Page 1

ART P001306017 - REV R20160906

P001306017

GIANT D263S / D263SW / D332ST / D332SWT EN-US

D263S / D263SW / D332ST /

D332SWT

WHEEL LOADER

OPERATOR MANUAL

EN-US - Original language

Page 2

2

Page 3

3

1 General information ................ 5

Preface - - - - - - - - - - - - - - - - -6

Manual usage - - - - - - - - - - - - - -7

Proper Machine Use - - - - - - - - - - -8

Service/Dealership Network - - - - - - -9

Vibration Information- - - - - - - - - - -9

2 Applications........................... 13

Wheel Loader application - - - - - - - 14

Exclusions- - - - - - - - - - - - - - - 14

Public road - - - - - - - - - - - - - - 15

Working surface - - - - - - - - - - - - 15

Attachments - - - - - - - - - - - - - - 16

Operating the machine- - - - - - - - - 17

3 Operation ............................... 21

Machine components - - - - - - - - - 22

Functions - - - - - - - - - - - - - - - 22

ROPS + FOPS protection - - - - - - - 24

Entering and Exiting - - - - - - - - - - 25

4 Safety ..................................... 27

SAFETY- - - - - - - - - - - - - - - - 28

Safety Signs- - - - - - - - - - - - - - 41

ANSI-Style and Common Safety Decal Locations. - - - - - - - - - - - - - - - - 43

Slopes- - - - - - - - - - - - - - - - - 52

Safety - Hydraulic parts - - - - - - - - 52

Safety precautions - - - - - - - - - - - 55

5 Technical data ....................... 67

Diesel engine - - - - - - - - - - - - - 68

General - - - - - - - - - - - - - - - - 69

Tipping loads - - - - - - - - - - - - - 70

Dimensions - - - - - - - - - - - - - - 71

Trailer - - - - - - - - - - - - - - - - - 73

Tyres - - - - - - - - - - - - - - - - - 73

6 Commissioning ..................... 75

First inspection - - - - - - - - - - - - 76

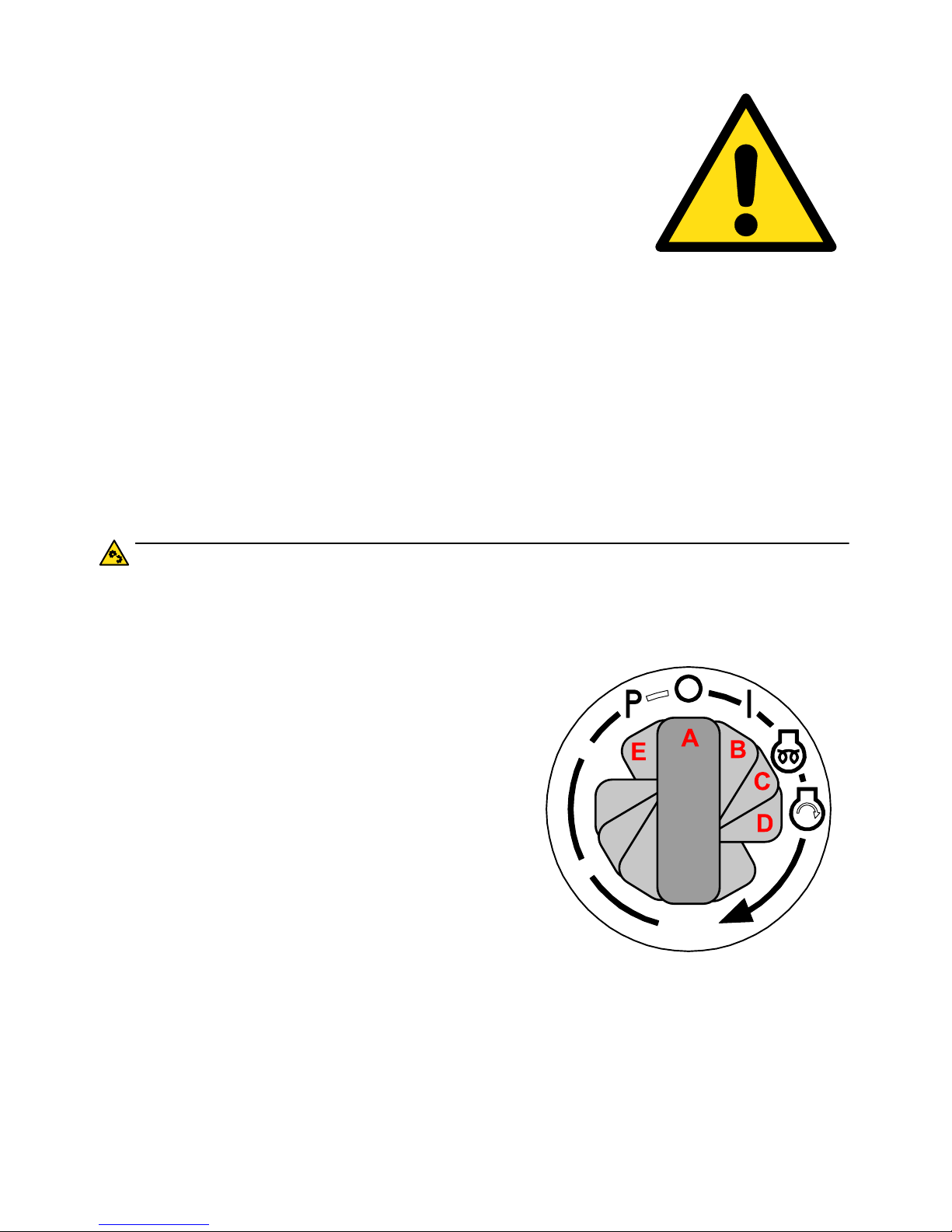

Ignition switch - - - - - - - - - - - - - 76

Driving - - - - - - - - - - - - - - - - 77

Parking - - - - - - - - - - - - - - - - 78

Joystick - - - - - - - - - - - - - - - - 79

Attachment locking - - - - - - - - - - 79

ATTACHMENT POSITION - - - - - - - 80

Third function - - - - - - - - - - - - - 81

Fourth function (electrical) - - - - - - - 81

Dashboard- - - - - - - - - - - - - - - 82

Alternator warning light- - - - - - - - - 82

Engine temperature - - - - - - - - - - 83

Engine temperature warning light - - - - 83

Engine oil pressure warning light - - - - 83

Combination switch - - - - - - - - - - 83

Switches in cabin - - - - - - - - - - - 84

Engine cover- - - - - - - - - - - - - - 84

Fuses - - - - - - - - - - - - - - - - - 85

Engine oil - - - - - - - - - - - - - - - 87

Tire pressure - - - - - - - - - - - - - 88

Wheel maintenance - - - - - - - - - - 88

Hydraulic oil level - - - - - - - - - - - 89

Grease points - - - - - - - - - - - - - 90

Refuel - - - - - - - - - - - - - - - - - 91

Driver's seat - - - - - - - - - - - - - - 91

Steering column - - - - - - - - - - - - 92

Pro-inching - - - - - - - - - - - - - - 93

Articulation lock bar - - - - - - - - - - 94

Tie down- - - - - - - - - - - - - - - - 95

Lifting - - - - - - - - - - - - - - - - - 96

Towing - - - - - - - - - - - - - - - - 97

Loading - unloading - - - - - - - - - - 98

7 Maintenance ...........................99

Performing maintenance - - - - - - - 100

Liquids- - - - - - - - - - - - - - - - 100

Brake fluid - - - - - - - - - - - - - - 101

Coolant Level - - - - - - - - - - - - 101

Coolant - - - - - - - - - - - - - - - 102

Engine oil - - - - - - - - - - - - - - 102

Engine oil and filter- - - - - - - - - - 103

Fuel - - - - - - - - - - - - - - - - - 104

Hydraulic oil - - - - - - - - - - - - - 104

Wheel nuts - - - - - - - - - - - - - 105

Maintenance Schedule - - - - - - - - 106

Maintenance log - - - - - - - - - - - 109

8 Malfunctions.........................117

Possible malfunctions - - - - - - - - 118

9 Environment.........................119

Care for the Environment- - - - - - - 120

Page 4

4

10 Serial numbers .................. 121

Serial number registration - - - - - - 122

11 index................................... 125

EC Declaration of Conformity - - - - 129

Page 5

5

1. GENERAL

INFORMATION

Page 6

6

1.General information

PREFACE

You have chosen for a GIANT Wheel Loader, ensuring versatile use and durability.

Thank you for your confidence in our products.

You will get the best benefit of this Wheel Loader by carefully following the safety,

maintenance and operation instructions in this manual.

We strongly recommend each operator to read this manual carefully before use.

Ensure that the Wheel Loader is always accompanied by this manual. For the

latest version of this manual, go to www.tobroco-giant.us.

Tobroco Machinery LLC is not responsible for damage and indirect damage

caused by operator error, lack of (skilled) maintenance and any other use other

than described in this manual. Tobroco Machinery LLC cannot be held liable for

any damages resulting from unauthorized modifications and/or additions to the

Wheel Loader, without our prior written consent.

Tobroco Machinery LLC continually strives to improve her products and services.

We therefore reserve the right to change the specifications in this user manual at

any time without prior notice. It is possible that the pictured drawings and photos

do not exactly match your Wheel Loader.

We are confident that you will be very satisfied with your new GIANT Wheel

Loader.

While the content of this manual has been prepared with the utmost care, some

information may nevertheless be incomplete, incorrect or may become outdated in

time. TO THE FULLEST EXTENT PERMISSIBLE BY LAW, Tobroco Machinery

LLC MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND,

WETHER EXPRESS OR IMPLIED, FOR THE CURRENCY, ACCURACY, OR

COMPLETENESS OF ANY INFORMATION, AS DEFINED ABOVE.

FURTHERMORE, Tobroco Machinery LLC MAKES NO REPRESENTATIONS OR

WARRANTIES IN CONNECTION TO ITS PRODUCTS AND/OR SERVICES,

INCLUDING WARRANTIES ABOUT ITS SERVICES’ AND PRODUCTS’

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, UNLESS

EXPLICITLY MADE AND PROVIDED BY Tobroco Machinery LLC IN WRITING

TO THE PURCHASER OF THE SERVICES AND/OR PRODUCTS.

