Page 1

Signet 2750 DryLoc® pH/ORP Sensor Electronics

English

*3-2750.090*

3-2750.090 Rev. K 01/13 English

1. Description

2. Specifi cations

SAFETY INSTRUCTIONS

1. Depressurize and vent system prior to installation or removal.

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. When using chemicals or solvents care should be taken and appropriate eye,

face, hand, body, and/or respiratory protection should be used.

1. Description

Signet 2750 pH/ORP Sensor Electronics provide two-wire 4 to 20mA loop output for pH and ORP measurements, without the expense

of local display and other luxuries available in full-featured transmitters. Preamplifi cation is built-in, reducing system costs while ensuring

absolute signal integrity up to 305 m/1,000 feet.

3. In-line Installation

4. 2750 In-line Assembly

5. Submersible Installation

6. Digital (S

3

L) wiring

7. 4 to 20 mA Loop wiring

8. Calibration

9. Troubleshooting

10. Ordering Information

These sophisticated fi eld-mount devices also provide the Digital (S

3

L) output; the latest development in leading-edge technology from

Signet. The 2750 Sensor Electronics self-confi gure for pH or ORP operation via automatic recognition of electrode type, and the DryLoc

electrode connector quickly forms a robust assembly for submersible and in-line installations.

NEMA 4X Junction Boxes are integral parts of the in-line version and are available as accessories for the submersible version. The

optional EasyCal feature allows simple push-button calibration and includes an LED for visual feedback.

2. Specifi cations

General

• Compatible Electrodes: Signet DryLoc Electrodes.

(PT1000 temperature sensor versions for pH)

• Operational Range: 0.00 to 14.00 pH, ±2000 mV ORP

0 °C to 85 °C (32 °F to 185 °F)

• Response Time (includes electrode response):

pH: <6 s for 95% of change

ORP: application dependent

pH Temp T90: 200 s (2724)

132 s (2726)

438 s (2756-WT)

Materials:

2750-1, -2 (in-line): PBT (thermal plastic polyester)

2750-3, -4 (submersible): CPVC

Cable for -3, -4 submersible versions:

5 m (15 ft) 3-conductor shielded, 22 AWG

• May be extended up to 3.48 m (100 ft) with current output

• May be extended up to 3.48 m (100 ft) with (S

Weight:

2750-1, -2 (in-line): 0.75 kg (1.75 lb)

2750-3, -4 (submersible): 0.64 kg (1.4 lb)

Environmental

• Ambient Temp.: 0 °C to 85 °C (32 °F to 185 °F

• Storage Temp.: -20 °C to 85 °C (-4 °F to 185 °F)

• Relative Humidity: 95% max, non-condensing

• Immunity: EN50082-2

• Emissions: EN50081-1

• Enclosure Rating:

2750-1, -2 (in-line): NEMA 4X/IP65 (with electrode connected)

2750-3, -4 (submersible): NEMA 6P/IP68 (with electrode and

watertight extension pipe connected)

Electrical

• Input Impedance: >10

• Input response time: 500 ms

• Temperature drift: ±0.002 pH per ºC

±0.1 mV ORP per ºC

• Input resolution: 0.02 pH, 1 mV ORP, 0.3 ºC

11

Ω

3

L) output

Current output:

• Description: pH: Fixed 4 to 20 mA, isolated,

0 to 14 pH (custom scaling available)

ORP: Fixed 4 to 20 mA, isolated,

–1000 to 2000 mV (custom scaling

available, –2000 to 2000 mV)

• Power: Regulated 12-24 VDC ± 10%,

20 mA max.

• Max Loop Resistance: 50 Ω max. @ 12V

325 Ω max. @ 18V

600 Ω max. @ 24V

• Accuracy: ±32 μA @ 25 ºC

• Temperature drift: ±1 μA per ºC

• Output resolution: ± 5 μA

• Error indication: 3.6 mA

3

Digital (S

• Description: Serial ASCII, TTL level 9600 bps

• Power: 5 VDC ± 10% regulated, 3 mA max

• Accuracy: pH: ± 0.03 pH @ 25 °C

ORP: ± 2 mV @ 25 °C

• Resolution: pH: 0.01 pH

ORP: 1 mV

Temp. 0.2 °C

• Error indication: Temp output "+999.9"

Standards and Approvals

• CE

• Manufactured under ISO 9001 for Quality, ISO 14001 for

Environmental Management and OHSAS 18001 for Occupational

Health and Safety.

