Glas-craft Super Maxi User Manual

Super

Maxi

Dispensing System

USER MANUAL

5845 WEST 82nd STREET, SUITE 102

INDIANAPOLIS, INDIANA 46278 U.S.A.

Phone (317) 875-5592

Fax (317) 875-5456

E-Mail sales@glascraft.com

Web www.glascraft.com

P

r

o

b

l

e

r

An ISO 9001

Approved

Company

Specialized Dispensing

Equipment and Technology

CE

CERTIFIED

CONTENTS

Introduction

ABOUT THIS MANUAL 1

RELATED MANUALS 1

Operation

Parts & Illustrations

SUPER MAXI SYSTEM LIST 2

OPTIONS 2

SERVICE KITS 2

SYSTEM SPECIFICATIONS 3

23600-00 SUPER MAXI SYSTEM ASSEMBLY 4

23600-00 SUPER MAXI SYSTEM ASSEMBLY 5

23600-00 SUPER MAXI SYSTEM ASSEMBLY 6

23620-00 SUPER MAXI CONTROL BOX ASSEMBLY 7

23620-00 SUPER MAXI CONTROL BOX DETAILS 8

SUPER MAXI 220V, SINGLE PHASE SCHEMATIC 9

23625-XX PROPORTIONING UNIT ASSEMBLY 10

23625-XX PROPORTIONING DETAILS 11

AM-600-00 AIR MOTOR 12

21835-00 FLUID SECTION ASSEMBLY 13

22075-00 DUAL HEAT EXCHANGER ASSEMBLY 14

22075-00 DUAL HEAT EXCHANGER ASSEMBLY 15

20005-48 HOSE ASSEMBLY 16

17254-01 PROBLER SPRAY GUN 17

Safety

SAFE HANDLING AND USE OF SPRAY EQUIPMENT 18

Installation

ASSEMBLY INSTRUCTIONS 21

AIR SUPPLY CONNECTION 21

ELECTRICAL CONNECTION 21

Overhaul Procedure

Limited Warranty Policy

30

Notes

31

If You Have An Equipment Problem

32

PRE-OPERATION CHECK LIST 22

INITIAL START-UP PROCEDURE

FILLING THE SYSTEM 22

OVER PRESSURE

SYSTEM PROTECTION 24

OVER PRESSURE

PROBLEM CORRECTION 24

CONTROL PANELS 24

PROPORTIONING PUMP 25

AIR MOTOR 25

SYSTEM SHUT- DOWN 25

BREAKING DOWN PUMP 27

DISASSEMBLE SUB-ASSEMBLIES

CLEANING

INSPECTION

RE-ASSEMBLE

FOR 19875-00 PUMPS 28

INTRODUCTION

About This Manual

Before operating, maintaining or servicing any Glas-Craft

system, read and understand all of the technical and

safety literature provided with Glas-Craft products. If you

do not have the manuals and safety literature for your

Glas-Craft system, contact your Glas-Craft distributor or

Glas-Craft, Inc.

In this Glas-Craft technical and safety publication, the

following advisories will be provided where appropriate:

NOTE

Is information about the procedure in progress.

CAUTION

Is imperative information about equipment protection.

WARNING

Is imperative information about personnel safety.

The information in this document is intended only to

indicate the components and their normal working

relationship typical use. Each assembly should be

directed by a Glas-Craft distributor or made from the

Glas-Craft assembly instructions provided.

This manual provides information for the assembly,

operation, maintenance and service of this Glas-Craft

product as used in a typical configuration. While it lists

standard specifications and procedures, some deviations

may be found.

In order to provide our users with the most up-to-date

technology possible, we are constantly seeking to

improve products. If technological change occurs after a

product is on the market, we will implement that

technology in future production and, if practical, make it

available to current users as a retrofit, up-date or

supplement. If you find some discrepancy between your

unit and the available documentation, contact your Glas-

Craft distributor to resolve the difference. Glas-Craft, Inc.

reserves the right to change or modify this product as it

deems necessary.

Careful study and continued use of this manual will

provide a better understanding of the equipment and

process, resulting in more efficient operation, longer

trouble-free service and faster, easier trouble-shooting.

Related Manuals

For detailed component installation, operation and

maintenance, refer to the following component manuals:

COMPONENT MANUAL

NUMBER

17254 Probler Gun GC-1023

1

PARTS & ILLUSTRATIONS

Includes

23600-00 Super Maxi FOAM SYSTEM

* 6" AIR MOTOR, 1 PHASE, 200/240 VAC, 50/60 HZ., 60 AMP

17254-01 PROBLER GUN ASSEMBLY

* W/ ROUND SPRAY MIXING CHAMBER

20005-48 HEATED HOSE ASSEMBLY, 50 FT.

