Page 1

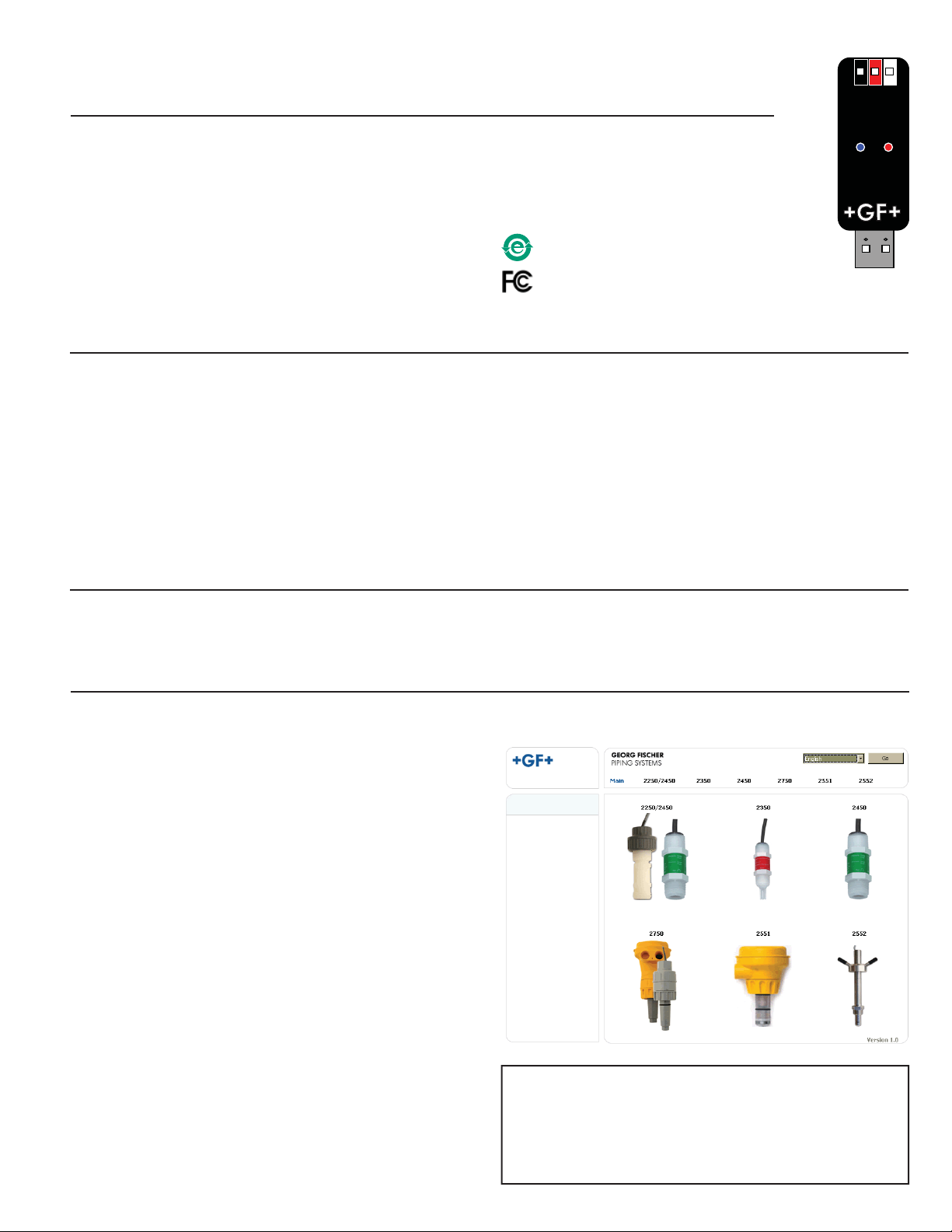

Signet 3-0250 USB-to-S3L Confi guration/Diagnostic Tool

*3-0250.090*

3-0250.090 Rev. C 10/12 English

English

Specifi cations

Compatibility

Signet 2250 Signet 2350 Signet 2450

Signet 2551 Signet 2552 Signet 2750

Indicators: Red: POWER ON

Blue: DATA COMMUNICATION

Enclosure: ABS

Input connections: 3-terminal connectors, max 14 AWG

Communication rate: Maximum 19.2 kbs

Input power: Computer USB port

Output power: 5 VDC ± 5%

Power consumption: 5 V @ 15 mA

The 3-0250 USB-to-S3L Confi guration/Diagnostic Tool interfaces with various Signet sensors to allow users to modify (all allowable)

