Page 1

Signet 4150 Stilling Chamber with automatic air release valve

*3-4150.096*

3-4150.096 Rev C 09/13 English

Description

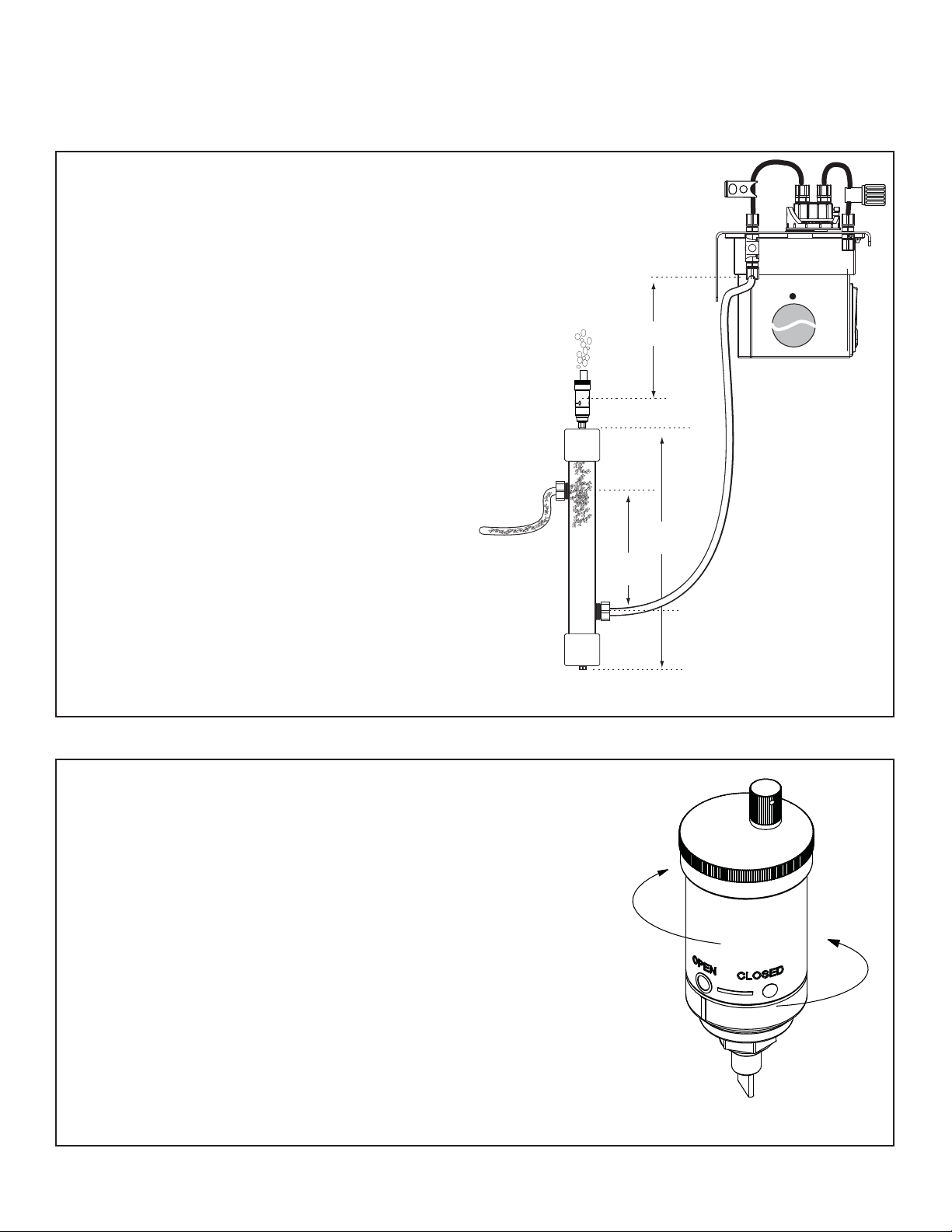

The Signet 4150 Stilling Chamber is used to remove air bubbles

from the fl ow stream before it passes through the measuring

cell of the Turbidimeter. Air bubbles will cause unstable or

incorrect readings if not eliminated from the fl ow stream.

The stilling chamber is a cylinder approximately 5 cm x 66 cm

(2 in. x 26 in.). Water enters the chamber via the outlet fi tting

near the top of the cylinder (see fi gure 1). As it passes through

the chamber, the fl ow velocity is reduced by the larger volume

of the chamber. This allows time for any entrained air to rise to

the top of the cylinder, where the automatic air vent releases it

into the environment.