23625-XX PROPORTIONING UNIT ASSEMBLY

22075-00 DUAL HEAT EXCHANGER ASSEMBLY

59934-04 DIOCTYL PHTHALATE, 1 QT.

17661-03 GUN SERVICE KIT

21845-00 PUMP FLUID SECTION SERVICE KIT (TWO SUPPLIED)

18467-01 FLUID FILTER (TWO SUPPLIED)

17195-00 MIXING CHAMBER REMOVAL TOOL

USER MANUALS

Options

21403-48 HIGH HEAT EXTENSION HOSE ASSY., 50 FT.

> maximum Hose length, 210 FT.

Service Kits

17661-03 GUN SERVICE KIT

2

SYSTEM SPECIFICATIONS

MATERIAL RATIO: 1:1 (FIXED)

MATERIAL VISCOSITY: 200-2000 CENTIPOISE (CPS) @ AMBIENT

(*system set -up for transfer feed)

(lower foot valves spring loaded)

OUTPUT: .042 GAL

MAX OUTPUT= 2.52 GAL / MIN @ 60 CYCLES / MIN

OPERATING TEMPERATURES: 32° F (0°C) - 190° F (88° C) CONTINUALLY VARIBLE

OPERATING PSI: 3200 PSI. MAX (over psi switches set)

2200 PSI. @ 100 PSI. AIR MOTOR

PURGING: AUTOMATIC PNEUMATIC, SOLVENT-FREE, CONSTANT

ELECTRICAL REQUIREMENTS: 208 VAC

50 AMPS

50/60 HZ

SINGLE PHASE

COMPRESSED AIR REQUIREMENTS: SYSTEM (includes 2:1 aro transfer pumps)

1.0 GAL PER MINUTE – 34.4 CFM @ 100 PSI.

1.5 GAL PER MINUTE – 50.6 CFM @ 100 PSI.

2.0 GAL PER MINUTE – 57.4 CFM @ 100 PSI.

NOTE: As output is increased, (achieved w/ chamber size on

gun or spray tip), pressure drop will be greater. Heater

temperature will also drop.

HEATERS: 1500 WATT RODS

3000 WATTS PER SIDE

6000 WATTS TOTAL

MAXIMUM HOSE LENGTH:

OVERALL DIMENSIONS:

SHIPPING WEIGHT:

3

21802-00

Machine Screw

Support Mast

23602-00

Decal

(SUP ER MAXI)

