Page 1

Signet 4630 Free Chlorine Analyzer System

Signet 4632 Chlorine Dioxide Analyzer System

*3-463X.090*

3-4630.090 Rev L 09/13

The Signet 4630 and 4632 Systems are EPA 334.0 Compliant.

Description

The Signet Chlorine Analyzer Systems are integrated, all-in-one chlorine panel systems

Signet

Chlorine Analyzer

designed to measure Free Chlorine or Chlorine Dioxide in drinking water and clean, fresh

water treatment applications.

This manual includes the 4630 Free Chlorine and 4632 Chlorine Dioxide Analyzer Systems.

Features:

• EPA 334.0 Compliant: The 4630 Free Chlorine and 4632 Chlorine Dioxide systems can

be used for reporting chlorine residuals in accordance with EPA Method 334.0.

• Complete chlorine analyzer system allows quick setup and easy installation. Connect

to a water source and plug it in.

• Unique integrated clear ow cell combines sensors, ow regulator, lter and variable

area ow indicator in one compact unit.

• Built-in variable area ow indicator facilitates ow rate con rmation at a glance.

• Integrated ow regulator with removable lter accepts inlet pressures of 1 to 8 bar

(15 to 120 psi) while maintaining constant ow and minimal pressure to the sensors.

• Water ows vertically into sensor tip, eliminating bubble entrapment. Raised exit in ow

cell sensor chamber ensures sensors stay submerged even when system and ow is

turned off.

• Flow cell accommodates two sensors; one chlorine and an optional pH sensor.

• Automatic pH and temperature compensation or manual pH value input capability for

accurate free chlorine readings.

• Easy viewing of the transmitter via the bright backlit LCD display.

• Moisture-proof NEMA 4X wiring enclosure.

English

Operating Instructions

Additional information can be found in the individual product manuals,

refer to www.gfsignet.com.

Click on Product Manuals under the Signet Quick Links section.

• 3-8630-3P Chlorine Transmitter Manual (3-8630.090-3)

• 3-2630 Series Amperometric Chlorine Electrode Manual (3-2630.090)

• 3-2650 Amperometric Electronics Manual (3-2650.090)

• 3-2724 pH/ORP Electrode Manual (3-2724.090)

• 3-2750 pH Electronics Manual (3-2750.090)

Safety

CAUTION!

1. Follow instructions carefully to avoid personal injury.

2. Do not exceed the maximum pressure or temperature speci cations.

3. Mounting the Chlorine System in an outdoor box, in areas with elevated temperatures,

may cause damage to the system if the enclosure's internal temperature exceeds the

temperature speci cation of the Chlorine Analyzer.

4. Do not alter product construction.

5. For use with clean fresh water only.

6. Disconnect AC power before opening wiring enclosure.

7. This panel system uses AC voltages. Wiring should be done by quali ed personnel only.

Page 2

Table of Contents

Warranty Information Table of Contents

Refer to your local Georg Fischer Sales of ce for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales of ce or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buffers, turbidity

standards or other solutions) are warranted out of box but not

warranted against any damage, due to process or application

failures (e.g. high temperature,

or mishandling (e.g. broken glass,

chemical poisoning, dry-out)

damaged membrane,

freezing and/or extreme temperatures).

Product Registration

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now

register online in one of the following ways:

• Visit our website www.gfsignet.com and

click on Product Registration Form

• If this is a pdf manual (digital copy),

click here

• Scan the QR Code on the left

Safety Information

Warning / Caution / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death

Electrostatic Discharge (ESD) / Electrocution Danger

Alerts user to risk of potential damage to product by ESD,

and/or risk of potential of injury or death via electrocution.

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during

installation and service of Signet products.

Pressurized System Warning

Sensor may be under pressure, take caution to vent

system prior to installation or removal. Failure to do so

may result in equipment damage and/or serious injury.

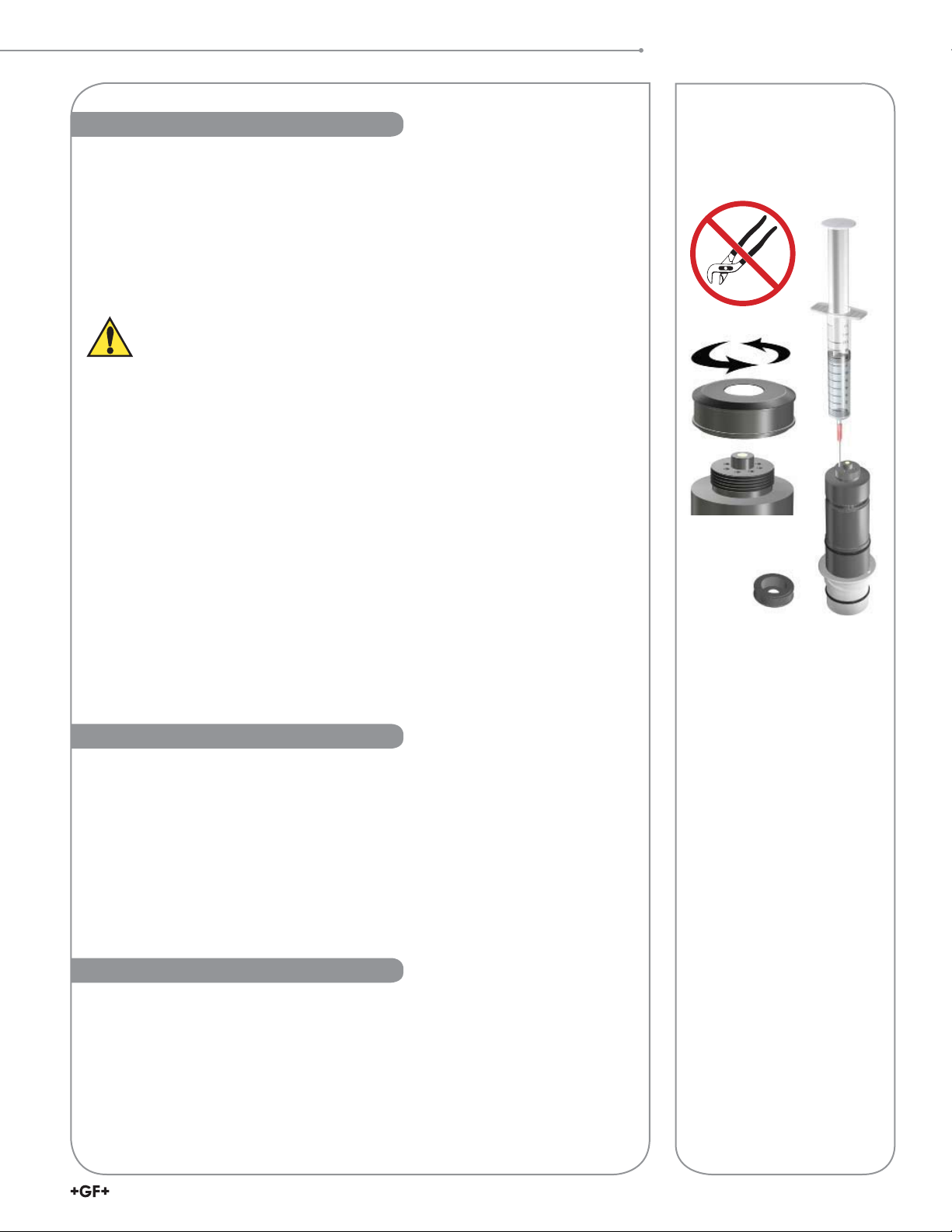

Hand Tighten Only

Overtightening may permanently damage product

threads and lead to failure of the retaining nut.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and

potentially void product warranty.

Note / Technical Notes

Highlights additional information or detailed procedure.

Description ............................................................................... 1

Warranty Information ................................................................ 2

Product Registration ................................................................ 2

Safety Information .................................................................... 2

Chlorine System Dimensions ................................................... 3

Chlorine System Speci cations ............................................... 3

4630 Chlorine Analyzer System Inventory............................... 4

Quick Start ............................................................................... 4

Panel Assembly........................................................................ 5

Component Identi cation: Flow Cell ........................................ 6

Mounting .................................................................................. 7

Wiring Input .............................................................................. 8

Wiring Output ........................................................................... 9

Electrical Box Wiring Schematic ............................................ 10

Chlorine Sensor Preparation ..................................................11

Chlorine Sensor Calibration ....................................................11

Chlorine Sensor Maintenance ................................................11

Sensor Installation.................................................................. 12

Tubing Connections ............................................................... 13

Water Flow ............................................................................. 13

8630 Chlorine Transmitter...................................................... 14

View Mode .......................................................................... 14

Editing Procedure ............................................................... 15

Calibrate Menu ................................................................... 17

Options Menu ..................................................................... 20

Chlorine Sensor Conditioning ............................................ 22

pH Sensor Calibration ........................................................ 22

Chlorine Sensor Calibration ............................................... 24

Output Settings - Loops and Relays .................................. 25

2650-7 DryLoc® Amperometric and 2750-7 pH Electronics ... 28

Wiring to the Signet 8630 Chlorine Transmitter ................. 28

Chlorine Electrode Overview ................................................. 29

2630 and 2632 Amperometric Chlorine Electrodes ........... 29

Calibration .......................................................................... 30

Maintenance ....................................................................... 30

2724 DryLoc pH Electrode ..................................................... 31

Calibration .......................................................................... 32

Appendix ................................................................................ 33

Maintenance - 463X Chlorine Analyzer Flow Cell ............. 33

Maintenance - 2630 Free Cl / 2632 ClO

Electrode .......... 36

2

Maintenance - 2724 DryLoc pH Electrode ......................... 38

Troubleshooting - 463X Chlorine Analyzer ........................ 39

Troubleshooting - 8630 Chlorine Transmitter .................... 40

8630 Transmitter Error Messages...................................... 41

Troubleshooting - 2630 Free Cl / 2632 ClO

Electrode ..... 43

2

Troubleshooting - 2750-7 pH Electronics........................... 43

Speci cations ......................................................................... 44

Ordering Information .............................................................. 48

Do Not Freeze

Products are temperature sensitive and may contain

DO NOT

FREEZE

2

freezable liquids. Freezing damage to pH, ORP, and

Chlorine electrodes voids product warranty.

463X Chlorine System Manual

Page 3

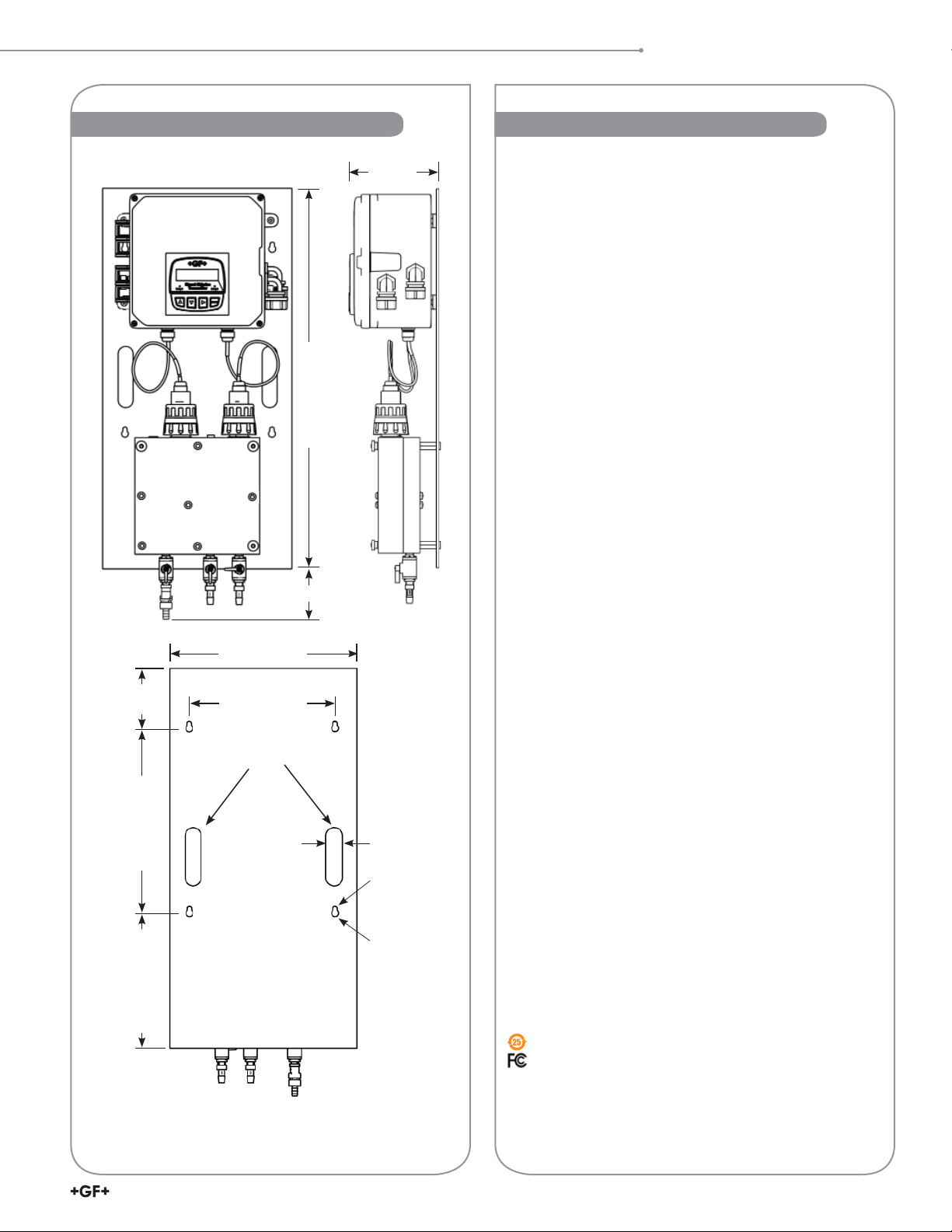

Speci cations and Dimensions

Chlorine System Dimensions Chlorine System Speci cations

79.3 mm (3.12 in.)

