Page 1

Signet 2850 Conductivity/Resistivity Sensor Electronics

English

*3-2850.090-1*

3-2850.090-1 Rev. H 06/12 English

SAFETY PRECAUTIONS

1. Depressurize and vent system prior to installation or removal.

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. When using chemicals or solvents, care should be taken and appropriate

eye, face, hand, body, and/or respiratory protection should be used.

Contents

1. Description

2. Specifi cations

3. In-Line Installation

4. Submersible Installation

5. Wiring 4 to 20 mA Output version

6. Wiring Digital (S3L) Output version

7. Wiring Dual Input Digital (S

8. Cell Constant Selection

9. Range Selection for 4 to 20 mA Output

10. Calibration

11. Maintenance

12. Ordering Information

1. Description

• Signet 2850 Conductivity/Resistivity Sensor Electronics provides either a two-wire 4 to 20 mA output or Digital (S3L) format.

• The 4 to 20 mA output models provide eight ranges for each electrode cell constant, plus the ability to invert each range.

• The EasyCal feature allows the devices to automatically recognize standard conductivity test solution values for simple fi eld calibration.

• The Conductivity sensor provided with integral systems will have its custom cell constant information programmed into the electronics

at the factory to provide a 1% sensor accuracy. See Section 8 for details.

3

L) Output version

2. Specifi cations

General

Compatible Electrodes: Any Signet Conductivity/

Resisitivity electrode

(2818-2823, 2839-2842)

Temperature Compensation: PT-1000 RTD (2% per °C)

Pure Water Compensation: Auto-switching when using

0.01 cell and raw conductivity

value < 0.5 S

EasyCal:

Automatic recognition of the following conductivity values:

• 146.93 S, 1408.8 S, 12856 S (@ 25 °C)

(Test solutions per ASTM D1125-95)

• 10 S, 100 S, 200 S, 500 S, 1000 S, 5000 S, 10,000 S,

50,000 S, 100,000 S (@ 25 °C)

Electrical

Power: 12 to 24 VDC (4 to 20 mA output)

5 VDC ±5% regulated, 3.0 mA

max. for Digital (S

(Reverse polarity and short circuit

protected)

Digital (S

• Accuracy: Conductivity: ±2% of reading

Temperature: ±0.5 °C

• Resolution: Conductivity: 0.1% of reading

Temperature: < 0.2 °C

• Update Rate: Single input models: < 600 ms

Dual input models: < 1.2 s

3

L) Output: Serial ASCII, TTL level 9600 bps

3

L) output

Current Output:

• Field-selectable ranges

• Factory set span:

0.01 cell (2818, 2819, 2839): 4 to 20 mA = 0 to 100 S

0.10 cell (2820, 2840): 4 to 20 mA = 0 to 1000 S

1.0 cell (2821, 2841): 4 to 20 mA = 0 to 10,000 S

10.0 cell (2822, 2842): 4 to 20 mA = 0 to 200,000 S

20.0 cell (2823): 4 to 20 mA = 0 to 400,000 S

• Max. Loop Resistance: 50 @ 12 VDC

325 @ 18 VDC

600 @ 24 VDC

• Accuracy: ±2% of output span

• Resolution: 7 A

• Update Rate: <600 ms

• Error Indication: 22 mA

Available data via Digital (S

• Raw conductivity

• Calibrated conductivity

• Calibrated temperature-compensated conductivity

• Temp. Error Indication: Open input and out-of-range

Environmental

Material: PBT

Enclosure Rating: NEMA 4X/IP65

Operating Temperature: -10 to 85 °C (14 to 185 °F)

Storage Temperature: -20 to 85 °C (-4 to 185 °F)

Relative Humidity: 0 to 95%, non-condensing

Shipping Weight: 0.75 kg (1.75 lb.)

3

L) Output:

diagnostics for temperature or

internal electronic error.

Standards and Approvals

• CE

• Manufactured under ISO 9001 and ISO 14001

China RoHS (Go to www.gfsignet.com for details)