parameters available inside the sensor, monitor the sensor's data on the PC/Laptop or to log the sensor's data to a fi le.

1. Collect the equipment and information that will be required:

• 3-0250 Setup Tool (Includes one USB-S

• 24 VDC ISOLATED power source.

• Personal computer with:

• Application-specifi c information:

®

• Intel

• Windows® 98, 2000, XP, Vista®, 7 or 8 operating systems.

• 40 MB free disk space

• Pipe data and measurement references for 2551, 2552 (Engineering units, Timebase, Averaging time, Sensitivity, Noise

• 4-20 mA span for 2250, 2350, 2450, 2551, 2552, 2750

Pentium® or higher or AMD 1800 or higher

rejection, Low fl ow cut off)

3

L Converter with extension cable and one CD-ROM with software)

Maximum current source: 50 mA

Maximum cable: 300 m (1000 ft.)

Storage temperature: -20 to 100 °C (-4 to 212 °F)

Relative Humidity: 0 to 90% non-condensing

Operating Temperature: -15 to 55 °C (5 to 131 °F)

(module only)

China RoHS (Go to www.gfsignet.com

for details)

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

2. Install the USB driver onto the computer:

• Windows 2000, XP, Vista, 7 or 8 operating system: Insert the CD-ROM into the computer. A Windows Installation Wizard will open to

install the USB driver onto your local hard drive.

• Windows 98 Operating System: READ THIS FILE FOR USB DRIVER INSTRUCTIONS.

3. To run the program from the CD:

• Right-click the START button and select EXPLORE. Navigate

to the CD drive.

• Double-click the 3-0250.exe fi le.

• The Setup screen shown here should be on the computer

display.

• Select a language option from the pull-down menu in the upper

right corner.

3a. To run the program from a local hard drive:

• Drag the 3-0250.exe fi le from the CD to the folder on the hard

drive.

• Drag the 2551Eng.pdf and the 2552Eng.pdf fi les to the same

folder as the 3-0250.exe fi le.

• Remove the CD.

• Double-click the 3-0250.exe fi le to start the program.

• The Setup screen shown here should be on the computer

display.

• Select a language option from the pull-down menu in the upper

right corner.

• Regional computer settings will determine number format

(1.234, 1 234 or 1,234)

• Do not use thousands separator when entering numeric values.

(1234.5, not 1,234.5 or 1 234.5).

• Click on the image of the product to begin.

Windows and Vista are registered trademarks of the Microsoft Corporation

in the United States and other countries. Intel and Pentium are registered

trademarks of Intel Corporation in the U.S. and/or other countries. AMD is

a trademark of Advanced Micro Devices, Inc.

Important:

Managed systems and network systems may have security

measures enabled that block the installation of this program.

See the network administrator or IT (Information Technology)

staff if the program cannot be installed.