China RoHS (Go to www.gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules. Operation is

subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

L) output:

Page 2

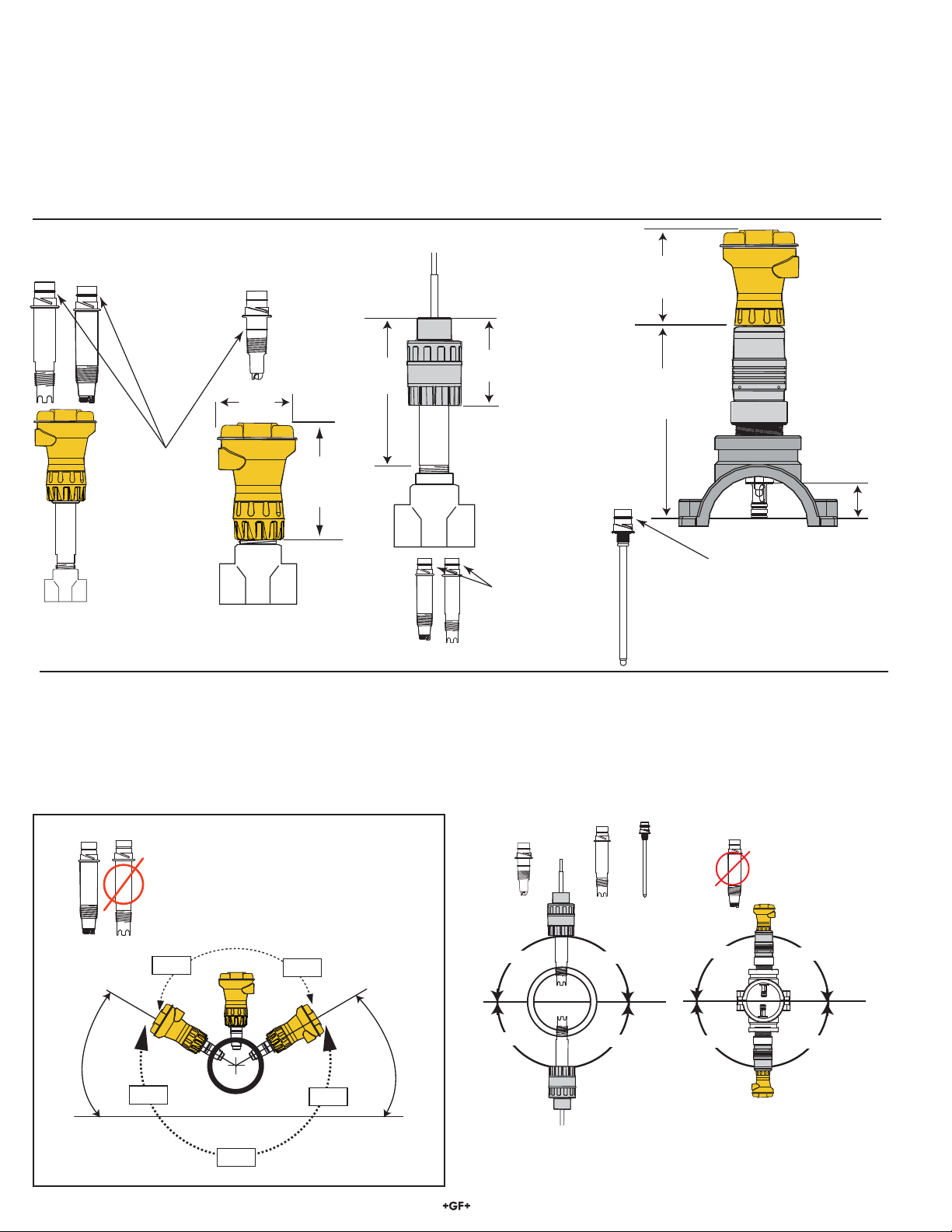

3. In-line Dimensions

• The 2750-1 in-line sensor (without EasyCal) is designed for applications where electrode calibration is facilitated by remote

equipment.

• The 2750-2 In-Line sensor includes EasyCal.

• A Signet installation fi tting (1/2 in. to 4 in.) or a Signet pipe adapter is required to secure the electrode in the pipe.

• The Signet Measurement and Instrumentation catalog offers a complete selection of fi ttings.