Page 2

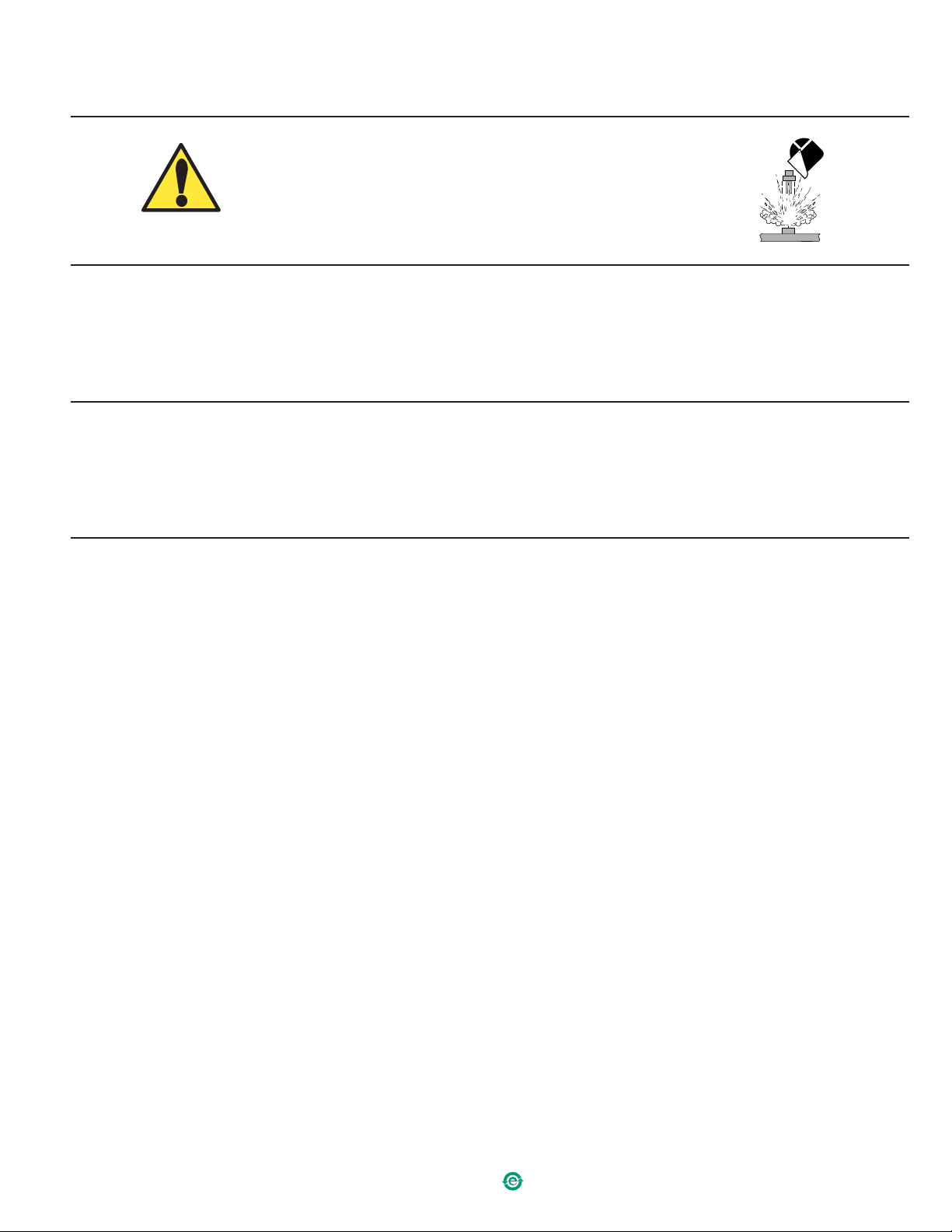

Dimensions

2850-51, -52 Integral mount 2850-61, -62, -63 Universal mount

95 mm

3.74 in.

95 mm

3.74 in.

Conductivity Sensor Dimensions

73.66 mm

(2.9 in.)

3-2818

41.91 mm

(1.65 in.)

12.7 mm

(0.5 in.)

32.39 mm

(1.28 in.)

85 mm

3.34 in.

4.6 m (15 ft)

cable (std)

152 mm

(6 in.)

107 mm

(4.2 in.)

49.5 mm

(1.95 in.)

12.7 mm

(0.5 in.)

3-2819, 3-2820, 3-2821

¾ in. NPT

2820-x

20.3 mm

(0.8 in.)

2821-x

7.6 mm

(0.3 in.)

82 mm

3.24 in.

T1 = 50 mm (2.0 in.)

T2 = 64 mm (2.5 in.)

152 mm

(6.0 in.)

126 mm

(5.0 in.)

3-2819, 3-2820, 3-2821

Sanitary

13 mm

(0.5 in.)

73.7 mm

2.90 in.

Operating Range Chart

(0.01 Cell)

59.3 mm

2.33 in.

3-2839 3-2840

UPW @ 25°C

USP

35.8 mm

1.41 in.

(1.0 Cell)

(0.10 Cell)

2818/2819/2839

2820/2840

21.5 mm

0.85 in.

(10.0 Cell)

2821/2841

Bottled

Water

(20.0 Cell)

2822/2842

2823

41.9 mm

1.65 in.

Cooling Tower

Waste Waters

203 mm

8.0 in.

89 mm

26.8 mm

1.13 in.

3.5 in.

3-28233-2841, 3-2842

Deionization Regen. Chemicals

Alkali Cleaners, Acids/Bases

0.010 μS

0

0

1 μS

0

10 μS

.

50 μS

100 μS

.

