Page 1

GA - 586ATV

¡]

REV. 4

¡^

USER'S MANUAL

PCI - ISA SOLUTION

Pentium

Processor PCI - ISA BUS MAINBOARD

REV. 4 First Edition

Page 2

GA-586ATV

Quick Installation Guide:

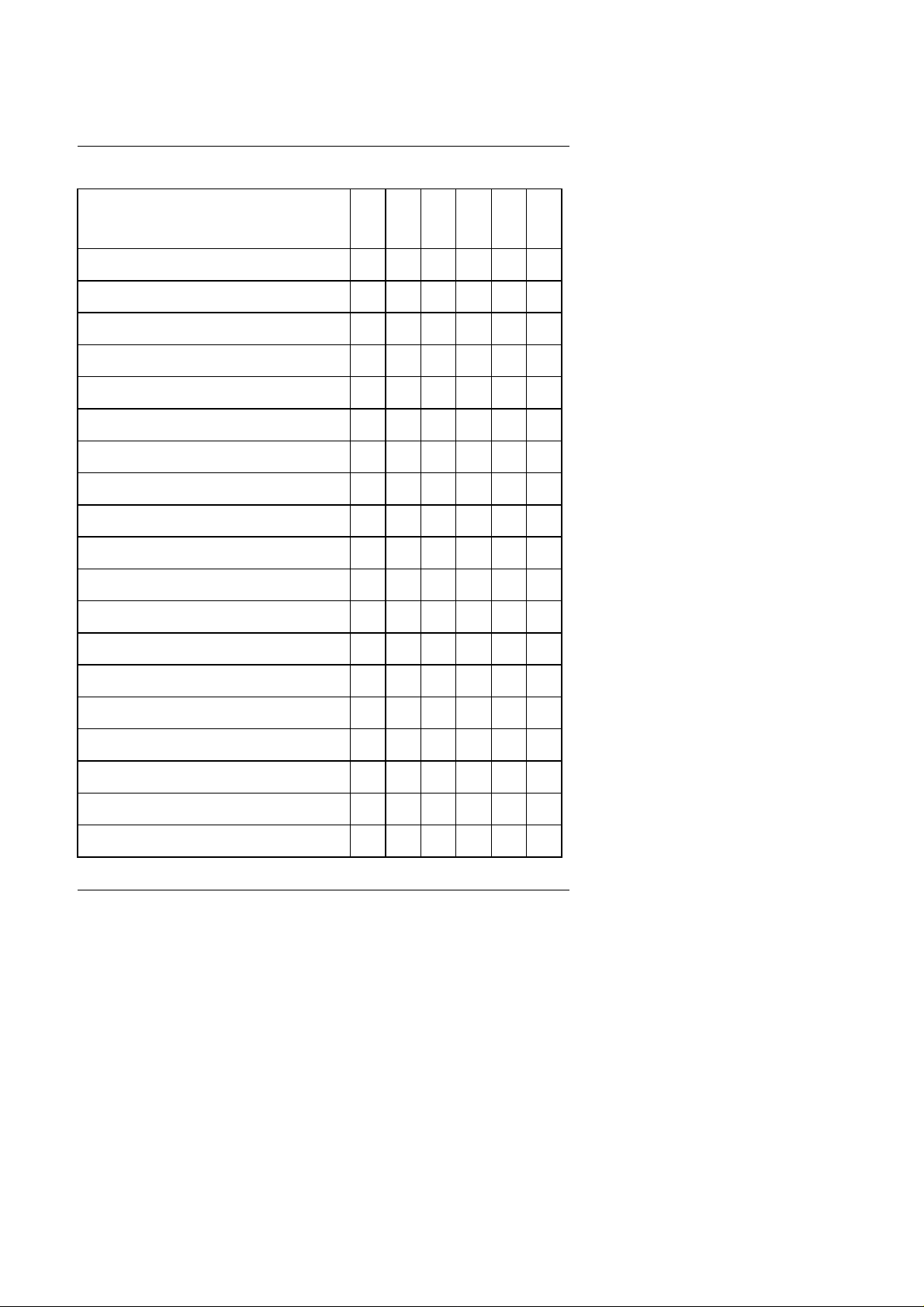

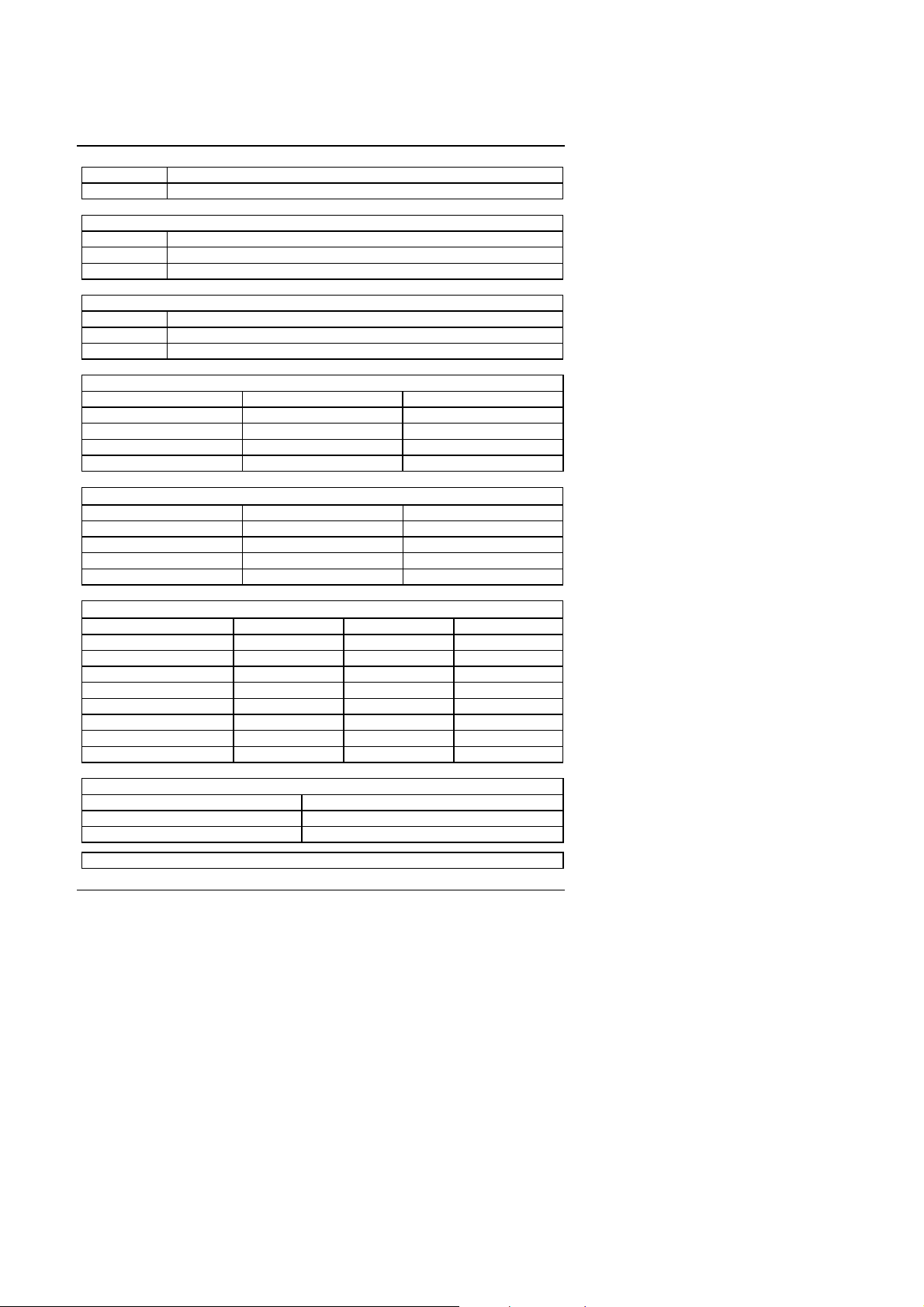

Intel / AMD K5 CPU SW1SW2SW3SW4SW5SW

6

1. Pentium Processor 75MHz ON ON OFF OFF ON OFF

2. Pentium Processor 90MHz ON OFF OFF OFF ON OFF

3. Pentium Processor 100MHz OFF ON OFF OFF ON OFF

4. Pentium Processor 120MHz ON OFF OFF ON ON OFF

5. Pentium Processor 133MHz OFF ON OFF ON ON OFF

6. Pentium Processor 150MHz ON OFF ON ON ON OFF

7. Pentium Processor 166MHz OFF ON ON ON ON OFF

8. Pentium Processor 200MHz OFF ON ON OFF ON OFF

9. MMX-166MHz OFF ON ON ON ON OFF

10. MMX-200MHz OFF ON ON OFF ON OFF

11. MMX-233MHz OFF ON OFF OFF ON OFF

12. P54CTB-166MHz OFF ON ON ON ON OFF

13. P54CTB-200MHz OFF ON ON OFF ON OFF

14. P54CTB-233MHz OFF ON OFF OFF ON OFF

15. AMD K5-PR75 ON ON OFF OFF ON OFF

16. AMD K5-PR90 ON OFF OFF OFF ON OFF

17. AMD K5-PR100 OFF ON OFF OFF ON OFF

18. AMD K5-PR133 OFF ON OFF ON ON OFF

19. AMD K5-PR166 OFF ON ON ON ON OFF

2

Page 3

Table of Contents

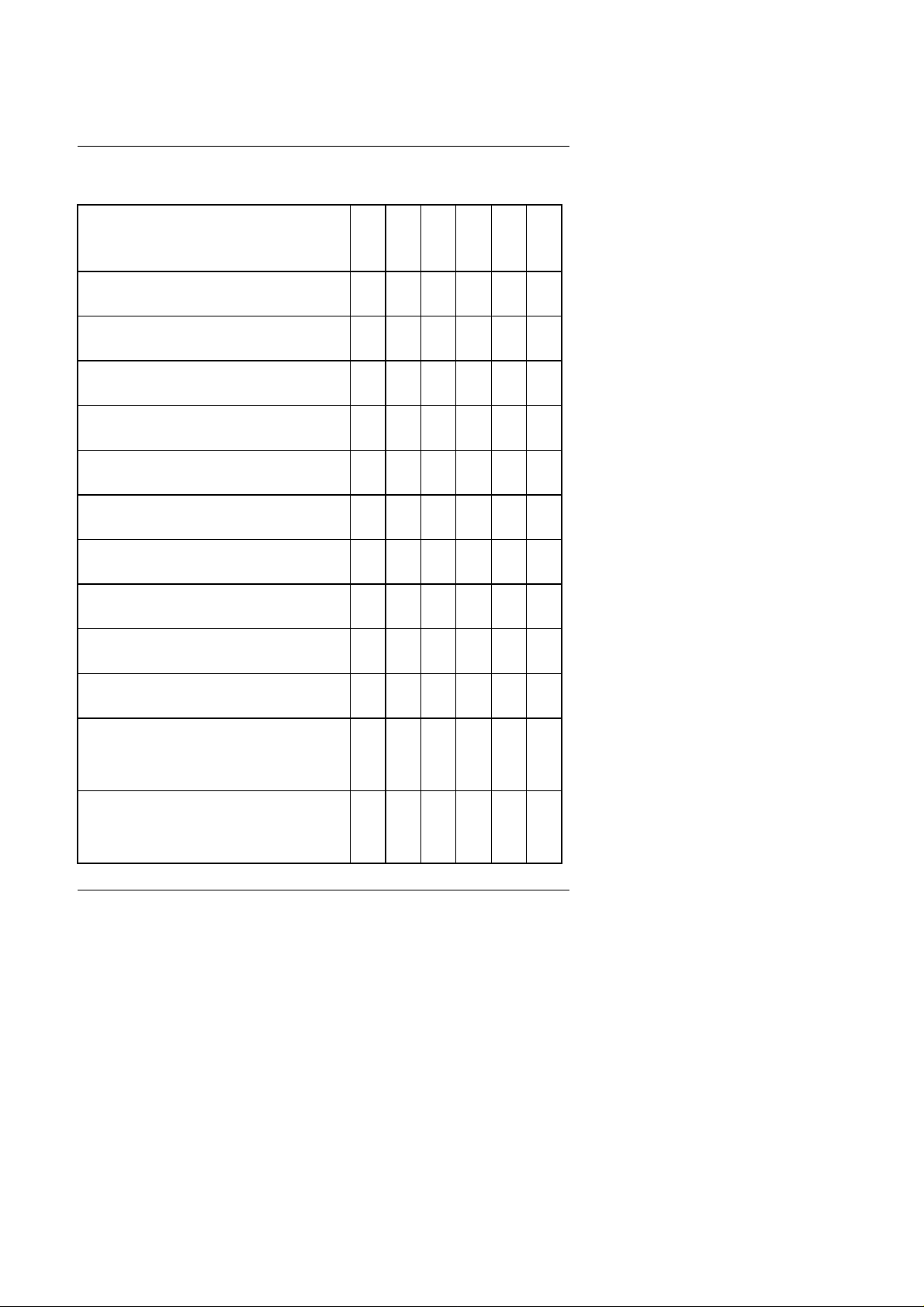

AMD-K6 / CyrIx / IBM CPU SW1SW2SW3SW4SW5SW

6

20. AMD-K6/166¡]2.9V¡^

21. AMD-K6/200¡]2.9V¡^

22. AMD-K6/233¡]3.2V¡^

23. Cyrix/IBM6X86-PR120+¡]100MHz¡^

24. Cyrix/IBM6X86-PR150+¡]120MHz¡^

25. Cyrix/IBM6X86-PR166+¡]133MHz¡^

26. Cyrix/IBM6X86-PR200+¡]150MHz¡^

27. Cyrix/IBM6X86L-PR150+¡]2.8V¡^

28. Cyrix/IBM6X86L-PR166+¡]2.8V¡^

29. Cyrix/IBM6X86L-PR200+¡]2.8V¡^

30.Cyrix/IBM6X86MX-PR166GP

OFF ON ON ON ON OFF

OFF ON ON OFF ON OFF

OFF ON OFF OFF OFF OFF

ON ON OFF ON ON OFF

ON OFF OFF ON ON OFF

OFF ON OFF ON ON OFF

OFF OFF OFF ON ON OFF

ON OFF OFF ON ON OFF

OFF ON OFF ON ON OFF

OFF OFF OFF ON ON OFF

ON OFF ON ON ON OFF

¡]150MHz¡^

31.Cyrix/IBMX686MX-PR200GP

¡]166MHz¡^

OFF ON ON ON ON OFF

3

Page 4

GA-586ATV

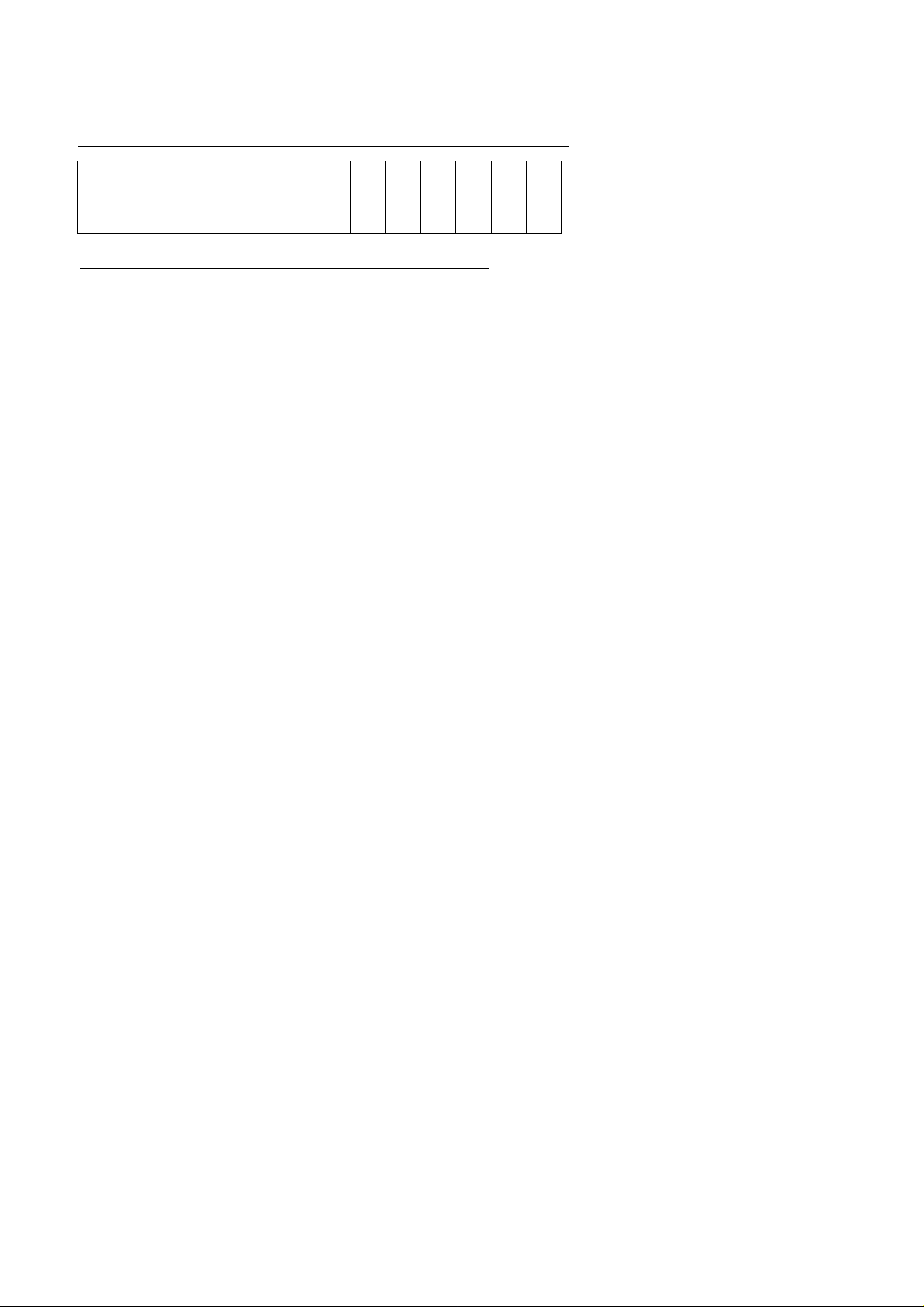

32.Cyrix/IBMX686MX-PR233GP

¡]188MHz¡^

OFF OFF ON ON ON OFF

¡° Auto-detect 2.8V / 2.9V or 3.3V / 3.5V CPU

The author assumes no responsibility for any errors or omissions which may

appear in this document nor does it make a commitment to update the

information contained herein.

4

Page 5

Table of Contents

Third-party brands and names are the property of their respective owners.

JULY 01, 1997 TAIPEI, TAIWAN

TABLE OF CONTENTS

1. INTRODUCTION................................................................................... 1-1

1.1. PREFACE.............................................................................................................1-1

1.2. KEY FEATURES................................................................................................... 1-1

1.3. PERFORMANCE LIST.........................................................................................1-2

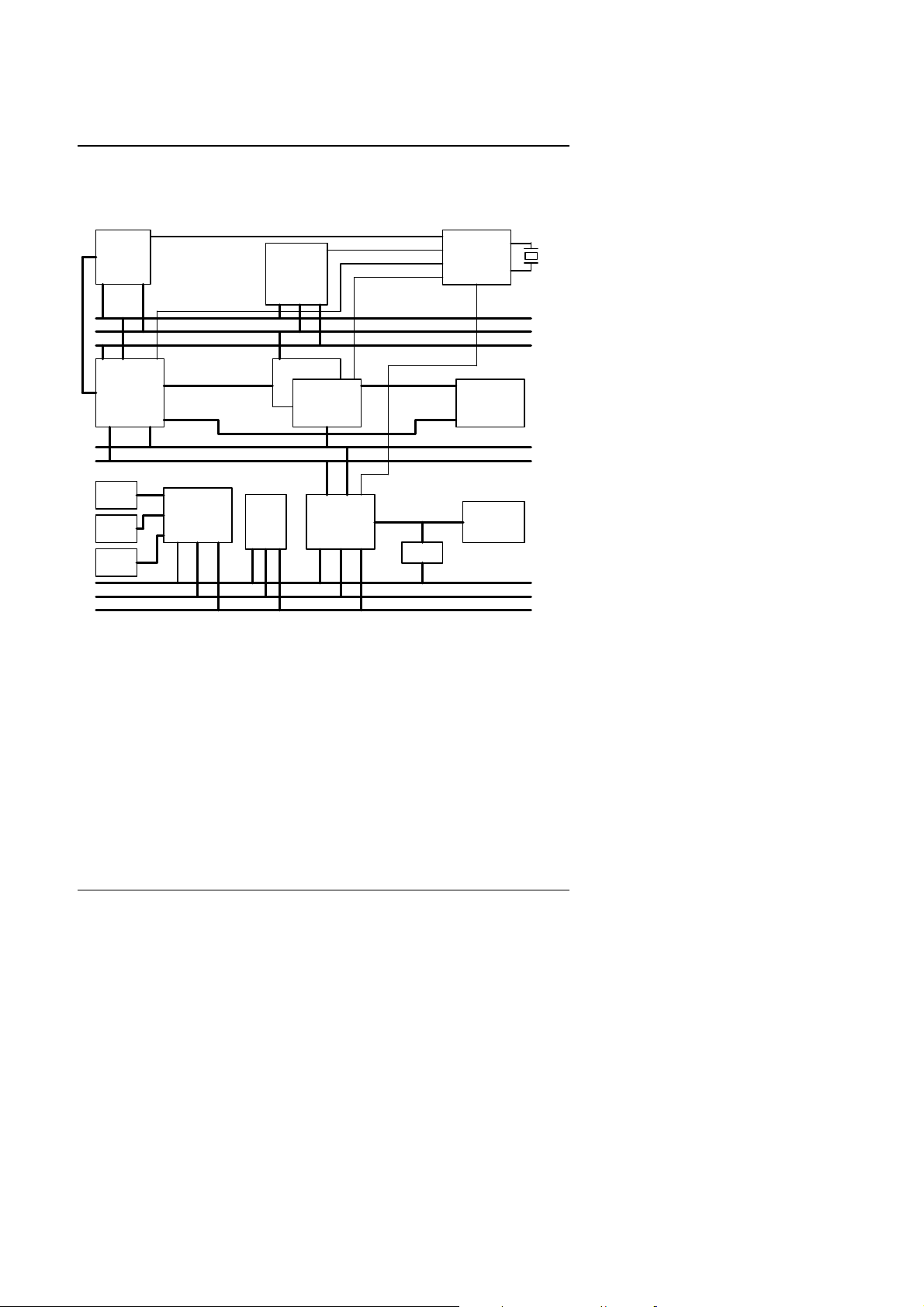

