Page 1

D263S / D263SW / D332ST /

D332SWT

WHEEL LOADER

OPERATOR’S MANUAL

EN - Original language

GIANT D263S / D263SW / D332ST / D332SWT EN

P001306011

ART P001306011 - REV R20161021

Page 2

EC DECLARATION OF CONFORMITY

The undersigned herewith declares that the stated Wheel Loader is in conformity

with the requirements of the listed European Directives:

Machine data:

Model: GIANT D263S / D263SW / D332ST / D332SWT

Category: Wheel Loader

Manufacturer: TOBROCO Machines

Industrielaan 2, 5061 KC Oisterwijk, Netherlands

Directives:

2006/42/EC: Machinery directive

2000/14/EC: Noise emission

2004/108/EC: Electromagnetic compatibility

97/68/EC: Pollutant emission

The machine has the following technical characteristics:

Noise level (LWA): < 101 dB(A)

Vibration level: < 2,5 m/s2

Engine emission: Stage IIIA

Oisterwijk, 2016-01-20

A.J.J. Brock, general director

2

Page 3

EC Declaration of Conformity - - - - - - 2

1 Introduction ............................. 5

Preface - - - - - - - - - - - - - - - - -6

2 Applications............................. 7

Wheel Loader application - - - - - - - -8

Exclusions- - - - - - - - - - - - - - - -8

Public road - - - - - - - - - - - - - - -8

Working surface - - - - - - - - - - - - -9

Attachments - - - - - - - - - - - - - - 10

Operating the machine- - - - - - - - - 10

3 Operation ............................... 13

Machine components - - - - - - - - - 14

Functions - - - - - - - - - - - - - - - 15

ROPS + FOPS protection - - - - - - - 16

4 Safety ..................................... 17

Safety Signs- - - - - - - - - - - - - - 18

Safety precautions - - - - - - - - - - - 20

5 Technical data ....................... 33

Dimensions - - - - - - - - - - - - - - 34

Diesel engine - - - - - - - - - - - - - 36

Tyres - - - - - - - - - - - - - - - - - 36

General - - - - - - - - - - - - - - - - 37

Trailer - - - - - - - - - - - - - - - - - 37

Tipping loads - - - - - - - - - - - - - 38

Engine oil pressure warning light - - - - 48

Combination switch - - - - - - - - - - 49

Switches in cabin - - - - - - - - - - - 49

Fuses - - - - - - - - - - - - - - - - - 50

Engine cover- - - - - - - - - - - - - - 51

Engine oil - - - - - - - - - - - - - - - 51

Coolant Level - - - - - - - - - - - - - 52

Tyre pressure - - - - - - - - - - - - - 53

Wheel maintenance - - - - - - - - - - 53

Hydraulic oil level - - - - - - - - - - - 53

Grease points - - - - - - - - - - - - - 54

Refuel - - - - - - - - - - - - - - - - - 54

Driver's seat - - - - - - - - - - - - - - 55

Steering column - - - - - - - - - - - - 55

Pro-inching - - - - - - - - - - - - - - 56

Articulation lock bar - - - - - - - - - - 56

Tie down- - - - - - - - - - - - - - - - 58

Lifting - - - - - - - - - - - - - - - - - 59

Towing - - - - - - - - - - - - - - - - 60

7 Maintenance ...........................61

Performing maintenance - - - - - - - - 62

Engine- - - - - - - - - - - - - - - - - 62

Liquids- - - - - - - - - - - - - - - - - 63

Brake fluid - - - - - - - - - - - - - - - 63

Coolant - - - - - - - - - - - - - - - - 64

Engine oil - - - - - - - - - - - - - - - 64

Fuel - - - - - - - - - - - - - - - - - - 64

Hydraulic oil - - - - - - - - - - - - - - 64

Wheel nuts - - - - - - - - - - - - - - 65

Maintenance Schedule - - - - - - - - - 65

6 Commissioning ..................... 39

First inspection - - - - - - - - - - - - 40

Ignition switch - - - - - - - - - - - - - 40

Driving - - - - - - - - - - - - - - - - 41

Parking - - - - - - - - - - - - - - - - 42

Parking (“SW” models)- - - - - - - - - 43

Joystick - - - - - - - - - - - - - - - - 44

Attachment locking - - - - - - - - - - 44

ATTACHMENT POSITION- - - - - - - 45

Third function - - - - - - - - - - - - - 46

Fourth function (electrical) - - - - - - - 46

Dashboard - - - - - - - - - - - - - - 47

Alternator warning light - - - - - - - - 47

Engine temperature - - - - - - - - - - 48

Engine temperature warning light - - - 48

8 Malfunctions...........................69

Possible malfunctions - - - - - - - - - 70

9 Environment...........................71

Care for the Environment- - - - - - - - 72

10 Serial numbers.....................73

Serial number registration - - - - - - - 74

11 index .....................................77

3

Page 4

4

Page 5

1. INTRODUCTION

5

Page 6

1.Introduction

PREFACE

You have chosen for a GIANT Wheel Loader, ensuring versatile use and durability.

Thank you for your confidence in our products.

You will get the best benefit of this Wheel Loader by carefully following the safety,

maintenance and operation instructions in this manual.

We strongly recommend each operator to read this manual carefully before use.

Ensure that the Wheel Loader is always accompanied by this manual.

TOBROCO Machines is not responsible for damage and indirect damage caused

by operator error, lack of (skilled) maintenance and any other use other than

described in this manual. The liability of TOBROCO Machines is also void when

modifications or extensions are applied to the Wheel Loader or accessories by the

owner or any other third party without our written consent.

TOBROCO Machines continually strives to improve her products and services. We

therefore reserve the right to change the specifications in this user manual at any

time without prior notice. It is possible that the pictured drawings and photos do not

exactly match your Wheel Loader.

We are confident that you will be very satisfied with your new GIANT Wheel

Loader.

6

Page 7

2. APPLICATIONS

7

Page 8

2.Applications

WHEEL LOADER APPLICATION

The Wheel Loader is designed for lifting and moving:

• Substances such as sand or gravel with closed or open bucket

• Materials and parts on pallets with pallet forks

• Manure with a manure fork

• Kerbs with kerb clamp

• Stones with stone clamp

• Trees with tree harvester

• Hay bales with bale fork

Use the Wheel Loader only for the above work. The CE marking is not applicable

for other activities.

EXCLUSIONS

The Wheel Loader is not designed for the lifting and moving of:

• Persons and animals

• Products where toxic and / or explosive substances may be released during

handling

• Products containing hazardous substances

• Tanks with liquid

• Combustibles

• Other liquids and dangerous substances not mentioned above

PUBLIC ROAD

Use of public roads with the Wheel Loader is NOT allowed, unless the

Wheel Loader is equipped with a road kit which includes automotive

lighting.

Please note:

• Driving on public roads should be avoided wherever possible. The different

dimensions and performance can result in unexpected situations for other

road users.

• Driving on the highway is absolutely not allowed.

• Obey national and local traffic and road regulations on public roads. This might

imply additional features on the Wheel Loader.

• Verify whether you need an insurance for driving on public roads, in addition to

the standard insurance.

8

Page 9

2.Applications

CAUTION:

CAUTION:

• The maximum allowable speed on public road depends on local law and regulations.

• Shield the attachments.

• Read the instructions that come with the attachment.

• Put the attachment in a position which does not block the vision of the driver

and which will not endanger other road users.