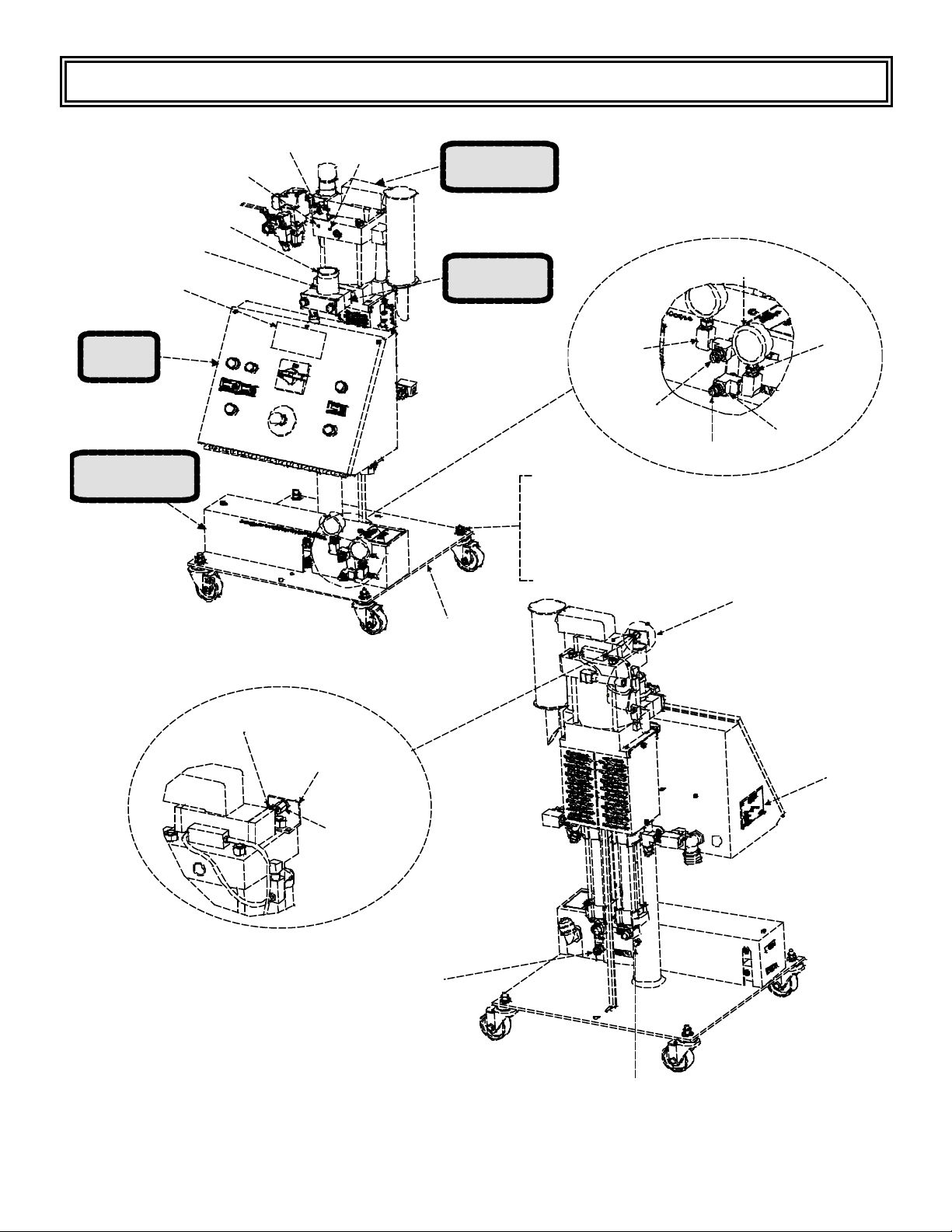

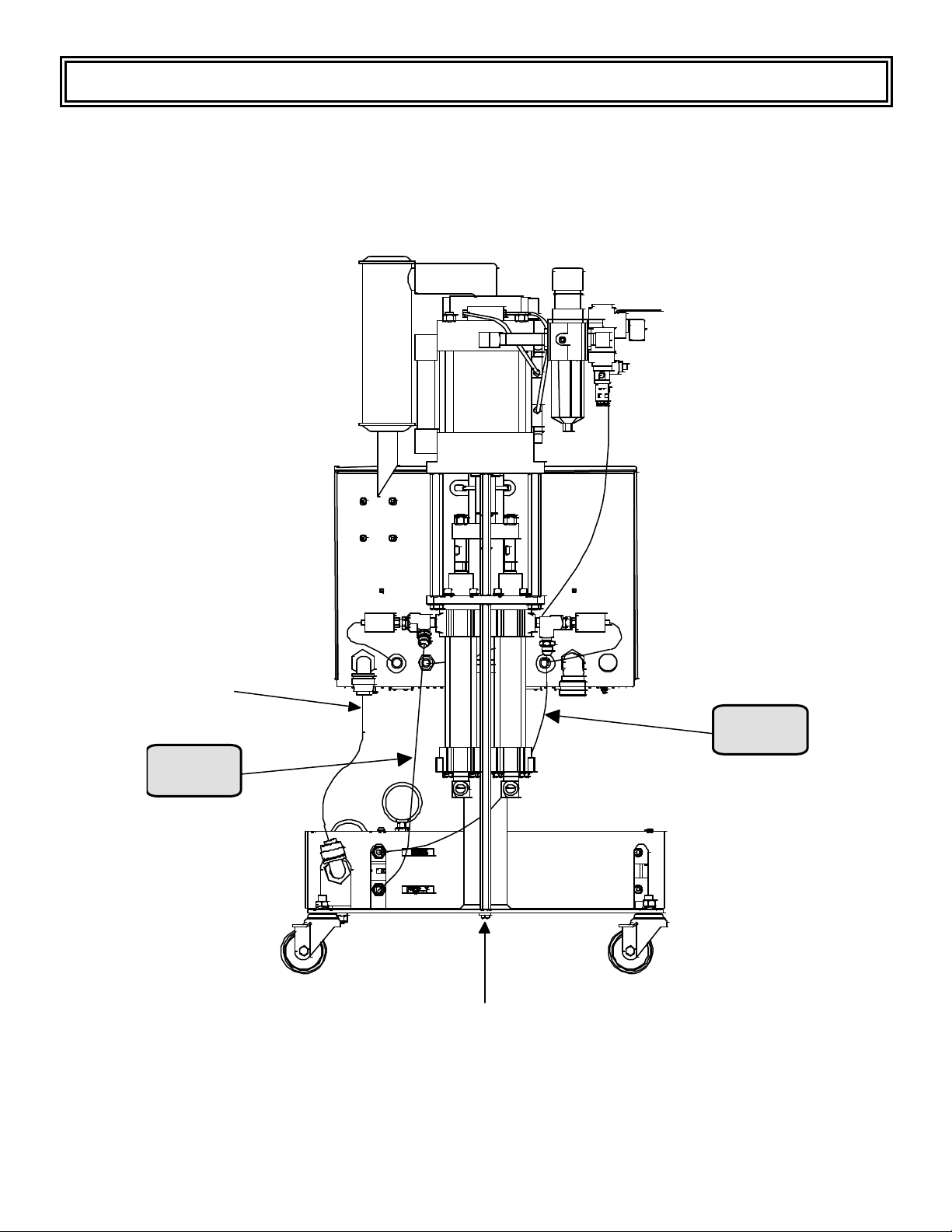

23600-00 SUPER MAXI SYSTEM ASSEMBLY

22084-00

Decal

(RETRACT)

19882-00

Cap

22086-02

Retra ct Switch Kit

22083-00

Decal

(RUN)

23625-00

Pr oportioning Unit

As sy.

19890-00

M ounting Clam p

As sy.

21881-00

Pressure Gauge

23620-00

Control Box

As sy.

22075-00

Dual H eat Exchanger

As sy.