1.4. BLOCK DIAGRAM................................................................................................1-3

1.5. INTRODUCE THE PCI - BUS..............................................................................1-4

1.6. FEATURES...........................................................................................................1-4

2. SPECIFICATION.................................................................................. 2-1

2.1. HARDWARE......................................................................................................... 2-1

2.2. SOFTWARE ......................................................................................................... 2-2

2.3. ENVIRONMENT ................................................................................................... 2-2

3. HARDWARE INSTALLATION .............................................................. 3-1

3.1. UNPACKING......................................................................................................... 3-1

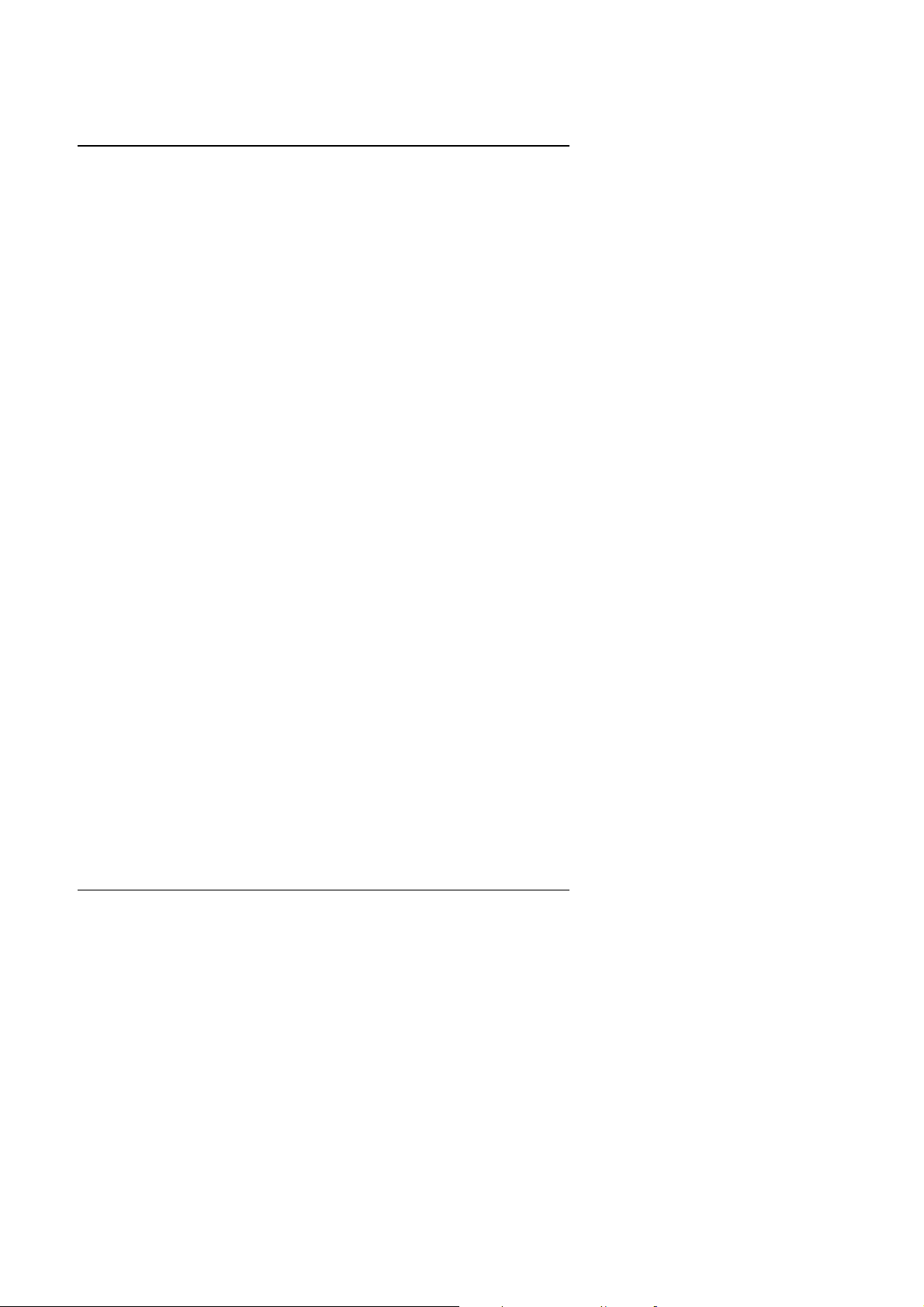

3.2. MAINBOARD LAYOUT (REV.3 AND ABOVE)........................................................3-2

3.3. QUICK REFERENCE FOR JUMPERS & CONNECTORS................................. 3-2

3.4. DRAM INSTALLATION.........................................................................................3-5

3.5. SRAM INSTALLATION......................................................................................... 3-6

3.5.1 Onboard Sync. SRAM (Pipe Line Burst SRAM)............................................3-6

3.6. CPU INSTALLATION AND JUMPERS SETUP...................................................3-6

3.7. CMOS RTC & ISA CFG CMOS SRAM................................................................3-6

3.8. SPEAKER CONNECTOR INSTALLATION......................................................... 3-7

3.9. POWER LED & KEY LOCK CONNECTOR INSTALLATION ............................. 3-7

5

Page 6

GA-586ATV

3.10. TURBO SWITCH CONNECTOR INSTALLATION............................................3-7

3.11. TURBO LED CONNECTOR INSTALLATION ................................................... 3-7

3.12. HARDWARE RESET SWITCH CONNECTOR INSTALLATION ..................... 3-7

3.13. GREEN FUNCTION INSTALLATION................................................................ 3-8

3.14. PERIPHERAL DEVICE INSTALLATION ........................................................... 3-8

3.15. KEYBOARD SETTING FUNCTION................................................................... 3-8

4. BIOS CONFIGURATION...................................................................... 4-1

4.1. ENTERING SETUP.............................................................................................. 4-1

4.2. CONTROL KEYS.................................................................................................. 4-2

4.3. GETTING HELP ................................................................................................... 4-3

