Page 1

Signet 3-2630-X Amperometric Free Chlorine Electrode

Signet 3-2632-X Amperometric Chlorine Dioxide Electrode

*3-2630.090*

3-2630.090

1. Description

The Signet Amperometric Chlorine Electrodes are designed to measure chlorine in fresh, clean water treatment applications.

Free Chlorine electrodes are available in measurement ranges of 0 to 2 ppm, 0 to 5 ppm or 0 to 20 ppm.

Chlorine Dioxide electrodes are available in measurement ranges of 0 to 2 ppm.

Electrodes require the Signet 2650 Amperometric Electronics to output a digital (S3L) signal to the Signet 8630 Chlorine Transmitter

Features:

• Utilizing smart-sensor technology, this electrode incorporates a unique embedded memory chip within the electrode to

• Signet's patented DryLoc® connector provides quick assembly and a secure connection. Gold-plated contacts and an O-ring

• Integrated temperature element for automatic temperature compensation.

• Separate drive electronics (Signet 2650) allow easy electrode replacement without running new cable.

Rev. M 09/13

CAUTION!

1. Follow instructions carefully to avoid personal injury or damage to electrode.

2. Prior to installation or removal:

a. Disconnect fl ow through system.

b. Drain below sensor level.

3. Confi rm chemical compatibility before use.

4. Do not exceed the maximum pressure or temperature specifi cations.

5. Do not alter product construction.

1. Description p.1 5. Maintenance p.2 9. Overview p.5

2. Sensor Preparation p.1 6. Storage and Disposal p.3 10. Troubleshooting p.6

3. Operation p.2 7. Installation p.4 11. Ordering p.7

4. Calibration p.2 8. Mounting Position p.4 12. Technical Data p.8

communicate a wide variety of information to the Signet 2650 electronics and Signet 8630 transmitter. Electrode type,

factory calibration data, service time, chlorine range, high and low pH (with optional Signet pH electrode), temperature limits

and more are stored on the chip. This information is accessible via the Signet 8630 transmitter.

seal ensure a waterproof and reliable interconnect to the Signet 2650 Amperometric Electronics.

