Page 1

R281-T91

R281-T94

Dual ThunderX2 Processors ARM Server

Service Guide

Rev. 1.0

Page 2

Copyright

© 2018 GIGA-BYTE TECHNOLOGY CO., LTD. All rights reserved.

The trademarks mentioned in this manual are legally registered to their respective owners.

Disclaimer

Information in this manual is protected by copyright laws and is the property of GIGABYTE.

Changes to the specications and features in this manual may be made by GIGABYTE without

prior notice. No part of this manual may be reproduced, copied, translated, transmitted, or published in any form or by any means without GIGABYTE's prior written permission.

Documentation Classications

In order to assist in the use of this product, GIGABYTE provides the following types of documentations:

For detailed product information, carefully read the User's Manual.

For More Information

For related product specications, the latest rmware and software, and related information, please visit

our website at:

http://www.gigabyte.com

For GIGABYTE distributors and resellers, additional sales & marketing materials are available from our

reseller portal:

http://reseller.b2b.gigabyte.com

For further information & technical assistance, please contact your GIGABYTE sales representative.

You may also message GIGABYTE server directly by email, Facebook or twitter

Email: server.grp@gigabyte.com

Facebook: https://www.facebook.com/gigabyteserver

Twitter: https://twitter.com/GIGABYTEServer

Page 3

Conventions

The following conventions are used in this user's guide:

NOTE!

Gives bits and pieces of additional

information related to the current topic.

CAUTION!

Gives precautionary measures to

avoid possible hardware or software problems.

WARNING!

Alerts you to any damage that might

result from doing or not doing specic actions.

Page 4

Server Warnings and Cautions

Before installing a server, be sure that you understand the following warnings and cautions.

WARNING!

To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it.

Pay particular attention to the plug, electrical outlet, and the point where the cord extends from

the server.

WARNING!

To reduce the risk of personal injury from hot surfaces, allow the drives

and the internal system components to cool before touching them.

WARNING!

This server is equipped with high speed fans. Keep away from hazardous

moving fan blades during servicing.

CAUTION!

• Do not operate the server for long periods with the access panel open or removed. Operat-

ing the server in this manner results in improper airow and improper cooling that can lead to

thermal damage.

• Danger of explosion if battery is incorrectly replaced.

• Replace only with the same or equivalent type recommended by the manufacturer.

• Dispose of used batteries according to the manufacturer’s instructions.

Page 5

Electrostatic Discharge (ESD)

CAUTION!

ESD CAN DAMAGE DRIVES, BOARDS, AND OTHER PARTS. WE RECOMMEND THAT YOU

PERFORM ALL PROCEDURES AT AN ESD WORKSTATION. IF ONE IS NOT AVAILABLE,

PROVIDE SOME ESD PROTECTION BY WEARING AN ANTI-STATIC WRIST STRAP ATTACHED TO CHASSIS GROUND -- ANY UNPAINTED METAL SURFACE -- ON YOUR SERVER

WHEN HANDLING PARTS.

Always handle boards carefully. They can be extremely sensitive to ESD. Hold boards only by

their edges without any component and pin touching. After removing a board from its protective

wrapper or from the system, place the board component side up on a grounded, static free surface. Use a conductive foam pad if available but not the board wrapper. Do not slide board over

any surface.

System power on/off: To remove power from system, you must remove the system from

rack. Make sure the system is removed from the rack before opening the chassis, adding, or

removing any non hot-plug components.

Hazardous conditions, devices and cables: Hazardous electrical conditions may be

present on power, telephone, and communication cables. Turn off the system and disconnect the

cables attached to the system before servicing it. Otherwise, personal injury or equipment damage can result.

Electrostatic discharge (ESD) and ESD protection: ESD can damage drives,

boards, and other parts. We recommend that you perform all procedures in this chapter only at

an ESD workstation. If one is not available, provide some ESD protection by wearing an antistatic

wrist strap attached to chassis ground (any unpainted metal surface on the server) when handling

parts.

ESD and handling boards: Always handle boards carefully. They can be extremely

sensitive to electrostatic discharge (ESD). Hold boards only by their edges. After removing a

board from its protective wrapper or from the system, place the board component side up on a

grounded, static free surface. Use a conductive foam pad if available but not the board wrapper.

Do not slide board over any surface.

Installing or removing jumpers: A jumper is a small plastic encased conductor that slips

over two jumper pins. Some jumpers have a small tab on top that can be gripped with ngertips

or with a pair of ne needle nosed pliers. If the jumpers do not have such a tab, take care when

using needle nosed pliers to remove or install a jumper; grip the narrow sides of the jumper with

the pliers, never the wide sides. Gripping the wide sides can dam-age the contacts inside the

jumper, causing intermittent problems with the function con-trolled by that jumper. Take care to

grip with, but not squeeze, the pliers or other tool used to remove a jumper, or the pins on the

board may bend or break.

Page 6

CAUTION!

Risk of explosion if battery is replaced incorrectly or with an incorrect type. Replace the battery

only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

Page 7

Table of Contents

Chapter 1 Hardware Installation .....................................................................................9

1-1 Installation Precautions .................................................................................... 9

1-2 Product Specications .................................................................................... 10

1-3 System Block Diagram ................................................................................... 13

Chapter 2 System Appearance ..................................................................................... 15

2-1 Front View ...................................................................................................... 15

2-2 Rear View ....................................................................................................... 15

2-3 Front Panel LED and Buttons ........................................................................ 16

2-4 Rear System LAN LEDs ................................................................................. 18

2-5 Hard Disk Drive LEDs .................................................................................... 19

2-6 Power Supply Unit LED .................................................................................. 20

Chapter 3 System Hardware Installation ......................................................................21

3-1 Removing and Installing the Chassis Cover .................................................. 22

3-2 Removing and Installing the Fan Duct ........................................................... 23

3-3 Removing and Installing Memory ................................................................... 24

3-3-1 Eight-Channel Memory Conguration ....................................................................24

3-3-2 Removing and Installing a Memory Module ...........................................................25

3-3-3 DIMM Population Table ..........................................................................................25

3-4 Removing and Installing the PCI Expansion Card ......................................... 26

3-5 Removing and Installing the Hard Disk Drive ................................................. 28

3-6 Replacing the Fan Assembly ..........................................................................29

3-7 Removing and Installing the Power Supply .................................................... 30

3-8 Cable Routing ................................................................................................ 31

Chapter 4 Motherboard Components ...........................................................................35

4-1 Motherboard Components ............................................................................. 35

4-2 Jumper Settings ............................................................................................. 37

Chapter 5 BIOS Setup .................................................................................................. 39

5-1 The Main Menu .............................................................................................. 41

5-2 Advanced Menu ............................................................................................. 44

5-2-1 Trusted Computing .................................................................................................45

5-2-2 S5 RTC Wake Setting .............................................................................................46

5-2-3 Network Stack Conguration ..................................................................................47

5-2-4 Info Report Conguration .......................................................................................48

5-2-5 NMVe Conguration ...............................................................................................49

- 7 -

Page 8

5-2-6 SATA Conguration.................................................................................................50

5-2-7 USB Conguration ..................................................................................................51

5-2-8 Chipset Conguration .............................................................................................52

5-2-9 Ethernet Adapter Conguration ..............................................................................53

5-2-10 MAC IPv4 Network Conguration ...........................................................................54

5-2-11 MAC IPv6 Network Conguration ...........................................................................55

5-3 Chipset Setup Menu ....................................................................................... 56

5-4 Security Menu ................................................................................................ 57

5-5 Boot Menu ...................................................................................................... 58

5-5-1 UEFI Application Boot Priorities .............................................................................60

5-5-2 UEFI NETWORK Drive BBS Priorities

.......................................................... 61

5-6 Save & Exit Menu ........................................................................................... 62

5-7 Server Management Menu ............................................................................. 64

5-7-1 System Event Log ..................................................................................................65

5-7-2 View Self Test Log ..................................................................................................66

5-7-3 View FRU Information ............................................................................................67

5-7-4 BMC Network Conguration ...................................................................................68

- 8 -

Page 9

Chapter 1 Hardware Installation

1-1 Installation Precautions

The motherboard/system contain numerous delicate electronic circuits and components which

can become damaged as a result of electrostatic discharge (ESD). Prior to installation, carefully

read the service guide and follow these procedures:

• Prior to installation, do not remove or break motherboard S/N (Serial Number) sticker or

warranty sticker provided by your dealer. These stickers are required for warranty validation.