4.3.1. Main Menu4.................................................................................................. 4-3

4.3.2. Status Page Setup Menu / Option Page Setup Menu.................................. 4-3

4.4. THE MAIN MENU.................................................................................................4-3

4.5. STANDARD CMOS SETUP MENU..................................................................... 4-5

4.6. BIOS FEATURES SETUP.................................................................................... 4-9

4.7. CHIPSET FEATURES SETUP...........................................................................4-13

4.8. POWER MANAGEMENT SETUP...................................................................... 4-14

4.9. PNP/PCI CONFIGURATION..............................................................................4-16

4.10. INTEGRATED PERIPHERALS........................................................................ 4-17

4.11. LOAD SETUP DEFAULTS............................................................................... 4-21

4.12. USER PASSWORD..........................................................................................4-22

4.13. IDE HDD AUTO DETECTION.......................................................................... 4-23

4.14. SAVE & EXIT SETUP.......................................................................................4-24

4.15. EXIT WITHOUT SAVING.................................................................................4-25

5. AT TECHNICAL INFORMATION.......................................................... 5-1

5.1. I/O BUS CONNECTOR PIN OUT........................................................................5-1

5.1.1. ISA SLOT PIN OUT......................................................................................5-1

5.1.2. PCI - BUS SLOT PIN OUT...........................................................................5-2

5.2. I/O & MEMORY MAP............................................................................................ 5-3

5.3. TIMER & DMA CHANNELS MAP......................................................................... 5-3

5.4. INTERRUPT MAP ................................................................................................ 5-4

6

Page 7

Table of Contents

5.5. RTC & CMOS RAM MAP ..................................................................................... 5-5

APPENDIX A: POST MESSAGE..............................................................A-1

APPENDIX B: POST CODES...................................................................B-1

APPENDIX C: BIOS DEFAULT DRIVE TABLE ........................................C-1

APPENDIX D: PROBLEM SHEET............................................................D-1

APPENDIX E: FCC DOCUMENT ............................................................. E-1

7

Page 8

Page 9

Introduction

1. INTRODUCTION

1.1. PREFACE

Welcome to use the GA - 586ATV motherboard. The motherboard is a 512

KB CACHE Pentium Processor based PC / AT compatible system with ISA

bus and PCI Local Bus, and has been designed to be the fastest PC / AT

system. There are some new features allow you to operate the system with

just the performance you want.

This manual also explains how to install the motherboard for operation, and

how to set up your CMOS CONFIGURATION with BIOS SETUP program.

1.2. KEY FEATURES

q Pentium

q Supports 321 Pins (Socket 7) ZIF white socket on board.

q Auto detect 3.3V - 3.5V and 2.8V - 2.9V CPU.

q Supports Pentium

q Supports 512 KB Pipeline Burst Sync. 2nd Cache.

q 4 Master / Slave PCI Bus slots, 3 ISA Bus slots.

q Supports 8 - 128 MB DRAM memory on board.

q Supports 2 channels Enhance PCI IDE ports for 4 IDE Device.

q Supports 2xCOM (16550), 1xLPT (EPP / ECP), 1x2.88MB Floppy port.

q USB function is ready for option.

q Supports Green function, Plug & Play function.

q Licensed AWARD BIOS, FLASH EEPROM for BIOS update.

q 2/3 BABY AT size, 4 layers PCB.

Processor based PC / AT compatible mainboard.

Processor, running at 75-233 MHz.

1-1

Page 10

GA-586ATV

1.3. PERFORMANCE LIST

The following performance data list is the testing results of some popular

benchmark testing programs. These data are just referred by users.

(The different Hardware & Software configuration will result in different

benchmark testing results.)

• CPU

• DRAM 32 MB EDO

• CACHE SIZE 512 KB Pipeline Burst SRAM

• DISPLAY Matrox Millennium 2MB

• STORAGE Onboard IDE port + Quantum Fireball 1280AT

• SOUND Creative 32 PnP

• O.S. Windows 95 OSR2

Pentium processor 233 MHz

with Display Driver at 1024 x 768 x 256 colors x 75Hz

CPU

Intel MMX-233 AMD K6-233

Software

Winbench 97

CPU mark32 471 566

Winstone 97

Business

Hi-End

46

20.8

48

20.7

Intel Media

Bench mark 1.0 298.31 247.98

1-2

Page 11

1.4. BLOCK DIAGRAM

Introduction

CACHE

S82437VX

Floppy

LPT

COM1

COM2

DLINK

MA

CLOCK

CPU

HD

S82438VX DRAM

AD

24MHz

I/O

ISA

SLOT

S82371SB

GENERATOR

14.718MHZ

CPU BUS

Address

Data

Control

MD

PCI BUS

AD

Control

IDE1

IDE2

74F245

ISA BUS

Address

Data

Control

1-3

Page 12

GA-586ATV

1.5. INTRODUCE THE PCI - BUS

Connecting devices to a CPU local bus can dramatically increase the speed

of I/O-bound peripherals with only a slight increase in cost over traditional

systems. This price / performance point has created a vast market potential

for local bus products. The main barrier to this market has been the lack of

an accepted standard for local bus peripherals. Many mainboard and chipset

manufactures developed their own local bus implementations, but they are

incompatible with each other. The VL (Video Electronics Standards

Association) local bus and PCI (Peripheral Component Interconnect) bus

specification was created to end this confusion.

The PCI - bus standard, under development since Jun. 1992, which is

designed to bring workstation-level performance to standard PC platform.

The PCI - bus removes many of the bottlenecks that have hampered PC for

several years. On the PCI - bus, peripherals operate at the native speed of

the computer system, thus enabling data transfer between peripherals and

the system at maximum speed. This performance is critical for bandwidthconstrained devices such as video, multimedia, mass storage, and

networking adapters.

PCI - bus standard provides end-users with a low-cost, extendible and

portable local bus design, which will allow system and peripherals from

different manufactures to work together.

1.6. FEATURES

q 32 bits bus transfer mode.

q Bus Master or Slave access.

q Memory burst transfer to 132 MB/sec.

q 33 MHz operation speed.

q 10 device loading ability.

q CPU independent.

1-4

Page 13

2. SPECIFICATION

2.1. HARDWARE

Specification

• CPU

• COPROCESSOR

• SPEED

• DRAM MEMORY

• CACHE MEMORY

• SHADOW RAM

• I/O BUS SLOTS

• USB PORTS

• IDE PORTS

• I/O PORTS

− Intel Pentium

processor (with MMX) 75 - 233

MHz.

− AMDK5, K6 and Cyrix / IBM 6

− 321 pins (socket 7) ZIF white socket on board.

− Automatically setup 3.3V ~ 3.5V / 2.8V ~ 2.9V for

x

86.

dual power CPU.

− Included in Pentium

− 50 / 60 / 66 / 75 MHz system and 25 / 30 / 33 / 37.5

Processor.

PCI-Bus speed.

− Hardware and Software speed switchable function.

− 2 banks 72 pins SIMM module socket on board.

− Use 4 / 8 / 16 / 32 MB 60~70 ns SIMM module

DRAM.

− 8 ~ 128 MB DRAM size.

− Support Fast Page / EDO DRAM access mode.

− 16 KB cache memory included in Pentium

Processor .

− 512 KB Pipeline Burst 2nd cache.

− Support Write Back cache function for both CPU &

on board cache.

− Main BIOS shadow function.

− Video BIOS shadow function programmable.

− Shadow RAM cacheable function.

− 4 Master / Slave PCI-BUS.

− 3 16 bits ISA BUS.

− Optional extended cable for dual USB port.

− 2 Enhanced IDE channels on board.(Using

IRQ14,15)

− Support Mode 3,4 IDE & ATAPI CD - ROM.

− Supports 2*16550 COM ports. (Using IRQ4, 3)

− Supports 1*EPP/ECP LPT port. (Using IRQ7 or 5

and DMA3 or 1)

− Supports 1*2.88MB Floppy port. (Using DMA2 &

IRQ6)

− Supports PS/2 Mouse. (Using IRQ12 )

2-1

Page 14

GA-586ATV

•

GREEN FUNCTION

• BIOS

• DIMENSION

− USB function optional.

− Standby & Suspend mode support.

− Green switch & LED support.

− IDE & Display power down support.

− Monitor all IRQ / DMA / Display / I/O events.

− 128KB FLASH EEPROM.

− Supports Plug & Play Function.

− 2/3Baby AT size / 4 layers.

2.2. SOFTWARE

• BIOS − Licensed AWARD BIOS.

− AT CMOS Setup, BIOS / Chipset Setup, Green

Setup, Hard Disk Utility included.

• O.S. − Operation with MS-DOS, Windows/95,

WINDOWS NT, OS/2, NOVELL and SCO

UNIX.

2.3. ENVIRONMENT

• Ambient Temp.

− 0°C to +45°C (Operating).

• Relative Hum. − 0 to +85% (Operating).

• Altitude − 0 to 10,000 feet (Operating).

• Vibration − 0 to 1,000 Hz.

• Electricity − 4.9 V to 5.2 V.

− 10 A to 15 A current.

2-2

Page 15

Hardware Installation

3. HARDWARE INSTALLATION

3.1. UNPACKING

The mainboard package should contain the following:

• The GA - 586ATV mainboard.

• USER'S MANUAL.

• Cable set for I/O Device.

• Diskette for BUS MASTER IDE Driver.

The mainboard contains sensitive electric components which can be easily

damaged by static electricity, so the mainboard should be left in its original

packing until it is installed.

Unpacking and installation should be done on a grounded anti-static mat.

The operator should be wearing an anti static wristband, grounded at the

same point as the anti-static mat.

Inspect the mainboard carton for obvious damage. Shipping and handling

may cause damage to your board. Be sure there are no shipping and

handling damages on the board before proceeding.

After opening the mainboard carton, extract the system board and place it

only on a grounded anti-static surface component side up. Again inspect the

board for damage. Press down on all of the socket IC's to make sure that

they are properly seated. Do this only on with the board placed on a firm flat

surface.

M

DO NOT APPLY POWER TO THE BOARD IF IT HAS BEEN DAMAGED.

You are now ready to install your mainboard. The mounting hole pattern on

the mainboard matches the IBM-AT system board. It is assumed that the

chassis is designed for a standard IBM XT/AT mainboard mounting.

Place the chassis on the anti-static mat and remove the cover. Take the

plastic clips, Nylon stand-off and screws for mounting the system board, and

keep them separate.