English

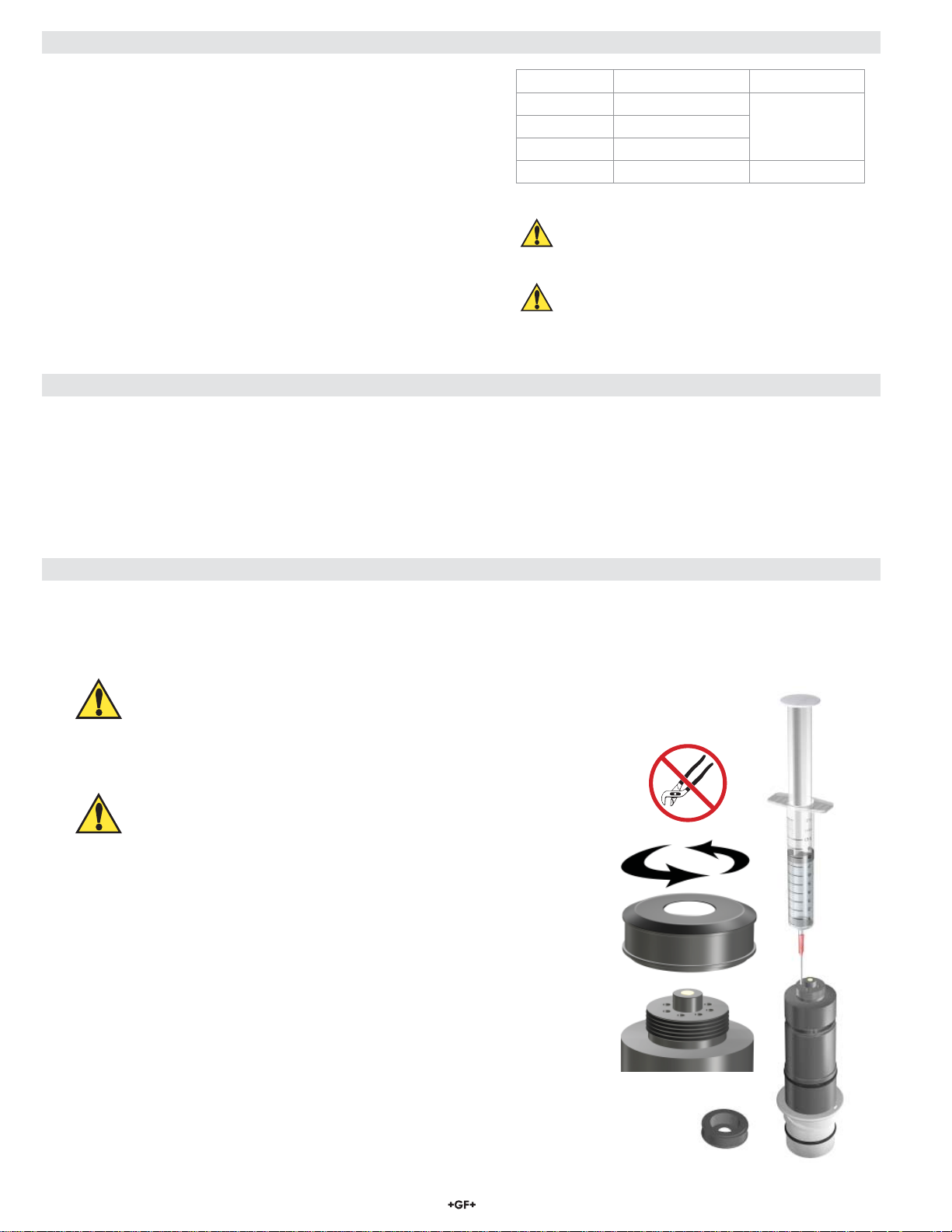

2. Sensor Preparation

• Chlorine sensors are shipped without internal electrolyte solution.

• Prior to installation and supplying power, Chlorine sensors must be fi lled with the appropriate internal electrolyte solution.

• Verify the correct electrolyte solution is utilized with the corresponding sensor.

• Free Chlorine and Chlorine Dioxide sensor require different electrolyte solutions.

Avoid skin or eye contact with electrolyte solution.

Wear rubber gloves and goggles.

* Material Safety Data Sheets (MSDS) are available online at www.gfsignet.com.

CAUTION:

Initial Fill Procedure:

When adding electrolyte, be prepared for an accidental spill.

Working near a sink is recommended.

1. Remove the protective bottle from the end of the electrode

2. Remove the membrane cap from the front of the sensor.

Note: When new sensors are shipped, the membrane cap is not tightened to the sensor

3. Fill supplied syringe with electrolyte solution.

4. Place the electrode on a level surface.

5. Insert syringe needle fully into one of the eight electrode holes while injecting with

electrolyte solution. Slowly injecting the electrolyte solution into the sensor to avoid

introducing air bubbles. The electrode holds approximately 14 milliliters of solution.

Slowly fi ll until solution begins to fl ow out of holes. Do not allow the solution to run

down the electrode and wet the electrical contacts in the DryLoc connector.

6. Slowly screw on the membrane cap fi nger tight. Do not use tools.

To avoid damage and contamination, do not touch the white membrane surface on

the membrane cap.

DO NOT touch the gold tip or the membrane of the sensor.

Page 2

3. Operation

Electrode Range: The electrode must match the type and range of

chlorine concentration to be measured.

Flow Rate:

The electrode must have a stable and constant fl ow of water past its

membrane for accurate measurement. When the sensor is installed

in the Tee fl ow cell 3-3610-2 (159 001 684), the fl ow rate must range

from 37.8 to 75.7 LPH (10 to 20 US g/h).

When the sensor is installed in the Flow Cell Block

3-4630.392 (159 001 690), the fl ow rate range should be

30.24 to 45.36 LPH (8 to 12 US gph).

Sensor Conditioning: 4 hours

A new electrode requires conditioning of 4 hours with the electrode

powered on and water fl owing past the head to generate a

stable reading.

Subsequent start-ups can require an electrode conditioning of up to two hours.

Part Number Chlorine Range Chlorine Type

3-2630-1 0 to 2 ppm (mg/L)

Free chlorine3-2630-2 0 to 5 ppm (mg/L)

3-2630-3 0 to 20 ppm (mg/L)

3-2632-1 0 to 2 ppm (mg/L) Chlorine Dioxide

The electrode should not be used in water

containing surfactants, oils, organic chlorine

or stabilizers such as cyanuric acid.

The maximum allowable operating pressure

must be less than 0.48 bar (7 psi).

Higher pressures will damage the electrode.

