Page 1

R130-134

Dual LGA2011 sockets R3 motherboard for Intel® E5-2600 V3 series processors

Service Guide

Rev. 1.0

Page 2

Copyright

© 2015 GIGA-BYTE TECHNOLOGY CO., LTD. All rights reserved.

The trademarks mentioned in this manual are legally registered to their respective owners.

Disclaimer

Information in this manual is protected by copyright laws and is the property of GIGABYTE.

Changes to the specifications and features in this manual may be made by GIGABYTE

without prior notice. No part of this manual may be reproduced, copied, translated, transmitted, or

published in any form or by any means without GIGABYTE's prior written permission.

Documentation Classications

In order to assist in the use of this product, GIGABYTE provides the following types of documentations:

For detailed product information, carefully read the User's Manual.

For more information, visit our website at:

http://b2b.gigabyte.com

You are a professional?

Get an access to our complete source of sales, marketing & technical materials at:

http://reseller.b2b.gigabyte.com

https://www.facebook.com/gigabyteserver

Page 3

Preface

Before using this information and the product it supports, please read the following general infor-

mation.

1. This Service Guide provides you with all technical information relating to the BASIC CON-

FIGURATION decided for GIGABYTE’s “global” product offering. To better t local market-

requirements and enhance product competitiveness, your regional ofce MAY have decided

toextend the functionality of a machine (e.g. add-on card, modem, or extra memory capabil-

ity).These LOCALIZED FEATURES will NOT be covered in this generic service guide. In

suchcases, please contact your regional ofces or the responsible personnel/channel to

provide youwith further technical details.

2. Please note WHEN ORDERING SPARE PARTS, you should check the most up-to-date

informationavailable on your regional web or channel. For whatever reason, if a part num-

ber change is made,it will not be noted in the printed Service Guide. For GIGABYTE-AU-

THORIZED SERVICEPROVIDERS, your GIGABYTE ofce may have a DIFFERENT part

number code to thosegiven in the FRU list of this printed Service Guide. You MUST use the

list provided by yourregional GIGABYTE ofce to order FRU parts for repair and service of

customer machines.

Page 4

Table of Contents

Box Contents ...................................................................................................................7

Safety, Care and Regulatory Information ........................................................................8

Chapter 1 Hardware Installation ................................................................................... 11

1-1 Installation Precautions .................................................................................. 11

1-2 Product Specications .................................................................................... 12

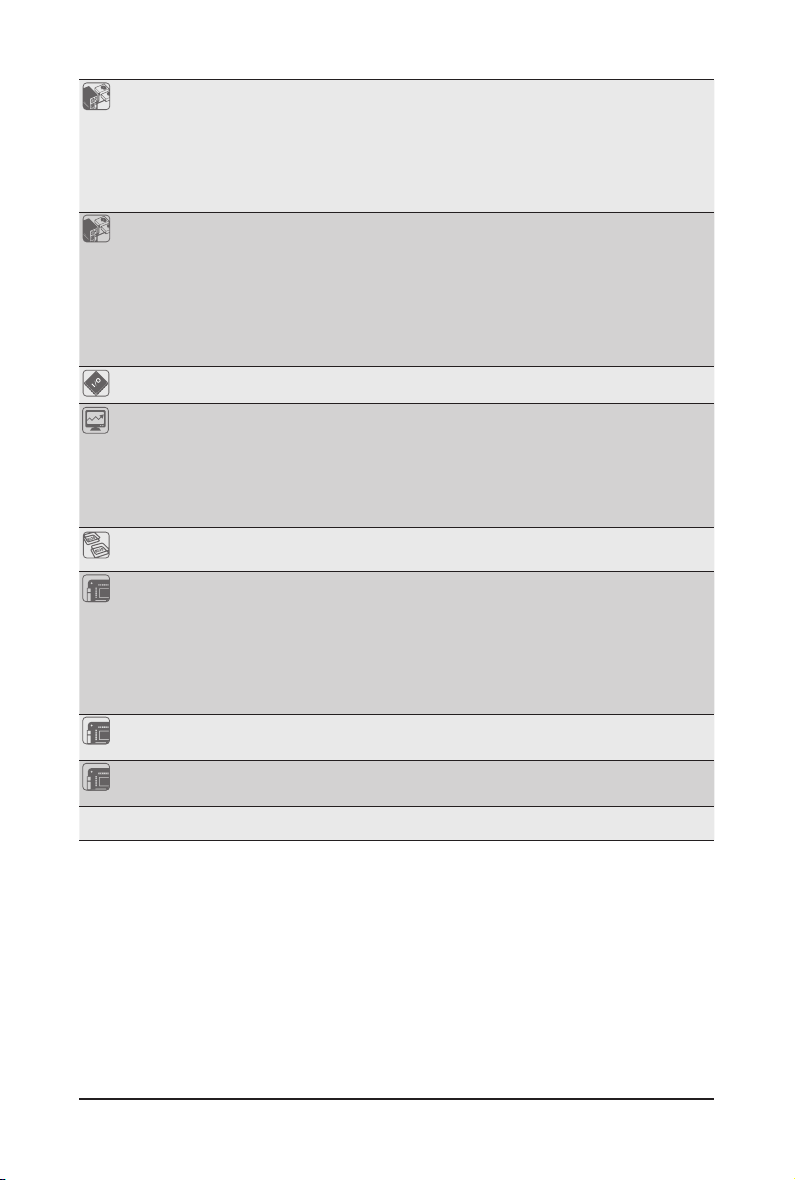

1-3 System Block Diagram ................................................................................... 15

Chapter 2 System Hardware Installation ......................................................................16

2-1 Removing Chassis Cover ............................................................................... 17

2-2 Removing and Installing the Fan Duct ........................................................... 18

2-3 Installing the CPU ......................................................................................... 19

2-4 Installing the Heat Sink ................................................................................. 20

2-5 Installing the Memory ..................................................................................... 21

2-5-1 Four Channel Memory Conguration .....................................................................21

2-5-2 Installing a Memory ...............................................................................................22

2-5-3 DIMM Population Table ..........................................................................................22

2-6 Installing the PCI Expansion Card ................................................................. 23

2-7 Installing the Hard Disk Drive ......................................................................... 24

2-8 Replacing the FAN Assemblly ........................................................................ 25

2-9 Replacing the Power Supply .......................................................................... 26

Chapter 3 System Appearance ..................................................................................... 27

3-1 Front View ...................................................................................................... 27

3-2 Rear View ....................................................................................................... 27

3-3 Front Panel LED and Buttons ........................................................................ 28

3-4 Rear System LAN LEDs ................................................................................. 30

3-5 Hard Disk Drive LEDs .................................................................................... 31

3-6 Cable Routing ................................................................................................ 32

Chapter 4 Motherboard Components ...........................................................................33

4-1 MD60-SC1 Motherboard Components ........................................................... 33

4-2 Jumper Setting .............................................................................................. 36

4-3 Back Plane Boad Components ...................................................................... 38

4-3-1 Back Plane BoadJ2/J3 Jumper Setting .......................................................... 39

Chapter 5 BIOS Setup .................................................................................................. 40

- 4 -

Page 5

5-1 The Main Menu .............................................................................................. 42

5-2 Advanced Menu ............................................................................................. 45

5-2-1 Serial Port Console Redirection .............................................................................46

5-2-2 PCI Subsystem Settings .........................................................................................50

5-2-2-1 PCI Express Settings ..............................................................................................52

5-2-3 Network Stack ........................................................................................................54

5-2-4 CSM Conguration .................................................................................................55

5-2-5 Post Report Conguration ......................................................................................57

5-2-6 Trusted Computing .................................................................................................58

5-2-7 USB Conguration ..................................................................................................59

5-2-8 Chipset Conguration .............................................................................................60

5-9 SIO Conguration ...................................................................................................61

5-2-10 iSCSI Conguration ................................................................................................65

5-3 Intel RC Setup Menu ...................................................................................... 66

5-3-1 Processor Conguration .........................................................................................67

5-3-1-1 Pre-Socket Conguration .......................................................................................70

5-3-2 Advanced Power Management Conguration ........................................................72

5-3-2-1 CPU P State Control ...............................................................................................73

5-3-2-2 CPU C State Control ..............................................................................................74

5-3-2-3 CPU T State Control ...............................................................................................75

5-3-3 Common RefCode Conguration ...........................................................................76

5-3-4 QPI Conguration ...................................................................................................77

5-3-5 Memory Conguration ............................................................................................79

5-3-5-1 Memory Topology ...................................................................................................81

5-3-5-2 Memory Thermal ....................................................................................................82

5-3-5-3 Memory Map ...........................................................................................................83

5-3-5-4 Memory RAS Conguration ....................................................................................84

5-3-6 IIO Conguration ....................................................................................................85

5-3-6-1 IOAT Conguration .................................................................................................86

5-3-6-2 Intel VT for Directed I/O (VT-d) ..............................................................................87

5-3-7 PCH Conguration .................................................................................................88

5-3-7-1 PCH Devices ..........................................................................................................89

5-3-7-2 PCH sSATA Conguration ......................................................................................90

5-3-7-2-1 SATA Mode Options ..............................................................................................93

5-3-7-3 PCH SATA Conguration ........................................................................................95

5-3-7-3-1 SATA Mode Options ..............................................................................................98

5-3-7-4 USB Conguration ................................................................................................100

5-3-8 Miscellaneous Conguration ................................................................................101

5-3-9 Server ME Conguration ......................................................................................102

5-3-10 Runtime Error Logging .........................................................................................103

5-3-10-1 Whea Setting ........................................................................................................104

5-3-10-2 Memory Error Enabling .........................................................................................105

- 5 -

Page 6

5-3-10-3 PCI/PCI Error Enabling .........................................................................................106

5-4 Server Management Menu ........................................................................... 107

5-4-1 System Event Log ................................................................................................109

5-4-2 View FRU Information ..........................................................................................110

5-4-3 BMC network conguration .................................................................................. 111

5-5 Security Menu .............................................................................................. 112

5-5-1 Secure Boot menu ...............................................................................................11 3

5-5-1-1 Key Management

...............................................................................................11 4

5-6 Boot Menu .................................................................................................... 116

5-7 Save & Exit Menu ......................................................................................... 118

5-8 BIOS POST Codes ...................................................................................... 120

5-9 BIOS POST Beep code ................................................................................ 124

5-9-1 PEI Beep Codes ...................................................................................................124

5-9-2 DEX Beep Codes .................................................................................................124

5-10 BIOS Recovery Instruction ........................................................................... 125

- 6 -

Page 7

Box Contents

R130-134 System

Driver CD

Two CPU Heat Sink

Rail Kit

• The box contents above are for reference only and the actual items shall depend on the product package you obtain.

The box contents are subject to change without notice.

• The motherboard image is for reference only.

- 7 -

Page 8

Safety, Care and Regulatory Information

Important safety information

Read and follow all instructions marked on the product and in the documentation before you operateyour sys-

tem. Retain all safety and operating instructions for future use.

• The product should be operated only from the type of power source indicated on the rating label.* If your

computer has a voltage selector switch, make sure that the switch is in the proper position foryour area.

The voltage selector switch is set at the factory to the correct voltage.

• The plug-socket combination must be accessible at all times because it serves as the main disconnect-

ing device.

• All product shipped with a three-wire electrical grounding-type plug only fits into a grounding-type

poweroutlet. This is a safety feature. The equipment grounding should be in accordance with local and

nationalelectrical codes. The equipment operates safely when it is used in accordance with its marked

electricalratings and product usage instructions

• Do not use this product near water or a heat source.* Set up the product on a stable work surface or so

as to ensure stability of the system.

• Openings in the case are provided for ventilation. Do not block or cover these openings. Make sure

youprovide adequate space around the system for ventilation when you set up your work area. Never

insertobjects of any kind into the ventilation openings.

• To avoid electrical shock, always unplug all power cables and modem cables from the wall outletsbefore

removing covers.

• Allow the product to cool before removing covers or touching internal components.

Precaution for Product with Laser Devices

Observe the following precautions for laser devices:

• Do not open the CD-ROM drive, make adjustments, or perform procedures on a laser device other than

those specied in the product's documentation.

• Only authorized service technicians should repair laser devices.

Precaution for Product with Modems, Telecommunications, or Local AreaNetwork Options

Observe the following precautions for laser devices:

• Do not connect or use a modem or telephone during a lightning storm. There may be a risk of electri-

calshock from lightning.

• To reduce the risk of re, use only No. 26 AWG or larger telecommunications line cord.

• Do not plug a modem or telephone cable into the network interface controller (NIC) receptacle.

• Disconnect the modem cable before opening a product enclosure, touching or installing internalcompo-

nents, or touching an uninsulated modem cable or jack.

• Do not use a telephone line to report a gas leak while you are in the vicinity of the leak.

- 8 -

Page 9

Federal Communications Commission (FCC) Statement

Warning

This is a class A product. In a domestic environment this product may cause radiointerfer-

enceIn which case the user may be required to take adequate measures.

This equipment has been tested and found to comply with the limits for a Class A digital device,pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection againstharmful interfer-

ence when the equipment is operated in a commercial environment. This equipmentgenerates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance withthe instruction manual, may

cause harmful interference to radio communications. Operation of thisequipment in a residential area is likely

to cause harmful interference in which case the user will berequired to correct the interference at his own ex-

pense.Properly shielded and grounded cables and connectors must be used in order to meet FCC emission-

limits. Neither the provider nor the manufacturer are responsible for any radio or television interferencecaused

by using other than recommended cables and connectors or by unauthorized changes ormodications to this

equipment. Unauthorized changes or modications could void the user's authority tooperate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired opera-

tion.

Canadian Department of Communications Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from digitalapparatus as

set out in the radio interference regulations of Industry Canada.Le present appareil numerique n'emet pas

de bruits radioelectriques depassant les limites applicables auxappareils numeriques de Classe A prescrites

dans le reglement sur le brouillage radioelectrique edicte parIndustrie Canada.