© All rights reserved by Tobroco Machinery LLC 2016

Page 7

7

1.General information

MANUAL USAGE

Contents and Use of this Manual

This operator manual provides detailed operating procedures for safe, effective

and proper machine use. Safe operation is detailed in the Safety chapter of this

manual. Specification, maintenance and troubleshooting information is also

included in this manual.

Improper operation, inspection and maintenance of the machine can result in

injury or death. Read and understand the contents of this manual completely and

become familiar with the machine before operation. Contact your authorized

dealer with any questions about information in this manual, if extra manuals are

required, or about availability of manuals in other languages.

Throughout this manual, information is provided set in or italic type and introduced

by the words Notice or Important. Carefully read and follow these messages to

improve operating and maintenance efficiency, to avoid breakdowns and damage,

and extend the life of the machine.

Note: Because of ongoing product improvements, illustrations and listings in this

manual may not exactly match the machine. Tobroco Machinery LLC reserves the

right to modify and improve products at any time without notice.

A storage facility is provided for manual storage. Store the operator manual in this

facility at all times.

This manual is considered a permanent part of the machine and should be with the

machine at all times. Replace this manual promptly if it becomes damaged, lost, or

stolen.

Ownership Change

If the machine is resold, include this operator manual as part of the sale.

If the machine was purchased “used,” or if the owner's address has changed,

please provide your dealer or Tobroco Machinery LLC with the owner's name and

current address, along with the machine model and serial numbers. This will allow

the registered owner information to be updated, so that the owner can be notified

directly in case of an important product issue, such as a safety update program.

Page 8

8

1.General information

Manufacturer Information

Products described in this manual manufactured by Tobroco Machinery LLC.

Machine Designation

Earth-Moving Machinery / Loaders / Compact / Seated Operator

PROPER MACHINE USE

Improper use of the machine can result in property damage, injury or death.

The machine is designed only for digging, picking up, lifting, transporting and

unloading materials. Use with approved attachments is also allowed. Use in any

other way is considered as contrary to the intended use. Compliance with, and

strict adherence to, the conditions of operation, service and repair, as specified by

the manufacturer, also constitute essential elements of the intended use.

The machine was designed and built according to the best available technology

and approved safety regulations in the countries where it is sold. However, it is

impossible to completely safeguard against abusive and/or improper use. The

operator must always consider potential safety risks and hazards during operation.

Accident prevention regulations, all other generally recognized regulations on

safety and occupational medicine, and all road traffic regulations, must be

observed at all times.

The machine must be maintained in proper operating condition. Any damaged or

malfunctioning parts must be repaired or replaced immediately.

Any arbitrary modifications carried out to the machine may relieve the

manufacturer of liability for any resulting damage or injury.

Using Attachments

Read all documentation provided with attachments to learn how to safely operate

and maintain them.

WARNING

Page 9

9

1.General information

Do not use the machine for any applications or purposes other than those

described in this manual or manuals supplied with attachments. Contact the

Tobroco Machinery LLC Service Department before using attachments or

equipment not approved by Tobroco Machinery LLC, or if there are any questions

about approved attachments. Use of non-approved attachments or unauthorized

modifications is prohibited.

SERVICE/DEALERSHIP NETWORK

Your dealership network stands ready to provide any assistance that may be

required, including providing genuine service parts. All service parts should be

obtained from your dealer. Provide complete information about the part and

include the machine model and serial numbers. Record these numbers in the

spaces provided in chapter "Serial Numbers".

Tobroco Machinery LLC strives to continuously improve its products and reserves

the right to make changes and improvements in the design and construction of any

part without incurring the obligation to install such changes on any previously

delivered machine.

VIBRATION INFORMATION

Compact construction equipment is generally used in harsh environments. This

type of usage can expose an operator to uncomfortable levels of vibration. It is

useful to understand exposure to vibration levels when operating compact

equipment and what can be done to reduce vibration exposure. As a result,

equipment operation can be more efficient, productive and safe.

An operator's exposure to vibration occurs in two ways:

• Whole-Body Vibration (WBV)

• Hand-Arm Vibration (HAV)

WBV issues are primarily addressed in this manual, because evaluations have

shown that operation of mobile compact construction equipment on work sites

typically results in HAV levels less than the allowed exposure limit of 2.5 m/s2.

Page 10

10

1.General information

Member States of the European Union must comply with the Physical Agents

(vibration) Directive, 2002/44/EC.

Effective control of vibration exposure for an operator involves more than just

vibration levels on the machine. The work site, how the machine is used, and

proper training all play important roles in reducing vibration exposure.

Vibration exposure results from:

• Work site conditions.

• How the machine is operated.

• The machine characteristics.

Common causes of high WBV levels:

• Using a machine that is improper for the task.

• Work site with potholes, ruts and debris.

• Improper operating techniques, such as driving too fast.

• Incorrect adjustment of the seat and controls.

• Other physical activities while using the machine.

Vibration Measurement and Actions

The vibration directive places the responsibility for compliance on employers.

Actions that should be followed by employers include:

• Assess the levels of vibration exposure.

• Determine from this assessment if operators will be exposed to vibration levels

above the limits stated in the directive.

• Take appropriate actions to reduce operator's exposure to vibration.

• Provide operators with information and training to reduce their exposure to

vibration.

• Keep good records and update operations and training on a regular basis.

If the assessment concludes that vibration level exposure is too high, one or more

of the following actions may be necessary:

1. Train operators

• Perform operations (accelerating, steering, braking, etc.) in a smooth manner.

• Adjust the controls, mirrors and seat suspension for comfortable operation.

• Travel across the smoothest parts of the work site and avoid ruts and potholes.

2. Choose proper equipment for the job

• Use machines with the proper power and capacity.

• Select machines with good suspension seats.

• Look for controls that are easy to use.

• Ensure good visibility from the operator's position.

Page 11

11

1.General information

3. Maintain the work site

• Smooth ruts and fill potholes in traffic areas whenever possible.

• Clean up debris frequently.

• Vary traffic patterns to avoid exposure to rough terrain.

4. Maintain the equipment

• Ensure correct tire pressures.

• Check that seat suspension and all controls work smoothly and properly.

Vibration Level

The typical whole-body vibration level for the machine is listed in the declaration of

conformity, see chapter “EC Declaration of conformity”.

Page 12

12

1.General information

Page 13

13

2. APPLICATIONS

Page 14

14

2.Applications

WHEEL LOADER APPLICATION

The Wheel Loader is designed for lifting and moving:

• Substances such as sand or gravel with closed or open bucket

• Materials and parts on pallets with pallet forks

• Manure with a manure fork

• Kerbs with kerb clamp

• Stones with stone clamp

• Trees with tree harvester

• Hay bales with bale fork

CAUTION:

Use the Wheel Loader only for the above work.

EXCLUSIONS

The Wheel Loader is not designed for the lifting and moving of:

• Persons and animals

• Products where toxic and / or explosive substances may be released during

handling

• Products containing hazardous substances

• Tanks with liquid

• Combustibles

• Other liquids and dangerous substances not mentioned above

Page 15

15

2.Applications

PUBLIC ROAD

CAUTION:

Be aware of the local traffic regulations. Make sure that your machine

complies with the laws and regulations in your area.

CAUTION:

Use of public roads with the Wheel Loader is NOT allowed, unless the

Wheel Loader is equipped with a GIANT road kit which includes automotive lighting.

Please note:

• Driving on public roads should be avoided wherever possible. The different

dimensions and performance can result in unexpected situations for other

road users.

• Driving on the highway is absolutely not allowed.

• Obey national and local traffic and road regulations on public roads. This might

imply additional features on the Wheel Loader.

• Verify whether you need an insurance for driving on public roads, in addition to

the standard insurance.

• The maximum allowable speed on public road depends on local law and regu-

lations.

• Shield the attachments.

• Read the instructions that come with the attachment.

• Put the attachment in a position which does not block the vision of the driver

and which will not endanger other road users.

• Use dimmed lights during the day where visibility is seriously restricted, and at

night.

WORKING SURFACE

CAUTION:

Driving on slopes should be avoided at all times! the risk of tipping

over increases extremely when driving on slopes.

• The Wheel Loader is designed for riding on flat, hard surfaces. Only drive on

slopes when the loader attachment is empty. In the event that the wheel loader

should drive on a slope, the maximum slope angle is 11.3º (20%).

• The stability of the Wheel Loader depends on the articulation angle, load and

the lifting height. For the maximum load see chapter “Technical Data”.

• The Wheel Loader is not designed to tow other vehicles except trailers with

specifications according to chapter “Technical Data”.

Page 16

16

2.Applications

ATTACHMENTS

Only original GIANT attachments and options are allowed on the Wheel Loader.

• Earth bucket

• High-tip bucket

• Pallet fork

• Manure fork

• Feed- and manure scraper

• Auger bucket

• Kerb stone clamp

• Brick clamp

• Silage cutter

• Mixing bucket

• Straw blower

• Bucket brush

•Hay Bale Fork

• Bale grabber

Make sure that the quick-coupling system on the

attachment is the same as that on the Wheel

Loader.

Do not overload the attachment. Refer to the

Technical data section of the attachment and of

the Wheel Loader. The lowest load limit of the

two is the one you must obey.

If you want to use a non-GIANT attachment,

make sure that you have a written consent from

Tobroco Machinery LLC that you can use this

attachment safely.

Tobroco Machinery LLC is excluded from any liability for damage and

consequential damage due to non-GIANT products

Page 17

17

2.Applications

OPERATING THE MACHINE

CAUTION:

Driving on slopes should be avoided. The risk of tipping over

increases extremely when driving on slopes.

CAUTION:

Only drive on slopes when the loader attachment is empty. In the

event that the wheel loader should drive on a slope, the maximum

slope angle is 11.3º (20%).

1. Get on and off safely when entering or leaving the operator’s cab. Face the

machine. Always maintain a three point contact with the steps and handrails.

Do not use control levers as handles. Do not jump on or off the machine.

Never try to get on or off a moving machine.

2. Do not start engine or operate levers from anywhere other than the seat.

3. Before starting the engine, fasten the seat belt, make sure that the direction

lever is set in the neutral position, the parking brake switch is actuated and the

bucket is lowered to the ground.