4. Calibration

A new chlorine electrode or one that has had the membrane cap changed must be calibrated. Refer to the Signet 8630 Chlorine

Transmitter manual for electrode and instrument calibration information. A diethyl-p-phenylenediamine (DPD) colorimeter test kit

(not included) is required for sensor calibration. A sample is taken and analyzed with the DPD test kit, then this value is entered into

the Signet 8630 transmitter.

• Calibrate after a membrane cap change.

• Check calibration one day after sensor is placed in service.

• Check calibration weekly to monthly depending on process requirements.

5. Maintenance

Verifying the sensors accuracy using the DPD method should be performed to determine if the sensor requires maintenance.

1. Inspect the membrane for dirt or damage. Replace the membrane if its torn or if the gold cathode is visible.

2. If the membrane is dirty clean the membrane by soaking it in 1 - 5% HCL and gently washed with a stream of DI water.

(do not use any mechanical device on the membrane)

Diluted HCl can irritate the eyes and skin, use proper safety equipment.

Do not use surface tension reducing chemicals, detergents or solvents on the membrane.

If a fresh water rinse does not clean the membrane, it will need to be replaced.

Keep spare membrane caps available. Membrane caps carry no warranty.

Avoid skin or eye contact with electrolyte solution.

Wear rubber gloves and goggles.

* Material Safety Data Sheets (MSDS) are available online at

www.gfsignet.com.

Additional caution should be taken when handling the

Chlorine Dioxide electrolyte solution.

