Page 1

Signet 8450-3 Pressure Transmitter

Output -

Output +

System Pwr

Loop System Pwr

Loop +

2

1

4

3

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

7

6

5

8052

92 mm

(3.6 in.)

97 mm

(3.8 in.)

56 mm

(2.2 in.)

41 mm

(1.6 in.

)

Optional

Rear

Cover

SIDE VIEW

Field Mount

96 mm

(3.8 in.)

96 mm

(3.8 in.)

96 mm

(3.8 in.)

quick-clips

gasket

panel

terminals

mounting

bracket

latch

Panel Mount

SIDE VIEW

FRONT VIEW

Field Mount &

Panel Mount

Panel Mount

Installation Detail

107 mm (4.2 in.)

42 mm

(1.7 in.)

65 mm

(2.5 in.)

*3-8450.090-3*

3-8450.090-3 Rev. J 01/13 English

English

CAUTION!

• Remove power to unit before wiring

input and output connections.

• Follow instructions carefully to avoid

personal injury.

Contents

1. Installation

2. Specifi cations

3. Electrical Connections

4. Menu Functions

Pres1: 4.5 psi

Pres2: 2.3 psi

Signet Pressure

Transmitter

ENTER

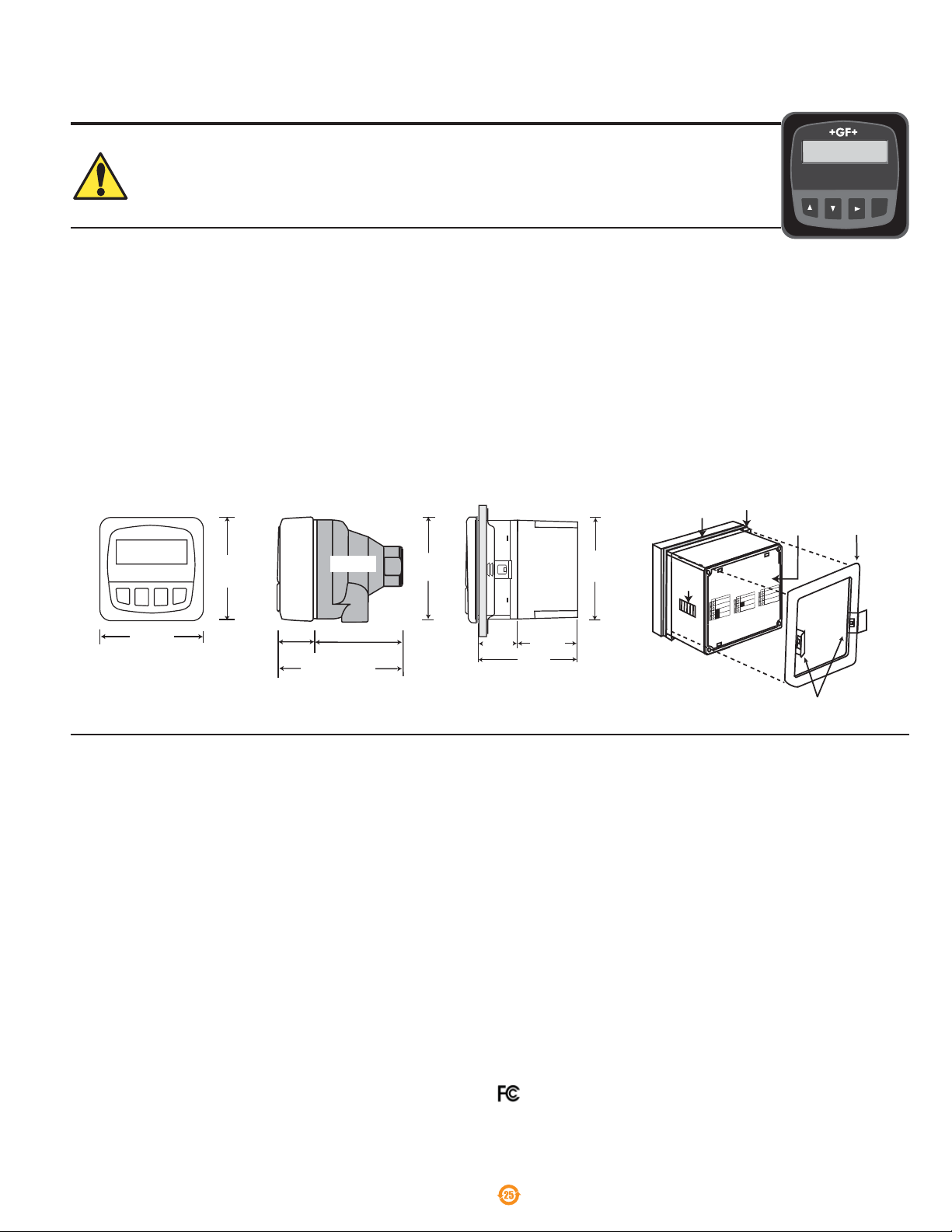

1. Installation

ProcessPro transmitters are available in two styles: panel mount and fi eld mount. The panel mount is supplied with the necessary

hardware to install the transmitter. This manual includes complete panel mounting instructions.

Field mounting requires one of two separate mounting kits. The 3-8052 integral kit joins the sensor and instrument together into a

single package. The 3-8050 Universal kit enables the transmitter to be installed virtually anywhere.

Detailed instructions for integral mounting or other fi eld installation options are included with the 3-8052 Integral kit or the 3-8050

Universal kit.

1.1 Panel Installation

1. The panel mount transmitter is designed for installation using a ¼ DIN Punch. For manual panel cutout, an adhesive template is