305 mm (12 in.)

165 mm

(6.5 in.)

578 mm (22.75 in.)

General

Compatible Signet Sensors:

• 3-2630-1 Free Chlorine Sensor 0-2 ppm

• 3-2630-2 Free Chlorine Sensor 0-5 ppm

• 3-2630-3 Free Chlorine Sensor 0-20 ppm

• 3-2632-1 Chlorine Dioxide Electrode 0-2 ppm

• 3-2724-00 Flat pH Electrode

Materials:

Panel: .......................................Black acrylic

Flow Cell: ..................................Acrylic

Wiring Enclosure: .....................Polycarbonate

Wetted Materials:

Flow cell, spacer rings: ............. Acrylic

Flow regulator housing ............. Polycarbonate

Strainer, e-clip, regulator spring,

oat: ........................................ Stainless steel

Valves, vent: .............................Polypropylene

Flow cell O-rings, diaphragm: ...EPDM, FKM

Chlorine electrode ....................PVC, PVDF or PTFE, FPM

pH electrode .............................

PPS, Glass, UHMW, PE, FPM

Sealing tape (valves, plug, vent) .. PTFE

Plug ..........................................Polyethylene

Performance

System Inlet Pressure Rating: .. 1 to 8 bar (15 to 120 psi)

Pressure Regulator:..................< 0.69 bar (10 psi) variation

over all ranges of ow and

pressure

Flow tolerance .......................... ±15% or rated speci cation

above

Flow rate limits ............................. 8 to 12 gph (US)

(30.24 to 45.36 LPH)

(3 in.)

76 mm

254 mm (10 in.)

Hand Holds

25 mm

330 mm (13 in.)

171 mm (6.75 in.)

Material Safety Data Sheets (MSDS) are available online

at www.gfsignet.com.

(1.0 in.)

Ø 7 mm

(0.27 in.)

Ø 13 mm

(0.52 in.)

Electrical

AC Input (standard): .................

DC Input (optional): ....................

100 to 240 VAC nominal

50 to 60 Hz, 0.17 A at 100 VAC

12 to 24 VDC ±10% regulated,

10 W, 250 mA max

Environmental Requirements

Storage Temperature: ...............

Operating Temperature: ............

Relative Humidity:.....................0 to 95%

Maximum Altitude: .................... 6562 ft (2000 m)

Shipping Weight: ......................22 lbs (10 kg)

Enclosure:.................................NEMA 4X (with output wire

0 °C to 65 °C (32 °F to 149 °F)

0 °C to 45 °C (32 °F to 113 °F)

glands sealed)

Standards and Approvals

• CE, UL, CUL, WEEE

• RoHS Compliant

• Manufactured under ISO 9001 for Quality,

ISO 14001 for Environmental Management and

OHSAS 18001 for occupational health and safety.

China RoHS (Go to www.gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

3463X Chlorine System Manual

Page 4

System Inventory

4630 Chlorine Analyzer System Inventory

1. Chlorine panel assembly

a. Built-in pressure regulator 15 to 120 psi.

b. 3/8 inch hose barb connectors.

2. 1 each 2630 series Free Chlorine sensor or 2632 Chlorine Dioxide sensor; each with protective cap

a. 1 spare membrane cap

b. 2 bottles of electrolyte solution

c. 1 syringe needle (taped to bottle)

d. 1 syringe

3. 1 each Flat pH sensor 3-2724-00 (159 001 545) (3-4630-11, -21, -31 and 3-4632-11 models only)

4. Manual package

a. English panel assembly manual

b. CD with multi-language manuals

c. Wall mounting hardware

d. Drill template

5. 1 each North American Type B power cord

6. Customer supplied

a. 3/8" hose input and drain

b. Hose clamps

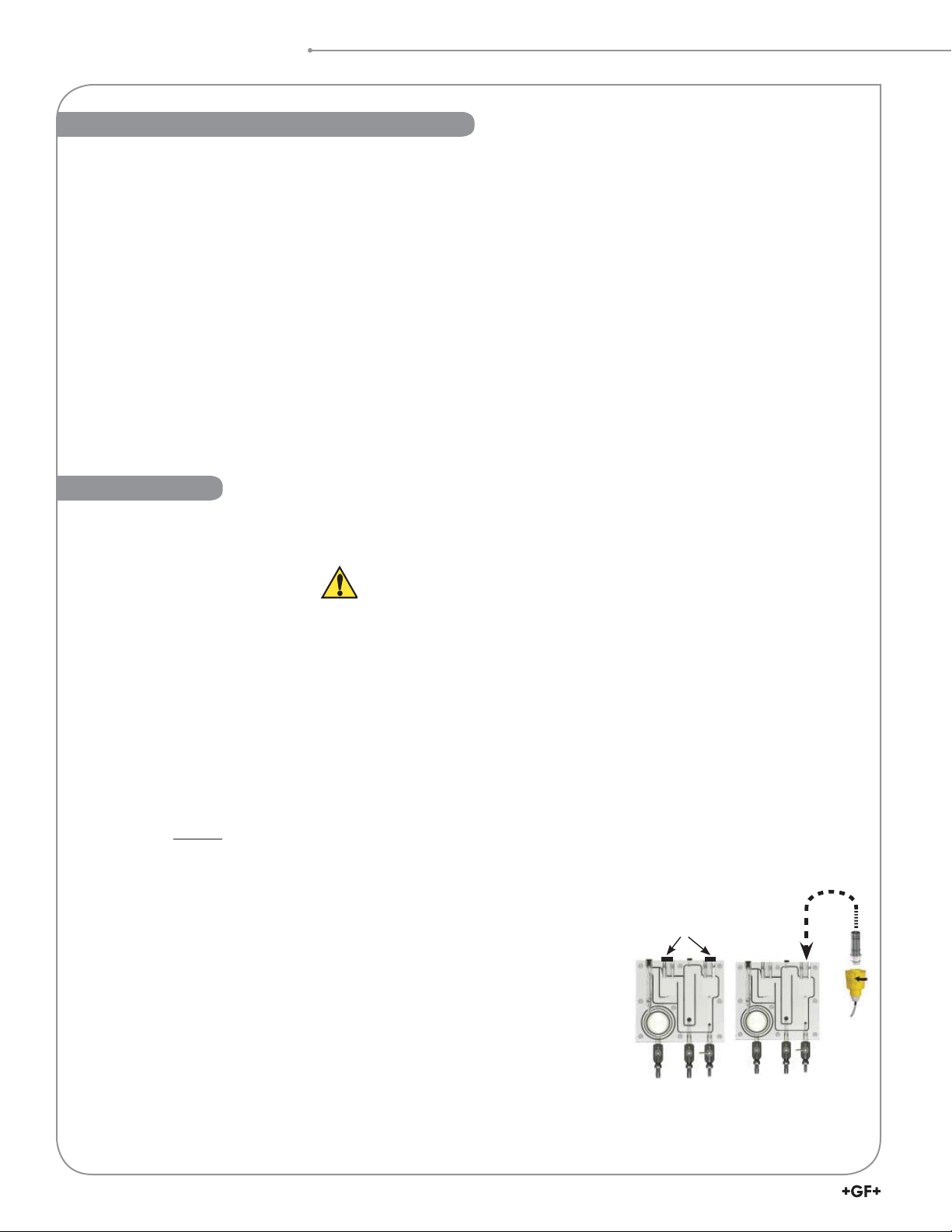

Quick Start

Follow the steps below to set up a new Chlorine Analyzer System. Refer to the individual component manuals for detailed information.

Step 1. Mount the panel on a vertical at surface using appropriate hardware.

Do not turn on power at this time.

Step 2. Open the wiring enclosure and wire input power

(see page 8: Wiring Input, page 9: Wiring Output, and page 10: Electrcial Box Wiring Schematic).

Step 3. Wire any 4 to 20 mA and relay output.

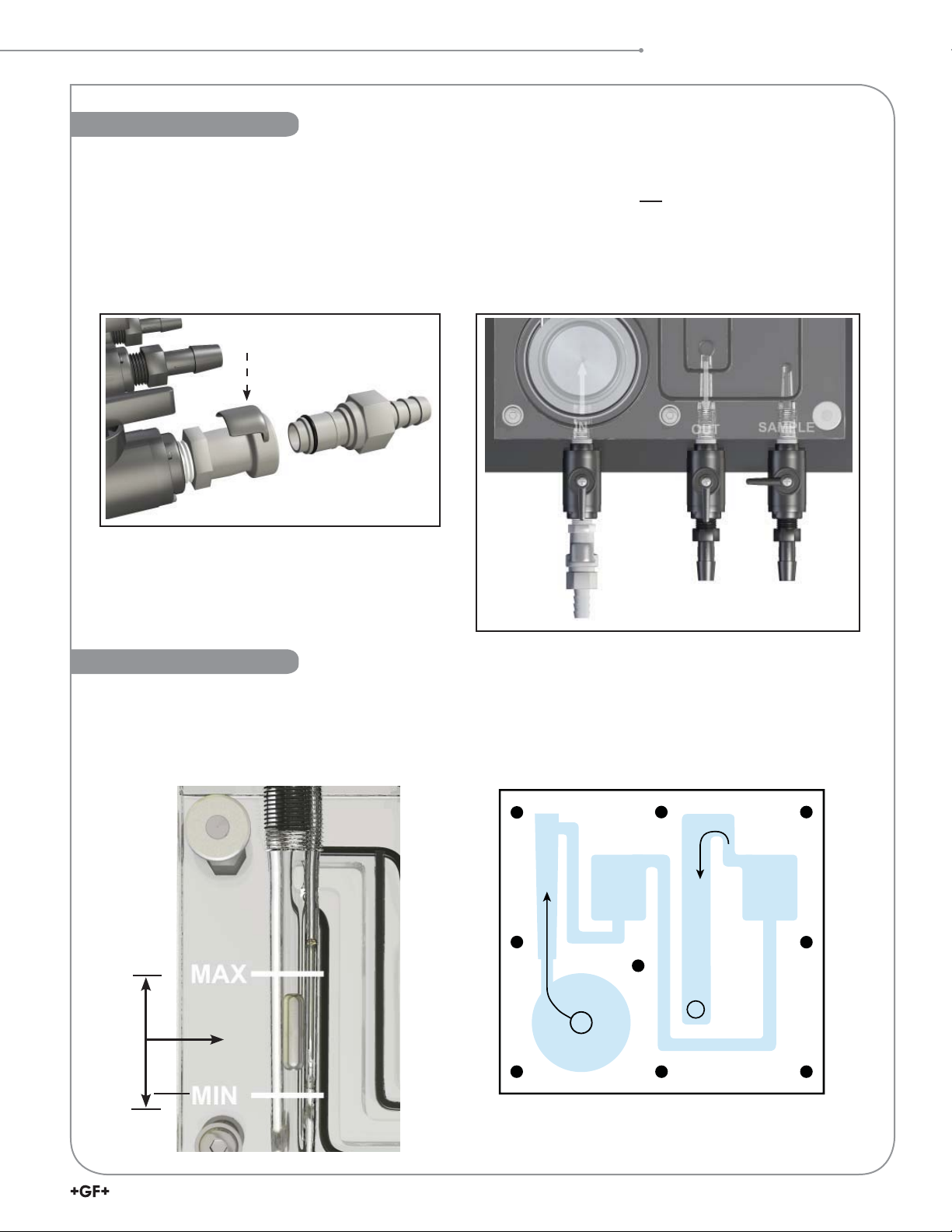

Step 4. Remove sensor access plugs from the ow cell (Figure 1).

If the optional pH sensor is NOT used, do not remove the left-side plug from the ow cell.

Step 5. Remove the protective cap from the chlorine electrode.

(Keep the electrode cap in a safe place for future use. It is recommended to use the cap to protect the sensor during

the removal of the electrode for cleaning or maintenance of the ow cell).

Step 6. Complete Sensor Preparation (see page 11) and install the chlorine sensor into the electronics

(see page 12: Sensor Installation). Install the chlorine electrode into the ow cell.

The chlorine sensor is installed in the right-side access port, optional pH sensor is installed in the left-side access port.

NOTE:

NOTE: If a Chlorine Dioxide sensor or a Free Chlorine sensor without optional pH sensor is used, pH value must be

Step 7. Repeat step 5 and 6 if the optional pH sensor is being used.

Step 8. Install the in uent water source to the "Inlet Port" nipple assembly of the ow

Step 9. Install 3/8-inch tubing and secure with a hose clamp on the "Drain" port and

Step 10. Verify the inlet and drain ball valves are in the open position and

Step 11. Turn on the in uent water source and check the system for leaks.

Step 12. Apply power to the system and allow system to initialize. Calibrate per instructions

NOTE: As factory default, the 4630-X Chlorine Panel Assembly is set to measure Free Chlorine. If a 2632 Chlorine Dioxide

All new chlorine and pH sensors require calibration during the start up of a system and throughout the life of the sensor.