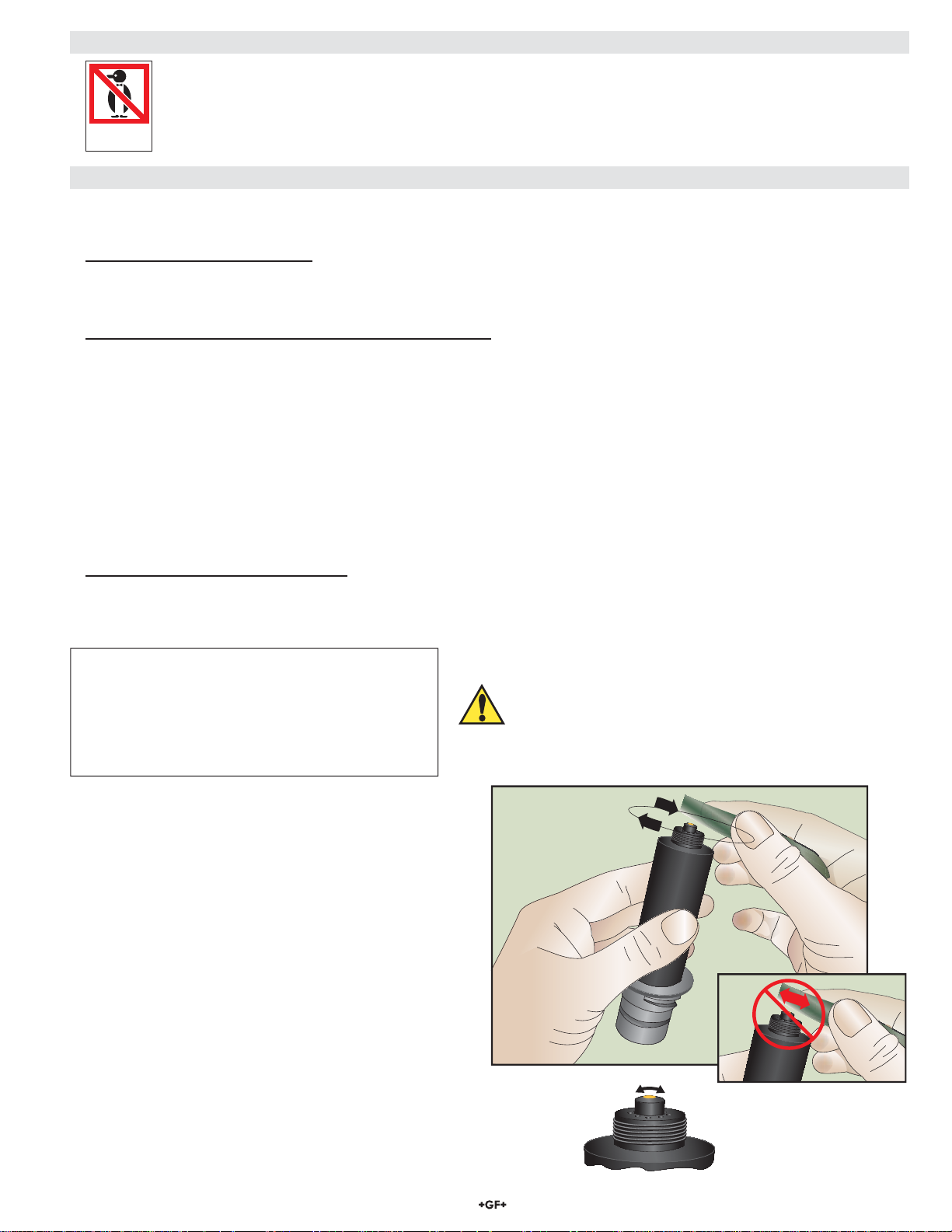

Refi ll Procedure:

When adding electrolyte, be prepared for an accidental spill.

Working near a sink is recommended.

1. Remove the membrane cap from the front of the sensor.

2. Turn the sensor upside down and shake the sensor vigorously to remove the

internal electrolyte.

3. Fill supplied syringe with electrolyte solution.

4. Place the electrode on a level surface.

5.

Insert syringe needle fully into one of the eight electrode holes while injecting with

electrolyte solution. Slowly injecting the electrolyte solution into the sensor to avoid

introducing air bubbles. The electrode holds approximately 14 milliliters of solution.

Slowly fi ll until solution begins to fl ow out of holes. Do not allow the solution to run

down the electrode and wet the electrical contacts in the DryLoc connector.

6. Slowly screw on the membrane cap fi nger tight. Do not use tools.

To avoid damage and contamination, do not touch the white membrane surface

on the membrane cap.

2 263X Series Chlorine Electrodes

Page 3

6. Storage and Disposal

Store electrode between –10 ºC to 60 ºC (–14 ºF to 140 ºF) at a relative humidity that does not exceed 95%.

DO NOT

FREEZE

6.1. Storage of the Sensor

If the sensor or panel assembly is to be removed from service for a period of time the sensor must be properly prepared for storage

and may need to be recommissioned.

Storage periods of 1 week or less:

• Close the drain valve, then close the inlet valve of the fl ow cell, to maintain water inside the fl ow cell to keep the membrane wet.

• If draining the fl ow cell is required, remove the sensor from the cell and the 2650 electronics and store in the shipping bottle with

tap water added.

Storage periods greater than 1 week, but less than 2 months:

• Remove the membrane cap and internal electrolyte solution.

• Rinse the sensor internal chamber with DI water or cold tap water; drain and allow to dry.

• Place the membrane cap back onto the sensor. INSTALL LOOSE, DO NOT COMPLETELY TIGHTEN THE CAP.

WHEN STORED DRY, THE MEMBRANE CAP MUST BE STORED RELAXED AND UNSTRESSED.

• Store sensor DRY in the shipping bottle, DO NOT ADD WATER.

The primary concerns when storing the electrode is membrane dehydration and freezing in extremely cold environments.

Recommissioning Procedure:

1. Fill the sensor with the electrolyte as outlined in Maintenance, Section 3, and install the membrane cap.

2. The sensor will have to be polarized in the fl ow cell with fl owing Chlorinated water before being used.

Note: This may take 30 to 120 minutes before calibration can be performed.

3. If the sensor does not recover after recommission, follow steps 1-10 outlined under

"Storage periods greater than 2 months."

4. If the sensor still fails to work properly, continue with steps 11-17.

Storage periods greater than 2 months:

• If the sensor has been in storage for a long period of time, or used in a chlorine free environment, the sensor may develop

a low slope (output), which may cause the sensor to have a slow response time.

• In this case, the sensor must be reconditioned.

Required to recondition a sensor:

• DI Water

• Beaker (any size available)

• Polishing Sheets (Included in sensor maintenance kit)

• Free Chlorine: Chlorine Bleach (13% concentration)

• Chlorine Dioxide: Aqueous Chlorine Dioxide solution

CAUTION!

Bleach

and Chlorine Dioxide solutions are

very corrosive and

may release dangerous gases if it comes in contact with acids.

• Wear proper protective clothing (gloves and eye protection)

• Avoid contact with skin and eyes

• Observe all warnings on safety data sheets

• Avoid spilling bleach and possible contact with acids

Reconditioning Procedure:

1. Remove the sensor from the 2750-7 electronics.

2. Remove the membrane cap.

3. Place the sensor on a fi rm fl at surface with the gold

cathode pointing upward.