provided as an installation guide. Recommended clearance on all sides between instruments is 1 inch.

2. Place gasket on instrument, and install in panel.

3. Slide mounting bracket over back of instrument until quick-clips snap into latches on side of instrument.

4. To remove, secure instrument temporarily with tape from front or grip from rear of instrument. DO NOT RELEASE.

Press quick-clips outward and remove.

2. Specifi cations

General

Compatibility: Signet 2450 Pressure Sensor

Accuracy: ±1% of full scale

Enclosure:

• Case: PBT

• Panel case gasket: Neoprene

• Window: Polyurethane coated polycarbonate

• Keypad: Sealed 4-key silicone rubber

• Weight: Approx. 325 g (12 oz.)

Display:

• Alphanumeric 2 x 16 LCD

• Update rate: 1 second

• Contrast: User selected, 5 levels

Electrical

Power: 12 to 24 VDC ±10%, regulated,

Sensor Input:

• Range: 0-250 psig, 0-17 bar, 0-1700 kPa

Current output:

• 4 to 20 mA, isolated, fully adjustable and reversible

• Max loop impedance: 50 Ω max. @ 12 V,

325 Ω max. @ 18 V,

600 Ω max. @ 24 V

• Update rate: 100 ms

• Accuracy: ±0.03 mA

60 mA max current

Open-collector output: Hi, Lo, Off, Programmable:

• Optically isolated, 50 mA max. sink, 30 VDC max. pull-up

voltage

• Hysteresis: User adjustable

Environmental

• Operating temperature: -10 °C to 70 °C (14 °F to 158 °F)

• Storage temperature: -15 °C to 80 °C (5 °F to 176 °F)

• Relative humidity: 0 to 95%, non-condensing

• Maximum altitude: 2000 m (6562 ft)

• Insulation category: II

• Rating: NEMA 4X/IP65 front

Standards and Approvals

• CE, UL listed

• Immunity: EN50082-2

• Emissions: EN55011 Class B

• Manufactured under ISO 9001 for Quality, ISO 14001

for Environmental Management and OHSAS 18001 for

Occupational Health and Safety.