10080-05

Ba rb Hose Fitting

22087-00

Retrac t Switch Bracket

21660-00

2-W ay Control Valv e

18291-00

Floor Mount Ma st

20368-00

S wivel Casters

7733-42

Nut

7734-10

Lock Washer

7486-04

Flat W asher

4342-23

Elbow Fitting

8560-17

Fitti ng

21315-00

Fitti ng

6782-23

Tee Fitting

22086-02

Retract Sw itch Kit

7966-17

Fitting

17826-00

Nam e Plate

14638-04

Blind Rivot

8560-03

Fitting

7957-32F

4

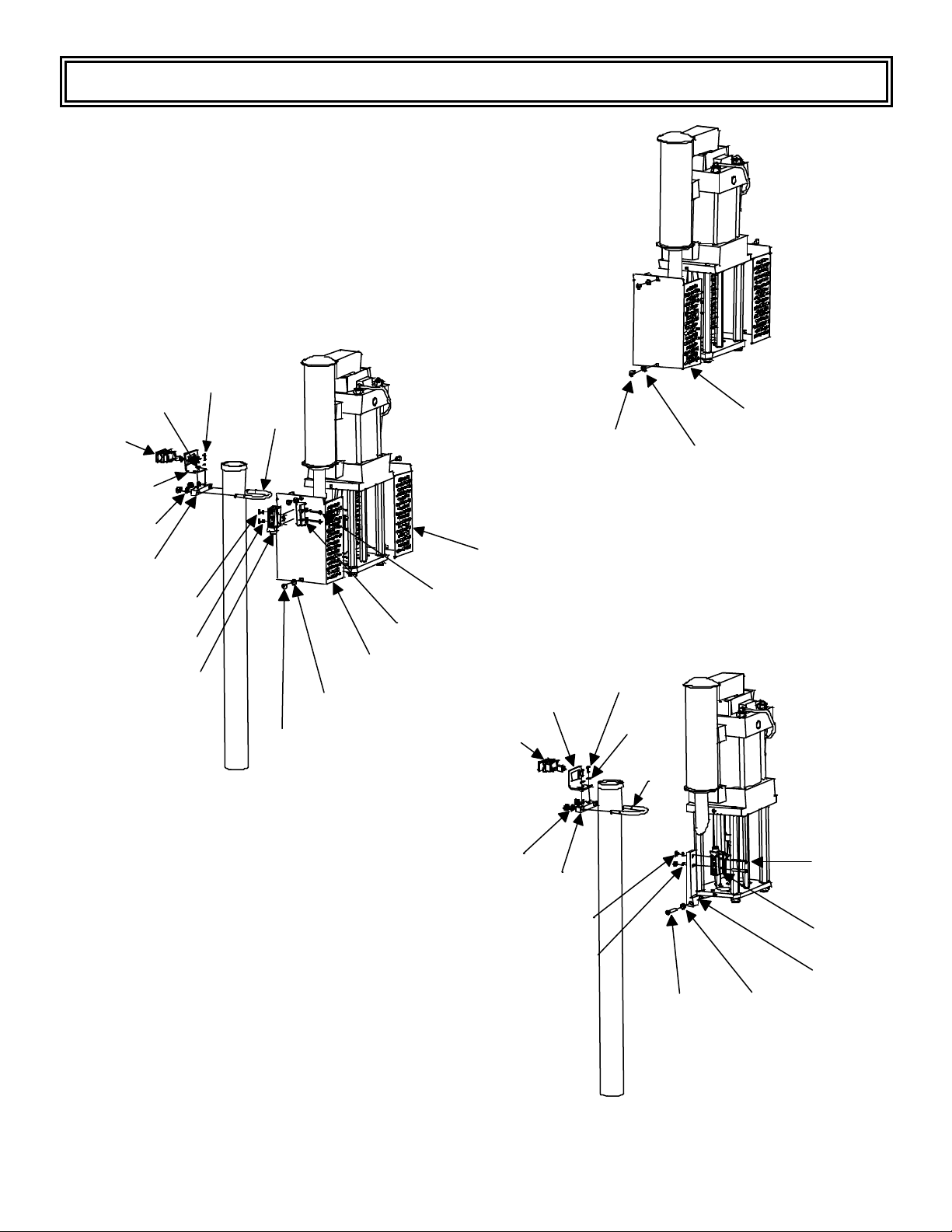

23600-00 SUPER MAXI SYSTEM ASSEMBLY

Flat Washer

21323-00

Flexible Conduit

21809-01

M aterial Hos e

As sy.

7957-32F

Machine Screw

7486-10

21809-02

M aterial Hos e

As sy.