• Use dimmed lights during the day where visibility is seriously restricted, and at

night.

Be aware of the local traffic regulations. Make sure that your machine

complies with the laws and regulations in your area.

WORKING SURFACE

• The Wheel Loader is designed for riding on flat, hard surfaces. Only drive on

slopes when the loader attachment is empty. In the event that the wheel loader

should drive on a slope, the maximum slope angle is 11.3º (20%).

• The stability of the Wheel Loader depends on the articulation angle, load and

the lifting height. For the maximum load see chapter “Technical Data”.

• The Wheel Loader is not designed to tow other vehicles except trailers with

specifications according to chapter “Technical Data”.

Driving on slopes should be avoided at all times! the risk of tipping

over increases extremely when driving on slopes.

9

Page 10

2.Applications

CAUTION:

ATTACHMENTS

Only original GIANT attachments and options

are allowed on the Wheel Loader:

• Earth bucket

• High-tip bucket

• Pallet fork

• Manure fork

• Feed- and manure scraper

• Auger bucket

• Kerb stone clamp

• Brick clamp

• Silage cutter

• Mixing bucket

• Straw blower

• Bucket brush

•Hay Bale Fork

• Bale grabber

TOBROCO Machines is excluded from any

liability for damage and consequential

damage due to non-GIANT products.

When using non-GIANT attachments it

is possible that specifications, such as

parallel system, tipping load and lifting

capacity are not being reached.

OPERATING THE MACHINE

1. Get on and off safely when entering or leaving the operator’s cab. Face the

machine. Always maintain a three point contact with the steps and handrails.

Do not use control levers as handles. Do not jump on or off the machine.

Never try to get on or off a moving machine.

2. Do not start engine or operate levers from anywhere other than the seat.

3. Before starting the engine, fasten the seat belt, make sure that the direction

lever is set in the neutral position, the parking brake switch is actuated and the

bucket is lowered to the ground.

4. Do not start engine by shorting across starter terminals.

5. Watch where you are going at all times. Watch for and avoid obstacles.

6. Never permit passengers on the machine. Keep bystanders away from the

machine during operation.

10

Page 11

2.Applications

7. When working around other machines, let the other operators know what you

are doing at all times.

8. Never allow anyone to get under or near the bucket or attachment when it is

raised.

9. When raising the bucket or attachment, take extra caution to prevent it from

touching overhead wires or other obstacles. Contact with wires may cause

fatal injuries.

10. Keep away from the muffler while the engine is running and immediately after

it has stopped.

11. Hazardous operation such as on dangerous terrain, beyond the load capacity

or contrary to the intended use of the machine must be avoided as it may

cause the machine to tip over.

12. Do not drive the machine close to edges of ditches or banks which may collapse under the weight of the machine, especially when the ground is loose or

wet.

13. Slow down for turns, uneven terrain and slopes to avoid tipping over.

14. When transporting a load, keep the loader bucket as low as possible to avoid

tipping over. Be extremely careful when working on inclines.

15. Operation on slopes can be dangerous. Rain, snow, gravel soft ground, etc.

will change the ground conditions. Do not operate the machine in questionable

ground conditions. If operating on a slope or ramp, always slow down, travel

straight up and down the incline and not across. Keep the bucket as low as

possible. If you do not follow these instructions, the machine can go out of

control and tip over.

16. Avoid turning on a slope.

17. Never perform digging or shoveling with the machine in the articulated condition, or the machine may tip over.

18. Never dig or shovel at high speed. Such operation can cause the machine to

lose stability and its rear wheels to lift off the ground, which may lead to serious personal injury or fatal accidents.

19. Do not go up or down a 20° or steeper hill. Otherwise, the machine may skid

sideways or turn on its side. If the ground is not level or is soft, limit the slope

below 11.3º (20%).

20. To avoid tipping over, do not operate the machine on any site where the terrain

cannot be ascertained, such as ground covered with seeds or snow and check

for hidden projections, dips, road shoulders, etc. beforehand, and take care

not to approach them during work.

21. Be sure to ease off the accelerator pedal at the end of filling in trenches or

areas at the edge of a steep slope or pond bank or at the brow of a hill. When

the external load is reduced, the machine speed will automatically increase,

therefore reduce speed to avoid entering ditches or tipping over.

11

Page 12

2.Applications

CAUTION:

22. To avoid the machine slipping or tipping over, do not operate the machine on

ungraded or soft terrain, such as land fills. Grade and compact the site beforehand at all times.

23. Do not run the engine indoors. Carbon monoxide gas from exhaust is colorless, odorless and deadly.

24. Check that no one is near the machine before starting the engine to avoid danger from the machine. Check that there are no flammable objects, such as

dead leaves, sheets of paper, or pieces of cloth near to the engine before starting the engine.

25. Be especially careful when reversing and watch the area behind the loader

exactly before starting to drive.

Caution with children

26. Serious accidents can occur if the operator does not pay attention to children

in the vicinity of the machine. Children are unpredictable!

27. Always keep an eye on children as they change their location continuously.

28. Make sure no children are within the working range of the machine.

29. Be extremely cautious when children approach the working area; stop working, if necessary.

30. Do not carry children on the machine.

31. Do not allow children to operate the machine.

32. Do not allow children to play around the machine.

Driving on slopes should be avoided at all times! the risk of tipping

over increases extremely when driving on slopes.

Only drive on slopes when the loader attachment is empty. In the event that the

wheel loader should drive on a slope, the maximum slope angle is 11.3º (20%).

12

Page 13

3. OPERATION

13

Page 14

3.Operation

123456789

1716

15

1413121110

18

19

20 23

22

21

MACHINE COMPONENTS

1. Tilt cylinder

2. Lifting arm

3. Dashboard

4. Steering wheel

5. Joystick control

6. Seatbelt buckle

7. Driver’s seat

8. Safety roof

9. Engine cover

10. Coupling pins

11. Attachment bracket

12. Wheel

13. Fuel tank filler cap

14. Articulation point

15. Steering cylinder

16. Battery

17. Hydraulic oil tank

18. Cooler

19. Engine exhaust

20. Diesel engine

21. Air filter

22. Drive pump

23. Work pump

14

Page 15

3.Operation

FUNCTIONS

This Wheel Loader is designed for lifting and moving heavy loads. Various

functions are powered by a diesel engine. All of these functions can be controlled

by the driver by means of a joystick, steering wheel, pedals, and various buttons.

These functions are:

• Forward and reverse drive

• Articulated steering

• Lifting and lowering

• Tilting of the tool carrier

• Locking the attachments

• Controlling / powering of attachments

The Wheel Loader is equipped with a dashboard, which contains various controls

and indicators.

The Wheel Loader is equipped with a lifting arm. The forces that can be provided

by the arm is strongly depending on the position of the lifting arm and the position

of the load.

Ensure at all times that the load is in the lowest possible position when driving and/

or steering. As the driver you are responsible for the safe operation of the

machine.

15

Page 16

3.Operation

FOPS: EN ISO 3449

ROPS: EN ISO 3471

ROPS + FOPS PROTECTION

The operator is protected in case the Wheel

Loader should tip over. The safety structure is

tested according to the "EN ISO 3471"

standard (ROPS: Roll-over protective

structures).

The operator is protected against falling

objects. The safety structure is tested

according to the "EN ISO 3449" standard

(FOPS: Falling-object protective structures).

All models are tested according to EN ISO

3449 (FOPS) and according to the EN ISO

3471 (ROPS).