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

China RoHS (Go to www.gfsignet.com for details)

Page 2

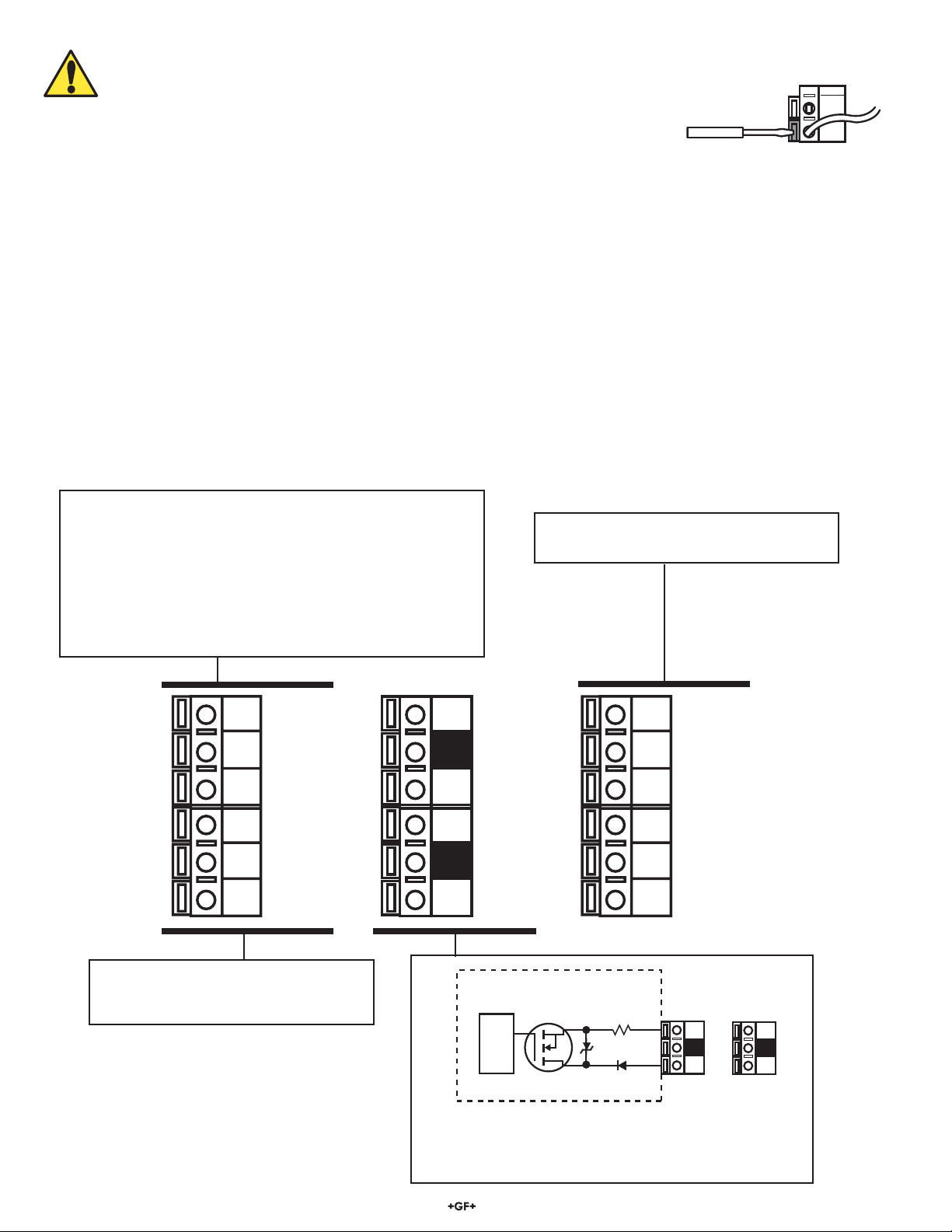

3. Electrical Connections

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

Output 2-

Output 2+

Output 1-

Output 1+

Loop 2-

Loop 2+

System Pwr

Loop -

System Pwr

Loop +

AUX

Power -

AUX

Power +

Snsr 2 Gnd

(WHITE)

Snsr 2 IN

(RED)

Snsr 2 V+

(BLACK)

Snsr 1 Gnd

(WHITE)

Snsr 1 IN

(RED)

Snsr 1 V+

(BLACK)

1

15

S

D

2

_

+

Internal open-collector

output circuit

Outputs

Isolation

Caution: Failure to fully open terminal jaws before removing wire may permanently damage instrument.