5

7734-04

COUNTER OPTION

Lock W asher

21470-00

Counter

21653-00

Counter Bracket

7734-07

Lock Washer

23603-00

Counter Bracket

23600-00 SUPER MAXI SYSTEM ASSEMBLY

7730-16C

Machine Screw

CP-126

7733-06

Nut

7734-03

Lock Washer

22101-00

Lim it Switch

U-Bolt

7734-06

Lock Washer

20188-16C

Machine Screw

7486-27

Flat Washer

21806-00

Left Sur round Guard

21807-00

Right Surround Guard

7735-40C

Machine Screw

21470-00

Counter

21653-00

Counter Bracket

20188-16C

Machine Screw

GUARD OPTION

7730-16C

Machine S crew

7733-04

Lock W asher

CP-126

U-Bolt

7734-06

Lock Washer

21807-00

Right Surround

G uard

GUARD WITH COUNTER OPTION

7734-07

Lock Washer

6

23603-00

Counter Bracket

7733-06

Nut

7734-03

Lock W asher

9944-48C

Machine Screw

7734-06

Lock Washer

8301-48C

Machine Screw

22101-00

Limit Sw itch

22512-00

Counter S witch

Bracket

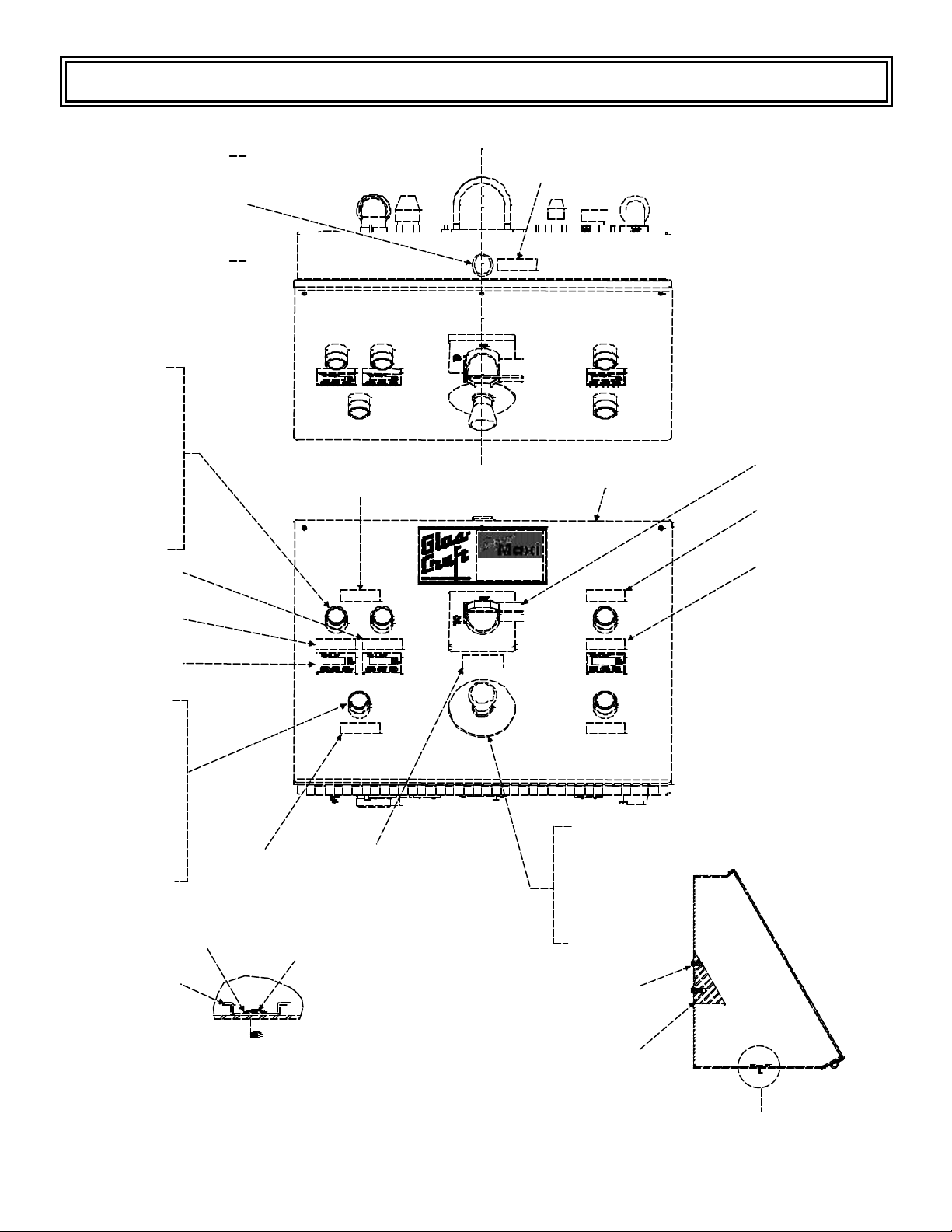

23620-00 SUPER MAXI CONTROL BOX ASSEMBLY

C

D

D

D is pe n s i ng

Sys t e m

RS-124

Decal

(MAIN)

23621-00

Super Ma xi

Control Box

21864-00

E mergency Stop

P ush Button

22104-00

Decal

21865-02

Contac t Block

21865-01

Contac t Block

Mounting Lamp Block

21887-01

Y ellow Color Cap

21862-00

Push Button

21867-03

Inscri ption Cap

21865-02

Contact Block

21361-00

Minia ture Lamp

21866-00

Coupling Pl ate

21886-00

Body

RS-119

De cal

(POLY)

RS-118

De cal

(IS O)

21356-01

Microprocess or

Control

21854-00

Push Button

21867-05

Inscri ption Cap

21887-03

Green Color Cap

21865-01

Contact Block

21361-00

Minia ture Lamp

21866-00

Coupling Pl ate

21886-00

Mountin Lamp Bl ock

17702-00

Pilot Lamp

22150-00

Pilot Light

21866-00

Coupling P late

21886-00

7486-28

Flat Washer

R S-122

Decal

(PRIMARY)

22753-00

(OVE RPRESSURE)

(O VERTEMP)

14638-02

Blind Rivot

Deca l

R S-124

Decal

(MAIN)

22178-00

O n/Off Power Switch

21355-00

Decal

(O VER TEMPERATURE)

R S-121

Decal

(HOSE)