A. Safety roof

B. Cabin

ROPS = Roll Over Protective Structure:

Protects the user if the Wheel Loader

unexpectedly tips over.

FOPS = Falling Objects Protective Structure:

Protects the driver against falling objects.

16

Page 17

4. SAFETY

17

Page 18

4.Safety

CAUTION:

CAUTION:

SAFETY SIGNS

This chapter explains the machine sign (safety decals) on the machine. To work

safely with the Wheel Loader and when carrying out maintenance it is essential

that you follow all instructions in this manual.

Warning! Risk of injury if the safety decals are no longer clearly visible or legible.

Immediately attach new safety decals!

The following icons indicate safety hazards for man and machine:

Risk of accidents and personal injuries

Risk of technical damage to the Wheel Loader

18

Page 19

5103010-01-A

5103010-13-A

5103010-03-A

5103010-05-A

5103010-04-A

5103010-06-A

5103010-11-A

5103010-15-A

5103010-10-A

5103010-13-A

4.Safety

19

Page 20

4.Safety

CAUTION:

CAUTION:

CAUTION:

CAUTION:

5103010-13-A

SAFETY PRECAUTIONS

Risk of serious injury.

Read the manual of the Wheel Loader thoroughly before using the

machine. This way you know exactly how to operate the Wheel

Loader safely.

Risk of serious injury.

For maintenance work: Stop engine, remove the ignition key and put

the Wheel Loader on the parking brake. See the user manual. This

prevents dangerous situations which can arise if the Wheel Loader

suddenly moves or when the lifting arm suddenly goes down. Also

think about unforeseen actions by others.

Risk of serious injury by collision.

Ensure that bystanders keep at least 10 meters distance from the

travel path of the Wheel Loader. Large bulky loads can interfere with

the driver’s sight.

Risk of injury due to entrapment by moving parts.

Operate the controls only from the driver’s seat. Ensure that

bystanders keep clear within a radius of 4 meters from the Wheel

Loader.

20

Page 21

CAUTION:

Risk of serious injury.

CAUTION:

CAUTION:

CAUTION:

Before driving, make sure you sit correctly in the driver’s seat

and always have your seat belt fastened. Make sure the

seat, pedals and your shoes are free of contaminants which

can cause accidents caused by slipping.

Risk of serious injury when overloading the

Wheel Loader.

The load on the Wheel Loader must not weigh more than

indicated in section ‘Technical Data’. Make sure the tool is

evenly loaded and balanced.

4.Safety

Risk of serious injury.

Hold the attachment approximately 30 cm above the ground when

driving over the road.

Risk of serious injuries on slopes.

The Wheel Loader is designed for working on flat and hard surfaces.

The maximum gradient is 3° at maximum load, driving with the lowest

speed. Larger inclinations are possible with smaller loads, at the

discretion and responsibility of the driver. Stay at the “high” side

during transport on a slope.

21

Page 22

4.Safety

CAUTION:

CAUTION:

CAUTION:

CAUTION:

Risk of injury from involuntary movement.

Injury may result due to lack of traction and braking force of the Wheel

Loader. Never drive across a slope. Only drive perpendicular (right)

up or down a slope.

Risk of serious injury when tipping over.

The Wheel Loader can tip over when riding on an uneven or damaged

surface. Never drive across a slope. The maximum angle of

inclination to ride is highly dependent on:

• The loading, weight and balance of the load.

• The driving style and speed of the driver.

• Circumstances and the capacity of the soil (such as loose sand)

and soil humidity.

Pay attention to your surroundings!

Wear clothes in which you feel good and in which you can move easily.

Risk of hearing damage.

This Wheel Loader can produce sound louder than 80 dB(A).

The driver is therefore obliged to be wearing ear protection.

22

Page 23

CAUTION:

Risk of serious injury from entrapment or fall.

CAUTION:

CAUTION:

It is not allowed to lift or transport persons with or on the Wheel

Loader.

Risk of serious injury from electrical power lines and other

conductors.

Keep a safe distance from electrically conductive objects such as

power lines, pylons and lamps. Nominal voltage safety distances:

• 0 to 1000 V: 1.0 m

• 1 kV to 110 kV: 3.0 m

• 110 kV to 220 kV: 4.0 m

• 220 kV to 380 kV: 5.0 m

• When unknown: 5.0 m

4.Safety

Risk of serious injury.

The hydraulic system operates under high pressure. A

leaky hose, pipe or coupling can cause serious injuries.

Prior servicing, the system has to be depressurised

completely!

A high pressure jet (up to 400 bar) easily penetrates

gloves, clothing and skin which causes serious injury and poisoning.

23

Page 24

4.Safety

CAUTION:

CAUTION:

CAUTION:

CAUTION:

CAUTION:

Risk of injury by burning.

The hydraulic components, hoses, piping, engine and exhaust are

very hot at operating temperatures.

Risk of damage.

When hearing an unusual noise: Immediately shut down the engine and check the

Wheel Loader and the hydraulic system for leaks. Check the lift and tilt parts for

damage, cracks and bends. Lower lift arm before inspection!

Prevent damage.

Tighten nuts and bolts periodically. See section ‘Maintenance’.

Prevent damage.

Check daily:

• Fixings and hinges of the lift and tilt parts of the Wheel Loader

• The attachment bracket for damage and bends

• Lift and tilt cylinders

• The hydraulic system for any damage or leaks

Risk of injury.

Ensure the Wheel Loader and its parts are fully and

correctly supported when doing maintenance. Make sure

the handbrake is applied.

24

Page 25

4.Safety

CAUTION:

CAUTION:

CAUTION:

CAUTION:

Risk of crushing.

• Avoid entrapment by the fan of the radiator.

• Risk of burns from hot engine parts, radiator or exhaust.

Fire hazard!

• Stay away from the fuel tank with cigarette lighter, match or other open fire.

• Only fill the fuel tank in a well-ventilated area (preferably in the open air).

• Keep the Wheel Loader free from combustibles.

Fire hazard!

Danger in flammable working environment. The Wheel Loader produces hot

exhaust gases and possible sparks from the exhaust. Keep the Wheel Loader free

of combustible substances. Be aware of flammable substances in the environment

such as dust, straw etc.. The Wheel Loader can optionally be equipped with a

holder for a fire extinguisher.

Risk of carbon monoxide (CO) suffocation.

People can be seriously injured when the exhaust gases are not sufficiently

removed. Always provide fresh air in the surroundings of the Wheel Loader.

25

Page 26

4.Safety

CAUTION:

CAUTION:

Danger when charging battery.

An explosive gas is being formed during charging of the

battery. Cigarettes and open flames are prohibited! Only

charge the battery in a well-ventilated area.

When handling batteries:

• Avoid skin contact with battery fluid. Wear protective

clothing, such as safety glasses and gloves. The liquid is a highly corrosive

acid. Upon contact, wash immediately with soap and water.

• In case of contact with eyes, rinse immediately with running water for at least

10 minutes and immediately get medical attention. Provide sufficient water and

soap and make sure there is assistance in vocal range when performing work.

• Prevent shorting (sparking), ensure that no electrical connection between the

battery poles is made. Make sure that no metal objects touch the battery, causing a spark or short circuit with the possible consequence of explosion.

• Any conductor (metal) contacting both poles will get extremely hot. Remove

personal items such as rings, bracelets, necklaces and watches when handling batteries.