Wiring Procedure

1. Remove 13 mm - 16 mm (0.5 in. - 0.625 in.) of insulation from wire end.

2. Press the orange terminal lever downward with a small screwdriver to open terminal jaws.

3. Insert exposed (non-insulated) wire end in terminal hole until it bottoms out.

4. Release orange terminal lever to secure wire in place. Gently pull on each wire to ensure a good connection.

Wiring Removal Procedure

1. Press the orange terminal lever downward with a small screwdriver to open terminal jaws.

2. When fully open, remove wire from terminal.

Wiring Tips:

• Do not route sensor cable in conduit containing AC power wiring. Electrical noise may interfere with sensor signal.

• Routing sensor cable in grounded metal conduit will help prevent electrical noise and mechanical damage.

• Seal cable entry points to prevent moisture damage.

• Only one wire should be inserted into a terminal. Splice double wires outside the terminal.

• If your system uses a single sensor, it must be located within 122 m (400 ft.) of the transmitter.

• If your system uses two sensors, the total length of cable connected to the transmitter is limited to 122 m (400 ft.)

• The 3 conductors from a dual-sensor system can be tied together and then a single set of wires continued on to the transmitter.

• For best performance, ground the sensor SHIELD wire to a local earth ground at a point near the sensor.

(Experiment with connecting the sensor shield wire to different local ground points to identify best signal quality.)

Terminals 3-4: Primary Loop Power

12-24 VDC ±10% system power and current loop connections.

SINGLE SENSOR system MUST use terminals 3-4.

Terminals 5-6: 12-24 VDC ± 10%

Power and current loop connections for second sensor.

• Maximum loop impedance:

50Ω max. at 12 V

325Ω max. at 18 V

600Ω max. at 24V

Terminals 11-16: Dual digital sensor inputs

See next page for more information.

2

1

Terminals 1-2: Auxiliary power is used

only if two sensors are connected to the

transmitter.

2 Signet 8450-3 Pressure Transmitter

Terminals 7-10: Open-Collector Outputs

• Two transistor outputs programmable as High or

Low alarm with adjustable hysteresis

• Outputs can be disabled (Off) if not used

Page 3

16

15

14

13

12

11

Signet 2450

Pressure Sensors

Terminals

White (Snsr 2 Gnd)

Red (Snsr 2 IN)

Black (Snsr 2 V+)

White (Snsr 1 Gnd)

Red (Snsr 1 IN)

Black (Snsr 1 V+)