4. Apply a small amount of water to the Blue (Course)

polishing paper (dull side).

5. Polish the gold electrode by moving the paper in a

circular pattern for 30 seconds. DO NOT go back and

forth in a single direction. See Figure 1.

6. Rinse the sensor tip with DI water.

7. Apply a small amount of DI water to the White

(Fine) polishing paper (dull side) and polish the gold

electrode by moving the paper in a circular pattern for

30 seconds. DO NOT go back and forth in a single

direction. See fi gure 1.

8. Rinse the sensor tip with DI water.

9. Top off the sensor with electrolyte and inspect

Figure 1

Curved Surface

membrane for dirt or damage. Replace if necessary.

10. Insert the sensor into the 2650 electronics and apply

power.

(Steps 11-17, See Next Page)

3263X Series Chlorine Electrodes

Page 4

6.1. Storage of the Sensor continued

Reconditioning Procedure Continued:

(Steps 1-10, See Previous Page)

11. Fill beaker with a 12 mm (½ inch) of the appropriate solution.

12. Position or suspend the sensor 0.2 mm to 12 mm (¼ in. to ½ in.) above the appropriate

solution. DO NOT SUBMERGE THE SENSOR. See Figure 2.

13. Apply power to the system.

14. Monitor the nA of the sensor (press the down arrow once on the 8630 transmitter).

The nA reading should start to rise. Response time and nA reading will depend upon the

temperature of the bleach.

15. Once the sensor's nA reading reaches approximately 300-360 nA allow the sensor to

remain in the beaker, suspended over the appropriate solution, for an additional 20 minutes.

• If sensor does not recover quickly, cover the beaker to avoid air contamination.

• Contact the factory for assistance (www.gfsignet.com).

16. After 20 minutes, remove the sensor and install it into the fl ow cell and

restore fl ow to the system.

17. Calibrate the sensor after the system has become stable.

6.2. Disposal

The electrode is not recyclable. Dispose of properly according to local, state and federal guidelines.

7. Installation

Figure 2

Align tab on electrode with notch on

fi tting. Insert until fully seated.

Lubricate O-rings with a non-petroleum

based, viscous lubricant (grease)

compatible with the system.

Do Not Use Lubricant or Sealing Tape on Threads.

Do Not Overtighten. Do Not Use Tools.

8. Mounting Position - PVC Tee

Best

45º or or45º

Flow

4 263X Series Chlorine Electrodes

Good

Flow Direction

Page 5

8. Mounting Position continued

Mount the fl ow cell where the sensor will be easily accessible.

To avoid air bubble entrapment, do not mount with downward fl ow.

NO

Flow

9. Overview

Chlorine in Water

Various forms of chlorine are used to disinfect water. Each form of chlorine has benefi ts and limitations which help determine the

specifi c application. The predominant categories used in disinfection are Free Chlorine, Total Chlorine and Chlorine Dioxide. Free

Chlorine is the sum of chlorine gas (Cl2), hypochlorous acid (HOCl) and hypochlorite (OCl-). Above pH 4.0 all of the molecular

chlorine is converted to HOCl and OCl-. Hypochlorous acid is a more potent disinfectant than hypochlorite and exists in a pH

dependent equilibrium as shown in Figure 3.

Free chlorine also combines with naturally occurring or human-introduced nitrogen compounds in the water to form chloramines, also

known as combined chlorine. Treatment operators introduce ammonia into the water to form monochloramine (NH

(NHCl2) and trichloramine (NCl3). Chloramines are a less effective disinfectant but have a longer residence time than the free chlorine

species. Total chlorine is the sum of free chlorine (Cl2, HOCl and OCl-) and combined chlorine (NH2Cl, NHCl2, NCl3).

Chlorine Measurement by Amperometric Sensors

Signet chlorine sensors are membrane-covered amperometric 2-electrode sensors. A gold or platinum cathode acts as the working

electrode with a silver halide acting as the counter electrode. Depending on the species to be analyzed, a polarization voltage is

applied between the two electrodes. When placed into service, the chlorine species of interest diffuses across the membrane and

is reduced at the cathode surface. For the case of total chlorine, the analyte reacts with the fi ll solution to produce an intermediate,

which is subsequently reduced at the cathode surface. At the same time, the silver anode is oxidized to form a silver halide. The

current generated at the cathode is proportional to the rate of diffusion through the membrane and the concentration of chlorine in the

sample. The current from the cathode to the anode is conditioned, digitized and transmitted by the associated electronics.

