Page 1

Signet 2818-2823 Series Conductivity Sensor

*3-2820.090*

3-2820.090-1 Rev. N 10/13

Description

English

Operating Instructions

2818

2822

2819

2823

2820

2821

Sanitary

Signet 2818-2823 Conductivity/Resistivity Electrodes are designed to provide

versatile installation and accurate sensing across a very broad dynamic range.

These electrodes are built with a controlled surface fi nish to ensure accuracy and

repeatability. The standard electrode is constructed 316 SS or Titanium, but there are

other materials available for maximum chemical compatibility. Reversible threads or

sanitary fl anges allow for maximum installation versatility.

Sanitary fl ange versions are available with an optional NIST Traceability Certifi cate

to meet USP requirements. Coupled with Signet patented measuring circuitry,

a three decade measurement range is achieved without the need for troublesome

electrode platinization. A platinum RTD (PT1000)

optimal temperature sensing.

located within the electrode allows

Features

• Standard process connections

• ¾” NPT Polypro

• Tri-clamp 1½”, 2”

• Opt. 1/2” NPT 316 SS

• 316 SS or Titanium standard electrode

• Alternative electrode materials available

• Hastelloy-C

• Monel

• In-line or submersible mounting

• NIST traceable certifi ed cells ±1% meet USP requirements

Table of Contents

Description.............................................................................................. 1

Features ................................................................................................. 1

Warranty Statement ................................................................................ 2

Product Registration ............................................................................... 2

Safety Information .................................................................................. 2

Dimensions ............................................................................................. 2

Specifi cations ......................................................................................... 3

Wiring ..................................................................................................... 3

Recommended Position ......................................................................... 3

Maintenance ........................................................................................... 4

In-Line Installation .................................................................................. 4

2822 Submersible Installation ................................................................ 4

2823 Submersible Installation ................................................................ 4

Page 2

General Information and Dimensions

3

Warranty Information

Refer to your local Georg Fischer Sales offi ce for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales offi ce or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buffers, turbidity

standards or other solutions) are warranted out of box but not

warranted against any damage, due to process or application

failures (e.g. high temperature,

mishandling (e.g. broken glass,

chemical poisoning, dry-out) or

damaged membrane, freezing

and/or extreme temperatures).

Product Registration

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now

register online in one of the following ways:

• Visit our website www.gfsignet.com and

click on Product Registration Form

• If this is a pdf manual (digital copy),

click here

• Scan the QR Code on the left

Safety Information

1. Do not remove from pressurized lines.

2. Do not exceed max. temperature/pressure specifi cations.

3. Wear safety goggles or fa shield during installation/service.

4. Do not alter product construction.

5. Disconnect instrument power before wiring this sensor.

6. Failure to follow safety instructions may result in

severe personal injury!

Warning / Caution / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during

installation and service of Signet products.

Pressurized System Warning

Sensor may be under pressure, take caution to vent

system prior to installation or removal. Failure to do so

may result in equipment damage and/or serious injury.