4. Do not start engine by shorting across starter terminals.

5. Watch where you are going at all times. Watch for and avoid obstacles.

6. Never permit passengers on the machine. Keep bystanders away from the

machine during operation.

7. When working around other machines, let the other operators know what you

are doing at all times.

8. Never allow anyone to get under or near the bucket or attachment when it is

raised.

9. When raising the bucket or attachment, take extra caution to prevent it from

touching overhead wires or other obstacles. Contact with wires may cause

fatal injuries.

10. Keep away from the muffler while the engine is running and immediately after

it has stopped.

11. Hazardous operation such as on dangerous terrain, beyond the load capacity

or contrary to the intended use of the machine must be avoided as it may

cause the machine to tip over.

12. Do not drive the machine close to edges of ditches or banks which may

collapse under the weight of the machine, especially when the ground is loose

or wet.

13. Slow down for turns, uneven terrain and slopes to avoid tipping over.

14. When transporting a load, keep the loader bucket as low as possible to avoid

tipping over. Be extremely careful when working on inclines.

15. Operation on slopes can be dangerous. Rain, snow, gravel soft ground, etc.

will change the surface conditions. Do not operate the machine in questiona-

Page 18

18

2.Applications

ble surface conditions. If operating on a slope or ramp, always slow down,

travel straight up and down the incline and not across. Keep the bucket as low

as possible. If you do not follow these instructions, the machine can go out of

control and tip over.

16. Avoid turning on a slope.

17. Never perform digging or shoveling with the machine in the articulated condi-

tion, or the machine may tip over.

18. Never dig or shovel at high speed. Such operation can cause the machine to

lose stability and its rear wheels to lift off the ground, which may lead to serious personal injury or fatal accidents.

19. Do not go up or down a 20° or steeper hill. Otherwise, the machine may skid

sideways or turn on its side. If the ground is not level or is soft, limit the slope

below 11.3º (20%).

20. To avoid tipping over, do not operate the machine on any site where the terrain

cannot be ascertained, such as ground covered with seeds or snow and check

for hidden projections, dips, road shoulders, etc. beforehand, and take care

not to approach them during work.

21. Be sure to ease off the accelerator pedal at the end of filling in trenches or

areas at the edge of a steep slope or pond bank or at the brow of a hill. When

the external load is reduced, the machine speed will automatically increase,

therefore reduce speed to avoid entering ditches or tipping over.

22. To avoid the machine slipping or tipping over, do not operate the machine on

ungraded or soft terrain, such as land fills. Grade and compact the site

beforehand at all times.

23. Do not run the engine indoors. Carbon monoxide gas from exhaust is

colorless, odorless and deadly.

24. Check that no one is near the machine before starting the engine to avoid dan-

ger from the machine. Check that there are no flammable objects, such as

dead leaves, sheets of paper, or pieces of cloth near to the engine before starting the engine.

25. Be especially careful when reversing and watch the area behind the loader

exactly before starting to drive.

Caution with children

26. Serious accidents can occur if the operator does not pay attention to children

in the vicinity of the machine. Children are unpredictable!

27. Always keep an eye on children as they change their location continuously.

28. Make sure no children are within the working range of the machine.

29. Be extremely cautious when children approach the working area; stop

working, if necessary.

30. Do not carry children on the machine.

31. Do not allow children to operate the machine.

32. Do not allow children to play around the machine.

Page 19

19

2.Applications

Page 20

20

2.Applications

Page 21

21

3. OPERATION

Page 22

22

3.Operation

MACHINE COMPONENTS

FUNCTIONS

This Wheel Loader is designed for lifting and moving loads. Do not exceed the

maximum loads as shown in chapter ‘Technical data’. Various functions are

powered by a diesel engine. All of these functions can be controlled by the driver

by means of a joystick, steering wheel, pedals, and various buttons. These

functions are:

• Forward and reverse drive.

• Articulated steering.

• Lifting and lowering.

• Tilting of the tool carrier.

1. Tilt cylinder

2. Lifting arm

3. Dashboard

4. Steering wheel

5. Joystick control

6. Seatbelt buckle

7. Driver’s seat

8. Safety roof

9. Engine cover

10. Coupling pins

11. Attachment bracket

12. Wheel

13. Fuel tank filler cap

14. Articulation point

15. Steering cylinder

16. Battery

17. Hydraulic oil tank

18. Cooler

19. Engine exhaust

20. Diesel engine

21. Air filter

22. Drive pump

23. Work pump

123456789

1716

15

1413121110

18

19

20 23

22

21

Page 23

23

3.Operation

• Locking the attachments.

• Controlling / powering of attachments.

The Wheel Loader is equipped with a dashboard, which contains various controls

and indicators.

The Wheel Loader is equipped with a lifting arm. The forces that can be provided

by the arm strongly depend on the position of the lifting arm and the position of the

load.

Ensure at all times that the load is in the lowest possible position when driving and/

or steering. As the driver you are responsible for the safe operation of the

machine.

Page 24

24

3.Operation

ROPS + FOPS PROTECTION

The Wheel Loader has a ROPS. The safety

structure is tested according to the "EN ISO

3471" standard (ROPS: Roll-over protective

structures).

The Wheel Loader has a FOPS. The safety

structure is tested according to the "EN ISO

3449" standard (FOPS: Falling-object

protective structures).

All models are tested according to EN ISO

3449 (FOPS) and according to the EN ISO

3471 (ROPS).

A. Safety roof

B. Cabin

FOPS = Falling Objects Protective Structure:

Protects the driver against falling objects.

ROPS = Roll Over Protective Structure:

Protects the user if the Wheel Loader

unexpectedly tips over.

FOPS: EN ISO 3449

ROPS: EN ISO 3471

A

B

Page 25

25

3.Operation

ENTERING AND EXITING

CAUTION:

Maintain three-point contact and face the machine

at all times when entering

and exiting. Do not use

the steering wheel for

entry or exit. Never enter

or exit a moving machine.

Failure to maintain threepoint contact may result

in injury.

A

B

C

A

B

C

Page 26

26

3.Operation

Page 27

27

4. SAFETY

Page 28

28

4.Safety

SAFETY

This manual and decals on the machine warn of safety hazards and should be

read and observed closely.

Before operating the machine, first read and study the safety information in this

manual. Additionally, anyone who operates or works on the machine must be

familiar with these safety precautions.

This safety alert symbol means ATTENTION! ALWAYS BE ALERT!

YOUR SAFETY IS INVOLVED! This symbol is used throughout this

operator manual and on the decals on the machine.

“DANGER” indicates an imminently hazardous situation,

which, if not avoided, will result in death or serious injury.

“WARNING” indicates a potentially hazardous situation,

which, if not avoided, could result in death or serious

injury.

“CAUTION” indicates a potentially hazardous situation,

which, if not avoided, may result in minor injury or

property damage. It is also used to alert users of unsafe

practices.

It is essential that operators are thoroughly trained in the safe operation of the

machine and handling loads. Operators must not be physically or mentally

impaired. Do not allow minors or unqualified personnel to operate the machine, or

to be near the machine unless they are properly supervised. It is recommended

that the operator be capable of obtaining a valid motor vehicle operator's license.

Use of this machine is subject to certain hazards that cannot be eliminated by

mechanical means, but only by exercising intelligence, care and common sense.

Such hazards include: hillside operation, overloading, load instability, poor

maintenance, and using the machine for a purpose for which it was not intended or

designed.

Tobroco Machinery LLC always takes operator's safety into consideration during

the design process. Guards and shields are provided, which protect the operator

and bystanders from moving parts and other hazards. Operators must be alert,

DANGER

WARNING

CAUTION

Page 29

29

4.Safety

however, because some areas cannot be guarded or shielded without preventing

or interfering with proper operation.

Different applications may require optional safety equipment. Be sure you know

the work site hazards and equip the machine and the operator as necessary. The

information in this manual does not replace any applicable safety rules and laws.

Before operating the machine, know the rules and laws for your area. Make sure

the machine is equipped as required according to these rules/laws.

Remember that some risks of injuries may not be immediately apparent.

Exhaust gases and noise pollution may not be visible, but these hazards can

cause permanent injuries.

Some photographs in this manual may show doors, guards and shields open or

removed for the purposes of illustration only. Be sure that all doors, guards and

shields are in the proper operating positions before starting the engine to operate

the machine.

ROPS/FOPS

The machine is for the safety of the operator always

equipped with a four-post ROPS/FOPS, which may

never be removed or modified. See chapter operation,

section ROPS + FOPS.

WARNING

Page 30

30

4.Safety

Mandatory Safety Shutdown Procedure

BEFORE cleaning, adjusting, lubricating, fueling, or servicing the machine, or

leaving it unattended:

1. Bring the machine to a complete stop on a level surface. Avoid parking on an

incline or hillside, but if this is not possible, park along the slope, not across.

Prevent the machine from moving, block the tires with wedges for example.

2. Be sure all working equipment and/or attachments are stopped and the

auxiliary valve is in neutral.