Class A equipment

This device has been tested and found to comply with the limits for a class A digital device pursuantPart 15 of

the FCC Rules. These limits are designed to provide reasonable protection againstharmful interference when

the equipment is operated in a commercial environment. This equipmentgenerate, uses, and can radiate

radio frequency energy, and if not installed and used in accordancewith the instructions, may cause harmful

interference to radio communication. Operation of thisequipment in a residential area is likely to cause harm-

ful interference, in which case the user will berequired to correct the interference at personal expence.

However, there is no guarantee that interference will not occur in a particular installation. If thisdevice does

cause harmful interference to radio or television reception, which can be determined bytuning the device off

and on, the user is encouraged to try to correct the interference by on or more ofthe following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the device and receiver

• Connect the device into an outlet on a circuit different from that to which the receiver isconnected'Consult

the dealer or an experienced radio/television technician for help.

- 9 -

Page 10

California Proposition 65

Warning:

This product contains a chemical, including lead , known to the State of California to cause cancer

http://www.p65warnings.ca.gov/

Warning:

This product contains a chemical, including lead , known to the State of California to cause birth defects or

other reproductive harm.

http://www.p65warnings.ca.gov/

WEEE Symbol Statement

The symbol shown below is on the product or on its packaging, which indicates that this product

must not be disposed of with other waste. Instead, the device should be taken to the waste

collection centers for activation of the treatment, collection, recycling and disposal procedure.

The separate collection and recycling of your waste equipment at the time of disposal will help to

conserve natural resources and ensure that it is recycled in a manner that protects human health

and the environment. For more information about where you can drop off your waste equipment for recycling,

please contact your local government ofce, your household waste disposal service or where you purchased

the product for details of environmentally safe recycling.

When your electrical or electronic equipment is no longer useful to you, "take it back" to your local or

w

regional waste collection administration for recycling.

If you need further assistance in recycling, reusing in your "end of life" product, you may contact us at the

w

Customer Care number listed in your product's user's manual and we will be glad to help you with your

effort.

Battery Warning:

the risk of ifre explosion. Replace the battery only with the same or equivalent type.

• Do not disassemble, crush, punchture batteries.

• Do not store or place your battery pack next to or in a heat source such as a re, heatgenerating

appliance, can or exhaust vent. Heating battery cells to temperatures above 65

cause explosion or re.

• Do not attempt to open or service batteries. Do not dispose of batteries in a re or with household waste.

Incorrectly installing a battery or using incompatible battery may increase

o

C (149oF) can

- 10 -

Page 11

Chapter 1 Hardware Installation

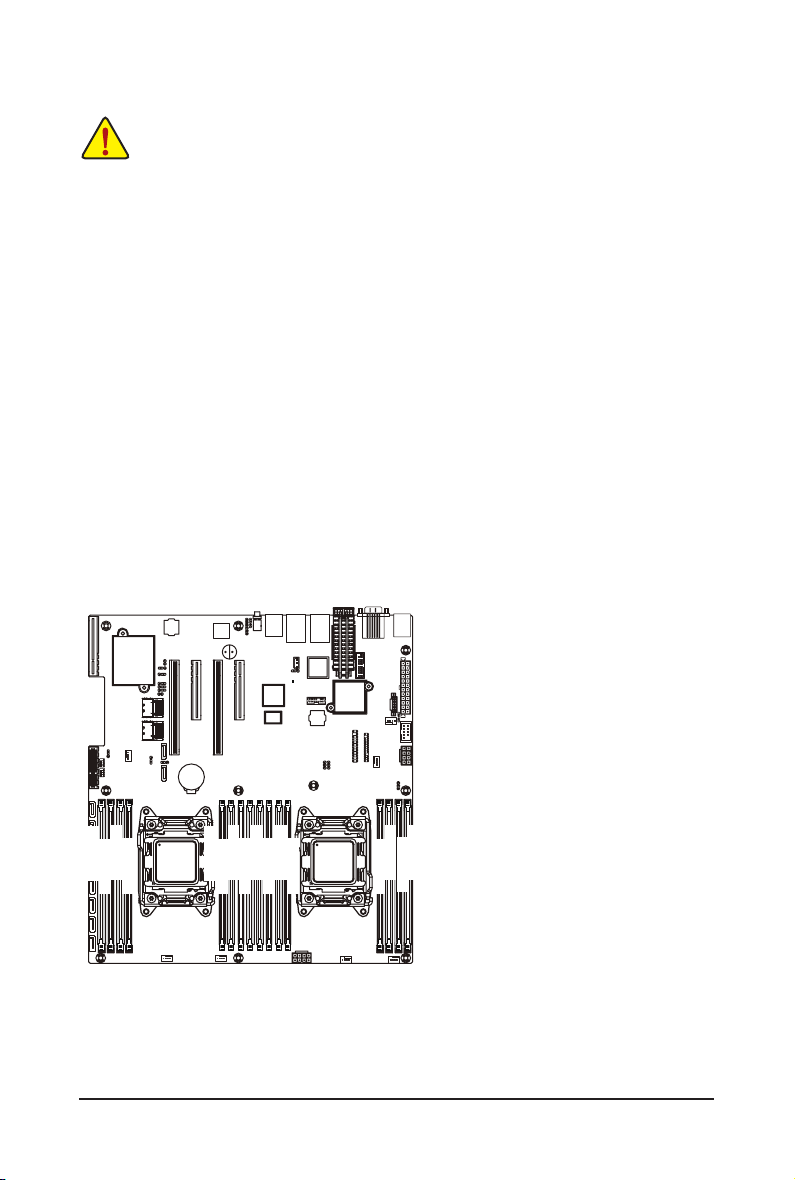

1-1 Installation Precautions

The motherboard/system contain numerous delicate electronic circuits and components which

can become damaged as a result of electrostatic discharge (ESD). Prior to installation, carefully

read the service guide and follow these procedures:

• Prior to installation, do not remove or break motherboard S/N (Serial Number) sticker or

warranty sticker provided by your dealer. These stickers are required for warranty validation.

• Always remove the AC power by unplugging the power cord from the power outlet before

installing or removing the motherboard or other hardware components.

• When connecting hardware components to the internal connectors on the motherboard,

make sure they are connected tightly and securely.

• When handling the motherboard, avoid touching any metal leads or connectors.

• It is best to wear an electrostatic discharge (ESD) wrist strap when handling electronic

components such as a motherboard, CPU or memory. If you do not have an ESD wrist

strap, keep your hands dry and rst touch a metal object to eliminate static electricity.

• Prior to installing the motherboard, please have it on top of an antistatic pad or within an

electrostatic shielding container.

• Before unplugging the power supply cable from the motherboard, make sure the power

supply has been turned off.

• Before turning on the power, make sure the power supply voltage has been set according to

the local voltage standard.

• Before using the product, please verify that all cables and power connectors of your

hardware components are connected.

• To prevent damage to the motherboard, do not allow screws to come in contact with the

motherboard circuit or its components.

• Make sure there are no leftover screws or metal components placed on the motherboard or

within the computer casing.

• Do not place the computer system on an uneven surface

• Do not place the computer system in a high-temperature environment.

• Turning on the computer power during the installation process can lead to damage to

system components as well as physical harm to the user.

• If you are uncertain about any installation steps or have a problem related to the use of the

product, please consult a certied computer technician.

.

- 11 - Hardware Installation

Page 12

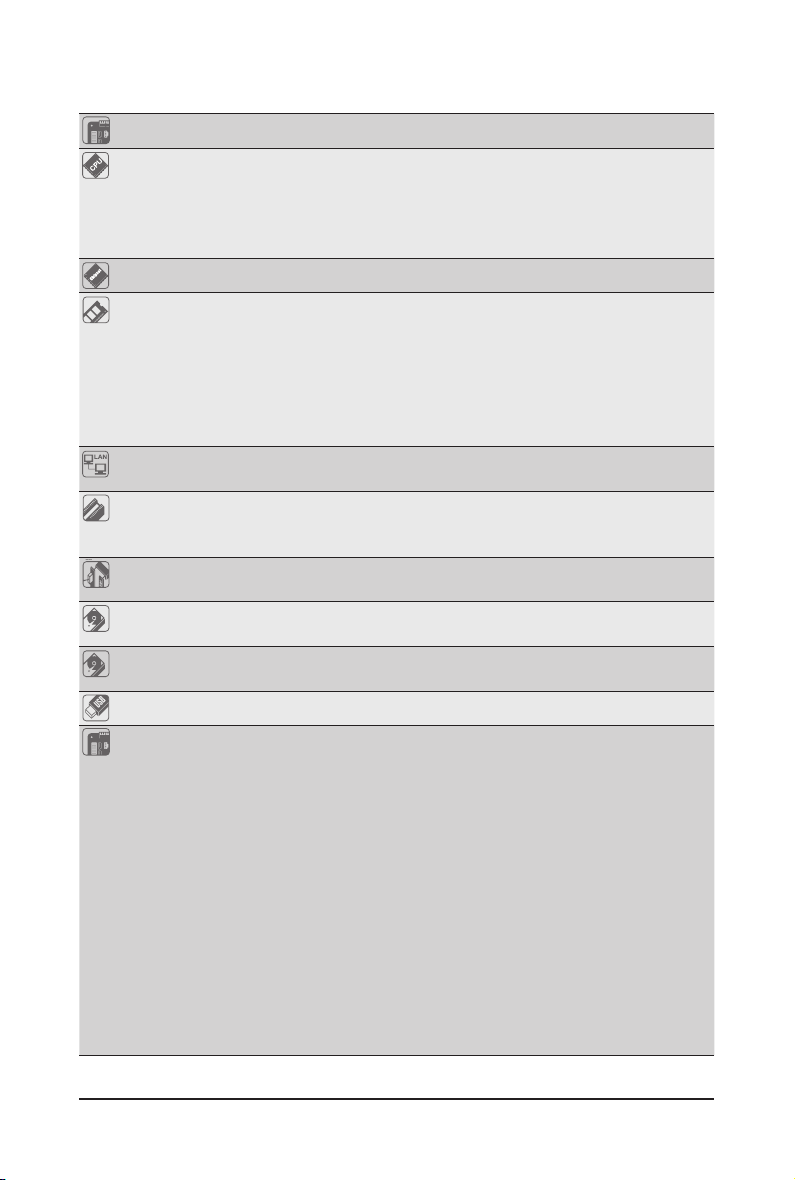

1-2 Product Specications

Motherboard w R130-134: MD 60-SC1

CPU w Support for Intel® Xeon® E5-2600 V3 series processors in the LGA2011 package

w L3 cache varies with CPU

w Supports Dual QuickPath Interconnect up to 9.6GT/s

w Enhanced Intel SpeedStep Technology (EIST)

w Support Intel Virtualization Technology (VT)

Chipset w Intel® C612 Express (Wellsburg) Chipset

Memory w 16 x 1.2V DDR4 DIMM sockets supporting up to 512GB RDIMM of system

memory

w 16 x 1.2V DD R4 DIMM sockets supp orting up to 1TB LRDIM M of system memory

w Four channel memory architecture

w Supports DDR4 2133MHz RDIMM memory modules

w Supports DDR4 2133MHz LR-DIMM memory modules

w Support for ECC RDIMM/LRDIMM memory modules

LAN w Intel® I350 supports 10/100/1000 Mbps

w 1 x Management LAN 10/100/1000Mpbs LAN port

Expansion Slot w 2 x Half-length low-prole slots

w 1 x PCIe x16 (Gen3 x8 bus) connector

w 1 x PCIe x8 (Gen3 x8 bus) connector

Onboard

Graphics

Mass Storage w 4 x 3.5” Hot-Swap SATA/SAS HDDs

System Fans w 3 x 40x40x56mm (23'000rpm)

USB w Up to 8 USB 3.0 ports (6 on the rear panel I/O, 2 at the front panel)

w ASPEED

w Activating SAS functions with CRA220-8 add-on card

w 3 x 40x40x28mm (18'000rpm)

