Page 1

Signet 3719 pH/ORP Wet-Tap

*3-3719.090*

3-3719.090 Rev L 12/11 English

English

• Do not exceed maximum temperature/pressure specifi cations.

• Wear safety goggles or face shield during installation/service.

• Do not attempt to disassemble the retraction housing and the

electrode piston.

• Do not alter product construction.

• Failure to follow safety instructions may result in severe

personal injury.

• Retract electrode before any pipe cleaning operation.

1. Description

2. Specifi cations

3. Dimensions

4. 3719 System Overview

5. Installation

6. Maintenance & Cleaning

7. Troubleshooting

8. Ordering Information

1. Description

The Signet 3719 pH/ORP Wet-Tap allows installation and removal of pH or ORP electrodes without the need for process shutdown

during routine electrode maintenance and calibration. Process isolation is achieved with a double O-ring seal on a unique and

compact retraction assembly; no separate valve is required. A cam-activated automatic locking mechanism, SafeLoc™, and the short

stroke design help to assure operator safety.

2. Specifi cations

General

• Compatible sensors:

2716-WT Twist-Lock pH Electrode

2717-WT Twist-Lock ORP Electrode

2756-WT DryLoc® pH Electrode

2756-WT-1 DryLoc® pH Electrode

2756 -WTP DryLoc® plastic pH electrode

2756-WTP-1 DryLoc® plastic pH electrode

2757-WT DryLoc® ORP Electrode

2757-WTP DryLoc® plastic ORP electrode

• Shipping Weight:

Wet-tap assembly: 1.2 kg (2.7 lbs.)

Electrode: 0.13 kg (0.3 lb)

• Process Connection: 3-3719-11: 1½ in. NPT

3-3719-21: 2 in. NPT

3-3719-12: ISO 7/1-R1½

3-3719-22: ISO 7/1-R2

Wetted materials

• Retraction Housing: CPVC

• O-rings: FPM

• Electrode Body: Glass OR Plastic

• Electrode junctions: Porous PTFE

• Electrode sensing surface:

Glass Membrane (pH)

Platinum (ORP)

• Electrode O-rings: FPM

Other Materials

• Locking Shroud: PVC

• Hardware: 316 stainless steel

Performance

• Maximum Flow Velocity: 3 m/s (10 ft/s)

• Effi ciency: > 97% @ 25 °C (77 °F)

• Response Time: pH: <5s for 95% of signal change

ORP: Application dependent

• Drift: < 2 mV per week

• Operating Range: pH: 0 to 14 pH

ORP: –2000 to +2000 mV

• Reference Junctions: Porous PTFE

• Electrolyte: 3.5M KCl

• Elements: Ag/AgCl

• Temp. Sensor (pH): 3K Balco (3-2716-WT,

3-2756-WT-1, WTP-1)

PT1000 (3-2756-WT, -WTP)

• Temp. response time ( 438 s

• Sodium Ion Error: < 0.05 pH in 0.1 molar

Na+ ion at 12.8 pH

• Impedance (pH): <150 MΩ @ 25 °C

Storage Temperature:

• Wet-tap assembly: -15 to 120 °C (5 to 248 °F)

• Electrode: 0 to 50 °C (32 to 122 °F)

WARNING!

If used in conditions that exceed recommended

pressure ratings, this product can pose a serious

hazard.

We urge customers to read the specifi cations

carefully before installing and operating this product.

Improper use can cause components and process

liquids to be expelled at high speeds and cause

serious personal injury.

Standards and Approvals

• Manufactured under ISO 9001 and 14001

25

China RoHS (Go to www.gfsignet.com for details)