• Always remove the AC power by unplugging the power cord from the power outlet before

installing or removing the motherboard or other hardware components.

• When connecting hardware components to the internal connectors on the motherboard,

make sure they are connected tightly and securely.

• When handling the motherboard, avoid touching any metal leads or connectors.

• It is best to wear an electrostatic discharge (ESD) wrist strap when handling electronic

components such as a motherboard, CPU or memory. If you do not have an ESD wrist

strap, keep your hands dry and rst touch a metal object to eliminate static electricity.

•

Prior to installing the motherboard, please have it on top of an antistatic pad or within an

electrostatic shielding container.

• Before unplugging the power supply cable from the motherboard, make sure the power

supply has been turned off.

• Before turning on the power, make sure the power supply voltage has been set according to

the local voltage standard.

• Before using the product, please verify that all cables and power connectors of your

hardware components are connected.

• To prevent damage to the motherboard, do not allow screws to come in contact with the

motherboard circuit or its components.

• Make sure there are no leftover screws or metal components placed on the motherboard or

within the computer casing.

• Do not place the computer system on an uneven surface

• Do not place the computer system in a high-temperature environment.

• Turning on the computer power during the installation process can lead to damage to

system components as well as physical harm to the user.

• If you are uncertain about any installation steps or have a problem related to the use of the

product, please consult a certied computer technician.

.

- 9 - Hardware Installation

Page 10

1-2 Product Specications

CPU

(R281-T91)

(R281-T94) 2 x Cavium™ ThunderX2® CN9980 ARM processors

Memory 24 x DIMM slots

LAN 2 x 10Gb/s SFP+ LAN ports (QLogic® QL41102)

Expansion Slot Riser Card CRS2131:

2 x Cavium™ ThunderX2® CN9975 ARM processors

64bit ARMv8 architecture

28 cores per processor, 2.0GHz

16nm technology

64bit ARMv8 architecture

32 cores per processor, 2.2GHz

16nm technology

DDR4 memory supported only

8-channel memory architecture per processor

RDIMM modules up to 64GB supported

1.2V modules: 2666/2400/2133 MHz

NOTE: G IGABYTE reco mmends that you foll ow the QVL when select ing memory

modules to avoid any system compatibility issues

NOTE: DDR4 2666 Mhz with 1DPC, DDR4 2400 with 2DPC

1 x 10/100/1000 management LAN port

- 1 x PCIe x16 slot (Gen3 x16 or x8), Full height half-length

- 1 x PCIe x8 slots (Gen3 x0 or x8), Full height half-length

- 1 x PCIe x8 slots (Gen3 x8), Full height half-length

Riser Card CRS2132:

- 1 x PCIe x16 slot (Gen3 x16 or x8), Full height half-length

- 1 x PCIe x8 slots (Gen3 x0 or x8), Full height half-length

- 1 x PCIe x8 slots (Gen3 x8), Full height half-length

Riser Card CRS2124:

- 1 x PCIe x8 slots (Gen3 x0 or x8), Low prole half-length

- 1 x PCIe x16 slot (Gen3 x16 or x8), Low prole half-length

2 x OCP mezzanine slots

- PCIe Gen3 x16

- Type1, P1, P2, P3, P4

Video Integrated in Aspeed® AST2500

2D Video Graphic Adapter with PCIe bus interface

1920x1200@60Hz 32bpp, DDR4 SDR AM

Hardware Installation - 10 -

Page 11

Storage Front side: 24 x 2.5" SATA/SAS hot-swappable HDD/SSD bays

Rear side: 2 x 2.5" SATA only hot-swappable HDD/SSD bays

Onboard Broadcom® SAS3008 controller

Onboard Broadcom® SAS35x36R expander

Bandwidth: SATAIII 6Gb/s or SAS 12Gb/s per port

- NOTE: GIGABYTE recommends that you follow the QVL when selecting hard

drives, to avoid any system compatibility issues

SAS Supported

Internal

Connectors

Front Panel

LED/Buttons

Rear Panel I/O 2 x USB 3.0

Backplane I/O Front side_CBP20O2: 24 x SATA/SAS ports

2 x Power supply connectors

2 x SlimSAS connectors

2 x SATA 7-pin connectors

1 x USB 3.0 header

1 x Front panel header

1 x HDD back plane board header

1 x PMBus connector

1 x IPMB connector

1 x Clear CMOS switch

1 x BIOS recovery switch

2 x USB 3.0

1 x Power button with LED

1 x ID button with LED

1 x Reset button

1 x System status LED

1 x HDD activity LED

2 x LAN activity LEDs

1 x VGA

1 x COM (RJ45 type)

2 x SFP+

1 x MLAN

1 x ID button with LED

Rear side_CBP2020: 2 x SATA/SAS ports

Bandwidth: SATAIII 6Gb/s or SAS 12Gb/s per port

- 11 - Hardware Installation

Page 12

System

Management

Aspeed® AST2500 management controller

Avocent® MergePoint IPMI 2.0 web interface:

Network settings

Network security settings

Hardware information

Users control

Services settings

IPMI settings

Sessions control

LDAP settings

Power control

Fan proles

Voltages, fans and temperatures monitoring

System event log

Events management (platform events, trap settings, email settings)

Serial Over LAN

vKVM & vMedia (HTML5)

Power Supply 2 x 1200W redundant PSUs

80 PLUS Platinum

AC Input:

- 100-240V~/ 12-7A, 50-60Hz

DC Input:

- 240Vdc/ 6A

DC Output:

- Max 1000W/ 100-240V~

+12V/ 80.5A

+12Vsb/ 3A

- Max 1200W/ 200-240V~ or 240Vdc input

+12 V/ 97A

+12Vsb/ 3A

Environment

Ambient

Operating temperature: 10°C to 35°C

Non-operating temperature: -40°C to 60°C

Temperature

Operating humidity: 8-80% (non-condensing)

Relative

Non-operating humidity: 20%-95% (non-condensing)

Humidity

System

Dimension

* We reserves the right to make any changes to the product specications and product-related information without

prior notice.

2U

438mm (W) x 87mm (H) x 730mm (D)

Hardware Installation - 12 -

Page 13

1-3 System Block Diagram

(Rear side)

2-bay 2.5" SATA

(Front side)

