Page 1

5090

Rotor

w/magnets

Black

Red

515 Circuit

Shield

SPAN

0

1

2

3

8

6

7

5

4

9

X 100

GPM

10

SPAN

Signet Monitor

LPM

x 1,000

GPM

x 10

m3/h

SPAN

0

1

2

3

8

6

7

5

4

9

10

SPAN

0

1

2

SPAN

0

1

2

SPAN

0

1

2

3

8

6

7

5

4

9

10

Signet 5090 Flow Monitor

Red

Blk

Shld

Sensor

Input

515

Black (AC signal out)

Red (AC signal out)

Silver (shield)

5090 Rear

Terminal

Connection

Red

Blk

Shld

Sensor

Input

Red

Blk

Shld

Sensor

Input

LISTED

77CJ

U

L

*3-5090.090-1*

3-5090.090-1 Rev. K 08/13

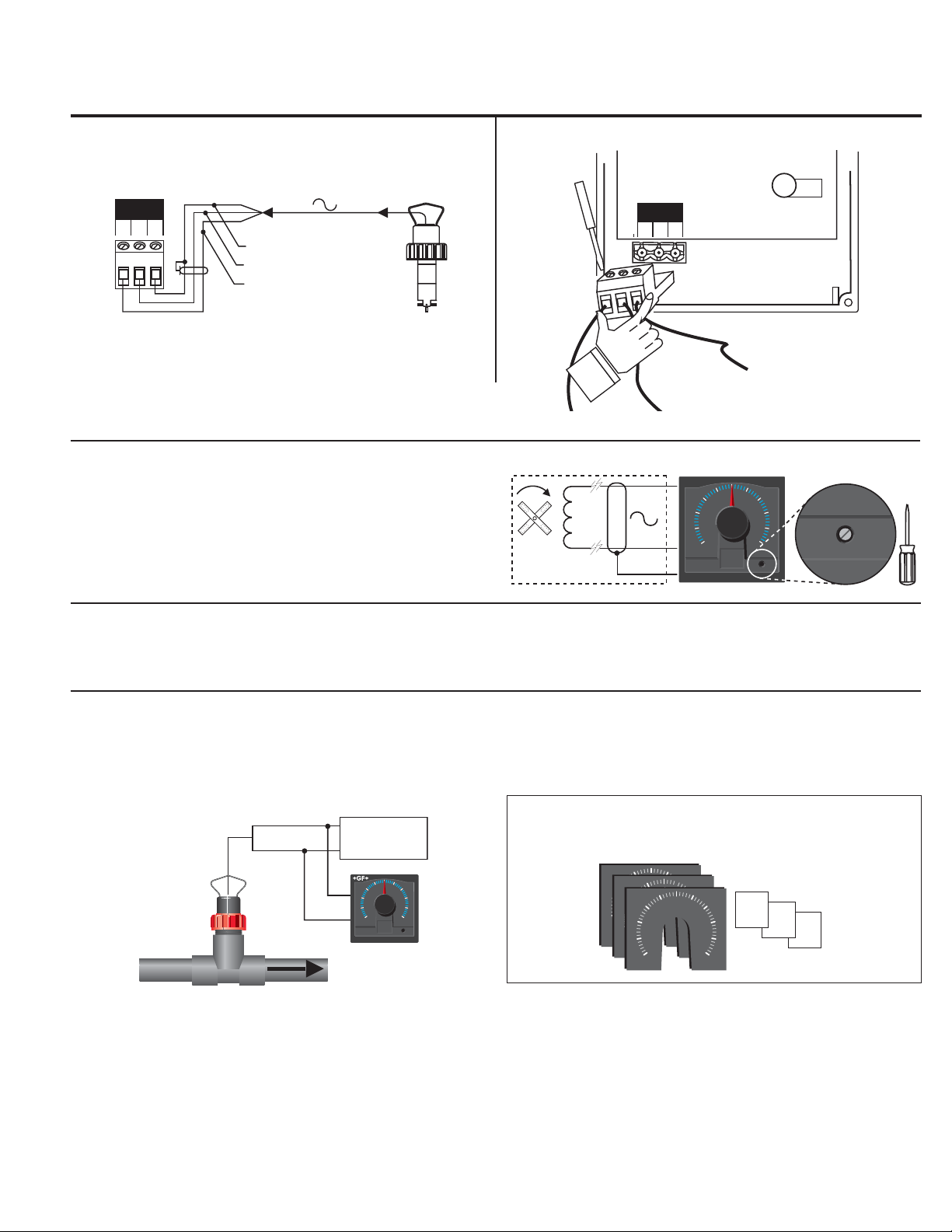

1. Compatible Sensor Wiring

Technical Notes:

• Remove terminal block for easy wiring (Fig. 1)

• Maintain cable shield through cable splice.

• Route sensor cable away from AC power lines.

• Use 2-conductor shielded cable for sensor cable extension up

to 61 m (200 ft).

2. Calibration

The 5090/515 fl ow metering system utilizes the AC signal

amplitude from the 515 sensor to drive the 5090 meter.

English

Fig. 1

The front panel meter movement adjustment (SPAN) is easily

accessed under the removable front window for simple calibration.

A dial kit with six dial ranges, assorted fl ow unit/multiplier decals,

and dial installation instructions is included for your convenience.

Equipment Required

• Frequency counter