®

AST2400 supports 16MB DDR3 VRAM

Internal

Connectors

Hardware Installation - 12 -

w 1 x 24-pin ATX main power connector

w 2 x 8-pin ATX 12V power connector

w 2 x Mini-SAS connectors (SATA3 6Gb/s signal)

w 8 x SAS connectors

w 2 x SATA3 6Gb/s connectors

w 1 x PMBus header

w 2 x CPU fan headers

w 5 x System fan headers

w 1 x Front panel header

w 1 x HDD Back plane borad header

w 1 x USB 3.0 header

w 1 x TPM module connector

w 1 x Serial port connector

w 2 x SAS SPGIO headers

w 1 x IPMB connector

Page 13

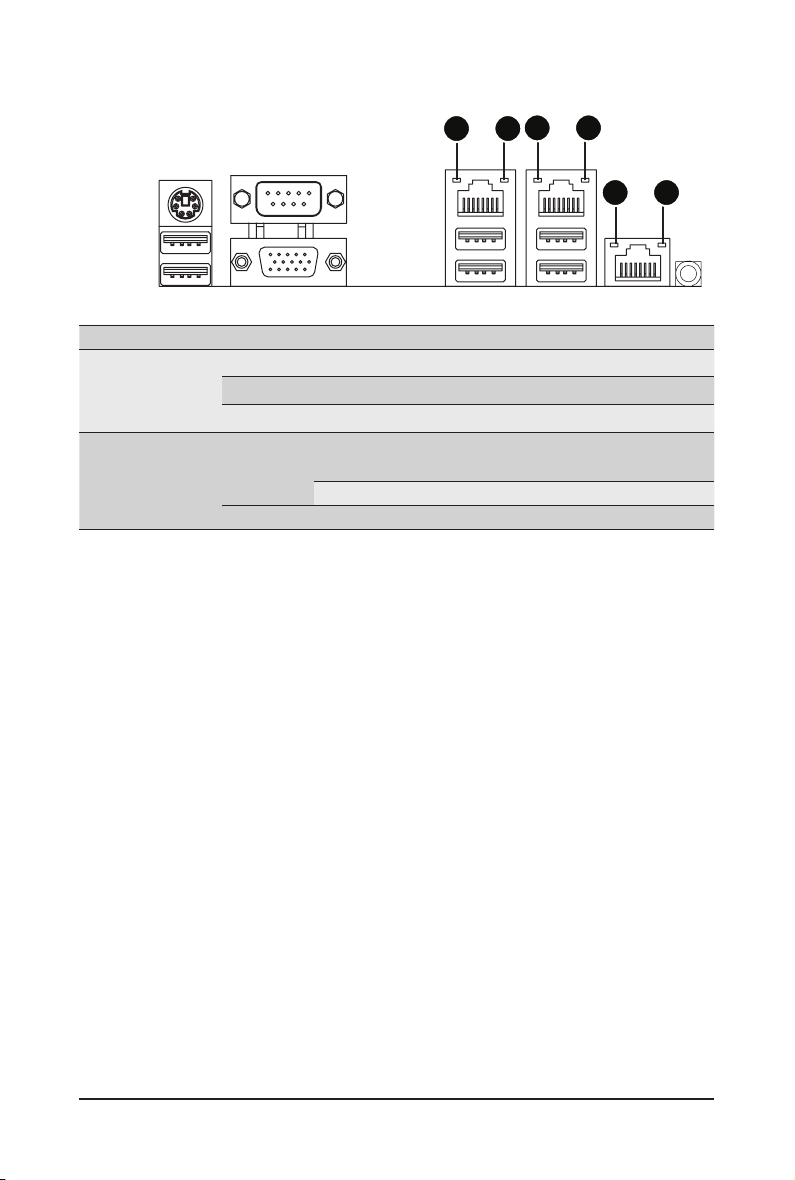

Rear Panel I/O w 6 x USB 3.0 ports

w 3 x RJ-45 ports (1 x 10/100/1000 Mbps dedicated management LAN port)

w 1 x COM port

w 1 x VGA port

w 1 x PS/2 connector

w 1 x ID Switch button with LED

Front Panel

LED/Buttons

w 1 x Power button/LED

w 1 x NMI button

w 1 x ID Switch button/LED

w 1 x Reset button

w 2 x LAN LED

w 1 x System status LED

w 1 x HDD status LED

I/O Controller w ASPEED® AST2400 BMC chip

Hardware

Monitor

w System voltage detection

w CPU/System temperature detection

w CPU/System fan speed detection

w CPU/System fan speed control

* Whether the CPU/system fan speed control function is supported will depend on

the CPU/system cooler you install.

BIOS w 1 x 128 Mbit ash

w AMI BIOS

Environment

Ambient

w Operating Temperature: 10oC to 35oC

w Non-operating Temperature: -40oC to 60oC

Temperature

Relative

Humidity

System

w Operating Humidity: 8-80% operating Humidity (non-condensing)

w Non-operating Humidity: 20-95% operating Humidity (non-condensing)

w 444Wx43Hx615D (mm)

Dimension

Electrical

w Fixed 1U PSU 600W 100-240VAC at 80 plus gold level

Power Supply

* GIGABY TE reserves the right to make any changes to the product specications and product-related information

without prior notice.

- 13 - Hardware Installation

Page 14

Hardware Installation - 14 -

Page 15

1-3 System Block Diagram

- 15 - Hardware Installation

Page 16

Chapter 2 System Hardware Installation

Pre-installation Instructions

Perform the steps below before you open the server or before you remove or replaceany

component.

• Back up all important system and data les before performing any hardwareconguration.

• Turn off the system and all the peripherals connected to it.

• Locate the pin one of the CPU. The CPU cannot be inserted if oriented incorrectly. (Or you may

locate the notches on both sides of the CPU and alignment keys on the CPU socket.)

• Apply an even and thin layer of thermal grease on the surface of the CPU.

• Do not turn on the computer if the CPU cooler is not installed, otherwise overheating and

damage of the CPU may occur.

• Set the CPU host frequency in accordance with the CPU specications. It is not recommended

that the system bus frequency be set beyond hardware specications since it does not meet the

standard requirements for the peripherals. If you wish to set the frequency beyond the standard

specifications, please do so according to your hardware specifications including the CPU,

graphics card, memory, hard drive, etc.

Hardware Installation - 16 -

Page 17

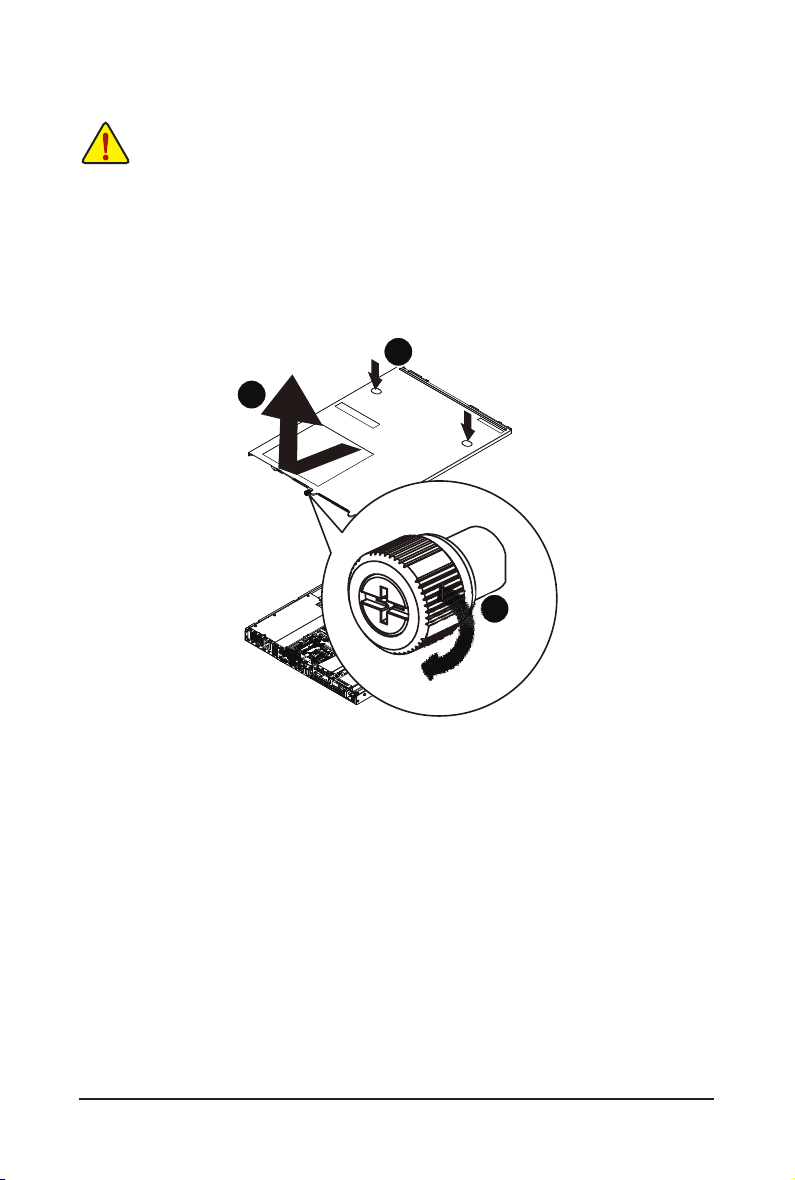

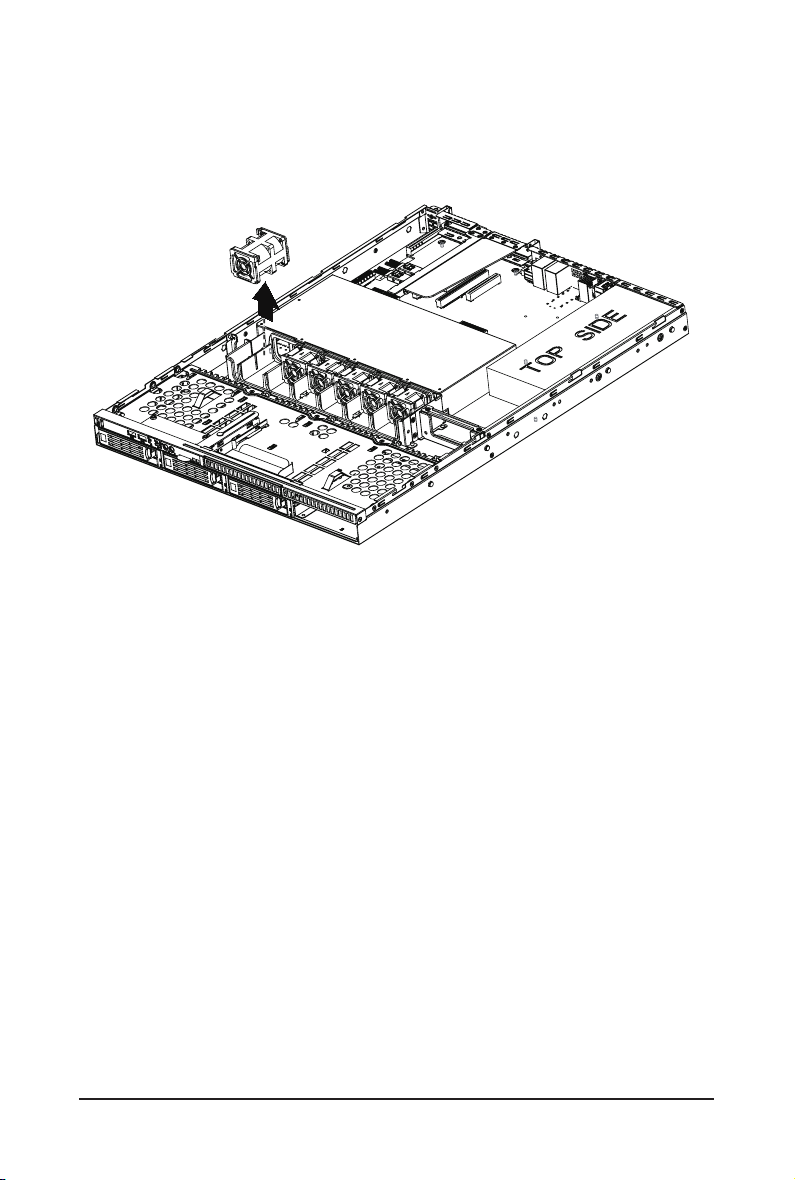

2-1 Removing Chassis Cover

Before you remove or install the system cover

• Make sure the system is not turned on or connected to AC power.

Follow these instructions to remove the system cover:

1. Loosen and remove the thumbscrew securing the front chassis cover.

2. Press the the indentation located at two sides of the cover.

3. Slide the cover horizontally to the back and remove the cover in the direction of the arrow.

2

3

1

- 17 - Hardware Installation

Page 18

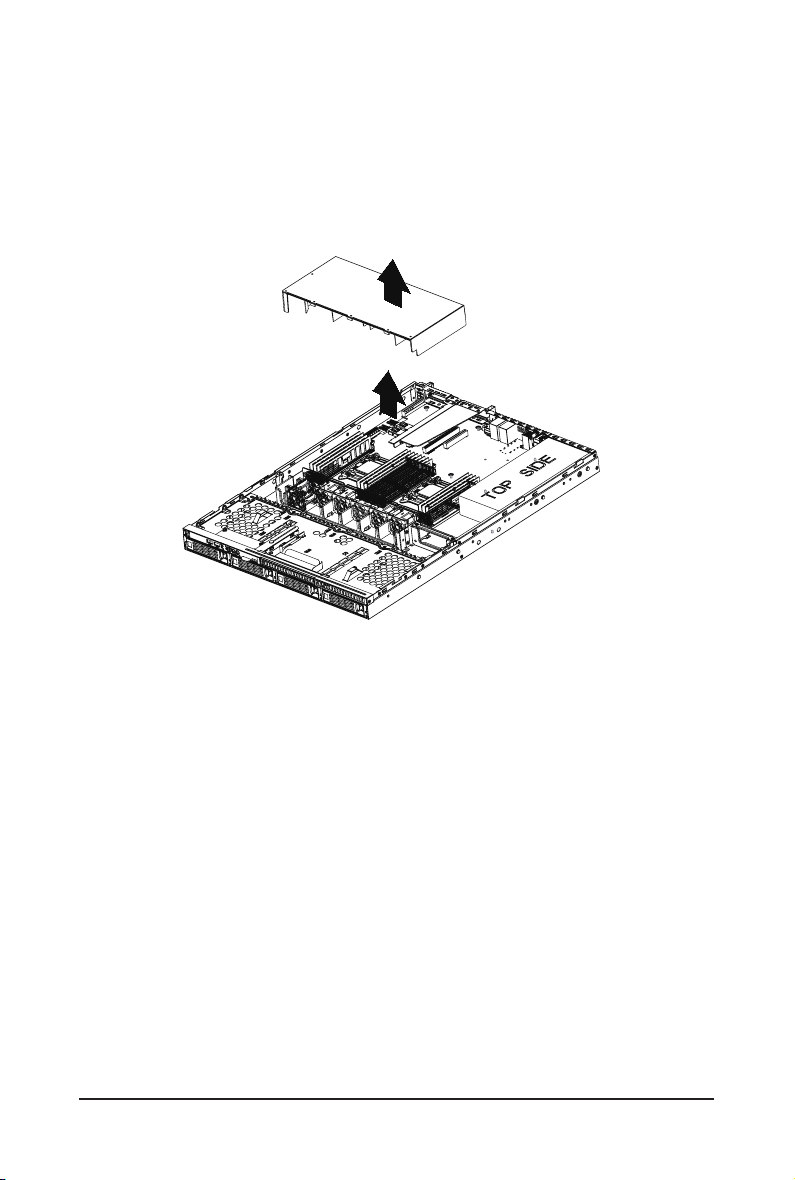

2-2 Removing and Installing the Fan Duct

Follow these instructions to remove/install the fan duct:

1. Lift up to remove the fan duct

2. To install the fan duct, align the fan duct with the guiding groove. Push down the fan duct into

chassis until its rmly seats

Hardware Installation - 18 -

Page 19

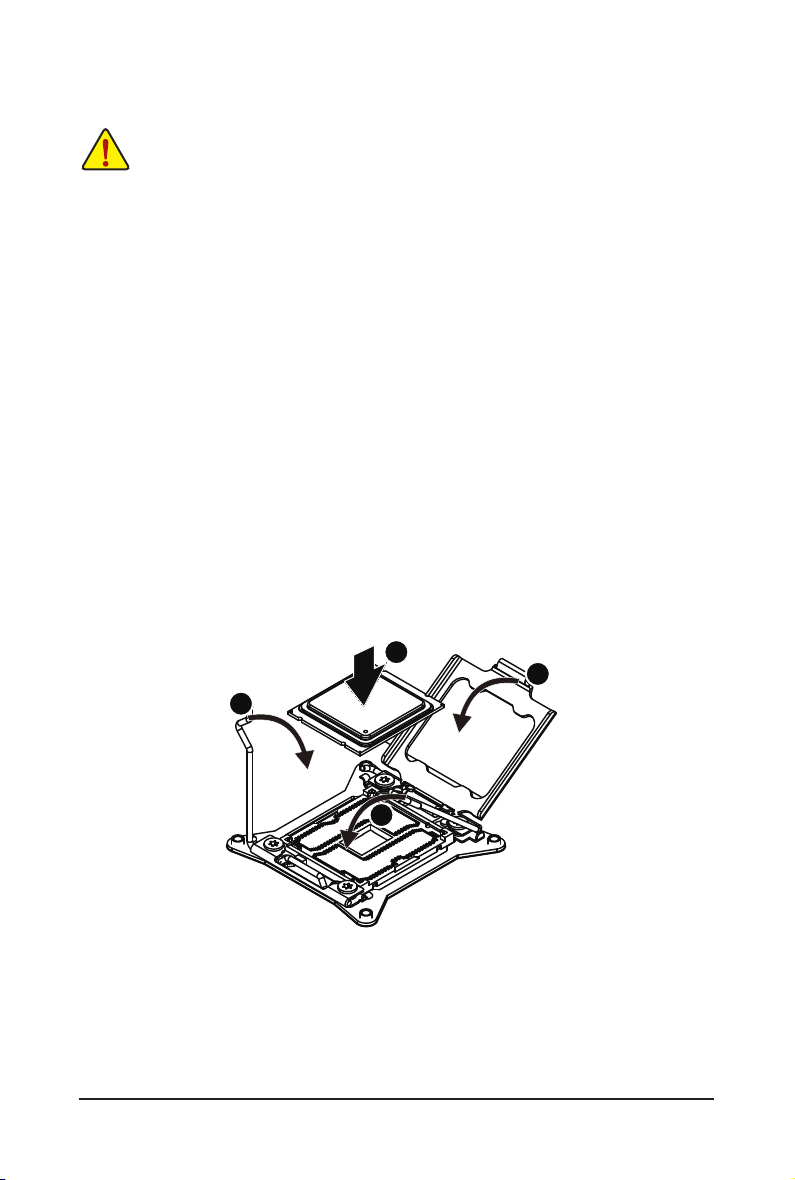

2-3 Installing the CPU

Read the following guidelines before you begin to install the CPU:

• Make sure that the motherboard supports the CPU.

• Always turn off the computer and unplug the power cord from the power outlet before installing

the CPU to prevent hardware damage.

• Unplug all cables from the power outlets.

• Disconnect all telecommunication cables from their ports.

• Place the system unit on a at and stable surface.

• Open the system according to the instructions.

WARNING!

Failure to properly turn off the server before you start installing components may cause serious

damage. Do not attempt the procedures described in the following sections unless you are a

qualied service technician.

Follow these instructions to install the CPU:

1. Raise the metal locking lever on the socket.

2. Remove the plastic covering on the CPU socket.Insert the CPU with the correct orientation. The

CPU only ts in one orientation.

3. Replace the metal cover.

4. Push the metal lever back into locked position.

1

2

3

4

- 19 - Hardware Installation

Page 20

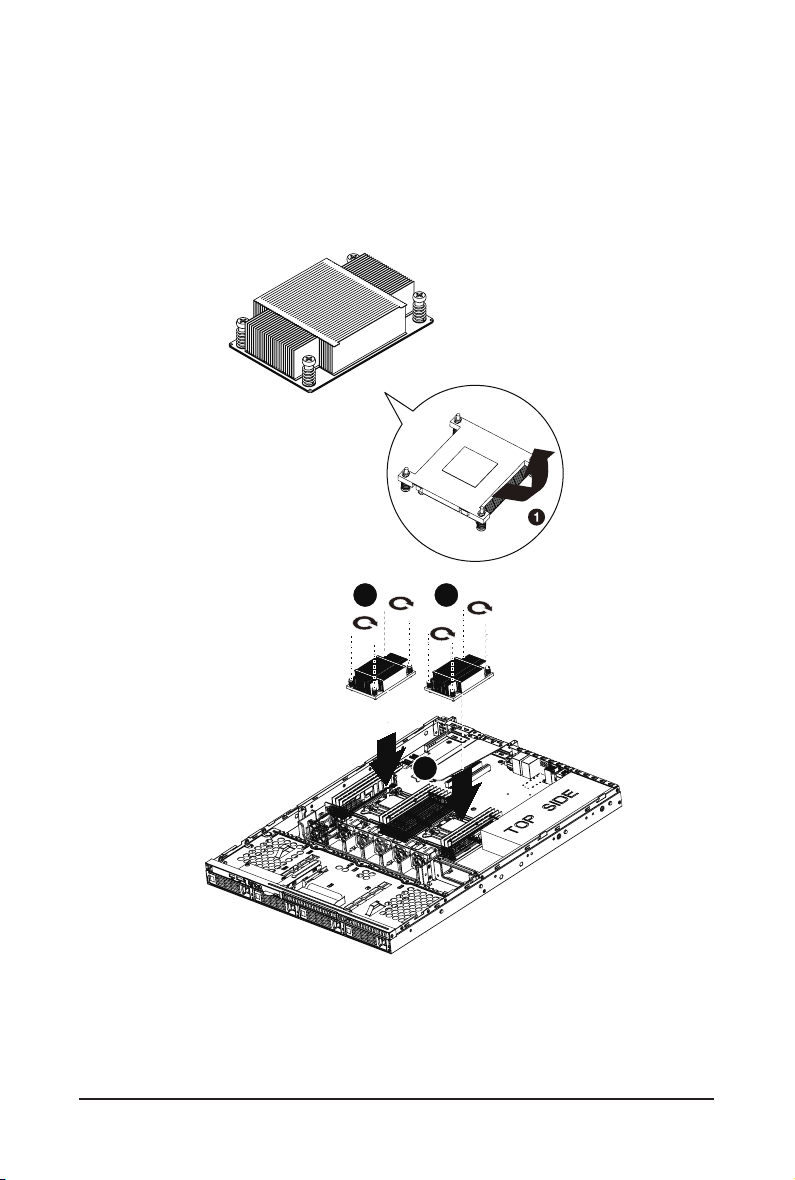

2-4 Installing the Heat Sink

Follow these instructions to install the heat sinks:

1. Apply thermal compound evenly on the top of the CPU. Remove the protective cover from the

underside of the heat sink.

2. Place the heat sink(s) on top of the CPU.

3. Tighten the four positioning screws.

3 3

Hardware Installation - 20 -

2

Page 21

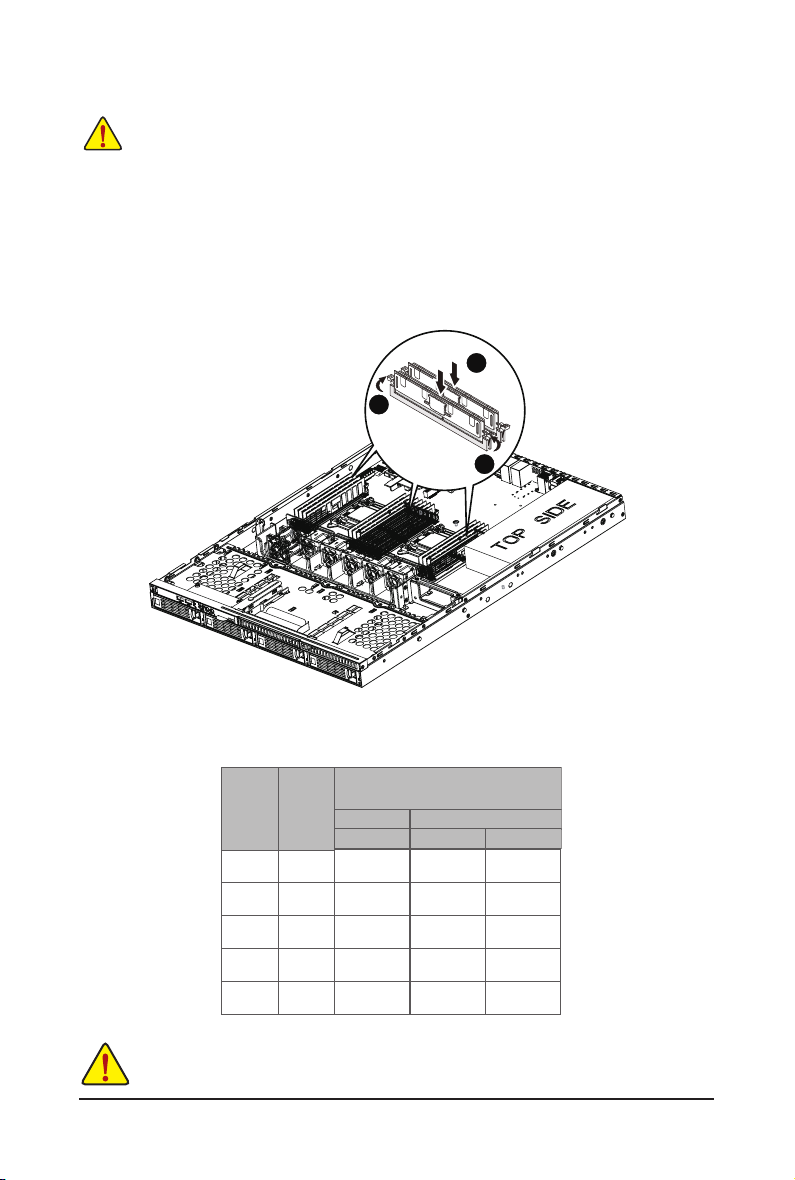

2-5 Installing the Memory

Read the following guidelines before you begin to install the memory:

• Make sure that the motherboard supports the memory. It is recommended that memory of the

same capacity, brand, speed, and chips be used.

• Always turn off the computer and unplug the power cord from the power outlet before installing

the memory to prevent hardware damage.

• Memory modules have a foolproof design. A memory module can be installed in only one

direction. If you are unable to insert the memory, switch the direction.

2-5-1 Four Channel Memory Conguration

This motherboard provides sixteen DDR4 memory sockets and supports Four Channel Technology. After

the memory is installed, the BIOS will automatically detect the specications and capacity of the memory.

Enabling Four Channel memory mode will be four times of the original memory bandwidth.

The four DDR4 memory sockets are divided into four channels each channel has two memory sockets as

following:

Channel 1: DIMM_P0_A0/DIMM_P0_A1 (For pimary CPU)/

DIMM_P1_E0/DIMM_P1_E1 (For secondary CPU)

Channel 2: DIMM_P0_B0/DIMM_P0_B1 (For pimary CPU)

DIMM_P1_F0/DIMM_P1_F1 (For secondary CPU)

Channel 3: DIMM_P0_C0/DIMM_P0_C1 (For pimary CPU)

DIMM_P1_G0/DIMM_P1_G1 (For secondary CPU)

Channel 4: DIMM_P0_D0/DIMM_P0_D1 (For pimary CPU)

DIMM_P1_H0/DIMM_P1_H1 (For secondary CPU)

DIMM_P0_D0

DIMM_P0_C0

DIMM_P0_D1

DIMM_P0_C1

DIMM_P0_A1

DIMM_P0_B1

DIMM_P0_B0

DIMM_P1_G0

DIMM_P1_H0

DIMM_P1_G1

DIMM_P0_A0

DIMM_P1_H1

DIMM_P1_E0

DIMM_P1_F0

DIMM_P1_E1

DIMM_P1_F1

- 21 - Hardware Installation

Page 22

2-5-2 Installing a Memory

Before installing a memory module, make sure to turn off the computer and unplug the power

cord from the power outlet to prevent damage to the memory module.

Be sure to install DDR4 DIMMs on this motherboard.

Follow these instructions to install the Memory:

1. Insert the DIMM memory module vertically into the DIMM slot, and push it down.

2. Close the plastic clip at both edges of the DIMM slots to lock the DIMM module.

3. Reverse the installation steps when you want to remove the DIMM module.

1

2

2

2-5-3 DIMM Population Table

1DPC

2133

2133

2133

2133

2133

Speed (MT/s);

2 Slot Per Channel

1DPC 2DPC

2133

2133

2133

2133

2133

Type

RDIMM

RDIMM

RDIMM

RDIMM

LRDIMM

Ranks Per

DIMM and

Data Width

Slot Per Channel (SPC) and DIMM Per Channel (DPC)

1 Slot Per Channel

SRx4

SRx8

DRx8

DRx4

QRx4

When only one DIMM is used, it must be populated in memory slot0 rst.

Memory populated sequence must be followed with slot0/slot1.