• The 2750-3 and 2750-4 submersible sensor electronics are recommended for in-line applications using the 2764 series differential

electrodes and the 2774 series Threaded DryLoc electrodes.

• 2764 and 2774 series electrodes thread directly into standard 1 in. or 3/4 in. NPT fi ttings.

115 mm

(4.5 in.)

89.4 mm

(3.52 in.)

248 mm

(9.75 in.)

Lubricate O-rings

with a non-petroleum

based, viscous lubricant

(grease) compatible

with the system.

Lubricate O-rings

with a non-petroleum

based, viscous lubricant

(grease) compatible

with the system.

94 mm

3.7 in.

178 mm

(7 in.)

140 mm

5.5 in.

Mounting position

2764 series electrodes must be mounted upright.

• Vertical (0°) position optimum

• Do not install within 30º of horizontal (Contact factory for horizontal or inverted installation requirements.)

• Recommended maximum fl ow rate 10 ft/s.

• Wet-tap electrodes, 2724, and 2774 series electrodes can be mounted at any angle.

45 mm

(1.75 in.)

Lubricate O-ring

with a non-petroleum

based, viscous lubricant

(grease) compatible

with the system.

OK

YES

Vertical ± 60°

NO

YES

OK

OK

30°

NO

OK

30°

NO

2

OK OK

OK

OK

OK

OK

OK

OK

Signet 2750 DryLoc pH/ORP Sensor Electronics

Page 3

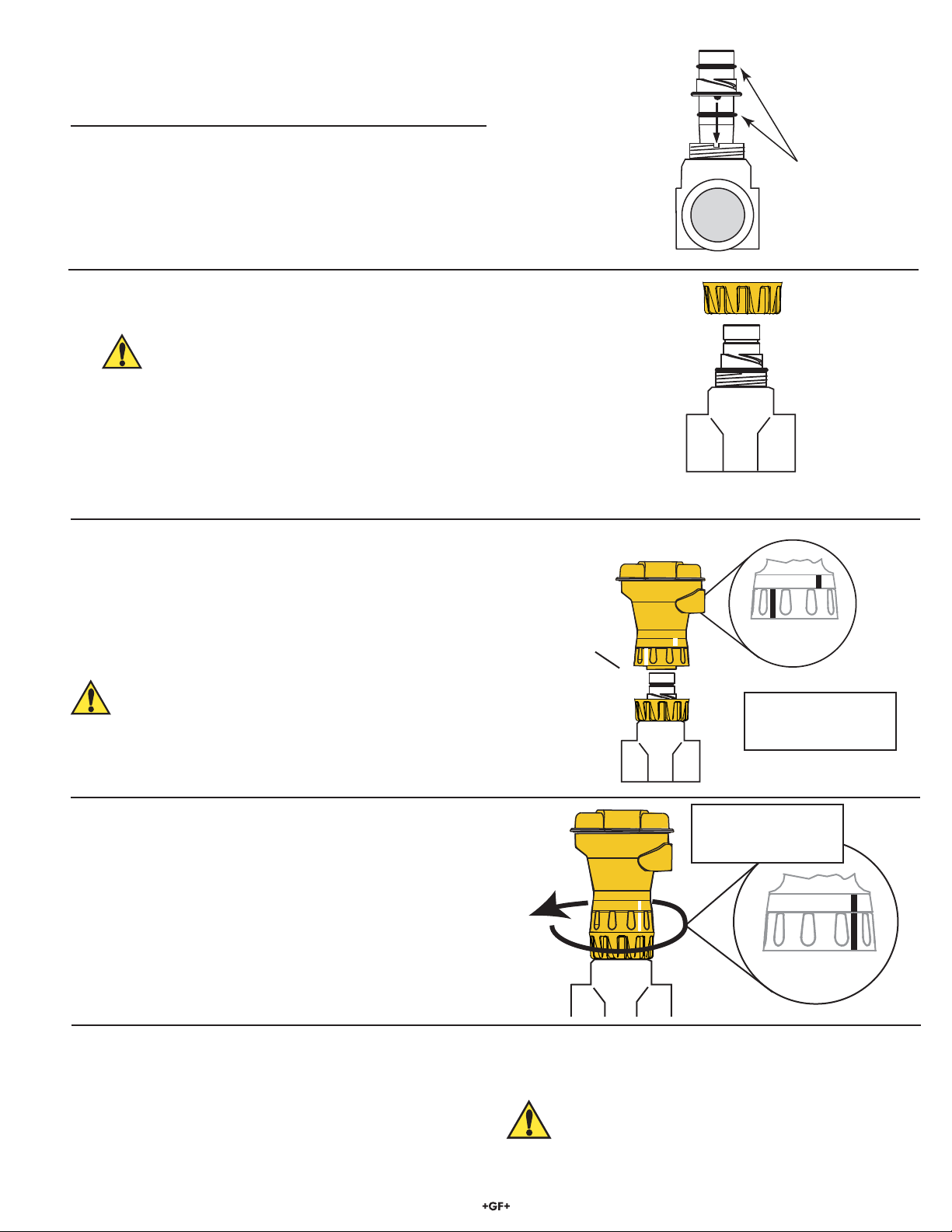

4. 2750 In-line pH Sensor Assembly

Note: This procedure applies to systems using standard 2724-2726 electrodes. If the 3719

pH/ORP Wet-Tap is used, refer to the 3719 manual for instructions.

1. Insert electrode into Signet installation fi tting. Seat the

electrode tabs into the alignment notches in the fi tting.

Lubricate O-rings

with a non-petroleum

based, viscous lubricant

(grease) compatible

with the system.

2. Thread the in-line retaining nut onto fi tting to secure the electrode

Retaining nut

into place.

HAND-TIGHTEN THE THREADED NUT ONTO THE INSTALLATION

FITTING. DO NOT USE TOOLS! DO NOT USE THREAD SEALANT OR

LUBRICANTS ON THE FITTING THREADS OR THE SENSOR CAP.

Chemical Compatibility Warning

The retaining nuts of pH and ORP sensors are not designed for prolonged contact with

aggressive substances. Strong acids, caustic substances and solvents or their vapor may

lead to failure of the retaining nut, ejection of the sensor and loss of the process fl uid with

possibly serious consequences, such as damage to equipment and serious personal injury.