1,000 μS 10,000 μS

50,000 μS

200,000 μS

400,000 μS 200 μS 100,000 μS 0.055 μS

0.5 μS 20 μS

2 2850 Conductivity/Resistivity Sensor Electronics

Page 3

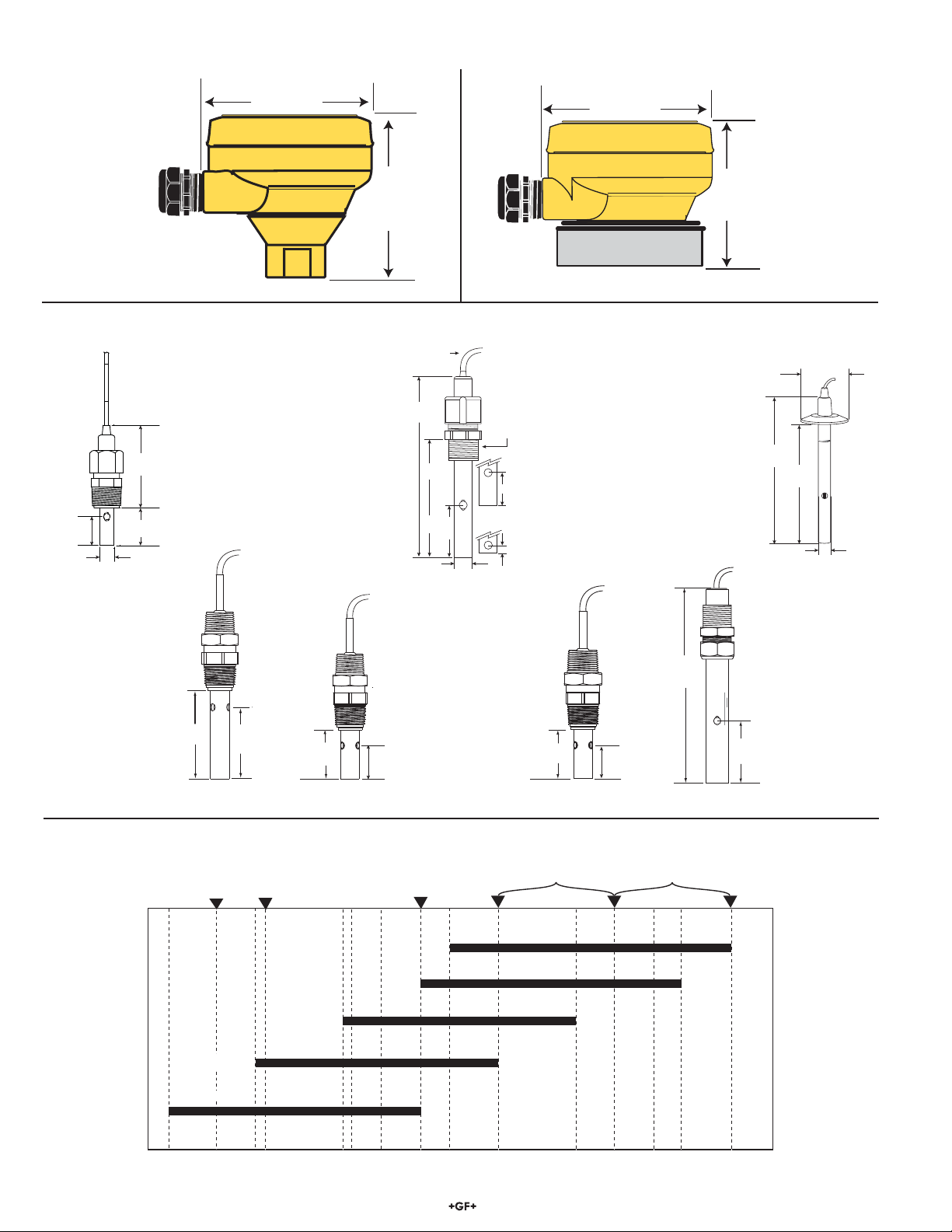

3. In-Line Installations

Most of the Conductivity/Resistivity electrodes used with the 2850

can be installed into standard 3/4 in. (NPT or ISO 7-R3/4) fi ttings.

The 2850-5X models are designed for integral systems, where

the electronics are attached directly to the sensor.

The preferred installation for in-line applications directs fl ow

straight into the electrode. This confi guration reduces the

probability of entrapped air bubbles, and provides the best

continuous sampling of the fl uid content.

If the electrode is mounted vertically in a tee, do not recess the

electrode orifi ces inside the tee. Mounting upside down may help

prevent air entrapment.

An oversized tee or fl ow cell may be helpful for inline installations.

At least 4 threads (ANSI B1.20.1) must be engaged to meet the

pressure rating as published in the specifi cations.

Use the 2850-6X models for in-line installations where the

electronics must be separated from the electrode. Conductivity

electrodes with sanitary fl ange fi ttings must be installed using this

option.