• Signet 515 Sensor installed in process line

• Standard and phillips head screwdriver

Procedure

1. Induce the maximum (stable) fl ow rate in your process line.

2. Using the frequency counter, monitor and record the 515

sensor frequency output:

Red

Frequency

Black

counter

5

4

6

3

2

1

0

GPM

X100

Signet Monitor

7

8

9

10

SPAN

4. Install the appropriate dial face and fl ow unit/multiplier decal

for the maximum fl ow rate (Step 3). Refer to dial installation

instructions included with dial kit.

The dial kit includes the following:

6 Dials:

Assorted Unit and Multiplier Decals:

X 10

X 100

X 1,000

X 10,000

0-2

0-4

0-6

0-8

0-10

0-100

Sensor Frequency = ___________________________ Hz

Technical note:

Sensor frequency MUST be greater than 45 Hz for full scale

needle defl ection.

3. Calculate the actual max. fl ow rate in your process line as follows:

Maximum fl ow rate = Sensor frequency (step 2) × A-Factor (Section 6)

Maximum Flow Rate = __________________________________

Example: A fl ow system's maximum fl ow rate is 18.3 GPM.

The proper dial and fl ow unit/multiplier decal for this fl ow system is:

0 - 2 dial + GPM × 10 decal.

5. Disconnect frequency counter.

Access and adjust the "SPAN" potentiometer to match the

calculated maximum fl ow rate from Step 3.

After adjustment, calibration is complete.