Cl), dichloramine

2

pH Compensation for Free Chlorine

Amperometric free chlorine sensors measure only hypochlorous

acid. As noted in the text above and in Figure 3, the ratio

of hypochlorous acid and hypochlorite is pH dependent. In

many applications the process pH is relatively stable and no

correction is needed. However, where the pH of the water

changes signifi cantly, accurate free chlorine measurement

requires pH compensation. With the addition of a pH sensor, the

Signet 8630 transmitter will automatically compensate the free

chlorine reading for changes in pH.

Automatic pH Compensation and Free Chlorine

In many applications, the process pH does not signifi cantly

fl uctuate and only a chlorine sensor and instrument are

necessary for accurate chlorine measurement.

It is when the pH varies that free chlorine concentration can

not accurately be determined without the use of automatic pH

compensation.

The addition of the Signet 3-2724-00 (159 001 545) pH

electrode along with its 3-2750-7 (159 001 671) preamplifi er

to the system makes pH compensation extremely easy and

automatic even with wide fl uctuations or high pH.

See Figure 4 for pH variation recommendations.

Example:

If the pH nominal value is 7.5 and the pH variation is ±0.2 then

automatic pH compensation is recommended.

If the pH nominal value is 7.0 and the pH variation is ±0.2 then

automatic pH compensation is not required.

100

90

80

70

60

50

40

30

% free chlorine

20

10

0

5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0

HOCl

OClØ

±0.3

±0.2

pH variation

±0.1

0

6.5 7.0 7.5 8.0 8.5 9.0

Automatic pH compensation recommended

=

in ranges within shaded area

pH at 25 °C

Sample pH

Figure 3

Figure 4

5263X Series Chlorine Electrodes

Page 6

10. Troubleshooting

Transmitter error messages related to calibration are detailed in the Signet 8630 Chlorine Transmitter operation manual.

Problem Possible Causes Remedies

Condition for 4 hours minimum prior to initial

calibration

Sensor cannot be calibrated.

Output is higher than DPD test

(out of range).

Sensor conditioning time too short

Interference from contaminants See technical data

Membrane cap damaged Replace cap and recondition

DPD chemicals bad Use fresh reagents

pH outside of working range See technical data

Sensor cannot be calibrated.

Output is lower than DPD test.

Sensor output very low

Unstable output from sensor

Sensor conditioning time too short

Chlorine content too low

Low fl ow rate Check to make sure fl ow rate is suffi cient

Air bubbles on electrode membrane

Low or no electrolyte in electrode Fill electrode with electrolyte

Organic chlorination agents present in water See technical data

Surfactants in water Remove surfactants and replace cap

Membrane cap coated Clean or replace membrane cap

Membrane cap loose Tighten or replace membrane cap

pH outside working range. See technical data

Sensor conditioning time too short

Chlorine content too low Add chlorine to validate

Only bound chlorine present. No free chlorine Check for chloramine with appropriate DPD test

Electrode not making good contact with electronics Inspect and reconnect

Air bubbles on electrode membrane

Membrane damaged

Electrode not making good contact with electronics Inspect and reconnect

Non-sensor problem

Condition for 4 hours minimum prior to initial

calibration

DPD value must be greater than 0.5 ppm to

calibrate

Inspect visually. Tap to remove bubbles. Mount

at an angle.

Condition for 4 hours minimum prior to initial

calibration

Inspect visually. Tap to remove bubbles. Mount

at an angle.

Replace membrane. Condition sensor for at

least 2 hours and recalibrate.

Check 3-2650 Electronics connection to

electrode (see 3-2650 manual for instructions).

Make sure connections are dry. Check

instrument hookup.