A new chlorine sensor requires a conditioning period of up to 4 hours with power on and chlorinated water owing past

the sensor prior to calibration. See page 24: Chlorine Sensor Calibration, for chlorine calibration and set up procedure.

"hard-coded" into the system (See page 23: Manual pH compensation).

If optional pH sensor is installed, see page 22 to complete pH Sensor Calibration.

Sensor access plugs

cell. Install 3/8-inch tubing and secure with a hose clamp.

(Not included. See page 13: Tubing Connections)

direct the tube to a proper drain. (Not included)

the sample port is in the off position (See page 13: Tubing Connections).

(See page 24: Chlorine Sensor Calibration and page 22: pH Sensor Calibration).

sensor is to be used to convert to a Chlorine Dioxide Panel Assembly, refer to the 8630-3 OPTIONS Menu on page 20.

Figure 1

4

463X Chlorine System Manual

Page 5

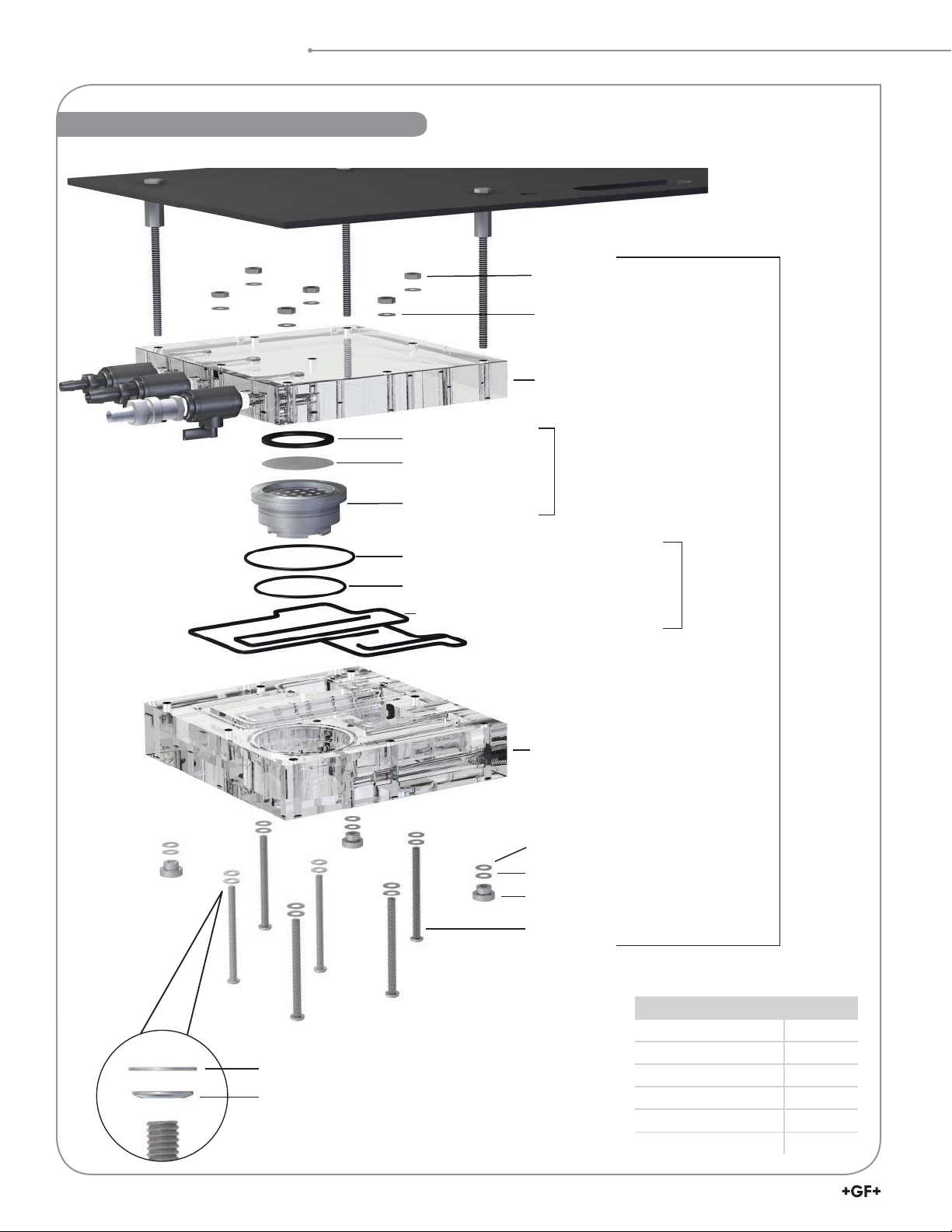

Panel Assembly

Panel Assembly

Wiring enclosure

Transmitter

3-8630-3P (159 001 673)

Power cable conduit

pH sensor

electronics

3-2750-7 (159 001 671)

pH electrode

3-2724-00 (159 001 545)

Flow range limits

Flow rate indicator

Vent

Cap

Output conduits

Amperometric chlorine

sensor electronics

3-2650-7 (159 001 670)

Chlorine electrode

3-2630-X (Free Chlorine)

3-2632-1 (Chlorine Dioxide)

Flow cell block

Flow regulator with strainer

Inlet port

Quick disconnect

2000-2525*

Quick disconnect plug

(3/8 inch hose)

2000-3825*

Drain port

(3/8 inch hose)

* Contact factory for quote

Flow cell O-rings

3/8" Ball valve

4300-5225*

3/8" Hose barb

2000-3804*

Sampling port

5463X Chlorine System Manual

Page 6

Component Identi cation

Component Identi cation: Flow Cell

Spacer ring

Stainless steel lter

Pressure regulator

Flow cell nut

Flat washer

Flow cell back block

Regulator Assembly

(3-4630.391)

(159 001 689)

Pressure regulator outer O-ring (large)

Pressure regulator outer O-ring (small)

Flow cell O-rings (4 segments)

Flow cell front block

Flat washer*

Disc spring (2700-0003)*

Knurled thumb nut (1700-2512)*

Flow cell bolt (2490-0554)

*Not included with

3-4630.392 (159 001 690)

Flow Cell

Rebuild Kit

(3-4630.390)

(159 001 688)

3-4630.392

(159 001 690)

Included in kit 3-4630.390

Item Quantity

Flow cell nut 6

Flat washer

Disc spring (curved washer)

6

463X Chlorine System Manual

Flat washer 15

Disc spring 9

Knurled thumb nut 3

Flow cell bolt 6

Page 7

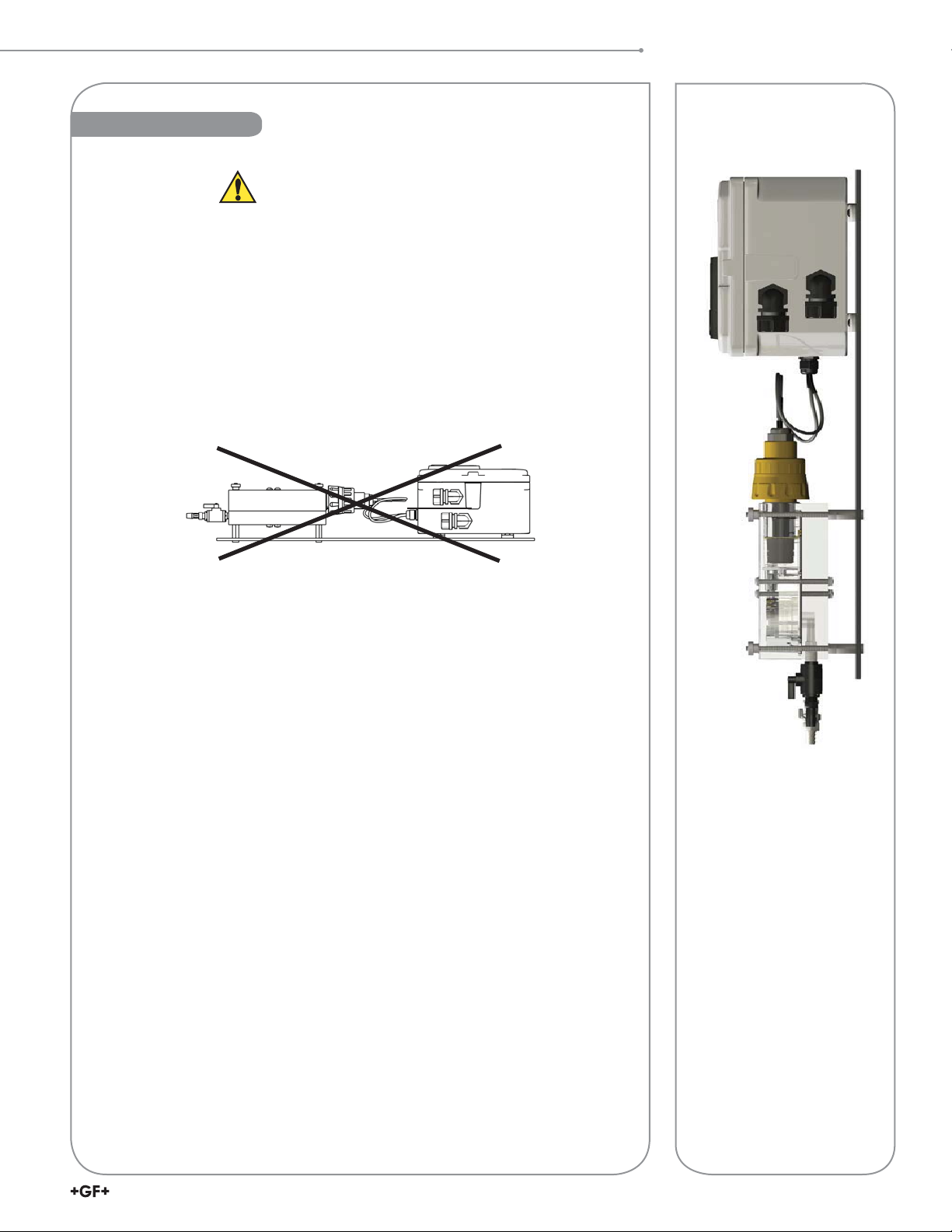

Mounting

Do not mount in direct sunlight.

• Bright light can promote algae growth. Indoor mounting is recommended.

• If the system is mounted outdoors, an outdoor enclosure for the whole system must be

used to protect the electronics and ow cell from light, rodents, insects and dirt.

• Mount the panel according to local electrical, building, and/or plumbing codes and

seismic requirements.

• Use four 6 mm (¼ in.) diameter screws or bolts of suf cient length to mount the panel to

a sturdy vertical surface. A mounting template is provided.

• Allow clearance on the sides and bottom for service to the unit.

• Keep panel system electronics and enclosure away from dripping water.

• The panel must be mounted vertically in an upright position.

Mounting

NO

7463X Chlorine System Manual

Page 8

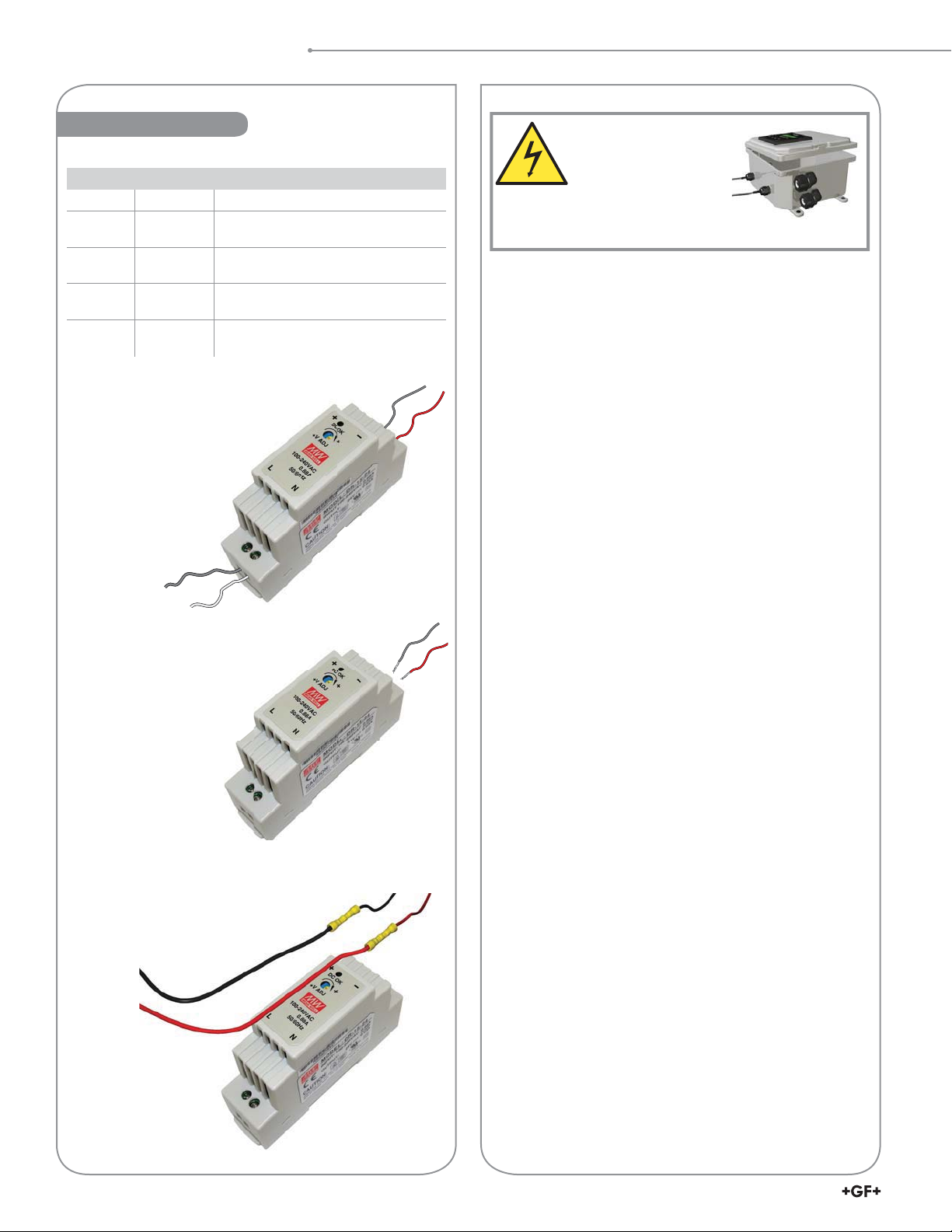

Wiring Input

Wiring Input

Power Supply Terminal Identi cation

Terminal Name Description

V. ADJ Voltage

DC ON Operation

+V, –V DC output

L, N Input

100 to 240 VAC input

Standard AC con guration

adjustment

indicator

terminals

terminals

Input for

100-240 VAC

Adjusts within ±10%; turning clockwise

increases output voltage

Green LED is lit when output voltage

is on

+V: Positive output terminal

–V: Negative output terminal

Accepts a wide range of voltages and

frequencies (100 to 240 VAC DC input)

Figure 2

Figure 3

WARNING

This panel system is

wired for AC voltages

that can injure or kill.