Retaining nuts that may have been in contact with such substances e.g. due to leakage or

spilling, must be replaced.

Note:

Keep the electrical interconnection between electrode and sensor

electronics dry and clean at all times.

3. Unlock the ring on base of 2750 (The ring is unlocked when the

lines on the ring and body of the 2750 are not aligned.)

Locking Ring

LUBRICATE O-RINGS WITH A NON-PETROLEUM BASED, VISCOUS

LUBRICANT (GREASE) COMPATIBLE WITH THE SYSTEM.

Unlocked

The molded alignment

marks are enhanced

for clarity.

4. Place 2750 onto top of electrode and turn until the assembly

drops into position.

5. Turn locking ring

1

/4 turn to secure the 2750 assembly.

(The ring is locked when the line on the ring and the line on the

body of the 2750 are aligned.)

In-Line Sensor and Electrode Removal

• To remove electronics assembly only:

Turn locking ring 1/4 turn; lift assembly straight up.

• To remove electrode from the pipe:

Remove electronics assembly, then unthread retaining cap;

pull electrode straight up.

• To remove the complete 2750 system:

Hold locking ring in place. Unthread retaining cap and pull

electrode straight up.

Signet 2750 DryLoc pH/ORP Sensor Electronics

The molded alignment

marks are enhanced

for clarity.

Locked

CAUTION!

• Do not remove the electrode from a pressurized pipe.

• Wear appropriate protective clothing when working

with chemicals in pressurized pipe.

3

Page 4

5. 2750-3, -4 Submersible Sensor Assembly and Installation

Fill with

3 to 4 in.

of sealant

106 mm

(4.2 in.)

94 mm

(3.7 in.)

1. Insert electrode into base

of the 2750-3 or 2750-4

and turn until keyed

contacts are seated.

2750-3: 3/4 in. NPT threads

2750-4: ISO 7-1/R3/4 threads

Lubricate O-rings with a nonpetroleum based, viscous

lubricant (grease) compatible

with the system.

2. Thread retaining cap over

electrode and hand-tighten

onto 2750.

3. Attach

3

/4 in. watertight pipe to the top of the 2750.

Secure the threaded connection to prevent any leakage.

• For additional defense against possible accumulation of

condensation at the back seal area of the sensor, fi ll the

lower 3-4 inches (75-100 mm) of conduit or extension

pipe with a fl exible sealant such as silicone.

Fill with

75-100 mm

(3 to 4 in.)

of sealant

208 mm

(8.2 in.)