4. Tank Installations

While the 2850-5X and -6X electronics cannot be submerged, either model will

accomodate tank installation.

Select any electrode with a 5 m (15 ft) cable. The cable may be cut to length, but it

CANNOT BE EXTENDED.

The universal adapter included with 2850-6X models can be attached to the top of a

tank or mounted to a surface near the tank.

Adapt the 2850-5X models to tank installations by attaching a clamp to the conduit.

32850 Conductivity/Resistivity Sensor Electronics

Page 4

5. Wiring 4 to 20 mA Output Version

• Maximum length of 4 to 20 mA loop is 300 meters (1000 ft)

to

9 VDC

26 VDC

6. Wiring Digital (S3L) Output Version

• The digital output is compatible with the

Signet 8900 Multi-Parameter Controller and

the Signet 9900 Transmitter.

• Refer to the wiring sections of the 8900

or 9900 manual to determine cable length

limitations.

• IMPORTANT: Provide Earth Ground as

indicated by symbol.

Note: The 2819-2823 and 2839-2842 sensors

can connect directly to the 9900 via the 9900's

optional Direct Conductivity/Resistivity Module

3-9900.394 (159 001 699).

I/O Module 3-8900.401-X

Frequency

Input

1

Frequency

Input 2

Freq. Input 2 (Red)

OR

S3L

Input

2

GND (White/Shield)

S3L

Input

1

GND (White/Shield)

Analog Output 1

Analog Output 2

9900 S3L Input

4 20

4-20 mA Loop Output

+5VDC (Black)

Freq. Input (Red)

GND (Shield)

+5VDC (Black)

S L (Red)

+5VDC (Black)

S L (Red)

(if applicable)

(if applicable)

1

2

3

4

5

6

3

7

8

9

3

10

11

+

12

-

13

+

14

-

DATA

V+

3-8900.621C

GND

SHLD

4

CTS

3

2

ON

1

3

V-

2

1

V+

3

2

1

SW1

Gnd

Data

V+

4

CTS

3

2

ON

1

D3

4

CTS

3

2

ON

1

SW1

D3

DC Power

Loop Voltage

Sensr Gnd

(SHIELD)

Sensr Gnd

(SHIELD)

Temp. IN

(WHITE)

Signal RTN

(BLK)

Temp. IN

(WHITE)

Signal RTN

(BLK)

Signal IN

(RED)

Signal IN

(RED)

7. Wiring Dual Input Digital (S3L) Output Version

• Dual input is available on Digital S3L output

model 3-2850-63 only, for use with the

Signet 8900 Multi-Parameter Controller.

• Sensors may be the same or different cell

constants.

• If the dual input model is used with a single

sensor, connect the sensor to channel 1 and

set all of the channel 2 switches to OFF.

• IMPORTANT: Provide Earth Ground as

indicated by symbol.

I/O Module 3-8900.401-X

+5VDC (Black)

Frequency

Input

Freq. Input (Red)

1

GND (Shield)

+5VDC (Black)

Frequency

Input 2

Freq. Input 2 (Red)

OR

S3L

Input

2

S3L

Input

1

3

S L (Red)

GND (White/Shield)

+5VDC (Black)

3

S L (Red)

GND (White/Shield)

Analog Output 1

(if applicable)

Analog Output 2

(if applicable)

White

3-9900.395

H COMM Module

Red

Black

3-8900.621C

1

2

3

4

5

6

7

8

9

10

11

+

12

-

13

+

14

-

3

Gnd

2

Data

1

V+

SW1

4

CTS

3

Ch 2

2

ON

1

4

CTS

3

Ch 1

2

ON

1

D3

Sensor 2

Sensor 1

4 2850 Conductivity/Resistivity Sensor Electronics

Page 5

S

1

3

O

CTS

8. Cell Constant Selection

Cell Constant Selection

• The 2850 is shipped from the factory with the custom cell

constant and temperature offset programmed into the singleinput electronics. SW3 will be preset to "Custom cell constant".

• Switch banks SW3 and SW4 are used to select the cell

constant of the electrode. The Dual Input model is illustrated.

Single input models use only SW3.

• Make all switch settings before connecting power. Switch

changes made with the power ON will take 15 to 20 seconds

before becoming effective.

• Use SW3 #1-3 to select the cell constant for the fi rst sensor.

• Use SW3 #4 to disable the PT1000 Temp Compensation

function in the 2850 (as required for USP applications.) This

disables the function for BOTH INPUTS.

• Use SW4 #1-3 to select the cell constant for the second sensor.

• Set SW4 #4 to OPEN to disable the second input.

SW3 Cell Constant and Temp Compensation

#1 #2 #3 #4 For Cell Constant

C C C O Custom

C O O O 0.01 cm

O C O O 0.1 cm

C C O O 1.0 cm

O O C O 10.0 cm

C O C O 20.0 cm

#4: Open = Temp Comp ON

Closed = Temp Comp OFF

SW4: #1, #2 and #3 operate the same as SW3.