Wiring should be performed by

quali ed personnel only.

Disconnect AC power before opening wiring enclosure.

Follow all local and government recommendations and

methods for installation of electrical connections to and

between the system and other devices.

System Input Power

• The panel system is pre-wired with an auto switching power

supply that is rated for 100 to 240 VAC 50/60 Hz input.

• Wire with NEC Class I, 300 volt, 105 C wire.

• A switch or circuit breaker rated at 15 amps AC shall be

included in the building installation.

• Install the circuit breaker in close proximity to the

equipment and within easy reach of the operator.

• Mark the circuit breaker as the disconnecting device for

the equipment.

• Grounding: The protective ground terminal must be

bonded to protective earth in the host equipment.

Part # 7300-0024 (159 001 693) shown.

Actual power supply may differ from Figure 2.

100 to 240 VAC Input Wiring

• Open the electrical box by loosening the four corner

screws of the front cover.

• Insert input power wiring into the pre-drilled access hole

on the left side of the electrical box using appropriate

conduit adapters to maintain the Type 4X rating. (Supplied

conduit connectors may have to be removed.)

• Install the input power wires into the proper terminals

on the power supply (Figure 2). Use only 12 to 26 AWG

copper wiring.

• Recommended torque for the terminals is 7 lb-in.

NOTE: When using alternate power supply

7300-7524 (159 000 687):

• Use 10-24 AWG copper wiring, 105 C, torque 4.4 lb-in.

12 to 24 VDC Input Wiring Conversion

• If the power source supplied to the system will be 12 to

24 VDC instead of 100 to 240 VAC, disconnect the red

and black output wires from the power supply (Figure 3)

and connect your UL approved limited-energy DC power

supply (Figure 4), using an insulated nylon parallel splice

–

+

connector such as T&B part number 2C-12 or equivalent.

• Insert input power wiring into the pre-drilled access hole

on the left side of the electrical box using the appropriate

conduit adapters to maintain the Type 4X rating.

(Customer may have to remove the supplied conduit

connectors.)

• A switch or circuit breaker rated at 5 amps DC shall be

included in the building installation.

• Install the circuit breaker in close proximity to the

equipment and within easy reach of the operator.

Figure 4

8

463X Chlorine System Manual

• Mark the circuit breaker as the disconnecting device for

the equipment.

Page 9

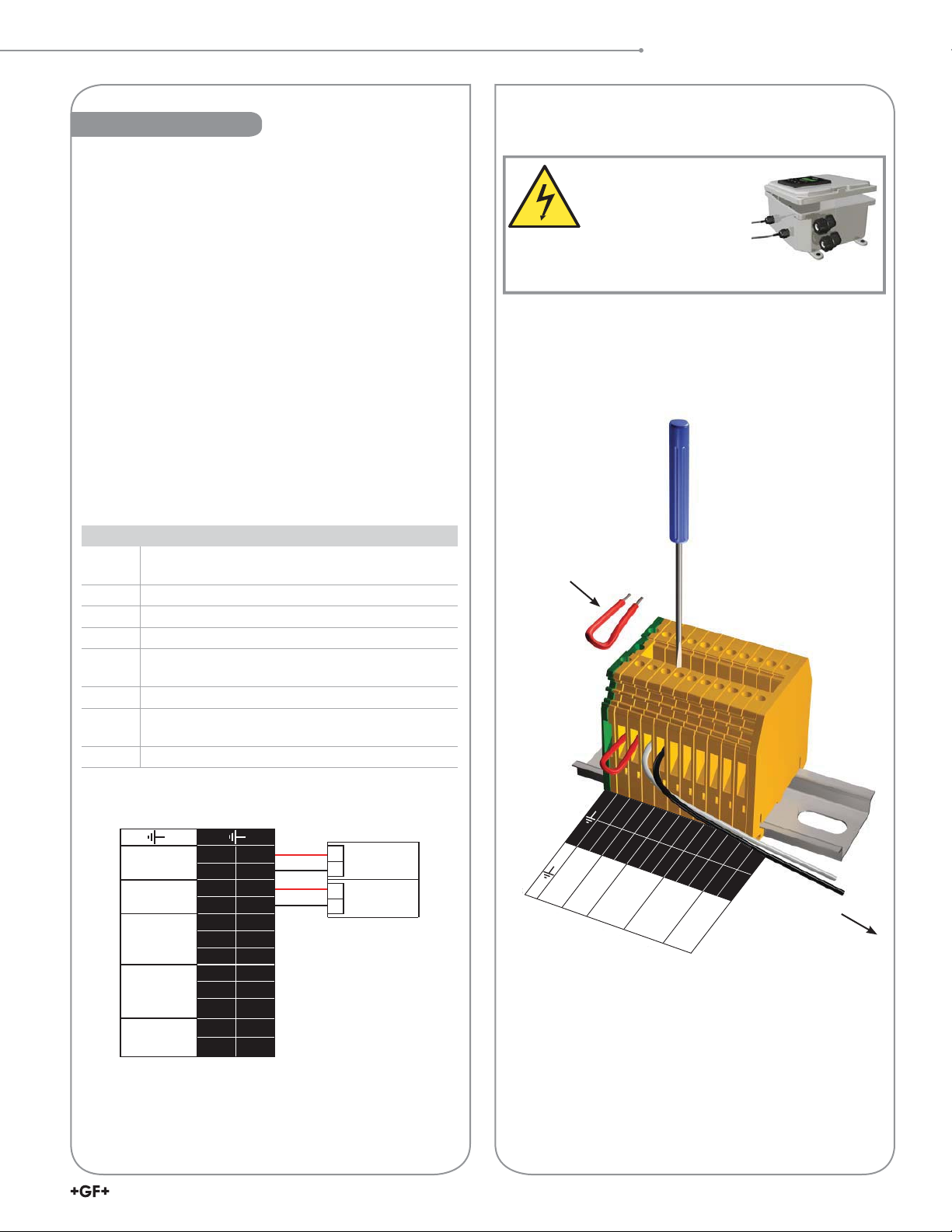

Wiring Output

Wiring Output

Follow all local and government recommendations and

methods for installation of electrical connections to and

between the system and other devices.

Output Connections

• Use the wiring enclosure terminal block for output wire

connections. Do not wire directly to the transmitter.

• Recommended torque for the terminals is 7 lb-in

• Do not run 4 to 20 mA loop cables in the same conduit as

the power or other high voltage wiring.

• Remove one installed jumper wire (from both of its terminals)

on the terminal block in the enclosure for each loop device

connected. Replace the jumper if you later remove your

loop device. If only one loop device is connected, remove

just one jumper wire from its two terminals.

• The panel system uses an active loop output wired to the

enclosure terminal block.

• If connecting to a PLC, use the PLC's passive input.

• The transmitter must have a jumper wire or loop

device always connected to Loop 1.

Wiring Label Legend

Ground

Earth Ground. Attach 4 to 20 mA loop cable

shield wire here to help eliminate possible noise.

Loop 1 4 to 20 mA Loop #1

Loop 2 4 to 20 mA Loop #2

Relay 1 Relay Output #1

NC

Relay Normally Closed (contact) when

de-energized

C Common

NO

Relay Normally Open (no contact) when

de-energized

Relay 2 Relay Output #2 (terminals same as Relay #1)

WARNING

This panel system is

wired for AC voltages

that can injure or kill.

Wiring should be performed by

quali ed personnel only.

Disconnect AC power before opening wiring enclosure.

Wiring a 4 to 20 mA loop device

Jumper wire removed

1 2 3 4 5 6 7 8 9 10 11 12

+

LOOP 1

–

+

LOOP 2

RELAY 1

RELAY 2

FLOW SW

PLC dual channel connection

–

NC C NO NC C NO A B

Red

Black

Red

Black

PLC Terminals

Channel 1

+

4 to 20 mA

-

Channel 2

+

4 to 20 mA

-

1 2 3 4 5 6 7 8 9 10 11 12

+

–

+

–

NC C NO NC C NO A B

LOOP 1

LOOP 2

RELAY 1

RELAY 2

to 4 to 20 mA

loop device

FLOW SW

9463X Chlorine System Manual

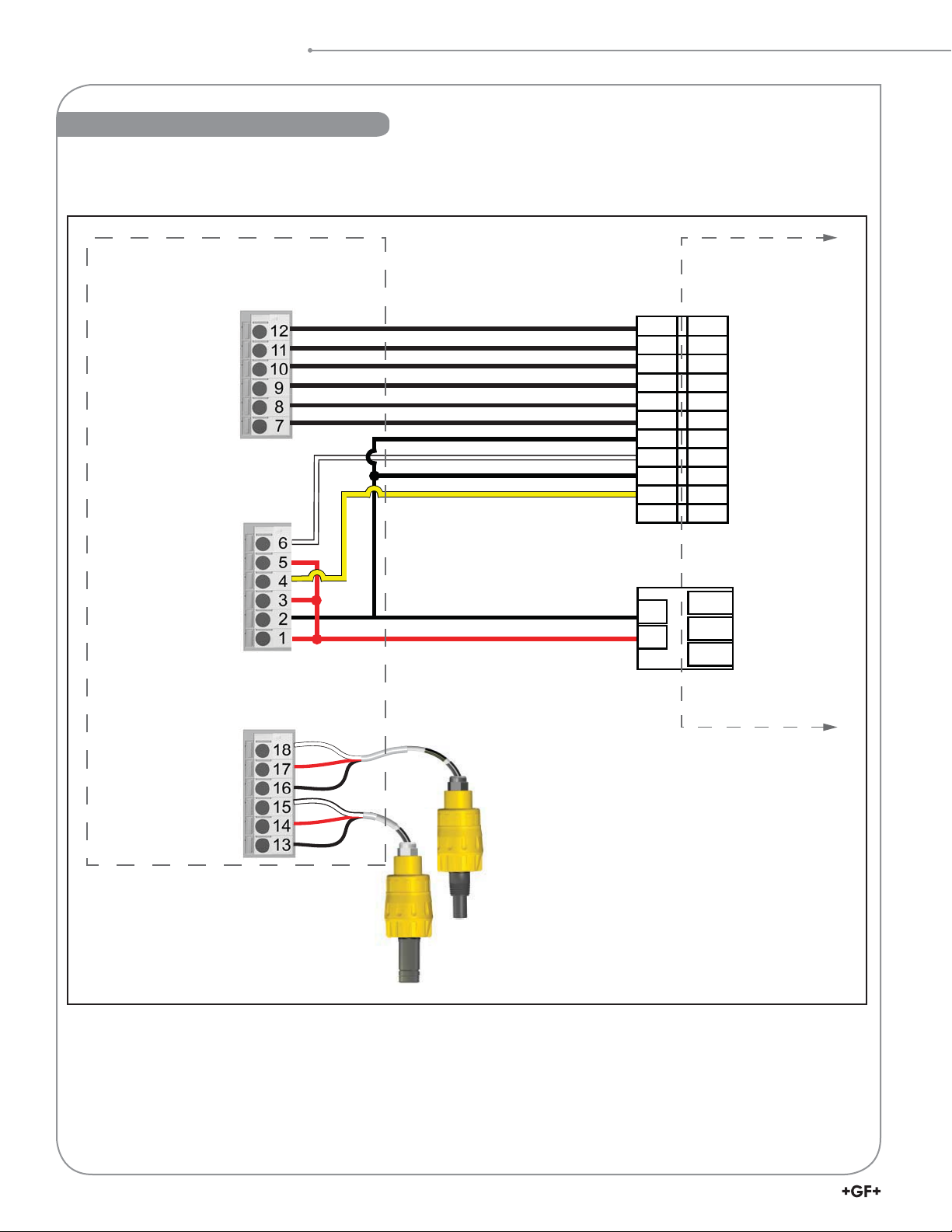

Page 10

Electrical Box Wiring Schematic

Electrical Box Wiring Schematic

3-8630-3P (159 001 673) Customer Wiring

Relay 2 (N.O.)