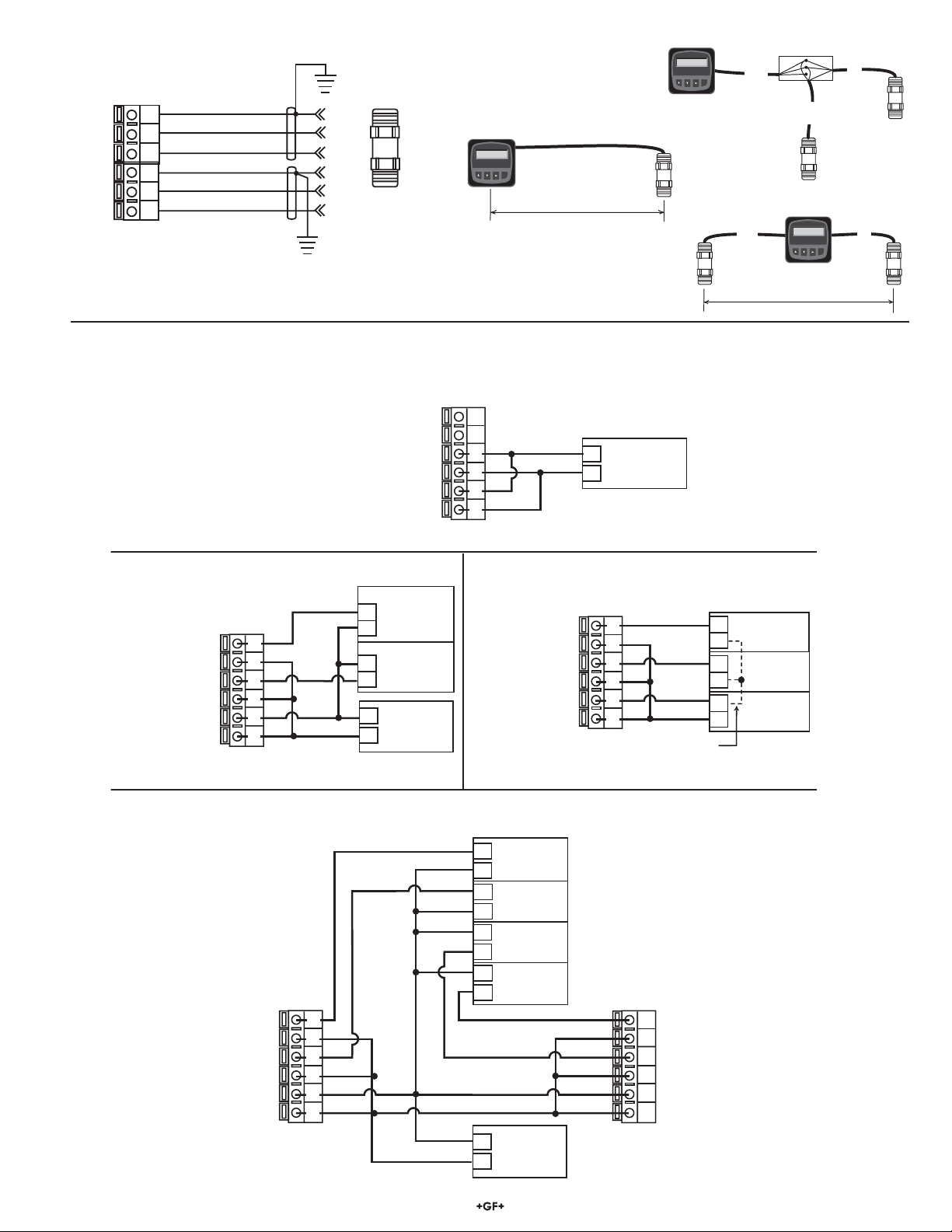

3.1 Sensor Input Connections

+

+

-

+

-

+

+

+

-

+

+

+

+

+

-

+

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

*

Example: Two transmitters connected to PLC/Recorder with separate power supply

Loop 2 Loop 2 +

System Power Loop 1 System Power Loop 1 +

AUX Power AUX Power +

Loop 2 -

Loop 2 +

System Power Loop 1 -

System Power Loop 1 +

AUX Power -

AUX Power +

PLC or Recorder

Channel 3

4-20 mA in

Channel 4

4-20 mA in

Transmitter 1

Terminals

Transmitter 2

Terminals

Channel 1

4-20 mA in

Channel 2

4-20 mA in

Power

Supply

12-24 VDC

* *

*

* *

*

*

*

Stand-alone application, no current loop used

Transmitter

Terminals

Power

Supply

12-24 VDC

Connection to a PLC with built-in power supply

Internal

PLC

Connection

PLC or Recorder

Loop 2 -

Loop 2 +

System Power Loop 1 -

System Power Loop 1 +

AUX Power -

AUX Power +

Transmitter

Terminals

Loop 2 -

Loop 2 +

System Power Loop 1 -

System Power Loop 1 +

AUX Power -

AUX Power +

Transmitter

Terminals

Loop 2 -

Loop 2 +

System Power Loop 1 -

System Power Loop 1 +

AUX Power -

AUX Power +

Power

Supply

12-24 VDC

PLC Terminals

Channel 1

4-20 mA

Power

Supply

12-24 VDC

Channel 2

4-20 mA

Channel 2

4-20 mA

Channel 1

4-20 mA

NC

NC

AUX power required only where two sensors are used

AUX power required only where two sensors are used

AUX power required only where two sensors are used

AUX power required only where two sensors are used

A

B

A

B

C

Signet Pressure

Transmitter

Pressure Cal:

0.0 psi >

ENTER

Signet Pressure

Transmitter

Pressure Cal:

0.0 psi >

ENTER

Transmitter

A + B 122 m (400 ft.)