3-1

Page 16

GA-586ATV

3.2. MAINBOARD LAYOUT (REV.3 and above)

J12

J10 J8

++

1

J11

J9

J6

J7

S1

123456

J5

+

1

ISA SLOT3

ISA SLOT2

ISA SLOT1

USB

J3

CPU

RTCBIOS

PCI4

U10

PCI3

GA-586ATV

PCI2

SYNC

SRAM

SYNC

SRAM

82438VX

82438VX

1

+

J4

SIMM4

SIMM1

CN6

IDE1 LPT PORT

IDE2

CN7

CN1

1

2

CN4

1

2

PCI1

FLOPPY

14

2

1

1

COMA

COMB

Power1

×Figure 3.1Ø

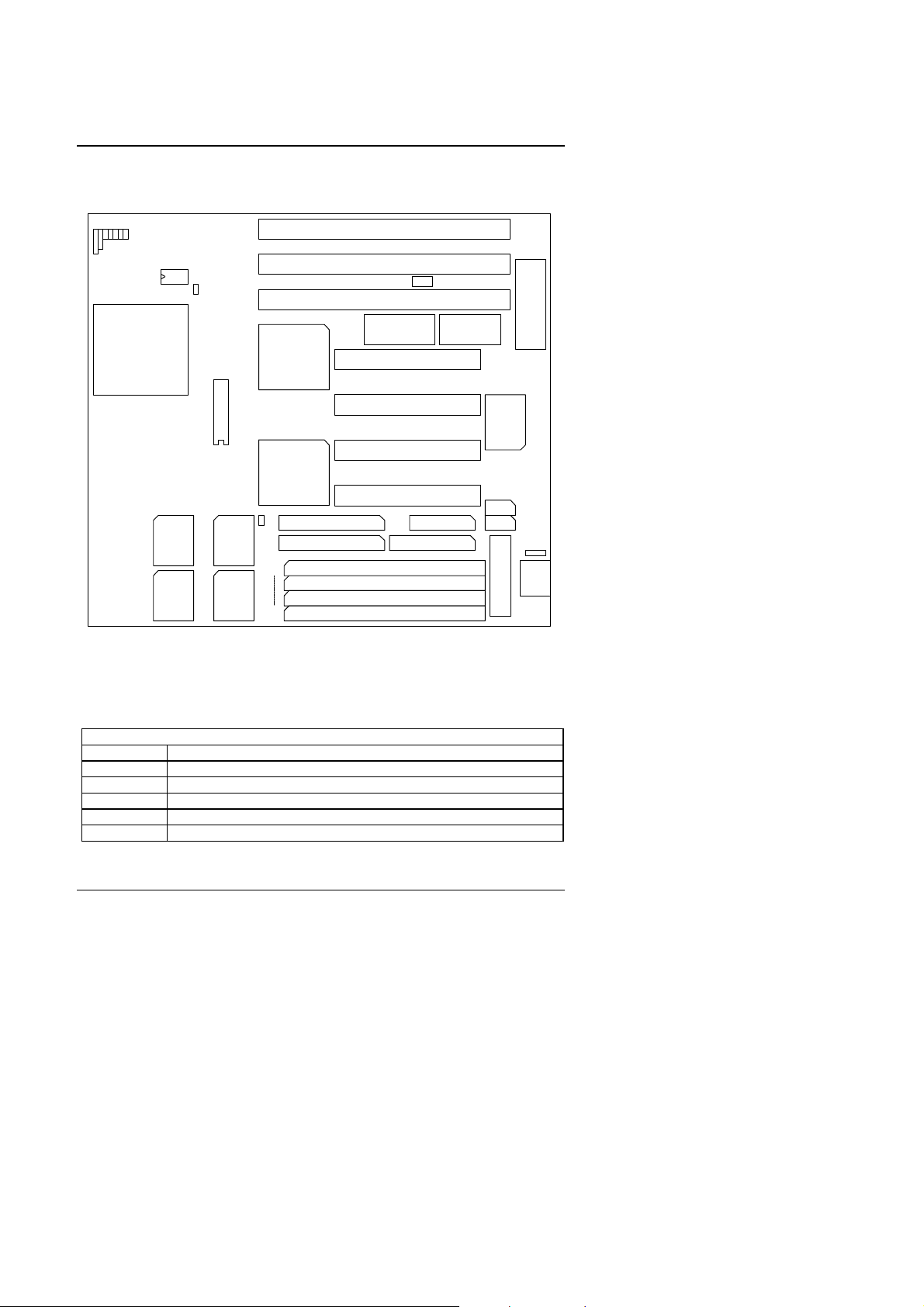

3.3. QUICK REFERENCE FOR JUMPERS & CONNECTORS

t J1: Keyboard Connector

Pin No. Function

1 Key Clock.

2 Key Data.

3 NC.

4 VCC (+5V).

5 GND.

CN2

CN3

PS/2 MOUSE

J2

1

J1

Keyboard

3-2

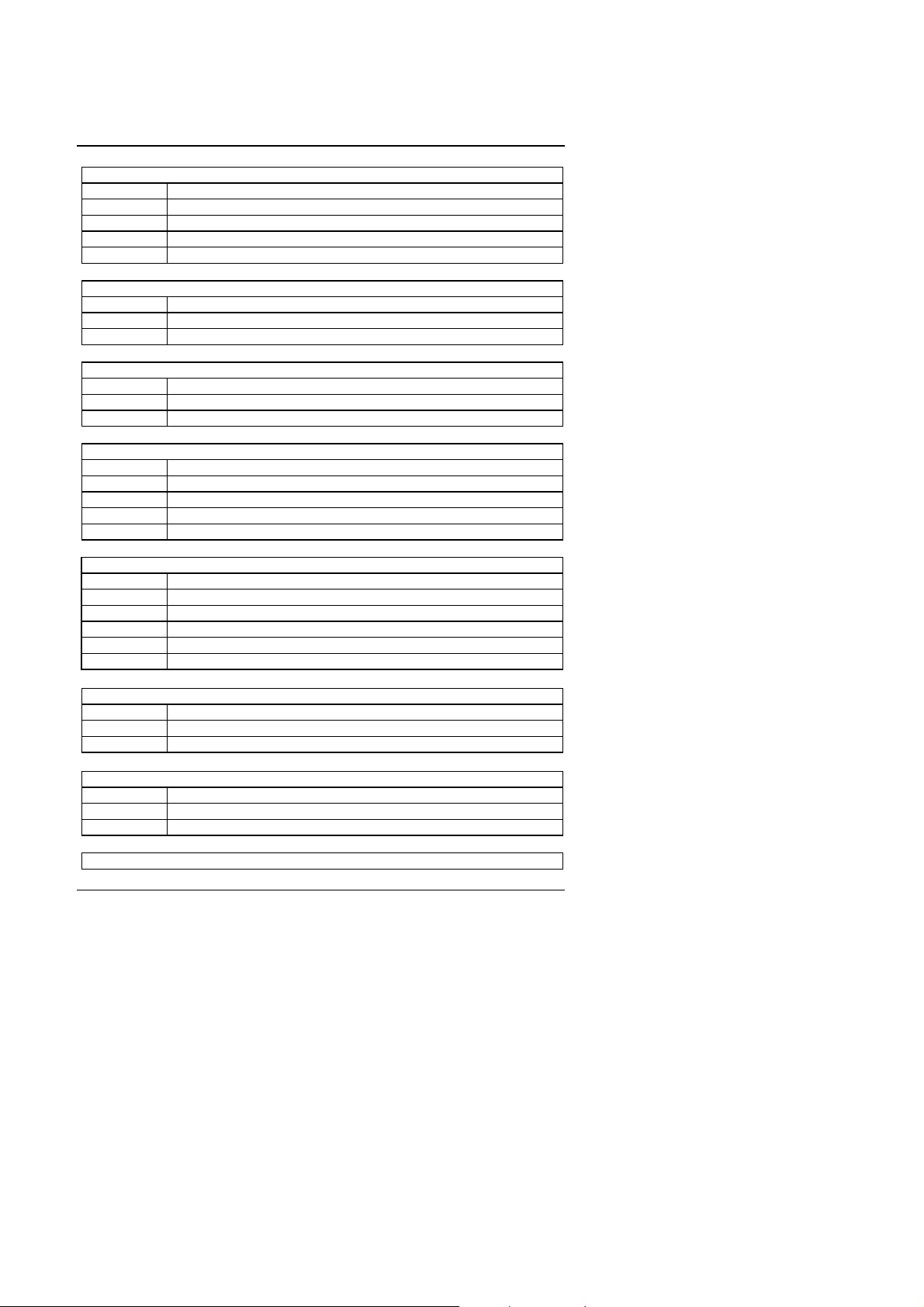

Page 17

t J2: PS/2 Mouse Connector

Pin No. Function

1 VCC.

2 GND.

3 MS-DATA.

4 MS-CLOCK.

t J4: IDE Hard Disk Active LED

Pin No. Function

1 LED anode (+).

2 LED cathode (-).

t J5: CPU Cooling Fan Power Connector

Pin No. Function

1 +12V

2 GND

t J6: Speaker Connector

Pin No. Function

1 VCC.

2 NC.

3 NC.

4 Data.

t J7: Power LED and Key-Lock Connector

Pin No. Function

1 LED anode (+).

2 NC.

3 LED cathode (-).

4 Key lock.

5 GND.

Hardware Installation

t J8: Green Function Switch

Pin No. Function

Close For system entering Green mode ( Suspend mode).

Open Normal operation.

t J9: Green Function LED

Pin No. Function

1 LED anode (+).

2 LED cathode (-).

t J10: Reset Switch

3-3

Page 18

GA-586ATV

Open For normal operation.

Close For hardware reset system.

t J11: Turbo Switch

Pin No. Function

Close For low speed (Non-cache).

Open For high speed.

t J12: Turbo LED Connector

Pin No. Function

1 LED anode (+).

2 LED cathode (-).

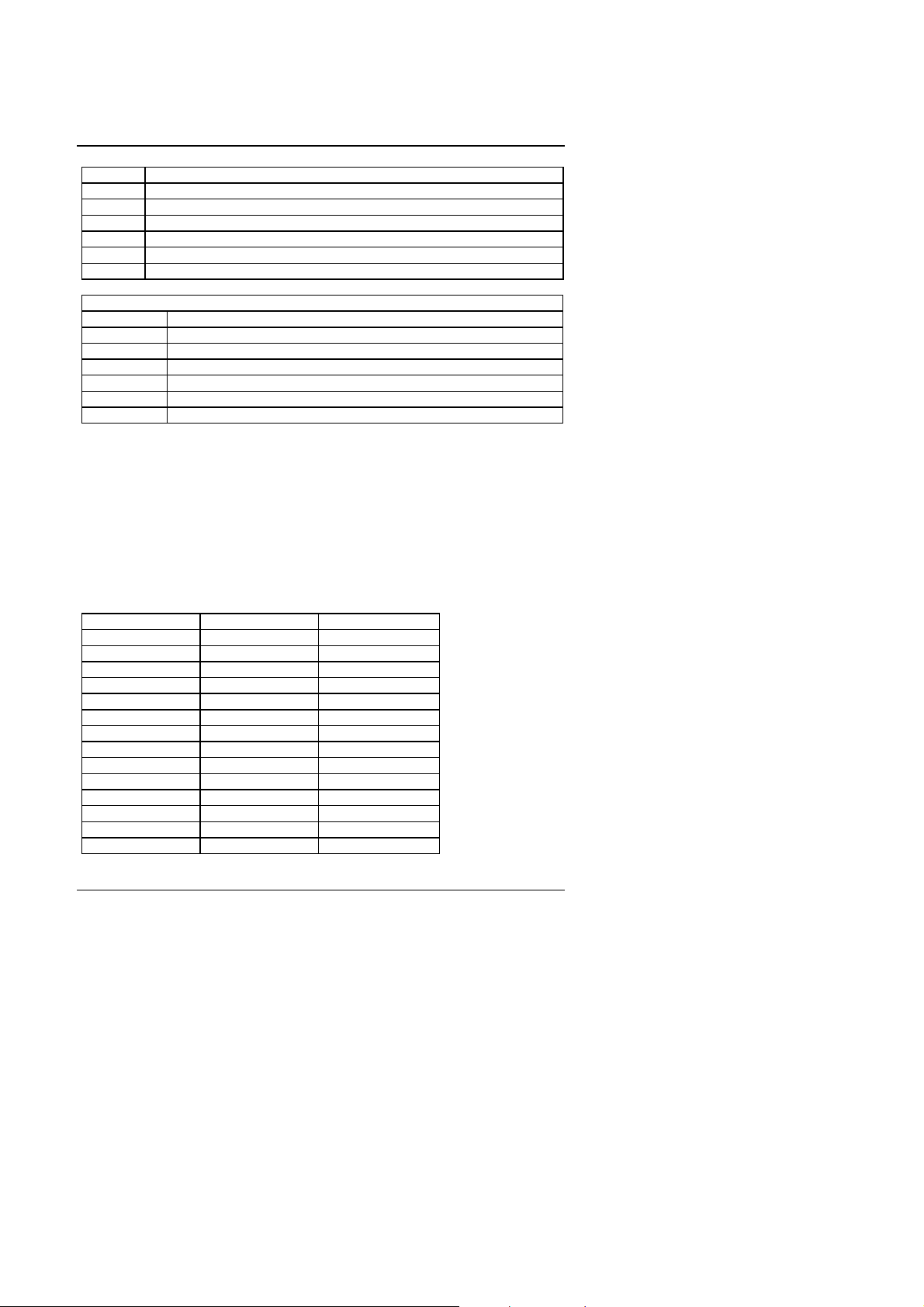

t S1-1,2: CPU BUS CLOCK

MHz 1 2

75 OFF OFF

66 OFF ON

60 ON OFF

50 ON ON

t S1-3,4: CPU INT. / EXT. CLOCK RATIO¡]For REV.3x¡^

RATIO 3 4

x 1.5 or x 3.5 OFF OFF

x 2 OFF ON

x 2.5 ON ON

x 3 ON OFF

t S1-3, 4, 6: CPU INT. / EXT. CLOCK RATIO¡]For REV.4x¡^

RATIO 3 4 6

x 1.5 or x 3.5 OFF OFF OFF

x 2 OFF ON OFF

x 2.5 ON ON OFF

x 3 ON OFF OFF

x 5.5 OFF OFF ON

x 4 OFF ON ON

x 4.5 ON ON ON

x 5 ON OFF ON

t S1-5: AMD K6 3.2V CPU support

CPU 5

AMD K6 3.2V CPU OFF

Intel & Cyrix & AMD K5, K6 (2.9V) ON

t CN1-4,6,7,J3 I/O Ports Connector

3-4

Page 19

Hardware Installation

CN2 For COM A (Serial port1)

CN3 For COM B (Serial port2)

CN4 For Floppy port

CN1 For LPT port

CN6 For Primary IDE port

CN7 For Secondary IDE port

J3 For Extended USB cable.

t Power Connector

Pin No. Function

1 Power Good signal

2,10,11,12 VCC (+5V)