For proper operation the stilling chamber must be mounted

lower than the sensor. For optimum results there should be at

least 76 cm (30 in.) as measured from midpoint of the air vent

to the inlet at the sensor.

The air vent has a maximum working pressure of 6 bar (90 psi)

and maximum temperature range to 106 °C (225 °F).

Inlet with

aerated water

Outlet with

clear water

MINIMUM 76 cm (30 in.)

66 cm

(26 in.)

24 cm

(9½ in.)

Pressure

Regulator

DESSICANT COMPARTMENT

OPEN ONLY FOR MAINTENANCE

3-4150 Turbidimeter

5/16 in. O.D. x 3/16 in. I.D. Tubing

Operating Instructions

Braukman Automatic Air Release Valve

1. Before fi lling the chamber, make sure the red vent cap is securely tight

and that the release valve is in the closed position (see fi gure 2) by

turning valve body clockwise. HAND-TIGHTEN ONLY to avoid damaging

the valve.

2. With the valve in the closed position, fl ush the system as required to

remove dirt, debris and contaminates.

3. Fill the system with the appropriate solution.

4. Start operation by turning the air release valve body counter-clockwise to

the open position (see fi gure 2).

5. For proper operation, make sure that the red vent cap is tightened all the

way to the stop position.

HAND-TIGHTEN ONLY.