J-box

Transmitter

A + B + C 122 m (400 ft.)

Signet Pressure

Transmitter

Pressure Cal:

0.0 psi >

ENTER

Transmitter

122 m (400 ft.)

3.2 System Power/Loop Connections

3Signet 8450-3 Pressure Transmitter

Page 4

Pres1: 4.5 psi

Pres2: 2.3 psi

ENTER

Signet Pressure

Transmitter

3.3 Open Collector Output

Hysteresis

Time

Low Setpoint

Process

Output energized

Output de-energized

Hysteresis

Time

High Setpoint

Process

The Open Collector output can be used as a switch that responds

when the process variable moves above or below a setpoint.

• Low:

Output triggers when process variable is less than the setpoint.

The output will relax when the process variable moves above the

setpoint plus the hysteresis value.

• High:

Output triggers when process variable is greater than the

setpoint. The output will relax when the process variable moves

below the setpoint plus the hysteresis value.

Delta Pressure (Differential Mode)

If two sensors are connected to the transmitter, the DELTA

(Sensor 1 - Sensor 2) can be assigned to output. To enable

differential mode, the selected output's "Source" selection must

be set to "DP".

For pressure and temperature transmitters ensure Sensor 1 is

equal to ID 1:

Sensor 1 - Sensor 2

Difference = 60

Example: 4-20 mA

Sensor 1 (80)

Sensor 2 (20)

ENTER

Loop1 Source: DP

Loop1 Range: 0-120

Loop1: = 12.00 mA

Example: Output

Output1 Source: DP

Output1 Mode: Low

Output1 Setpoint: 70

Output1 = ON

VIEW menu

• During normal operation, the ProcessPro displays the VIEW menu.

• When using the CALIBRATE or OPTIONS menus, the ProcessPro will return to the VIEW menu if no

activity occurs for 10 minutes.

• To select the item you want displayed, press the UP or DOWN arrow keys. The items will scroll in a

continuous loop.

• Changing the display selection does not interrupt system operations.

• No keycode is necessary to change display selection.

• Output settings cannot be edited from the VIEW menu.

View Menu

4 Signet 8450-3 Pressure Transmitter

Display Description

Press1: 7.89 psi

Press2: 4.56 psi

Delta Pressure:

3.33 psi

Monitor Pressure 1 and Pressure 2 simultaneously.

This is the permanent view display.

Monitor the delta pressure (Channel 1 rate - channel 2 rate = Delta Pressure)

This is a permanent display.

The displays below are temporary. After 10 minutes the display returns to the permanent display.

Loop 1 Output:

12.00 mA

Loop 2 Output:

Monitor the 4 to 20 mA output for Loop 1 and 2.

7.65 mA

Last CAL:

02-10-09

Monitor date for scheduled maintenance or date of last calibration.

(See description in Calibrate Menu.)

Page 5

Output1 Setpnt:

1

0.00 psi

Output1 Setpnt:

0

0.00 psi

ENTER

Output1 Setpnt:

0

0.00 psi

Output Setpnt:

09.00 psi

Output1 Setpnt:

Saving

Output1 Setpnt:

09.00 psi >

ProcessPro Editing Procedure:

CALIBRATE: ----

Enter Key Code

CALIBRATE: *---

Enter Key Code

CALIBRATE: **--

Enter Key Code

CALIBRATE: ***-

Enter Key Code

>

Switch ID:

>

Switch ID:

10.00 psi >

Output1 Setpnt:

Step 1. Press and hold ENTER key:

• 2 seconds to select the CALIBRATE menu

• 5 seconds to select the OPTIONS menu.

Step 2. The Key Code is UP-UP-UP-DOWN keys in sequence.