Danger of personal injury.

One can be injured if the cable diameter or the electrical connection of the rectifier,

fuses, earth connection etcetera has not been carried out correctly.

26

Page 27

4.Safety

CAUTION:

CAUTION:

Risk of serious injury!

Do not let the Wheel Loader be controlled by:

• Persons under the age of 16.

• Persons between the age of 16 to 18 years without

supervision from any (experienced) person over 18

years.

• Persons without Wheel Loader experience and without

supervision.

• Persons of who can be expected that they are not aware of the dangers of a

Wheel Loader, such as for example a temporary workforce.

The Wheel Loader may only be driven by experienced drivers who have read this

manual thoroughly and after you, the owner of Wheel Loader, have given a

complete instruction on the operation and safety of the Wheel Loader.

The owner of the Wheel Loader is responsible for the fact that only trained and

authorized persons are allowed to drive Wheel Loader.

Risk of serious injury.

If safety instructions are not passed to other drivers, it can

lead to serious injury. Let other drivers at all times read this

manual thoroughly before they control the Wheel Loader.

27

Page 28

4.Safety

CAUTION:

CAUTION:

CAUTION:

Prevent injury.

Use of public roads with the Wheel Loader is NOT allowed, unless the Wheel

Loader is equipped with the country-specific “Roadway Package”, supplied by the

manufacturer. Driving on public roads with a loaded attachment (bucket, pallet fork

etc.) is NOT allowed.

Please note:

• The different dimensions and handling cause unexpected situations for other

road users. Driving on public roads should therefore be avoided as much as

possible.

• Driving on the highway is not permitted.

• When driving on public roads, the Wheel Loader is subject to the governmental and local traffic rules and requirements.

• In addition to the current insurance policies, an insurance for driving on public

roads may be required.

• The maximum speed of an earthmoving machine is 25 km per hour.

• Attachments should be protected. Read the manual of the attachment.

• The attachment should be in a position such that it will not interfere with the

driver’s sight or endanger other road users. Also make sure that the vehicle

lighting remains visible for other road users. Read the manual of the attachment.

Risk of serious injury.

Adjust your speed according to road conditions.

• Make sure you always have control of the Wheel Loader.

• Reduce your speed on rough terrain and when taking sharp turns.

• Be especially careful when manoeuvring and reversing.

• Ensure a good overview of the work environment.

Risk of injury.

When the safety icons are not (longer) clearly visible or legible, immediately apply

new decals (contact your dealer).

28

Page 29

4.Safety

CAUTION:

CAUTION:

CAUTION:

5103010-01-A

Risk of injury.

Maintenance and repair work may only be performed by professionals who are

approved by TOBROCO Machines.

Only original and TOBROCO Machines approved components are allowed to be

used on the Wheel Loader.

Risk of injury.

The driver provides the limits for ‘safe working’ with the Wheel Loader. Do not take

any risks. Take care with obstacles, uneven terrain and in crowded areas.

Risk of injury by falling load.

• The driver can be struck by falling objects.

• It is not allowed to stack and lift (multiple) objects or

loose cargo above the attachment’s height.

29

Page 30

4.Safety

CAUTION:

CAUTION:

Risks when handling cargo.

Working with the Wheel Loader may entail additional risks. Through the load it is

also possible that driving characteristics and responsiveness of the Wheel Loader

is strongly influenced.

Therefore observe the following precautions:

• The load on the Wheel Loader must not weigh more than indicated in section

“Technical data”. Make sure the load in/on the tool is evenly balanced.

• Move the Wheel Loader with the tool up to 30 cm above the ground.

• Adjust your speed according to road and environmental conditions.

• Make sure you always have full control over the Wheel Loader.

• Reduce your driving speed on rough terrain and sharp turns.

• Be especially careful when manoeuvring and reversing.

• Provide a good overview on the work environment.

• The driver determines the limits for ‘safe working’ with the Wheel Loader.

• Do not take risks. Take care with obstacles, uneven terrain and crowded

areas.

• It is not allowed to transport (multiple) objects or loose cargo that protrudes

above the attachment. The Wheel Loader requires a (FOPS) safety roof or

cabin when using certain attachments. The Wheel Loader can tip over when

driving over uneven or damaged terrain. Moderate your speed.

• There is a risk of injury from involuntary movement due to lack of tension and

braking force of the Wheel Loader.

• Only drive perpendicular to an incline or slope. Do not drive across slopes.

Danger of technical damage!

Never tilt the attachment bracket when driving

without attachment and with fully retracted lifting

arm. Especially when the Wheel Loader is

equipped with a special attachment bracket

(e.g. Euro bracket). This can severely damage

the tyre!

30

Page 31

4.Safety

CAUTION:

Danger of technical damage!

Welding activities should only be performed by qualified

personnel! Ensure supervision by qualified personnel

when welding on or nearby containers which contain

flammable materials! Contact your dealer if you have any

questions.

• Disconnect the positive terminal from the alternator

before starting any welding activities on the loader.

• Turn the main mass switch OFF.

• Attach the welding clamp as close as possible to the welding area.

• The welding current may not pass through any bolt, joint, gear or hydraulic cylinder.

• After welding, reconnect all the electrical connections and check their function.

31

Page 32

4.Safety

32

Page 33

5. TECHNICAL DATA

33

Page 34

5.Technical data

DIMENSIONS

Nº Dimension Standard X-TRA

A

Wheel base

B Total length 2670 2720

C Length with bucket 3360 3390

D Seat height 1140 1140

E Height 2230 2230

F Frame height 1550 1150

G Dump height 1830 1360

H Height of pivot point 2560 2070

I Height with bucket 3140 2640

J Rollback angle, low 41º 44º

K Rollback angle, high 52º 55º

L Dump angle 44º 41º

M Angle of departure 27º 27º

N Diameter of standard wheel 670 670

O Turning radius with bucket 2260 2470

P Outside turning radius 1900 2260

Q Inside turning radius 1040 1160

1370 1420

R Track width 815 800

S Total width 890 1100

All dimensions in mm, measured on standard wheels.

34

Page 35

5.Technical data

35

Page 36

5.Technical data

DIESEL ENGINE

SSW

Make / Model Kubota D1105 Kubota D1105-T

Power 19 kW / 25 hp 24 kW / 33 hp

Rotational speed min. 1050 rpm 1050 rpm

Rotational speed max. 3000 rpm 3000 rpm

Displacement 1123 cm³ 1123 cm³

Tor que 72 Nm @ 2100 rpm 88 Nm @ 2050 rpm

TYRES

Type Tyre pressure Vehicle width

SSWSW X-TRA

7x12 AS 340 kPa / 3,4 bar 89 cm * 89 cm * ---

27x8.5-15 SKID 340 kPa / 3,4 bar 97 cm --- ---

26x12-12 SKID 340 kPa / 3,4 bar 110 cm 110 cm 110 cm

26x12-12 AS 300 kPa / 3,0 bar 110 cm 110 cm 110 cm *

26x12-12 LG 300 kPa / 3,0 bar 110 cm 110 cm 110 cm

27x10.5-15 AS 420 kPa / 3,0 bar --- 103 cm 103 cm

10x75-15.3 AS 400 kPa / 4,0 bar --- 101 cm 101 cm

300x60-12 TR 320 kPa / 3,2 bar 110 cm 110 cm 110 cm

31x15.5-15 TR 300 kPa / 3,0 bar --- 123 cm 123 cm

31x15.5-15 AS 300 kPa / 3,0 bar --- 123 cm 123 cm

* Standard tyres

36

Page 37

GENERAL

5.Technical data

D263S D332ST

Engine

Power train

Drive hydraulics 84 l/min, 380 bar

Work hydraulics 42 l/min, 170 bar

Driving speed 12 km/h

Operating weight 1960 kg 1980 kg

Shipping weight 1480 kg 1500 kg

D263SW D263SW X-TRA D332SWT D332SWT X-TRA

Engine

Power train

Drive hydraulics 84 l/min, 380 bar

Work hydraulics 42 l/min, 170 bar

Driving speed 12 km/h

Operating weight 1850 kg 1900 kg 1850 kg 1900 kg

Shipping weight 1500 kg 1550 kg 1500 kg 1550 kg

Hydrostatic with automotive control

Hydrostatic with automotive control

Kubota diesel engine

Kubota diesel engine

TRAILER

Max. vertical load coupling towing device 100 kg

Max. trailer weight unbraked 750 kg

Drive at walking pace with attached trailer.