3 +12V

4 -12V

5,6,7,8 GND

9 -5V

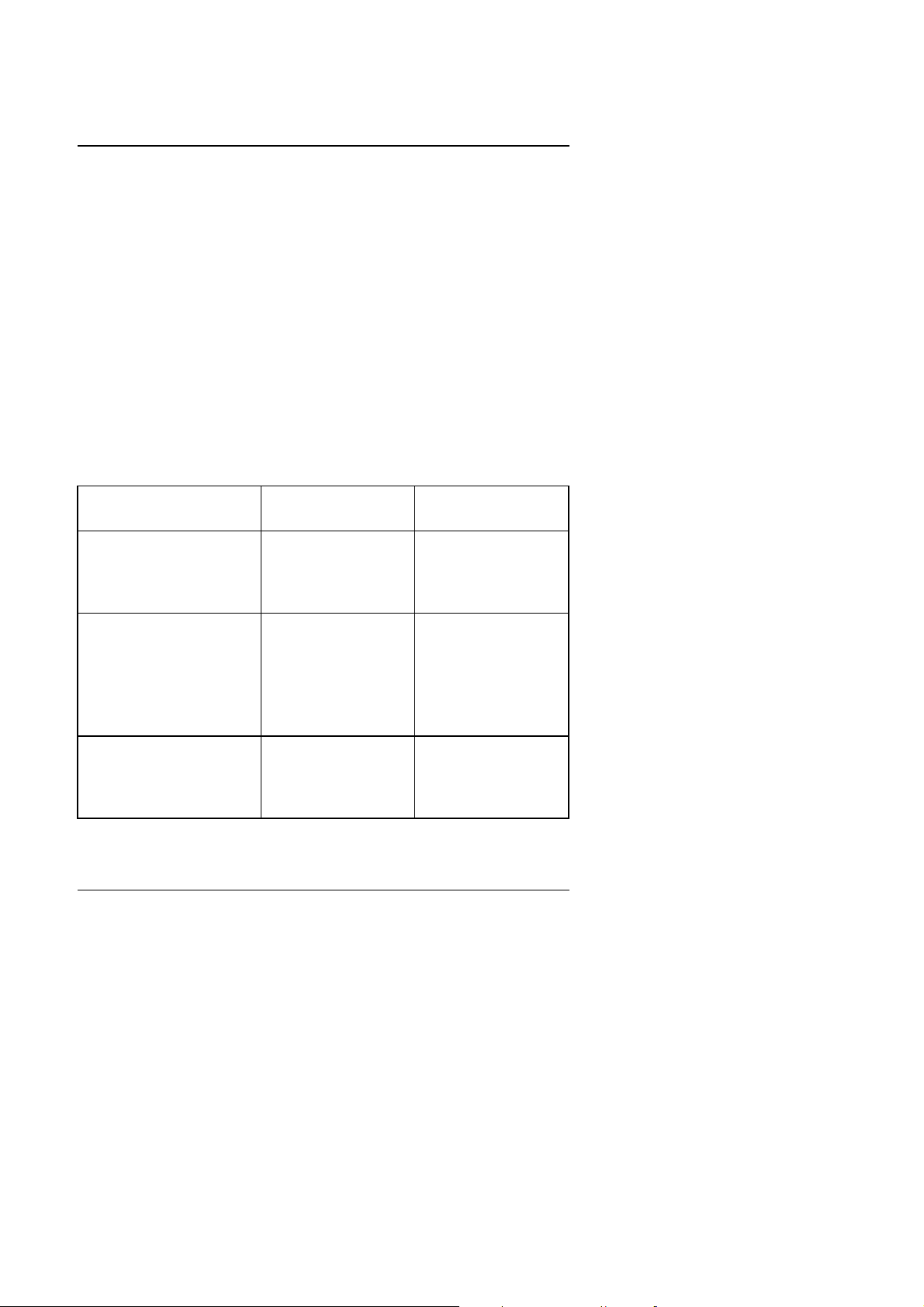

3.4. DRAM INSTALLATION

The mainboard can be installed with 4 / 8 / 16 / 32 MB 72 pins SIMM module

DRAM, and the DRAM speed must be 60 or 70 ns. The DRAM memory

system on mainboard consists of bank 0 & bank 1.

Each bank consist of 2 PCs 72 pins SIMM module DRAM. Because the 72

pins SIMM module is 32 bits width, using 2 PCs which can match a 64 bits

system. The total memory size is 8 - 128 MB, and various configuration of

DRAM types in the following TABLE are for reference:

BANK0 BANK1 TOTAL SIZE

4MB * 2pcs. 8MB

4MB * 2pcs. 4MB * 2pcs. 16MB

8MB * 2pcs. 16MB

8MB * 2pcs. 4MB * 2pcs. 24MB

8MB * 2pcs. 8MB * 2pcs. 32MB

16MB * 2pcs. 32MB

16MB * 2pcs. 4MB * 2pcs. 40MB

16MB * 2pcs. 8MB * 2pcs. 48MB

16MB * 2pcs. 16MB * 2pcs. 64MB

32MB * 2pcs.

32MB * 2pcs. 4MB * 2pcs. 72MB

32MB * 2pcs. 8MB * 2pcs. 80MB

32MB * 2pcs. 16MB * 2pcs. 96MB

32MB * 2pcs. 32MB * 2pcs. 128MB

The DRAM installation position refer to Figure 3.1, and notice the Pin 1 of

64MB

3-5

Page 20

GA-586ATV

SIMM module must match with the Pin 1 of SIMM socket when the DRAM

SIMM module is installed.

Insert the DRAM SIMM module into the SIMM socket at 45 degree angle. If

there is a wrong direction of Pin 1, the DRAM SIMM module couldn't be

inserted into socket completely.

After completely insert SIMM module into socket, then press the SIMM

module in vertical direction until the left and right metal holders can keep the

SIMM module standing up con-firmly.

3.5. SRAM INSTALLATION

3.5.1 Onboard Sync. SRAM (Pipe Line Burst SRAM)

Sync SRAM consists of 2 PCs Pipeline Burst 64 K x 32- 6/7 for 512KB Sync.

SRAM. The TAG SRAM (U10) is 16KBx8-12.

3.6. CPU INSTALLATION AND JUMPERS SETUP

The system's speed depends on the frequency of CLOCK GENERATOR.

The user can change the selection to set up the system speed to 50 MHz, 60

MHz, 66 MHz or 75 MHz for Intel 75 - 233 MHz 3.3V ~ 3.5V and 2.8V ~ 2.9V

dual power plane Pentium

The mainboard can use Intel Pentium Processor (MMX or PODP), Cyrix

6x86 and AMD K5 / K6 processor and the CPU speed must match with the

frequency of CLOCK GEN. It will cause system hanging up if the CLOCK

GEN.'S frequency is higher than CPU's.

Processor.

M

The CPU is a sensitive electric component and it can be easily

damaged by static electricity, so users must keep it away from

metal surface when the CPU is installed onto mainboard.

M

When the user installs the CPU on socket, please notice the PIN 1

of CPU is in the same corner as the PIN 1 of socket!

M

Before the CPU is installed, the mainboard must be placed on a flat

plane in order to avoid being broken by the pressure of CPU

installation.

3.7. CMOS RTC & ISA CFG CMOS SRAM

3-6

Page 21

Hardware Installation

There're RTC & CMOS SRAM on board, they have a power supply from

internal battery to keep the DATA inviolate & effective. The RTC is a REALTIME CLOCK device which provides the DATE & TIME to system. The

CMOS SRAM is used for keeping the information of ISA device system

configuration, so the system can automatically boot OS. every time.

Due to the life-time of 3V Li-battery is 5 years, the user can change a new

one to replace old one after it can not work.

3.8. SPEAKER CONNECTOR INSTALLATION

There is always a speaker in AT system for sound purpose. The 4 - Pins

connector J6 is used to connect speaker.

The speaker can work well in both direction of connector when it is installed

to the connector J6 on mainboard.

3.9. POWER LED & KEY LOCK CONNECTOR INSTALLATION

There are a system power LED lamp and a key on the panel of case. The

power LED will light on when system is powered-on, and the key can lock the

keyboard input or unlock it, both of them are connected to a 5 PIN connector.

The connector should be installed to J7 of mainboard in correct direction.

3.10. TURBO SWITCH CONNECTOR INSTALLATION

The TURBO switch on the panel is used for controlling the system speed.

Some program developed on XT should be executed with a low speed

system, so a high speed system needs the speed switching function to

change its running speed.

The mainboard uses 50 MHz speed method to implement DE-TURBO

switching function. The J11 on mainboard should be connected to the

TURBO switch on panel, and user can push in or pop out the TURBO switch

to enable or disable the turbo function of system.

NOTE: If the system already use 50MHz clock, then the TURBO function

will inactive.

3.11. TURBO LED CONNECTOR INSTALLATION

The TURBO LED on panel can indicate the current speed status of system.

The TURBO LED connector should be installed to J12 in correct direction.

3.12. HARDWARE RESET SWITCH CONNECTOR INSTALLATION

3-7

Page 22

GA-586ATV

The RESET switch on panel provides users with HARDWARE RESET

function which is almost the same as power-on/off. The system will do a cold

start after the RESET switch is pushed and released by user.

The RESET switch is a 2 PIN connector and should be installed to J10 on

mainboard.

3.13. GREEN FUNCTION INSTALLATION

For the purpose of power saving, there are two jumpers, J8 and J9, to make

sure the power saving function doing well.

The J9 is a indicator (green LED) for green function. If the green LED is ON,

the system is operating in green mode.

The J8 is a switch to force the system get into green mode immediately.

3.14. PERIPHERAL DEVICE INSTALLATION

After the device installation and jumpers setup, the mainboard can be

mounted into the case and fixed by screw. To complete the mainboard

installation, the peripheral device could be installed now. The basic system

needs a display interface card and a disk device.

If the PCI - Bus device is to be installed in the system, any one of four PCI Bus slots can be used no matter Slave or Master PCI - Bus device being

installed. After installing the peripheral device, the user should check

everything again, and prepare to power-on the system.

3.15. KEYBOARD SETTING FUNCTION

After booting the O.S., there are some special functions used by keyboard as

follows:

"CTRL_ALT_DEL" − Pressing these keys simultaneously will cause

system to Warm Start (Software Reset).

3-8

Page 23

BIOS Configuration

4. BIOS CONFIGURATION

Award's BIOS ROM has a built-in Setup program that allows users to modify

the basic system configuration. This type of information is stored in batterybacked CMOS SRAM so that it retains the Setup information when the power

is turned off.

4.1. ENTERING SETUP

Power ON the computer and press <Del> immediately will allow you to enter

Setup. The other way to enter Setup is to power on the computer, when the

below message appears briefly at the bottom of the screen during the POST

(Power On Self Test), press <Del> key or simultaneously

press <Ctrl>, <Alt>, and <Esc> keys.

Ÿ

TO ENTER SETUP BEFORE BOOT PRESS CTRL-ALT-ESC OR DEL KEY

If the message disappears before you respond and you still wish to enter

Setup, restart the system to try again by turning it OFF then ON or pressing

the "RESET" bottom on the system case. You may also restart by

simultaneously press <Ctrl>,<Alt>, and <Del> keys.

If you do not press the keys at the correct time and the system does not boot,

an error message will be displayed and you will again be asked to,

Ÿ

PRESS F1 TO CONTINUE, CTRL-ALT-ESC OR DEL TO ENTER SETUP

4-1

Page 24

GA-586ATV

4.2. CONTROL KEYS

Up arrow Move to previous item

Down arrow Move to next item

Left arrow Move to the item in the left hand

Right arrow Move to the item in the right hand

Esc key Main Menu - Quit and not save changes into CMOS

PgUp key Increase the numeric value or make changes

PgDn key Decrease the numeric value or make changes

F1 key General help, only for Status Page Setup Menu and Option Page

F2 key Change color from total 16 colors

F3 key Calendar, only for Status Page Setup Menu

F4 key Reserved

F5 key Restore the previous CMOS value from CMOS, only for Option Page

F6 key Load the default CMOS value from BIOS default table, only for Option

F7 key Load the default

F8 key Reserved

Status Page Setup Menu and Option Page Setup Menu - Exit current

page and return to Main Menu

Setup Menu

Setup Menu

Page Setup Menu

F9 key Reserved

F10 key Save all the CMOS changes, only for Main Menu

4-2

Page 25

BIOS Configuration

4.3. GETTING HELP

4.3.1. Main Menu

The on-line description of the highlighted setup function is displayed at the

bottom of the screen.

4.3.2. Status Page Setup Menu / Option Page Setup Menu

Press F1 to pop up a small help window that describes the appropriate keys

to use and the possible selections for the highlighted item. To exit the Help

Window press <Esc>.

4.4. THE MAIN MENU

Once you enter Award BIOS CMOS Setup Utility, the Main Menu (Figure 4.1)

will appear on the screen. The Main Menu allows you to select from seven

setup functions and two exit choices. Use arrow keys to select among the

items and press <Enter> to accept or enter the sub-menu.

ROM PCI / ISA BIOS

CMOS SETUP UTILITY

AWARD SOFTWARE, INC.

STANDARD CMOS SETUP

BIOS FEATURES SETUP

CHIPSET FEATURES SETUP

POWER MANAGEMENT SETUP

PNP/PCI CONFIGURATION

INTEGRATED PERIPHERALS

LOAD SETUP DEFAULTS

ESC

: Quit

F10

: Save & Exit Setup (Shift)F2

Time, Date, Hard Disk Type, ...

Figure 4.1: Main Menu

USER PASSWORD

IDE HDD AUTO DETECTION

SAVE & EXIT SETUP

EXIT WITHOUT SAVING

: Select Item

: Change Color

4-3

Page 26

GA-586ATV

• Standard CMOS setup

This setup page includes all the items in a standard compatible BIOS.

• BIOS features setup

This setup page includes all the items of Award special enhanced

features.

• Chipset features setup

This setup page includes all the items of chipset special features.

• Power management setup

This setup page includes all the items of Green function features.

• PNP/PCI configuration

This setup page includes all the configurations of PCI & PNP ISA

resources.

• Integrated peripherals

This setup page includes all onboard peripherals.

• Load setup defaults

BIOS defaults indicates the most appropriate value of the system

parameter which the system would be in safe configuration.

• User password

Change, set, or disable password. It allows you to limit access to the

system and Setup, or just to Setup.

• IDE HDD auto detection

Automatically configure hard disk parameter.

• Save & exit setup

Save CMOS value changes to CMOS and exit setup.

• Exit without save

Abandon all CMOS value changes and exit setup.

4-4

Page 27

BIOS Configuration

4.5. STANDARD CMOS SETUP MENU

The items in Standard CMOS Setup Menu (Figure 4.2) are divided into 9

categories. Each category includes no, one or more than one setup items.

Use the arrows to highlight the item and then use the <PgUp> or <PgDn>

keys to select the value you want in each item.

ROM PCI / ISA BIOS

STANDARD CMOS SETUP

AWARD SOFTWARE, INC.

Date (mm:dd:yy)

Time (hh:mm:ss)

Primary

Primary

Secondary Master

Secondary

Driver A

Driver B

Floppy 3 Mode Support : Disabled

Video

Halt On : All Errors

ESCF1: Quit

: Help (Shift)F2

: Tue, Mar 25 1997

: 10 : 45 : 00

Master

Slave

Slave

: 1.44M , 3.5 inch.