#4 turns input 2 OFF when set to OPEN.

(Open = Off, Closed = On)

-1

-1

-1

-1

-1

2

3

1

N

4

D3

W1

ON

1

2

SW3

Ch 1

CTS

4

3

ON

1

2

SW4

Ch 2

2

CTS

4

3

Example: 1.0 cell constant, temp comp ON

CTS

ON

1

4

3

2

Example: 1.0 cell constant, temp comp OFF

CTS

ON

1

4

3

2

NOTE: To work correctly

with the 9900, the 2850 must

be set for the custom cell

constant or the actual probe

cell constant and the 9900

set for a 1.0 cell constant.

Closed

Open

Closed

Open

Custom Cell Constant

0.01/cm

0.1/cm

1.0/cm

10.0/cm

20.0/cm

CTS

ON

1

2

Closed

Open

4

3

-1

CTS

ON

1

2

Closed

Open

4

3

-1

CTS

ON

1

2

Closed

Open

4

3

-1

CTS

ON

1

2

Closed

Open

4

3

-1

CTS

ON

1

2

Closed

Open

4

3

-1

CTS

ON

1

2

Closed

Open

4

3

9. Range Selection for 4 to 20 mA Output

• The Range selection switch bank (SW2) provides eight range

selections for each cell constant. Each range can be inverted,

making a total of 16 range options.

• Select a range from the table below and set SW2 as indicated.

Example (refer to shaded selections of chart):

• The electrode installed is the 3-2840-1, with a 0.10 cell constant.

• The required output is 4 to 20 mA = 0 to 100 S.

• Set SW2 switch bank to C-C-O-O.

• To invert range (4 to 20 mA = 100 to 0 S), close switch #4.

SW2 Switch Setting 0.01 Cell

0.10 Cell

C = Closed

O = Open

1.0 Cell 10.0 Cell 20.0 Cell

CTS

ON

4

1

2

SW2

3

SW1

D3

1 3 2

CTS

ON

4

1

3

2

SW2

SW3

CTS

ON

4

1

3

2

#1 #2 #3 #4 Resistivity Ranges in BOLD

CCCO10 to 20 MΩ 0 to 2 S 0 to 20 S 0 to 200 S 0 to 400 S

CCCC20 to 10 MΩ 2 to 0 S 20 to 0 S 200 to 0 S 400 to 0 S

OCCO 2 to 10 MΩ 0 to 5 S 0 to 50 S 0 to 500 S 0 to 1000 S

OCCC 10 to 2 MΩ 5 to 0 S 50 to 0 S 500 to 0 S 1 000 to 0 S

COCO 0 to 2 MΩ 0 to 10 S 0 to 100 S 0 to 1 000 S 0 to 2 000 S

COCC 2 to 0 MΩ 10 to 0 S 100 to 0 S 1 000 to 0 S 2 000 to 0 S

O O C O 0 to 1 S 0 to 50 S 0 to 5 000 S 0 to 5 000 S 0 to 10 000 S

O O C C 1 to 0 S 50 to 0 S 500 to 0 S 5 000 to 0 S 10 000 to 0 S

CCOO

0 to 5 S

0 to 100 S

0 to 1 000 S 0 to 10 000 S 0 to 20 000 S

C C O C 5 to 0 S 100 to 0 S 1 000 to 0 S 10 000 to 0 S 20 000 to 0 S

O C O O 0 to 10 S 0 to 200 S 0 to 2 000 S 0 to 50 000 S 0 to 100 000 S

O C O C 10 to 0 S 200 to 0 S 2 000 to 0 S 50 000 to 0 S 100 000 to 0 S

C O O O 0 to 50 S 0 to 500 S 0 to 5 000 S 0 to 100 000 S 0 to 200 000 S

C O O C 50 to 0 S 500 to 0 S 5 000 to 0 S 100 000 to 0 S 200 000 to 0 S

OOOO 0 to 100 S 0 to 1 000 S 0 to 10 000 S 0 to 200 000 S 0 to 400 000 S

O O O C 100 to 0 S 1000 to 0 S 10 000 to 0 S 200 000 to 0 S 400 000 to 0 S

C = CLOSED O = OPEN Switch #4 inverts the output: OPEN = 4 to 20 mA, CLOSED = 20 to 4 mA

52850 Conductivity/Resistivity Sensor Electronics

Page 6

10. Calibration

• All 2850 Conductivity/Resistivity Sensor Electronics are factory calibrated for maximum out-of-the-box accuracy.

• The EasyCal feature allows calibration to be performed at the sensor.