Page 2

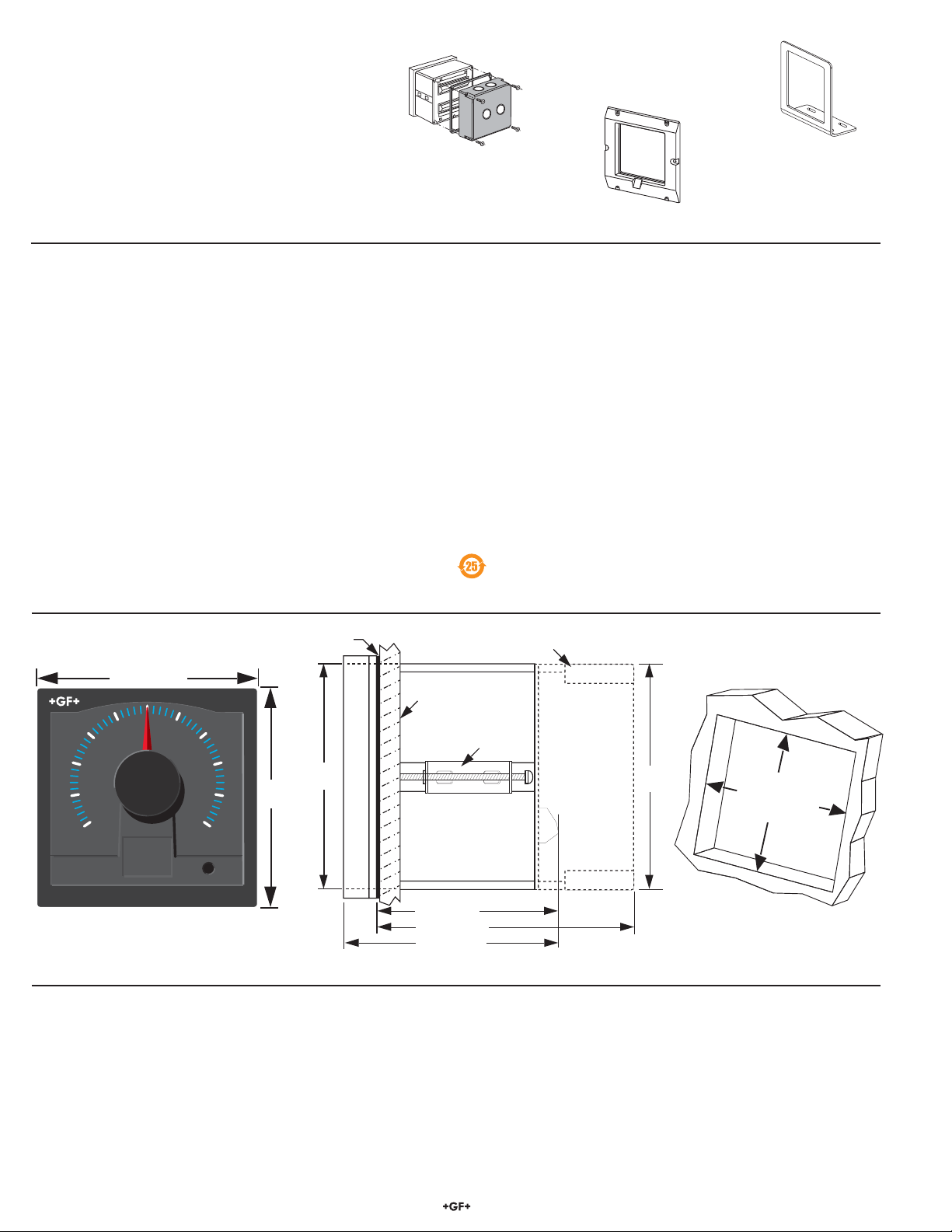

SIDE VIEW

Mounting Clamp (2 ea.)

Optional Splashproof Rear Cover

88 mm

(3.5 in.)

Mounting Panel

Panel

Gasket

91 mm

(3.6 in.)

76 mm (3 in.)

88 mm (3.5 in.)

96 mm (3.8 in.)

3. Parts and Accessories

There are no user replaceable components in the 5090.

Unauthorized repair attempts may void warranty.

• Front snap-on bezel, 3-5000.525 (code 198 840 226)

• Assorted fl ow unit/multiplier decal sheet,

3-5090.611 (code 198 840 228)

• 5090 Instruction sheet, 3-5090.090-1

(code 198 869 912)

Splashproof rear cover

3-5000.395

(code 198 840 227)

5 x 5 inch adapter plate for

retrofi tting Signet 500 series

3-5000.399 (code 198 840 224)

Optional surface

mount bracket

3-5000.598

(code 198 840 225)

4. Specifi cations

General

Sensor compatibility: Signet 515 only

Minimum full scale range: 7 fps

• Weight: Approximately 450 g (16 oz.)

Display:

• Type: Taut-band suspension meter movement, 250° defl ection

(not suitable for prolonged exposure to vibration)

• Repeatability: ±1% of full scale

Materials

• Case: ABS plastic

• Panel and case gasket: Neoprene

• Window: Hard-coated polycarbonate

Dimensions

96 mm (3.8 in.)

5

4

3

2

1

0

6

7

8

9

96 mm

(3.8 in.)