Page 2

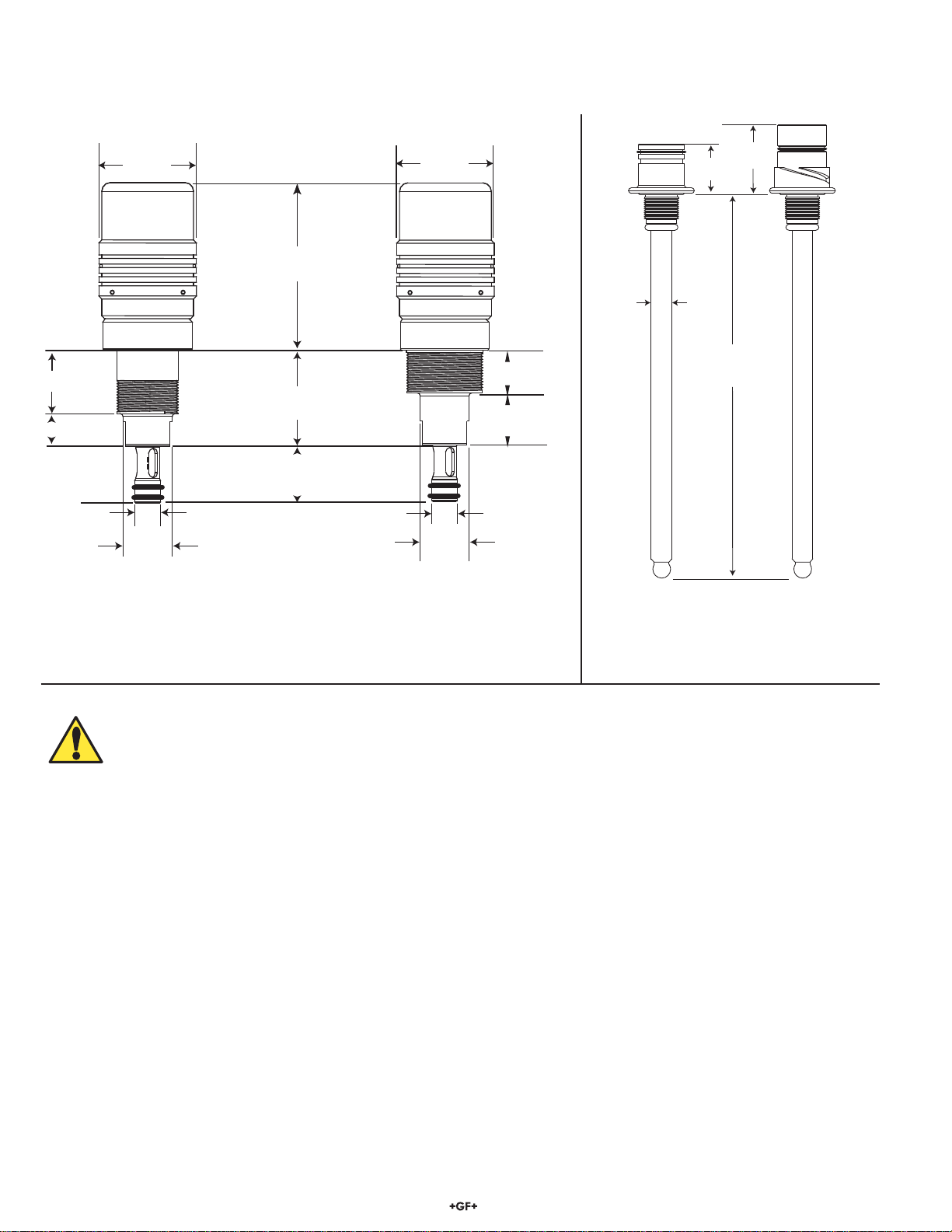

76 mm

(3.0 in.)

130 mm

(5.13 in.)

49 mm

(1.94 in.)

45 mm

(1.75 in.)

39 mm

(1.52 in.)

20 mm

(0.8 in.)

75 mm

(2.94 in.)

Pipe thread

1

1

/2 in. NPT

or

ISO 7-R1

1

/

2

76 mm

(3.0 in.)

39 mm

(1.52 in.)

20 mm

(0.8 in.)

Pipe thread

2 in. NPT

or

ISO 7-R2

34 mm

(1.32 in.)

41 mm

(1.62 in.)

25 mm

(1.00 in.)

3. Dimensions

12 mm

(0.47 in.)

30,5 mm

(1.2 in.)

218 mm

(8.57 in.)

35 mm

(1.4 in.)

3719-1 Wet-tap

11/2 in. outlet for

21/2 to 4 in. pipe

3719-2 Wet-tap

2 in. outlet for

6 to 12 in. pipe

CAUTION!