21823-00

Din Ra il

D etail

C

7

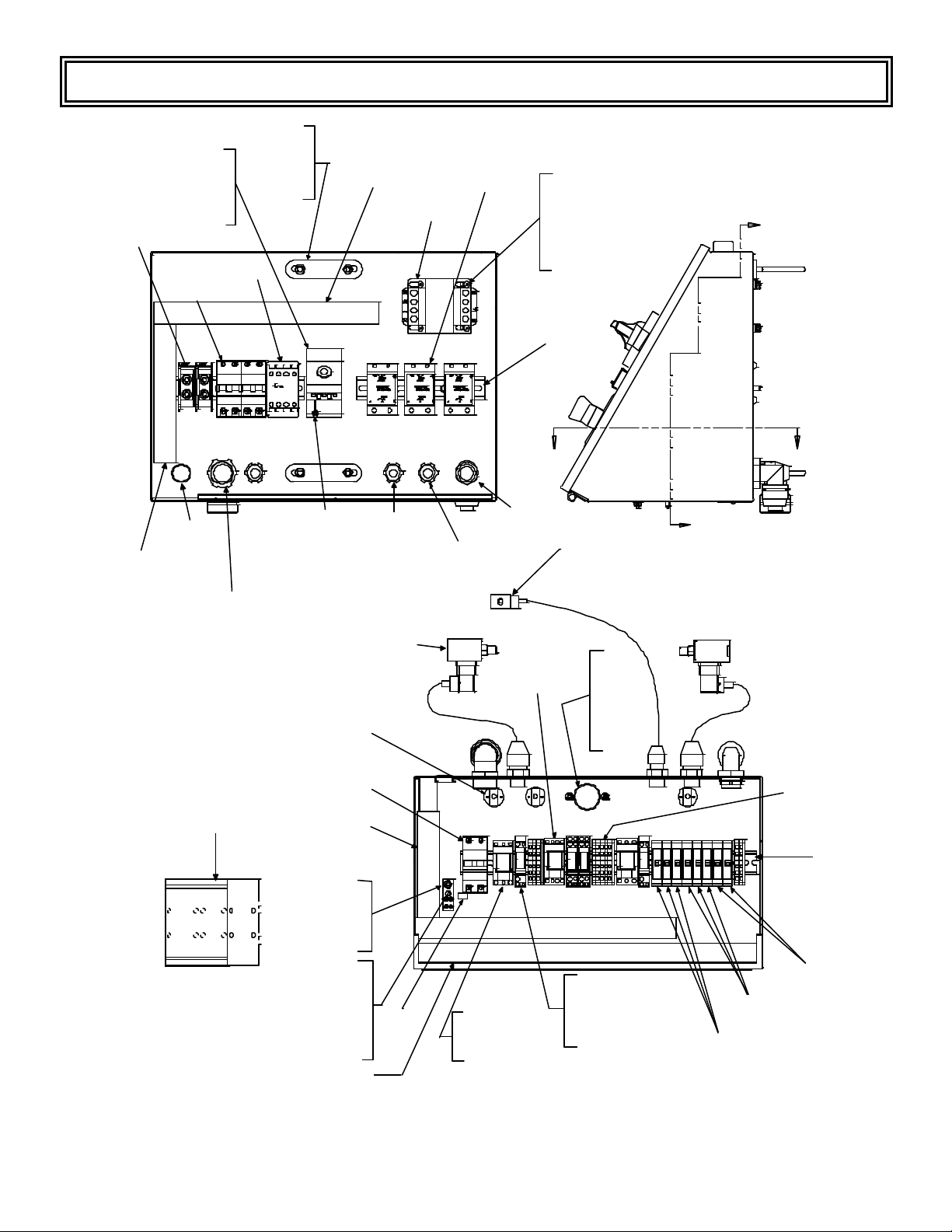

20188-20C

Mac hine Screw

21722-00

Mounting Bra cket

S ee Detail

23620-00 SUPER MAXI CONTROL BOX DETAILS

0

Wiring Duct

Mounting Block Bracket

On/Off Switch Block

22157-00

Termina l Block

22158-00

Te rminal Block Spacer

21722-00

22171-01

22174-01

Cover

21888-06

Circ uit Breaker

Strap Washer

22709-02

Contactor

CP-126

U-Bolt

19941-00

7734-07

Lock Washer

22527-00

Wi ring Duct Cover

22528-00

Wiring Duct

22142-00

Control Box Transformer

22146-02

50 Amp Relay

21824-16C

Ma chine Screw

7486-27

Fla t Washer

7734-03

Loc k Washer

7733-06

Nut

21823-00

Di n Rail

A

22527-00

Wiri ng Duct Cover

22528-00

Wiring Duct

22716-01

Hole Plug

T -4-161-01

Cable Connector

22159-00

Thermo Bl ock Cover

7735-16C

Ma chine Screw

7734-03

Loc k Washer

Section A-A

Hi gh Pressure Switch

22502-00

Circul ar Panel Jack

21334-00

The rmocouple Wire

21888-05

Circ uit Breaker