: None

: EGA/VGA

: Auto

: None

: None

: None

HEAD PRECOMP LANDZ SECTOR

CYLSHARD DISKS TYPE MODE

SIZE

0

0

0

0

Extended Memory:

Expanded Memory:

: Select Item

: Change Color

000 0

Base Memory:

Other Memory:

Total Memory:

PU/PD/+/- : Modify

0

0000 0

0000 0

0000 0

640 K

15360 K

0 K

384 K

16384 K

AUTO

Figure 4.2: Standard CMOS Setup Menu

• Date

The date format is <day>, <date> <month> <year>. Press <F3> to show

the calendar.

day The day, from Sun to Sat, determined by the BIOS and is

display-only

date The date, from 1 to 31 (or the maximum allowed in the

month)

month The month, Jan. through Dec.

year The year, from 1900 through 2099

---------

---------

---------

4-5

Page 28

GA-586ATV

• Time

The time format in <hour> <minute> <second>. The time is calculated

base on the 24-hour military-time clock. For example, 1 p.m. is

13:00:00.

• Primary HDDs / Secondary HDDs

The category identify the types of hard disk drive C drive F 4 devices

that has been installed in the computer. There are 45 pre-defined types

and a user definable type. Type 1 to Type 45 are pre-defined. Type User

is user-definable and type Auto will automatically detect HDD's type..

Press PgUp or PgDn to select a numbered hard disk type or type the

number and press <Enter>. Note that the specifications of your drive

must match with the drive table. The hard disk will not work properly if

you enter improper information for this category. If your hard disk drive

type is not matched or listed, you can use Type User to define your own

drive type manually.

If you select Type User, related information is asked to be entered to the

following items. Enter the information directly from the keyboard and

press <Enter>. Those information should be provided in the

documentation form your hard disk vendor or the system manufacturer.

CYLS. number of cylinders

HEADS number of heads

PRECOMP write precomp

LANDZONE landing zone

SECTORS number of sectors

If a hard disk has not been installed select NONE and press <Enter>.

• Drive A type / Drive B type

The category identify the types of floppy disk drive A or drive B that has

been installed in the computer.

None No floppy drive installed

360K, 5.25 in. 5-1/4 inch PC-type standard drive; 360 kilobyte

capacity.

1.2M, 5.25 in. 5-1/4 inch AT-type high-density drive; 1.2 megabyte

capacity (3-1/2 inch when 3 Mode is Enabled).

720K, 3.5 in. 3-1/2 inch double-sided drive; 720 kilobyte capacity

4-6

Page 29

BIOS Configuration

1.44M, 3.5 in. 3-1/2 inch double-sided drive; 1.44 megabyte

capacity.

• Floppy 3 Mode Support (for Japan Area)

Disable Normal Floppy Drive.

Drive A Drive A is 3 mode Floppy Drive.

Drive B Drive B is 3 mode Floppy Drive.

Both Drive A & B are 3 mode Floppy Drive.

• Video

The category detects the type of adapter used for the primary system

monitor that must matches your video display card and monitor.

Although secondary monitors are supported, you do not have to select

the type in setup.

EGA/VGA Enhanced Graphics Adapter/Video Graphics Array. For

EGA, VGA, SVGA, or PGA monitor adapters

CGA 40 Color Graphics Adapter, power up in 40 column mode

CGA 80 Color Graphics Adapter, power up in 80 column mode

MONO Monochrome adapter, includes high resolution

monochrome adapters

• Halt on

The category determines whether the computer will stop if an error is

detected during power up.

NO errors The system boot will not be stopped for any error

that may be detected

All errors Whenever the BIOS detects a non-fatal error the

system will be stopped and you will be prompted

All, But Keyboard The system boot will not stop for a keyboard

error; it will stop for all other errors

All, But Diskette The system boot will not stop for a disk error; it

will stop for all other errors

All, But Disk/Key The system boot will not stop for a keyboard or

4-7

Page 30

GA-586ATV

disk error; it will stop for all other errors

• Memory

The category is display-only which is determined by POST (Power On

Self Test) of the BIOS.

Base Memory

The POST of the BIOS will determine the amount of base (or

conventional) memory installed in the system. The value of the

base memory is typically 512 K for systems with 512 K memory

installed on the motherboard, or 640 K for systems with 640 K

or more memory installed on the motherboard.

Extended Memory

The BIOS determines how much extended memory is present

during the POST. This is the amount of memory located above

1 MB in the CPU's memory address map.

Expanded Memory

Expanded Memory in memory defined by the

Lotus/Intel/Microsoft (LIM) standard as EMS. Many standard

DOS applications can not utilize memory above 640 K, the

Expanded Memory Specification (EMS) swaps memory which

not utilized by DOS with a section, or frame, so these

applications can access all of the system memory.

Memory can be swapped by EMS is usually 64 K within 1 MB

or memory above 1 MB, depends on the chipset design.

Expanded memory device driver is required to use memory as

Expanded Memory.

Other Memory

This refers to the memory located in the 640 K to 1024 K

address space. This is memory that can be used for different

applications. DOS uses this area to load device drivers to keep

4-8

Page 31

as much base memory free for application programs. Most use

for this area is Shadow RAM.

4.6. BIOS FEATURES SETUP

ROM PCI / ISA BIOS

BIOS FEATURES SETUP

AWARD SOFTWARE, INC.

Virus Warning

CPU Internal Cache

External Cache

Quick Power On Self Test

Boot Sequence

Swap Floppy Drive : Disabled

Boot Up Floppy Seek

Boot Up NumLock Status

Typematic Rate Setting

Typematic Rate (Chars/Sec)

Typematic Delay (Msec)

Security Option

PCI/VGA Palette Snoop : Disabled

OS Select For DRAM >64MB : Non-OS2

: Disabled

: Enabled

: Enabled

: Enabled

: A, C, SCSI

: Enabled

: On

: Disabled

: 6

:250

: Setup

BIOS Configuration

Video BIOS Shadow

C8000 - CBFFF Shadow

CC000 - CFFFF Shadow : Disabled

: Enabled

: Disabled

: DisabledD0000 - D3FFF Shadow

: DisabledD4000 - D7FFF Shadow

: DisabledD8000 - DBFFF Shadow

: DisabledDC000 - DFFFF Shadow

ESC

: Quit

F1

: Help

F5

: Old Values

F7 : Load Setup Defaults

PU/PD/+/(Shift)F2

: Select Item

: Modify

: Color

Figure 4.3: BIOS Features Setup

• Virus Warning

This category flashes on the screen. During and after the system boots

up, any attempt to write to the boot sector or partition table of the hard

disk drive will halt the system and the following error message will

appear, in the mean time, you can run anti-virus program to locate the

problem. Default value is Disabled.

Enabled Activate automatically when the system boots up causing

a warning message to appear when anything attempts to

access the boot sector or hard disk partition table

Disabled No warning message to appear when anything attempts to

4-9

Page 32

GA-586ATV

access the boot sector or hard disk partition table

• CPU Internal Cache / External Cache

These two categories speed up memory access. However, it depends on

CPU / chipset design. The default value is Enabled.

Enabled Enable cache

Disabled Disable cache

• Quick Power On Self Test

This category speeds up Power On Self Test (POST) after you power on

the computer. If it is set to Enable, BIOS will shorten or skip some check

items during POST. The default value is Enabled.

Enabled Enable quick POST

Disabled Normal POST

• Boot Sequence

This category determines which drive computer searches first for the

disk operating system (i.e., DOS). Default value is A,C, SCSI.

X1, X2, X3 System will first search for X1 disk drive then X2 disk

drive and then X3 disk drive.

• Swap Floppy Drive

The default value is Disabled.

Enabled Floppy A & B will be swapped under DOS

Disabled Floppy A & B will be normal definition

• Boot Up Floppy Seek

During POST, BIOS will determine if the floppy disk drive installed is 40

or 80 tracks. 360 K type is 40 tracks while 720 K, 1.2 M and 1.44 M are

all 80 tracks.

The default value is Enabled.

Enabled BIOS searches for floppy disk drive to determine if it is 40

or 80 tracks, Note that BIOS can not tell from 720 K,

1.2 M or 1.44 M drive type as they are all 80 tracks

4-10

Page 33

BIOS Configuration

Disabled BIOS will not search for the type of floppy disk drive by

track number. Note that there will not be any warning

message if the drive installed is 360 K

• Boot Up NumLock Status

The default value is On.

On Keypad is number keys

Off Keypad is arrow keys

• Typematic Rate Setting

The default value is Disabled.

Enabled Enable Keyboard typematic rate setting.

Disabled Disable Keyboard typematic rate setting.

• Typematic Rate (Chars/Sec)

The default value is 6.

6-30 Set the maximum typematic rate from 6 chars. per second

to 30 chars. per second.

• Typematic Delay (mSec)

The default value is 250.

250-1000 Set the time delay from first key to repeat the same key

in to computer.

• Security Option

This category allows you to limit access to the system and Setup, or just

to Setup. The default value is Setup.

System The system will not boot and access to Setup will be

denied if the correct password is not entered at the prompt

Setup The system will boot, but access to Setup will be denied if

the correct password is not entered at the prompt

M

To disable security, select PASSWORD SETTING at Main Menu and

then you will be asked to enter password. Do not type anything and

4-11

Page 34

GA-586ATV

just press <Enter>, it will disable security. Once the security is

disabled, the system will boot and you can enter Setup freely.

• OS Select For DRAM>64MB

The default value is Non-OS2.

Non-OS2 Using non-OS2 operating system.

OS2 Using OS2 operating system and DRAM>64MB.

• Video BIOS Shadow

It determines whether video BIOS will copied to RAM, however, it is

optional from chipset design. Video Shadow will increase the video

speed.

The default value is Enable.

Enabled Video shadow is enabled

Disabled Video shadow is disabled

• C8000 - CFFFF Shadow / D0000 - DFFFF Shadow

These categories determine whether optional ROM will be copied to

RAM by 16 K byte.

The default value are Disabled.

Enabled Optional shadow is enabled

Disabled Optional shadow is disabled

• PCI/VGA Palette Snoop

The default value are Disabled.

Enabled For having Video Card on ISA Bus and VGA Card on

PCI Bus.

Disabled For VGA Card only.

4-12

Page 35

4.7. CHIPSET FEATURES SETUP

ROM PCI / ISA BIOS

CHIPSET FEATURES SETUP

AWARD SOFTWARE, INC.

BIOS Configuration

DRAM Wait State

DRAM Read Burst (EDO/FP)

DRAM Write Burst Timing

Memory Hole At 15M-16M

: 1DRAM Precharge Wait State

: 1

: x333/x444

: x333

: Disabled

Figure 4.4: Chipset Features Setup

• DRAM Precharge Wait State

The default value is 1.

0 0 Wait State, for 60~70ns DRAM.

1 1 Wait State, for 70ns DRAM.

: Quit

F1

: Help

F5

: Old Values

F7 : Load Setup Defaults

PU/PD/+/(Shift)F2

: Select ItemESC

: Modify

: Color

• DRAM Wait State

The default value is 1.

0 0 Wait State, for 60~70ns DRAM.

1 1 Wait State, for 70ns DRAM.

4-13

Page 36

GA-586ATV

• DRAM Read Burst (EDO/FP)

The default value is x333/x444.

x222/x333 2 Burst Wait State, for 60~70ns DRAM.

x333/x444 3 Burst Wait State, for 70ns DRAM.

• DRAM Write Burst Timing

The default value is x333.

x222 2 Burst Wait State, for 60~70ns DRAM.

x333 3 Burst Wait State, for 70ns DRAM.

• Memory Hole At 15M-16M

The default value is Disabled.

Disabled Normal Setting.

Enabled Set Address=15~16MB remap to ISA BUS.

4.8. POWER MANAGEMENT SETUP

ROM PCI / ISA BIOS

POWER MANAGEMENT SETUP

AWARD SOFTWARE, INC.

Power Management

PM Control by APM

Video Off Method

Standby Mode

Suspend Mode : Disabled

HDD Power Down

: Enabled

: Yes

: DPMS

: Disabled

: Disabled

** Power Down & Resume Events **

IRQ3 (COM 2)

IRQ4 (COM 1)

IRQ5 (LPT 2)

IRQ6 (Floppy Disk)

IRQ7 (LPT 1)

IRQ8 (RTC Alarm) : OFF

IRQ9 (IRQ2 Redir)

IRQ10 (Reserved)

IRQ11 (Reserved)

IRQ12 (PS/2 Mouse)

IRQ14 (Hard Disk)

IRQ15 (Reserved)

: ON

: ON

: OFF

: ON

: OFF

: OFF

: OFF

: OFF

: ON

: ON

: OFF

: Quit

F1

: Help

F5

: Old Values

F7 : Load Setup Defaults

4-14

PU/PD/+/(Shift)F2

: Select ItemESC

: Modify

: Color

Page 37

BIOS Configuration

Figure 4.5: Power Management Setup

• Power Management

The default value is Enabled.

Enabled Enable Green function.

Disabled Disable Green function.

Please disable Green Function for Non-S CPU in OS/2, Unix, Window

NT & Novell system.

• PM Control by APM

The default value is No.

Yes Enable software APM function.

No Disable software APM function.

• Video off Method

The default value is DPMS Support.

V/H SYNC + Blank BIOS will turn off V/H-SYNC when gets into

Green mode for Green monitor power saving.

Blank Screen BIOS will only black monitor when gets into

Green mode.

DPMS Support BIOS will use DPMS Standard to control VGA

card. (The Green type VGA card will turn of

V/H-SYNC automatically.)

• Standby Mode ( for Network Card using )

The default value is Disable.

Disable Disable Standby Mode.

1 min - 1

Hour

Setup the timer to enter Standby Mode.

• Suspend mode ( for CPU stop clock Mode )

The default value is Disable.

Disable Disable Suspend Mode.