Fig 1

CLOSED

OPENED

Figure 2 Shown in

Open Position

Page 2

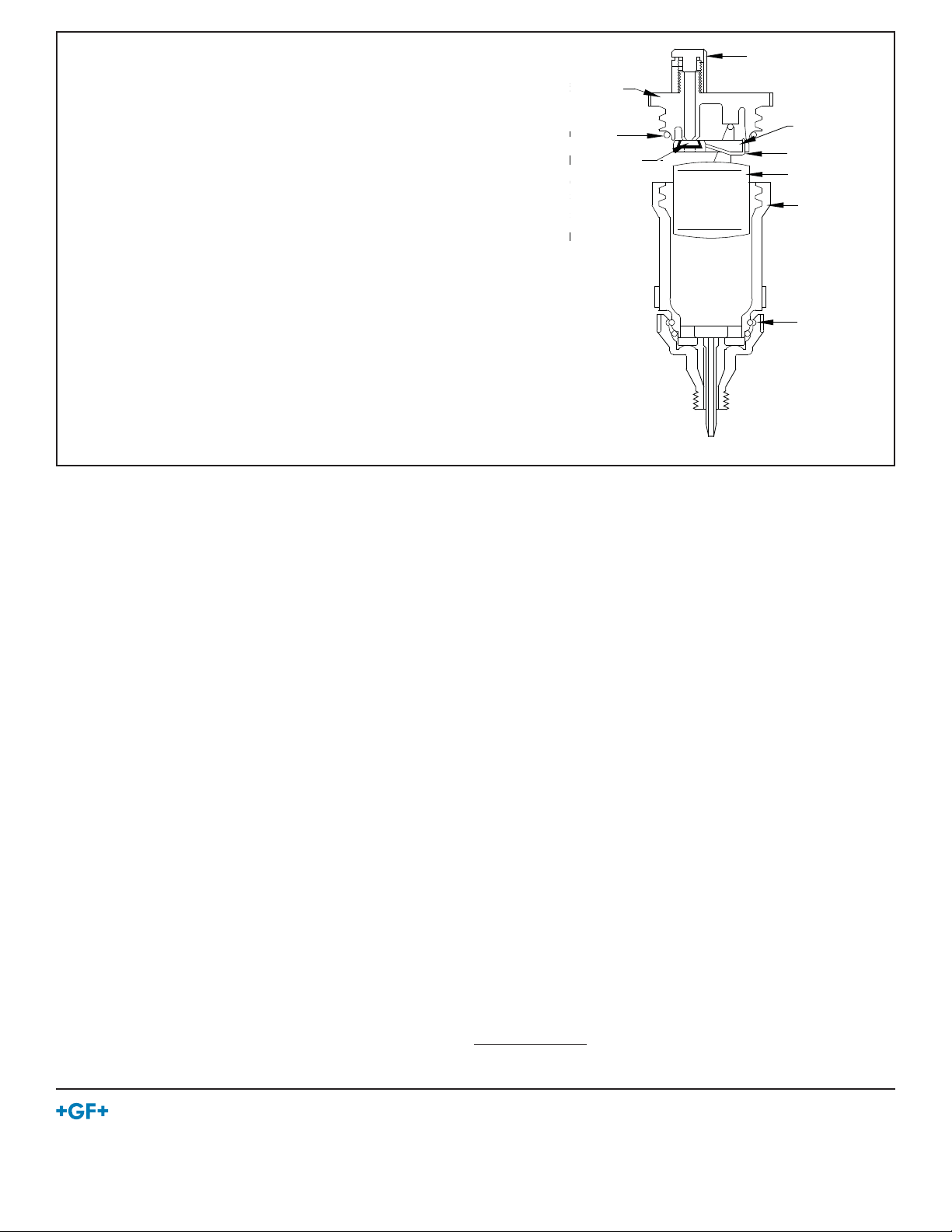

Cleaning Instructions

1. Turn the valve body clockwise to the closed position, isolating the

valve from the system. See fi gure 2.

2. Remove the fl oat assembly by unscrewing the top of the body

and lifting the black cover assembly up. See fi gure 3.

3. Carefully clean the seat area of any dirt or debris.

4. Carefully clean any dirt or debris from inside the vent chamber.

5. Reinstall the clean fl oat assembly, making sure that the O-ring is not

damaged and is seated properly. See fi gure 3.

6. Reinstall the black cover assembly on the air release valve body.

HAND-TIGHTEN ONLY.

7. Operate by turning the air release valve body counter-clockwise to the

open position.

HAND-TIGHTEN ONLY. See fi gure 3.

8. For proper operation, make sure that the red vent cap is tightened all

the way to the stop. HAND-TIGHTEN ONLY.

Ordering Information

Part Number Code Description

4150-0003 159 001 587 Stilling/Bubble Chamber

BLACKCOV ER

ASSEMBLY

O-RING

SEAT AREAMAKE SURE

AREA IS FREE

OF DIRTAN D

DEBRIS

Figure 3

RED VENT CAP

WITH LEAKAGE

GUARD.

VENTLEVER

SPRING

FLOAT

CONSTRUCT ED

FOR EASY IN

LINE SERVICE .

SHUTOFFIS

BUILT-IN NO

DRAINDOWN

REQUIRED.

3-4150-1 159 001 596 Turbidimeter, White Light, 0 to 1000 NTU/FNU

3-4150-2 159 001 597 Turbidimeter, Infrared, 0 to 1000 NTU/FNU

3-4150-3 159 001 598 Turbidimeter, White Light, 0 to 100 NTU /FNU With AutoClean

3-4150-4 159 001 599 Turbidimeter, Infrared, 0 to 100 NTU/FNU With AutoClean

3-4150-5 159 001 600 Turbidimeter, White Light, 0 to 1000 NTU/FNU With AutoClean

3-4150-6 159 001 601 Turbidimeter, Infrared, 0 to 1000 NTU/FNU With AutoClean

4150-0001 159 001 593 Pressure Regulator

4150-0004 159 001 589 Replacement cuvette with ultrasonic transducer

4150-0005 159 001 595

Tubing Kit: 1-shutoff clamp, 1-backpressure valve,

2-connecting tubing with fi ttings, 1-drain vent

4150-0007 159 001 602 Replacement cuvette set (3 glass cuvettes)

3-4150.380 159 001 588 Replacement Desiccant

3-4150.381 159 001 613 **Replacement Desiccant cap with gasket (Special Order Only)

3-4150.382 159 001 650 Turbidity Lamp Replacement kit, White

3-4150.386 159 001 652 O-ring kit for cuvette

3-4150-24V 159 001 723 **24 Volt Power Supply (Special Order Only)

3822-4000 159 001 592 *Formazin Stock Solution, 4000 NTU/FNU, 500 ml

3822-4001 159 001 585 *Calibration Kit, Turbidity, 100, 10 & 0.02 NTU/FNU

3822-4002 159 001 591 *Formazin Stock Kit

3822-4003 159 001 586 *Calibration Kit, Turbidity, 1000, 10 & 0.02 NTU/FNU

* Material Safety Data Sheets (MSDS) are available online at www.gfsignet.com

** signet-specialproduct@georgfi scher.com.

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-4150.096 Rev C 09/13 English © Georg Fischer Signet LLC 2013

Loading...

Loading...