When using clamp-on saddle fi ttings (customer-supplied), the system temperature and

pressure is limited by the saddle specifi cations.

The process temperature is limited to 40 °C (104 °F) maximum when using saddles.

2716-WT pH electrode

2717-WT ORP electrode

2756-WT(-1) pH electrode, glass

2756-WTP(-1) pH electrode, plastic

2757-WT ORP electrode, glass

2757-WTP ORP electrode, plastic

2 Signet 3719 pH/ORP Wet-Tap

Page 3

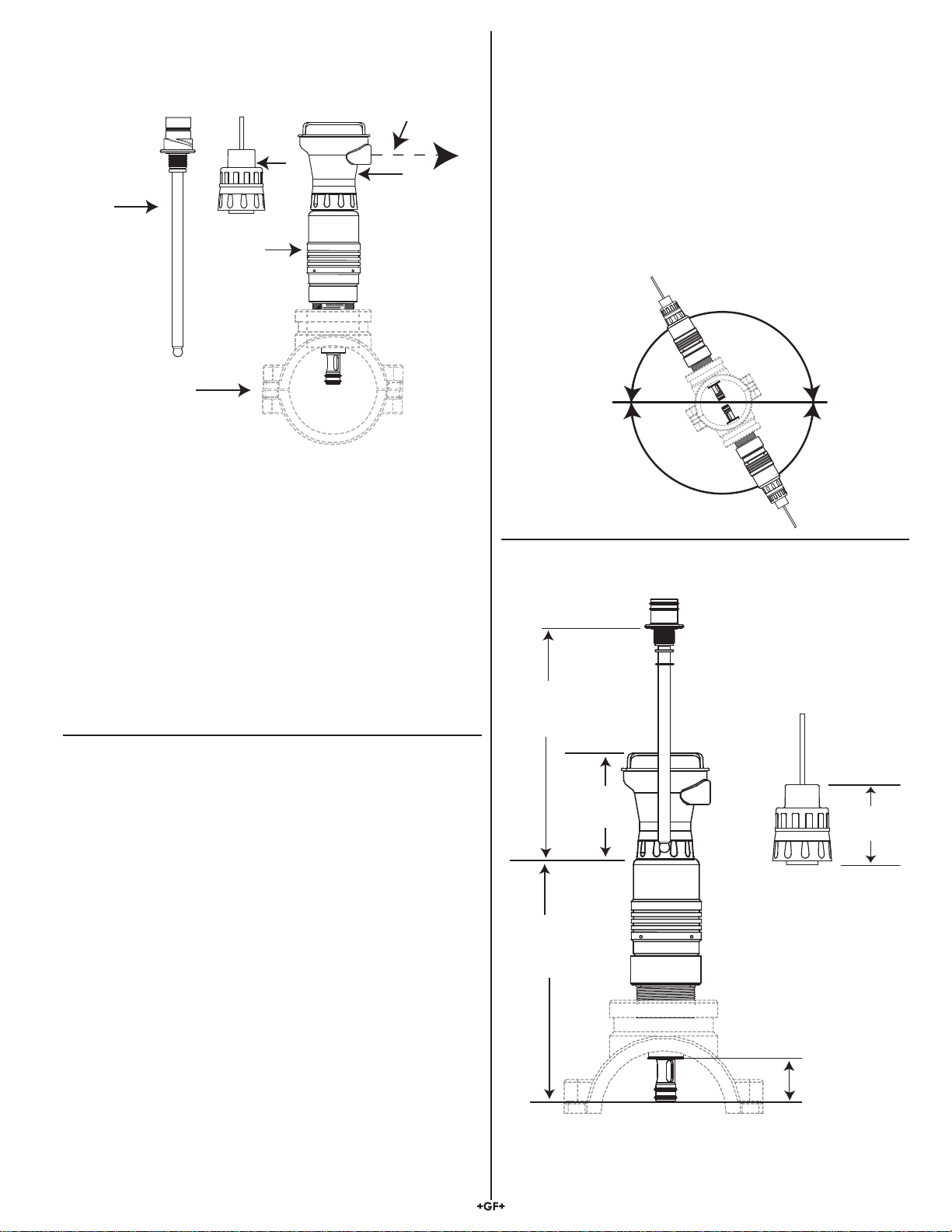

4. 3719 System Overview

a

b

c

d

e

d

a) 3719 pH/ORP Wet-Tap

b) Customer-supplied Low-Profi le Clamp-on Saddle Fitting

(ASTM sizes 2½ to 12 in.)

c) DryLoc® pH or ORP Electrode (6 versions available; see

ordering infomation on page 8.)