24-bay 2.5" SAS/SATA HDD/SDD

2 x SlimLine

CCPI2 x 24 , 25G/s

OCP2

: PCIe x16

OCP1

: PCIe x16

SAS

Expander

SPI Flash

DDR4 512MB

64MB

VRAM

PCIe3.0 X16

VGA

COM

CPU_1

CN9975

DDR - 8 IMC

8

x

16

x

PCIe3.0

PCIe3.0

16

x

PCIe3.0

Switch

Switch

Switch

2 x

SATAIII

CPU_0

8 Channels

DDR4

CN9975

DDR - 8 IMC

2666/2400/2133 MHz 2666/2400/2133 MHz

USB2.0 X1

PCIe 2.0 X1

PCIe 3.0 X4

Front 2 x USB 3.0

Rear 2 x USB 3.0

2 x 10G SFP+ LAN

MLAN

USB3.0 X2

USB3.0 X2

QL41102

RTL8211E

USB 3.0

HUB

PHY

8

x

16

x

PCIe3.0

PCIe3.0

ASPEED

AST2500

MAC BMC

SAS3008

PCIe3.0 X16

CRS2124

CRS2132

CRS2131

PCIe x8

PCIe x8

PCIe x8

PCIe x8

PCIe x8

8 Channels

DDR4

PCIe x16

PCIe x16

PCIe x16

- 13 - Hardware Installation

Page 14

This page intentionally left blank

Hardware Installation - 14 -

Page 15

Chapter 2 System Appearance

1

2

3

2

3

HDD #0

HDD #1

HDD #2

HDD #3

HDD #4

HDD #5

HDD #6

HDD #7

HDD #8

HDD #9

HDD #10

HDD #11

HDD #12

HDD #13

HDD #14

HDD #15

HDD #16

HDD #17

HDD #18

HDD #19

HDD #20

HDD #21

HDD #22

HDD #23

Primary

PSU

Secondary

PSU

Rear HDD #0

Rear HDD #1

1 2 4 53

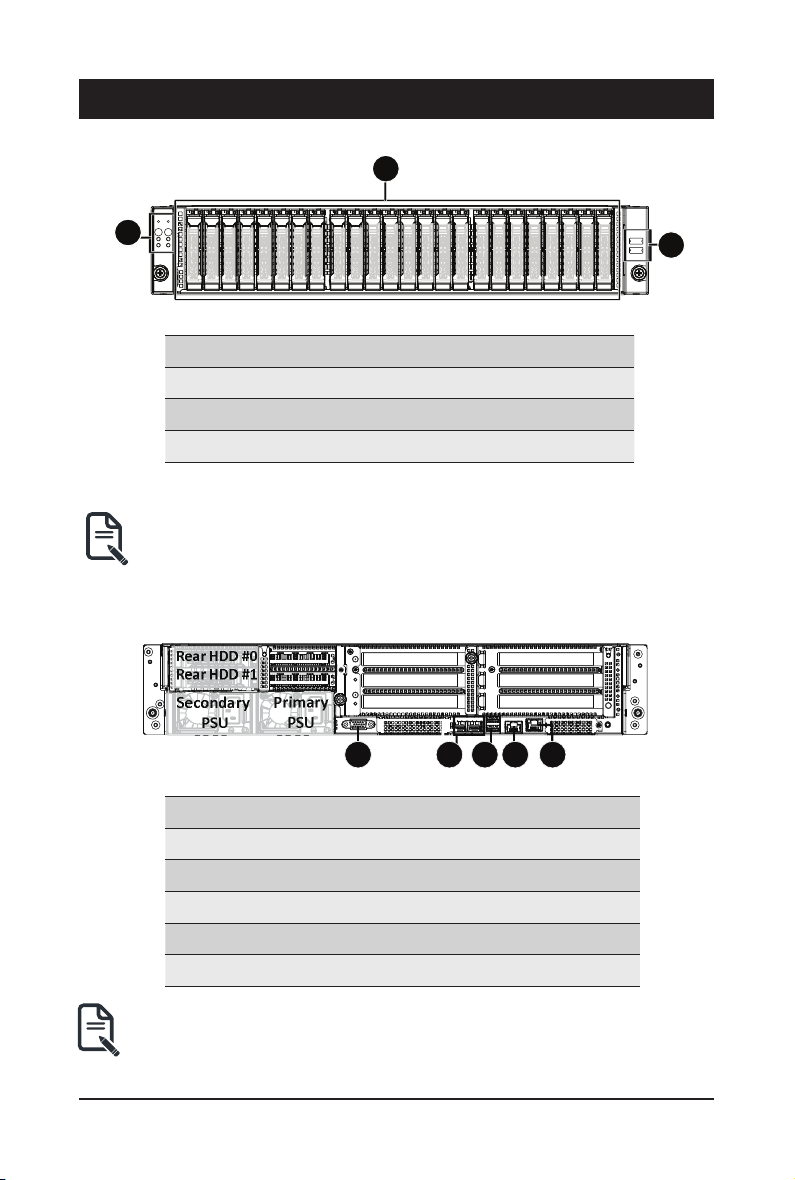

2-1 Front View

No. Description

1.

2. HDD Bays

3. Front USB 3.0 ports

• Refer to Chapter 2-3 Front Panel LED and Buttons for a detailed description of the function

of the LEDs.

2-2 Rear View

Rear HDD #0

Rear HDD #1

Secondary

PSU

Front Panel LEDs and buttons

Primary

PSU

1 2 4 53

No. Description

1. VGA port

2. 10 GbE SFP+ LAN Port x 2

3. USB 3.0 Port x 2

4. COM Port (RJ45 type)

5. 10/100/1000 Server management LAN port

• Refer to Chapter 2-4 Rear System LAN LEDs for a detailed description of the function of

the LEDs.

- 15 - System Appearance

Page 16

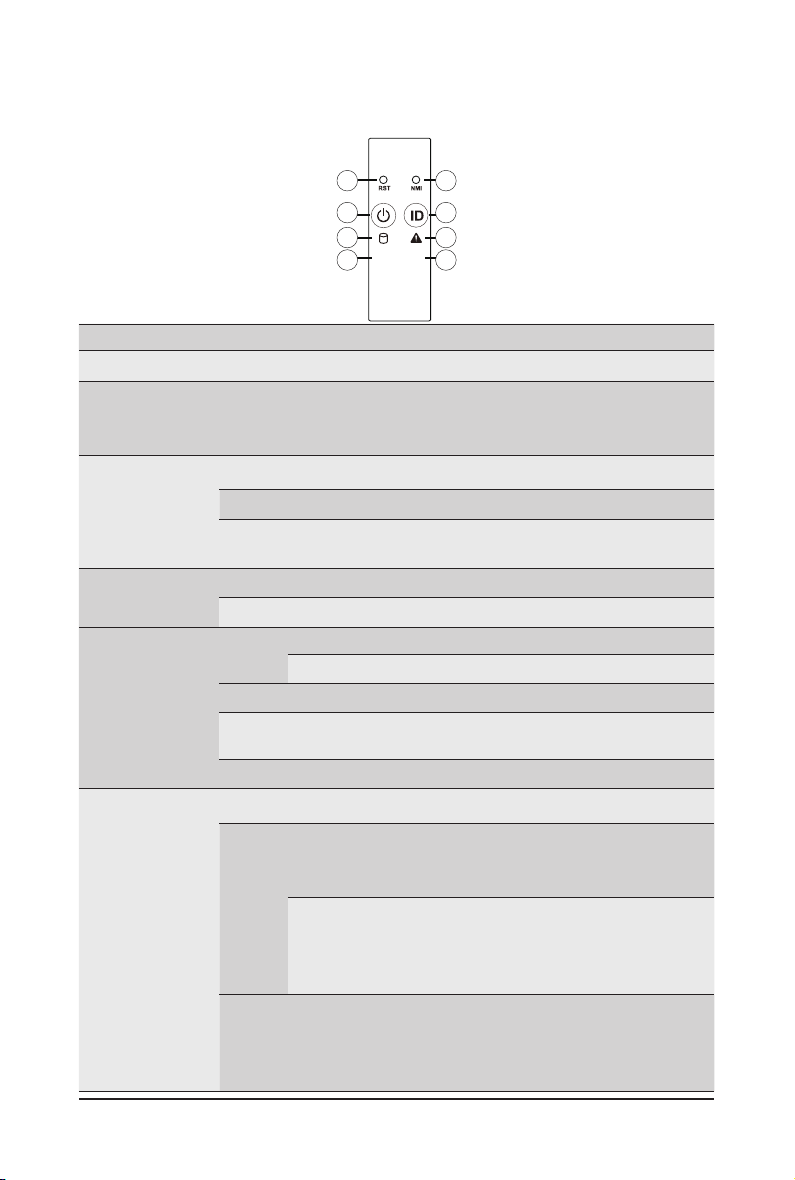

2-3 Front Panel LED and Buttons

1

3

5

L1

7

2

4

6

L2

8

No. Name Color Status Description

Reset Button -- -- Press this button to reset the system.

1.

Press this button for the server to generate a NMI to the

NMI button -- --

2.

Green On Indicates the system is powered on.

3.

4.

5.

6.

Power button

with LED

ID Button

with LED

HDD Status

LED

System

Status LED

Green Blink System is in ACPI S1 state (sleep mode).

N/A Off

Blue On Indicates the system identication is active.

N/A Off Indicates the system identication is disabled.