10

Electrical

Power Requirements: None

Environmental

Operating temperature: -10 °C to 65 °C (14 °F to 149 °F)

Storage temperature: -15 °C to 80 °C (5 °F to 176 °F)

Relative humidity: 0 to 95%, non-condensing

Enclosure:

• Rating: NEMA 4X/IP65 front

• Dimensions: 1/4 DIN, 96 x 96 x 88 mm (3.8 x 3.8 x 3.5 in.)

Standards and Approvals

• UL, CUL

• RoHS Compliant

• Manufactured under ISO 9001 for Quality,

ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety.

China RoHS (Go to www.gfsignet.com for details)

92 x 92 mm

(3.62 x 3.62 in.)

GPM

X 100

SPAN

Signet Monitor

5. Maintenance

Front View

Panel cutout

Never wipe the front window with static retentive cloths such as wool or polyester which may induce a static charge. If a static charge

develops on the window, the indication needle may appear erratic or non-functional. When this occurs, clean the front window with an

anti-static cloth, or a soft cotton cloth and anti-static spray or a mild liquid soap solution to remove the static charge.

Clean the instrument case and front panel with a soft cotton cloth dampened with a mild liquid soap solution.

2

Signet 5075 Flow Monitor

Page 3

6. Signet 515 Flow Sensor A-Factors

-------------- A-FACTORS ----------------

PIPE

SIZE

SCH 80 PVC TEES FOR SCH 80 PVC PIPE

1/2 IN. PV8T005 0.1250 0.4729 0.0284

3/4 IN. PV8T007 0.2328 0.8812 0.0529

1 IN. PV8T010 0.3435 1.3002 0.0780

1 1/4 IN. PV8T012 0.7195 2.7233 0.1634

1 1/2 IN. PV8T015 1.0242 3.8767 0.2326

2 IN. PV8T020 1.8473 6.9920 0.4195

2 1/2 IN. PV8T025 2.7481 10.4016 0.6241

3 IN. PV8T030 4.4310 16.7714 1.0063

4 IN. PV8T040 7.8681 29.7807 1.7868

SCH 80 CPVC TEES FOR SCH 80 CPVC PIPE

1/2 IN. CPV8T005 0.1250 0.4729 0.0284

3/4 IN. CPV8T007 0.2328 0.8812 0.0529

1 IN. CPV8T010 0.3435 1.3002 0.0780

1 1/4 IN. CPV8T012 0.7195 2.7233 0.1634

1 1/2 IN. CPV8T015 1.0242 3.8767 0.2326

SCH 80 PVC SADDLES FOR SCH 80 PVC PIPE

2 IN. PV8S020 1.8473 6.9920 0.4195

2 1/2 IN. PV8S025 2.7481 10.4016 0.6241

3 IN. PV8S030 4.4310 16.7714 1.0063

4 IN. PV8S040 7.8681 29.7807 1.7868

6 IN. PV8S060 14.4152 54.5614 3.2737

8 IN. PV8S080 25.3115 95.8039 5.7482

SCH 80 PVC SADDLE ON SCH 40 PVC PIPE

2 IN. PV8S020 2.1938 8.3035 0.4982

2 1/2 IN. PV8S025 3.1789 12.0321 0.7219

3 IN. PV8S030 4.7477 17.9702 1.0782

4 IN. PV8S040 8.9177 33.7536 2.0252

6 IN. PV8S060 16.0871 60.8897 3.6534

8 IN. PV8S080 27.8714 105.4932 6.3296

CARBON STEEL TEES ON SCH 40 PIPE

1/2 IN. CS4T005 0.1621 0.6134 0.0368

3/4 IN. CS4T007 0.2829 1.0709 0.0643

1 IN. CS4T010 0.4251 1.6091 0.0965