System will not boot normally with incorrect populated sequence.

Hardware Installation - 22 -

1866

1866

1866

1866

2133

Page 23

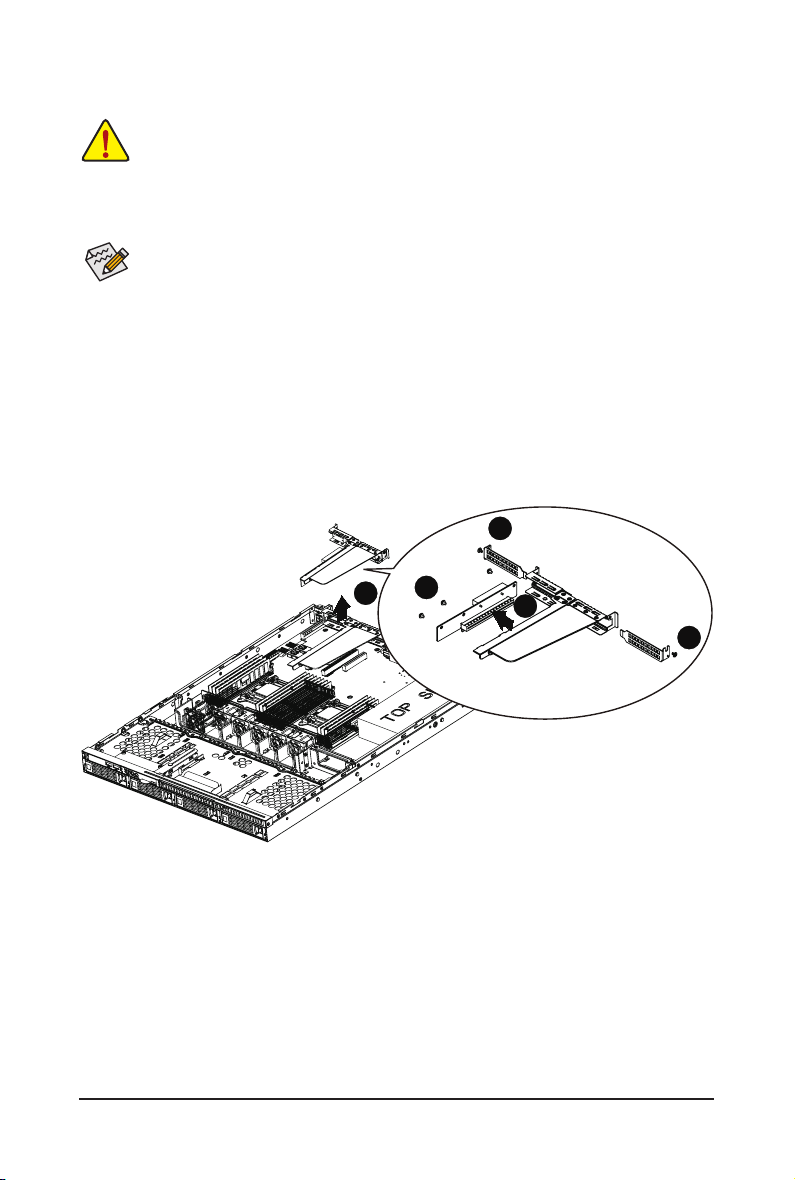

2-6 Installing the PCI Expansion Card

• Voltages can be present within the server whenever an AC power source is connected. This

voltage is present even when the main power switch is in the off position. Ensure that the

system is powered-down and all power sources have been disconnected from the server prior to

installing a PCI card.

Failure to observe these warnings could result in personal injury or damage to equipment.

• The PCI riser assembly does not include a riser card or any cabling as standard. To install a PCI

card, a riser card must be installed.

Follow these instructions to PCI Expansion card:

1. Lift the riser bracket slightly.

2. Turn around the riser bracket and loosen the PCI bracket screws.

3. Attach the mini PCI card slot to the riser bracket.

4. Securing the mini PCI card with three screws.

5. Orient the PCI card with the riser guide connector and push into the slot until the PCI card sits in the

PCI card connector.

6. To install the riser bracket follow the instructions for removing the riser bracket in the reverse order.

2

1

4

3

- 23 - Hardware Installation

2

Page 24

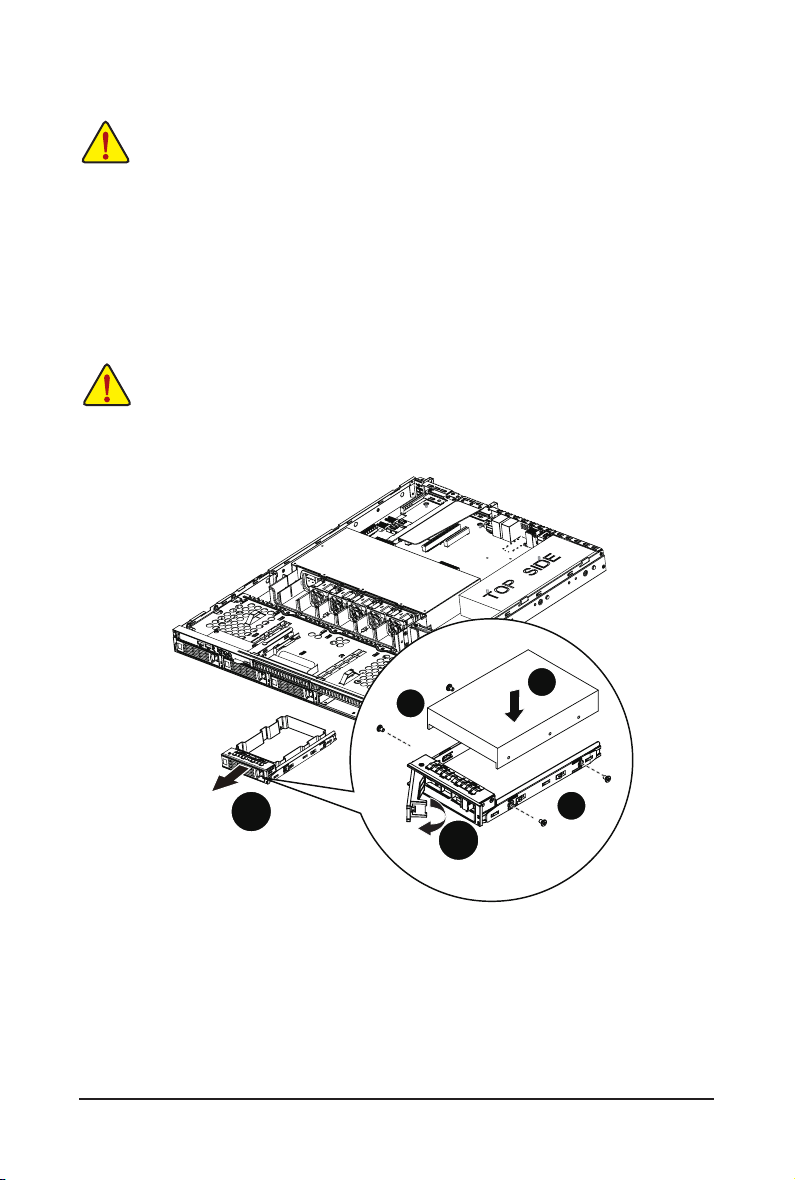

2-7 Installing the Hard Disk Drive

Read the following guidelines before you begin to install the Hard disk drive:

• Take note of the drive tray orientation before sliding it out.

• The tray will not t back into the bay if inserted incorrectly.

• Make sure that the HDD is connected to the HDD connector on the backplane.

Follow these instructions to install the Hard disk drive:

1. Press the release button.

2. Pull the locking lever to remove the HDD tray. Remove the HDD dummy cover.

3. Slide hard disk into blank.

4. Secure the hard drive to the tray with four (4) screws as shown. Do not over tighten thescrews.

5. Slide the blank into the bay until it locks into place.

CAUTION!

We strongly recommand using enterprise level hard disk drive in Gigabyte server system. For more

information of recommanded HDDs, please visit Gigabyte website: https://www.gigabyte.com and

serach for the specic product QVL from Support & Dowloads.

2

Hardware Installation - 24 -

3

4

4

1

Page 25

2-8 Replacing the FAN Assemblly

Follow these instructions to replace the fan assembly:

1. Lift up the fan assembly from the chassis.

2. Reverse the previous step to install the replacement fan assembly.

- 25 - Hardware Installation

Page 26

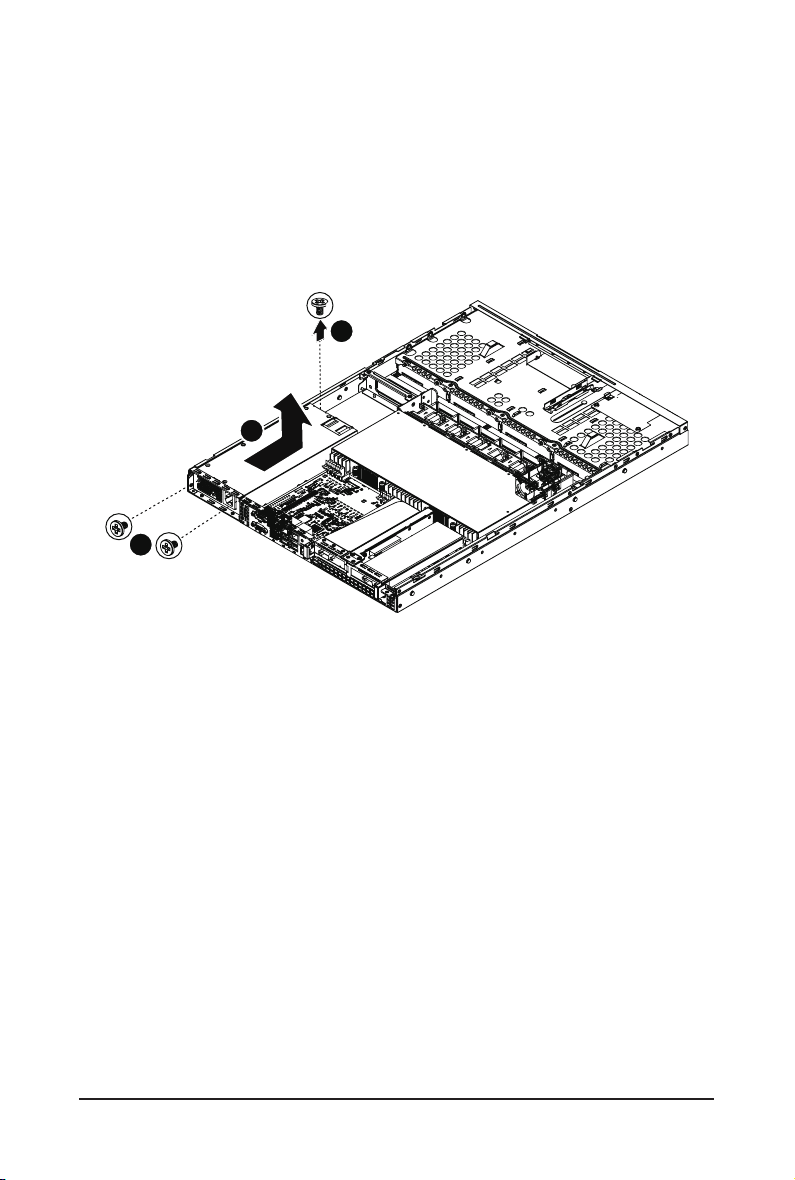

2-9 Replacing the Power Supply

Follow these instructions to replace the power supply:

1. Disconnect the three power cables.

2. Remove the four screws securing on the power supply.

3. Lift the power supply out of the chassis in the direction of the arrow.

4. Insert the replacement power supply rmly into the chassis. Connect the AC power cord to the

replacement power supply.

1

2

1

Hardware Installation - 26 -

Page 27

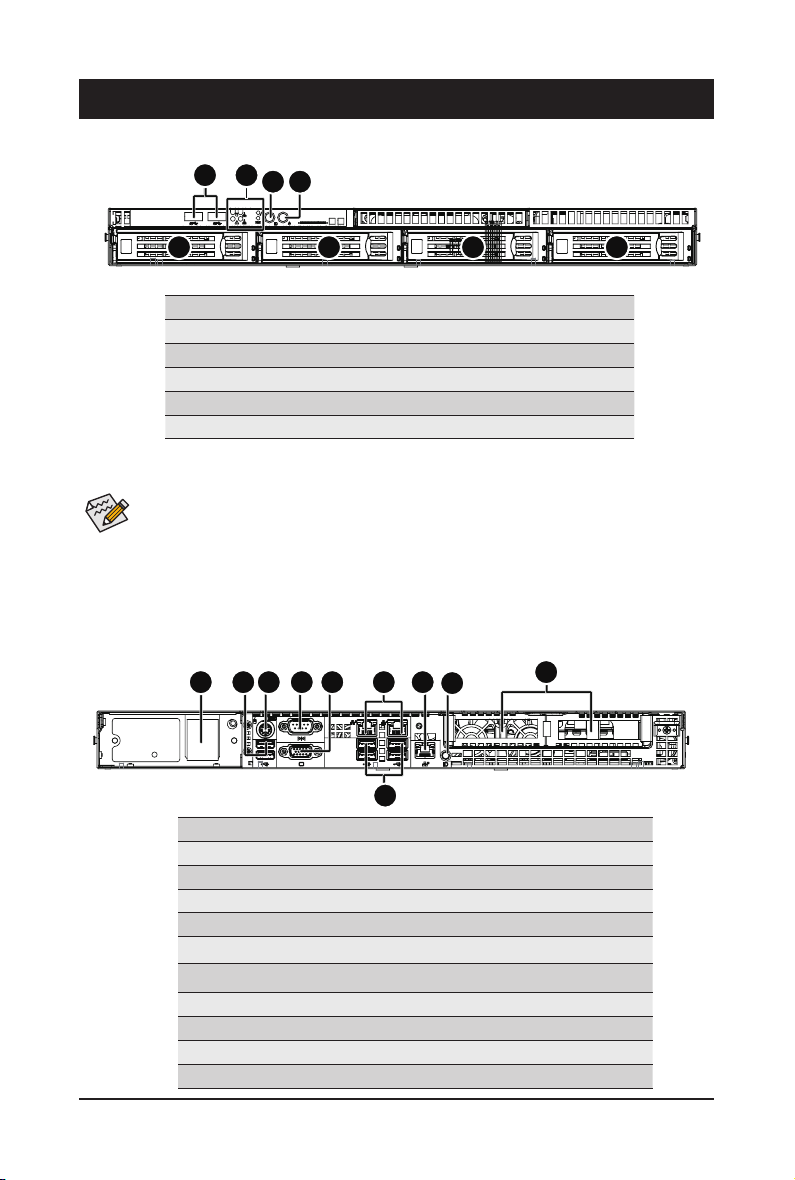

Chapter 3 System Appearance

3-1 Front View

2 3

1

No. Decription

1.