Relay 2 (COM)

Relay 2 (N.C.)

Relay 1 (N.O.)

Relay 1 (COM)

Relay 1 (N.C.)

Loop 2 -

Loop 2

System Power Loop 1 -

System Power Loop 1

AUX Power -

AUX Power

Transmitter

Terminals

+

+

+

Black

Black

Black

Black

Black

Black

Black

White

Black

Yellow

Black

Red

Terminal

Block

10

9

8

7

6

5

4

3

2

1

GND

– V

+V

10

9

8

7

6

5

4

3

2

1

GND

GND

N

L

NO

COM RELAY 2

NC

NO

COM RELAY 1

NC

– LOOP 2

+ LOOP 2

– LOOP 1

+ LOOP 1

EARTH GROUND

Ground

Digital (S

Ground

Digital (S

3

V+

3

V+

Power Supply

24 VDC

White

L)

L)

Red

Black

White

Red

Black

Signet pH Sensor Electronics

3-2750-7 (159 001 671)

Signet Chlorine Sensor Electronics

3-2650-7 (159 001 670)

10

463X Chlorine System Manual

Page 11

Chlorine Sensor Preparation

2630 Free Chlorine Electrode

2632 Chlorine Dioxide Electrode

• Chlorine sensors are shipped without internal electrolyte solution.

• Prior to installation and supplying power, Chlorine sensors must be lled with the

appropriate internal electrolyte solution.

• Verify the correct electrolyte solution is utilized with the corresponding sensor.

• Free Chlorine and Chlorine Dioxide sensor require different electrolyte solutions.

Avoid skin or eye contact with electrolyte solution.

Wear rubber gloves and goggles.

* Material Safety Data Sheets (MSDS) are available online at www.gfsignet.com.

Initial Fill Procedure:

When adding electrolyte, be prepared for an accidental spill.

Working near a sink is recommended.

1. Remove the protective bottle from the end of the electrode

2. Remove the membrane cap from the front of the sensor.

Note: When new sensors are shipped, the membrane cap is not tightened to the sensor

3. Fill supplied syringe with electrolyte solution.

Additional caution should be taken when handling Chlorine Dioxide electrolyte solution.

4. Place the electrode on a level surface.

5. Insert syringe needle fully into one of the eight electrode holes while injecting with

electrolyte solution. Slowly injecting the electrolyte solution into the sensor to avoid

introducing air bubbles. The electrode holds approximately 14 milliliters of solution.

Slowly ll until solution begins to ow out of holes. Do not allow the solution to run

down the electrode and wet the electrical contacts in the DryLoc connector.

6. Slowly screw on the membrane cap nger tight. Do not use tools. To avoid damage

and contamination, do not touch the white membrane surface on the membrane cap.

Sensor Preparation

CAUTION:

DO NOT touch the gold tip or

the membrane of the sensor.

Chlorine Sensor Calibration

A new chlorine electrode or one that has had the membrane cap changed must be

calibrated. See page 24, 8630 Transmitter information on calibration of the chlorine

sensor. A diethyl-p-phenylenediamine (DPD) colorimeter test kit (not included) is required

for sensor calibration. A sample is taken and analyzed with the DPD test kit, then this

value is entered into the Signet 8630 transmitter.

• Calibrate after a membrane cap change (requires 4 hour stabilization time).

• Calibrate after the internal electrolyte is replaced (requires 2 hour stabilization time).

• Check calibration one day after sensor is placed in service.

• Check calibration weekly to monthly depending on process requirements.

Chlorine Sensor Maintenance

The sensor membrane and internal electrolyte solution must be replaced over the life

of the electrode. To maintain accurate chlorine measurements, GF Signet recommends

that the internal electrolyte be replaced every 3 to 6 months, or when Chlorine readings

drift low and/or cannot maintain a calibration longer than 5 days. Actual interval between

maintenance of the sensor will be dependent on the actual applications, chlorine level and

contaminates in the water. See Appendix page 36; Maintenance and Storage.

Keep spare membrane caps available. Membrane caps carry no warranty.

NOTE: Inspect and change the

membrane cap if damaged.

See page 36, Maintenance, for

cleaning procedure.

11463X Chlorine System Manual

Page 12

Sensor Installation

Sensor Installation

• Remove sensor access plugs from the ow cell (pg. 4, Figure 1).

Note: Chlorine Sensor Preparation must be completed prior to installation, see page 11.

• Holding the 3-2750-7 (159 001 671) or 3-2650-7 (159 001 670) electronics inverted, open the DryLoc

turning the upper locking ring ¼-turn counter-clockwise.

• Insert the electrode facing up. Turn the locking ring ¼-turn clockwise to lock the electronics in place.

• The mechanism will “click” when it is locked.

• Install the complete assembly into the ow cell and ensure the key on the electrode aligns with the key slot on the ow cell.

Avoid skin or eye contact with electrolyte solution.

Wear rubber gloves and goggles.

Material Safety Data Sheets (MSDS) are available

online at www.gfsignet.com.

Do Not Use Lubricant or Sealing Tape on Threads.

Do Not Overtighten. Do Not Use Tools.

Do Not Drop or Strike the Membrane.

DryLoc® Connection to Sensor Electronics

®

connector by

3-2724-00

(159 001 545)

pH electrode

Locking Ring

3-2750-7

(159 001 671)

pH electronics

Lubricate O-rings with

a non-petroleum

based, viscous

lubricant (grease)

compatible with the

system.

Signet 3-2630-X

Signet 3-2632

Chlorine Electrode

3-2630-X

FCL electrode

3-2632

ClO2 electrode

Locking Ring

LockLock

3-2650-7

(159 001 670)

Amperometric Electronics

12

Signet 3-2724-00

(159 001 545)

Flat pH Electrode

Signet 3-2650-7

Electronics

Signet 3-2750-7

pH Electronics

463X Chlorine System Manual

Page 13

Tubing Connections

Water Flow

Use suitable 9.5 mm (3/8 in) ID tubing that is rated for your

inlet pressure. Use hose clamps.

Inlet Quick Release Connection

Press down gray plunger to release. Water ow is

automatically shut off when disconnected.

Valve position for start up and normal use.

Note: Turn off inlet valve rst when stopping water ow.

• The drain tube must be positioned lower than the in uent

water source to allow proper ow through the ow cell.

The ow cell must drain by gravity, not system pressure.

• When testing, allow the sample to ow for a few seconds

before collection.

Inlet

Drain

(to atmosphere)

Sampling port

( ow off)

Water Flow

Flow Rate

The ow rate is in the proper range when the oat is

between the Min. and Max. markers on the ow cell. The

ow range limits are 30.24 to 45.36 L/h (8 to 12 gal/h).

OK

For Low Flow applications ( ow less than 1 bar/15 psi), the

Flow Regulator can be removed and the ow adjusted using

the Flow Cell ball valve. (NOTE: The inlet hose barb will also

need to be changed. Contact factory for details.)

pH Cl

IN

OUT

13463X Chlorine System Manual

Page 14

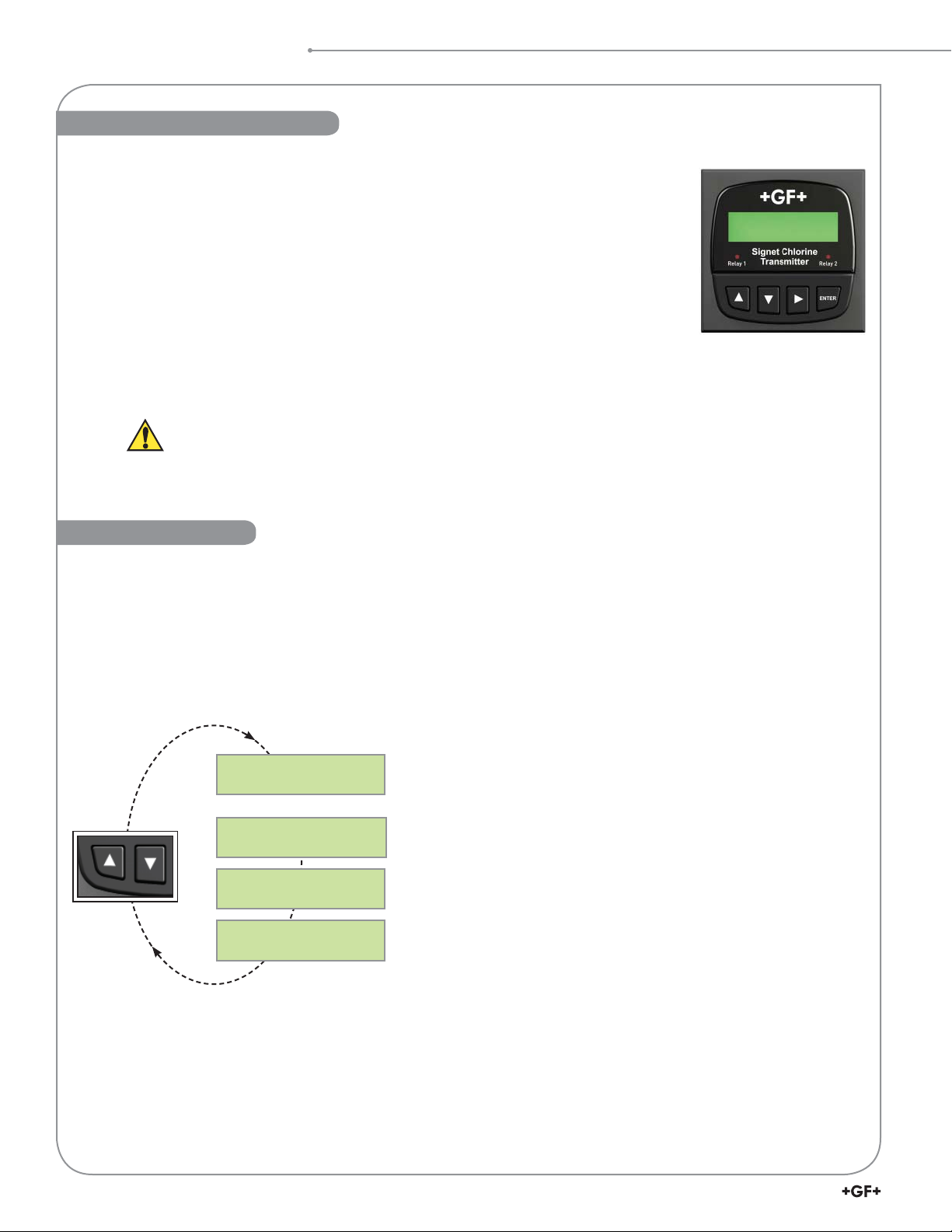

8630 Chlorine Transmitter

8630 Chlorine Transmitter

The Signet 8630 ProcessPro® Chlorine Transmitter displays and transmits free chlorine or chlorine

dioxide, along with pH information when connected to Signet Amperometric Chlorine Sensors and

a Signet pH Sensor.

Features of the 8630 include:

• Displays Free Chlorine measurements from 0 to 20 ppm (parts per million) or Chlorine Dioxide

measurements from 0 to 2 ppm.

• Speci es all compatible chlorine sensors.

• Automatic pH and temperature compensation or manual pH input to calculate accurate

free chlorine measurements.

• Simple setup and easy customization with the 4-button keypad.

• Dual 4 to 20 mA outputs with two built-in SPDT mechanical relays.

• Easy viewing via the bright backlit LCD display.

CAUTION!

• Remove power to unit before wiring input or output connections.

• Follow instructions carefully to avoid personal injury or damage to the transmitter.

8630

Chlorine

8630 View Mode

• The View Menu is displayed during normal operation.

• To select a VIEW display, press the or keys. The selections will scroll in a continuous loop. There are four pages to view.

• Changing the VIEW display does not interrupt system operations.

• No key code is necessary to change display selection.

• Output settings cannot be edited from the VIEW menu.

• All menus time-out after 10 minutes and return to the previous operating display.

• When editing the CALIBRATE or OPTIONS menus, the transmitter will return to the default display after 10 minutes and then

the VIEW menu in another 10 minutes if no activity occurs.

FCl: 2.67 ppm

7.10 pH 25.3 °C

The example View menus below return to the default display after 10 minutes.

Cl Raw: 103.8 nA

pH Raw: -5.9 mV

Loop 1 10.68 mA

Loop 2 8.56 mA

Last CAL:

10-18-10

View chlorine, pH and temperature values from the sensor.

FCl = free chlorine, ClO2 = chlorine dioxide.

Chlorine (nA) and pH raw (mV) signals from the sensors.

For reference only.

View of current loop 1 and loop 2 output.

View of the last calibration date. Editable in the Calibrate Menu.