Green

Amber On

Green/

Amber

N/A Off

Green On

Amber

processor. If multiple-bit ECC errors occur, the server will

effectively be halted.

• System is not powered on or in ACPI S5 state (power off)

• System is in ACPI S4 state (hibernate mode)

On

Indicates locating the HDD.

Blink

Indicates accessing the HDD.

Indicates HDD error.

Blink

Indicates HDD rebuilding.

Indicates no HDD access or no HDD error.

Indicates system is operating normally.

Indicates a critical condition, may include:

On

-System fan failure

-System temperature

Indicates non-critical condition, may include:

Blink

-Redundant power module failure

-Temperature and voltage issue

Indicates system is not ready, may include:

N/A Off

System Appearance - 16 -

-POST error

-NMI error

-Processor or terminator is missing

Page 17

7.

8.

LAN1 Active/

Link LED

LAN2 Active/

Link LED

Green On

Green Blink

N/A Off

Green

Green Blink

N/A Off

On

Indicates a link between the system and the network or

no access.

Indicates data trasmission or receiving is occuring.

Indicates no data transmission or receiving is occuring.

Indicates a link between the system and the network or

no access.

Indicates data trasmission or receiving is occuring.

Indicates no data transmission or receiving is occuring.

- 17 - System Appearance

Page 18

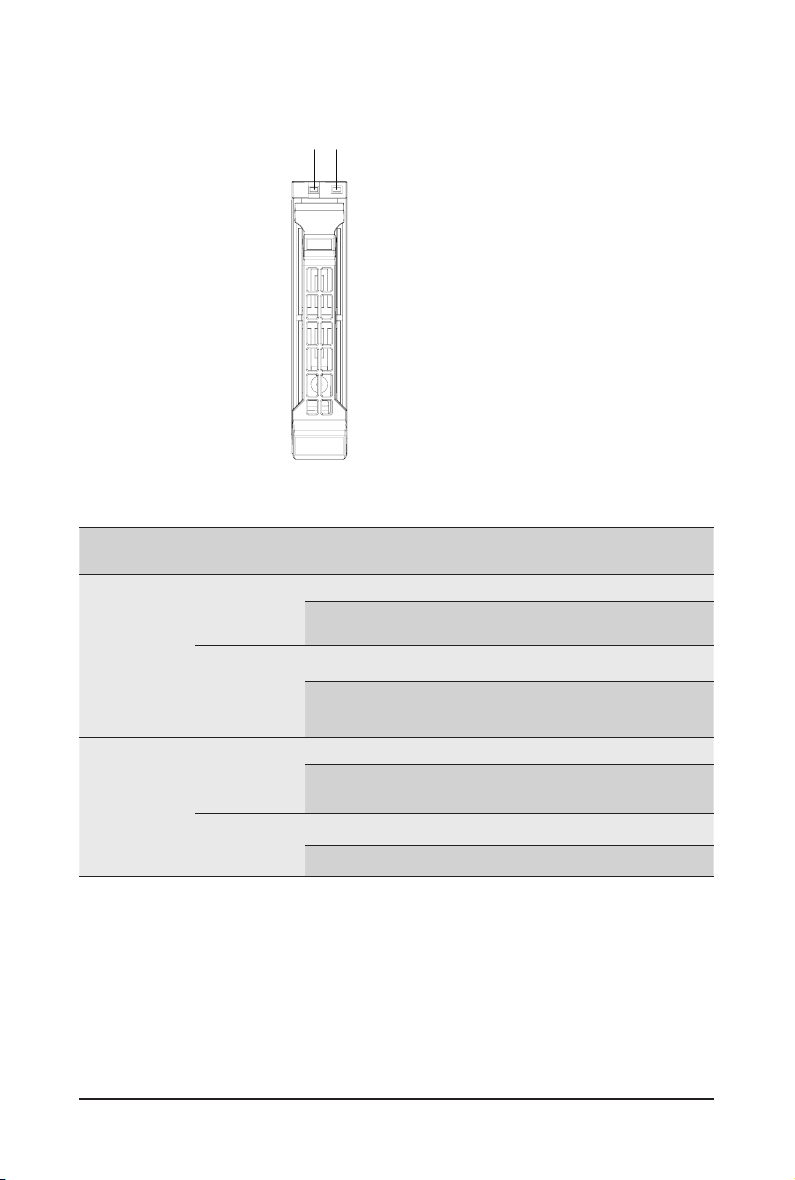

2-4 Rear System LAN LEDs

3 4

1 2

No. Name Color Status Description

Yel low On 10 Gbps data rate

10GbE

1.

2.

3.

4.

Speed LED

10GbE

Link/

Activity

LED

1GbE

Speed LED

1GbE

Link/

Activity

LED

Green On 1 Gbps data rate

N/A Off 100 Mbps data rate

On Link between system and

Green

Blink Data transmission or receiving is occurring

N/A Off No data transmission or

Yel low On 1 Gbps data rate

Green On 100 Mbps data rate

N/A Off 10 Mbps data rate

On Link between system and

Green

Blink Data transmission or receiving is occurring

N/A Off No data transmission or

21

network or no access

receiving is occurring

network or no access

receiving is occurring

System Appearance - 18 -

Page 19

2-5 Hard Disk Drive LEDs

LED#1

LED#2 (Reserved/No Function)

RAID SKU LED #1 Locate HDD

No RAID

conguration

(via HBA, ICH)

conguration

(via HW RAID

Card, or SW

RAID Card)

NOTE:

*1: Depends on HBA/Utility Spec.

*2: Blink cycle depends on HDD's activity signal.

*3: If HDD is pulled out during rebuilding, the disk status of this HDD is regarded as faulty.

RAID

Disk LED

(LED on

Back Panel)

Removed

HDD Slot

(LED on

Back Panel)

Disk LED

Removed

HDD Slot

Rebuilding HDD

Fault

Access

HDD Present

(No Access)

Green O N(*1) OFF Green OFF

Amber OFF OFF Amber OFF

Green O N(*1) OFF Green --

Amber OFF OFF Amber --

Green ON OFF Alternately OFF

Amber OFF ON

(Low Speed:

2 Hz)

OFF

Green O N(*1) OFF (*3) --

Amber OFF ON (*3) --

- 19 - System Appearance

Page 20

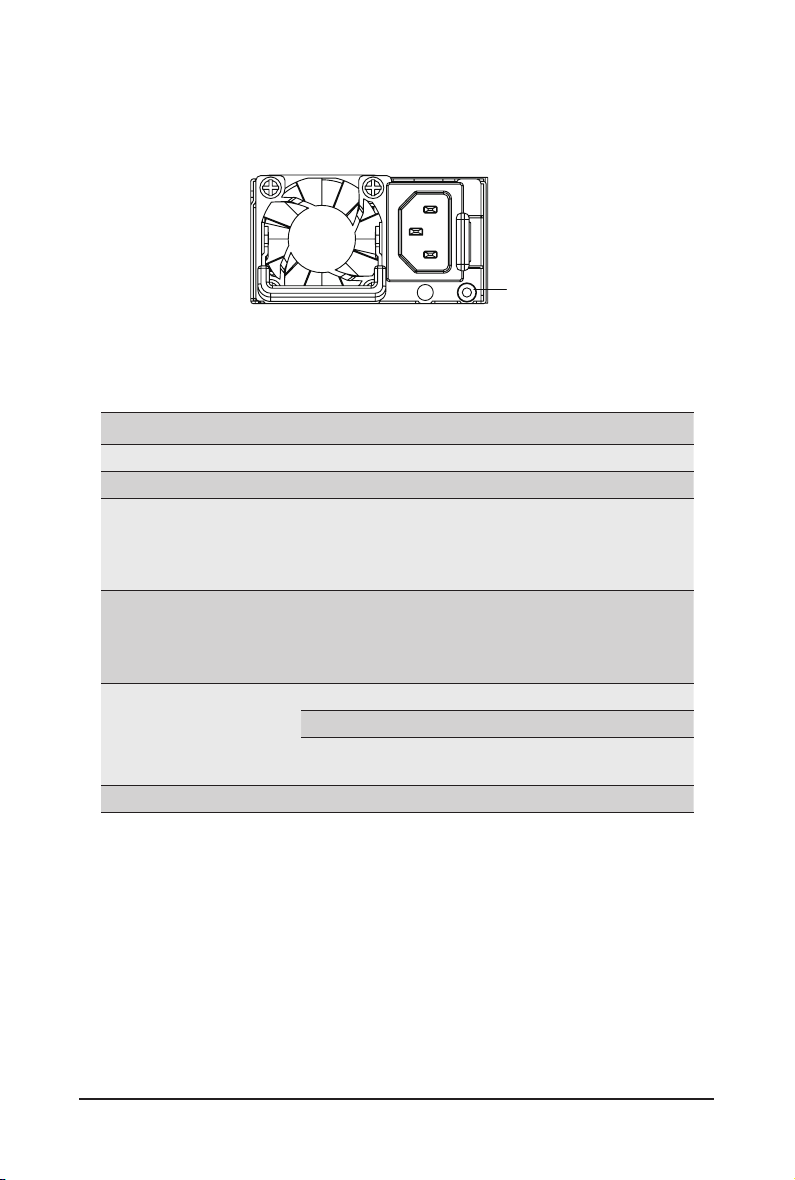

2-6 Power Supply Unit LED

State Description

Green ON Output ON and OK

Off No AC power to all power supplies

Green BLINKING

1 Sec./On

1 Sec./Off

0.5Hz

Green BLINKING

0.25 Sec./On

0.25 Sec./Off

2Hz

Amber

Amber (*3)

PSU Sleep Mode (cold Redundant/Ofine mode)

PSU LED

Standby Mode (normal)

Standby Mode (with OTP range)

12V Fault (OVP, UVP, OCP, SCP, and OTP)

Power Supply fan lock (15 seconds

including Standby mode)

System Appearance - 20 -

Page 21

Chapter 3 System Hardware Installation

Pre-installation Instructions

Computer components and electronic circuit boards can be damaged by discharges of static

electricity. Working on computers that are still connected to a power supply can be extremely

dangerous. Follow the simple guidelines below to avoid damage to your computer or injury to

yourself.

• Always disconnect the computer from the power outlet whenever you are working inside the

computer case.

• If possible, wear a grounded wrist strap when you are working inside the computer case.

Alternatively, discharge any static electricity by touching the bare metal system of the computer

case, or the bare metal body of any other grounded appliance.

• Hold electronic circuit boards by the edges only. Do not touch the components on the board

unless it is necessary to do so. Do not ex or stress the circuit board.

• Leave all components inside the static-proof packaging until you are ready to use the component

for the installation.

- 21 - System Hardware Installation

Page 22

3-1 Removing and Installing the Chassis Cover

Before you remove or install the system cover

• Make sure the system is not turned on or connected to AC power.

Follow these instructions to remove the chassis covers:

1. Loosen and remove the thumbscrew securing the chassis cover.

2. Push down on the indentations located on the side of the chassis cover.

3. Slide the chassis cover to the rear of the system and then remove the cover in the direction of the

arrow.

4. To reinstall the chassis cover follow steps 1-3 in reverse order.

2

3

2

2

1

System Hardware Installation - 22 -

Page 23

3-2 Removing and Installing the Fan Duct

Follow these instructions to remove the fan duct:

1. Lift up to remove the fan duct.

2. To reinstall the fan duct, align the fan duct with the guiding groove. Push down the fan duct until it is

rmly seated on the system.

1

2

- 23 - System Hardware Installation

Page 24

3-3 Removing and Installing Memory

Read the following guidelines before you begin to install the memory:

• Make sure that the motherboard supports the memory. It is recommended that memory of the

same capacity, brand, speed, and chips be used.

• Always turn off the computer and unplug the power cord from the power outlet before installing

the memory to prevent hardware damage.

• Memory modules have a foolproof design. A memory module can be installed in only one

direction. If you are unable to insert the memory, switch the direction.

3-3-1 Eight-Channel Memory Conguration

This motherboard provides 32 DDR4 memory sockets and supports Eight Channel Technology. After the

memory is installed, the BIOS will automatically detect the specications and capacity of the memory.

21

CPU0

(Primary)

DIMM_P0_A0

DIMM_P0_A1

DIMM_P0_C0

DIMM_P0_C1

DIMM_P0_E0

DIMM_P0_D1

DIMM_P0_D0

DIMM_P0_B1

DIMM_P0_B0

DIMM_P0_H0

DIMM_P0_F0

DIMM_P0_G0

System Hardware Installation - 24 -

DIMM_P1_L1

DIMM_P1_L0

DIMM_P1_J1

DIMM_P1_J0

DIMM_P1_P0

DIMM_P1_N0

CPU1

(Secondary)

DIMM_P1_K0

DIMM_P1_K1

DIMM_P1_M0

DIMM_P1_O0

DIMM_P1_I0

DIMM_P1_I1

Page 25

3-3-2 Removing and Installing a Memory Module

Before installing a memory module, make sure to turn off the computer and unplug the power

cord from the power outlet to prevent damage to the memory module.

Be sure to install DDR4 DIMMs on to this motherboard.

Follow these instructions to install a DIMM module:

1. Insert the DIMM memory module vertically into the DIMM slot and push it down.

2. Close the plastic clip at both edges of the DIMM slots to lock the DIMM module.

3. Reverse the installation steps when you want to remove the DIMM module.

2

1

2

3-3-3 DIMM Population Table

Speed (MT/s); Voltage (V)

Slot Per Channel (SPC)

Type

Ranks Per

DIMM and

Data Width

DIMM

Capacity

(GB)

DIMM Per Channel (DPC)

1 Slot per

Channel

2 Slots per

Channel

RDIMM

RDIMM

RDIMM

SRx4

DRx8

DRx4

DIMM Density

4Gb8Gb

NA 16GB

8GB 16GB

16GB 32GB

- 25 - System Hardware Installation

1DPC

1.2V

2666

1DPC

1.2V

2666

2DPC

1.2V

2400

Page 26

3-4 Removing and Installing the PCI Expansion Card

• Voltages can be present within the server whenever an AC power source is connected. This

voltage is present even when the main power switch is in the off position. Ensure that the system

is powered off and all power sources have been disconnected from the server prior to installing a

PCIe card.

• Failure to observe these warnings could result in personal injury or damage to equipment.

• The PCI riser assembly does not include a riser card or any cabling as standard. To install a

PCIe card, a riser card must be installed.

Follow these instructions to PCI Expansion card:

1. Loosen and remove the thumbscrew on the riser bracket.

2. Remove the screw securing the riser bracket.

3. Lift up the riser bracket out of system.

4. Loosen and remove the screw securing the slot cover from riser bracket.

5. Orient the PCIe card with the riser guide slot and push in the direction of the arrow until the PCIe

card sits in the PCIe card connector.

NOTE: Some riser brackets allow for single or multiple PCIe cards. Repeat steps 4-5 as necessary.

6. Secure the PCIe card with the screw.

7. Reverse steps 1-3 to install the riser bracket.

1

System Hardware Installation - 26 -

1

2

2

Page 27

7

5

6

3

3

3

4

4

5

7

6

6

5

7

- 27 - System Hardware Installation

Page 28

3-5 Removing and Installing the Hard Disk Drive

Read the following guidelines before you begin to install the hard disk drive:

• Take note of the drive tray orientation before sliding it out.

• The tray will not t back into the bay if it is inserted incorrectly.

• Make sure that the HDD is connected to the HDD connector on the backplane.