2. Front USB 3.0 ports

3. Front Panel LEDs and buttons

4. ID button and LED

5. Power button and LED

• Please Go to Chapter 3-3 Front Panel LED and Buttons for detail description of function LEDs.

4 5

1 1 1

HDD bays

3-2 Rear View

1 2 3 4 5 687

9

10

No. Decription

1. Power supply module cord socket

2. USB 3.0 ports

3. PS/2 Keyboard and Mouse connector

4. Serial port

5. VGA port

6. RJ-45 LAN ports

7. 10/100/1000 Server management LAN port

8. USB 3.0 ports

9. ID switch button

10. Low-prole riser card bay

- 27 - Hardware Installation

Page 28

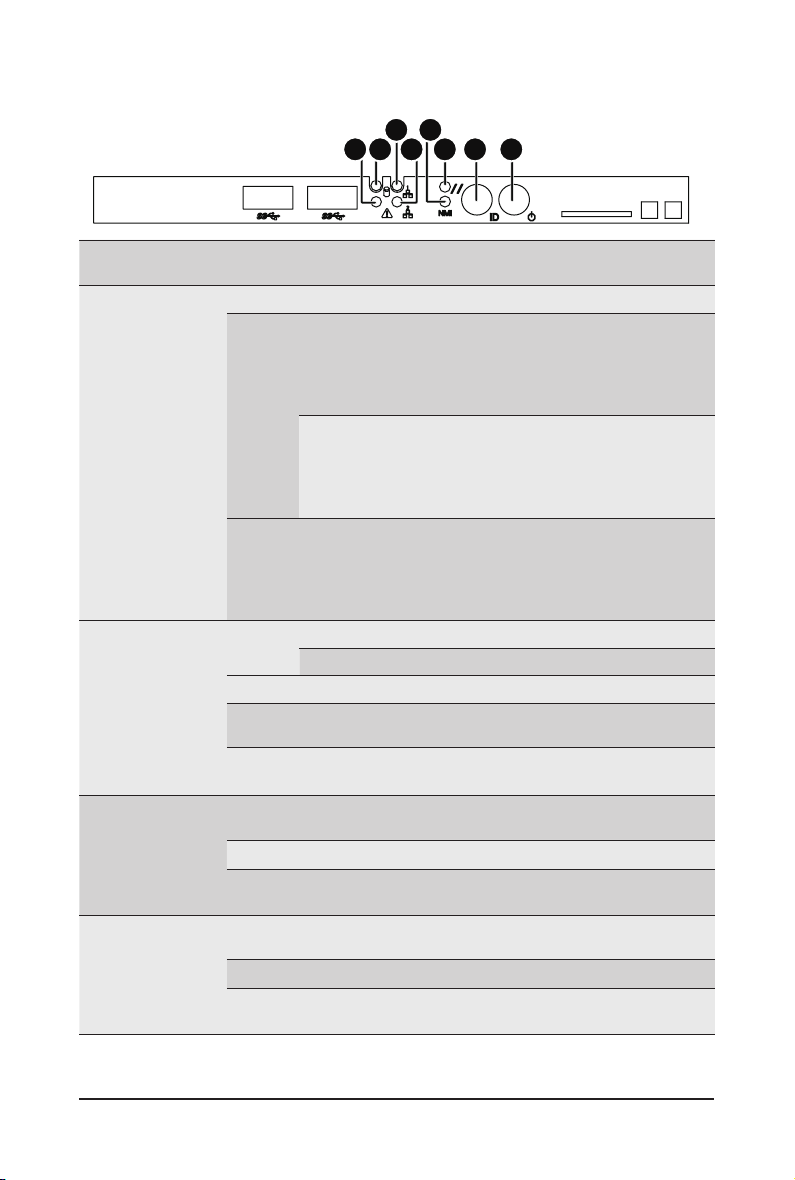

3-3 Front Panel LED and Buttons

3 5

1

2

4 6 7 8

No. Name Color Status Critical

Event

Green Solid On N/A System is operating normally.

Solid On Yes

Amber

System

1

2.

3.

4.

Status LED

HDD Status

LED

LAN1 Active/

Link LED

LAN2 Active/

Link LED

N/A Off N/A

Green

Amber On N/A HDD fault

Green/

Amber

N/A Off N/A

Green

Green Blink N/A Data transmission or receiving is occurring

N/A Off N/A

Green

Green Blink N/A Data transmission or receiving is occurring

N/A Off N/A

Blink N/A

On N/A HDD locate

Blink N/A HDD access

Blink N/A HDD rebuilding

Solid On N/A

Solid On N/A

Description

Critical condition, may indicates the following:

• Power module failure

• System fan failure

• Power supply voltage issue

• System temperature/voltage issue

Non-critical condition, may

indicates the following:

• Redundant power module failure

• Temperature and voltage issue

• Chassis intrusion

System is not ready.

May indicate the following:

• POST error

• NMI error

• Processor or terminator missing

• No HDD access

• No HDD fault

Link between system and network

or no access

No data transmission or

receiving is occurring

Link between system and network

or no access

No data transmission or

receiving is occurring

- 28 - Hardware Installation

Page 29

Press the button server generates a NMI to the

NMI button

5.

Reset Button Press the button to reset the system.

6

7.

8.

ID Button

and LED

Power button

and LED

Blue Solid On N/A System identication is active.

N/A Off N/A System identication is disabled.

Green Solid On N/A System is powered on

Green Blink N/A System is in ACPI S1 state (sleep mode)

N/A Off N/A

processor if the multiple-bit ECC errors occur,

which effectively halt the server.

• System is not powered on or in ACPI S5

state (power off)

• System is in ACPI S4 state

(hibernate mode)

Hardware Installation - 29 -

Page 30

3-4 Rear System LAN LEDs

21

No. Name Color Status Description

Yel lo w On 1 Gbps data rate

Green On 100 Mbps data rate

N/A Off 10 Mbps data rate

On Link between system and

Green

Blink Data transmission or receiving is occurring

N/A Off No data transmission or receiving is occurring

network or no access

1.

2.

1GbE

Speed LED

1GbE

Link/

Activity LED

21

21

- 30 - Hardware Installation

Page 31

3-5 Hard Disk Drive LEDs

1

2

No Description Multi Color LEDs

LED Active

Green

1 HDD Access Blink Off

HDD Locate On Off

HDD Failure Off On

HDD connected and rebuilding data

2 Reserve

Blink

LED Active

Amber

Blink

(Alternative)

Hardware Installation - 31 -

Page 32

3-6 Cable Routing

2

1

3

5

4

1

PSU

1

1

3

6

5 366 36

3

1

3

66

4

2

7

No. Suggest Cable No. Suggest Cable

1. System main power cable 2. Front panel USB 3.0 cable

3. SATA/SAS HDD cable 4. Front switch cable/Front LED cable

5. HDD back plane board power cable 6. System fan power cable

7. QSFP LAN LED cable

- 32 - Hardware Installation

Page 33

Chapter 4 Motherboard Components

4-1 MD60-SC1 Motherboard Components

55

54

53

52

44

43

42

41

40

62 63 646566 67

61

59

60

58

57

56

51

50

47

49

46

48

45

38

39

34

1 2 3 4 5 6 7 8

68

69

70

31

32

33

27

28

29

30

10

1617

9

11

12

13

14

15

18

19

20

21

22

36 3537

Hardware Installation - 33 -

23242526

Page 34

Item Code Description

1 SW_ID ID switch button

2 MLAN BMC Management LAN por t

3 USB3_LA N1 LAN1 port (top) / USB 3.0 ports (bottom)/

4 USB3_LAN2 LAN2 port (top) / USB 3.0 por ts (bottom)/

5 TPM TPM module connector

6 COM1_VG A Serial port (top)/VGA port (buttom)

7 F_USB 3 USB 3.0 header

8 PS2_USB3 PS/2 connector (top)/USB 3.0 ports (buttom)

9 ATX1 24 pin main power connector

10 PMBUS PMBus connector

11 LAN4_ACT LAN4 active LED header (LAN Port #2)

12 LAN3_ACT LAN3 active LED header (LAN Port #1)

13 COM2 Serial port cable header

14 SYS _FAN5 System fan connector#5

15 P12V_ AUX2 8 pin power connector (for secondary CPU)

16 BP_1 HDD back plane board header

17 FP_1 Front panel header

18 CPU1_FAN CPU1 fan connector (for Secondary CPU)

19 DIMM _P1_E0 Channel 1 slot 0 (for secondary CPU)

20 DIMM _P1_ E1 Channel 1 slot 1 (for secondary CPU)

21 DIMM_P1_F0 Channel 2 slot 0 (for secondary CPU)

22 DIMM _P1_ F1 Channel 2 slot 1 (for secondary CPU)

23 SYS_FA N4 System fan connector #4

24 SYS_FAN3 System fan connector#3

25 CPU1 Intel LGA2011 Socket R3 (Secondary CPU)

26 P12V_ AUX1 8 pin power connector (for primar y CPU)

27 DIMM_P1_H1 Channel 4 slot 1 (for secondary CPU)

28 DIMM_P1_H0 Channel 4 slot 0 (for secondary CPU)

29 DIMM_P1_G1 Channel 3 slot 1 (for secondary CPU)

30 DIMM_P1_G0 Channel 3 slot 0 (for secondary CPU)

31 DIMM_P0_A0 Channel 1 slot 0 (for primar y CPU)

32 D IM M_ P0_A1 Channel 1 slot 1 (for primary CPU)

33 DIMM_P0_B0 Channel 2 slot 0 (for primary CPU)

34 DIMM_P0_B1 Channel 2 slot 1 (for primary CPU)

35 SYS_FA N2 System fan connector #2

36 CPU0 Intel LGA2011 Socket R3 (Primary CPU)

37 SYS_FAN1 System fan connector#1

38 DIMM_P0_D1 Channel 4 slot 1 (for primary CPU)

39 DIMM_P0_D0 Channel 4 slot 0 (for primary CPU)

40 DIMM_P0_C1 Channel 3 slot 1 (for primary CPU)

41 DIMM_P0_C0 Channel 3 slot 0 (for primary CPU)

- 34 - Hardware Installation

Page 35

42 S AS0 ~7

43 SAS_SGP2 SAS SGPIO header#2

44 RAID_SLOT2 PCI Express x4 slot (Proprietary slot)

45 BAT Battery socket

46 SATA_ DOM4 SATA port 4 DOM suppor t jumper

47 SATA 5 SATA 3 6Gb/s connector

48 SATA4 SATA 3 6Gb/s connector

49 SATA_ DOM 5 SATA port 5 DOM support jumper

50 CP U0_ FAN CPU0 fan connector (for Primary CPU)

51 CLR_CMOS Clear CMOS jumper

52 SAS_SGP1 SAS SGPIO header#1

53 MINI_CN1 Mini-SAS cable connector#1 supports SATA3 6Gb/s

54 MINI_CN2 Mini-SAS cable connector#2 supports SATA3 6Gb/s

55 RAID_SLOT1 PCI Express x8 slot

56 CASE_OPEN Case open intrusion alert header

57 ME_UPDATE ME update jumper

58 BIOS_PWD Clearing Supervisor Password jumper

59 BIOS_RCVR BIOS recovery jumper

60 ME_RCVR ME recovery jumper

61 S3_MASK S3 Power On Select jumper

62 SW_RAID Intel/LSI Software RAID Key jumper

63 PCIE_1 PCI Express x16 slot

64 PCIE_2 P CI E xp re ss x 8 sl ot (Sha re d ba ndwidth with

65 PCIE_3 PCI Express x16 slot

66 PCIE_4 PCI Express x8 slot

67 MLAN_LINK BMC Management LAN port link LED header

68 MLAN_ACT BMC Management LAN port active LED header

69 IPMB IPMB connector

70 BMC_FRB Force to Stop FRB Timer jumper

SAS 6Gb/s connectors (Gigabyte extension card

required)

PCIE_3)

CAUTION! If a SATA type hard drive is connected to the motherboard, please ensure the jumper is

closed and set to 2-3 pins (Default setting), in order to reduce any risk of hard disk damage. Please

refer to Page 37 for SATA_DOM4 and SATA_DOM5 jumper setting instruction.

Hardware Installation - 35 -

Page 36

4-2 Jumper Setting

8

6

7

5

4

3

2

1

9

No. Jumper Code Jumper Setting

Pin No. Denition

SATA _DOM4 (SATA

1.

port 4 DOM Jumper)

SATA _DOM5

2.

(SATA 5 DOM Jumper)

CLR_CMOS

3.

(Clearing CMOS Jumper)

CAUTION! If a SATA type hard drive is connected to the system, please ensure the jumper is

closed and set to 2-3 pins (Normal mode), in order to reduce any risk of hard disk damage.

