEAR EXTENDED PARTS & LABOR WARRANTY:

Glastender’s one-year parts and labor warranty on self-contained refrigeration units, excluding beer line chillers, can be extended to two years

with the purchase of a two year parts and labor warranty. Specify part

number EWR2 ($150 net price) when ordering.

EXPORT WARRANTY - One year parts only.

EXCLUSION OF WARRANTIES

EXCEPT AS PROVIDED ABOVE, GLASTENDER MAKES

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

OR NON-INFRINGEMENT.

LIMITATION OF REMEDIE S AN D D AMAGES

If Buyer makes a valid and timely claim as outlined above, Glastender’s

liability and Buyer’s remedies under this agreement will be limited solely

to labor charges authorized and/or replacement or credit, at Glastender’s

option, with respect to Products returned at Buyer’s expense within thirty (30) days after warranty repair. GLASTENDER’S LIABILITY WILL

IN NO EVENT BE GREATER IN AMOUNT THAN THE PURCHASE

PRICE OF THE RETURNED PRODUCTS. GLASTENDER

WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCE FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING,

BUT NOT LIMITED TO, LABOR COSTS EXCEPT AS COVERED

UNDER OUR WARRANTY, LOST PROFITS OR THE LOSS OF

PERISHABLE PRODUCTS RESULTING FROM THE USE OF OR

INABILITY TO USE OUR PRODUCTS OR FROM OUR PRODUCTS’

INCORPORATION INTO OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT. NEITHER PARTY WILL HAVE ANY

NEGLIGENCE OR OTHER TORT LIABILITY TO THE OTHER, OR

TO ANY THIRD PARTY, ARISING FROM ANY BREACH OF THIS

AGREEMENT.

GOVERNING LAW - JURISDICTION

The terms and conditions of an order are to be governed and construed

according to the laws of the State of Michigan, without regard to conflict

of laws principles. Buyer hereby consents to the jurisdiction and venue

of the courts located in Saginaw County, Michigan.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Customer Service Representative.

Glastender shall not be liable for loss of use, revenue, or profit, or for any other indirect, incidental, special, or consequential

damage including, but not limited to, product spoilage or loss.

This warranty is conditioned upon Glastender receiving notice of any

defect subject to this warranty within sixty (60) days of its discovery

by the end user or dealer. All products are warranted only for the initial

place of installation. Removal of a product automatically terminates this

warranty.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

11

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

03/03/10

IMPORTANT!!

Attention Refrigeration Service Companies

Please review the important warranty information on this page. If you

believe a service call should be covered by the factory, please call

the factory for authorization between 8AM and 5PM EST, Monday

through Friday.

Loading...

Loading...