Driving with a trailer on public roads is NOT allowed.

37

Page 38

5.Technical data

CAUTION:

TIPPING LOADS

Tipping loads are measured in straight position, without additional counter weights.

D263S D332ST D263SW D263SW

X-TRA

S 1040 kg 1060 kg 1040 kg 1500 kg 1040 kg 1665 kg

T 800 kg 810 kg 800 kg 1100 kg 800 kg 1100 kg

U 580 kg 590 kg 580 kg 750 kg 580 kg 750 kg

V 430 kg 435 kg 430 kg 550 kg 430 kg 550 kg

W 1375 kg 1400 kg 1375 kg 1500 kg 1375 kg 1500 kg

X 835 kg 850 kg 835 kg 900 kg 835 kg 900 kg

Y 595 kg 615 kg 595 kg 650 kg 595 kg 650 kg

D332SWT D332SWT

X-TRA

Lifting arm drift

The lifting device slowly drops. Depending on the load can be up to 1

cm per minute (measured at the point "U"). Keep this in mind when

parking the machine with a raised load.

38

Page 39

6. COMMISSIONING

39

Page 40

6.Commissioning

CAUTION:

FIRST INSPECTION

• The Wheel Loader has been lubricated, adjusted and

piloted by your supplier.

• Before use, remove the articulation lock bar (transport

protection).

• The Wheel Loader is powered by a diesel engine. This

engine is equipped with an electric starter.

• Always check the oil levels before you start (see section ‘Maintenance’).

• Make sure the fuel tank contains sufficient fuel.

• Beware of fire! Stay away from the fuel tank with cigarette lighter, match or

other spark-inducing items. Keep the articulated loader free of combustibles.

• The Wheel Loader is top heavy and tilt sensitive. Especially with the loaded

tool in the upper position. Make sure the centre of gravity of the load to be

lifted is in the middle of the tool. Note that the ground under the Wheel Loader

is sufficiently load bearing and flat.

• Contact your dealer in case you have any questions.

IGNITION SWITCH

A. Stop engine

B. Contact on

C. Glowing (preheating)

D. Start engine (spring loaded)

E. Parking (unused)

Starting order:

1. Check whether the direction switch is set to

neutral

2. Turn the ignition switch to position C and

hold this for about 5 seconds

3. Turn the ignition switch to position D and

hold this position until the engine has

started

4. Release the ignition switch; it will return in it's previous position

Never press the accelerator all the way when you start. This causes

damage to the engine.

40

Page 41

6.Commissioning

DRIVING

Make sure you are aware of all hazards and operation of the Wheel Loader before

driving. Make sure you are familiar with the control devices of the Wheel Loader:

• Parking = parking brake

• Braking = left foot pedal

• Accelerating = right foot pedal (inching pedal)

Accelerator pedal

Upon depressing the accelerator pedal (1), the

coupling with the engine is automatically made

and the selected function is powered. Releasing

the accelerator pedal will automatically slow

down the Wheel Loader.

Inching pedal

Depressing the inching pedal (2) disconnects

the hydraulic drive. This way the vehicle speed

can be adjusted while keeping a constant

engine speed.

41

Page 42

6.Commissioning

PARKING

Make sure you stop at the desired location.

1. Apply the parking brake

2. Set the selector switch to “neutral” (mid position)

3. Turn the ignition switch to “O” and wait until

the engine has stopped.

42

Page 43

PARKING (“SW” MODELS)

Make sure you stop at the desired location.

1. Press the parking brake button to apply the

parking brake

2. Set the selector switch to “neutral” (mid position)

3. Turn the ignition switch to “O” and wait until

the engine has stopped.

6.Commissioning

43

Page 44

6.Commissioning

CAUTION:

JOYSTICK

The joystick controls the following functions:

1. Tilt bucket upwards

2. Raise bucket

3. Tilt bucket downwards

4. Lower bucket

5. High / low gear (optional)

6. Forward / neutral / reverse

7. Drive reset switch, 4th function electrical

(optional)

ATTACHMENT LOCKING

mechanical lock

To (un)lock attachments; turn ball valve

(A) upwards.

• Locking: Move lever (B) to the right

to move the locking pins (C) outward.

• Unlocking: Move the lever (B) to

the left to move the locking pins (C)

inward.

• Verify whether the attachment has

been locked correctly.

Verify whether the attachment has been locked correctly.

44

Page 45

ATTACHMENT POSITION

When accessing public road:

6.Commissioning

1. Place the attachment approximately 15 cm above the road

2. Make sure that the protection is in place

3. Lock the position by turning the valves

45

Page 46

6.Commissioning

A

THIRD FUNCTION

To activate the 3rd function, move ball valve (A)

down.

Move the lever (B) to operate the 3rd function

(C).

FOURTH FUNCTION (ELECTRICAL)

(Optional)

• Press the button on the

joystick and move joystick left or right to

operate the 4th function

(A).

46

Page 47

6.Commissioning

DASHBOARD

The following switches, instruments and warning lights are placed on the

dashboard:

1. Parking brake

2. Engine temperature

3. Direction indicator, left *

4. Alternator warning light

5. Reverse drive

6. Engine oil pressure

warning light

7. Engine temperature

warning light

8. Glow plug indicator

9. Direction indicator, right

10. Forward drive

11. Differential lock *

12. Rotating beacon switch *

13. Work light switch

14. Alarm light switch *

15. Lighting fuses

16. Fuel gauge

17. High beam *

18. Hour meter

19. Road lights *

20. Combination switch *

* optional

Once you turn on the ignition, all indicator lights will be lit. Once the engine is

running, the warning lights will go out.

ALTERNATOR WARNING LIGHT

When this warning light turns on, the alternator is malfunctioning or the machine is

not running!

Stop the engine and check the V-belt, if necessary contact your GIANT dealer.

47

Page 48

6.Commissioning

ENGINE TEMPERATURE

During normal operation the meter is pointing in the middle, between 40 °C and

90 °C.

Stop the engine if the meter reaches the red zone. Check the coolant level and the

V-belt which powers the water pump. Check cooling system for leaks.

ENGINE TEMPERATURE WARNING LIGHT

This warning light indicates that the engine is too hot. Stop the engine, check the

coolant level and fan belt. Check the cooling system for leaks and/or refill with

coolant. See section ‘Maintenance’.