("DryLoc®" refers to the electrode connector style)

d) 2750 or 2760 DryLoc® pH/ORP Preamplifi er/Sensor

electronics

e) Output signal options:

2750:

- Digital (S3L)

- 4 to 20 mA

2760:

- Analog mV Output- Digital (S3L)

All components (items a–d) are sold separately.

5. Installation

5.1 Notes on Location, Orientation and Required Clearance

• The 3719-1 is designed for use in pipes up to 4 in.

• The 3719-2 is designed for use in pipes from 6 to 12 in.

• Select a location that will provide suffi cient clearance to

remove and insert the electrode.

• The 3719 can be mounted in any orientation, including

horizontal and inverted. Avoid the 12 o'clock position. In the

presence of sediment, avoid the 6 o'clock position.

• If inverted, use caution when removing the sensor.

Residual fl uid may be present in the retraction housing.

Keep electrode connector clean and dry at all times.

Any angle OK

• Provide 20 inches (minimum) clearance from the top of the

pipe for electrode removal..

218 mm

(8.57 in.)

250 mm

(9.9 in.)

115 mm

(4.5 in.)

OR

89.4 mm

(3.5 in.)

45 mm

(1.75 in.)

3Signet 3719 pH/ORP Wet-Tap

Page 4

5.2 Installation in Pipe Sizes 2.5 to 12 Inches

3-3719-11

pH/ORP Wet-Tap

(Fully Inserted)

• For reliable in-line measurements of pH and ORP, it is

imperative to position the electrode tip into the process

stream.

• Because of its compact “short stroke” design, the 3719

requires low-profi le fi ttings to ensure proper positioning in

pipe sizes DN65 to DN300 (2.5 to 12 inches).

• It is strongly recommended to use low-profi le PP clamp-

on saddle fi ttings (customer-supplied).

• Choose the 3719 version (-11 or -21) appropriate to the size

of the branch connection of the required fi tting:

Use -11 for sizes DN65 to DN100 (2.5 to 4 in), and -21 for

sizes DN150 to DN300 (6 to 12 in.)

5.3 Installation in Pipe Sizes less than 2.5 Inches

• It is possible to install the 3719 into pipe sizes below

2.5 inches by creating a “fl ow cell” with standard piping

components.

• One simple solution, using a tee fi tting and reducer bushings,

is shown in the example below.

3-3719-11

pH/ORP Wet-Tap

1½ in. NPT

Threads

2 in. Tee

(S x S x S)

Flush Style Reducer Bushing

(Spg x FT) 2 in. x 1½ in.

Flush Style Reducer

Bushings (Spg x S)

2 in. x ½ in.

2 in. x ¾ in.

2 in. x 1 in.

2 in. x 1¼ in.

2 in. x 1½ in.

5.4 Installation (Wet-Tap Into Fitting)

The 3719 is packaged with no electrode installed, and with the electrode piston in the fully inserted position.

• Examine the female threads at the top of the electrode piston. Do not install electrode if threads are damaged.

• Examine the two O-rings at the lower end of the assembly. Do not install if O-rings are missing or there are any

signs of damage.

• Lubricate O-rings with a non-petroleum based, viscous lubricant (grease) compatible with the system.

• The pipe can be pressurized after completion of step 4.

• DO NOT ATTEMPT TO REMOVE THE RETRACTION HOUSING FROM A PRESSURIZED PIPING SYSTEM!

• Many similar confi gurations are conceivable in a wide

variety of materials, but be very careful to verify dimensional

compatibility.

• Select an appropriate installation orientation to avoid the

entrapment of air inside the fl ow cell.

• Contact your local Georg Fischer Sales and Support offi ce

for assistance.

Grasp the retraction housing below the locking

shroud; turn the locking shroud 1/4-turn clockwise.