Follow these instructions to install a hard disk drive:

1. Press the release button.

2. Extend the locking lever.

3. Pull the locking lever in the direction of the arrow to remove the HDD tray.

4. Slide the hard disk into the HDD tray.

5. Install 4 screws to secure the hard drive to the HDD tray.

6. Reinsert the HDD tray into the slot and close the locking lever.

1

2

3

5

System Hardware Installation - 28 -

4

5

Page 29

3-6 Replacing the Fan Assembly

Follow these instructions to replace a fan assembly:

1. Flip the latches on the top of the fan outwards.

2. Using the latches, lift up the fan assembly from the chassis.

3. Reverse the previous steps to install the replacement fan assembly.

1

2

- 29 - System Hardware Installation

Page 30

3-7 Removing and Installing the Power Supply

Before you remove or install the power supply unit:

• Make sure the system is not turned on or connected to AC power.

Follow these instructions to replace the power supply:

1. Press the retaining clip on the left side of the power supply unit along the direction of the arrow.

2. Pull the power supply handle at the same time and pull out the power supply unit.

3. Insert the replacement power supply unit rmly into the chassis. Connect the AC power cord to the

replacement power supply.

4. Repeat steps 1-3 for replacement of the second power supply.

1

2

System Hardware Installation - 30 -

3

Page 31

3-8 Cable Routing

Front Panel Board Cable

Rear HDD Back Panel Board Power Cable

Front Panel USB 3.0 Cable

Rear HDD Back Panel Board Signal Cable

- 31 - System Hardware Installation

Page 32

SAS Expansion Card to Back Plane Board

Cable #0/#1/#2

SAS Expansion Card to Back Plane Board

Cable #3/#4/#5

0

1

2

SAS Expansion Card Power Cable

3

4

5

On-Board SATA to HDD Back Plane Board

Cable #0/#1

01

System Hardware Installation - 32 -

Page 33

HDD Back Panel Board Power Cable HDD Back Panel Board Signal Cable

System Fan Cable

- 33 - System Hardware Installation

Page 34

This page intentionally left blank

System Hardware Installation - 34 -

Page 35

Chapter 4 Motherboard Components

ON

4-1 Motherboard Components

OFF

10

8

21

7

6

8

9

5

4

2

DIMM_P0_D1

DIMM_P0_D0

DIMM_P0_B1

DIMM_P0_B0

1

DIMM_P0_H0

DIMM_P0_F0

CPU0

(Primary)

3

11

14

12

13

DIMM_P0_E0

DIMM_P0_G0

DIMM_P0_A1

DIMM_P0_C0

DIMM_P0_C1

2223

14

17

DIMM_P1_J1

DIMM_P1_J0

DIMM_P0_A0

15

16

DIMM_P1_P0

DIMM_P1_N0

DIMM_P1_L1

DIMM_P1_L0

18 19

CPU1

(Secondary)

DIMM_P1_K0

DIMM_P1_K1

DIMM_P1_M0

DIMM_P1_O0

2021

DIMM_P1_I0

DIMM_P1_I1

Item Description

1 2 x 4 Pin GPGPU Power Connector

2 2 x 4 Pin GPGPU Power Connector

3 Front Panel Header

4 Front Panel USB 3.0 Connector

5 BMC Firmware Readiness LED

6 HDD Back Plane Board Connector

7 IPMB Connector

8* OCP Mezzanine Connector #1 (Supports NCSI Function)

9 System Battery

- 35 - Motherboard Components

Page 36

10 Riser Connector #2

11 SlimLine SAS Connector (SATA3/SAS/#4~#7/From LSI)

12 SlimLine SAS Connector (SATA3/SAS/#0~#3/From LSI)

13 2 x 4 Pin GPGPU Power Connector

14 OCP Mezzanine Connector #2

15 Riser Connector #3

16 Riser Connector #4

17 TPM Module Connector

18 Power Supply Connector #1 (Primary)

19 Power Supply Connector #2 (Secondary)

20 HDD Back Plane Board Power Connector (Rear HDD)

21* HDD Back Plane Board Power Connector (Front HDD)

22 SATA3 6Gb/s Connector #0

23 SATA3 6Gb/s Connector #1 (From CPU0)

24 Power supply connector#2 (secondary)

25 2 x 2 Pin extention card power connectors

26 2 x 7 Pin system main power connector

NOTE! Set the NCSI switch to On to enable NCSI fucnction.

Motherboard Components - 36 -

Page 37

4-2 Jumper Settings

NCSI Switch

Onboard LAN

21

OCP Connector #1

21

2&3B6(7

21',3

SLOT

PCIe Bandwidth

PCIe x16

PCIe x8/x8

PCIe x4/x4/x4/x4

OCP #1

Switch 4 and 3

ON and ON

ON and OFF ON and OFF

OFF and OFF

OCP #2

Switch 2 and 1

ON and ON

OFF and OFF

DIMM_P0_D0

DIMM_P0_D1

DIMM_P0_F0

DIMM_P0_H0

6<6B-3

DIMM_P0_B0

DIMM_P0_B1

21',3

1

2

3

4

CPU0

(Primary)

RVSD

CLR_PASSWD

RVSD

RVSD

DIMM_P1_J0

DIMM_P1_J1

DIMM_P1_L0

DIMM_P1_L1

DIMM_P1_N0

DIMM_P1_P0

DIMM_P0_G0

DIMM_P0_E0

DIMM_P0_C1

DIMM_P0_C0

DIMM_P0_A1

DIMM_P0_A0

ON

Reserved/No Function

Clear supervisor password

Reserved/No Function

Reserved/No Function Reserved/No Function

OFF

Reserved/No Function

Normal [Default]

Reserved/No Function

- 37 - Motherboard Components

CPU1

(Secondary)

DIMM_P1_K1

DIMM_P1_K0

DIMM_P1_I1

DIMM_P1_I0

DIMM_P1_O0

DIMM_P1_M0

Page 38

This page intentionally left blank

Motherboard Components - 38 -

Page 39

Chapter 5 BIOS Setup

BIOS (Basic Input and Output System) records hardware parameters of the system in the EFI on the

motherboard. Its major functions include conducting the Power-On Self-Test (POST) during system startup,

saving system parameters and loading operating system, etc. BIOS includes a BIOS Setup program that

allows the user to modify basic system conguration settings or to activate certain system features. When the

power is turned off, the battery on the motherboard supplies the necessary power to the CMOS to keep the

conguration values in the CMOS.

To access the BIOS Setup program, press the <F2> or <ESC> key during the POST when the power is

turned on.

• BIOS ashing is potentially risky, if you do not encounter problems of using the current BIOS

version, it is recommended that you don't ash the BIOS. To ash the BIOS, do it with caution.

Inadequate BIOS ashing may result in system malfunction.

• It is recommended that you not alter the default settings (unless you need to) to prevent system

instability or other unexpected results. Inadequately altering the settings may result in system's

failure to boot. If this occurs, try to clear the CMOS values and reset the board to default values.

(Refer to the Exit section in this chapter or introductions of the battery/clearing CMOS jumper in

Chapter 1 for how to clear the CMOS values.)

BIOS Setup Program Function Keys

<f><g> Move the selection bar to select the screen

<h><i> Move the selection bar to select an item

<+> Increase the numeric value or make changes

<-> Decrease the numeric value or make changes

<Enter> Execute command or enter the submenu

<Esc> Main Menu: Exit the BIOS Setup program

Submenus: Exit current submenu

<F1> Show descriptions of general help

<F3> Restore the previous BIOS settings for the current submenus

<F9> Load the Optimized BIOS default settings for the current submenus

<F10> Save all the changes and exit the BIOS Setup program

- 39 - BIOS Setup

Page 40

Main

This setup page includes all the items in standard compatible BIOS.

Advanced

This setup page includes all the items of AMI BIOS special enhanced features.

(ex: Auto detect fan and temperature status, automatically congure hard disk parameters.)

Chipset

This setup page includes all the submenu options for conguring the function of processor, network,

North Bridge, South Bridge, and System event logs.

Security

Change, set, or disable supervisor and user password. Conguration supervisor password allows you to

restrict access to the system and BIOS Setup.

A supervisor password allows you to make changes in BIOS Setup.

A user password only allows you to view the BIOS settings but not to make changes.

Boot

This setup page provides items for conguration of boot sequence.

Save & Exit

Save all the changes made in the BIOS Setup program to the CMOS and exit BIOS Setup. (Pressing

<F10> can also carry out this task.)

