Page 1

Instruction Sheet for pH Buffer Calibration Kit

*3-2700.095*

3-2700.095 Rev A 12/08

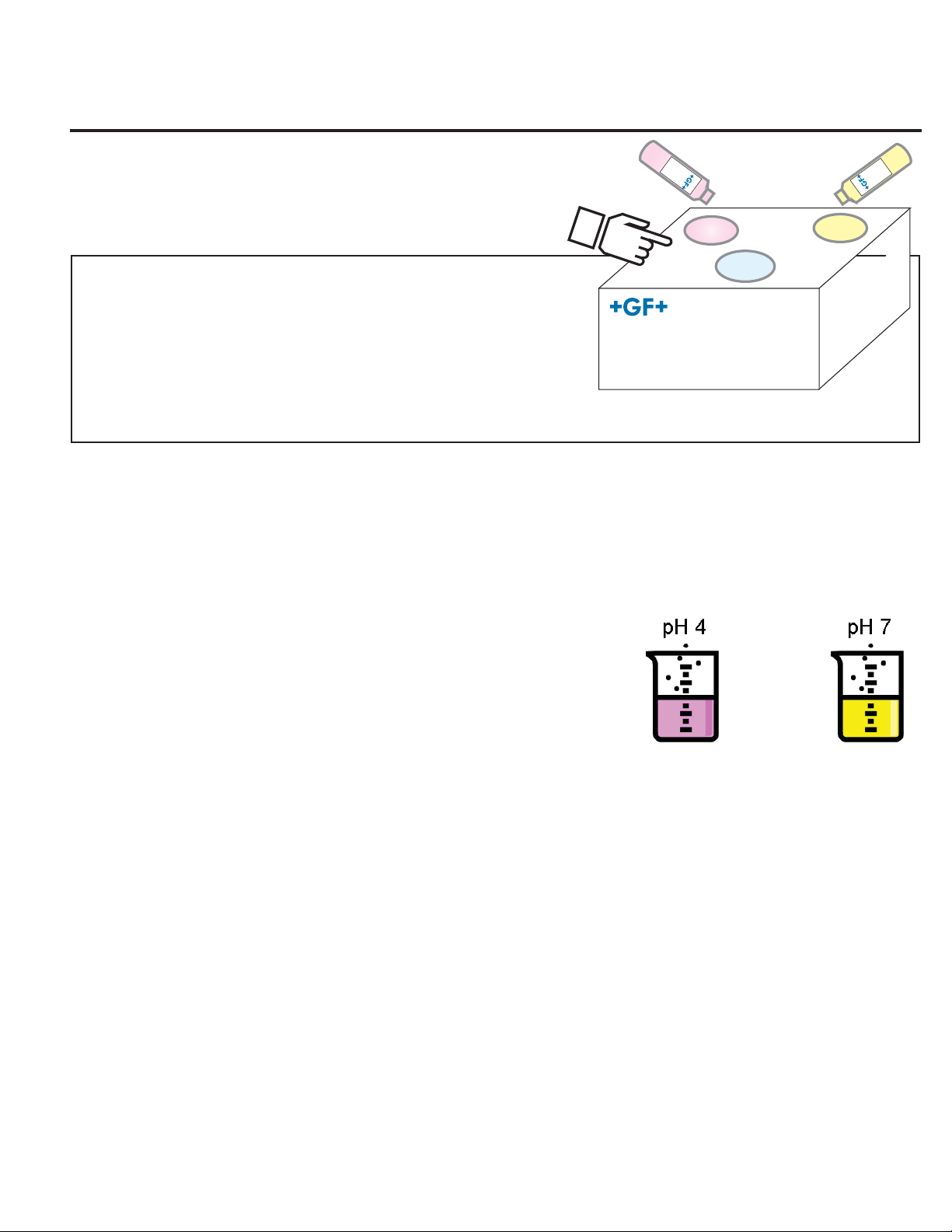

This kit comes with the following items:

1. One pint bottle of pH 4 buffer solution PN 3822-7004

2. One pint bottle of pH 7 buffer solution PN 3822-7007

3. Three reusable polypropylene buffer cups

4. One calibration stand with three punch-out holes

To set up calibration stand:

1. Take out all items from box.

2. Close box with fl aps inserted into side of box. The box is now ready to

be used as a calibration stand.

3. Punch out holes on top of box using perforated cut-out marks.

4. Place buffer containers in holes.

5. Fill one container with rinse water; tap or deionized water is acceptable.

6. Fill the other two containers with about 1 inch of liquid buffer solutions.

The calibration stand is now ready to be used.

pH Calibration Procedure

pH 4

pH 7

Rinse

1. Rinse the sensor off in the rinse water cup. Gentle pat dry with a soft, dry cloth or tissue. Warning: Do not let the rinse water drip

into the buffer solution; this will dilute the solution and may lead to offset buffer values.

2. Gently place the pH sensor in the fi rst buffer solution ( pH 7). Wait until the output from the sensor is stable on the instrument display.

3. Follow the instrument’s instructions regarding buffer recognition.

4. Rinse the sensor with water. Warning: Do not let the rinse water drip into the buffer solution; this will dilute the solution and

may lead to offset buffer values.

5. Dry the sensor gently by patting it with a dry, clean cloth or tissue.

6. Place the sensor in a cup containing the second buffer solution (pH 4 or pH 10). The

second solution used will depend on the typical pH value of the application.