1 1/4 IN. CS4T012 0.9892 3.7442 0.2246

1 1/2 IN. CS4T015 1.3230 5.0077 0.3005

2 IN. CS4T020 2.2416 8.4845 0.5091

STAINLESS STEEL TEES ON SCH 40 PIPE

1/2 IN. CR4T005 0.1671 0.6327 0.0380

3/4 IN. CR4T007 0.2961 1.1209 0.0673

1 IN. CR4T010 0.4719 1.7862 0.1072

1 1/4 IN. CR4T012 0.9691 3.6682 0.2201

1 1/2 IN. CR4T015 1.4848 5.6199 0.3372

2 IN. CR4T020 2.6906 10.1839 0.6110

GALVANIZED IRON TEES ON SCH 40 PIPE

1 IN. IR4T010 0.5740 2.1724 0.1303

1 1/4 IN. IR4T012 0.9527 3.6060 0.2164

1 1/2 IN. IR4T015 1.2851 4.8642 0.2919

2 IN. IR4T020 2.0367 7.7089 0.4625

BRONZE TEES ON SCH 40 PIPE

1 IN. BR4T010 0.5740 2.1724 0.1303

1 1/4 IN. BR4T012 0.9527 3.6060 0.2164

1 1/2 IN. BR4T015 1.2851 4.8642 0.2919

2 IN. BR4T020 2.0367 7.7089 0.4625

SIGNET

FITTING

Signet 5090 Flow Monitor

------------------- 1 Hz = ------------------U.S. GPM LPM m3/h

----------------- A-FACTORS -------------------

PIPE

SIZE

COPPER TEE FITTINGS ON COPPER PIPE

1/2 IN.SK K

1/2 IN. SK L 0.1448 0.5480 0.0329

3/4 IN.SK K

3/4 IN. SK L 0.3140 1.1885 0.0713

1 IN.SK K

1 IN. SK L 0.5007 1.8950 0.1137

1 1/4 IN.SK K

1 1/4 IN. SK L 0.7022 2.6577 0.1595

1 1/2 IN.SK K

1 1/2 IN. SK L 1.0878 4.1171 0.2470

2 IN.SK K

2 IN. SK L 2.0975 7.9391 0.4763

STAINLESS STEEL WELDOLETS ON SCH 40 PIPE

2 1/2 IN. CR4W025 3.1915 12.0798 0.7248

3 IN. CR4W030 4.9302 18.6606 1.1196

4 IN. CR4W040 8.6207 32.6293 1.9578

5 IN. CR4W050 11.4068 43.1749 2.5905

6 IN. CR4W060 16.2602 61.5447 3.6927

8 IN. CR4W080 28.1690 106.6197 6.3972

10 IN. CR4W100 44.4444 168.2222 10.0933

12 IN. CR4W120 62.5000 236.5625 14.1938

CARBON STEEL WELDOLETS ON SCH 40 PIPE

2 1/2 IN. CS4W025 3.1915 12.0798 0.7248

3 IN. CS4W030 4.9302 18.6606 1.1196

4 IN. CS4W040 8.6207 32.6293 1.9578

5 IN. CS4W050 11.4068 43.1749 2.5905

6 IN. CS4W060 16.2602 61.5447 3.6927

8 IN. CS4W080 28.1690 106.6197 6.3972

10 IN. CS4W100 44.4444 168.2222 10.0933

12 IN. CS4W120 62.5000 236.5625 14.1938

COPPER/BRONZE BRAZOLETS ON SCH 40 PIPE

2 1/2 IN. BR4B025 3.1915 12.0798 0.7248

3 IN. BR4B030 4.9302 18.6606 1.1196

4 IN. BR4B040 8.6207 32.6293 1.9578

5 IN. BR4B050 11.4068 43.1749 2.5905

6 IN. BR4B060 16.2602 61.5447 3.6927

8 IN. BR4B080 28.1690 106.6197 6.3972

10 IN. BR4B100 44.4444 168.2222 10.0933

12 IN. BR4B120 62.5000 236.5625 14.1938

SCH 80 IRON SADDLES ON SCH 80 PIPE

2 IN. IR8S020 1.8541 7.0179 0.4211

2 1/2 IN. IR8S025 2.7003 10.2205 0.6132

3 IN. IR8S030 4.4709 16.9225 1.0154

4 IN. IR8S040 7.8329 29.6475 1.7789

5 IN. IR8S050 10.2389 38.7543 2.3253