1 P5V

2 SATA4 Pin7

3 GND

Pin No. Denition

1 P5V

2 SATA5 Pin7

3 GND

1-2 Close: Normal operation (Default setting)

2-3 Close: Clear CMOS data

- 36 - Hardware Installation

Page 37

No.

4.

Jumper Code Jumper Setting

ME _UPDATE

(ME Update Jumper)

BIOS_PWD

(Clearing Supervisor

5.

Password Jumper)

BIOS_RCVR

6.

(BIOS Recovery Jumper)

ME_RCVR

7.

(ME Recovery Jumper)

S3_MASK (S3 Power

8.

On Select Jumper)

BMC_FRB

(Force to Stop FRB

9.

Timer Jumper)

1-2 Close: Normal operation (Default setting)

2-3 Close: ME recovery mode.

1-2 Close: Normal operation. (Default setting)

2-3 Close: Skip supervisor password.

1-2 Close: Normal operation (Default setting)

2-3 Close: BIOS recovery mode.

1-2 Close: Normal operation (Default setting)

2-3 Close: ME recovery mode.

1-2 Close: Stop an initial power on when BMC is not ready.

2-3 Close: Keep initial power on. (Default setting)

1-2 Close: Normal operation (Default setting)

2-3 Close: Force to Stop FRB Timer

Hardware Installation - 37 -

Page 38

4-3 Back Plane Boad Components

1

3

2

4

5

6

789

10

11

12

14 15

13

16

19 1820212223

Item Code Description

1 FAN1 System fan connector #1

2 FAN2 System fan connector #2

3 FAN3 System fan connector #3

4 FAN4 System fan connector #4

5 FAN5 System fan connector #5

6 FAN6 System fan connector #6

7 FAN7 System fan connector #7

8 FAN8 System fan connector #8

9 FAN9 System fan connector #9

10 FAN10 System fan connector #10

11 FAN11 System fan connector #11

12 FAN12 System fan connector #12

13 J4 Dene HDD Type jumper

1-2 Close: SAS

2-3 Close: SATA

14 J3 SATA/LSI/SCU Switch jumper*

Please refer to the following table for jumper

15 J2 SATA/LSI/SCU Switch jumper*

Please refer to the following table for jumper

16 J1 Test LED jumper

1-2 Cose: Test mode

2-3 Close: Normal operation

17 SAS1 SAS connector #1

18 BPB_CON_TP1 Back Plane board connector

19 SAS2 SAS connector #2

20 SGPIO1 SGPIO connector

21 CD-ROM_PWR CD-ROM power connector

22 SAS3 SAS connector #3

23 SAS4 SAS connector #4

17

Hardware Installation - 38 -

Page 39

4-3-1 Back Plane BoadJ2/J3 Jumper Setting

J2 J3

LSI, SCU 2-3 Close 2-3 Close

SATA 2-3 Close 1-2 Close

Hardware Installation - 39 -

Page 40

Chapter 5 BIOS Setup

BIOS (Basic Input and Output System) records hardware parameters of the system in the EFI on the

motherboard. Its major functions include conducting the Power-On Self-Test (POST) during system startup,

saving system parameters and loading operating system, etc. BIOS includes a BIOS Setup program that

allows the user to modify basic system conguration settings or to activate certain system features. When the

power is turned off, the battery on the motherboard supplies the necessary power to the CMOS to keep the

conguration values in the CMOS.

To access the BIOS Setup program, press the <F2> key during the POST when the power is turned on.

• BIOS ashing is potentially risky, if you do not encounter problems of using the current BIOS

version, it is recommended that you don't ash the BIOS. To ash the BIOS, do it with caution.

Inadequate BIOS ashing may result in system malfunction.

• It is recommended that you not alter the default settings (unless you need to) to prevent system

instability or other unexpected results. Inadequately altering the settings may result in system's

failure to boot. If this occurs, try to clear the CMOS values and reset the board to default values.

(Refer to the Exit section in this chapter or introductions of the battery/clearing CMOS jumper in

Chapter 1 for how to clear the CMOS values.)

BIOS Setup Program Function Keys

<f><g> Move the selection bar to select the screen

<h><i> Move the selection bar to select an item

<+> Increase the numeric value or make changes

<-> Decrease the numeric value or make changes

<Enter> Execute command or enter the submenu

<Esc> Main Menu: Exit the BIOS Setup program

Submenus: Exit current submenu

<F1> Show descriptions of general help

<F3> Restore the previous BIOS settings for the current submenus

<F9> Load the Optimized BIOS default settings for the current submenus

<F10> Save all the changes and exit the BIOS Setup program

BIOS Setup - 40 -

Page 41

Main

This setup page includes all the items in standard compatible BIOS.

Advanced

This setup page includes all the items of AMI BIOS special enhanced features.

(ex: Auto detect fan and temperature status, automatically congure hard disk parameters.)

Intel RC Setup

This setup page includes all the submenu options for conguring the function of processor, network,

North Bridge, South Bridge, and System event logs.

Server Management

Server additional features enabled/disabled setup menus.

Security

Change, set, or disable supervisor and user password. Conguration supervisor password allows you to

restrict access to the system and BIOS Setup.

A supervisor password allows you to make changes in BIOS Setup.

A user password only allows you to view the BIOS settings but not to make changes.

Boot

This setup page provides items for conguration of boot sequence.

Exit

Save all the changes made in the BIOS Setup program to the CMOS and exit BIOS Setup. (Pressing

<F10> can also carry out this task.)

Abandon all changes and the previous settings remain in effect. Pressing <Y> to the confirmation

message will exit BIOS Setup. (Pressing <Esc> can also carry out this task.)

- 41 - BIOS Setup

Page 42

5-1 The Main Menu

Once you enter the BIOS Setup program, the Main Menu (as shown below) appears on the screen. Use

arrow keys to move among the items and press <Enter> to accept or enter other sub-menu.

Main Menu Help

The on-screen description of a highlighted setup option is displayed on the bottom line of the Main Menu.

Submenu Help

While in a submenu, press <F1> to display a help screen (General Help) of function keys available for the

menu. Press <Esc> to exit the help screen. Help for each item is in the Item Help block on the right side of

the submenu.

• When the system is not stable as usual, select the Restore Defaults item to set your system to

its defaults.

• The BIOS Setup menus described in this chapter are for reference only and may differ by BIOS

version.

BIOS Setup - 42 -

Page 43

BIOS Information

Porject Name

Display the project name information.

Porject Version

Display version number of the BIOS setup utility.

BIOS Build Date and Time

Displays the date and time when the BIOS setup utility was created.

BMC Information

BMC Firmware Version

Display BMC rmware version information.

SDR Version

Display the SDR version information.

FRU Version

Display the FRU version information.

Processor Information

CPU Brand String/Max CPU Speed/CPU Signature/Processors Core/Microcode Patch

Displays the technical specications for the installed processor.

Memory Information

Total Memory

Display the total memory size of the installed memory.

Memory Frequency

Display the frequency information of the installed memory.

- 43 - BIOS Setup

Page 44

Onboard LAN Information

LAN1/LAN2/LAN3/LAN4 MAC Address

Display LAN1/LAN2/LAN/LAN4 MAC address information.

System Date

Set the date following the weekday-month-day- year format.

System Time

Set the system time following the hour-minute- second format.

BIOS Setup - 44 -

Page 45

5-2 Advanced Menu

The Advanced menu display submenu options for conguring the function of various hardware components.

Select a submenu item, then press Enter to access the related submenu screen.

- 45 - BIOS Setup

Page 46

5-2-1 Serial Port Console Redirection

BIOS Setup - 46 -

Page 47

- 47 - BIOS Setup

Page 48

COM1/COM2/Serial Over LAN Console Redirection Settings

Console Redirection

Select whether to enable console redirection for specied device. Console redirection enables users to

manage the system from a remote location.

Options available: Enabled/Disabled. Default setting is Disabled.

(Note)

Console Redirection Settings

Terminal Type

Select a terminal type to be used for console redirection.

Options available: VT100/VT100+/ANSI /VT-UTF8. Default setting is ANSI.

Bits per second

Select the baud rate for console redirection.

Options available: 9600/19200/38400/57600/115200. Default setting is 115200.

Data Bits

Select the data bits for console redirection.

Options available: 7/8. Default setting is 8.

Parity

A parity bit can be sent with the data bits to detect some transmission errors.

Even: parity bi is 0 if the num of 1's in the data bits is even.

Odd: parity bit is 0 if num of 1's in the data bits is odd.

Mark: parity bit is always 1. Space: Parity bit is always 0.

Mark and Space Parity do not allow for error detection.

Options available: None/Even/Odd/Mark/Space. Default setting is None.

Stop Bits

Stop bits indicate the end of a serial data packet. (A start bit indicates the beginning). The standard

setting is 1 stop bit. Communication with slow devices may require more than 1 stop bit.

Options available: 1/2. Default setting is 1.

Flow Control

Flow control can prevent data loss from buffer overow. When sending data, if the receiving buffers are

full, a 'stop' signal can be sent to stop the data ow. Once the buffers are empty, a 'start' signal can be

sent to re-start the ow. Hardware ow control uses two wires to send start/stop signals.

Options available: None/Hardware RTS/CTS. Default setting is None.

VT-UTF8 Combo Key Support

Enable/Disable VT-UTF8 Combo Key Support.

Options available: Enabled/Disabled. Default setting is Enabled.

Recorder Mode

When this mode enabled, only text will be send. This is to capture Terminal data.

Options available: Enabled/Disabled.

Default setting is Disabled.

Resolution 100x31

Enables or disables extended terminal resolution. Default setting is Enabled.

Options available: Enabled/Disabled.

(Note)

(Note)

(Note)

(Note) Advanced items prompt when this item is dened.

BIOS Setup - 48 -

Page 49

Legacy OS Redirection Resolution

(Note)

On Legacy OS, the number of Rows and Columns supported redirection.

Options available: 80x24/80X25. Default setting is 80x24.

Putty KeyPad

(Note)

Select function FunctionKey and KeyPad on Putty.

Options available: VT100/LINUX/XTERMR6/SCO/ESCN/VT400. Default setting is VT100.

Redirection After BIOS POST

(Note)

This option allows user to enable console redirection after O.S has loaded.

Options available: Always Enable/Boot Loader. Default setting is Always Enable.

Out-of-Bnad Mgmt Port

Microsoft Windows Emerency Management Service (EMS) allows for remote management of a Windows

Server OS through a serial port.

Options available: COM1/COM2. Default setting is COM1.

(Note) Advanced items prompt when this item is dened.

- 49 - BIOS Setup

Page 50

5-2-2 PCI Subsystem Settings

PCI Express Slot #1/#2/#3/#4/#5 I/O ROM

When enabled, This setting will initialize the device expansion ROM for the related PCI-E slot.

Options available: Enabled/Disabled. Default setting is Enabled.

Onboard LAN#1/#2 Controller

Enable/Disable onboard LAN devices.

Options available: Enabled/Disabled. Default setting is Enabled.

Onboard LAN #1/#2 I/O ROM

Enable/Disable onboard LAN devices and initialize device expansion ROM.

Options available: Enabled/Disabled. Default setting is Enabled.

PCI Devices Common Settings

PCI Latency Timer

Value to be programmed into PCI Latency Timer Register.

Options available: 32 PCI Bus Clocks/64 PCI Bus Clocks/96 PCI Bus Clocks/128 PCI Bus Clocks/160

PCI Bus Clocks/192 PCI Bus Clocks/224 PCI Bus Clocks/248 PCI Bus Clocks/.

Default setting is 32 PCI Bus Clocks.

VGA Palette Snoop

Enable/Disable VGA Palette Tegisters Snooping.

Options available: Enabled/Disabled. Default setting is Disabled.

Above 4G Decoding

Enable/Disable Above 4G Decoding.

Options available: Enabled/Disabled. Default setting is Disabled.

BIOS Setup - 50 -

Page 51

SR-IOV Support

If system has SR-IOV capable PCIe Devices, this option enables or disables Single Root IO

Virtualization Support.

Options available: Enabled/Disabled. Default setting is Disabled.

PCI Express Settings

Press [Enter] for conguration of advanced items.

- 51 - BIOS Setup

Page 52

5-2-2-1 PCI Express Settings

PCI Express Device Register Settings

Relaxed Ordering

Enable/DIsable PCI Express Device Relaxed Ordering feature.

Options available: Enabled/Disabled. Default setting is Disabled.

Extended Tag

Wnen this feature is enabled, the system will allow device to use 8-bit Tag eld as a requester.

Options available: Enabled/Disabled. Default setting is Disabled.

No Snoop

Enable/Disable PCI Express Device No Snoop option.

Options available: Enabled/Disabled. Default setting is Enabled.

Maximum Playload

Set maximum playload for PCI Express Device or allow system BIOS to select the value.

Options available: Auto/128 Bytes/256 Bytes/512 Bytes/1024 Bytes/2048 Bytes/4096 Bytes.

Default setting is Auto.

PCI Express Link Register Settings

Extended Synch

Wnen this feature is enabled, the system will allow generation of Extended Synchronization patterns.

Options available: Enabled/Disabled. Default setting is Disabled.

Link Training Retry

Dene the number of Retry Attempts software wil take to retrain the link if previous training attempt was

unsuccessful.

Options available: Disabled/2/3/5.Default setting is 5.

BIOS Setup - 52 -

Page 53

Link Training Timeout (us)

Dene the number of Microseconds software will wait before polling 'Link Training' bit in Link Status

register. Press <+> / <-> keys to increase or decrease the desired values. Value rang is from 10 to

10000 us.

Unpopulated Links

When this item is set to 'Disable Link, the system will operate power save feature for those unpopulated

PCI Express links.

Options available: Keep Link ON/ Disable Link. Default setting is Keep Link ON.

- 53 - BIOS Setup

Page 54

5-2-3 Network Stack

Network stack

Enable/Disable UEFI network stack.

Options available: Enabled/DIsabled. Default setting is Disabled.