Page 2

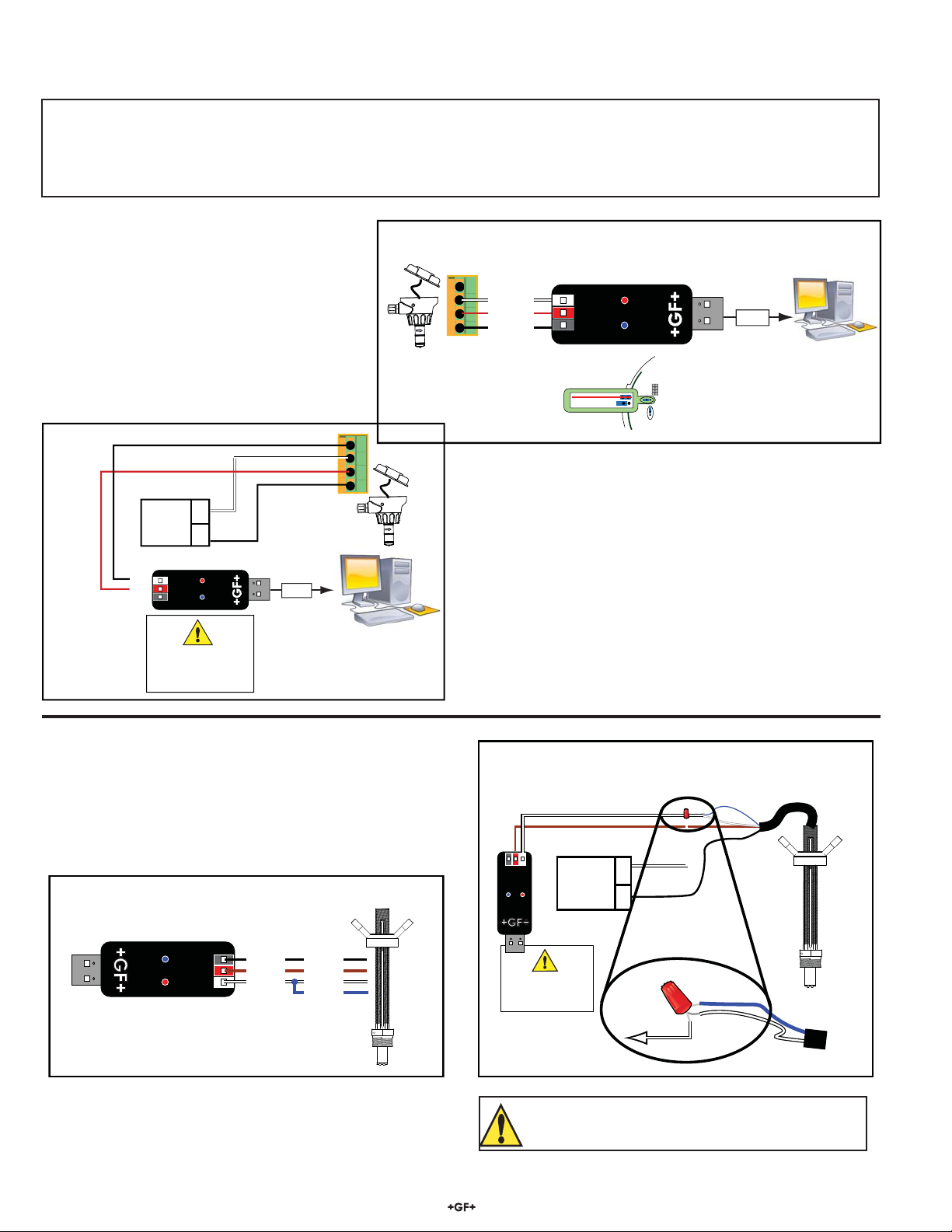

2551 and 2552 Magmeters

The setup capability of the 0250 is more complex with the magmeters than with other sensors. Read these instructions carefully before

attempting to modify a Magmeter.

Connect the Magmeter to the computer:

• Connect the Magmeter to the 3-0250 as illustrated.

• For 3-2551-11 models: The frequency/digital jumper MUST be in the Digital position.

• Connect the isolated 24 VDC power source to 4-20 mA model Magmeters.

• Connect the Signal Converter to any open USB port on the computer.

System connections

Signet 2551 Blind Magmeter

2551 Blind Magmeter

4-20 mA Out

Isolated

24 VDC

GND

Data

5V out+

Do not connect power

-

+

CAUTION!

directly to this device.