4-15

Page 38

GA-586ATV

1 min - 1

Setup the timer to enter Suspend Mode.

Hour

• HDD Power Down

The default value is Disable.

Disable Disable HDD Power Down mode function.

1-15 mins Enable HDD enter Power Down mode between 1 to 15

mins.

4.9. PNP/PCI CONFIGURATION

ROM PCI / ISA BIOS

PNP/PCI CONFGURATION

AWARD SOFTWARE, INC.

Resources Controlled by : Manual

Reset Configuration Data : Disabled

IRQ-3 assigned to

IRQ-5 assigned to

IRQ-7 assigned to

IRQ-9 assigned to

IRQ-10 assigned to

IRQ-11 assigned to

IRQ-12 assigned to

IRQ-14 assigned to

IRQ-15 assigned to

DMA-0 assigned to

DMA-1 assigned to

DMA-3 assigned to

DMA-5 assigned to

DMA-6 assigned to

DMA-7 assigned to

: Legacy ISA

: Legacy ISAIRQ-4 assigned to

: PCI/ ISA PnP

: Legacy ISA

: PCI/ ISA PnP

: PCI/ ISA PnP

: PCI/ ISA PnP

: Legacy ISA

: Legacy ISA

: Legacy ISA

: PCI/ ISA PnP

: PCI/ ISA PnP

: PCI/ ISA PnP

: PCI/ ISA PnP

: PCI/ ISA PnP

: PCI/ ISA PnP

: Quit

F1

: Help

F5

: Old Values

F7 : Load Setup Defaults

Figure 4.6: PCI Slot Configuration

PU/PD/+/(Shift)F2

: Select ItemESC

: Modify

: Color

• Resources Controlled by

The default value is Manual.

Manual User can set the PnP resource (I/O Address, IRQ & DMA

4-16

Page 39

BIOS Configuration

channels) used by legacy ISA DEVICE.

Auto BIOS automatically use these PnP resources.

• IRQ (3,4,5,7,9,10,11,12,14,15),DMA(0,1,3,5,6,7) assigned to

The default value is "Legacy ISA" or "PCI/ISA PnP".

Legacy ISA The resource is used by Legacy ISA device.

PCI/ISA PnP The resource is used by PCI/ISA PnP device (PCI or

ISA).

4.10. INTEGRATED PERIPHERALS

ROM PCI / ISA BIOS

INTEGRATED PERIPHERALS

AWARD SOFTWARE, INC.

IDE HDD Block Mode : Enabled

IDE Primary Master PIO

IDE Primary Slave PIO

IDE Secondary Master PIO

IDE Secondary Slave PIO

On-Chip Primary PCI IDE

On-Chip Secondary PCI IDE

PCI Slot IDE 2nd Channel

: Auto

: Auto

: Auto

: Auto

: Enabled

: Enabled

: Enabled

Onboard FDD Controller

Onboard Serial Port1

Onboard Serial Port2

Onboard Parallel Port

Onboard Parallel Mode

USB Controller : Disabled

: Enabled

: COM1/3F8

: Auto

: 378H/IRQ7

: SPP

Figure 4.7: Load Setup Defaults

• IDE HDD Block Mode

The default value is Enabled.

: Quit

F1

: Help

F5

: Old Values

F7 : Load Setup Defaults

4-17

PU/PD/+/(Shift)F2

: Select ItemESC

: Modify

: Color

Page 40

GA-586ATV

Enabled Enable IDE HDD Block Mode

Disabled Disable IDE HDD Block Mode

• IDE Primary Master PIO (for onboard IDE 1st channel).

The default value is Auto.

Auto BIOS will automatically defect the IDE HDD Accessing

mode.

Mode0~4 Manually set the IDE Accessing mode.

• IDE Primary Slave PIO (for onboard IDE 1st channel).

The default value is0 Auto.

Auto BIOS will automatically defect the IDE HDD Accessing

mode.

Mode0~4 Manually set the IDE Accessing mode.

• IDE Secondary Master PIO (for onboard IDE 2nd channel).

The default value is Auto.

Auto BIOS will automatically defect the IDE HDD Accessing

mode.

Mode0~4 Manually set the IDE Accessing mode.

• IDE Secondary Slave PIO (for onboard IDE 2nd channel).

The default value is Auto.

Auto BIOS will automatically defect the IDE HDD Accessing

mode.

Mode0~4 Manually set the IDE Accessing mode.

• On-Chip Primary IDE

The default value is Enabled.

4-18

Page 41

Enabled Enable onboard 1st channel IDE port.

Disabled Disable onboard 1st channel IDE port.

• On-Chip Secondary IDE

The default value is Enabled.

Enabled Enable onboard 2nd channel IDE port.

Disabled Disable onboard 2nd channel IDE port.

• PCI Slot IDE 2nd Channel

The default value is Enabled.

Enabled Enable PCI BUS Device’ s 2nd IDE Channel

Disabled Disable PCI BUS Device’ s 2nd IDE Channel

• Onboard FDD Controller

The default value is Enabled.

Enabled Enable onboard FDD port.

Disabled Disable onboard FDD port.

BIOS Configuration

• Onboard Serial Port 1

The default value is COM1/3F8.

Auto BIOS will automatically setup the port A address.

COM1/3F8 Enable onboard Serial port A and address is 3F8H.

COM2/2F8 Enable onboard Serial port A and address is 2F8H.

COM3/3E8 Enable onboard Serial port A and address is 3E8H.

COM4/2E8 Enable onboard Serial port A and address is 2E8H.

Disabled Disable onboard Serial port A.

• Onboard Serial Port 2

The default value is COM2/2F8.

Auto BIOS will automatically setup the port B address.

COM1/3F8 Enable onboard Serial port B and address is 3F8H.

4-19

Page 42

GA-586ATV

COM2/2F8 Enable onboard Serial port B and address is 2F8H.

COM3/3E8 Enable onboard Serial port B and address is 3E8H.

COM4/2E8 Enable onboard Serial port B and address is 2E8H.

Disabled Disable onboard Serial port B.

• Onboard Parallel port

The default value is 378H/IRQ7.

378H Enable onboard LPT port and address is 378H/IRQ7.

278H Enable onboard LPT port and address is 278H/IRQ5.

Disabled Disable onboard LPT port.

3BCH Enable onboard LPT port and address is 3BCH/IRQ7.

• Onboard Parallel Mode

The default value is SPP.

SPP Using Parallel port as Normal Printer Port.

EPP Using Parallel port as Enhanced Parallel Port.

ECP Using Parallel port as Extended Capabilities Port.

ECP+EPP Using Parallel port as ECP & EPP mode.

• USB Controller

The default value is Disabled.

Enabled Enable the USB function.

Disabled Disable the USB function.

4-20

Page 43

4.11. LOAD SETUP DEFAULTS

ROM PCI / ISA BIOS

LOAD SETUP DEFAULTS

AWARD SOFTWARE, INC.

BIOS Configuration

STANDARD CMOS SETUP

BIOS FEATURES SETUP

CHIPSET FEATURES SETUP

POWER MANAGEMENT SETUP

PNP/PCI CONFIGURATION

INTEGRATED PERIPHERALS

LOAD SETUP DEFAULTS

ESC

: Quit

F10

: Save & Exit Setup (Shift)F2

Load SETUP Defaults except Standard CMOS SETUP

Load SETUP Defaults (Y/N)? N

USER PASSWORD

IDE HDD AUTO DETECTION

SAVE & EXIT SETUP

EXIT WITHOUT SAVING

: Select Item

: Change Color

Figure 4.7: Load Setup Defaults

• Load SETUP Defaults

To load SETUP defaults value to CMOS SRAM, enter "Y". If not, enter

"N".

M

If there is any problem occurred, loading SETUP DEFAULTS step is

recommended.

4-21

Page 44

GA-586ATV

4.12. USER PASSWORD

When you select this function, the following message will appear at the

center of the screen to assist you in creating a password.

ENTER PASSWORD

ROM PCI / ISA BIOS

USER PASSWORD

AWARD SOFTWARE, INC.

STANDARD CMOS SETUP

BIOS FEATURES SETUP

CHIPSET FEATURES SETUP

POWER MANAGEMENT SETUP

PNP/PCI CONFIGURATION

INTEGRATED PERIPHERALS

LOAD SETUP DEFAULTS

ESC

: Quit

F10

: Save & Exit Setup (Shift)F2

Enter Password:

Change / Set / Disable Password

USER PASSWORD

IDE HDD AUTO DETECTION

SAVE & EXIT SETUP

EXIT WITHOUT SAVING

: Select Item

: Change Color

Figure 4.8: Password Setting

Type the password, up to eight characters, and press <Enter>. The

password typed now will clear and previously entered password from CMOS

memory. You will be asked to confirm the password. Type the password

again and press <Enter>. You may also press <Esc> to abort the selection

and not enter a password.

To disable password, just press <Enter> when you are prompted to enter

password. A message will confirm the password being disabled. Once the

password is disabled, the system will boot and you can enter Setup freely.

PASSWORD DISABLED

If you select System at Security Option of BIOS Features Setup Menu, you

will be prompted for the password every time the system is rebooted or any

time you try to enter Setup. If you select Setup at Security Option of BIOS

Features Setup Menu, you will be prompted only when you try to enter

4-22

Page 45

Setup.

4.13. IDE HDD AUTO DETECTION

ROM PCI / ISA BIOS

IDE HDDD AUTO DETECTION

AWARD SOFTWARE, INC.

CYLS. HEAD PRECOMP LANDZ SECTOR

SIZETYPEHARD DISKS MODE

Select Primary Master Option (N=Skip): N

OPTION SIZE CYLS. HEAD PRECOMP LANDZ SECTOR MODE

1 (Y)

2

3

521

521

521

1060

530

530

16

65535

32

32

65535

ESC

0

: Skip

1059

1059

1059

63

63

63

BIOS Configuration

NORMAL

LBA

LARGE

Figure 4.9: IDE HDD Auto Detection

Type "Y" will accept the H.D.D. parameter reported by BIOS.

Type "N" will keep the old H.D.D. parameter setup. If the hard disk cylinder

NO. is over 1024, then the user can select LBA mode or LARGER mode for

DOS partition LARGE than 528 MB.

4-23

Page 46

GA-586ATV

4.14. SAVE & EXIT SETUP

AWARD SOFTWARE, INC.

ROM PCI / ISA BIOS

SAVE & EXIT SETUP

STANDARD CMOS SETUP

BIOS FEATURES SETUP

CHIPSET FEATURES SETUP

POWER MANAGEMENT SETUP

PNP/PCI CONFIGURATION

INTEGRATED PERIPHERALS

LOAD SETUP DEFAULTS

ESC

: Quit

F10

: Save & Exit Setup (Shift)F2

SAVE to CMOS and EXIT (Y/N)? N

Save Data to CMOS & Exit SETUP

USER PASSWORD

IDE HDD AUTO DETECTION

SAVE & EXIT SETUP

EXIT WITHOUT SAVING

: Select Item

: Change Color

Figure 4.10: Save & Exit Setup

Type "Y" will quit the Setup Utility and save the user setup value to RTC

CMOS SRAM.

Type "N" will return to Setup Utility.

4-24

Page 47

4.15. EXIT WITHOUT SAVING

ROM PCI / ISA BIOS

EXIT WITHOUT SAVING

AWARD SOFTWARE, INC.

BIOS Configuration

STANDARD CMOS SETUP

BIOS FEATURES SETUP

CHIPSET FEATURES SETUP

POWER MANAGEMENT SETUP

PCI CONFIGURATION

INTEGRATED PERIPHERALS

LOAD SETUP DEFAULTS

ESC

: Quit

F10

: Save & Exit Setup (Shift)F2

Quit Without Saving (Y/N)? N

Abandon all Datas & Exit SETUP

USER PASSWORD

IDE HDD AUTO DETECTION

SAVE & EXIT SETUP

EXIT WITHOUT SAVING

: Select Item

: Change Color

Figure 4.11: Exit Without Saving

Type "Y" will quit the Setup Utility without saving to RTC CMOS SRAM.

Type "N" will return to Setup Utility.