ENGINE OIL PRESSURE WARNING LIGHT

This warning light indicates an insufficient oil pressure. Stop the engine

immediately. Check the oil level every day with the dipstick and add oil if

necessary. See section ‘Maintenance’.

48

Page 49

COMBINATION SWITCH

(option, otherwise horn button)

1. Klaxon

2. Road lights off

3. Parking lights

4. Dipped-beam headlamps

5. Right turn signal

6. Left turn signal

7. Headlamp flasher

8. Main-beam headlamps

SWITCHES IN CABIN

Switches located at the right side of the seat

(Options with cabin)

• Main power switch (ground / mass)

• Work lights rear (roof)

• Work lights front (roof)

• Front windshield wiper

6.Commissioning

49

Page 50

6.Commissioning

CAUTION:

FUSES

The Wheel Loader contains the

following fuses, which are located

at various locations:

A. Fuses in steering column

B. Fuses on dashboard

C. Fuses at right side of the

driver’s seat

1. Ignition switch

2. Dashboard instruments

3. Rotation beacon

4. Reset, Fourth function, Differential lock

5. Brake light, Parking brake

6. Joystick

7. Fuel feed pump

8. Stop solenoid

9. Horn, Reversing alarm

10. Direction indicators

11. Work light

12. Automotive lighting

13. Front position lamp

14. Front position lamp

15. High beam

16. High beam

17. Low beam

18. Low beam

19. Interior lighting

20. Radio

21. Radio

22. Switch for additional equipment

23. Switch for additional equipment

24. Front windshield wiper

25. Rear windshield wiper

26. Work light cab rear

27. Work light cab front

28. 12V Auxiliary

29. Ventilation

30. Spare

Danger! Fire hazard!

Never replace a fuse wire with one of a higher rating. This can cause a fire!

50

Page 51

ENGINE COVER

To open:

• Stop the engine

• Unlock with key

• Press the unlock button and lift the engine cover

by hand

To Close:

• Close the hood (you will hear a “click”)

• Lock with key

ENGINE OIL

Check only with the Wheel Loader on a level

surface and the engine is turned off for at

least 3 minutes. The oil level should be

between the markers. Refill if needed.

6.Commissioning

51

Page 52

6.Commissioning

CAUTION:

COOLANT LEVEL

Check the coolant level of the engine cooler. Make

sure the coolant has been divided equally

throughout the chambers of the cooler (see

image).

It is dangerous to open the cooler closure when the engine is warm!

The coolant level in the overflow tank should

be somewhere between the minimum and

maximum level.

Caution! The overflow tank is not a

reserve tank. Always check the coolant

level in the engine cooler.

52

Page 53

6.Commissioning

TYRE PRESSURE

Tyre pressure affects fuel consumption of the Wheel Loader. It has also effects the

life of the tyres and axes. See section Technical Data for the correct tyre pressure.

WHEEL MAINTENANCE

Wheel bolts have to be re-tightened every 50 hours. See

section "Maintenance".

HYDRAULIC OIL LEVEL

Check only when engine is cold and with the tool

in the lower position. Check the oil level with the

dipstick of the oil filler cap (under the hood, on

the left). The level should be within the lower

5 cm of the dipstick.

53

Page 54

6.Commissioning

CAUTION:

5103010-25-A

GREASE POINTS

The Wheel Loader is to be lubricated

weekly

• Main pivot linkage

• Boom cylinder

• Boomerang

• Locking pens

• Tool bracket hinge

• Lifting cylinder

• Steering cylinder

Grease all indicated grease points

weekly. Oil all other moving parts

regularly, such as pedals, handles and

hinges according to the intensity of use.

All lubrication points are indicated by a yellow decal with a

grease pump:

at the following points:

REFUEL

1. Use your key to unlock and remove the fuel cap

2. Fill the tank with diesel

3. Close the fuel cap tightly and lock with key.

Use only clean, high quality diesel for the Wheel Loader. It is recommended to use an additional filter when refuelling.

54

D

Page 55

DRIVER'S SEAT

Adjust the seat to suit your personal preference:

1. Horizontal adjustment

2. Armrest adjustment

3. Backrest adjustment

4. Suspension adjustment

STEERING COLUMN

Adjust the steering column to suit your personal needs:

1. Take place on the driver's seat

2. Pull the lever (A) towards you

3. Tilt the steering column in position

4. Push the lever (A) away from you

6.Commissioning

55

Page 56

6.Commissioning

CAUTION:

Pro-Inching®

PRO-INCHING

Pro-Inching is a combination of a hand throttle

and hand inching and is extremely suitable for

the use of hydraulically powered implements

like sweepers and mowers. Never use the

Pro-Inching function on public roads.

How does it work?

The hand throttle lever is used to increase the

engine speed. The machine doesn’t move at

this moment. The accelerator pedal

automatically changes into a driving pedal

and allows you to comfortably control the

vehicle speed. The remaining power is used

for powering the attachment.

Do not use Pro-Inching on public

roads! The machine can react differently than usual.

ARTICULATION LOCK BAR

The articulation lock bar must be mounted before transporting the Wheel Loader

(i.e. on a conveyor). This is also applicable when lifting the Wheel Loader.

56

Page 57

6.Commissioning

Before commissioning the Wheel Loader you must remove the articulation lock bar

and place it in the appropriate holder.

57

Page 58

6.Commissioning

CAUTION:

TIE DOWN

The Wheel Loader is equipped with eyelets for fixation to a trailer or other transport

platform.

Preparations

Make sure you have addressed all issues stated:

• Place the Wheel Loader in a straight position on the trailer

• Turn off the engine and apply the parking brake

• Mount the articulation lock

• Tie down the machine at the front and rear, using the appropriate eyelets‘

Caution! Lower the lifting arm for transport!

58

Page 59

6.Commissioning

5103010-23-A

LIFTING

The lifting of the Wheel Loader is only permitted if the following conditions are met:

• The transport lock has been fitted correctly

• The lifting device has sufficient lifting capacity (minimum operating weight)

• The lifting chains has sufficient lifting capacity (minimum operating weight)

• All attachments are disconnected

• There is no loose lying object present on the Wheel Loader (danger of falling

objects during lifting)

• There are no bystanders near the Wheel Loader when lifting.

• A safe distance is kept from the machine when lifting.

The Wheel Loader must be lifted evenly (horizontally) by using the front and rear

lifting points

Lifting points are marked with the following symbol:

59

Page 60

6.Commissioning

CAUTION:

CAUTION:

2

1

TOWING

Towing the Wheel Loader is only allowed to remove it out of a danger

zone.

Preparations

Before towing you need to open the bypass of

main drive pump:

• Turn off the engine

• Open the engine cover

• Fold the seat forward

• Turn nut (1) loose, making a half turn counter clockwise.

• Loosen the hex bolt (2) clockwise until the

bolt touches the spring plate (this is the case

if you feel resistance).

• Now turn the hex bolt another half a turn in.

The spring is now pressed and the bypass is

activated.

• Turn the nut (1) clockwise to secure with a

force of 22 Nm ('hand tight').

How to tow

• Mount the towing cable to the trailer coupling (back of machine) or the towing

eyelets (front or rear).

• Tow with a maximum speed of 3 km/h (walking speed)

• Tow the articulated loader until the danger zone has been left (max. 200

meters)

• Turn the bolt of the bypass back to the old position.

Caution! The pump may become hot during towing!