6 IN. IR8S060 14.6699 55.5257 3.3315

8 IN. IR8S080 25.7511 97.4678 5.8481

10 IN. IR8S100 39.2157 148.4314 8.9059

12 IN. IR8S120 56.6038 214.2453 12.8547

SCH 80 IRON SADDLE ON SCH 40 PIPE

2 IN. IR8S020 2.2371 8.4676 0.5081

2 1/2 IN. IR8S025 3.1915 12.0798 0.7248

3 IN. IR8S030 5.0042 18.9408 1.1364

4 IN. IR8S040 8.7591 33.1533 1.9892

5 IN. IR8S050 11.2570 42.6079 2.5565

6 IN. IR8S060 15.9574 60.3989 3.6239

8 IN. IR8S080 28.1690 106.6197 6.3972

10 IN. IR8S100 44.4444 168.2222 10.0933

12 IN. IR8S120 62.5000 236.5625 14.1938

SIGNET

FITTING

CUKT005

CUKT007

CUKT010

CUKT012

CUKT015

CUKT020

---------------------- 1 Hz = ----------------------U.S. GPM LPM m3/h

0.1354 0.5124 0.0307

0.2828 1.0704 0.0642

0.4718 1.7857 0.1071

0.6801 2.5743 0.1545

1.0533 3.9869 0.2392

2.0429 7.7325 0.4639

3

Page 4

A-Factors for DIN Pipes

------------------------------ A-FACTORS -------------------------------

PIPE

SIZE

POLYPROPYLENE FITTINGS (DIN/ISO AND BS AND ANSI)

DN 15 PPMT005 0.1246 0.4716 0.0283 727 310 036

DN 20 PPMT007 0.2165 0.8196 0.0492 727 310 037

DN 25 PPMT010 0.4250 1.6086 0.0965 727 310 038

DN 32 PPMT012 0.7182 2.7185 0.1631 727 310 039

DN 40 PPMT015 1.1704 4.4299 0.2658 727 310 040

DN 50 PPMT020 2.0273 7.6734 0.4604 727 310 041

PVDF FITTINGS (DIN/ISO AND BS AND ANSI)

DN 15 SFMT005 0.1426 0.5396 0.0324 735 310 036

DN 20 SFMT007 0.2630 0.9954 0.0597 735 310 037

DN 25 SFMT010 0.4389 1.6613 0.0997 735 310 038

DN 32 SFMT012 0.7567 2.8640 0.1718 735 310 039

DN 40 SFMT015 1.3796 5.2219 0.3133 735 310 040

DN 50 SFMT020 2.3159 8.7655 0.5259 735 310 041

SIGNET

FITTING

---------------------------------- 1 Hz = -----------------------------------U.S. GPM LPM m3/h CODE

11/16/2000

DN 15 PVMT005 0.1234 0.4671 0.0280 198 150 480

DN 20 PVMT007 0.2471 0.9352 0.0561 198 150 481

DN 25 PVMT010 0.4037 1.5279 0.0917 198 150 482

DN 32 PVMT012 0.7048 2.6679 0.1601 198 150 483

DN 40 PVMT015 1.1571 4.3796 0.2628 198 150 484

DN 50 PVMT020 2.0168 7.6336 0.4580 198 150 485

DN 65 PVMS025 3.4312 12.9870 0.7792 198 150 538

DN 80 PVMS030 4.8037 18.1818 1.0909 198 150 539

DN 100 PVMS040 7.3731 27.9071 1.6744 198 150 540

DN 150 PVMS060 14.6778 55.5556 3.3333 198 150 543

DN 200 PVMS080 29.3556 111.1111 6.6667 198 150 545

A-Factor Conversion Formulas:

1 U.S. gallon =

0.83267 Imperial gallon

0.003785 Cubic meters

0.000003069 Acre feet

8.3454 Pounds of water

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-5090.090-1 Rev. K 08/13 English © Georg Fischer Signet LLC 2013

Loading...

Loading...