USB

2551 Blind Magmeter

Frequency/S

4

3

2

1

3

L Out

4

3

GND

2

Data

1

5V out+

Freq/Digital jumper

must be in Digital position

FREQUENCY OUT

3

L) OUT

DIGITAL (S

USB

JP2

System connections

Signet 2552 Metal Magmeter

Signet 2552

Frequency/S

3

L Out

+5 VDC

Data

Ground

Black

Brown

White

Blue

Signet 2552

4-20 mA Out

Blue

White

Brown

Black

Blue

White

Isolated

24 VDC

CAUTION!

Do not connect power

directly to this device.

*Wire 3

-

+

* Additional wire required

Wire Nut

To -VDC

*Wire 2

*Wire 1

CAUTION!

TURN 24 VDC POWER OFF WHEN WIRING THE MAGMETER.

2

Signet 0250 Setup Tool

Page 3

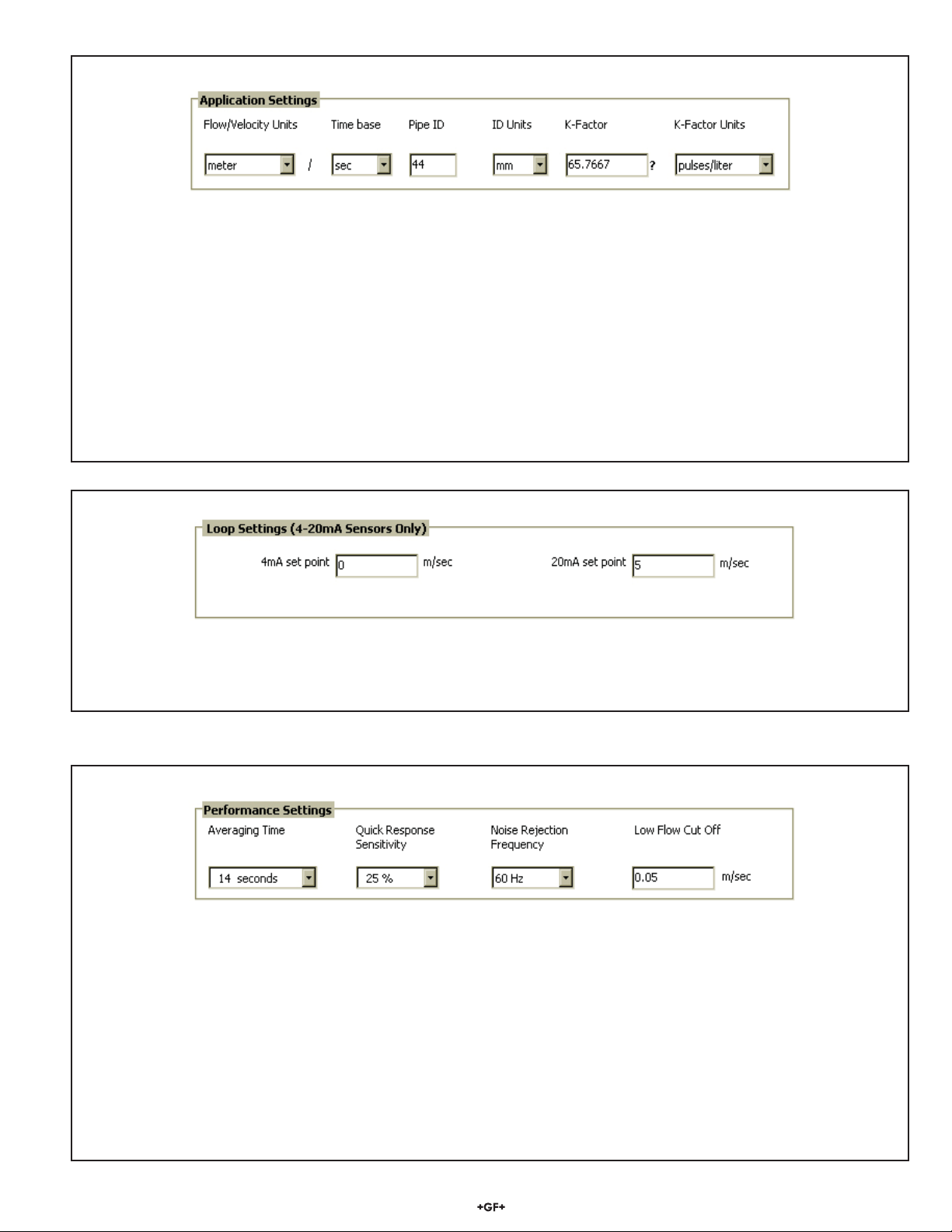

2551 and 2552 Magmeter Setup

1. Set the general information about the pipe and application preferences in the Application Settings fi elds.

Flow/Velocity Units (factory set: Meters)

• Select the engineering units from the list: meters, feet, cubic meters, liters, cu. ft., U.S. gallons, Imp. gallons.

Timebase (factory set: Seconds)

• Set the timebase preference: seconds, minutes, hours, days

Pipe ID (Inside Diameter) (factory set: 44.0)

• Enter the inside diameter of the pipe.

ID Units: (factory set: millimeters)

• Select inches or mm for the dimensions of the pipe.

K-Factor (factory set: 65.7667)

• K-factors are published as "pulses per gallon" and "pulses per liter" in the Magmeter manual.

• Click the "?" to open a copy of the manual (manual fi le must be placed in the same directory as the 3-0250.exe application fi le).

K-factor units (factory set: pulses/liter)

• Select pulses/gallon or pulses/liter.

2. Set the 4-20 mA span (If applicable)

4 mA Setpoint (factory set: 0 m/s)

• Enter the fl ow rate where the Loop output must equal 4 mA.

20 mA Setpoint (factory set: 5 m/s)

• Enter the fl ow rate where the Loop output must equal 20 mA.

3. Set the Performance Settings to best accomodate the unique conditions in the pipe.

Averaging Time (Factory set:14 s)