60

Page 61

7. MAINTENANCE

61

Page 62

7.Maintenance

PERFORMING MAINTENANCE

Periodic maintenance should be performed by a licensed and qualified dealer. An

overview of all GIANT dealers can be found at www.tobroco.nl.

You can perform the following maintenance tasks yourself:

• Pivot points - greasing

• Wheel nuts - tightening

• Coolant - add or replace

• Motor Oil - add or replace

• Hydraulic filter - replace

• Hydraulic Oil - add or replace

• Air filters - clean or replace

• Cyclone filter - clean

• Radiator and fan - clean

Contact your dealer in case of any doubt.

ENGINE

Maintenance according to schedule

Add / replace engine oil

A. Filler cap

B. Oil dipstick

C. Drain plug

62

Page 63

7.Maintenance

CAUTION:

LIQUIDS

Overview

Engine oil SAE 10W-40 API CF // MIL-L-2104C // ACEA A2/B2,

A3/B3

Fuel

Hydraulic oil VG 46 DIN 51524: part 3 // ISO 11158: type

Axles and gearbox oil SAE 85W-90 LS API GL-5 // ZF TE-ML 05C/12C/16E

Brake fluid VG 46 DIN 51524: part 3 // ISO 11158: type

Coolant

Diesel EN 590 // GB 252 // ASTM D975 2-

D // JIS K 2204

HV

HV

-26 °C Standard engine coolant

BRAKE FLUID

The braking system of the wheel loader works with ordinary hydraulic oil.

Use absolutely no standard brake fluid (like DOTx)!

63

Page 64

7.Maintenance

COOLANT

Standard used coolant gives protection up to -24°C (-12°F). There are two types of

anti-freeze available; use the permanent type (PT) for this engine. When the antifreeze is mixed with water, the antifreeze mixing ratio must be less than 50%.

Vol %

Anti-freeze

40 -24 -12 106 222

50

Freezing Point Boiling Point

°C °F °C °F

-37 -37 108 226

ENGINE OIL

The engine oil should have properties of API classification “CF” or ACEA A3/B3

grades or higher. Change the type of engine oil according to the ambient

temperature:

above 25°C (77°F) SAE30 or SAE10W-30 / SAE 15W-40

0°C to 25°C (32°F to 77°F) SAE20 or SAE10W-30 / SAE 15W-40

below 0°C (32°F) SAE10 or SAE10W-30 / SAE 15W-40

FUEL

Standard diesel fuel according to one of the following technical specifications:

•EN590

• ASTM D975 2D

• JIS K 2204

HYDRAULIC OIL

The standard hydraulic oil used has viscosity class “VG 46”. Change the type of

hydraulic oil according to the (average) ambient temperature:

above 25°C (77°F) VG 68

64

Page 65

0°C to 25°C (32°F to 77°F) VG 46

CAUTION:

below 0°C (32°F) VG 32

WHEEL NUTS

Maintenance according to schedule

Correct tightening torque:

Wheel nut Torque

M14 150 Nm (111 lbf.ft)

M16 200 Nm (148 lbf.ft)

M18 280 Nm (207 lbf.ft)

M20 450 Nm (332 lbf.ft)

Keep the thread clean and free from damage.

7.Maintenance

MAINTENANCE SCHEDULE

The following lists are intended as an indication of the maintenance intervals.

Intensive use or use in extreme conditions requires shorter maintenance intervals!

65

Page 66

7.Maintenance

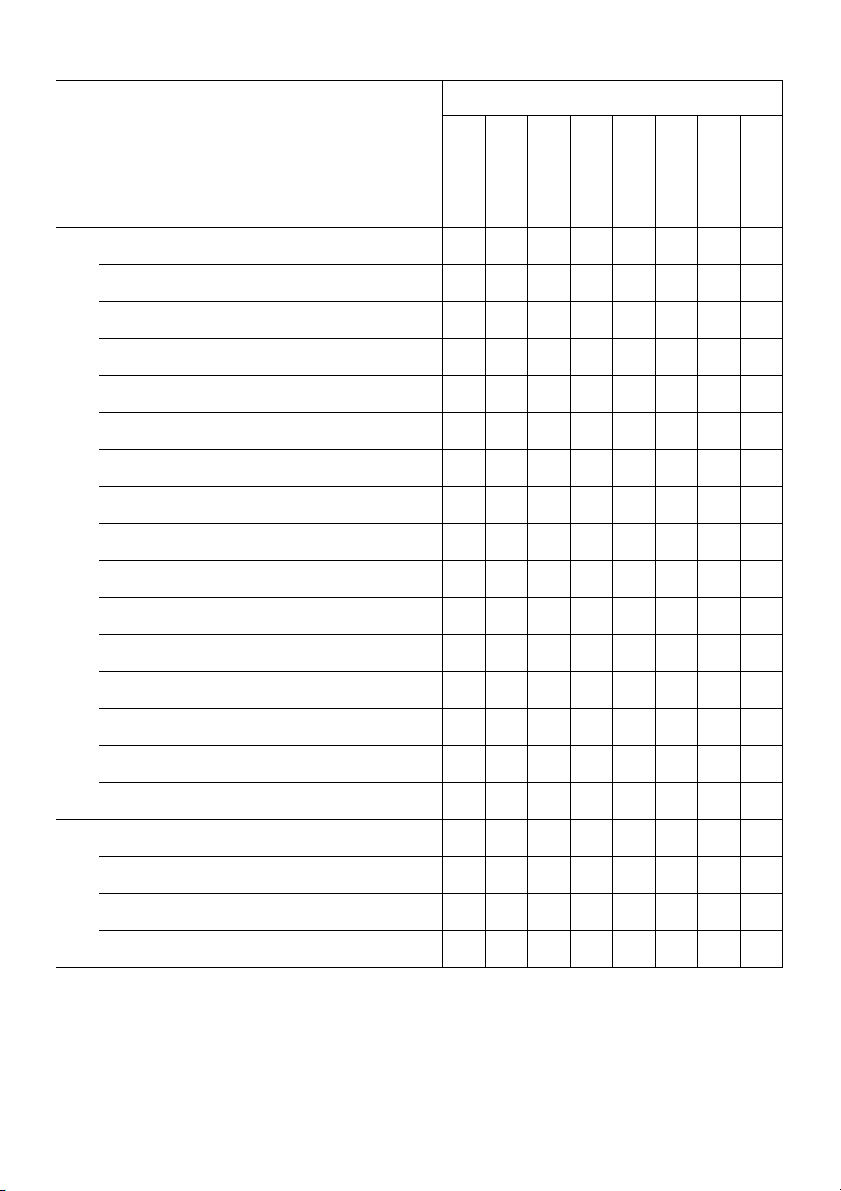

C = Check and clean if necessary

R = Replace

F = First time / initial interval

* = Only for vehicles with wheel motors

** = If applicable

First 50

Operating hours

Every 100

Every 250

Every 500

Every 750

Every 1000

Every 3000

Yea rly

Engine oil RR R

Engine oil filter RR R

Cyclone filter ** CC

Main air filter CR R

Safety air filter ** CR R

Fan V-belt ** CR R

Engine cooler CC

Coolant

Coolant level

Engine

Oil level

Valve clearance

Injection nozzle and pressure

CC C

CC

RR

C

C

Turbocharger **

Injection pump

Engine suspension

Engine speed

Fuel pre-filter (coarse filter)

Main fuel filter (fine filter)