14

463X Chlorine System Manual

Page 15

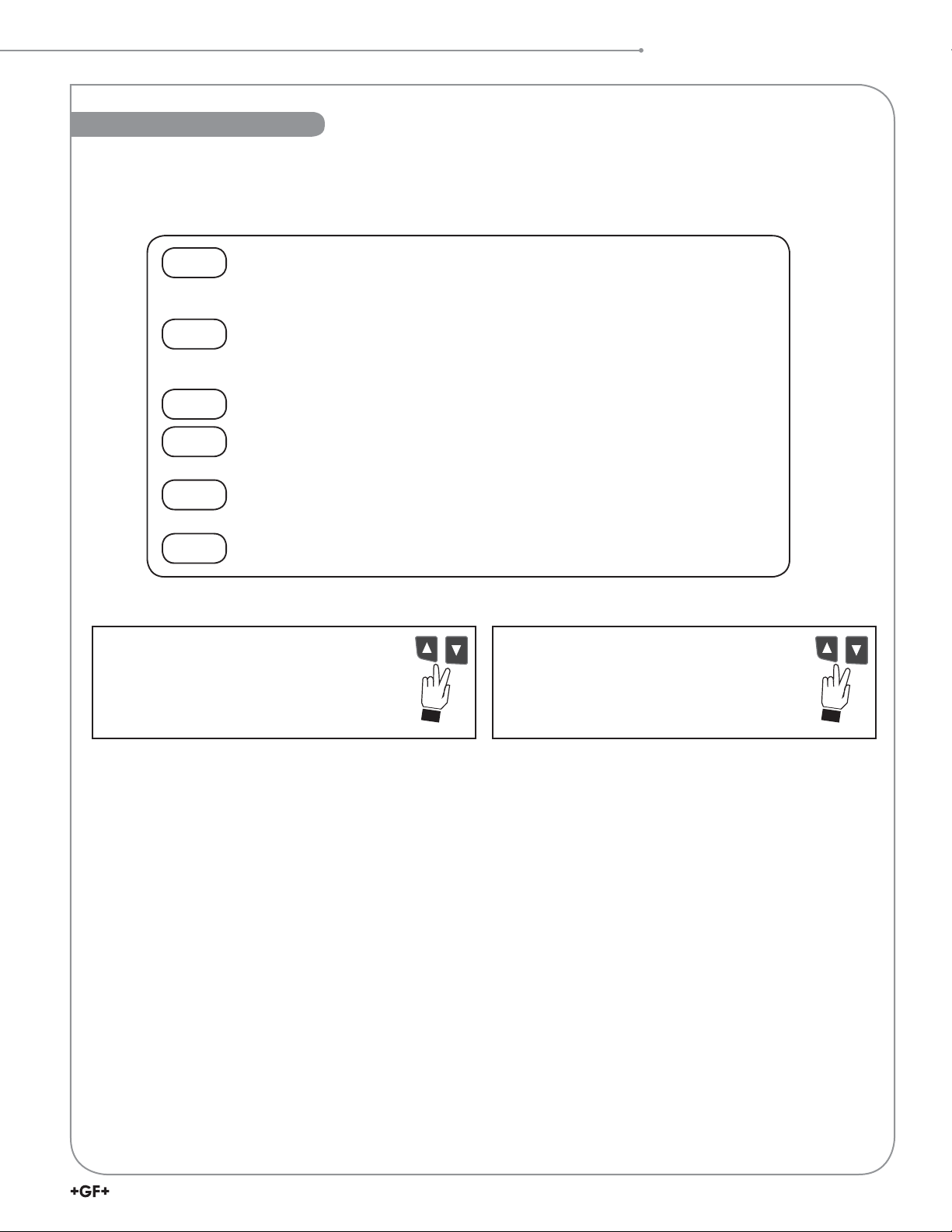

8630 Editing Procedure

8630 Editing Procedure

The 8630-3 (159 001 662) has two menus the user can edit: CALIBRATE and OPTIONS.

• The CALIBRATE menu allows you to calibrate and initialize sensors, de ne current loops and set relay functions.

• The OPTIONS menu allows you to set sensor type, adjust and test current loops, test relays and more.

Step 1. Press and hold the ENTER key:

• 2 seconds to select the CALIBRATE menu.

• 5 seconds to select the OPTIONS menu.

Step 2. Enter the Key Code.

The Key Code is --- keys in sequence.

• After entering the Key Code, the display will show the rst item in the selected menu.

Step 3. Scroll the menu in a loop with the or arrow keys.

Step 4. Press the key to select the menu item to be edited.

• The rst display element will begin ashing.

Step 5. Press the or keys to edit the ashing element.

• The key advances the ashing element.

Step 6. Press the ENTER key to save the new setting and return to Step 3.

Made an Error?

Press the and keys simultaneously

while any element is ashing. This will recall

the last saved value of the item being edited

and will return you to Step 3.

Press the and keys simultaneously

after saving the last setting to return to

View menu.

Finished Editing?

15463X Chlorine System Manual

Page 16

8630 Editing Procedure

Example: Calibration

Access the CALIBRATE Menu:

ENTER

ENTER

Press and hold the ENTER key for 2 seconds to access

the CALIBRATE menu.

Enter the Key Code:

The CALIBRATE and OPTIONS menus require a

password (KEY CODE). Pressing the , , , keys

in sequence unlocks the display and the rst menu item

will appear. If no key is pressed for 5 minutes while the

display is showing "Enter Key Code", it will return to the

VIEW menu.

Scroll the Menu:

Press the or keys to scroll through the Menu.

While in this mode, pressing the and keys

simultaneously will return the display to the VIEW menu.

If no key is pressed for 10 minutes, the display will

return to the VIEW menu.

Step 1.

Step 2.

Step 3.

(Hold)

ENTER

ENTER

CALIBRATE menu

OR

2s

CALIBRATE:---Enter Key Code

CALIBRATE:--Enter Key Code

CALIBRATE:-Enter Key Code

CALIBRATE:Enter Key Code

Cl Zero

Calibration: >

Cl Zero

Calibration: >

Last Cal:

09-18-09 >

OPTIONS

5s

menu

Select the item to be edited:

In this example, "Last Cal" (last calibration date) is

chosen to edit. Pressing the key selects the menu

item and enters the screen into edit mode.

Edit the ashing element:

This is the edit mode.

The or keys change the ashing element.

The key advances the ashing element in a

continuous loop. In this example, the "Last Cal" date

was changed from 09-18-09 to 10-18-09.

All output functions remain active during editing.

Only the ashing element can be edited.

Press ENTER to save the new value.

ENTER

ENTER

When you have set your desired value, pressing the

ENTER key stores the value on the screen, making it

immediately available to output functions and exits you

back to Step 3.

Step 4

Step 5.

Step 6.

Last Cal:

.

09-18-09 >

Last Cal:

09-18-09

Last Cal:

19-18-09

Last Cal:

19-18-09

Last Cal:

10-18-09

Last Cal:

Saving

Last Cal:

10-18-09

Example

ENTER

ENTER

16

463X Chlorine System Manual

Page 17

8630 Calibrate Menu

8630 Calibrate Menu

The menus below are displayed here in the order seen when scrolling down through the Calibrate Menu.

NOTE:

For greater accuracy it is recommended that the initial calibration of the system should be in the following order:

1. Temperature

2. pH electrode (if optional pH sensor is installed. If manual pH sensor is selected enter the pH value into the

option menu prior to calibrating the chlorine sensor)

3. Chlorine sensor.

• Although the Calibrate Menu can be navigated upwards or downwards, it is best to navigate downwards when editing Current

Loop and Relay settings as previous entries can in uence subsequent menus.

• Chlorine and pH calibration screens will be shown only when a valid sensor is detected.

(Hold)

ENTER

ENTER

2s

Press the or Arrow

key to scroll through the menus.

Calibrate Menus

Factory settings shown

Chlorine Units:

ppm >

Cl Zero

Calibration: >

Cl In Process

Calibration: >

Reset Cl to

Factory Cal: >

Cl Temperature

Calibration: >

NOTE: The next two pH calibration screens will be shown only when a valid pH sensor is detected.

pH Standard

Calibration: >

pH Slope

Calibration: >

This is the rst screen. Choose units of measurement: ppm or mg/l.

When > is pressed, the “live” readings are shown. The nA value is displayed, but cannot be

edited and is used for diagnostic and calibration purposes. When in Edit Mode, pressing Enter

stores the displayed value as your zero reference.

Enter process chlorine value determined from a DPD test kit here.

This menu resets Cl readings, Zero Calibration and temperature back to Factory Calibration.

WARNING! User entered Cl calibration settings will be lost.

Enter process temperature from a reference thermometer: °C or °F. Units are set up in the

Options Menu.

Set pH standard value. This applies a linear offset to the pH measurement.

Applies a slope to the pH measurement. The slope and standard value must be at least

2 pH units apart.

Press the key to enter Edit mode.

Description

Press the Enter key to save

ENTER

ENTER

your settings.

Reset pH to

Factory Cal: >

Loop 1 Source:

Chlorine >

Loop 1 Rng: ppm

0.00 5.00 >

Loop 2 Source:

pH >

Loop 2 Rng: pH

00.0 14.00 >

Reset pH standard, slope or back to Factory Calibration.

WARNING! User entered pH calibration settings will be lost.

Current Output Functions

Choose chlorine or pH for this 4 to 20 mA current loop.

Select the minimum and maximum values for the current loop output. Units are derived from

Loop 1 Source. If the Source 1 is changed, be sure to re-edit this page.

Choose pH or chlorine for this 4 to 20 mA current loop.

Select the minimum and maximum values for the current loop output. Units are derived from

Loop 2 Source. If Source 2 is changed, be sure to re-edit this page.

17463X Chlorine System Manual

Page 18

8630 Calibrate Menu

8630 Calibrate Menu - continued

Verify all relay settings if the Relay Source is changed.

Relay Functions

Relay 1 Mode:

Off >

If Low or High Mode was chosen:

Choose mode of operation: Off, Low, High, Window, or Pulse. If Off, all subsequent Relay 1

functions are inactive and not visible.

Relay 1 Source:

Chlorine >

Relay 1 Setpnt:

0.00 ppm >

Relay 1 Hys:

0.20 ppm >

Relay 1 Delay:

0.0 secs >

If Window Mode was chosen:

Relay 1 Source:

Chlorine >

Relay1 Rng: ppm

0.00 5.00 >

Relay 1 Hys:

0.20 ppm >

Relay 1 Delay:

0.0 secs >

Choose chlorine or pH for Relay 1.

In Low or Hi Mode, Relay 1 will be activated when the process reaches this value.

Units of measure re ect Relay 1 Source.

Relay 1 will be deactivated at Relay 1 Setpoint ± this hysteresis setting depending on High or

Low Setpoint selection.

Set the time delay for Relay 1 to activate after reaching the Setpoint.

Range: 0 to 6400 seconds.

Choose chlorine or pH for Relay 1.

Enter the range where Relay 1 will activate above and below this setpoint.

Relay 1 will be deactivated at Range setpoints ± this hysteresis setting.

Set time delay for Relay 1 to activate after reaching the setpoints set in Relay 1 Range.

If Pulse Mode was chosen:

Relay 1 Source:

Chlorine >

Relay1 Rng: ppm

0.00

5.00 >

Relay1 PlsRate:

120 pulses/min >

Relay 2 Mode:

Off >

If Low or High Mode was chosen:

Choose Relay 2 mode of operation: Off, Low, High, Window, or Pulse.

To disable this relay choose Off.

Relay 2 Source:

pH >

Relay 2 Setpnt:

0.00 pH >

Relay 2 Hys:

0.20 pH >

Relay 2 Delay:

0.0 secs

>

Choose chlorine or pH for Relay 1.

Enter the range where Relay 1 will activate above and below this setpoint.

Set the maximum pulse rate. Range: 1 to 400 pulses/min.

Choose pH or chlorine for Relay 2. This menu screen and all subsequent Relay 2 screens

below do not appear if Relay 2 Mode is set to Off.

In Low or High Mode, Relay 2 will be activated when the process reaches this value.

Units of measure re ect Relay 2 Source.

Relay 2 will be deactivated at Relay 2 Setpoint ± this hysteresis setting depending on High or

Low Setpoint selection.

Set the time delay for Relay 2 to activate after reaching the Setpoint.

Range: 0 to 6400 seconds.

18

463X Chlorine System Manual

Page 19

8630 Calibrate Menu - continued

If Window Mode was chosen:

8630 Calibrate Menu

Relay 2 Source:

pH >

Relay 2 Rng: ppm

0.00 5.00 >

Relay 2 Hys:

0.20 ppm >

Relay 2 Delay:

0.0 secs >

If Pulse Mode was chosen:

Relay 2 Source:

pH >

Relay2 Rng: pH

0.00 14.0 >

Relay2 PlsRate:

120 pulses/min >

Find New

Sensor(s): >

Choose pH or chlorine for Relay 2.

Enter the range where Relay 2 will activate above and below this setpoint.

This relay will be deactivated at Relay 2 Range setpoints ± this hysteresis.

Set the time delay for Relay 2 to activate after reaching the setpoints set in the

Relay 2 Range.

Choose pH or chlorine for Relay 2.

Enter the range where Relay 2 will activate above and below this setpoint.

Set the maximum pulse rate. Range: 1–400 pulses/min.

Required only when a new sensor is changed while the power is on. Choose Yes or No.

Last Cal

10-18-09 >

Edit the calibration date.

End of Calibrate Menu

19463X Chlorine System Manual

Page 20

8630 Options Menu

8630 Options Menu

The menus below are displayed here in the order seen

when scrolling down through the Calibrate Menu.

Press the or Arrow key to

scroll through the menus.

Options Display

(Factory settings shown)

Contrast:

3 >

Cl Sensor Type:

Free Cl >

pH Input

Sensor >

If Manual pH input was chosen:

Manual pH Value

7.000 pH

Adjust the LCD contrast for best viewing. A setting of 1 is lower contrast, 5 is higher.

Select the chlorine sensor: Free Cl or ClO2.