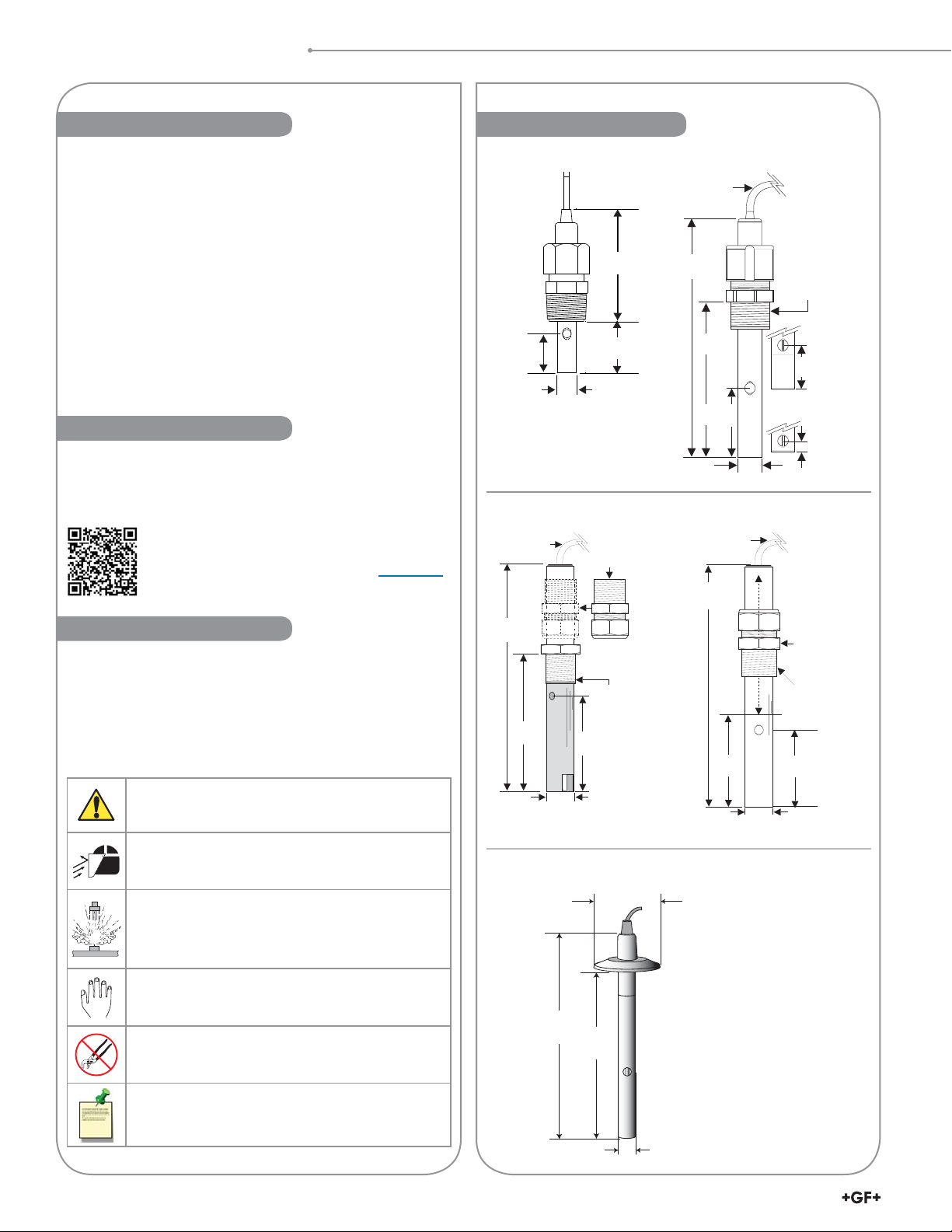

Dimensions

2818

2.39 mm

(1.28 in.)

2822

4.6 m (15 ft.)

cable (std.)

147 mm

(5.8 in.)

submersion fitting

86 mm

(3.4 in.)

19 mm

(0.75 in.)

58.4 mm

(2.3 in.)

73.66 mm

(2.9 in.)

41.91 mm

(1.65 in.)

12.7 mm

(0.50 in.)

¾ in. NPT

Optional 316 SS

kit #3-2820.390

¾ in. NPT

Sanitary

2819, 2820, 2821

4.6 m (15 ft)

cable (std)

152 mm

(6 in.)

107 mm

(4.2 in.)

49.5 mm

(1.95 in.)

12.7 mm

(0.5 in.)

2823

4.6 m (15 ft)

cable (standard)

203 mm

(8.0 in.)

89 mm

(3.5 in.)

19 mm

(0.75 in.)

T1 = 50 mm (2.0 in.)

T2 = 64 mm (2.5 in.)

¾ in. NPT

2820-x

sensor tip

(nosepiece)

20.3 mm

(0.8 in.)

2821-x

sensor tip

(nosepiece)

7.6 mm

(0.3 in.)

Reversible

fitting assy

for submersion

mounting

¾ in. NPT

76.2 mm

(3.0 in.)

Hand Tighten Only

Overtightening may permanently damage product

threads and lead to failure of the retaining nut.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and

potentially void product warranty.

152 mm

(6.0 in.)

126 mm

(5.0 in.)

Note

Tri-clamp is available for

2819, 2820, 2821 only.

T1 or S1 is for 1 to 1½ in.

tees or fl anges.

Note / Technical Notes

Highlights additional information or detailed procedure.

13 mm

2

Signet 2818-2823 Series Conductivity Sensor Instruction Manual

(0.5 in.)

T2 or S2 is for 2 in. tees

or fl anges.

Page 3

Specifi cations and Wiring

*Required

installation

postition for

0.01 cell

Use caution to avoid air bubbles or sediment

trapping inside the electrode cavity.

In-line Submersible

OR

Specifi cations

General

Cell Constant

2818 ................................... 0.01 cm

2819 ................................... 0.01 cm

2820 ................................... 0.1 cm

2821 ................................... 1.0 cm

2822 ................................... 10.0 cm

2823 ................................... 20.0 cm

Operating Range:

2818 ................................... 0.055 to 100 μS (10 kΩ to 18.2 MΩ)

2819 ................................... 0.055 to 100 μS (10 kΩ to 18.2 MΩ)

2820 ................................... 1 to 1000 μS (1 kΩ to 1 MΩ)

2821 ................................... 10 to 10,000 μS (5 to 5000 ppm)

2822 ...................................

2823 ...................................

Cell Constant Accuracy .......... ±2% (certified cells ±1%)

Temp. Compensation Device.. PT1000

Cable Length

Standard ............................. 4.6 m (15 ft)

Maximum ............................ 30 m (100 ft)

2818 & 2819-1 .................... 7.6 m (25 ft) max. when used

Sanitary fitting size .................1 in., 1½ in., 2 in.