22527-00

Cord Grip

22528-00

Wiring Duct

22162-00

Conductor Connector

20226-00

Se t Screw

8160-12F

Se t Screw

9943-40F

Shoulder Screw

7486-03

Flat Washer

7734-04

Lock Washer

7733-07

Nut

22527-00

Wiri ng Duct Cover

22528-00

RS-141-02

Cord Grip

5307-01

Conduit Nut

21830-00

21848-00

De cal

RS-141-01

Cord Grip

5307-01

Conduit Nut

22422-01

10 Amp Relay

22423-01

10 Amp Relay Socket

B

21081-02

Swi vellok Connector

22422-02

5 Amp Relay

22423-02

7 A mp Relay Socket

Section

21839-00

3 -Wire Connector

7733-06

Nut

7734-03

Loc k Washer

7486-27

Fla t Washer

21815-00

Rec eptacle

21892-01

10 Amp Relay Socket

21893-01

Sock et

21894-00

Eject Cl ip

B-B

A

21164-00

1/ 2 Amp Fuse

21889-00

Fuse Holder

21164-02

2 A mp Fuse

B

22506-00

Te rminal

22507-00

Te rminal Cover

21823-0

Din Rail

21164-02

2 A mp Fuse

8

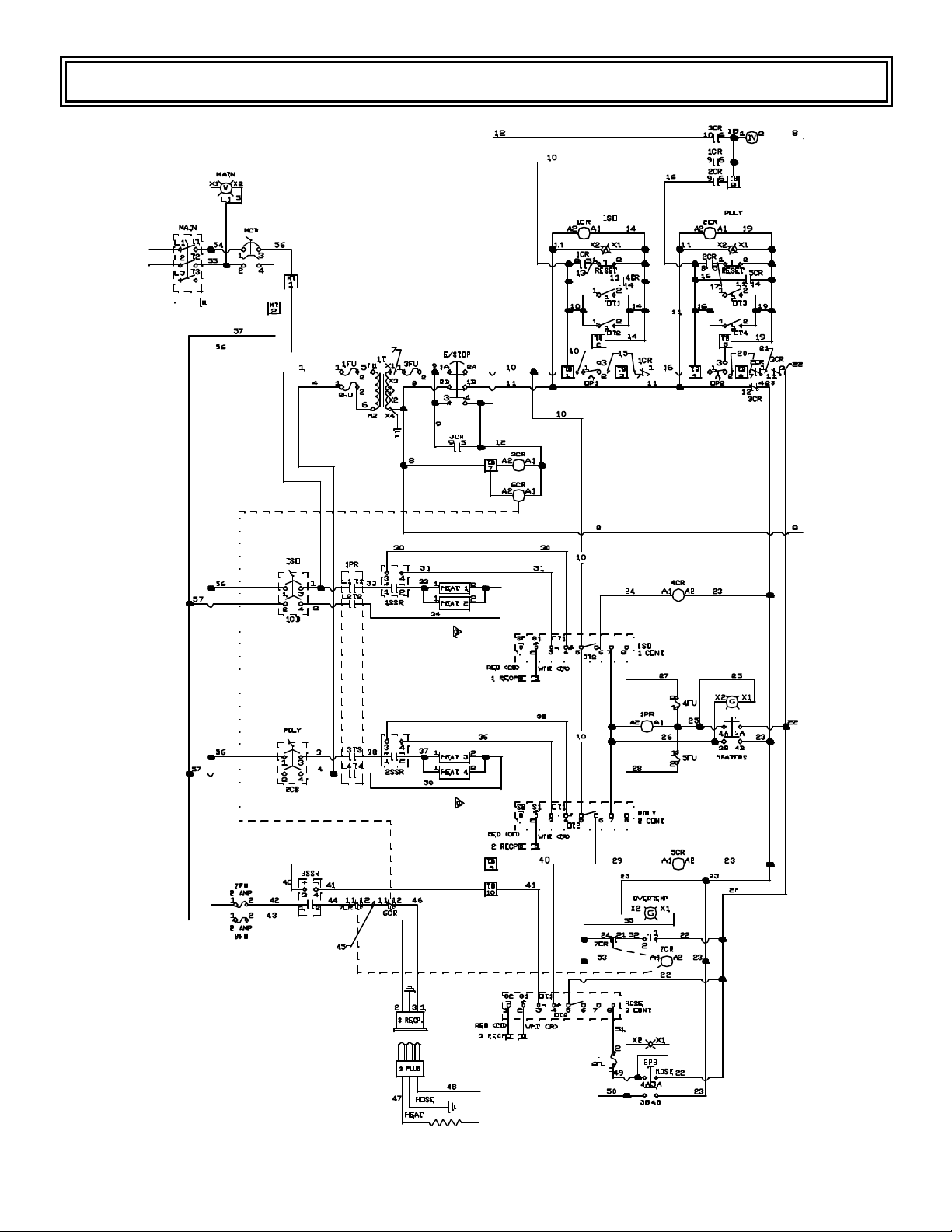

SUPER MAXI 220V, SINGLE PHASE SCHEMATIC

9

Loading...

Loading...