• After entering the Key Code, the display will show the fi rst item in the selected menu.

Step 3. Scroll menu with UP or DOWN arrow keys.

Step 4. Press RIGHT ARROW key to select menu item to be edited.

• The fi rst display element will begin fl ashing.

Step 5. Press UP or DOWN keys to edit the fl ashing element.

• RIGHT ARROW key advances the fl ashing element.

Step 6. Press ENTER key to save the new setting and return to Step 3.

Notes on Step 1:

• The View Menu is normally displayed.

• The CALIBRATE and OPTIONS menus require a KEY CODE.

Press &

hold for

access:

VIEW

ENTER

Notes on Step 2:

If no key is pressed for 5 minutes while display is showing "Enter

Key Code", the display will return to the VIEW menu.

2s 5s

CALIBRATE

OPTIONS

Notes on Steps 3 and 4:

• Refer to pages 6 and 7 for complete listing of menu items and their use.

• From the Step 3 display, pressing the UP and DOWN keys simultaneously will

return the display to the VIEW menu.

• If no key is pressed for 10 minutes, display will also return to the VIEW menu.

Step 3: Finished Editing?

Press the UP and DOWN keys simultaneously after

saving the last setting to return to normal operation.

First item in

CALIBRATE menu

Step 3

Step 4

Notes on Steps 5 and 6:

• All output functions remain active during editing.

• Only the fl ashing element can be edited.

• RIGHT ARROW key advances the fl ashing element in a continuous loop.

• Edited value is effective immediately after pressing ENTER key.

• If no key is pressed for 10 minutes unit will restore the last saved value and return to step 3.

• Step 6 (pressing ENTER key) always returns you to Step 3.

• Repeat steps 3-6 until all editing is completed.

Step 5: Made an Error?

Press the UP and DOWN keys simultaneously

while any element is fl ashing. This will recall the

last saved value of the item being edited and

return you to Step 3.

Step 5

Step 6

5Signet 8450-3 Pressure Transmitter

Page 6

Calibrate Menu

Display

(Factory settings shown)

Switch ID

PSI

Pressure Units:

psi >

Set:

Pressure1

Set:

Pressure2

Loop 1 Source

Pressure1

Loop 1 Range: psi

0.0 → 100.0 >

Output 1 Source

Pressure1

Description

Reverses the identifi cation of Sensor inputs: Pressure 1 becomes identifi ed as Pressure 2,

Pressure 2 becomes identifi ed as Pressure1.

Use this function to make corrections if the sensors are in the wrong order for a DELTA

PRESSURE measurement.

Select Pressure units for both input channels: psi, bar or kPa.

Provides a maximum 5 psi offset to match 8450 to external reference.

Enter “-999” to restore the original Factory calibration value.

Changes to this setting will become effective when the display exits the Calibrate menu.

Select the INPUT SIGNAL represented by this 4-20 mA output:

Pressure 1, Pressure 2, or Delta Pressure (Pressure1 - Pressure2.)

Check the 2450 Sensor instructions for the range capability of your sensor.

Be sure to modify this setting if you change the Pressure Units.

Select the INPUT SIGNAL represented by this Open Collector Output:

Pressure 1, Pressure 2, or the Delta Pressure (Pressure1 - Pressure2.)

Output1 Mode:

Low >

Output1 Setpnt:

10.0 psi >

Output1 Hys:

5 >

Last CAL:

2-10-09

Select the desired mode of operation for the Open Collector output. Options available are

High or Low. The signal may be disabled (Off) if not used.

In Low or High Mode, the Open Collector output #1 will be activated when the pressure

reaches this value. Be sure to modify this setting if you change the Pressure Units.

The Open Collector output will be de-energized at Setpoint ± Hysteresis, depending on High

or Low Setpoint selection.

Use this “note pad” to record important dates, such as annual recertifi cation or scheduled

maintenance.

Menu items will repeat for Loop 2 and Output 2.