Wetted Materials

O-Rings .................................. EPR (EPDM)

Electrodes...............................

Sanitary fitting .........................

2822 Body ..............................CPVC

Insulator Material

2818/2819/2820/2821

2823

.................................... PEEK

.......... Carbon fiber reinforced PTFE

Process Connection ...............¾ in. NPT threads;

Shipping Weight

2818/2819/2820/2821/2822

2823

.................................... 0.3 kg (0.6 lb)

... 0.4 kg (0.8 lb)

Environmental Requirements

Temperature Accuracy ........ 0.3 °C

Max. Pressure/Temperature Ratings

2818/2819/2820/2821 Fittings:

Standard Polypropylene ..... 6.9 bar @ 100 °C (100 psi @ 212 °F)

(3-2820.392) ½ NPT 316 SS

... 13.8 bar @ 120 °C (200 psi @ 248 °F)

Sanitary Connection ........... 6.9 bar @ 120 °C (100 psi @ 248 °F)

2822........................................ 6.9 bar @ 95 °C (100 psi @ 203 °F)

2823........................................ 6.9 bar @ 150 °C (100 psi @ 302 °F)

Standards and Approvals

• RoHS Compliant

China RoHS (Go to www.gfsignet.com for details)

-1

-1

-1

-1

-1

-1

100 to 200,000 μS (50 to 100,000 ppm)

200 to 400,000 μS (100 to 200,000 ppm)

with 8850 & 8860. Do Not splice cable.

316L Stainless Steel (1.4408, DIN 17440)

or Titanium

316L Stainless Steel or Titanium

®

Standard 316 SS fitting &

Optional 316 SS submersion

adapter fitting (3-2820.390)

Wiring

3-9900.092 Direct Conductivity/Resistivity Module

DC Power

Loop Voltage

SHIELD

TEMP (WHT)

ISO GND (BLK)

H COMM Module

SIGNAL (RED)

Cond/Res Module

Red

Black

2818 - 2823

White

Shield

2850 Conductivity/Resistivity Sensor Electronics

Sensr Gnd

(SHIELD)

Gnd

Data

3

2

1

V+

SW1

4

CTS

3

2

ON

1

D3

Temp. IN

(WHITE)

Signal RTN

(BLK)

Signal IN

(RED)

Recommended Position

SHIELD (SILVER)

ISO GND (BLK)

SIGNAL (RED)

TEMP (WHT)

Alternate wetted materials and overall lengths are

available through special order.

Cable length extensions

through special order.

For resistivity measurements above 10 MΩ and/or

below 20°C, maximum cable length is 25 ft. (7.6 m).

to 100 ft. (30 m) are available

Signet 2818-2823 Series Conductivity Sensor Instruction Manual

3

Page 4

Installation and Maintenance

1 2

1-1/4 turns

past finger

tight

3/4 in. NPT

Customer supplied

coupling

Customer supplied

pipe

Sealant

Sealant

Fill with

3 in. to 4 in.

of sealant

Customer

supplied

pipe tee/

reducer

Standard

fitting kit

Mark hole

position

3/4 in. NPT

Hand

tighten only!

O-ring Sealant

Hole up

Customer

supplied

pipe tee/

reducer

Sealant

1-1/4 turns

past finger tight

Hole upMark hole position

Install behind

hole ONLY!

Customer supplied

pipe tee/reducer

3/4 in. NPT

Sealant

Hand

tighten only!

O-ring Sealant

Hole upMark hole

position

Customer

supplied

pipe tee/

reducer

1/2 in. NPT

3-2820.392

Optional

fitting kit

In-Line Installation

2818/2819/2820/2821

2822

2823

*Installation tip: Mark the sensor body to indicate the position of the vent hole. During installation,

align the vent hole mark so it faces upward or against the process fl ow to prevent air bubble entrapment.

2823 Submersible Installation

• Attach ¾ in. watertight pipe to the top of the sensor.

• Secure the threaded connection to prevent any leakage.

• For additional defense against possible accumulation of

condensation at the back seal area of the sensor, fi ll the lower

75 mm to 100 mm (3 in. to 4 in.) of conduit or extension pipe with

a fl exible sealant such as silicone.

2822 Submersible Installation

submersion

#3-2820.390

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2820.090-1 Rev N 10/13 English © Georg Fischer Signet LLC 2013

1 2

Optional

fitting kit

Sealant

Customer supplied

pipe

Sealant

Customer supplied

coupling

3/4 in. NPT

1-1/4 turns

past finger

tight

Maintenance

• Any coatings on electrodes will cause readings to drift or show

poor response.

• Clean metallic surfaces with a mild detergent and a non-abrasive

brush or cotton swab.

2823-1 Sensor Tip Removal Procedure:

Sensor tip

(end view)

8-32

A

C

D

Sensor tip

(side view)

Electrode

Sensor tip

(side view)

Electrode

Insulator

Insulator

B

Cotton swab

Clean electrode

Clean metal body

Loading...

Loading...