1 2

Pull the locking shroud straight up until

both O-rings are fully seated inside the

retraction housing.

Locking Shroud

Retraction Housing

Lubricated O-rings

4 Signet 3719 pH/ORP Wet-Tap

Page 5

1

2

3

4

OR

OR

Lubricate O-Rings

Lubricate O-Rings

3 4

Turn the shroud 1/4-turn counterclockwise

and lift it completely away from the

electrode piston.

Electrode Piston

The electrode piston is locked in position

by SS locking pins.

DO NOT tamper with the locking pins!

If the piston is depressed with no

electrode installed, the pipe contents are

exposed.

• Thread the Wet-Tap into the pipe fi tting.

• Smaller pipes may require bracing to support the Wet-Tap

weight and the longitudinal forces required for operation.

• Use an appropriate thread sealant to prevent leaks.

• The piping system can now be safely pressurized.

• Inspect the installation for leaks.

5.5 Electrode Installation

Before installation, lubricate O-rings with

a non-petroleum based, viscous lubricant

(grease) compatible with the system.

1. Remove the safety plug from top of

2. Place the Locking Shroud over electrode;

3. Turn the shroud 1/4-turn counterclockwise to

4. Install the matching electronics assembly or

electrode piston. Slide electrode straight

down into electrode piston. Thread electrode

into place until connector shoulder is fl ush

with top of electrode piston. Hand tighten

only.

WARNING:

Do not fl ex the electrode when inserting

into the Wet-Tap assembly. The electrode

can be permanently damaged if it is fl exed

during installation.

turn ¼-turn clockwise to unlock the piston,

then press down fi rmly on the locking

shroud to lower the electrode piston into the

pipe.

lock the piston.

preamplifi er onto the electrode connector.

2750 2760

DO NOT ATTEMPT TO REMOVE THE

RETRACTION HOUSING FROM A

PRESSURIZED PIPING SYSTEM!

5Signet 3719 pH/ORP Wet-Tap

Page 6

5.6 Electrode Removal

The electrode in any pH or ORP system

requires periodic service, calibration or

replacement. When removing the electrode

from the wet-tap assembly, it is very important

to exercise caution and follow the instructions

carefully.

1. Remove the preamplifi er from the top of

the wet-tap assembly.

2. Turn the locking shroud

to unlock the piston.

3. Pull up on the locking shroud to retract the

electrode piston into the pipe.

DANGER!

The piston should retract easily from a pressurized pipe.

If the piston offers resistance, there is a danger that the

piston is coated with deposits from the process.

STOP! DO NOT FORCE THE PISTON UP!

It may damage the O-rings or break off the piston tip.

Return the locking shroud to the LOCKED position and follow the

steps in the box below.

4. Turn the locking shroud ¼-turn counterclockwise and lift up to remove it from the wet-tap assembly.

5. Remove the electrode by turning it counterclockwise.

For safety, keep your body clear of the top of the wet-tap assembly while removing the electrode.

1

/4-turn clockwise

1

2

3 4

3

5

5

DANGER!

If any fl uid is observed leaking from the electrode threads, STOP! DO NOT REMOVE THE ELECTRODE.

There is a danger that the piston tip has been damaged.

Tighten the electrode back down to reseal the assembly and follow the steps in the box below.

If the piston does not retract easily, or if any fl uid is observed leaking from the electrode

threads, the pipe must be drained before the 3719 can be safely removed.

• Stop the fl ow and depressurize the pipe.

• Remove the entire 3719 assembly from the pipe.

• Remove the electrode from the assembly

• Clean any scaling and debris found on or in the piston tip and surrounding area.

6. Electrode Maintenance and Cleaning

Cleaning

Cleaning techniques vary depending on the type of coating present on the glass electrode surface or reference junction.

• Remove soft coatings by vigorous stirring, or with directed spray of a suitable detergent or solvent onto the glass electrode surface.

• Use chlorine bleach or mild detergent to remove soft coatings. Rinse electrode tip in clean water after cleaning.

• Use the least harsh chemical available to remove hard coatings without attacking the materials of construction.

(For example, remove calcium carbonate with a 5% HCL (muriatic acid) solution.