Note:

Keep the electrical interconnection between electrode and sensor

electronics dry and clean at all times.

Use standard installation

hardware to connect the

submersible 2750-3 or -4

directly to external equipment.

OR

The 8052-1 NPT Mount Junction box

(or 8052-2 with EasyCal) connects to

3

/4 in. pipe or conduit and provides

convenient wiring termination.

107 mm

(4.2 in.)

94 mm

(3.7 in.)

Fill with

3 to 4 in.

of sealant

55 mm

(2.16 in.)

OR

The 8050-1 Universal Mount junction

box (or 8050-2 with EasyCal) mounts

fl at onto a wall or can be strapped to

a post or pipe.

1/2 in. NPT threads

Cable supplied: 5 m (15 ft) 3-conductor + shld, 22 AWG.

May be extended up to 183 m (600 ft) with current output.

May be extended up to 305 m (1000 ft) with Digital

3

L) output.

(S

4

Signet 2750 DryLoc pH/ORP Sensor Electronics

Page 5

6. Digital (S3L) wiring

• When the 2750 is powered with 5 VDC, the digital (S3L) serial data output is automatically selected.

• S3L data is used exclusively by Signet instruments.

• Remove approximately 10 mm (0.4 in.) of insulation and tin each conductor before inserting into connectors.

3

S

3

L with no junction box

S

L with Junction box

Black

Red

White

+5 VDC

3

S

L data

Signal Ground

Shield

3

• Connect the 2750 cable directly to S

L I/O terminals.

• 8900 users: If this direct wiring is used, set the CALIBRATE

menu to "perform calibration at INSTRUMENT"

7. 4 to 20 mA Loop wiring

SW2

Run

Cal

4

SW1

D1

3

2

1

-

S

+

4

3

2

+5 VDC

3

L data

S

Signal Ground

1

Optional

Earth ground

• When the 2750 includes a terminal block, connect the 2750

terminals as shown to any S

3

L I/O port.

• 8900 users: If the 2750 includes the EasyCal accessory,

set the CALIBRATE menu to "perform Calibration at either

SENSOR or INSTRUMENT"

• If SENSOR, use standard pH buffer values (pH 4, 7, or 10) to

perform periodic calibration.

• If INSTRUMENT, any pH value can be used.

• When the 2750 is powered with 12 to 24 VDC, the 4 to 20 mA loop output is automatically selected.

• Remove approximately 10 mm (0.4 in.) of insulation and tin each conductor before inserting into connectors.

Current Loop with no junction box

Black

Red (no connection)

White

Shield

Optional

Earth Ground

4

4 to 20 mA loop

monitor

+

-

20

Power Supply

DC 12 to 24 V

• Connect the 2750 cable directly to a Loop device as shown.

• This confi guration does not provide any calibration capability

within the 2750 system. Periodic calibration must be

performed at the external equipment.

Current loop with Junction box

SW2

Run

Cal

SW1

4

D1

3

2

1

+

-

S

Optional

Earth Ground

4

3

2

1

4 to 20 mA loop

• When the 2750 includes a terminal block, connect the 2750

terminals to the Loop device as shown.

• If the 2750 includes the EasyCal accessory, use standard pH

buffer values (pH 4, 7, or 10) to perform periodic calibration.

+

-

4 20

monitor

Power Supply

DC 12 to 24 V

Signet 2750 DryLoc pH/ORP Sensor Electronics

5

Page 6

8. Calibration

All 2750 pH/ORP Sensor Electronics are factory-calibrated for maximum out-of-the-box accuracy. Periodic calibration is required to

compensate for electrode aging.

The optional EasyCal feature allows calibration to be performed local to the sensor.

SW1 EasyCal button

SW2 RUN/CALIBRATE switch for S

D1 EasyCal Indicator (green LED)

SW2

Run

SW1

+

-

S

EasyCal Procedure:

The fi rst step (Reset) is recommended each time an electrode is replaced, but is NOT necessary upon initial installation or periodic

calibration. In fact, for periodic calibration it is best for the electrode/sensor assembly to remain intact to minimize the possibility of

moisture or other contamination entering the electrical interconnection area. The electrode/sensor connection must remain dry and clean

at all times.

4

3

2

1

Cal

D1

3

L system

+

-

S

SW1

SW2

Run

4

3

2

1

Cal

BLK

RED

WHT

SHLD

D1

1. Reset the 2750 pH/ORP Sensor to factory calibration: With no electrode connected to the Sensor, press and hold SW1 until the LED

(D1) comes on steady then goes off again (approx. 10 seconds). When the LED goes off, release SW1; reset is complete.