• Set the time the Magmeter will use as the averaging period. Example: With averaging at 14 seconds, each display is an average

of the previous 14 seconds input. Use higher averaging times to smooth the display and current output where the fl ow in the pipe

is erratic.

Quick Response Sensitivity (Factory set: 25)

• Set the percentage of change in the fl ow rate required to allow the Magmeter to override the AVERAGING and jump

to a new fl ow rate immediately. (2551 maximum range is 10 m/s)

A detailed explanation of Averaging and Sensitivity functions is provided on Page 5.

Noise Rejection Frequency (Factory set: 60 Hz)

• Select 50 Hz or 60 Hz according to local AC power specifi cations.

Low Flow Cut-off (Factory set: 0.05 m/s)

• Set the fl ow rate where all Magmeter outputs will be forced to zero.

(When the fl ow rate drops below this value, the frequency output will be 0 Hz. and the current output will be 4 mA.)

Signet 0250 Setup Tool

3

Page 4

4. Click "Write" to copy the new settings into the Magmeter.

• To repeat the same settings in another Magmeter, disconnect the Magmeter and connect the second Magmeter.

Note: For 4-20 mA models, remove 24 VDC power before rewiring.)

• Click "Write" again.

Note: All settings are lost when you exit the program. If the settings will be used again, click "SAVE". Name the fi le and save it on

the computer hard drive.

Sensor Information

Serial Number, Sensor Type:

• This sensor information is read from the Magmeter when you press the "Read" button.

Messages:

• Displays messages related to the current selection. Error messages and procedure instructions will appear here.

Controls

• Read: Read and display the existing settings from the Magmeter.

• Write: Write from the display into the Magmeter.

• Save: Save from the display to a fi le (*.bdf).

• Load: Load from a saved fi le into the display.

• Factory: Restores Application, Loop and Performance settings to original factory values.

Note: The blue LED on the 3-0250 blinks during data communication between the computer and the sensor.