3. Lower the lift arm and attachment completely.

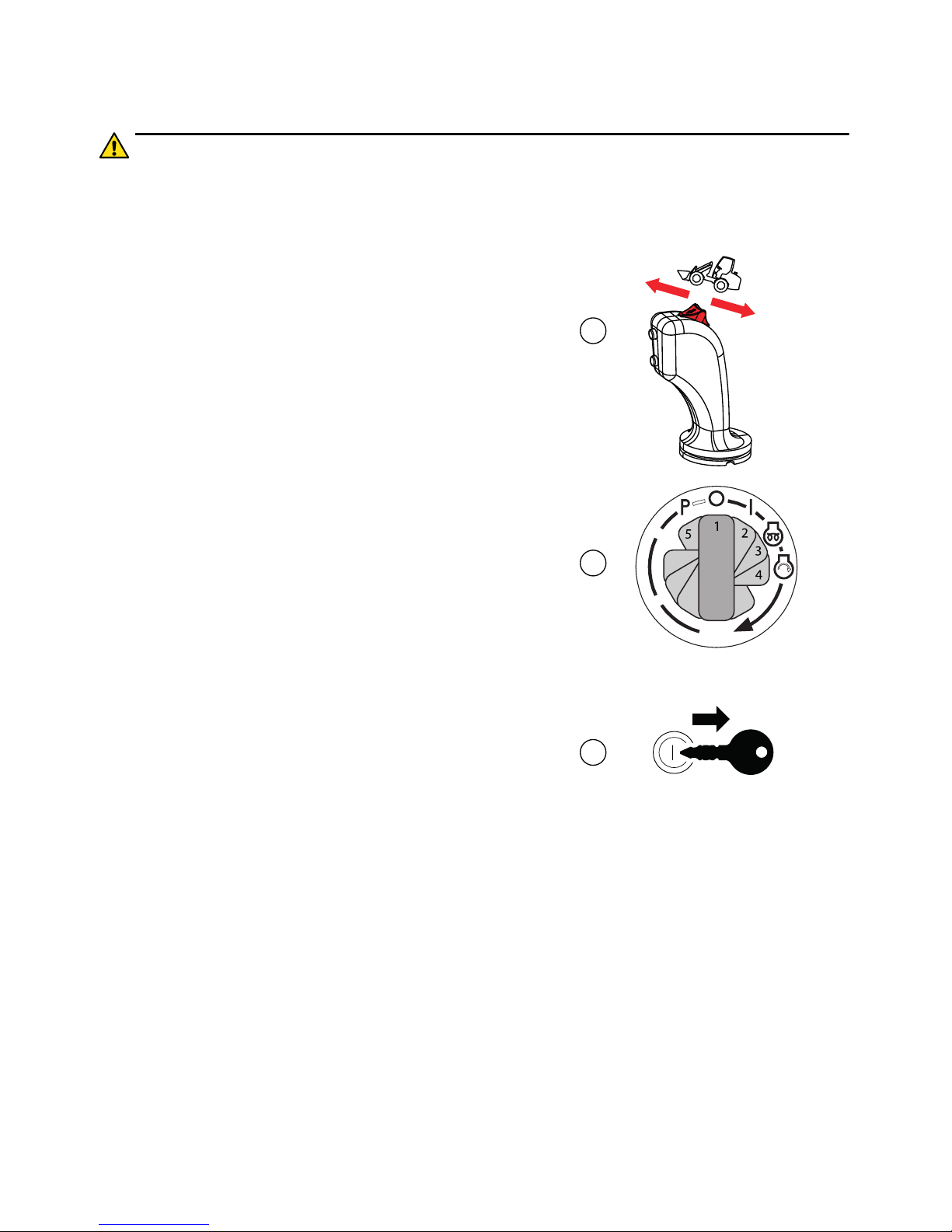

4. Place forward/reverse drive switch (on top of the joystick) into the neutral

position.

5. Apply the parking brake.

6. Move the throttle to low idle position and shut off the engine.

7. Wait for all movement to stop. Turn the ignition key to the "I" or RUN position

and move the multi-purpose joystick in all directions to verify that the hydraulic

system is de-pressurized.

8. If so equipped, press the auxiliary hydraulics pressure relief control. After

pressing, make sure this control returns to the neutral position.

9. Turn off the ignition.

10. Unfasten the seat belt and remove the ignition key and take it with you. Exit

the machine using the hand holds.

ONLY when these precautions have been taken can you be sure it is safe to

proceed. Failure to follow this procedure could result in death or serious injury.

Before Starting

• Do not remove or modify the Roll-Over Protective Structure ("ROPS"). Modifi-

cations, such as welding, drilling or cutting, can weaken the structure and

reduce the protection it provides. A damaged ROPS cannot be repaired - it

must be replaced.

• Never operate the machine without a ROPS or FOPS installed.

• To ensure safe operation, replace damaged or worn-out parts with genuine

service parts.

• The machine is designed and intended to be used only with approved attach-

ments. To avoid possible personal injury, equipment damage and performance

problems, use only attachments that are approved for use on and within the

operating capacity of the machine, see chapter “Technical data”. Contact the

Tobroco Machinery LLC service department for information on attachment

approval and compatibility with specific machine models. Tobroco Machinery

LLC cannot be responsible if the machine is used with a non-approved attachment.

Page 31

31

4.Safety

• Remove all trash and debris from the machine every day, especially in the

engine compartment, to minimize the risk of fire.

• Always face the machine and use the hand holds and steps when entering and

exiting the machine. Do not jump off the machine. See chapter “Operation”.

• Do not use other starting aids than the engine pre-heating. Engine pre-heating

can cause ether or other starting fluid to detonate, causing injury or damage.

• Walk around the machine and inspect it before using it. Look for damage,

loose or missing parts, leaks, etc.

• Warn all nearby personnel before starting the machine.

• Check for proper tire pressure in all four tires before operating the machine

and add air if necessary. Improperly pressurized tires adversely affect machine

stability. Regularly check wheel fasteners for tightness. See chapter “Maintenance”.

• Contact the proper local authorities for utility line locations BEFORE starting to

dig. In North America, contact the North American One-Call Referral System

at 8-1-1 in the U.S., or 1-888-258-0808 in the U.S. and Canada.

• Below-ground hazards also include water mains, tunnels and buried founda-

tions. Know what is underneath the work site before starting to dig.

• Before working near power lines (either above-ground or buried cable type),

always contact the power utility and establish a safety plan with them.

• If temperatures are changing, be cautious of dark and wet patches when work-

ing or traveling over frozen ground. Stay away from ditches, overhangs and

other weak support surfaces.

• The operator's area, steps and hand holds must be free of oil, dirt, ice and

unsecured objects.

• If a lighting system is installed, check its operation before working in darkness.

• Always keep lights, mirrors and windows clean. Poor visibility can cause acci-

dents.

• NEVER start the engine if there is any indication that maintenance or service

work is in progress, or if a warning tag is attached to the controls.

• Replace damaged safety decals and a lost or damaged operator manual.

• Terrain and soil conditions at the work site, approaching traffic, weather-

related hazards and any above-or below-ground obstacles and hazards

should be observed and monitored by all work crew members.

• Adjust the seat to allow full actuation of all controls. Never adjust the seat

during machine operation.

• Read the operator manual provided with each attachment used with the

machine before starting the engine.

• Before working on or with the machine, remove jewelry, tie back long hair, and

do not wear loose-fitting garments, such as, scarves, ties, unzipped jackets,

etc., which could become caught in the moving parts of the machine and

cause injury.

Page 32

32

4.Safety

During Operation

• ALWAYS fasten the seat belt securely and properly. Never operate the

machine without the seat belt fastened around the operator.

• Check indicators and displays for normal conditions after starting the engine.

Listen for unusual sounds and remain alert for other potentially hazardous

conditions.

• Control the machine cautiously and gradually until fully familiar with all the

controls and handling.

• Do not overload the machine. See chapter “Technical data”.

• Do not raise or drop a loaded bucket or attachment suddenly. Abrupt move-

ments under load can cause serious instability.

• Check that attachments are securely fastened to the attachment hitch before

working.

• Never activate the float function with the bucket or attachment loaded or

raised, because this will cause the lift arm to lower or bucket to dump rapidly.

• Never operate the machine without a ROPS or FOPS installed.Machine stabil-

ity is affected by: the weight of the load being carried, height of the load,

machine speed, turn angle, width of the machine across the tires, abrupt control movements and driving over uneven terrain.

DISREGARDING ANY OF THESE FACTORS

CAN CAUSE THE MACHINE TO TIP, THROWING

THE OPERATOR OUT OF THE SEAT OR

MACHINE, RESULTING IN DEATH OR SERIOUS INJURY.

Therefore: ALWAYS operate with the seat belt fastened around the operator.

• Do not exceed the machine's rated operating capacity; see chapter “Technical

data”. Be aware that effective operating capacity is reduced when the machine

is turned.

• Machine stability is reduced when the machine is turned.

• Be aware that attachments effect the handling and balance of the machine.

Adjust the operation of the machine as necessary when using attachments.

• Carry the load low. Move the controls smoothly and gradually, and operate at

speeds appropriate for the conditions.

• Do not use the machine to lift or transport people. Do not allow others to ride

on the machine or attachments, because they could fall or cause an accident.

• Always look to the rear, over both shoulders, before backing up.

• Only start the engine while seated in the operator's seat with the seat belt fas-

tened around the operator.

• Only operate the controls while seated in the operator's seat with the seat belt

properly fastened.

• Always keep hands and feet inside the operator's compartment while operat-

ing the machine.

WARNING

Page 33

33

4.Safety

• New operators must first operate the machine in an open area away from

bystanders. Practice with the controls until the machine can be operated safely

and efficiently.

• Wear safety goggles, ear and head protection as needed while operating the

machine. Operator must wear protective clothing when appropriate.

• Exhaust fumes can kill. Do not operate the machine in an enclosed area with-

out adequate ventilation. Internal combustion engines deplete the oxygen supply within enclosed spaces and may create a serious hazard unless the

oxygen is replaced.

• Do not drive too close to an excavation or ditch. Be sure that the surrounding

ground has adequate strength to support the weight of the machine and the

load.

• Never allow anyone under a raised lift arm. Lowering the lift arm or a falling

load can result in death or serious personal injury.

• Avoid slowing suddenly while carrying a load. Sudden slowing can cause the

load to drop off the attachment, or cause the machine to tip over.

• Be aware of overhead obstacles. Any object near the lift arm could represent a

potential hazard, or cause the operator to react suddenly and cause an accident. Use a spotter or signal person when working near bridges, phone lines,

work site scaffolds, or other obstructions.

• Slow down the work cycle and use slower travel speeds in congested or popu-

lated areas. Use commonly understood signals so that other members of the

work crew can warn the operator to slow or halt work in a potentially hazardous situation.

• Use a signal person if you cannot see the entire work area clearly, in high traf-

fic areas and whenever the operator's view is not clear.

• Do not place limbs near moving parts. Severing of body parts can result.

• Do not use the loader to lift or transport people.

• Stay alert for people moving through the work area. When loading a truck, the

operator should always know where the driver is.

• Do not drive into materials at high speeds to avoid being thrown forward and

injured.

• Do not turn off the ignition switch while driving. Turning off the ignition will

cause sudden hydrostatic braking, which may cause possible loss of control,

injury and/or tipping of the machine.

• The engine hood must never be opened while the engine is running.