2. Connect an electrode to the 2750 pH/ORP Sensor.

3. If S3L output is being used, place SW2 in the “Cal” position. If 4 to 20 mA output is being used, SW2 position is of no

consequence.

4. Place the electrode/sensor assembly into a calibration solution as follows: (If the electrode is “healthy”, then the 2750 will

automatically recognize the solution. The order in which the solutions are used during the calibration procedure is of no

consequence.)

• For pH calibration, use any two of these international standards: pH 4.0, 7.0 or 10.0 buffer solutions.

(Signet part number 3-0700.390 contains one capsule of each value)

• To produce standards for ORP calibration, mix the chemical Quinhydrone into pH 7.0 and 4.0 buffers to saturation (1/8g per 50ml).

• Regardless of the size of the container used for calibration, one inch of solution is adequate to completely submerge the tip of the

electrode.

• Allow at least 30 seconds for the electrode response to stabilize before calibration.

5. Press and hold SW1 for approximately 8 to 10 seconds. During this time, the LED (D1) will come on steady then go back off.

Release SW1 (If the LED blinks several times rapidly, the calibration was not successful. See the troubleshooting section.)

6. Remove the electrode/sensor assembly from the fi rst calibration solution, rinse the electrode with clean water, and place it in

a second solution.

• Allow at least 30 seconds for the electrode response to stabilize before calibration.

7. Press and hold SW1 for approximately 8 to 10 seconds. During this time, the LED will come on steady then go back off. Release

SW1. (If the LED blinks several times rapidly, the calibration was not successful. See the troubleshooting section.)

8. For S3L systems ONLY: Return SW2 to the RUN position.

Calibration is complete. Return the system to service.

6

Signet 2750 DryLoc pH/ORP Sensor Electronics

Page 7

9. Troubleshooting

LED and Output Condition Possible Causes Suggested Solutions

Current Out:

LED off, current output is 3.6 mA

S3L: Temp out is +999.9

During EasyCal, the LED blinks rapidly

for 4 seconds and the current output is

frozen at a random fi xed value.

After completing calibration procedure,

the output values are inaccurate.

• No electrode installed.

• Bad/dirty contacts between electrode

and 2750.

• The buffer solution is outside of the

accepted tolerance for the 2750.

• The electrode is depleted (> 1.1 pH or

65 mV offset).

• Insuffi cient time allowed for electrode

stabilization during calibration.

• Install electrode.

• Check interconnection between

electrode and 2750, clean contacts.

• pH system: Use fresh 4 pH, 7 pH,

or 10 pH buffer and restart the

calibration.

• ORP system: Use fresh 4pH and

7 pH buffer solution saturated with

quinhydrone.

• Replace the electrode.

• Recalibrate; verify that test solutions

are at room temperature and wait

at least 30 seconds after placing

electrode in solution before pressing

S1 EasyCal button.

Signet 2750 DryLoc pH/ORP Sensor Electronics

7

Page 8

10. Ordering Information

Mfr. Part No. Code Description

3-2750-1 159 000 744 In-line Sensor Electronics w/Junction Box

3-2750-2 159 000 745 In-line Sensor Electronics w/Junction Box and EasyCal

3-2750-3 159 000 746 Submersible Sensor Electronics with 15 ft. cable, 3/4 in. NPT threads

3-2750-4 159 000 842 Submersible Sensor Electronics with 15 ft. cable, ISO 7-1/R3/4 threads

Parts and Accessories

Mfr. Part No. Code Description

DryLoc pH Electrodes

3-2724-00 159 001 547 Flat pH Electrode, DryLoc, PT1000, ¾ in. NPT or Signet fi ttings

3-2724-01 159 001 548 Flat pH Electrode, DryLoc, PT1000, ISO 7/1 R¾ or Signet fi ttings

3-2726-00 159 001 555 Bulb pH Electrode, DryLoc, PT1000, ¾ in. NPT or Signet fi ttings

3-2726-01 159 001 556 Bulb pH Electrode, DryLoc, PT1000, ISO 7/1 R¾ or Signet fi ttings

3-2726-HF-00 159 001 551 Bulb pH Electrode, DryLoc, PT1000, HF resistant, ¾ in. NPT or Signet fi ttings