• If the process value is below pH 7, then use a pH 4 buffer solution.

• Sometimes pH 10 buffer solution is used when the typical process value is above

7 pH, however, pH 4 buffer is suffi cient if pH 10 buffer is not available.

7. Wait until the output from the sensor is stable.

8. Follow the instructions in the instrument manual regarding buffer recognition.

9. Rinse the sensor with water. Warning: Do not let the rinse water drip into the

buffer solution; this will dilute the solution and may cause offset buffer values.

10. Dry the sensor gently by patting it with a dry, clean cloth or tissue.

11. If the calibration was successful, put the sensor back on-line. If it was not successful, clean the sensor and recalibrate. If the sensor

cannot be calibrated, the electrode may need to be replaced.

Calibration Tips:

1. The pH solutions can be used for calibrating more than one sensor within a day. However, the solutions must remain free of debris

and must not be diluted by rinse water from previous calibrations.

Note: Use fresh buffer solutions for best results.

2. ORP solutions can be created using pH 4 and pH 7 buffer solutions saturated with quinhydrone, but these solutions are very unstable

and may not read properly after exposure to air for a prolonged time. These solutions must be discarded after a few hours.

3. Tap or deionized water may be used to rinse the electrodes between each buffer solution.

4. Calibration solutions change value with varying temperature. Sensors will not calibrate properly if the sensor is not at ambient

temperature. Take note of all temperature variations of the sensors and the calibration solutions.

5. Do not pour used buffer solutions back into the bottle; dilute with plenty of water and fl ush them down the drain.

6. Store electrodes in pH 4 buffer when not in use.

7. Calibrate sensors on a regular basis.

8. If the pH sensor does not calibrate within acceptable limits, clean the electrode and calibrate again. If the sensor continues to

calibrate outside of acceptable limits, the electrode is spent and must be disposed.

9. Acceptable pH ranges during calibration are as follows:

pH 7: High: 7.8 pH = -50 mV Low: 6.2pH = 50 mV

pH 4: High: 4.8 = 227 mV Low: 3.2 = 127mV

pH 10: High: 10.8 = -227 mV Low: 9.2 = -127 mV

Page 2

Most common errors associated with buffer calibration

1. Failure to compensate for the buffer value at the actual temperature; see buffer bottles for temperature corrected

values.

2. Accepting a calibration value before the sensor has had time to fully respond.

• This also occurs as a result of a warm pH sensor being placed in a cool buffer solution; full stabilization and a

correct pH reading will not occur until all components of the pH sensor and the buffer have reached the same

temperature.

3. Some automatic buffer calibration features, such as the Signet EasyCal feature, help eliminate these errors by

identifying and temperature correcting the calibration buffer and not allowing the calibration procedure to be

completed until a stable reading has been reached.

When to calibrate:

• When the sensor is new and initially installed.

• When the sensor is cleaned for regularly scheduled maintenance.

Caution:

• Always wear protective gloves and appropriate eyewear when using calibration solutions.

• In rare cases, calibration solutions may come in contact with skin or eyes. Rinse solution off of skin or out of eyes

by fl ushing with tap water for 5 minutes.

Sensor Cleaning

Problem Suggested Solution

Hard Coatings Use a dilute acid solution (HCl solution of 5% or less). If the electrode has been used in applications

with a pH value higher than 7 pH, soak the electrode for 2 to 5 minutes.

Use a dilute alkaline solution (NaOH solution at 5% or less) if the electrode has been used in

applications with pH values less than 7 pH, soak the electrode for 2 to 5 minutes.

Alternating immersion in acidic and alkaline solutions may be necessary for thorough cleaning.

A soft bristle brush, like a toothbrush, may be used to remove coatings.

Soft Coatings Spray or vigorously stir the electrode with a mild detergent (such as dishwashing liquid)

Chlorine bleach can also be used.

Oily or Organic Coatings Spray or vigorously stir the electrode with a mild detergent or an appropriate solvent that will not

attack the materials of construction. (isopropyl alcohol or similar)

ORP Platinum Coating Gently wipe the electrode surfaces with a paper towel.

After Cleaning Always rinse the electrode with water after cleaning.

Soak the electrode in a pH 4 buffer (with KCl if available) for at least 10 minutes after cleaning.

Replacement Parts and other accessories:

Mfr. Part No. Code Description

3822-7004 159 001 581 pH 4 buffer solution, 1 pint (473 ml) bottle

3822-7007 159 001 582 pH 7 buffer solution, 1 pint (473 ml) bottle

3822-7010 159 001 583 pH10 buffer solution, 1 pint (473 ml) bottle

3-0700.390 198 864 403 pH buffer kit (1 each 4, 7, 10 pH buffer in powder form)

3-2700.395 159 001 605 Calibration kit ; includes 3 reusable polypropylene buffer cups, one sensor stand, 1

pt pH 4 buffer solution, 1 pt pH 7 buffer solution

Special Request NIST Traceable Certifi cate

3822-7115 159 001 606 20 gm bottle Quinhydrone for ORP calibration

Georg Fischer Signet LLC, 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

3-2700.095 Rev. A 12/08 © Georg Fischer Signet LLC 2008 Printed in U.S.A. on recycled paper

Loading...

Loading...