Abandon all changes and the previous settings remain in effect. Pressing <Y> to the confirmation

message will exit BIOS Setup. (Pressing <Esc> can also carry out this task.)

Server Management

Server additional features enabled/disabled setup menus.

BIOS Setup - 40 -

Page 41

5-1 The Main Menu

Once you enter the BIOS Setup program, the Main Menu (as shown below) appears on the screen. Use

arrow keys to move among the items and press <Enter> to accept or enter other sub-menu.

Main Menu Help

The on-screen description of a highlighted setup option is displayed on the bottom line of the Main Menu.

Submenu Help

While in a submenu, press <F1> to display a help screen (General Help) of function keys available for the

menu. Press <Esc> to exit the help screen. Help for each item is in the Item Help block on the right side of

the submenu.

• When the system is not stable as usual, select the Restore Defaults item to set your system

to its defaults.

• The BIOS Setup menus described in this chapter are for reference only and may differ by

BIOS version.

- 41 - BIOS Setup

Page 42

Parameter Description

BIOS Information

Access Level Displays the access privilege level information.

Project Name

(Note)

Displays the project name information.

Project Version Displays version number of the BIOS setup utility.

Build Date and Time Displays the date and time when the BIOS setup utility was created.

BMC Information

BMC Firmware Version

(Note)

(Note)

Displays BMC rmware version information.

Processor Information

Displays the technical specications for the installed processor(s).

Memory Information

Total Memory

Memory Frequency

(Note)

(Note)

Displays the total memory size of the installed memory.

Displays the frequency information of the installed memory.

Memory Slot Information Press [Enter] to view the installed memory information.

Onboard LAN MAC Address

Information

LAN1 MAC Address

LAN2 MAC Address

(Note)

(Note)

(Note)

Displays LAN MAC address information.

Displays LAN MAC address information.

(Note) Corresponds to the model name of GIGABYTE server you are using.

BIOS Setup - 42 -

Page 43

Parameter Description

System Date Sets the date following the weekday-month-day-year format.

System Time Sets the system time following the hour-minute-second format.

- 43 - BIOS Setup

Page 44

5-2 Advanced Menu

The Advanced menu display submenu options for conguring the function of various hardware components.

Select a submenu item, then press [Enter] to access the related submenu screen.

BIOS Setup - 44 -

Page 45

5-2-1 Trusted Computing

Parameter Description

Conguration

Security Device Support

Current Status Information Displays current TPM status information.

Enable/Disable the TPM support feature.

Options available: Enable/Disable. Default setting is Enable.

- 45 - BIOS Setup

Page 46

5-2-2 S5 RTC Wake Setting

Parameter Description

Enable or disable System wake on alarm event. When enabled, System

(Note)

Wake system from S5

Wake up year Press <+> and <-> to dene the wake up year.

Wake up month Press <+> and <-> to dene the wake up month.

Wake up Date Press <+> and <-> to dene the wake up date.

Wake up hour Press <+> and <-> to dene the wake up hour.

Wake up minute Press <+> and <-> to dene the wake up minute.

Wake up second Press <+> and <-> to dene the wake up second.

will wake on the hr:min:sec specied.

Default setting is Disabled.

(Note) This item appears when Wake system from S5 is set to Enabled.

BIOS Setup - 46 -

Page 47

5-2-3 Network Stack Conguration

Parameter Description

Network Stack

Ipv4 PXE Support

Ipv4 HTTP Support

Ipv6 PXE Support

Ipv6 HTTP Support

PXE boot wait time

Media detect count

(Note)

(Note)

(Note)

(Note)

(Note)

(Note)

Enable/Disable the UEFI network stack.

Options available: Enabled/Disabled. Default setting is Enabled.

Enable/Disable the Ipv4 PXE feature.

Options available: Enabled/Disabled. Default setting is Enabled.

Enable/Disable the Ipv4 HTTP feature.

Options available: Enabled/Disabled. Default setting is Disabled.

Enable/Disable the Ipv6 PXE feature.

Options available: Enabled/Disabled. Default setting is Disabled.

Enable/Disable the Ipv6 HTTP feature.

Options available: Enabled/Disabled. Default setting is Disabled.

Press the <+> / <-> keys to increase or decrease the desired values.

Press the <+> / <-> keys to increase or decrease the desired values.

(Note) This item appears when Network Stack is set to Enabled.

- 47 - BIOS Setup

Page 48

5-2-4 Info Report Conguration

Parameter Description

Info Report Conguration

Post Report

Post Report

Delay Time

Error Message Report

Post Error Message

Enable/Disable the POST Report support.

Options available: Enabled/Disabled. Default setting is Enabled.

Post Report wait time 0~10 seconds.

Options available: 0/1/2/3/4/5/6/7/8/9/Until Press ESC.

Enable/Disable the POST Error Message support.

Options available: Enabled/Disabled. Default setting is Enabled.

BIOS Setup - 48 -

Page 49

5-2-5 NMVe Conguration

Parameter Description

NVMe Conguration Displays the NVMe devices connected to the system.

- 49 - BIOS Setup

Page 50

5-2-6 SATA Conguration

Parameter Description

SATA Conguration

SATA Controller # Displays the SATA device connected to the system.

BIOS Setup - 50 -

Page 51

5-2-7 USB Conguration

Parameter Description

USB Conguration

USB Module Version Displays the USB module version information.

USB Controller Displays the USB controller information.

USB Devices: Displays the USB devices connected to the system.

XHCI Hand-off

USB Mass Storage Driver

(Note)

Support

Enable/Disable the XHCI (USB 3.0) Hand-off support.

Options available: Enabled/Disabled. Default setting is Enabled.

Enable/Disable the USB Mass Storage Driver Support.

Options available: Enabled/Disabled. Default setting is Enabled.

(Note) This item is present only if you attach USB devices.

- 51 - BIOS Setup

Page 52

5-2-8 Chipset Conguration

Parameter Description

Denes the power state to resume to after a system shutdown that is

due to an interruption in AC power. When set to Last State, the system

will return to the active power state prior to shutdown. When set to

Restore on AC Power Loss

Skip Above 4G Decoding for VGA

P2P Bridge IO Size

Chassis Opened Warning

(Note)

Power Off, the system remains off after power shutdown.

Options available: Last State/Power Off/Power On. The default setting

depends on the BMC setting.

Enable/Disable 64bit capable devices to be decoded in Skip Above 4G

Address VGA Space.

Options available: Enabled/Disabled. Default setting is Disabled.

Sets P2P Bridge IO aligned to the size.

Options available: 0x100/0x150/0x1000. Default setting is 0x1000.

Enable/Disable the chassis intrusion alter function.

Options available: Enabled/Disabled/Clear. Default setting is

Disabled.

(Note) When the power policy is controlled by BMC, please wait for 15-20 seconds for BMC to save the

last power state.

BIOS Setup - 52 -

Page 53

5-2-9 Ethernet Adapter Conguration

Parameter Description

Firmware Image Properties Press [Enter] to access the related submenu screen.

Device Level Conguration Press [Enter] to access the related submenu screen.

Port Level Conguration Press [Enter] to access the related submenu screen.

Partitioning Mode

Device Name

Chipset Type

PCI Device ID

PCI Address

Link Status

Link Speed

Permanent MAC Address

Virtual MAC Address

Options available: Default/NPAR.

Default setting is Default.

Displays the technical specications for the Network Interface

Controller.

Displays the technical specications for the Network Interface

Controller.

Displays the technical specications for the Network Interface

Controller.

Displays the technical specications for the Network Interface

Controller.

Displays the technical specications for the Network Interface

Controller.

Displays the technical specications for the Network Interface

Controller.

Displays the technical specications for the Network Interface

Controller.

Displays the technical specications for the Network Interface

Controller.

- 53 - BIOS Setup

Page 54

5-2-10 MAC IPv4 Network Conguration

Parameter Description

Conguraed

Enable DHCP

Local IP Address Press [Enter] to congigure Local IP address.

Local NetMask Press [Enter] to congigure Local NetMask.