3-2726-HF-01 159 001 552 Bulb pH Electrode, DryLoc, PT1000, HF resistant, ISO 7/1 R¾ or Signet fi ttings

3-2726-LC-00 159 001 559 Bulb pH Electrode, DryLoc, PT1000, Low conductivity, ¾ in. NPT or Signet fi ttings

3-2726-LC-01 159 001 560 Bulb pH Electrode, DryLoc, PT1000, Low conduct., ISO 7/1 R¾ or Signet fi ttings

3-2756-WT 159 000 834 Electrode, pH (glass), DryLoc, bulb, PT1000, wet-tap

3-2756-WTP 159 001 390 Electrode, pH (plastic), DryLoc, bulb, PT1000, wet-tap

3-2764-2 159 000 944 Electrode, pH, DryLoc, fl at, PT1000, differential, 1 in. NPT process connection

3-2766-2 159 000 950 Electrode, pH, DryLoc, bulb, PT1000, differential, 1 in. NPT process connection

3-2774-1 159 000 956 Electrode, pH, DryLoc, fl at, PT1000, ¾

3-2776-1 159 000 960 Electrode, pH, DryLoc, fl at, PT1000, ¾ in. NPT process connection

in. NPT process connection

DryLoc ORP (Redox) Electrodes

3-2725-60 159 001 561 Flat ORP Electrode, 10KΩ ID, ¾ in. NPT or Signet installation fi ttings

3-2725-61 159 001 561 Flat ORP Electrode, 10KΩ ID, ¾ in. ISO 7/1 R¾ or Signet installation fi ttings

3-2757-WT 159 000 835 Electrode, ORP (glass), DryLoc, bulb, 10KΩ ID, wet-tap

3-2757-WTP 159 001 391 Electrode, ORP (plastic), Dryloc, bulb, 10KΩ ID, wet-tap

3-2765-1 159 000 946 Electrode, ORP, DryLoc, fl at, 10KΩ ID, differential, 1 in. NPT process connection

3-2767-1 159 000 952 Electrode, ORP, DryLoc, bulb, 10KΩ ID, differential, 1 in. NPT process connection

3-2775 159 000 957 Electrode, ORP, DryLoc, fl at, 10KΩ ID, ¾ in. NPT process connection

3-2777 159 000 961 Electrode, ORP, DryLoc, bulb, 10 KΩ ID, ¾ in. NPT process connection

Accessories

3-0700.390 198 864 403 pH Buffer Kit

3-2700.395 159 001 605 Calibration kit: included 3 PP cups, cup stand, 1 pint pH 4.01, 1 pint pH 7.00

3-2759 159 000 762 pH/ORP Simulator/System tester

3-2759.391 159 000 764 Adapter cable to connect 2759 and 2750

3-8050-1 159 000 753 Universal Mount Junction Box

3-8050-2 159 000 754 Universal Mount Jct. Box w/EasyCal

3-8050.390-1 159 001 702 Retaining nut Valox

®

3-9900.392-1 159 000 839 Liquid tight connector kit, NPT (1 connector)

3-9900.392-2 159 000 840 Liquid tight connector kit, PG 13.5 (1 connector)

3822-7004 159 001 581 pH 4.01 buffer solution, 1 pint (473 ml) bottle

3822-7007 159 001 582 pH 7.00 buffer solution, 1 pint (473 ml) bottle

3822-7010 159 001 583 pH10.00 buffer solution, 1 pint (473 ml) bottle

3822-7115 159 001 606 20 gram bottle Quinhydrone for ORP calibration

5523-0322 159 000 761 Cable, 3-conductor + shield (blk/red/wht/shld) 22 AWG (per ft)

P31515-0P200 159 000 630 Universal Pipe Adapter PVC

P31515-0C200 159 000 631 Universal Pipe Adapter CPVC

P31515-0V200 159 000 459 Universal Pipe Adapter PVDF

7300-7524 159 000 687 24 VDC power supply, 7.5W, 300 mA

7300-1524 159 000 688 24 VDC power supply,, 15W, 600 mA

7300-3024 159 000 689 24 VDC power supply, 30W, 1.3 A

7300-5024 159 000 690 24 VDC power supply, 50 W, 2.1 A

7300-1024 159 000 691 24 VDC power supply, 100W, 4.2 A

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2750.090 Rev. K 01/13 English © Georg Fischer Signet LLC 2013

Loading...

Loading...