4-25

Page 48

Page 49

GA-586ATV

5. AT TECHNICAL INFORMATION

5.1. I/O BUS CONNECTOR PIN OUT

5.1.1. ISA SLOT PIN OUT

B01

A01

-I/O CH CHKGND

B02

A02

A03

A04

A05

A06

A07

A08

A09

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

SD07

SD06

SD05

SD04

SD03

SD02

SD01

SD00

-I/O CH RDY

AEN

SA19

SA18

SA17

SA16

SA15

SA14

SA13

SA12

SA11

SA10

SA09

SA08

SA07

SA06

SA05

SA04

SA03

SA02

SA01

SA00

-MEMCS16

-MASTER

RESET

+5V

IRQ9

-5V

DRQ2

-12V

0WS

+12V

GND

-SMEMW

-SMEMR

-IOW

-IOR

-DACK3

-DRQ3

-DACK1

-DRQ1

-REFRESH

BCLK

IRQ7

IRQ6

IRQ5

IRQ4

IRQ3

-DACK2

T/C

BALE

+5V

OSC

GND

B03

B04

B05

B06

B07

B08

B09

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

-I/OCS16

IRQ10

IRQ11

IRQ12

IRQ15

IRQ14

-DACK0

DRQ0

-DACK5

DRQ5

-DACK6

DRQ6

-DACK7

DRQ7

+5V

GND

D01

D02

D03

D04

D05

D06

D07

D08

D09

D10

D11

D12

D13

D14

D15

D16

D17

D18

C01

C02

C03

C04

C05

C06

C07

C08

C09

C10

C11

C12

C13

C14

C15

C16

C17

C18

SBHE

LA23

LA22

LA21

LA20

LA19

LA18

LA17

-MEMR

-MEMW

SD08

SD09

SD10

SD11

SD12

SD13

SD14

SD15

5-1

Page 50

5.1.2. PCI - BUS SLOT PIN OUT

B01

A01

-12V

NC

GND

NC

VCC

VCC

INTB#

INTD#

PST#1

NC

PST#2

GND

GND

NC

GND

CLK

GND

REQ#

VCC

AD_31

AD_29

GND

AD_27

AD_25

NC

CBE#3

AD_23

GND

AD_21

AD_19

NC

AD_17

CEB#2

GND

IRDY#

NC

DEVSEL#

GND

LOCK#

PERR#

B02

B03

B04

B05

B06

B07

B08

B09

B10

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

B25

B26

B27

B28

B29

B30

B31

B32

B33

B34

B35

B36

B37

B38

B39

B40

A02

A03

A04

A05

A06

A07

A08

A09

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A34

A35

A36

A37

A38

A39

A40

NC

+12V

NC

NC

VCC

INTA#

INTC#

VCC

NC

VCC

NC

GND

GND

NC

RST#

VCC

GNT#

GND

NC

AD_30

NC

AD_28

AD_26

GND

AD_24

IDSEL

NC

AD_22

AD_20

GND

AD_18

AD_16

NC

FRAME#

GND

TRDY#

GND

STOP#

NC

SDONE

AT Technical Information

B41

NC

GND

GND

GND

VCC

VCC

VCC

NC

NC

NC

B42

B43

B44

B45

B46

B47

B48

B49

B52

B53

B54

B55

B56

B57

B58

B59

B60

B61

B62 A62

SERR#

CBE#1

AD_14

AD_12

AD_10

AD_08

AD_07

AD_05

AD_03

AD_01

A41

A42

A43

A44

A45

A46

A47

A48

A49

A52

A53

A54

A55

A56

A57

A58

A59

A60

A61

SBO#

GND

PAR

AD_15

NC

AD_13

AD_11

GND

AD_09

CBE#0

NC

AD_06

AD_04

GND

AD_02

AD_00

VCC

NC

VCC

VCC

5-2

Page 51

GA-586ATV

5.2. I/O & MEMORY MAP

MEMORY MAP:

I/O MAP:

[0000000-009FFFF] System memory used by DOS and application program.

[00A0000-00BFFFF] Display buffer memory for VGA/ EGA/CGA/MONOCHROME adapter.

[00C0000-00DFFFF] Reserved for I/O device BIOS ROM or RAM buffer.

[00E0000-00EFFFF] Reserved for PCI device ROM.

[00F0000-00FFFFF] System BIOS ROM.

[0100000-BFFFFFF] System extension memory.

[000-01F] DMA controller.(Master)

[020-021] INTERRUPT controller.(Master)

[022-023] CHIPSET control registers I/O ports.

[040-05F] TIMER control registers.

[060-06F] KEYBOARD interface controller.(8042)

[070-07F] RTC ports & CMOS I/O ports.

[080-09F] DMA register.

[0A0-0BF] INTERRUPT controller.(Slave)

[0C0-0DF] DMA controller.(Slave)

[0F0-0FF] MATH COPROCESSOR

[1F0-1F8] HARD DISK controller.

[278-27F] PARALLEL port-2.

[2B0-2DF] GRAPHICS adapter controller.

[2F8-2FF] SERIAL port-2.

[360-36F] NETWORK ports.

[378-37F] PARALLEL port-1

[3B0-3BF] MONOCHROME & PRINTER adapter.

[3C0-3CF] EGA adapter.

[3D0-3DF] CGA adapter.

[3F0-3F7] FLOPPY DISK controller.

[3F8-3FF] SERIAL port-1.

5.3. TIMER & DMA CHANNELS MAP

TIMER MAP: TIMER Channel-0 System timer interrupt

TIMER Channel-1 DRAM REFRESH request

TIMER Channel-2 SPEAKER tone generator

DMA CHANNELS: DMA Channel-0 Available

DMA Channel-1 IBM SDLC

DMA Channel-2 FLOPPY DISK adapter

DMA Channel-3 Available

DMA Channel-4 Cascade for DMA controller 1

DMA Channel-5 Available

DMA Channel-6 Available

DMA Channel-7 Available

5-3

Page 52

AT Technical Information

5.4. INTERRUPT MAP

NMI: Parity check error

IRQ (H/W): 0 System TIMER interrupt from TIMER-0

1 KEYBOARD output buffer full

2 Cascade for IRQ 8-15

3 SERIAL port 2

4 SERIAL port 1

5 PARALLEL port 2

6 FLOPPY DISK adapter

7 PARALLEL port 1

8 RTC clock

9 Available

10 Available

11 Available

12 Available

13 MATH coprocessor

14 HARD DISK adapter

15 Available

5-4

Page 53

GA-586ATV

5.5. RTC & CMOS RAM MAP

RTC & CMOS: 00 Seconds

01 Second alarm

02 Minutes

03 Minutes alarm

04 Hours

05 Hours alarm

06 Day of week

07 Day of month

08 Month

09 Year

0A Status register A

0B Status register B

0C Status register C

0D Status register D

0E Diagnostic status byte

0F Shutdown byte

10 FLOPPY DISK drive type byte

11 Reserve

12 HARD DISK type byte

13 Reserve

14 Equipment byte

15 Base memory low byte

16 Base memory high byte

17 Extension memory low byte

18 Extension memory high byte

19-2d

2E-2F

30 Reserved for extension memory low byte

31 Reserved for extension memory high byte

32 DATE CENTURY byte

33 INFORMATION FLAG

34-3F Reserve

40-7f Reserved for CHIPSET SETTING DATA

5-5

Page 54

Page 55

Appendix A: Post Message

APPENDIX A: POST MESSAGE

When the BIOS encounters an error that requires the user to correct

something, either a beep code will sound or a message will be displayed in a

box in the middle of the screen and the message PRESS F1 TO CONTINUE,

CTRL-ALT-ESC OR DEL TO ENTER SETUP will be shown in the

information box at the bottom.

• POST BEEP

Currently there is only one beep code in BIOS. This code indicates that

a video error has occurred and the BIOS cannot initialize the video

screen to display any additional information. This beep code consists of

a single long beep followed by two short beeps.

• ERROR MESSAGE

Once or more of the following messages may be displayed if the BIOS

detects an error during the POST. This list includes message for both

the ISA and the EISA BIOS.

Ö CMOS BATTERY HAS FAILED

CMOS battery is no longer functional. It should be replaced.

Ö CMOS CHECKSUM ERROR

Checksum of CMOS is incorrect. This can indicate that CMOS has

become corrupt. This error may have been caused by a weak battery.

Check the battery and replace if necessary.

Ö DISK BOOT FAILURE, INSERT SYSTEM DISK AND PRESS ENTER

No boot device was found. Insert a system disk into Drive A: and press

<Enter>. If you assumed the system would boot from the hard drive,

make sure the controller is inserted correctly and all cables are properly

attached. Also be sure the disk is formatted as a boot device. Then

reboot the system.

Ö DISKETTE DRIVES OR TYPES MISMATCH ERROR - RUN SETUP

Type of diskette drive installed in the system is different from the CMOS

definition. Run Setup to re-configure the drive type correctly.

A-1

Page 56

GA-586ATV

Ö DISPLAY SWITCH IS SET INCORRECTLY

Display switch on the motherboard can be set to either monochrome or

color. This indicates the switch is set to a different setting than indicated

in Setup. Determine which setting is correct, and then either turn off the

system and change the jumper, or enter Setup and change the VIDEO

selection.

Ö DISPLAY TYPE HAS CHANGED SINCE LAST BOOT

Since last powering off the system, the display adapter has been

changed. You must configure the system for the new display type.

Ö EISA Configuration Checksum Error

PLEASE RUN EISA CONFIGURATION UTILITY

The EISA non-volatile RAM checksum is incorrect or cannot correctly

read the EISA slot. This can indicate either the EISA non-volatile

memory has become corrupt or the slot has configured incorrectly. Also

be sure the card is installed firmly in the slot.

Ö EISA Configuration Is Not Complete

PLEASE RUN EISA CONFIGURATION UTILITY

The slot configuration information stored in the EISA non-volatile

memory is incomplete.

F When either of these errors appear, the system will boot in ISA mode,

which allows you to run the EISA Configuration Utility.

Ö ERROR ENCOUNTERED INITIALIZING HARD DRIVE

Hard drive cannot be initialized. Be sure the adapter is installed correctly

and all cables are correctly and firmly attached. Also be sure the correct

hard drive type is selected in Setup.

Ö ERROR INITIALIZING HARD DISK CONTROLLER

Cannot initialize controller. Make sure the cord is correctly and firmly

installed in the bus. Be sure the correct hard drive type is selected in

Setup. Also check to see if any jumper needs to be set correctly in the

hard drive.

A-2

Page 57

Appendix A: Post Message

Ö FLOPPY DISK CNTRLR ERROR OR NO CNTRLR PRESENT

Cannot find or initialize the floppy drive controller. Make sure the

controller is installed correctly and firmly. If there are no floppy drives

installed, be sure the Diskette Drive selection in Setup is set to NONE.

Ö Invalid EISA Configuration

PLEASE RUN EISA CONFIGURATION UTILITY

The non-volatile memory containing EISA configuration information was

programmed incorrectly or has become corrupt. Re-run EISA

configuration utility to correctly program the memory.

F When this error appears, the system will boot in ISA mode, which allows

you to run the EISA Configuration Utility.

Ö KEYBOARD ERROR OR NO KEYBOARD PRESENT

Cannot initialize the keyboard. Make sure the keyboard is attached

correctly and no keys are being pressed during the boot.

If you are purposely configuring the system without a keyboard, set the

error halt condition in Setup to HALT ON ALL, BUT KEYBOARD. This

will cause the BIOS to ignore the missing keyboard and continue the

boot.

Ö Memory Address Error at ...

Indicates a memory address error at a specific location. You can use

this location along with the memory map for your system to find and

replace the bad memory chips.

Ö Memory parity Error at ...

Indicates a memory parity error at a specific location. You can use this

location along with the memory map for your system to find and replace

the bad memory chips.

Ö MEMORY SIZE HAS CHANGED SINCE LAST BOOT

Memory has been added or removed since the last boot. In EISA mode

use Configuration Utility to re-configure the memory configuration. In

ISA mode enter Setup and enter the new memory size in the memory

fields.

A-3

Page 58

GA-586ATV

Ö Memory Verify Error at ...

Indicates an error verifying a value already written to memory. Use the

location along with your system's memory map to locate the bad chip.

Ö OFFENDING ADDRESS NOT FOUND

This message is used in conjunction with the I/O CHANNEL CHECK and

RAM PARITY ERROR messages when the segment that has caused the

problem cannot be isolated.

Ö OFFENDING SEGMENT:

This message is used in conjunction with the I/O CHANNEL CHECK and

RAM PARITY ERROR messages when the segment that has caused the

problem has been isolated.

Ö PRESS A KEY TO REBOOT

This will be displayed at the bottom screen when an error occurs that

requires you to reboot. Press any key and the system will reboot.

Ö PRESS F1 TO DISABLE NMI, F2 TO REBOOT

When BIOS detects a Non-maskable Interrupt condition during boot, this

will allow you to disable the NMI and continue to boot, or you can reboot

the system will the NMI enabled.

Ö RAM PARITY ERROR - CHECKING FOR SEGMENT ...

Indicates a parity error in Random Access Memory.

Ö Should Be Empty But EISA Board Found

PLEASE RUN EISA CONFIGURATION UTILITY

A valid board ID was found in a slot that was configured as having no

board ID.

F When this error appears, the system will boot in ISA mode, which allows

you to run the EISA Configuration Utility.

Ö Should Have EISA Board But Not Found

PLEASE RUN EISA CONFIGURATION UTILITY

The board installed is not responding to the ID request, or no board ID

has been found in the indicated slot.

A-4

Page 59

Appendix A: Post Message

F When this error appears, the system will boot in ISA mode, which allows

you to run the EISA Configuration Utility.

Ö Slot Not Empty

Indicates that a slot designated as empty by the EISA Configuration

Utility actually contains a board.

F When this error appears, the system will boot in ISA mode, which allows

you to run the EISA Configuration Utility.

Ö SYSTEM HALTED, (CTRL-ALT-DEL) TO REBOOT ...

Indicates the present boot attempt has been aborted and the system

must be rebooted. Press and hold down the CTRL and ALT keys and

press DEL.

Ö Wrong Board In Slot

PLEASE RUN EISA CONFIGURATION UTILITY

The board ID does not match the ID stored in the EISA non-volatile

memory.

F When this error appears, the system will boot in ISA mode, which allows

you to run the EISA Configuration Utility.

A-5

Page 60

Page 61

GA-586ATV

APPENDIX B: POST CODES

F EISA POST codes are typically output to port address 300h. ISA POST

codes are typically output to port address 80h.

POST Name Description

C0 Turn Off Chipset

Cache

1 Processor Test 1 Processor Status (1 FLAGS) Verification.

2 Processor Test 2 Read/Write/Verify all CPU registers except SS, SP,

3 Initialize Chips Disable NMI, PIE, AIE, UEI, SQWV.

4 Test Memory

Refresh Toggle

5 Blank video,

Initialize keyboard

6 Reserved

7 Test CMOS

Interface and

Battery Status

BE Chipset Default

Initialization

C1 Memory presence

test

C5 Early Shadow OEM Specific-Early Shadow enable for fast boot.

C6 Cache presence

test

8 Setup low memory Early chip set initialization.

OEM Specific-Cache control.

Test the following processor status flags

carry, zero, sign, overflow,

The BIOS will set each of these flags, verify they are

set, then turn each flag off and verify it is off.

and BP with data pattern FF and 00.

Disable video, parity checking, DMA.

Reset math coprocessor.

Clear all page registers, CMOS shutdown byte.

Initialize timer 0, 1, and 2, including set EISA timer to a

known state.

Initialize DMA controllers 0 and 1.

Initialize interrupt controllers 0 and 1.

Initialize EISA extended registers.

RAM must be periodically refreshed in order to keep