Local Gateway Press [Enter] to congigure Local Gateway.

Local DNS Servers Press [Enter] to congigure Local DNS Server.

Save Changes and Exit

Option available: Enabled/Disabled.

Default setting is Enabled.

Option available: Enabled/Disabled.

Default setting is Enabled.

When you nish the conguration in this page, press enter to save and

to exit the conguration.

BIOS Setup - 54 -

Page 55

5-2-11 MAC IPv6 Network Conguration

Parameter Description

Enter Conguration Menu Press [Enter] to access the related submenu screen.

- 55 - BIOS Setup

Page 56

5-3 Chipset Setup Menu

Parameter Description

SOC Conguration

Selects CPPC OS Scaling for Turbo and Non-Turbo options.

Default will run cores ar a nomimal supported frequency.

Turbo/CCPC Mode

Symmertic Multi-Treading

DDR Speed

Option avaiable: Default/Autonomous - CPPC off/Autonomous - CPPC

On/ OSPM Turbo/ OSPM Non-Turbo.

Default setting is Default.

Option avaiable: 4/2/1.

Default setting is 4.

Option avaiable: Auto/1600/1866/2133/2400/2666

Default setting is Auto.

BIOS Setup - 56 -

Page 57

5-4 Security Menu

The Security menu allows you to safeguard and protect the system from unauthorized use by setting up

access passwords.

There are two types of passwords that you can set:

• Administrator Password

Entering this password will allow the user to access and change all settings in the Setup Utility.

• User Password

Entering this password will restrict a user’s access to the Setup menus. To enable or disable

this eld, a Administrator Password must rst be set. A user can only access and modify the

System Time, System Date, and Set User Password elds.

Parameter Description

Administrator Password Press [Enter] to congure the administrator password.

User Password Press [Enter] to congure the user password.

- 57 - BIOS Setup

Page 58

5-5 Boot Menu

The Boot menu allows you to set the drive priority during system boot-up. BIOS setup will display an error

message if the legacy drive(s) specied is not bootable.

BIOS Setup - 58 -

Page 59

Parameter Description

Boot Conguration

Number of seconds to wait for setup activation key. 65535 (0xFFFF)

Setup Prompt Timeout

Bootup NumLock State

Quiet Boot

FIXED BOOT ORDER

Priorities

Boot Option #1 / #2 / #3 / #4 /

#5

UEFI sUEFI Application Boot

Priorities

UEFI Network Drive BBS

Prioritie

means indenite waiting.

Press the numeric keys to input the desired values.

Enable/Disable the Bootup NumLock function.

Options available: On/Off. Default setting is On.

Enable/Disable showing the logo during POST.

Options available: Enabled/Disabled. Default setting is Enabled.

Press [Enter] to congure the boot priority.

By default, the server searches for boot devices in the following

sequence:

1. Hard drive.

2. CD-COM/DVD drive.

3. USB device.

4. Network.

5. UEFI.

Press [Enter] to congure the boot priority.

Press [Enter] to congure the boot priority.

- 59 - BIOS Setup

Page 60

5-5-1 UEFI Application Boot Priorities

The UEFI application boot priorities submenu allows you to specify the boot device priority from the available

UEFI applications during system boot-up. BIOS setup will display an error message if the legacy drive(s)

specied is not bootable.

BIOS Setup - 60 -

Page 61

5-5-2 UEFI NETWORK Drive BBS Priorities

The UEFI network drive BBS priorities submenu allows you to specify the boot device priority from the

available UEFI network drives during system boot-up. BIOS setup will display an error message if the legacy

drive(s) specied is not bootable.

- 61 - BIOS Setup

Page 62

5-6 Save & Exit Menu

The Exit menu displays the various options to quit from the BIOS setup. Highlight any of the exit options then

press Enter.

BIOS Setup - 62 -

Page 63

Parameter Description

Save Options

Save Changes and Exit

Discard Changes and Exit

Save Changes and Reset

Discard Changes and Reset

Save Changes

Discard Changes

Default Options

Restore Defaults

Save as User Defaults

Restore User Defaults

Boot Override Press [Enter] to congure the device as the boot-up drive.

Saves changes made and closes the BIOS setup.

Options available: Yes/No.

Discards changes made and exits the BIOS setup.

Options available: Yes/No.

Restarts the system after saving the changes made.

Options available: Yes/No.

Restarts the system without saving any changes.

Options available: Yes/No.

Saves changes made in the BIOS setup.

Options available: Yes/No.

Discards changes made and closes the BIOS setup.

Options available: Yes/No.

Loads the default settings for all BIOS setup parameters. Setup Defaults

are quite demanding in terms of resources consumption. If you are using

low-speed memory chips or other kinds of low-performance components

and you choose to load these settings, the system might not function

properly.

Options available: Yes/No.

Saves the changes made as the user default settings.

Options available: Yes/No.

Loads the user default settings for all BIOS setup parameters.

Options available: Yes/No.

- 63 - BIOS Setup

Page 64

5-7 Server Management Menu

Parameter Description

BMC Self Test

Status

BMC Device ID Displays BMC device ID information.

BMC Device

Revision

BMC Firmware

Revision

IPMI Version Displays IPMI version information.

BMC Interface (s) Displays BMC interface information.

System Event Log Press [Enter] to congure advanced items.

BMC Self Test Log Press [Enter] to congure advanced items.

View FRU

Information

BMC network

conguration

Displays BMC Self Test status information.

Displays BMC device revision information.

Displays BMC rmware revision information.

Press [Enter] to view the advanced items.

Press [Enter] to congure advanced items.

(Note) Advanced items prompt when this item is set to Enabled.

BIOS Setup - 64 -

Page 65

5-7-1 System Event Log

Parameter Description

Enabling / Disabling Options

Change this item to enable or disable all features of System Event

SEL Components

Erasing Settings

Erasing SEL

When SEL is Full

Custom EFI Logging Options

Log EFI Status Codes

Logging during boot.

Options available: Enabled/Disabled. Default setting is Enabled.

Choose options for erasing SEL.

Options available: No/Yes, On next reset/Yes, On every reset. Default

setting is No.

Choose options for reactions to a full SEL.

Options available: Do Nothing/Erase Immediately. Default setting is Do

Nothing.

Enable/Disable the logging of EFI Status Codes (if not already converted

to legacy).

Options available: Disabled/Both/Error code/Progress code. Default

setting is Error code.

- 65 - BIOS Setup

Page 66

5-7-2 View Self Test Log

Parameter Description

Log area usage = 00 out of 20

logs

Choose options for erasing log.

Erase Log

When log is full

Options available: No/Yes, On next reset/Yes, On every reset. Default

setting is No..

Choose options for reactions to a full log.

Options available: Do Nothing/Clear Log. Default setting is Clear Log.

BIOS Setup - 66 -

Page 67

5-7-3 View FRU Information

The FRU page is a simple display page for basic system ID information, as well as System product

information. Items on this window are non-congurable.

(Note) Corresponds to the model name of GIGABYTE server you are using.

- 67 - BIOS Setup

Page 68

5-7-4 BMC Network Conguration

Parameter Description

BMC network conguration

Switch NCSI and dedicated LAN and send KCS command.

Select NCSI and Dedicated

LAN

Lan Channel 1

Conguration Address source

Station IP address Displays IP Address information.

Subnet mask

Router IP address Displays the Router IP Address information.

Station MAC address Displays the MAC Address information.

Real-time synchronize BMC

network parameter values

Options available: Do Nothing/Mode1 (Dedicated)/Mode2(NSCI)/Mode3

(Failover).

Default setting is Mode1 (Dedicated).

Select to congure LAN channel parameters statically or dynamically

(DHCP). Do nothing option will not modify any BMC network parameters

during BIOS phase.

Options available: Unspecied/Static/DynamicBmcDhcp. Default setting

is DynamicBmcDhcp.

Displays Subnet Mask information.

Please note that the IP address must be in three digitals, for example,

192.168.000.001.

Press [Enter] to synchronize the BMC network parameter values.

BIOS Setup - 68 -

Loading...

Loading...