Fuel lines

Fuel system

Drain water from fuel tank

66

C

C

CC

C

RR

R

CC

CC C

Page 67

7.Maintenance

C = Check and clean if necessary

R = Replace

F = First time / initial interval

* = Only for vehicles with wheel motors

** = If applicable

Dashboard warning lights

Dashboard instruments

Lighting

Electrics

Battery

Hydraulic oil filter

Suction screen

Hydraulic oil

Oil Cooler

Hydraulic oil level

Hydraulics

Hydraulic fittings (tighten)

Filler cap

Auxiliary connection dust plugs

Operating hours

First 50

Every 100

Every 250

Every 500

Every 750

Every 1000

Every 3000

Yea rly

CC

CC

CC

C

RR*R R

RR

RR

CC

CC

CC

RR

Check daily

Transmission oil axles / hubs **

Transmission oil gearbox **

Oil level axles / hubs **

Clean oil breather **

Gearbox oil level **

Braking oil (hydraulic oil!) **

Transmission

Bleeding brakes **

Handbrake adjustment **

Brake shoes / pads **

FRR

FRR

CC

CC

CC

CC R

CC

CC

C

67

Page 68

7.Maintenance

C = Check and clean if necessary

R = Replace

F = First time / initial interval

* = Only for vehicles with wheel motors

** = If applicable

Tyres, wheels and wheel nuts

Coupling with drive shafts **

Bushings and bolts

Frame

Lubrication of pivot points

First 50

Every 100

CC

CC

CC

Operating hours

Every 250

Every 500

Every 750

Lubricate daily

Every 1000

Every 3000

Yea rly

68

Page 69

8. MALFUNCTIONS

69

Page 70

8.Malfunctions

POSSIBLE MALFUNCTIONS

Problem Solution

Engine will not start

No fuel in the tank Fill tank with fuel

Ventilation opening of the fuel cap

Clean the fuel cap

is partially clogged

Battery is empty Recharge battery

Other causes

Problem Solution

Engine has not enough power

Contact your dealer

Air filter clogged Clean or change the filter

Fuel is old / outdated Drain fuel tank and fill with 'fresh' fuel

Fuel filters are (partially) blocked Replace fuel filters

Ventilation opening of the fuel cap

Clean or replace the fuel cap

is partially clogged

Problem Solution

The Wheel Loader will not drive

Too little hydraulic oil in reservoir Add hydraulic oil

Broken hydraulic hose between

Replace hydraulic hose

engine and hydraulic pump

Control valve (s) of joystick defec-

Consult your GIANT dealer

tive

When experiencing other problems or malfunctions, contact your GIANT dealer.

70

Page 71

9. ENVIRONMENT

71

Page 72

9.Environment

CARE FOR THE ENVIRONMENT

General

The remains of old oil, oiled rags, filters, batteries and any cleaners must be

disposed off as chemical waste.

Environmental Implications

The life of the Wheel Loader depends on maintenance, operating hours, use and

environmental conditions (dust, pollution, humidity, temperature, etc.). Good

maintenance is the key for keeping your Wheel Loader in good and reliable

condition for a long time.

Decommissioning

Let the dismantling be carried out by a qualified decommissioning and demolition

company that has the required permits. Assign a competent responsible person for

monitoring the decommissioning.

Waste disposal

Assign a competent person responsible for

monitoring the disposal of waste. Sort

dismantled materials on material properties

and pollution. Separate all materials that fall

into the category of chemical waste such as

batteries, oil, lubricants and some electrical

components. Dispose of these materials as

chemical waste. Bring waste materials to

approved waste disposal companies which

have the required permits.

72

Page 73

10. SERIAL NUMBERS

73

Page 74

10.Serial numbers

TOBROCO MACHINES

INDUSTRIELAAN 2

5061 KC OISTERWIJK

NETHERLANDS

MADE IN THE

NETHERLANDS

SERIAL NUMBER REGISTRATION

Serial numbers are located on the nameplates of the main components. To order

parts or components it is required to specify serial numbers. You can also find the

serial numbers on the EC-declaration. To ensure that you always have the

required serial numbers at hand, the following fields can be filled in with these

serial numbers.

Wheel Loader identification plate

The vehicle can be identified by the label on the right side of the machine, below

the steering column. The serial number of the machine is also printed in the frame.

These are located at the upper side of the left hydraulic tank and on top of the fuel

tank.

A. Make

B. Type

C. Model

D. Serial number

E. Engine power

F. Operating mass

G. Year of construction

H. Maximum gross weight

I. Shipping mass

J. Maximum front axle load

K. Maximum rear axle load

L. Manufacturer

74

Page 75

Vehicle serial number

MADE IN JAPAN

Serial No. : - - - - - - -

- - - - - -

Code No. : - - - - - -- - - - - - -

Diesel engine

10.Serial numbers

Frame

75

Page 76

10.Serial numbers

Drive pump

76

Page 77

11. INDEX

77

Page 78

11.index

78

Page 79

A

Accelerator pedal ...................................41

Alternator warning light

Angle of departure

Articulation lock bar

Attachment locking

attachments ...........................................10

..........................47

................................. 34

................................56

.................................44

B

Brake fluid ..............................................63

C

Care for the Environment .......................72

Combination switch

Coolant

Coolant Level

...................................................64

................................49

.........................................52

D

Dashboard .............................................47

Diesel engine .........................................36

Dimensions

Driver’s seat ...........................................55

Driving .................................................... 41

Dump angle

............................................ 34

............................................ 34

E

EC Declaration of Conformity ..................2

Engine ....................................................62

Engine cover ..........................................51

Engine oil

Engine oil pressure warning light ...........48

Engine temperature ...............................48

Engine temperature warning light

........................................ 51, 64

..........48

F

First inspection .......................................40

Fourth function (electrical) .....................46

Fuel ........................................................64

Functions

Fuses .....................................................50

...............................................15

G

General ..................................................37

Grease points ......................................... 54

H

Height .................................................... 34

How to tow

Hydraulic oil

Hydraulic oil level

.............................................60

...........................................64

................................... 53

I

Ignition switch ........................................40

Inching pedal

......................................... 41

J

Joystick ..................................................44

L

Length with bucket .................................34

Lifting

..................................................... 59

................................................... 63

Liquids

M

Machine components ............................. 14

Maintenance Schedule

mechanical lock .....................................44

.......................... 65

P

Parking ...................................... 42, 43, 56

Performing maintenance ........................ 62

Possible malfunctions

Preface .................................................... 6

Preparations ....................................58, 60

............................ 70

R

Refuel .................................................... 54

Rollback angle

ROPS + FOPS protection ...................... 16

.......................................34

S

Safety precautions .................................20

Safety Signs ........................................... 18

Seat height

Serial number registration ...................... 74

Steering column ..................................... 55

Switches in cabin

............................................. 34

................................... 49

T

Third function ......................................... 46

79

Page 80

Tie down

Tipping loads

Total length

Towing

Track width

Trailer

Turning radius

Tyre pressure .........................................53

Tyres

................................................58

.......................................... 38

............................................ 34

...................................................60

............................................. 34

.....................................................37

........................................34

...................................................... 36

W

Wheel base ............................................34

Wheel maintenance

Wheel nuts

width

.............................................65

.......................................................34

...............................53

80

Page 81

Page 82

Page 83

83

Page 84

TOBROCO Machines

Industrielaan 2

5061 KC Oisterwijk

Netherlands

www.tobroco.nl

84

Loading...

Loading...