• Remove oily or organic coatings with detergents or an appropriate solvent that does not attack the materials of construction.

• ORP electrode surface (platinum) can be gently sanded with 600 grit wet and dry silicone or carbide sandpaper, jewelers rouge,

crocus cloth, or very fi ne steel wool.

• Never scrape or sand the glass electrode surface.

• Treat glass electrode surfaces with appropriate care to avoid breakage.

• Lubricate O-rings with a non-petroleum based, viscous lubricant (grease) compatible with the system.

Wet-Tap Maintenance

• The Wet-Tap assembly should be operated (retracted) on a monthly basis

• The O-rings on the piston tip should be inspected and lubricated annually, and whenever the system is off line for maintenance.

• Lubricate O-rings with a non-petroleum based, viscous, lubricant (grease) compatible with the system.

6 Signet 3719 pH/ORP Wet-Tap

Page 7

7. Troubleshooting

Offset in pH Electrodes

Electrode offsets occur due to:

• Clogged reference junction

• Aged or contaminated reference solution/wire

• A constant output near 0 mV in all buffer solutions indicates a shorted electrode that must

be replaced.

Check offsets in a pH 7 buffer @ 25 °C. The theoretical output is 0 mV. Any deviation from 0

mV is the pH electrode offset. The mV offset will track across the entire pH range. The slope is

usually not affected by offset changes. (i.e., pH 7= +10 mV, pH 4= +187 mV); slope = 59 mV.

pH Electrode Offset pH 7 buffer @ 25 °C

Theoretical: pH 7.0 (0.0 mV)

New electrode: pH 7 ± 0.25 pH (±15 mV)

Reliable: pH 7 ± 0.85 pH (± 50 mV)

Electrode offsets greater than 0.85 pH (50 mV) indicate the electrode requires cleaning

or replacement. See Maintenance and Cleaning section.

Offset in ORP Electrodes

• ORP electrode offsets are usually caused by clogged reference junctions or by an aged or contaminated reference solution/wire.

• Offsets should be checked in pH 7 buffer saturated with quinhydrone @ 25 °C. The theoretical output is +86 mV.

Any deviation from +86 mV is the ORP electrode offset (e.g., +90 mV).

• Quinhydrone is the oxidizer measured by the ORP electrode and is required for calibration.

To measure ORP electrode offset, saturate 50 mL of pH 4 and pH 7 buffers with ⅛ g quinhydrone.

A new ORP electrode measures these values ±15 mV. The electrode continues to be functional until the offset from these values

exceeds 50 mV. Electrodes with offset greater than 50 mV should be cleaned and replaced if necessary.

Theoretical mV Values @ 25 °C

pH mV

2 +296 mV

3 +237 mV

4 +177 mV

5 +118 mV

6 +59 mV

7 0 mV

8 -59 mV

9 -118 mV

10 -177 mV

11 -237 mV

12 -296 mV

4 pH w/Quinhydrone 7 pH w/Quinhydrone

Temp: 20 °C 25 °C 30 °C 20 °C 25 °C 30 °C

ORP: 268 mV 263 mV 258 mV 92 mV 86 mV 79 mV

Slope in pH electrodes

Electrode slope is the mV output per pH unit. At 25C the theoretical slope is 59.16 mV per pH. The graph below illustrates potential

pH error when a temperature-compensated instrument is not used.

• Coatings on the glass may affect sensor slopes. See Maintenance and Cleaning section.

• Temperature affects electrode slope. Calibrate temperature before calibrating the standard and slope.

°C

23456789101112

pH

15 0.15 0.12 0.09 0.06 0.03 0 0.03 0.06 0.09 0.12 0.15

2500000000000

35 0.15 0.12 0.09 0.06 0.03 0 0.03 0.06 0.09 0.12 0.15

45 0.3 0.24 0.18 0.12 0.06 0 0.06 0.12 0.18 0.24 0.3

55 0.45 0.36 0.27 0.18 0.09 0 0.09 0.18 0.27 0.36 0.45

Slope in ORP electrodes

ORP slope errors are caused by contamination of the platinum electrode surface. Cleaning the electrode surface will usually restore

proper values, response time, and stability. Many systems require both pH and ORP calibration. To conserve calibration reference

solutions, use pH 7 and 4 buffers for pH calibration fi rst. ORP calibration can be performed with the same buffers after adding

quinhydrone.