• In cold weather, avoid sudden drive movements and stay away from even

slight slopes. The machine can slide sideways on icy slopes.

• Snow accumulation can hide potential hazards. Use care while operating and

while using the machine to clear snow.

• If the machine becomes damaged or malfunctions, stop the machine immedi-

ately and lock and tag it. Repair the damage or malfunction before using the

machine again.

Page 34

34

4.Safety

• Never jump off the machine. Never get on or off a moving machine. Always

leave the machine while facing the machine using the steps and hand-holds.

See chapter “Operation”.

Provision for Stability / Avoiding Rollover Accidents

• Machine stability is affected by: the weight and center of gravity of the load

being carried, height of the load, machine speed, turn angle, width of the

machine across the tires, abrupt control movements and driving over uneven

and/or soft terrain. DISREGARDING ANY OF THESE FACTORS CAN

CAUSE THE MACHINE TO TIP, THROWING THE OPERATOR OUT OF THE

SEAT OR MACHINE, RESULTING IN DEATH OR SERIOUS INJURY. Do not

exceed the machine's rated operating capacity, especially when turning,

because this reduces the load that will cause the machine to tip over. Carry the

load low, and operate at speeds appropriate for the conditions.

• Operate the controls smoothly to prevent jerking or bouncing. Operate on

level, stable surfaces. Load, unload and turn on solid, level ground.

• Drive up and down inclines, not across them. Drive slowly on inclines. Keep

the heavy end of the machine pointed uphill.

• Evenly distribute the load on the attachment. Secure unstable loads so they do

not shift or fall.

• Do not make sharp turns on inclines. Avoid steep inclines.

• Use care on loose ground. Loose, soft ground or uneven, broken terrain can

cause dangerous side-load conditions and possible tip over and injury.

• If you must drive across railroad tracks, ditches, curbs or similar surfaces,

cross straight up and down the slopes and drive slowly.

• Stay away from steep edges on loading docks, ramps, ditches, retaining walls

and trenches.

• Avoid sharp turns and high speeds while carrying loads. The stability of the

machine is greatly reduced during sharp turns. Additionally, the load may shift

to the side during turns, greatly increasing the possibility of a rollover.

• When unloading trucks or lifting loads off elevated surfaces, approach the load

straight ahead and back straight away with the load. Slowly lower the load to

the lowest possible transport position before turning.

• To avoid tipping, keep loads as low as possible during transport and while turn-

ing. Keep the bottom of the bucket or load no higher than wheel axle height

during transport and turning.

• Do not turn the machine when lifting loads. As loads are lifted, a drastic shift in

stability can occur, which can greatly increase the possibility of a tip-over or

rollover.

• Keep tires inflated to recommended pressure.

• If the machine becomes unstable and starts to tip, keep the seat belt fastened,

hold on firmly and brace yourself. Lean away from the point of impact and stay

with the machine. If tipping occurs, DO NOT jump from the machine. The

Page 35

35

4.Safety

machine is equipped with rollover protection, which can only protect the operator while in the operator's seat. Trying to escape from a tipping machine can

result in death or serious personal injury.

• The ROPS must be replaced if a overturn incident occurs. The protection

offered by the ROPS will be impaired if it has been damaged in an overturn

incident.

• Never operate the machine without a ROPS or FOPS installed.

Electrical Energy

• Stay away from high-voltage lines. Serious injury or death can result from con-

tact or proximity to high-voltage electric lines. The machine does not have to

make physical contact with power lines for current to be transmitted. Use a

spotter and hand signals to keep away from power lines not clearly visible to

the operator.

• Depending upon the voltage in the power line and atmospheric conditions,

strong current shocks can occur if the bucket is closer than 3 m (10 ft.) to the

power line. Very high voltage and rainy weather can further increase the safe

operating distance.

• If the machine comes into contact with a live wire:

- Do not leave the machine.

- If possible, drive the machine out of the danger area.

- Warn others not to approach or touch the machine.

- Have the live wire de-energized.

- Do not leave the machine until the wire has been safely de-energized.

• Work on the machine's electrical system must be performed only by licensed

technicians.

• Inspect and check the machine's electrical equipment at regular intervals.

- Problems found, such as loose connections or scorched cables, much be

repaired before using the machine.

• Only use proper, original equipment fuses/circuit breakers with the specified

current rating. Turn off the machine immediately if there is any indication of a

problem with the electrical system.

Service Safety Practices

• Only trained and authorized personnel, with a full awareness of safe proce-

dures, should be allowed to operate or perform maintenance or service on the

machine.

• Use warning tag/control lockout procedures during service. Alert others that

service or maintenance is being performed by tagging operator's controls - and

other machine areas if required - with a warning notice.

• Never attempt to bypass the key switch to start the engine.

• Always wear safety glasses with side shields when striking metal against

metal. In addition, it is recommended that a softer (chip-resistant) material be

Page 36

36

4.Safety

used to cushion the blow, otherwise, serious injury to the eyes or other parts of

the body could result.

• Stay clear from underneath the operator's platform as it is tilted.

• Always secure the operator's platform in the tilted position with the tilt support.

Never allow anyone under the operator platform if the tilt support is not in

place.

• Always secure the operator's platform to the chassis with anchor bolts, nuts

and washers before driving and using the machine.

• Check operator's platform tilt components and tilt support components at regu-

lar intervals. Replace damaged or worn parts immediately.

• Do not smoke or have any spark- or flame-producing equipment or materials in

the area while filling the fuel tank or working on the fuel or hydraulic systems.

• Keep fuel and other fluid reservoir caps tight. Do not start the engine until caps

have been secured.

• Always lower lift arm or elevated items, or securely support/secure them,

before performing any maintenance or service on the machine.

• Do not attempt to remove the radiator cap after the engine has reached oper-

ating temperature or if it is overheated. At operating temperatures, engine

coolant is extremely hot and under pressure. Always wait for the engine to cool

before attempting to relieve pressure and remove the radiator cap. Failure to

heed this warning could result in severe burns.

• Use solid support blocking. Never rely on jacks or other inadequate supports

when maintenance work is being done. Never work under any equipment supported only by jacks.

• Refer to the parts manual for information about assembly of components.

Always use the correct parts and the proper torques - incorrect fastener connections can dangerously weaken assemblies.

• Exhaust fumes can kill. Do not operate the machine in an enclosed area

unless there is adequate ventilation.

• Operators should also be aware of any open windows, doors or ductwork into

which exhaust gases may be carried, exposing others to danger.

• Do not run the engine if repairs are being performed alone. There should

always be at least two people working together if the engine must be run

during service.

• Always use adequate tools while working on the machine. Inappropriate tools

could break or slip, causing injury, or they may not adequately perform

intended functions.

• Unless necessary for servicing the engine, do not open the engine cover while

the engine is running.

• Do not use the machine when maintenance is scheduled to be performed.

Postponing maintenance can result in a serious reduction of the service life of

the machine, more serious and costly equipment failures, and contribute to

unsafe operating conditions.

Page 37

37

4.Safety

• Only tow the machine as described in this manual (see chapter “Commission-

ing”).

• Do not work on hot engines, cooling systems or hydraulic systems. Wait for

the engine to cool. When engine lubrication oil, gearbox lubricant or other fluids require changing, wait for fluid temperatures to decrease to a moderate

level before removing drain plugs.

• All safety equipment must be maintained so it is always in good condition.

• Safety-critical parts must be periodically replaced. Replace the following

potentially fire-related components as soon as they begin to show signs of

deterioration:

- Fuel system flexible hoses, fuel tank overflow drain hose and the fuel filler

cap.

- Hydraulic system hoses, especially the pump outlet lines. Replace hydraulic

hoses every 6 years from the date of manufacture (month or quarter, and year)

is indicated on the hydraulic hoses.

• Keep mounting brackets and hose and cable routing straps tight. Hose routing

should have gradual bends.

• After cleaning the machine, examine all fuel, lubricant and hydraulic oil lines

for leaks, chafe marks and damage. Tighten any loose connections and repair

or replace parts as necessary.

• When handling oil, grease and other chemical substances, follow the product-

related safety requirements Material Safety Data Sheet (MSDS) carefully to

prevent burning or scalding.

• Do not use the machine in an environment where the hot muffler could present

a fire hazard, such as hay or straw storage facilities.

Battery Hazards

• Use the battery disconnect switch, or disconnect the negative battery cable

from the negative battery terminal, before performing electrical service or electrical welding on the machine (see chapter “Commissioning’).

• When disconnecting at the battery terminals, remove the cable connected to

the negative terminal first. When installing a battery, connect the positive terminal cable first.

• Sparks and open flames can set off explosive battery gas from incidental con-

tact or static discharge. Turn off all switches and the engine when working on

batteries. Keep battery terminals tight. Contact between a loose terminal and

post can create an explosive spark.

• When jump-starting from another machine, do not allow the machines to

touch. Wear safety glasses or goggles while battery connections are made.

• Never jump-start the machine if it has a frozen battery. The battery could

explode. Thaw a frozen battery before charging it or attaching jumper cables.

• Flush eyes with water for 10-15 minutes if battery acid is splashed in the face

and consult a medical doctor immediately. Anyone swallowing battery acid

Page 38

38

4.Safety

must have immediate medical aid. Call the Poison Control Center at 1-800222-1222 in the United States.

Fire Hazards

• The machine must be cleaned on a regular basis to avoid the buildup of flam-

mable debris, such as leaves, straw, etc. Accumulated debris, particularly in

the engine compartment, creates a fire hazard.

• The machine has several components that operate at high temperatures

under normal operating conditions, primarily the engine and exhaust systems.

Also, the electrical system, if not properly maintained or if damaged, can arc or

produce sparks. These conditions make it extremely important to avoid circumstances where explosive dust or gases can be ignited by arcs, sparks or

heat.

• Add fuel, oil, antifreeze and hydraulic fluid to the machine only in well-venti-

lated areas. The machine must be parked with controls, lights and switches

turned off. The engine must be turned off before fueling.

• Do not smoke while filling the fuel tank, while working on the fuel or hydraulic

systems, or while working around the battery.

• Take care to avoid spilling combustible fluids, such as oil or fuel, on a hot

engine.