The 2839-2842 Conductivity sensors come with a certifi cate of calibration. This certifi cate provides information regarding the actual cell

constant and temperature offset as tested and verifi ed according to NIST standards. This information has been programmed into the

2850 electronics as its default factory value. If required, the sensor can be recertifi ed by contacting the GF Signet repair department.

a. SW2: 4 to 20 mA output range selection switch bank

b. Power and 4 to 20 mA or Digital (S3L) output terminal block

c. SW3 and SW4: Electrode Cell Constant selection switch banks

d. D3: LED indicator

e. SW1: EasyCal Push-button

f. Conductivity Electrode connections

4

3

2

1

CTS

ON

3

2

1

4

CTS

3

CH 2

2

ON

1

a

b

4

CTS

3

CH 1

c

2

ON

1

SW1

d

D3

f

e

10.1 EasyCal

EasyCal is a single-point calibration system. During this procedure, if the measured value is within ±10% of any of the test values listed

below, the 2850 will automatically recognize the test value and calibrate the output to that value.

Note:

The fi rst step (Reset) is recommended each time an electrode is replaced, but is NOT necessary upon initial installation or periodic

calibration.

1. Reset the 2850 Sensor to factory calibration: Set all switches on SW3 (and SW4 for dual input) to OPEN. Apply power, wait at least

3 seconds, then press and hold SW1 until the LED (D3) comes on steady then goes off again (approx. 10 seconds). When the LED

goes off, release SW1; reset is complete. Reset SW3 and SW4 to the proper settings.

2. Place the electrode/sensor assembly into the conductivity test solution appropriate to your operating range. Shake the electrode to

dislodge any air bubbles visible on the surface of the electrode.

• 146.93 S, 1408.8 S, 12856 S (per ASTM D1125-95)

• 10 S, 100 S, 200 S, 500 S, 1000 S, 5000 S, 10,000 S, 50,000 S, 100,000 S.

• Allow at least 2 minutes for the electrode response to stabilize.

3. Press and hold SW1 for approximately 8 to 10 seconds. During this time, the LED will come on steady then go back off. (If the LED

blinks several times rapidly, the calibration was not successful. See the troubleshooting section).

Calibration is complete. Return the system to service.

Calibrating the Dual-Input model 3-2850-63

• The 2850-63 can only be calibrated if both inputs are used, or if input 2 is disabled.

• To disable input 2: Set SW4, #4 to OPEN.

• Place each sensor into a test solution that represents the operating range of that sensor. When SW1 is pressed, the 2850 will

calibrate both inputs simultaneously.

• Dual input applications usually include one sensor with a smaller cell constant and one sensor with a larger cell constant. Place the

larger cell constant on input 1. This allows periodic recalibration of the larger cell by simply turning input 2 OFF.

6 2850 Conductivity/Resistivity Sensor Electronics

Page 7

11. Maintenance

• The 2850 requires no periodic maintenance.

• Coatings on the electrode may cause slow response or drift.

Clean metallic surfaces with a mild detergent and a non-abrasive brush or cotton swab.

11.1 Troubleshooting

LED and Output Condition Possible Causes Suggested Solutions

Current Out:

LED off, current output is 22 mA

3

L) out: "Check Sensor"

(S

During EasyCal, the LED blinks rapidly

for 4 seconds.

After completing calibration procedure,

the output values are inaccurate.

The output of the 2850 indicates a value

that is off by a factor of 10 (e.g. 10x,

100x the correct value)

• SW3 and SW4 set to all OPEN (factory

setting).

• No electrode installed.

• SW3 (and SW4) not set correctly.

• System not ready.

• Measured value of the test solution is

outside the ±10% tolerance.

• The electronics or the electrode is

defective.

• Insuffi cient time allowed for electrode

stabilization during calibration procedure.

• Test solutions are contaminated.

• EasyCal performed with temp comp

OFF, then temp comp turned ON for

measurement. (or vice versa)

• The cell constant selection on the 2850

(SW3 or SW4) does not match the actual

input.

• Normal for new system.

• Install electrode.

• Set SW3 and SW4 correctly.

• Retry (recycle power).

• Use fresh test solutions and restart the

calibration.

• Replace the electronics or the

electrode.

• Recalibrate and wait at least 2 minutes

after placing electrode in solution before

pressing SW1.

• Use fresh test solutions and restart the

calibration.

• Match the 2850 switch settings to agree

with the sensor being used.

Electronic Certifi cation

Signet offers conductivity simulators in fi ve different values. These tools enable the user to validate the performance of the electronics

independently of the electrode. This requirement is defi ned by ASTM D 1125-95 (Standard Test Methods for Electrical Conductivity and

Resistivity of Water) which is commonly used for USP 24 applications.

3-2850.101-1 (159 001 392) 1.0 S ±0.1% 3-2850.101-2 (159 001 393) 2.5 S ±0.1%

Cond. - Resist.