Red LED indicates power

GND

Data

+5V from USB port

Blue LED indicates data transmission

4

Signet 0250 Setup Tool

Page 5

Magmeter Averaging and Sensitivity Settings

Because ideal fl ow conditions are often impossible to acheive, the fl ow rate is often erratic, which in turn causes any control features

(ie; relays, 4-20 mA loops, etc.) that are associated with the fl ow rate to also be erratic.

The best solution to these problems is to correct any piping defi ciency that causes the instability. This may involve longer straight runs

upstream, reducing the pipe size to maintain a full pipe at all times, and other installation changes. In many situations, however, these

measures are simply not possible.

The Magmeter provides several tools that are designed to "work around" these defi ciencies. They are called "Performance Settings"

and can be modifi ed only through the 3-0250 Setup Tool. The noise rejection and the Low Flow Cutoff settings are self-explanatory. The

Averaging and the Sensitivity features should be studied before making adjustments.

Averaging Time in Seconds (Factory set: 14 seconds)

• Set the time the Magmeter will use as the averaging period.

With averaging at 14 seconds, each display is an average of the previous 14 seconds input.

Use higher averaging times to smooth the display and current output where the fl ow in the pipe is erratic.

Quick Response Sensitivity (Factory set: 25% of Maximum Range, or 2.5 m/s)

• Set the percentage of change in the fl ow rate required to allow the Magmeter to override the AVERAGING and jump to a new fl ow

rate immediately. (maximum range is 10 m/s)

The pictures below illustrate the effect of these settings.

No AVERAGING, no SENSITIVITY

With AVERAGING set to 0 (zero) the SENSITIVITY is ineffective,

and the fl ow rate may be very unstable. This will cause the output

signals to respond erratically.

AVERAGING Only

With AVERAGING set to 60 seconds and SENSITIVITY set to

100%, the fl ow rate is stabilized, but a sharp change in fl ow rate

is not represented for 60 seconds or longer. This can cause

system problems if one of the operating setpoints falls within this

range.

AVERAGING and SENSITIVITY

With AVERAGING at 60 seconds and SENSITIVITY set to 25%,

the fl ow rate is stabilized, but the sudden shift in fl ow is refl ected

very quickly.

Velocity

Time

Velocity

Time

10 s 20 s 30 s 40 s 50 s 60 s 70 s

10 s 20 s 30 s 40 s 50 s 60 s 70 s

Signet 0250 Setup Tool

Velocity

Time

10 s 20 s 30 s 40 s 50 s 60 s 70 s

5

Page 6

Signet 2250 Hydrostatic Level Sensor Setup

2250 Wiring

GND

Data

+5V

Signet 2250

Hydrostatic

Level Sensor

2250 Operation

1. Select the engineering units for the application: inches,

feet, centimeters or meters.

2. Set the Level measurement where the Loop output must

equal 4 mA.

3. Set the Level measurement where the Loop output must

equal 20 mA.

• Minimum setting for both endpoints is 0.

• Maximum setting for both endpoints is based on the

maximum pressure rating of the sensor.

• Maximum setting, -XU sensor (0-10 psi)

• 7.03 m = 703.1 cm = 23.07 ft. = 276.8 in.

• Maximum setting, -XL sensor (0-50 psi)

• 35.15 m = 3515.0 cm = 115.33 ft. = 1384.0 in.

4. Click "Write" to copy settings from the display into the

Magmeter.

Click "Save" to save the settings from the display to a

computer fi le.

5. To use a saved fi le:

• Click "Load"

• Navigate to the saved fi le

• Select Open

• Click "Write"

• Click "Read" to confi rm

GND

Data

+5V out

Windows PC

USB

Signet 2350 Temperature Sensor Setup

2350 Wiring

2350 Operation

1. Select the engineering units for the application:

°C (Celsius) or °F (Fahrenheit).

2. Set the Temperature measurement where the Loop output

must equal 4 mA.

• Minimum setting -10 °C (14 °F)

• Maximum setting 100 °C (212 °F)

3. Set the Temperature measurement where the Loop output

must equal 20 mA.

• Minimum setting -10 °C (14 °F)

• Maximum setting 100 °C (212 °F)

4. Click "Write" to copy the settings from the display into the

Magmeter.