• Static electricity can produce dangerous sparks at the fuel-filling nozzle. In

very cold, dry weather or other conditions that could produce static discharge,

keep the tip of the fuel nozzle in constant contact with the fuel filler neck, to

provide a ground. Be sure that a ground wire is connected from the machine to

the service truck before fueling begins.

• Keep fuel and other fluid reservoir caps tight and do not start the engine until

caps have been secured.

• It is recommended that a 2.27 kg (5 lbs.) or larger, multi-purpose "A/B/C" fire

extinguisher be mounted within reach of the operator. Check the fire extinguisher periodically and be sure that work site crew members are trained in its

use.

• Oil leaks can ignite on hot components. Repair any damaged or leaking com-

ponents before using machine.

Transporting the Machine

Obey federal, state and local over-the-road regulations. Check restrictions

regarding weight, height, width and length of a load. The hauling vehicle, trailer

and load must all be in compliance with applicable regulations (see chapter

“Commissioning”).

Page 39

39

4.Safety

Lifting the Machine with a Crane

Only lift the machine according to the following guidelines:

• The crane and rigging equipment must have sufficient capacity. See chapter

"Technical Data”.

• Secure the machine against unintentional movement. Use taglines as needed.

• Do not lift the machine with persons on or in the machine.

• Any person guiding the crane operator must be within sight or sound of the

crane operator.

• Lift the machine only with the standard bucket installed, with the bucket empty

and in the transport position.

• Persons must stay clear of, and not under, the machine when it is lifted.

• Fasten the rigging equipment so the machine is horizontal when it is lifted.

• Do not lift the machine by the cab. Attach the rigging equipment only at the lift

points identified with the safety decal for lifting points.

• Lift the machine according to "Lifting", see chapter “Commissioning”.

Page 40

40

4.Safety

Hazard and Hazard Avoidance Symbols

Safety Decals

The machine has decals around the machine that provide safety information and

precautions. These decals must be kept legible. If missing or illegible, they must

be replaced promptly. Replacements can be obtained from your dealer. Refer to

the Parts Manual for decal part numbers and ordering information.

Rotating Fan

Keep Away

Fire Hazard

Read Maint-

enance/Service

Information

Safety Hazard Run-Over

Hazard

Injected Fluid

Hazard

Hot Liquids

Hazard

Poisonous

Vapors Hazard

No Smoking No Open

Flame

Read Operator

Manual

Wear Seatbelt

Keep Distance Waer Eye

Protection

Avoid Power

Lines

Remove Key Crush Hazard

Crush Hazard Hot Surface

Hazard

Safety Lock

Falling Object

Hazard

Page 41

41

4.Safety

SAFETY SIGNS

This chapter explains the machine sign (safety decals) on the machine. To work

safely with the Wheel Loader and when carrying out maintenance it is essential

that you follow all instructions in this manual.

Warning! Risk of injury if the safety decals are no longer clearly visible or legible.

Immediately attach new safety decals!

The following icons indicate safety hazards for man and machine:

CAUTION:

Risk of accidents and personal injuries

CAUTION:

Risk of technical damage to the Wheel Loader

Page 42

42

4.Safety

New Decal Application

Surfaces must be free of dirt, dust, grease and foreign material before applying the

decal. Remove the smaller portion of the decal backing paper and apply the

exposed adhesive to the clean surface, maintaining proper position and alignment.

Peel the rest of the backing paper and apply hand pressure to smooth out the

decal surface. Refer to the following pages for proper decal locations.

If replacing a part that has a decal on it, ensure that the replacement part has the

same deca

l

Page 43

43

4.Safety

ANSI-STYLE AND COMMON SAFETY DECAL LOCATIONS.

CAUTION:

Not all the decals are used on the machine

ANSI-Style and Common Safety Decal Location

A Lift Point Decal

Located at the rear of the machine and near

the lift holes/rods near the top of the front

frame.

• Apply lift hooks only in these location,

See chapter “Commissioning”.

D-L

T

V

J-X-L-H

Q

N-R

B

C

G

E

E

K-M1

S

O

M2

A

5103008-16-A

Page 44

44

4.Safety

B WARNING: Do not modify ROPS; replace

damaged ROPS; wear seat belt;

NEVER REMOVE ROPS.

Located inside the ROPS structure.

• The protection offered by this ROPS will

be impaired if it has been subjected to

any modification, structural damage, or

has been involved in an overturn

incident, this ROPS must be replaced

after a roll-over. Seat belts must be

worn while operating vehicle.

C WARNING: Crush Hazard

Located on top of the articulation joint on

both sides.

• Keep away from machine when it is

being operated.

• Lock frames together when machine is

serviced or shipped.

D USE DIESEL FUEL ONLY!

Located next to the fuel filler neck.

E Tie-down point, located on lift arm (front,

both sides) and frame (rear, both sides).

• Only use tie-down points indicated on

loader when transporting loader.

F IMPORTANT

Located next to the fuel filler neck.

• Use ONLY diesel fuel according to one

of the following technical specifications:

• EN590

• ASTM D975 2D

• JIS K 2204.

See chapter “Maintenance”.

ANSI-Style and Common Safety Decal Location

The protection offered by this ROPS will be

impaired if it has been subjected to any

modification, structural damage, or has been

involved in an overturn incident. This ROPS

must be replaced after a rollover. Seat belts

must be worn while operating vehicle.

WARNING

5103008-03-A

NEVER REMOVE ROPS.

Keep away from machine when it

is being operated.

Lock frames together when

machine is serviced or shipped.

CRUSH HAZARD

5103008-06-A

WARNING

D

5103008-22-A

5103008-15-A

IMPORTANT

Use diesel fuel according to one of the following

technical specifications:

5103008-08-A

EN590

ASTM D975 2D

JIS K 2204

Page 45

45

4.Safety

G WARNING: Crush Hazard

Located on both side of the lift arm.

• Before operating, verify full

engagement of loader attachment

bracket locking pin to the attachment.

H USE HYDRAULIC FLUID ONLY!

Located next to the hydraulic fluid reservoir

filler neck.

J WARNING: Rotating Fan / Hot Surface

Hazards

Located on the right side of the firewall

inside the engine compartment.

On machines with air conditioning, located

on the back of the air conditioning enclosure.

• Keep hands out or stop engine.

• Do not touch hot engine or hydraulic

system parts.

ANSI-Style and Common Safety Decal Location

Before operating, verify full egagement of loader

attachment bracket locking pin to the attachment.

CRUSH HAZARD

5103010-12-A

WARNING

5103008-11-A

5103008-09-A

WARNING

AVOID INJURY

ROTATING FAN

Keep hands out or stop

engine.

HOT SURFACE

Do not touch hot engine or

hydraulic system parts.

Page 46

46

4.Safety

K WARNING: Avoid Injury or Death

Located on the left side of the firewall inside

the engine compartment.

On machines with air conditioning, located

on the back of the air conditioning enclosure.

• Keep safety devices working.

• Jump start per Operator Manual

procedure.

• Keep guards, screens and windows in

place.

• Do not smoke while fuelling or servicing

machine.

• Clean debris from engine compartment

daily to avoid fire. Keep fire

extinguisher nearby.

• Do not use hand to find hydraulic leaks.

• Escaping oil under pressure can be

invisible and penetrate skin.

• Allow radiator to cool before removing

cap. Loosen cap slowly to avoid burns.

L IMPORTANT

Located on top of the radiator inside the

engine compartment.

• Do not use ether or other starting fluids

to start this engine — warranty may be

voided.

M1 WARNING: Avoid Injury or Death

Located on the left side of the control column.

• ALWAYS wear seatbelt.

• No riders! Never use work tool as work

platform.

• Keep out from under lift arm unless lift

arm is supported.

• Operate only from operator’s seat.

• Prevent load rolling down lift arm onto

operator.

ANSI-Style and Common Safety Decal Location

AVOID INJURY OR DEATH

Keep safety devices working.

Jump start per Operator´s Manual procedure.

Clean debris from engine compartment daily to avoid

fire. Keep the fire extinguisher nearby.

Do not use hand to find hydraulic leaks. Escaping oil

under pressure can be invisible and penetrate skin.

Allow radiator to cool before removing cap. Loosen cap

slowly to avoid burns.

Keep guards, screens and windows in place.

Do not smoke while fueling or servicing machine.

Keep guards, screens and windows in place.

5103008-31-A

WARNING

Do not use ether or other

starting fluids to start this

engine.

Warranty may be voided.

IMPORTANT

5103008-08-A

AVOID INJURY OR DEATH

ALWAYS wear seatbelt.

No by-riders! Never use work

tool as work platform.

Keep out from under lift arm

unless lift arm is supported.

Operate only from operator´s

seat.

Prevent load rolling down lift

arm onto operator.