Response Time/Stability

Response time and stability are affected by the condition of the glass surface (ORP electrode - Platinum surface), reference junction,

and reference solution. Restoration to acceptable levels can often be accomplished by cleaning the electrode's glass surface (ORP

electrode - platinum surface) and reference junction.

pH and ORP electrodes are similar to batteries; they age with time and usage.

The following information will help maximize electrode life:

• High temperatures or concentrated acids/caustics will accelerate electrode aging.

• Never store the electrode tip in deionized (DI) water.

• Never expose electrode to temperatures below –12 °C (10 °F) or allow it to dehydrate. These conditions will damage the electrode.

7Signet 3719 pH/ORP Wet-Tap

Page 8

8. Ordering Information

Mfr. Part No. Code Description

3-3719-11 159 000 804 pH/ORP Wet-Tap, 11/2 in. NPT

3-3719-21 159 000 805 pH/ORP Wet-Tap, 2 in. NPT

3-3719-12 159 000 806 pH/ORP Wet-Tap, ISO 7/1-R 1.5

3-3719-22 159 000 807 Wet-Tap Assembly, ISO 7/1-R 2

Parts and accessories

3-2716-WT 159 000 809 Electrode, pH, twist-lock, bulb, 3 KΩ, wet-tap

3-2717-WT 159 000 811 Electrode, ORP, twist-lock, bulb, 10 KΩ ID, wet-tap

®

3-2756-WT 159 000 834 Electrode, pH, DryLoc

3-2756-WT-1 159 001 383 Electrode, pH, DryLoc®, bulb, 3 KΩ, wet-tap

3-2756-WTP 159 001 390 Electrode, pH, DryLoc®, plastic bulb, PT1000, wet-tap

3-2756-WTP-1 159 001 384 Electrode, pH, DryLoc®, plastic bulb, 3 KΩ, wet-tap

3-2757-WT 159 000 835 Electrode, ORP, DryLoc®, bulb, 10 KΩ ID, wet-tap

3-2757-WTP 159 001 391 Electrode, ORP, DryLoc

3-2750-1 159 000 744 In-line DryLoc® pH/ORP Sensor with J-Box

3-2750-2 159 000 745 In-line DryLoc® pH/ORP Sensor with J-Box and EasyCal

3-2760-11 159 001 367 In-line Preamplifi er with ¾ in. NPT threads and 4.6 m (15 ft) cable

3-2760-21 159 001 368 In-line Preamplifi er with ¾ in. ISO threads and 4.6 m (15 ft) cable

3-2760-31 159 001 369 In-line Connector with 4.6 m (15 ft) cable and ¾ in. NPT threads

3-2760-41 159 001 370 In-line Connector with 4.6 m (15 ft) cable and ISO 7/1R ¾ threads

, bulb, PT1000, wet-tap

®

, plastic bulb, 10 KΩ ID, wet-tap

3-3719.390 159 000 855 3719 Locking Shroud

1220-0114 159 000 854 3719 O-ring, FPM, Piston Tip

3-2700.395 159 001 605 pH Calibration Kit: includes 3 Polypropylene cups, box used as stand, 1 pint

pH 4.01, 1 pint pH 7.00

3-0700.390 198 864 403 pH buffer kit (1 each 4,7,10 pH buffer in powder form, makes 50 ml of each)

3822-7115 157 001 606 20 gm bottle Quinhydrone for ORP calibration (must use ph 4.01 and/or pH 7.00

buffer solutions)

3-3719.390

Locking shroud

3-2756-WT Dry-Loc pH electrode

3-2756-WT-1 Dry-Loc pH electrode

3-2756-WTP Dry-Loc pH electrode

3-2756-WTP-1 Dry-Loc pH electrode

3-2757-WT Dry-Loc pH electrode

3-2757-WTP Dry-Loc ORP electrode

1220-0114

O-rings

3-2716-WT pH electrode

3-2717-WT ORP electrode

Georg Fischer Signet LLC, 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-3719.090 Rev L 12/11 English © Georg Fischer Signet LLC 2011

Loading...

Loading...