OR

Press "Save" to save the settings from the display to a

computer fi le.

To use a saved fi le:

• Click "Load"

• Navigate to the saved fi le

• Select Open

• Click "Write"

• Click "Read" to confi rm.

GND

Data

+5V

Signet 2350

Temperature

Sensor

GND

Data

+5V out

Windows PC

USB

6

Signet 0250 Setup Tool

Page 7

Signet 2450 Pressure Sensor Setup

2450 Wiring

GND

Data

+5V

Signet 2450

Pressure

Sensor

Operation

1. Select the engineering units for the application: kpa, bar

or psi

2. Set the Pressure measurement where the Loop output

must equal 4 mA.

• Minimum setting 0 psi

• Maximum setting 10, 50 or 250 psi

3. Set the Pressure measurement where the Loop output

must equal 20 mA.

• Minimum setting 0 psi

• Maximum setting 10, 50 or 250 psi

4. Click "Write" to copy the settings from the display into the

Magmeter.

• Click "Save" to save the settings from the display to a

computer fi le.

To use a saved fi le:

• Click "Load"

• Navigate to the saved fi le

• Select Open

• Click "Write"

• Click "Read" to confi rm

GND

Data

+5V out

Windows PC

USB

Signet 2750 pH Sensor Setup

2750 Wiring

GND

Data

+5V

Signet 2750

pH/ORP

Sensor,

Submersible

2750 Operation

1. Select the engineering units for the application: pH or ORP

2. Set the pH or ORP measurement where the Loop output

must equal 4 mA.

• Minimum setting 0 pH, -1000 mV ORP

• Maximum setting 14 pH, 2000 mV ORP

3. Set the pH or ORP measurement where the Loop output

must equal 20 mA.

• Minimum setting 0 pH, -1000 mV ORP

• Maximum setting 14 pH, 2000 mV ORP

4. Click "Write" to copy the settings from the display into the

Magmeter.

• Press "Save" to save the settings from the display to a fi le.

To use a saved fi le:

• Click "Load"

• Navigate to the saved fi le

• Select Open

• Click "Write"

• Click "Read" to confi rm.

GND

Data

+5V out

+

4

3

-

2

S

1

Signet 2750 pH/ORP

Sensor, Inline

+5V in

Data

GND

Windows PC

USB

GND

Data

+5V out

Signet 0250 Setup Tool

7

Page 8

Datalogger Operation

The 0250 can serve as a fi eld data logger that downloads data directly into a *.csv (Comma Separated Value) fi le.

Note: The 0250 does NOT have internal memory to store data. It must be connected to a computer to use the datalog function.

• Select the sensor type, click on "Read".

• Click Monitor/Verify Sensor to open a datalog setup window.

• Enter the Logging Interval. This value represents the time between log records.

The minimum interval is 1 second, and the maximum interval is 86400 seconds (24 hours). Example: If the Log Interval is set to

60 seconds, the 0250 will record the temperature once every minute.

• The 0250 saves data fi les in *.csv format. The maximum number of records allowed for this type of fi le is 65535.

If the logging interval is 60 seconds, the largest fi le possible is 65535 records, or 1092 hours of continuous recorded data.

• To initiate a log session click Begin Monitor or Begin Log to File.

Begin Monitor

• This function starts monitoring the sensor output and displays values on a graph, but does not store the data permanently. During

the monitoring session the Begin Log to File and Save Log functions are disabled, while the Pause and End Log functions are

enabled. Save Log enables a monitoring session to be saved immediately after End log is clicked.

Begin Log to File

• This function prompts the user to create a fi le on a computer drive before it starts monitoring. The system then begins recording the

sensor output and display values on a graph. During a Log-to-fi le session the Begin Monitor and Save Log functions are disabled,

while the Pause and End Log functions are enabled.

Sample of data fi le downloaded to Microsoft Excel

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-0250.090 Rev. C 10/12 English © Georg Fischer Signet LLC 2012

Loading...

Loading...