Simulator

@ 25°C

For use with Signet

2850 Conductivity

NIST Traceable

3-2850.101-3 (159 001 394) 10.0 S ±0.1% 3-2850.101-4 (159 001 395) 18.2 M ±0.1%

3-2850.101-5 (159 001 396) 10.0 M ±0.1%

Before using the Simulator:

Before using the simulators, disconnect all electrodes and reset the 2850 Electronics to factory calibration:

1. Set all switches on SW3 (and SW4 for dual input) to OPEN. Turn the power on, wait at least 3 seconds

2. Press and hold SW1 until the LED (D3) comes on steady then goes off again (approx. 10 seconds).

3. When the LED goes off, release SW1. Reset is complete.

To validate input 1:

1. Turn the power off.

2. Set SW3 to accept a 0.01 cell constant. Leave SW4 in the all-OPEN position.

3. Install the simulator into the 2850 at the input 1 conductivity electrode terminals.

4. Connect the 2850 output terminals to the appropriate display instrument. Turn the power on.

• The display should indicate a conductivity value within ±2% of the simulator value.

• If the output is x10 or x100 of the correct value, recheck step 2. The 2850 is not set to accept a 0.01 cell constant.

• If the correct value is displayed, the electronics are calibrated to ASTM D 1125 specifi cations. Remove the simulator and reset

SW3 to the correct cell constant before reinstalling the electrode.

• If the correct value is not displayed, contact the factory.

To validate input 2:

1. Turn the power off.

2. Set SW4 to accept a 0.01 cell constant.

3. Install the simulator into the 2850 at the input 2 conductivity electrode terminals.

4. Set SW3 switches to the all-OPEN position.

5. Turn the power on and repeat step 4.

Remember to reset all switches to their correct position before resuming normal operation.