5103008-14-A

WARNING

Page 47

47

4.Safety

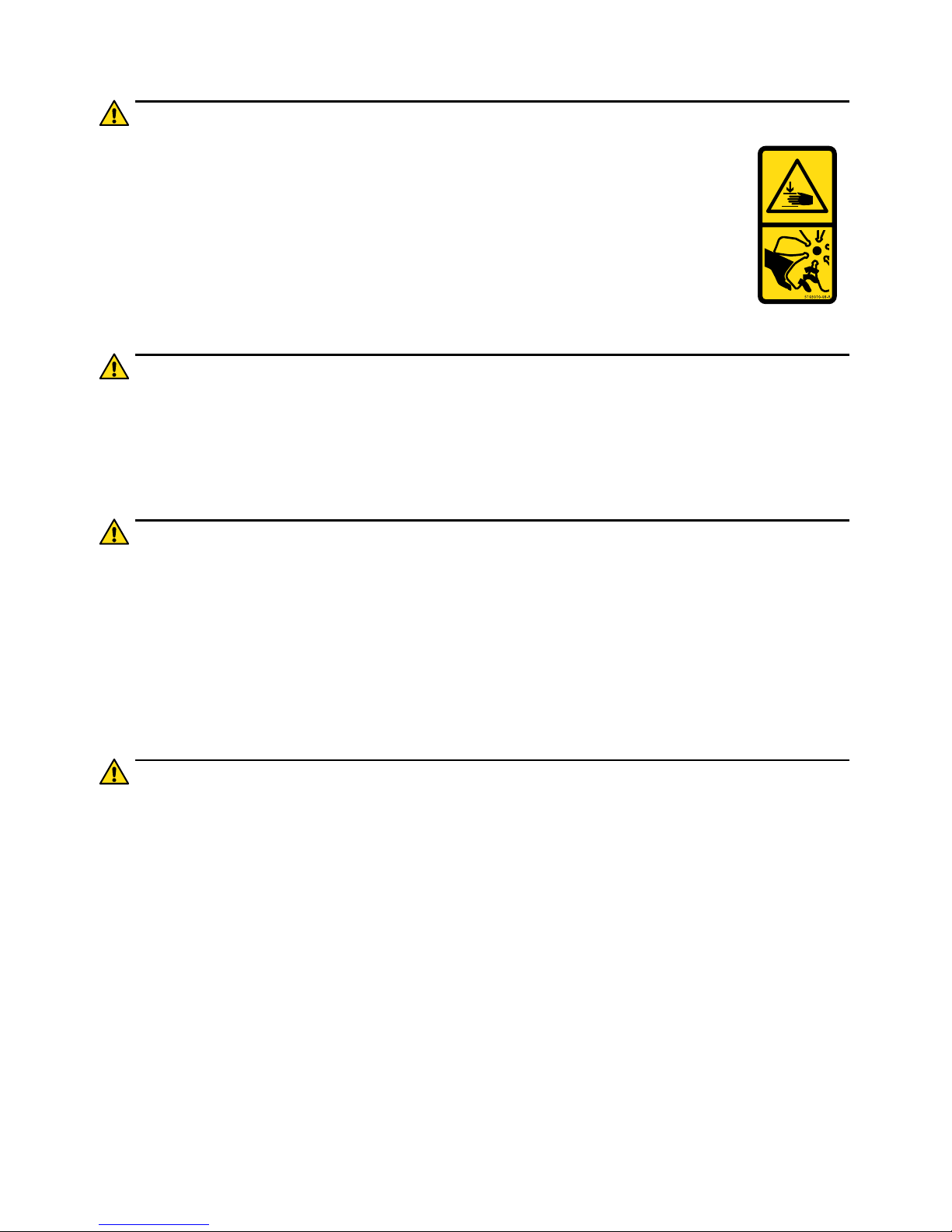

M2 WARNING: Avoid Overturn

Side stability is reduced when:

1) turning; 2) operating on rough terrain or

side slopes; and 3) carrying load raised.

• Carry load low.

• Do not exceed Rated Operating

Capacity.

• Avoid steep slopes and high speed

turns.

• Travel up and down slopes with heavy

end uphill.

N WARNING: Avoid Injury or Death

Located on the control column, facing the

operator.

Always follow “Mandatory Safety Shut down

Procedure.”

1) Lower equipment to ground.

2) Reduce throttle, apply parking brake.

3) Shift to neutral.

4) Stop engine, remove key.

ANSI-Style and Common Safety Decal Location

5103008-36-A

WARNING

AVOID OVERTURN

Side stability is reduced when: 1) turning;

2) operating on rough terrain or

side slopes; and 3) carrying load raised.

Carry load low.

Do not exceed Rated Operating

Capacity.

Avoid steep slopes and high speed

turns.

Travel up and down slopes with heavy

end uphill.

STOP

P

WARNING

AVOID INJURY OR DEATH

Always follow “Mandatory Safety Shutdown

Procedure.”

1) Lower equipment to ground.

2) Reduce throttle, apply parking brake.

3) Shift to neutral.

4) Stop engine, remove key.

5103008-07-A

1

2

3

4

N

Page 48

48

4.Safety

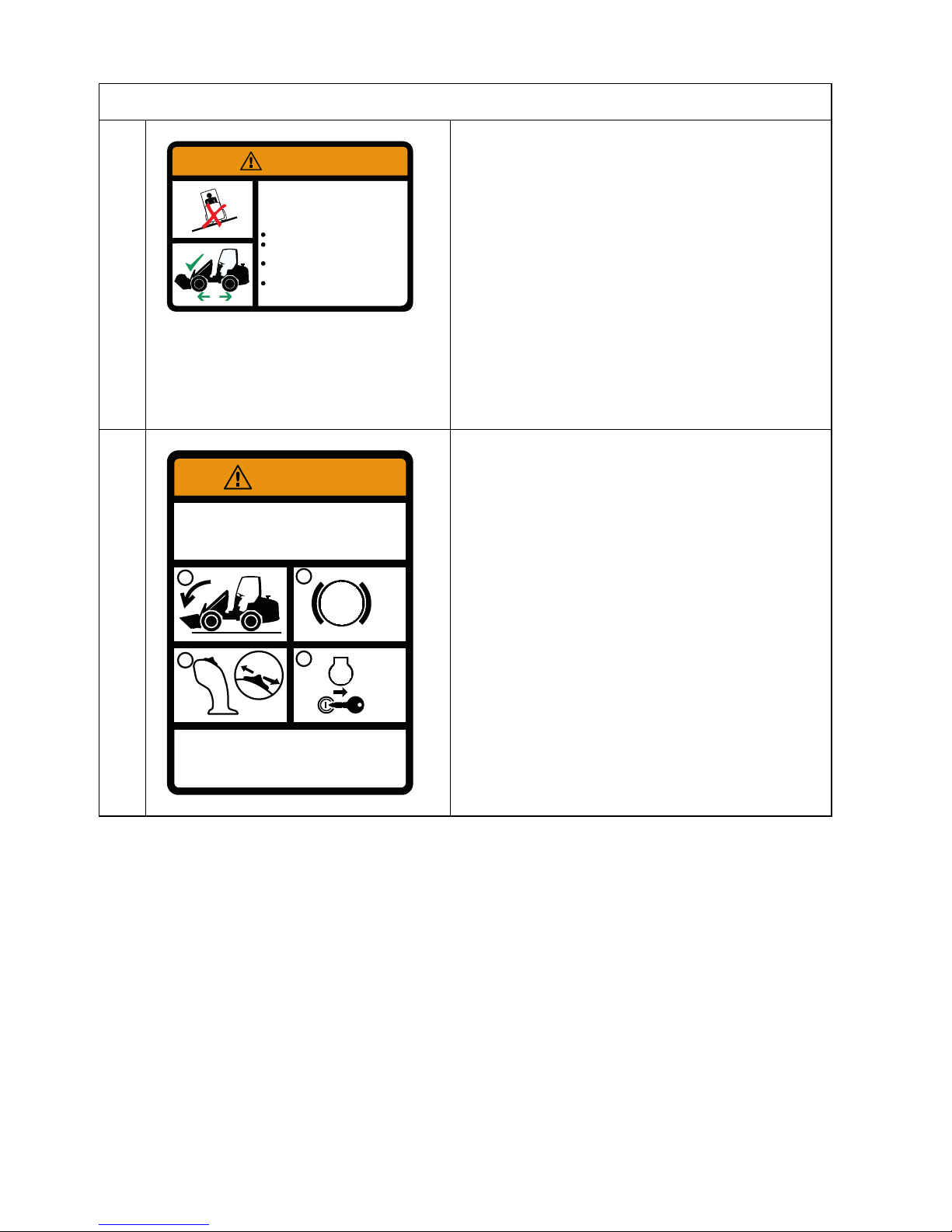

O WARNING: Avoid Injury or Death

Located on the control column, facing the

operator.

• Maintain 3-point contact during entry

and exit.

• Inspect work area; avoid all hazards.

• Look in the direction of travel. Keep

children and bystanders away.

• Start and operate machine only from

seat.

• Never carry riders. Do not lift personnel

in bucket.

• Operate only in well ventilated area.

• Keep away from electric power lines,

avoid contact.

• Do not wear loose clothing while

operating or servicing machine.

• Wear any needed Personal Protective

Equipment.

P WARNING: Crush Hazard

Located under the operator’s platform on

top of the left rear wheel well.

• Be sure lock mechanism is securely

engaged before working under ROPS/

FOPS.

• Read instructions for use in Operator

Manual.

ANSI-Style and Common Safety Decal Location

AVOID INJURY OR DEATH

5103008-13-A

Maintain 3-point contact during entry and exit.

Inspect work area; avoid all hazards.

Look in the direction of travel. Keep children and

bystanders away.

Start and operate machine only from operators seat.

Never carry riders. Do not lift personnel in bucket.

Operate only in well ventilated area.

Keep away from electric power lines, avoid contact.

Do not wear loose clothing while operating or

servicing machine.

Wear any needed Personal Protective Equipment.

WARNING

CRUSH HAZARD

Be sure lock mechanism

is securely engaged

before working under

ROPS / FOPS.

Read instructions for use

in Operator Manual.

5103008-10-A

WARNING

Page 49

49

4.Safety

Q WARNING: Read Operator Manual

Located behind the operator’s seat on the

document box cover.

• Read Operator Manual and all safety

signs before using machine.

• The owner is responsible to ensure all

users are instructed on safe use and

maintenance.

• Check machine before operating.

Service per Operator Manual.

• Contact dealer (or manufacturer) for

information and service parts.

R WARNING: Falling Object Hazard

Located under the parking hand brake lever.

• Falling-Object Protective Structure

(FOPS) must be installed if there is a

risk of falling objects.

S WARNING: Avoid Injury or Death

Located on the control column, facing the

operator.

• Hold on to the steering wheel if the

loader tips over.

• NEVER jump out the loader.

ANSI-Style and Common Safety Decal Location

5103008-35-A

WARNING

AVOID INJURY OR DEATH

Read Operator Manual and all safety signs

before using machine.

The owner is responsible to ensure all users are

instructed on safe use and maintenance.

Check machine before operating. Service per

Operator Manual.

Contact dealer (or manufacturer) for information

and service parts.

5103008-02-A

Falling-Object Protective

Structure (FOPS) must

be installed if there is

a risk of falling objects.

FALLING OBJECT HAZARD

WARNING

WARNING

AVOID INJURY OR DEATH

Hold on to the steering wheel if

the loader tips over.

NEVER jump out of the loader.

5103008-26-A

Page 50

50

4.Safety

T WARNING: Avoid Injury or Death

Located under the parking brake lever.

• When parked; driving or working the

doors must always be closed.

• NEVER remove the doors.