6 263X Series Chlorine Electrodes

Page 7

11. Ordering Information

Mfr. Part No. Code Description

3-2630-1 159 001 746 Free Chlorine electrode, 0 to 2 ppm (mg/L)

3-2630-2 159 001 662 Free Chlorine electrode, 0 to 5 ppm (mg/L)

3-2630-3 159 001 747 Free Chlorine electrode, 0 to 20 ppm (mg/L)

3-2632-1 159 001 767 Chlorine Dioxide electrode, 0 to 2 ppm (mg/L)

Accessories and Replacement Parts

Mfr. Part No. Code Description

3-2630.391 159 001 674 Free Chlorine electrolyte, 30 mL

3-2632.391 159 310 160 Chlorine Dioxide electrolyte solution, 30 mL

3-2630.392 159 001 675 Free Chlorine replacement PVDF membrane (1) (sensors sold prior to Nov 1, 2012)

3-2630.394 159 310 164

3-2630.396 159 001 676 Free Chlorine maintenance kit - (2) electrolyte, (2) PVDF membranes, and Polishing Paper

3-2630.398 159 310 166 Free Chlorine Sensor maintenance kit - (2) electrolyte, (2) PTFE membranes, (2) Silicone Bands,

3-2632.398 159 310 165 Chlorine Dioxide maintenance kit - (2) electrolyte, (2) PTFE membranes, (2) Silicone Bands, and

3-2600.510 159 500 422 Silicone Band, Chlorine electrode

Free Chlorine and Chlorine Dioxide Replacement PTFE membrane (1) (sensors sold after Nov 1, 2012)

(sensors sold prior to Nov 1, 2012)

and Polishing Paper (sensors sold after Nov 1, 2012)

Polishing Paper

7263X Series Chlorine Electrodes

Page 8

12. Technical Data

Dimensions

25.15 mm (.99 in.)

General

Polarization Source:

Signet 2650 Amperometric Electronics

Compatible Flow Cells:

Signet 3-3610-1 (159 001 683)

Signet 3-3610-2 (159 001 684)

Signet 3-4630.392 (159 001 690)

Mounting:

Signet DryLoc connection

Materials:

CPVC

Free Chlorine (prior to Nov 1, 2012):

Membrane material: PVDF

Free Chlorine (after to Nov 1, 2012) and Chlorine Dioxide:

Membrane material: PTFE

Free Chlorine and Chlorine Dioxide:

O-ring material: FPM

Working electrode: Gold

Counter reference electrode: Silver halide

Wetted Materials:

PVC, PVDF or PTFE, FPM, Nylon, Silicone

Performance

Electrode:

Repeatability: ± 0.08 ppm (mg/l) or 3% of selected

range whichever is less

Free Chlorine Slope: 10 to 60 nA/ppm (mg/l) @ 25 ºC

Chlorine Dioxide Slope: 40 to 200 nA/ppm (mg/l) @ 17 ºC

Response time, T90: < 2 minutes

System: (including electronics and instrument)

Accuracy: < ±3% of electrode signal after calibration

Resolution: ≤ 0.5% of electrode range

Sensor Conditioning:

New, fi rst start-up: 4 hours maximum before calibration

Subsequent start-ups: 2 hours maximum

Temperature Element:

PT1000

74.4 mm (2.93 in.)

26.4 mm (1.04 in.)

109.2 mm (4.3 in.)

Operational Ranges and Limits

Free Chlorine:

Range: 3-2630-1: 0 to 2 ppm (mg/L)

3-2630-2: 0 to 5 ppm (mg/L)

3-2630-3: 0 to 20 ppm (mg/L)

pH Operating Range:

5.5 pH to 8.5 pH

Chlorine Dioxide:

Range: 3-2632-1: 0 to 2 ppm (mg/L)

pH Operating Range:

Maximum

Operating

4.0 pH to 11 pH

T emperature:

0 °C to 45 °C (32 °F to 113 °F)

Maximum Operating Pressure:

Membrane: 0.48 bar @ 25 °C (7 psi @ 77 °F)

Flow Velocity Across Membrane Surface:

Minimum: 15 cm/s (0.49 ft/s)

Maximum: 30 cm/s (0.98 ft/s)

Free Chlorine Cross Sensitivity:

Chlorine Dioxide, ozone, bromine

Chlorine Dioxide Cross Sensitivity:

Free Chlorine, ozone

Chemical Compatibility:

< 50% ethanol/water, < 50% glycerol/water

Environmental Requirements

Storage Temperature (dry):

-10 ºC to 60 ºC (-4 ºF to 140 ºF)

System Temperature:

-10 ºC to 60 ºC (-4 ºF to 140 ºF)

Relative Humidity:

0 to 95% indoor/outdoor non-condensing to rated ambient

Standards and Approvals

CE, WEEE

Manufactured under ISO 9001

RoHS Compliant

China RoHS (Go to www.gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2630.090 Rev. M 09/13 English © Georg Fischer Signet LLC 2013

Loading...

Loading...