Choose Manual or Sensor. If Sensor is chosen, the pH value from the connected pH sensor will be

used. Choose Manual to enter a pH value manually when no sensor is connected or if measuring

chlorine dioxide.

Enter your pH value here if a pH sensor is not connected.

(Hold)

ENTER

ENTER

Press the key to enter Edit mode.

Description

5s

OPTIONS menu

Press the Enter key to save

ENTER

ENTER

your settings.

Temp Display:

°C >

Averaging:

Off >

Decimal:

***.** >

Loop 1 Adjust:

4.00 mA >

Loop 1 Adjust:

20.00 mA >

Loop2 Adjust:

4.00 mA >

Loop2 Adjust:

20.00 mA >

Test Loop 1:

>

Test Loop 2:

>

Choose units of °C or °F.

OFF gives the fastest response to input changes. LOW = 4.5 seconds, HIGH = 9 seconds of averaged

response. Increase averaging to steady the display.

Select the decimal point for the display. Maximum of 2 decimal places.

Adjust the minimum current output for Loop 1. The display value represents the precise

current output. Range: 3.80 mA to 5.00 mA.

Adjust maximum current output for Loop 1. Range: 19.00 mA to 21.00 mA.

Adjust the minimum current output for Loop 2. Range: 3.80 mA to 5.00 mA.

Adjust maximum current output for Loop 2. Range: 19.00 mA to 21.00 mA.

Press UP or DOWN keys to manually output any current value from 3.6 mA to 21.00 mA to test

Loop 1 output.

Press UP or DOWN keys to manually output any current value from 3.6 mA to 21.00 mA to test

Loop 2 output.

20

463X Chlorine System Manual

Page 21

8630 Options Menu - continued

8630 Options Menu

Test Relay 1:

Test Relay 2:

>

Read Sens Data:

No >

If Yes was chosen:

Cl Sensor S/N:

xxxxxxxxx

Cl Type & Range:

2630 xxx.x ppm

Zero Cal: ppm&nA

xxx.xx xxxx.x

In Proc: ppm&nA

xxx.xx xxxx.x

Temp at Cal:

xxxx.x °C

pH at Cal:

xxx.xx pH

Press UP or DOWN keys to manually toggle Relay 1 Off and On. The left LED on the front of

the transmitter con rms operation.

>

Press UP or DOWN keys to manually toggle Relay 2 Off and On. The right LED on the front of the

transmitter con rms operation.

If "YES" is selected the following (Read Only) screens will be shown.

If "NO" then this menu ends the Options Menu.

View the sensor serial number.

Identify the chlorine sensor type connected and its ppm range.

View user entered Zero Calibration data in ppm and nA.

View user In-Process Calibration value when it was entered in the Calibrate Menu.

Temperature recorded during user In-Process Calibration.

pH value recorded during user In-Process Calibration.

Temp Offset:

xxxx.x °C

Elapsed Time:

xxxxx. hrs

Low & High: °C

-xxxx.x +xxxx.x

Temperature offset calculated from user entered temperature calibration from Calibrate Menu.

Total hours of operation.

Lowest and highest temperatures the Cl sensor has been subjected to during operation.

End of Options Menu

21463X Chlorine System Manual

Page 22

pH Sensor Calibration

Chlorine Sensor Conditioning

A new chlorine sensor or one that has had the electrolyte

or membrane replaced must be conditioned to generate

stable and accurate readings. To condition a chlorine sensor,

the sensor and sensor electronics must be installed and

powered, and must also have chlorinated water ow across

the membrane.

Chlorine Sensor Conditioning

1. Turn on and adjust water ow rate. Condition a new

chlorine sensor for 4 hours. Conditioning time for a

membrane cap replacement and/or electrolyte re ll is

2 hours.

2. Keep of ine any 4 to 20 mA devices or relay actuated

output devices that connect to the transmitter.

NOTE: The membrane cap may have to be replaced when

electrolyte is changed. Replace membrane if damaged.

The electrolyte should be replaced every 3 to 6 months.

pH Sensor Calibration

If a pH sensor is part of the system, use the Calibration

Kit 3-2700.395 (159 001 605) prior to initially installing

the sensor and during its normal lifetime. If a pH sensor is

not available but pH determination is necessary, measure

process pH with a separate test and enter the value in the

Options Menu.

NOTE: Temperature must be calibrated before calibrating the

pH sensor. See Chlorine Sensor section.

Refer to your pH sensor manual.

The pH sensor needs to be calibrated against two different pH

buffer references to calibrate the offset (standard) and slope.

Electrode offset is any deviation from 0 mV in a pH 7 buffer at

25 °C. Slope is the ratio of mV to pH units.

• Always keep any output devices of ine when calibrating.

Set pH Offset (Standard)

The transmitter must be powered on and the pH sensor must

be connected.

1. Turn off the water ow through the system, then remove

the pH sensor from its ow cell.

2. Using pH buffer 7.0, place enough pH buffers into

clean calibration cups, supplied with the pH calibration

kit 3-2700.395 (159 001 605), to cover the tip of the

electrode.

3. Pour distilled water in another clean cup for rinsing the

electrode between buffers.

4. Rinse probe, place the pH sensor in the pH 7.0 buffer

and allow the mV reading to stabilize.

Example: Set pH Standard to 7.00.

5. Go to the Calibrate Menu.

6. Scroll down 5 menus to the pH Standard menu.

7. Press to enter Edit Mode.

8. Enter the pH value of the buffer that the electrode is

placed in; 7.00 in this case.

9. Press the Enter button to save the setting.

10. Exit to the View Menu.

EXAMPLE

EXAMPLE

Step 4

FCl: 2.67 ppm

View Menu

7.11 pH 25.3°C

(Hold)

ENTER

ENTER

5

6

7

8

pH buffer value

entered here

NOTE: The pH sensor will not calibrate when the mV value

exceeds 50 mV from the original new electrode speci cation.

Electrode: pH 4.01 = + 177 mV.

pH Standard

Calibration: >

pH Standard Cal:

07.00 pH/ 0 mV

ENTER

ENTER

2s

5X

Calibrate Menu

22

463X Chlorine System Manual

Page 23

Set pH Slope

1. Remove the pH sensor from the rst buffer solution and

rinse it in distilled water.

2. Place the pH sensor in a different buffer solution

(example: pH 4.01). The pH standard and slope must be

at least 2 pH units apart.

3. Note the pH and mV readings on the View Menu and

allow it to stabilize.

Example: Set pH slope to 4.01.

EXAMPLE

4. Scroll down 1 menu to the pH Slope menu.

5. Press to enter Edit Mode.

6. Enter the pH value of the buffer that the electrode is

placed in; 4.01 in this case.

7. Press the Enter button to save the settings.

8. Exit to the View Menu.

9. Replace the pH sensor back into its ow cell.

10. Turn on the water ow.

The pH sensor calibration is complete.

EXAMPLE

4

5

6

pH buffer value

entered here

pH Sensor Calibration

pH Standard Cal:

07.00 pH/ 0 mV

pH Slope

Calibration:

pH Slope Cal:

04.01 pH/ +177 mV

ENTER

ENTER

View Menu

Calibrate Menu

>

Set Manual pH Compensation

If the pH of the application is stable, then the pH of the

application can be entered manually and will be used to

calculate the free chlorine measurements.

NOTE: Chlorine dioxide does not require pH compensation.

Example: Change the pH input from Sensor to Manual

and enter a pH value of 7.22.

1. Go to the Options Menu.

2. Scroll down 2 menus to the pH Input menu.

3. Press to enter Edit Mode.

4. Choose Manual and press Enter.

5. Scroll down 1 menu to the Manual pH Value menu.

6. Press to enter Edit Mode.

7. Enter your new process pH value: 7.22.

8. Press the Enter button to save the setting.

9. Exit to the View Menu.

EXAMPLE

EXAMPLE

pH Input

Sensor >

pH Input

4

Sensor Manual

ENTER

ENTER

pH Input

5

Manual

Manual pH Value

7

7.220 pH

ENTER

ENTER

Options MenuStep 2

Manual chosen

>

New pH value entered

23463X Chlorine System Manual

Page 24

Chlorine Sensor Calibration

Chlorine Sensor Calibration

Chlorine sensors need to be calibrated for accuracy. After the

4 hour conditioning period, Temperature Calibration,

Zero Point Calibration and In-Process Calibration needs to

be performed. Any 4 to 20 mA or relay output devices should

be of ine.

Chlorine Sensor Temperature Calibration

The temperature element inside the chlorine sensor needs

to be calibrated. Use a reference thermometer to verify the

actual temperature of the sample. This value is then entered

in Step 4 to calibrate the system.

Tip: Remove the pH electrode from the ow cell and insert

the reference thermometer. If no pH sensor is being used,

remove the cell plug to insert the thermometer. Replace the

plug after calibration.

Example: Set the calibrated temperature to 25.3 ºC.

1. Go to the Calibrate Menu.

2. Scroll down 3 menus to the Cl Temperature menu.

3. Press to enter Edit Mode.

4. Enter the temperature reading. Example: 25.3.

5. Press the Enter button to save the setting.

6. Exit to the View Menu.

Zero Point Calibration

The chlorine sensor needs to be calibrated against two

chlorine references: zero chlorine and the process chlorine.

Typically the zero point calibration is very stable. Calibration

must be done with every new sensor and any time a

membrane cap is replaced.

1. Keep of ine any 4 to 20 mA devices or relay actuated

output devices that connect to the transmitter.

2. Turn off the water ow and remove the powered chlorine

sensor with the electronics still attached.

3. Place the sensor tip in distilled water.

4. Wait until the reading stabilizes, then save the

calibration. Stirring the sensor in water is not necessary,

but allows the signal to stabilize faster.

Example: Set the Zero Point Calibration at 1.0 nA.

5. Go to the Calibrate Menu.

6. Scroll down one menu to the Cl Zero menu.

7. Press to enter Edit Mode. The live sensor readings in

ppm and nA will be ashing. These readings cannot be

modi ed, but can only be saved as displayed.

8. Press the Enter button at the lowest reading to save the

setting or press to escape without changes.

9. Exit to the View Menu.

10. After Zero Point Calibration is complete, replace the

sensor back into the ow cell and turn the water ow

back on.

11. Wait until the chlorine readings stabilize once again, then

perform a chlorine In-Process Calibration.

EXAMPLE

EXAMPLE

EXAMPLE

Step 2

New temp. value

Cl Temperature

Calibration: >

Cl Temp: Cal

4

+025.3 °C

ENTER

ENTER

EXAMPLE

Step 6

The signal level during a Zero Point

Calibration must be at least 1 nA lower

than the In-Process Calibration point.

Cl Zero:

Calibration

Zero Cal: ppm&nA

8

0.20 / 001.0

ENTER

ENTER

>

Lowest value noted for

Zero Cal.

Calibrate Menu

Calibrate Menu

24

463X Chlorine System Manual

Page 25

In-Process Calibration

A diethyl-p-phenylenediamine (DPD) colorimeter test kit (not

included) is required for sensor calibration. A sample is taken

and analyzed with the DPD test kit, then this value is entered

into the Signet 8630 transmitter.

Chlorine Sensor Calibration

1. Take a water sample from the Sampling Port (after

purging it) from a stabilized and running system.

2. Use this sample to measure the chlorine content with

a colorimetric DPD test kit (not included). Refer to the

DPD kit instructions on how to perform this test.

NOTE: For greater accuracy, it is recommended

that the DPD test be repeated three times and

the results averaged together.

3. Record the test results.

Example: Set the Chlorine In-Process to 2.67 ppm.

4. Go to the Calibrate Menu.

5. Scroll down 2 menus to the Cl In-Process menu.

6. Press to enter Edit Mode.

7. Enter the chlorine reading determined from the DPD test

into the edit screen: 2.67 ppm. The Cl ppm is editable

and must be at least 0.2 ppm.

8. Press the Enter button to save the setting.

9. Exit to the View Menu.

Calibration is complete for the chlorine sensor.

EXAMPLE

EXAMPLE

Step 5

DPD Cl ppm value

entered here.

The signal level during an In-Process

Calibration must be at least 1 nA higher

than the previous Zero Calibration point.

Cl In Process

Calibration: >

In Proc: ppm&nA

7

2.67 / 103.8

ENTER

ENTER

Calibrate Menu

Output Settings - Loops and Relays

Con gure the current loop and relay functions if applicable.

NOTE: The current and relay outputs can be tested in the

Options Menu.

Current Loop Settings

Current outputs are passive outputs that can be spanned in

the forward and reverse direction. Example: 0 to 5 or 5 to 0.

Example: Set a current loop source as chlorine and the

operational range to 0 to 5 ppm.

1. Go to the Calibrate Menu.

2. Scroll down to the Loop 1 Source menu.

3. Press to enter Edit Mode.

4. Choose either the chlorine or pH sensor as the source

that will control this loop: Chlorine.

5. Press the Enter button to save the setting.

6. Scroll down 1 menu to the Loop 1 Rng menu.

7. Press to enter Edit Mode.

8. Select the minimum and maximum process values for

the current loop output: 0 to 5 ppm.

9. Press the Enter button to save the setting.

10. Exit to the View Menu.

EXAMPLE

NOTE:

When integrated into the 463X Chlorine Panel Assembly,

the loop outputs are wired into Active outputs via the

terminal strip found inside the 463X enclosure.