U WARNING: Avoid Injury or Death

Located under the parking brake lever.

• When parked; driving or working the

doors must always be closed.

• NEVER remove the doors.

V WARNING: Avoid Injury

Located along the door.

• By entry and exit of the operator keep a

safe distance.

• Maintain 3-point contact during entry

and exit. Do not grasp steering wheel

during entry and exit.

ANSI-Style and Common Safety Decal Location

AVOID INJURY OR

DEATH

When parked; driving or

working, the doors must

always be closed.

NEVER remove the doors.

WARNING

5103008-25-A

AVOID INJURY OR

DEATH

When parked; driving or

working, the doors must

always be closed.

NEVER remove the doors.

WARNING

5103008-24-A

WARNING

5103008-22-A

AVOID INJURY

By entry and exit

of the operator

keep a safe

distance.

Maintain 3-point

contact during

entry and exit.

Do not grasp

steering wheel

during entry and

exit.

Page 51

51

4.Safety

W WARNING: Avoid Injury

Located along the door.

• By entry and exit of the operator keep a

safe distance.

• Maintain 3-point contact during entry

and exit. Do not grasp steering wheel

during entry and exit.

X Oil specification

Y Break fluid specification

Z Escape route

AA Indicates the grease points

ANSI-Style and Common Safety Decal Location

WARNING

5103008-23-A

AVOID INJURY

By entry and exit

of the operator

keep a safe

distance.

Maintain 3-point

contact during

entry and exit.

Do not grasp

steering wheel

during entry and

exit.

CONSULT YOUR DEALER FOR INFORMATION

Engine Oil: Mobil Super 2000 X1 10W40

Hydraulic Oil: Mobil Nuto H46

Transmission Oil: Mobilube LS 85W90

Coolants: Coolant -26ºC (-14ºF)

5103008-37-A

CONSULT YOUR DEALER FOR INFORMATION

5103008-38-A

Oil Brakesystem: Mobil Nuto H46

According to:

DIN 54524 Part 3 HVLP

ISO 1158 HV

ISO Viscosity Class: 46 cSt

WARNING:

DO NOT USE STANDARD BREAK FLUID!

5103008-39-A

5103010-25-A

Page 52

52

4.Safety

SLOPES

CAUTION:

If possible, do not drive on slopes. Do not drive across slopes.

When you drive on slopes, there is a risk of injury due to these causes:

• The machine can tip over.

• There is less traction and braking force of the wheels which can cause unexpected movement of the machine.

Only drive on slopes in these conditions:

• The attachment is empty.

• The lift arm is in the lowest position.

• The maximum angle of the slope is not more than 11.3° (20%).

• You drive straight up and down the slope.

• The machine is unarticulated.

• You drive up and down the slope with the heaviest end uphill.

When you operate the machine, including loads, the maximum slope at maximum

load at the lowest speed is limited to 3° (5.3%). Steeper slopes are possible with

smaller loads, at your discretion and responsibility. The maximum angle of the

slope depends on these factors:

• The loading, weight, position and balance of the load.

• Your driving style and speed.

• Circumstances and the capacity of the surface, such as loose sand, and

humidity of the surface.

Stay at the ‘high’ side during transport on a slope.

When you load or unload the machine from a trailer, obey the instructions in the

chapter ‘Commissioning’.

SAFETY - HYDRAULIC PARTS

• Exposed hydraulic hoses could react with explosive force if struck by a falling

or overhead items. NEVER allow hoses to be hit, bent or interfered with.

Replace any hoses that are damaged.

• Keep unprotected body parts, such as face, eyes, and arms as far away as

possible from a suspected leak.

• Do not smoke or have any spark- or flame-producing equipment or materials in

the area while working on the hydraulic systems.

Page 53

53

4.Safety

• Do not attempt to loosen or disconnect any hydraulic lines, hoses, fittings, covers or caps without first relieving hydraulic circuit pressure. Relieve hydraulic

pressure by performing the Mandatory Safety Shutdown Procedure of the

machine, and then slowly loosening the hydraulic reservoir filler cap. Be careful not to touch any hydraulic components that have been in recent operation,

because they can be hot and cause burns.

• Do not work on hot hydraulic systems. Wait for the systems to cool. When fluids require changing, wait for fluid temperatures to decrease to a moderate

level before removing drain plugs.

• Prior servicing, the system has to be depressurized completely!

• Safety-critical parts must be periodically replaced. Replace hydraulic system

hoses as soon as they begin to show signs of deterioration, especially the

pump outlet lines. Replace hydraulic hoses every 6 years from the date of

manufacture (month or quarter, and year) is indicated on the hydraulic hoses.

• After cleaning the attachment, check all hydraulic oil lines for leaks, chafe

marks and damage. Tighten any loose connections and repair or replace parts

as necessary.

• Add hydraulic fluid to the attachment only in well-ventilated areas.

• Escaping fluid under pressure can be invisible and can penetrate the skin and

cause serious injury. If any fluid is injected into your skin, see a doctor at once.

Injected fluid must be surgically removed by a doctor or gangrene may result.

If your doctor is not familiar with this type of injury, ask him or her to research it

immediately to determine proper treatment.

Page 54

54

4.Safety

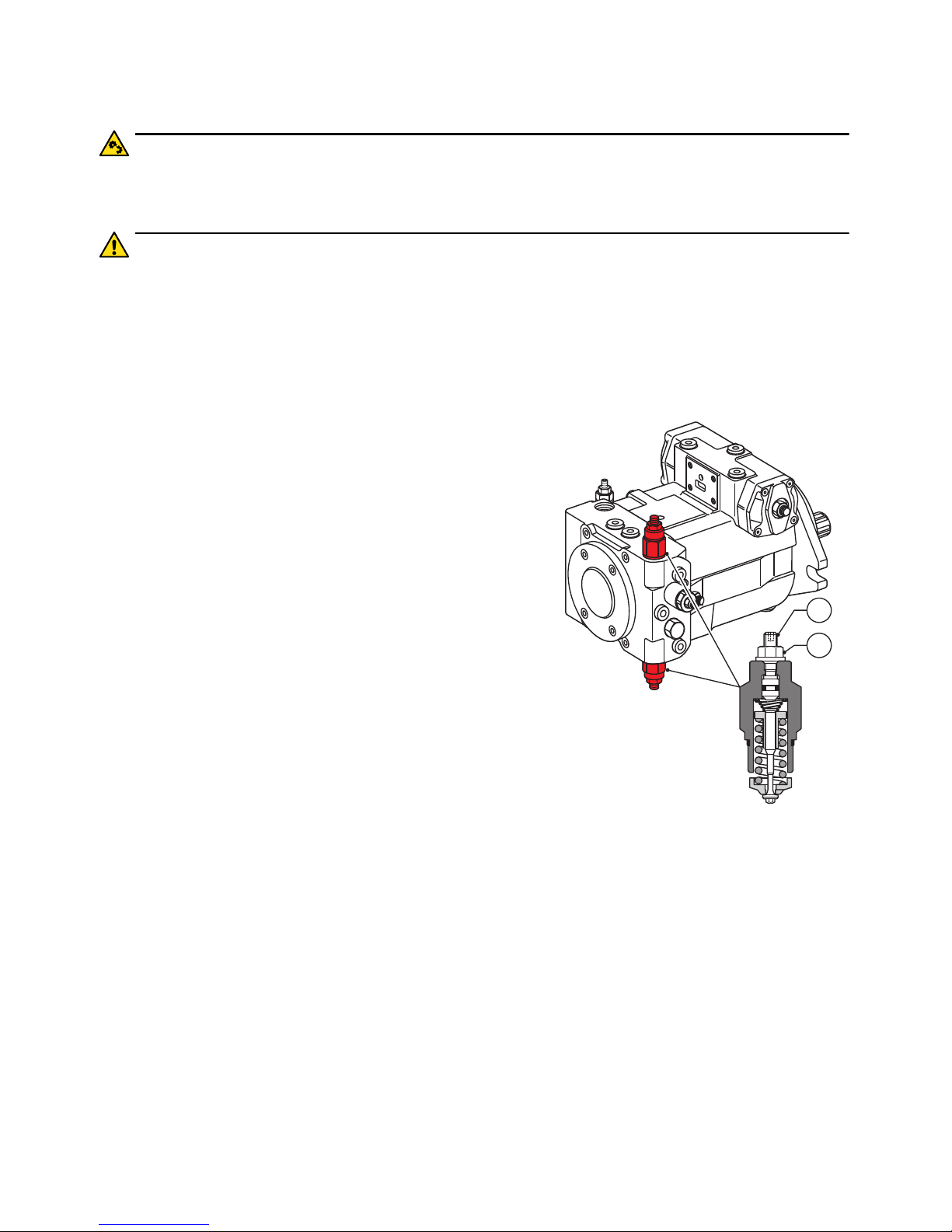

• Wear safety glasses, protective clothing and use a piece of cardboard or wood

when searching for hydraulic leaks. DO NOT USE YOUR HANDS! SEE

ILLUSTRATION.

Page 55

55

4.Safety

SAFETY PRECAUTIONS

CAUTION:

Risk of serious injury.

Read the operator manual of the Wheel Loader thoroughly before

using the machine. This way you know exactly how to operate the

Wheel Loader safely.

CAUTION:

Risk of serious injury.

For maintenance work: Stop engine, remove the ignition key and put

the Wheel Loader on the parking brake. See the operator manual.

This prevents dangerous situations which can arise if the Wheel

Loader suddenly moves or when the lifting arm suddenly goes down.

Also think about unforeseen actions by others.

CAUTION:

Risk of serious injury by collision.

Ensure that bystanders keep at least 10 meters (11 yards) distance

from the travel path of the Wheel Loader. Large bulky loads can

interfere with the driver’s sight.

CAUTION:

Risk of injury due to entrapment by moving parts.

Operate the controls only from the driver’s seat. Ensure that

bystanders keep clear within a radius of 4 meters (4.4 yards) from the

Wheel Loader.

5103010-13-A

Page 56

56

4.Safety

CAUTION:

Risk of serious injury.

Before driving, make sure you sit correctly in the driver’s seat

and always have your seat belt fastened. Make sure the

seat, pedals and your shoes are free of contaminants which