72850 Conductivity/Resistivity Sensor Electronics

Page 8

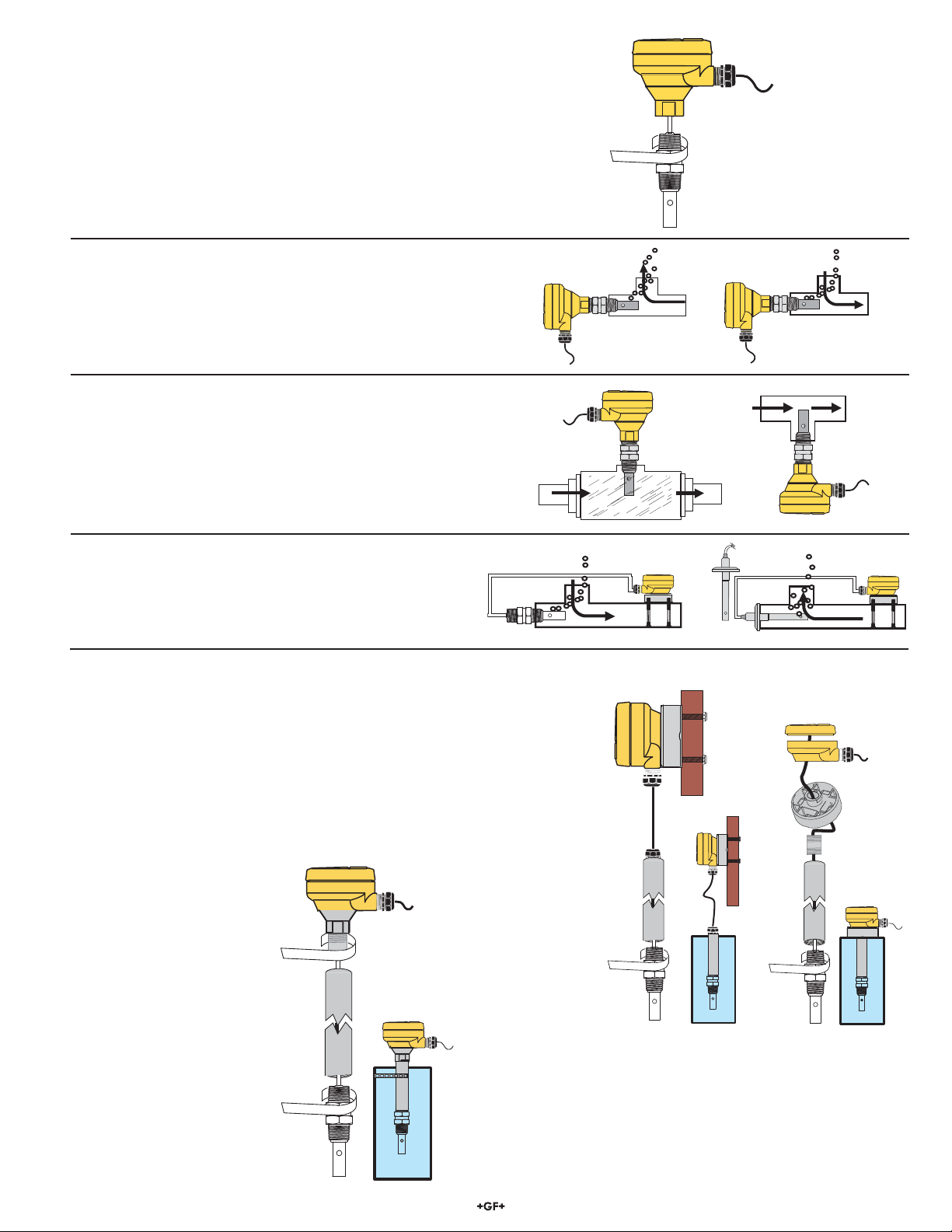

12. Ordering Information

Mfr. Part No. Code Description

3-2850-51 159 001 398 2850 Sensor Electronics w/ Digital Output and ¾ inch adapter

3-2850-52 159 001 399 2850 Sensor Electronics w/ 4 to 20 mA Output and ¾ inch adapter

3-2850-61 159 001 400 2850 Sensor Electronics w/ Digital Output and Universal adapter

3-2850-62 159 001 401 2850 Sensor Electronics w/ 4 to 20 mA Output and Universal adapter

3-2850-63 159 001 402 2850 Sensor Electronics w/ Dual Inputs, Digital Outputs and Universal adapter (see NOTE)

3

3-2850-51-39 159 001 339 Integral 2850 system, Digital (S

3-2850-51-40 159 001 340 Integral 2850 system, Digital (S3L) output, 0.1 cell, NPT threads

3-2850-51-41 159 001 341 Integral 2850 system, Digital (S3L) output, 1.0 cell, NPT threads

3-2850-51-42 159 001 342 Integral 2850 system, Digital (S3L) output, 10.0 cell, NPT threads

3-2850-51-39D 159 001 343 Integral 2850 system, Digital (S3L) output, 0.01 cell, ISO threads

3-2850-51-40D 159 001 344 Integral 2850 system, Digital (S3L) output, 0.1 cell, ISO threads

3-2850-51-41D 159 001 345 Integral 2850 system, Digital (S3L) output, 1.0 cell, ISO threads

3-2850-51-42D 159 001 346 Integral 2850 system, Digital (S3L) output, 10.0 cell, ISO threads

3-2850-52-39 159 001 347 Integral 2850 system, 4 to 20 mA output, 0.01 cell, NPT threads

3-2850-52-40 159 001 348 Integral 2850 system, 4 to 20 mA output, 0.1 cell, NPT threads

3-2850-52-41 159 001 349 Integral 2850 system, 4 to 20 mA output, 1.0 cell, NPT threads

3-2850-52-42 159 001 350 Integral 2850 system, 4 to 20 mA output, 10.0 cell, NPT threads

3-2850-52-39D 159 001 351 Integral 2850 system, 4 to 20 mA output, 0.01 cell, ISO threads

3-2850-52-40D 159 001 352 Integral 2850 system, 4 to 20 mA output, 0.1 cell, ISO threads

3-2850-52-41D 159 001 353 Integral 2850 system, 4 to 20 mA output, 1.0 cell, ISO threads

3-2850-52-42D 159 001 354 Integral 2850 system, 4 to 20 mA output, 10.0 cell, ISO threads

L) output, 0.01 cell, NPT threads

Parts and Accessories

Mfr. Part No. Code Description

3-9000.392-1 159 000 839 Liquid-tight connector kit, 1 set, 1/2 in. NPT

3-9000.392-2 159 000 841 Liquid-tight connector kit, 1 set, PG 13.5

3-2850.101-1 159 001 392 Plug-in NIST-traceable recertifi cation tool, 1.0 S

3-2850.101-2 159 001 393 Plug-in NIST-traceable recertifi cation tool, 2.5 S

3-2850.101-3 159 001 394 Plug-in NIST-traceable recertifi cation tool, 10.0 S

3-2850.101-4 159 001 395 Plug-in NIST-traceable recertifi cation tool, 18.2 M

3-2850.101-5 159 001 396 Plug-in NIST-traceable recertifi cation tool, 10.0 M

NOTE: Dual-input unit (3-2850-63) is available only in the universal adapter confi guration with Digital S3L output for use with the 8900

Controller.

95 mm

(3.74 in.)

82 mm

(3.24 in.)

95 mm

(3.74 in.)

85 mm

(3.34 in.)

Cond. - Resist.

Simulator

@ 25°C

For use with Signet

2850 Conductivity

NIST Traceable

3-2850-61

3-2850-62

3-2850-63

Electronics w/Universal adapter

3-2850-51

3-2850-52

Electronics w/ ¾-in. adapter

3-2850-51-XX

3-2850-52-XX

Integral System

3-2850.101-X

NIST-traceable

recertifi cation tool

Georg Fischer Signet LLC, 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2850.090-1 Rev. H 06/12 English © Georg Fischer Signet LLC 2012

Loading...

Loading...