EXAMPLE

Step 2

Loop 1 Source:

Chlorine >

Set and save

Loop 1 Rng: ppm

6

0.00 5.00 >

Set and save

Calibrate Menu

25463X Chlorine System Manual

Page 26

1 4 mg/l

Output (pulses per minute)

Ending

Point

Input (mg/l)

Starting

Point

0

20

40

60

80

100

Pulse

Hysteresis

Time

Low Setpoint

Process

Relay energized

Relay de-energized

Hysteresis

Time

High Setpoint

Process

Time

High Limit

Hysteresis

Hysteresis

Low Limit

Process

Window

Output Settings

Mechanical Relay Functions

The 8630 relays are selectable and con gurable and can

be used as switches that respond when the process value

moves above or below a user de ned setpoint. They can

be used for Low Alarm, High Alarm or Proportional Pulse

triggering related to the process value. Relay functions,

hysteresis and time delay settings are set up in the

CALIBRATE menu and can be tested in the OPTIONS menu.

Low Setpoint:

Relay is energized when the measured value is less than

the setpoint.

High Setpoint:

Relay is activated when the measured value is higher than

the setpoint.

Window:

Relay is off within the window of two setpoints minus the

hysteresis. Relay is activated when the value is higher or

lower than the high and low setpoint.

Pulse-frequency Operation:

The transmitter can output a pulse at the rate de ned by

the settings in the CALIBRATE menu and the sensor input.

The maximum pulse square wave output from the relays is

400 pulses per minute. Example usage would be to control

solenoid operated dosing pumps.

Example: As the process value drops below the setpoint

(4 mg/l) the output will start pulsing in relation to the process

value, the maximum pulse endpoint and the programmed

pulses/minute. The pulse rate will increase as the process

value decreases and approaches the programmed endpoint.

This functionality can be used to precisely control the

process.

• The output will be 0 pulses/minute when the input value is

greater than 4 mg/l.

• The output will be 35 pulses/minute when the input value is

3 mg/l.

• The output will be 100 pulses/minute when the input value

is 1 or less.

The starting point, endpoint and maximum pulse rate are

select able in the CALIBRATE menu.

26

463X Chlorine System Manual

Page 27

Relay Settings

Relay energized

Relay de-energized

Output Settings

Example: Set a relay to energize at a low setpoint of

1.0 ppm with a time delay of 15 seconds and de-energize

at 1.30 ppm.

• Once a setting is saved it immediately becomes

active.

1. Go to the Calibrate Menu.

2. Scroll down to the Relay 1 Mode menu.

3. Press to enter Edit Mode.

4. Scroll down and choose Low.

5. Press Enter.

6. Scroll down to the Relay 1 Source menu. The default

is Free Chlorine.

7. Scroll down to the Relay 1 Setpnt menu.

8. Press to enter Edit Mode.

9. Set the ppm value to trigger the relay: 1.00 ppm.

10. Press Enter.

11. Scroll down to the Relay 1 Hys menu.

12. Press to enter Edit Mode.

13. Set the hysteresis (dead zone) for this relay. This affects

the turn off only: 0.3 ppm.

14. Press Enter.

15. Scroll down to the Relay 1 Delay menu.

16. Press to enter Edit Mode.

17. Set the turn-on delay in seconds for the relay: 15 secs.

18. Press Enter.

19. Exit to View Mode.

EXAMPLE

1.30

1.00

Cl ppm

Low

Setpoint

EXAMPLE

Step 4

Relay 1 Mode:

Low >

Relay 1 Source:

6

Chlorine >

Relay 1 Setpnt:

9

1.00 ppm >

Time

Time Delay

Calibrate Menu

Set and save

Set and save

Set and save

• Relay function can be tested in the Options Menu.

13

17

Relay 1 Hys:

0.30 ppm >

Set and save

Relay 1 Delay:

15.0 secs >

Set and save

27463X Chlorine System Manual

Page 28

2650-7 and 2750-7 Electronics

2650-7 Amperometric and 2750-7 pH DryLoc® Electronics

• The Signet 2650-7 Amperometric Electronics provide the polarization voltage and signal conditioning required by the Signet

2630-X and 2632-X Sensors.

• The Signet 2750-7 pH Electronics conditions and ampli es the output from the Signet 2724-00 pH Electrode.

• Both units output a Digital (S3L) signal to the Signet 8630 Chlorine Transmitter.

CAUTION!

• Remove power before wiring.

• Follow instructions carefully to avoid personal injury or

damage to the electronics.

Wiring to the Signet 8630 Chlorine Transmitter

The electronics are pre-wired from the factory to the transmitter. Refer to the following

schematics when replacing the electronics.

White

Red

Black

Shield

Signal Ground

Digital (S

3

L) data

+5 VDC

18

17

16

Gnd

I/O

V

+

N/C

pH

Signet 3-2750-7

(159 001 671)

White

Red

Black

Shield

Signal Ground

Digital (S

3

L) data

+5 VDC

15

14

13

Gnd

I/O

V

+

N/C

Chlorine

Signet 3-2650-7

(159 001 670)

8630

Chlorine

8630

Chlorine

• Refer to the wiring diagram above to connect the 2650 cable to the terminals on the 8630 Chlorine Transmitter.

• For calibration and con guration please refer to the 8630 Calibrate Menu discussions above.

28

463X Chlorine System Manual

Page 29

Chlorine Electrodes

Chlorine Electrode Overview

These electrodes require the Signet 2650 Amperometric Electronics module to communicate with the Signet 8630-3P

Chlorine Transmitter.

Electrode Range: The electrodes must match the type and range of chlorine concentration to be measured.

Flow Rate: The electrodes must have a stable and constant ow of water past its membrane for accurate measurement.

When the sensor is installed in the Flow Cell Block 3-4630.392 (159 001 690), the ow rate range is controlled by the internal

ow regulator and the ow rate is reduced to 30.24 to 45.36 LPH (8 to 12 US gph).

Sensor Conditioning: A new chlorine electrode requires conditioning of up to 4 hours with the electrode powered on and

chlorinated water owing across the membrane to generate a stable reading. Subsequent start-ups can require an electrode

conditioning of up to 2 hours.

The electrodes should not be used in water containing

surfactants, oils, organic chlorine or stabilizers such as

cyanuric acid.

The maximum allowable operating pressure must be

less than 1 bar (15 psi). Higher pressures will damage

the electrodes.

CAUTION!

1 Follow instructions carefully to avoid personal injury or damage to electrode.

2. Prior to installation or removal:

a. Disconnect ow through system.

b. Drain below sensor level.

3. Con rm chemical compatibility before use.

4. Do not alter product construction.

2630 Amperometric Chlorine Electrodes

The Signet 3-2630 Amperometric Chlorine Electrodes are designed to measure

free chlorine in ranges of 0 to 2 ppm, 0 to 5 ppm or 0 to 20 ppm.

Mfr. Part No. Code Chlorine Range Chlorine Type

3-2630-1 159 001 746 0 to 2 ppm (mg/L)

3-2630-2 159 001 662 0 to 5 ppm (mg/L) Free chlorine

3-2630-3 159 001 747 0 to 20 ppm (mg/L) Free chlorine

Free chlorine

Lubricate O-rings

with a non-petroleum

based, viscous lubricant

(grease) compatible with

the system.

2632 Amperometric Chlorine Dioxide Electrodes

The Signet 2632 Amperometric Chlorine Dioxide Electrode is designed to measure

chlorine dioxide (ClO

The Signet 2632 Amperometric Chlorine Dioxide Electrode has an integrated

temperature element for automatic temperature compensation.

Mfr. Part No. Code Chlorine Range Chlorine Type

3-2632-1 159 001 767 0 to 2 ppm (mg/L)

) in a range of 0 to 2 ppm.

2

Chlorine Dioxide

Lubricate O-rings

with a non-petroleum

based, viscous lubricant

(grease) compatible with

the system.

29463X Chlorine System Manual

Page 30

Chlorine Electrodes

pH Compensation for Free Chlorine

Amperometric free chlorine sensors measure only

hypochlorous acid. As noted in the text above and in Figure

1, the ratio of hypochlorous acid and hypochlorite is pH

dependent. In many applications the process pH is relatively

stable and no correction is needed. However, where the pH

of the water changes signi cantly, accurate free chlorine

measurement requires pH compensation. With the addition

of a pH sensor, the Signet 8630 transmitter will automatically

compensate the free chlorine reading for changes

in pH.

Automatic pH Compensation and Free Chlorine

In many applications, the process pH does not signi cantly

uctuate and only a free chlorine sensor and instrument is

necessary for accurate chlorine measurement. It is when

the pH varies that free chlorine concentration can not

accurately be determined without the use of automatic pH

compensation.

The addition of the Signet 3-2724-00 (159 001 545) pH

electrode along with its 3-2750-7 (159 001 671) preampli er

to the system makes pH compensation extremely easy and

automatic even with wide uctuations or high pH.

See Figure 2 for pH variation recommendations.

Example:

If the pH nominal value is 7.5 and the pH variation is ± 0.2

then automatic pH compensation is recommended.

If the pH nominal value is 7.0 and the pH variation is ± 0.2

then automatic pH compensation is not required.

100

90

80

70

60

50

40

30

% free chlorine

20

10

0

5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0

HOCl

OClˉ

pH at 25 °C

Figure 1

±0.3

±0.2

Calibration

A new chlorine electrode or one that has had the membrane

cap changed must be calibrated. See page 24, 8630

Transmitter information on calibration of the chlorine sensor.

A diethyl-p-phenylenediamine (DPD) colorimeter test kit (not

included) is required for sensor calibration. A sample is taken

and analyzed with the DPD test kit, then this value is entered

into the Signet 8630 transmitter.

• Calibrate after a membrane cap change

(requires 4 hour stabilization time).

• Calibrate after the internal electrolyte is replaced

(requires 2 hour stabilization time).

• Check calibration one day after sensor is placed in service.

• Check calibration weekly to monthly depending on

process requirements.

Maintenance

The sensor membrane and internal electrolyte solution

must be replaced over the life of the electrode. To maintain

accurate chlorine measurements, GF Signet recommends

that the internal electrolyte be replaced every 3 to 6 months,

or when Chlorine readings drift low and/or cannot maintain

a calibration longer than 5 days. Actual interval between

maintenance of the sensor will be dependent on the actual

applications, chlorine level and contaminates in the water.

See Appendix page 36; Maintenance and Storage.

Keep spare membrane caps available.

Membrane caps carry no warranty.

pH variation

±0.1

0

6.5 7.0 7.5 8.0 8.5 9.0

Sample pH

Automatic pH compensation recommended

=

in ranges within shaded area

Figure 2

NOTE: Inspect and change the membrane cap if damaged.

See page 36, Maintenance, for cleaning procedure.

30

463X Chlorine System Manual

Page 31

2724 pH Electrode

K5

2724 DryLoc pH Electrode

CAUTION!

1. Use appropriate eye, face, hand, body and/or respiratory protection when using chemicals or solvents.

2. Prior to installation or removal:

a. Depressurize and vent system.

b. Drain below sensor level.

3. Con rm chemical compatibility before use.

4. Do not alter product construction.

Lubricate O-rings

with a non-petroleum

based, viscous lubricant

WARNING: 3-2724-00 (159 001 545) is the only recommended

electrode to be used in the Chlorine Analyzer System.

Electrode Date Code

The electrode date code indicates the manufacturing date of the electrode. Electrodes should be put into service as

soon as possible and should not remain in the box for more than two years. Over time, the storage solution (found in

the "boot" covering the electrode tip) will evaporate or leak, allowing the delicate sensing tip and reference junction dry.

(grease) compatible with

the system.

To rehydrate a dry electrode, soak it in pH 4 buffer for 24 to 48 hours. Electrodes more than 2 years old may still be

functional, but will take longer to rehydrate. Restoration may not be effective for severely dehydrated electrodes.

First Digit = Month

N = January

M = February

L = March

K = April

J = May

H = June

G = July

F = August

E = September

D = October

C = November

B = December

Removing the electrode from In-line installations

The use of this product assumes that operators are trained and are familiar with this type of device.

They should be knowledgeable of the potential risks associated with pressurized piping systems.

Operators MUST follow all necessary safety procedures.

K5

Example: K5 = manufactured in April 2010

Second Digit = Year

5 = 2010

6 = 2011

7 = 2012

8 = 2013

9 = 2014

0 = 2015

1 = 2016

2 = 2017

3 = 2018

4 = 2019

In-line removal Instructions:

1. Depressurize and vent the piping system.

2. Drain the system to below sensor level.

3. Wear safety goggles or face shield during removal.

Use all appropriate eye, face, hand, body and/or respiratory protection when working with chemicals or solvents.

4. Place a Lockout tag on the pipe when the sensor is removed for maintenance to prevent accidental opening and

exposure to potentially hazardous chemicals.

31463X Chlorine System Manual

Page 32

2724 pH Electrode

Calibration

pH Calibration Procedure

1. Rinse the sensor off in the rinse water cup. Gently pat dry with a soft, dry cloth or tissue. Warning: Do not let the rinse

water drip into the buffer solution; this will dilute the solution and may change the buffer values.

2. Place the pH sensor in the rst buffer solution (pH 7). Wait until the output from the sensor is stable on the instrument display.

3. Follow the instrument’s instructions regarding buffer recognition.

4. Rinse the sensor with water. Warning: Do not let the rinse water drip into the buffer solution; this will dilute the

solution and may change the buffer values.

5. Dry the sensor gently by patting it with a dry, clean cloth or tissue.

6. Place the sensor in a cup containing the second buffer solution (pH 4 or pH 10). The second solution used will depend on

the typical pH value of the application.