6 Signet 8450-3 Pressure Transmitter

Page 7

Options Menu

Display

(Factory settings shown)

Description

Contrast:

3 >

Decimal

*****. >

Averaging

Off >

Adjust the LCD contrast for best viewing. A setting of 1 is lowest contrast, 5 is highest. Select

lower contrast if the display is in warmer ambient surroundings.

Set the decimal to the best resolution for your application. The display will automatically scale

up to this resolution. Select *****., ****.*, ***.**, **.*** or *.****

OFF provides the quickest output response to changes in fl ow. Longer averaging period

produces more stable display and output response. Select LOW, HIGH or OFF.

Output1 Active

Low >

Output2 Active

Active HIGH: This setting is used to turn a device (pump, valve) ON at the setpoint.

Active LOW: This setting is used to turn a device OFF at the setpoint.

Low >

Loop1 Adjust

4.00 mA >

Loop1 Adjust

20.00 mA >

Adjust the minimum and maximum current output. Use this setting to match the system output

to any external device. The display value represents the precise current output.

Adjustment limits:

• 3.80 mA < 4.00 mA > 5.00 mA

• 19.00 mA < 20.00 mA > 21.00 mA

Test Loop 1:

>

Test Loop 2:

Press UP or DOWN keys to manually order any output current value from 3.6 mA to

21.00 mA to test current loop output.

>

Test Output 1:

>

Test Output 2:

Press UP or DOWN keys to manually toggle the state of open collector output.

>

Menu items will repeat for Loop 2 and Output 2.

7Signet 8450-3 Pressure Transmitter

Page 8

Troubleshooting

Display Condition Possible Causes Suggested Solutions

Check Sensor?

Too much error

CHECK SENSOR

Reset to Factory

Calibration

Relay is always activated

SETUP READ ERROR

Press Any Key

• Sensor not wired properly.

• Sensor connected to 8450 while

power is on.

• Defective sensor.

The value entered in Set Pressure fi eld is

greater than 5 psi deviation from sensor

input. (The 8450 allows a maximum of

5 psi calibration offset.).

Value in SET PRESSURE fi eld is -999.

• Hysteresis value too large

• Defective transmitter

Memory fault occurred.

• Correct sensor wiring.

• Recycle power with all sensors connected.

• Replace defective sensor.

• Confi rm calibration values.

• Remove sensor from installation, check

8450 reading (should be zero). If necessary,

Set Pressure to zero, reinstall sensor, then

recalibrate.

Entering "-999" in this fi eld will remove all user

calibration input and restore the factory values.

• Change the hysteresis value

• Replace transmitter

• Press any key to reload factory presets.

• Reprogram all setpoints.

• If this message appears again, replace the

8450.

Ordering Information

Mfr. Part No. Code Description

3-8450-1 159 000 041 Pressure transmitter, Field mount

3-8450-1P 159 000 042 Pressure transmitter, Panel mount

3-8450-2 159 000 043 Pressure transmitter, Field mount with relays

3-8450-2P 159 000 044 Pressure transmitter, Panel mount with relays

3-8450-3 159 000 045 Pressure transmitter, Field mount with dual input/output

3-8450-3P 159 000 046 Pressure transmitter, Panel mount with dual input/output

Accessories

Mfr. Part No. Code Description

3-8050 159 000 184 Universal mounting kit

3-8052 159 000 188 3/4 in. Integral mounting kit

3-8052-1 159 000 755 3/4 in. NPT mount junction box

3-8050.395 159 000 186 Splashproof rear cover

3-8050.396 159 000 617 RC Filter kit (for relay use)

3-0000.596 159 000 641 Heavy duty wall mount bracket

3-5000.598 198 840 225 Surface Mount Bracket

3-9000.392 159 000 368 Liquid tight connector kit for rear cover (includes 3 connectors)

3-9000.392-1 159 000 839 Liquid tight connector kit, NPT (1 piece)

3-9000.392-2 159 000 841 Liquid tight connector kit, PG13.5 (1 piece)

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-8450.090-3 Rev. J 01/13 English © George Fischer Signet, Inc. 2013

Loading...

Loading...