Ipv4 PXE Support

Enable/Disable Ipv4 PXE feature.

Options available: Enabled/DIsabled. Default setting is Enabled.

Ipv6 PXE Support

Enable/Disable Ipv6 PXE feature.

Options available: Enabled/DIsabled. Default setting is Enabled.

PXE boot wait time

Press <+> / <-> keys to increase or decrease the desired values.

Media detect time

Press <+> / <-> keys to increase or decrease the desired values.

(Note)

(Note)

(Note)

(Note)

(Note) This item appears when Network Stack is set to Enabled.

BIOS Setup - 54 -

Page 55

5-2-4 CSM Conguration

Compatibility Support Module Conguration

CSM Support

Enable/Disable Compatibility Support Module (CSM) support.

Options available: Enabled/Disabled. Default setting is Enabled.

CSM16 Module Version

Display CSM Module version information.

Gate20 Active

Upon Request: GA20 can be disabled using BIOS services.

Always: Do not allow disabling GA20; this option is useful when any RT code is executed above 1MB.

Options available: Upon Request/Always. Default setting is Upon Request.

Option ROM Messages

Option ROM Messages.

Options available: Force BIOS/Keep Current. Default setting is Force BIOS.

INT19 Endless Retry

Enabled: Allowed headless retry boot

Options available: Enabled/Disabled. Default setting is Enabled.

Boot option lter

Determines which devices system will boot to.

Options available: UEFI and Legacy/Legacy only/UEFI only. Default setting is UEFI and Legacy.

- 55 - BIOS Setup

Page 56

Option ROM execution

Network

Controls the execution UEFI and Legacy PXE OpROM.

Options available: Do not launch/UEFI/Legacy. Default setting is Legacy.

Storage

Controls the execution UEFI and Legacy Storage OpROM.

Options available: Do not launch/UEFI/Legacy. Default setting is Legacy.

Video

Controls the execution UEFI and Legacy Video OpROM.

Options available: Do not launch/UEFI/Legacy. Default setting is Legacy.

Other PCI devices

Determines OpROM execution policy for devices other than network, Storage, or Video.

Options available: UEFI/Legacy. Default setting is UEFI.

BIOS Setup - 56 -

Page 57

5-2-5 Post Report Conguration

Post Report Conguration

Error Message Report

Post Error Message

Enable/Disable Info Error Message support.

Options available: Enabled/Disabled. Default setting is Enabled.

- 57 - BIOS Setup

Page 58

5-2-6 Trusted Computing

Conguration

Security Device Support

Select Enabled to activate TPM support feature.

Options available: Enabled/Disabled. Default setting is Disabled.

Current Status Information

Display current TPM status information.

BIOS Setup - 58 -

Page 59

5-2-7 USB Conguration

USB Conguration

USB Devices:

Display the USB devices connected to the system.

XHCI Hand-off

Enable/Disable XHCI (USB 3.0) Hand-off support.

Options available: Enabled/Disabled. Default setting is Enabled.

EHCI Hand-off

Enable/Disable EHCI (USB 2.0) Hand-off function.

Options available: Enabled/Disabled. Default setting is Disabled.

USB Mass Storage Driver Support

Enable/Disable USB Mass Storage Driver Support.

Options available: Enabled/Disabled. Default setting is Enabled.

Port 60/64 Emulation

Enable I/O port 60h/64h emulation support. This should be enabled for the complete USB Keyboard

Legacy support for non-USB aware OS.

Options available: Enabled/Disabled. Default setting is Enabled.

(Note)

(Note) This item is present only if you attach USB types of device.

- 59 - BIOS Setup

Page 60

5-2-8 Chipset Conguration

Restore on AC Power Loss

Denes the power state to resume to after a system shutdown that is due to an interruption in AC power.

When set to Last State, the system will return to the active power state prior to shutdown. When set to

Stay Off, the system remains off after power shutdown.

Options available: Last State/Stay Off/Power On. The default setting depends on the BMC setting.

(Note)

Deep Sleep (EuP)

Enable/Disable Deep Sleep mode.

Options available: Enabled/Disabled. Default setting is Disabled.

Fan Curve Mode

Congure ystem fan curve mode

Options available: Full Dpeed Mode/Performance ModeBalanced mode/Energy Saving Mode.

Default setting is Performance Mode.

Chassis Opened Warning

Enable/Disable Chassis intrusion alter funtion.

Options available: Enabled/Disabled. Default setting is Disabled.

(Note) When the power policy is controlled by BMC, please wait for 15-20 seconds for BMC to save the

last power state.

BIOS Setup - 60 -

Page 61

5-9 SIO Conguration

- 61 - BIOS Setup

Page 62

BIOS Setup - 62 -

Page 63

AMI SIO Driver Version

Display the AMI SIO driver version information.

Super IO Chip Logical Device(s) Conguration

[*Active*] Serial Port 1/2

Press [Enter] for confuguration of advanced items.

[*Active*] PS2 Keyboard

Press [Enter] for confuguration of advanced items.

[*Active*] PS2 Mouse

Press [Enter] for confuguration of advanced items.

Serial Port 1 Conguration

Use This Device

When enabled allows you to congure the serial port 1 settings. When set to Disabled, displays no

conguration for the serial port.

Options available: Enabled/Disabled. Default setting is Enabled.

Logical Device Settings:

Current:

Display the Serial Port 1 base I/O addressand IRQ.

Possible:

Congure Serial Port 1 base I/O addressand IRQ.

Option available:

Use Automatic Settings

IO=3F8h; IRQ=4; DMA;/

IO=3F8h; IRQ=3,4,5,7,9,10,11,12; DMA;/

IO=2F8h; IRQ=3,4,5,7,9,10,11,12; DMA;/

IO=3E8h; IRQ=3,4,5,7,9,10,11,12; DMA;/

- 63 - BIOS Setup

Page 64

IO=2E8h; IRQ=3,4,5,7,9,10,11,12; DMA;

Default setting is Use Automatic Settings.

Serial Port 2 Conguration

Use This Device

When enabled allows you to congure the serial port 2 settings. When set to Disabled, displays no

conguration for the serial port.

Options available: Enabled/Disabled. Default setting is Enabled.

Logical Device Settings:

Current:

Display the Serial Port 2 base I/O addressand IRQ.

Possible:

Congure Serial Port 2 base I/O addressand IRQ.

Option available:

Use Automatic Settings/

IO=2F8h; IRQ=3; DMA;/

IO=3F8h; IRQ=3,4,5,7,9,10,11,12; DMA;/

IO=2F8h; IRQ=3,4,5,7,9,10,11,12; DMA;/

IO=3E8h; IRQ=3,4,5,7,9,10,11,12; DMA;/

IO=2E8h; IRQ=3,4,5,7,9,10,11,12; DMA;/

Default setting is Use Automatic Settings.

PS2 Keyboard Conguration

Logical Device Settings:

Current:

Display the PS2 keyboard base I/O addressand IRQ.

Possible:

Congure PS2 keyboard base I/O addressand IRQ.

Option available: Use Automatic Settings/IO=60h; IO=64h; IRQ=1.

Default setting is Use Automatic Settings.

PS2 Mouse Conguration

Logical Device Settings:

Current:

Display the PS2 mouse base I/O addressand IRQ.

Possible:

Congure PS2 nouse base I/O addressand IRQ.

Option available: Use Automatic Settings/IRQ=12;. Default setting is Use Automatic Settings.

BIOS Setup - 64 -

Page 65

5-2-10 iSCSI Conguration

iSCSI Initiator Name

Add an Attempts

Press [Enter] for conguration of advanced items.

Delete Attempts

Press [Enter] for conguration of advanced items.

Change Attempt Order

Press [Enter] for conguration of advanced items.

- 65 - BIOS Setup

Page 66

5-3 Intel RC Setup Menu

Intel RC Setup menu displays submenu options for conguring the function of North Bridge and South Bridge.

Select a submenu item, then press Enter to access the related submenu screen.

RC Revision

Display Intel RC version information.

BIOS Setup - 66 -

Page 67

5-3-1 Processor Conguration

- 67 - BIOS Setup

Page 68

Processor Conguration

Pre-Socket Conguration

Press [Enter] for conguration of advanced items.

Processor Socket/Processor ID/Processor Frequency/Processor Max Raito/

Processor Min Raio/Microcode Revision/L1 Cache RAM/L2 Cache RAM/L3 Cache RAM/

Processor 0/1Version

Displays the technical specications for the installed processor.

Hyper-Threading [All]

The Hyper Threading Technology allows a single processor to execute two or more separate

threads concurrently. When hyper-threading is enabled, multi-threaded software applications can

execute their threads, thereby improving performance.

Options available: Enabled/Disabled. Default setting is Enabled.

Execute Disable Bit

When enabled, the processor prevents the execution of code in data-only memory pages. This provides

some protection against buffer overow attacks.

When disabled, the processor will not restrict code execution in any memory area. This makes the

processor more vulnerable to buffer overow attacks.

Options available: Enabled/Disabled. Default setting is Enabled.

Enable Intel TXT Support

Enable/Disable Intel Trusted Execution Technology support function.

Options available: Enabled/Disabled. Default setting is Disabled.

VMX (Vanderpool Technology)

Enable/Disable Vanderpool Technology. This will take effect after rebooting the system.

Options available: Enabled/Disabled. Default setting is Enabled.

Enable SMX (Intel Safer Mode Extensions Technology)

Enable/Disblae Intel Safer Mode Extensions (SMX) support function.

Options available: Enabled/Disabled. Default setting is Disabled.

Hardware Prefetcher

Select whether to enable the speculative prefetch unit of the processor.

Options available: Enabled/Disabled. Default setting is Enabled.

Adjacent Cache Line Prefetch

When enabled, cache lines are fetched in pairs. When disabled, only the required cache line is fetched.

Options available: Enabled/Disabled. Default setting is Enabled.

DCU Streamer Prefetch

Enable prefetch of next L1 Data line based upon multiple loads in same cache line.

Options available: Enabled/Disabled. Default setting is Enabled.

DCU IP Prefetch

Enable prefetch of next L1 Data line based upon sequential load history.

Options available: Enabled/Disabled. Default setting is Enabled.

DCU Mode

Congure DCU mode.

Options available: 32KB 8Way Without ECC/16KB 4Way With ECC. Default setting is 32KB 8Way

Without ECCC.

BIOS Setup - 68 -

Page 69

Direct Cache Access (DCA)

Options available: Auto/Enabled/Disabled. Default setting is Auto.

DCA Prefetch Delay

Options available: Disabled/8/16/24/32/40/48/56/64/72/80/88/96/104/112. Default setting is 32.

X2APIC

Options available: Enabled/Disabled. Default setting is Disabled.

AES-NI

Enable/Disable AES-NI (Intel Advanced Encryption Standard New Instructions) support function.

Options available: Enabled/Disabled. Default setting is Enabled.

- 69 - BIOS Setup

Page 70

5-3-1-1 Pre-Socket Conguration

BIOS Setup - 70 -

Page 71

CPU Socket 0/1 Conguration

Press [Enter] for conguration of advanced items.

Cores Enabled (for CPU socket 0/1)

Number of Cores to enable. 0 means all cores. 14 Cores is available. Press the numeric keys to adjust

desired values.

- 71 - BIOS Setup

Page 72

5-3-2 Advanced Power Management Conguration

Advanced Power Management Conguration

Power Technology

Option available:Disable/Energy Efcient/Custom. Default setting is Energy Efcient.

Cong TDP

Options available: Enabled/Disabled. Default setting is Disabled.

CPU P State Control

Press [Enter] for conguration of advanced items.

CPU C State Control

Press [Enter] for conguration of advanced items.

CPU T State Control

Press [Enter] for conguration of advanced items.

BIOS Setup - 72 -

Page 73

5-3-2-1 CPU P State Control

EIST (P-State)

Conventional Intel SpeedStep Technology switches both voltage and frequency in tandem between high

and low levels in response to processor load.

Options available: Enabled/Disabled. Default setting is Enabled.

Turbo Mode

When this item is enabled, tje processor will automatically ramp up the clock speed of 1-2 of its

processing cores to improve its performance.

When this item is disabled, the processor will not overclock any of its core.

Options available: Enabled/Disabled. Default setting is Enabled.

P-state coordination

In HW_ALL mode, the processor hardware is responsible for coordinating the P-state among logical

processors dependencies. The OS is responsible for keeping the P-state request up to date on all

logical processors.

In SW_ALL mode, the OS Power Manager is responsible for coordinating the P-state among logical

processors with dependencies and must initiate the transition on all of those Logical Processors.

In SW_ANY mode, the OS Power Manager is responsible for coordinating the P-state among logical

processors with dependencies and may initiate the transition on any of those Logical Processors.

Options available: HW_ALL/SW_ALL/SW_ANY. Default setting is HW_ALL.

- 73 - BIOS Setup

Page 74

5-3-2-2 CPU C State Control

Package C State Limit

Congure state for the C-State package limit.

Options available: C0/C1 state/C2 state/C6(non Retention) state/C6(Retention) state.

Default setting is C6(non Retention) state.

CPU C3/C6 Report

Allows you to determine whether to let the CPU enter C3/C6 mode in system halt state. When enabled,

the CPU core frequency and voltage will be reduced during system halt state to decrease power

consumption. The C3/C6 state is a more enhanced power-saving state than C1.

Options available: Enabled/Disabled.

Default setting for C3 is Disabled; default setting for C6 is Enabled.

BIOS Setup - 74 -

Page 75

5-3-2-3 CPU T State Control

ACPI T-States

Enable/Disable CPU throttling by OS. Thorttling reduces power comsumption.

Options available: Enabled/Disabled. Default setting is Enabled.

- 75 - BIOS Setup

Page 76

5-3-3 Common RefCode Conguration

Common RefCode Conguration

Isoc Mode

Options available: Auto/Enabled/Disabled. Default setting is Auto.