Page 1

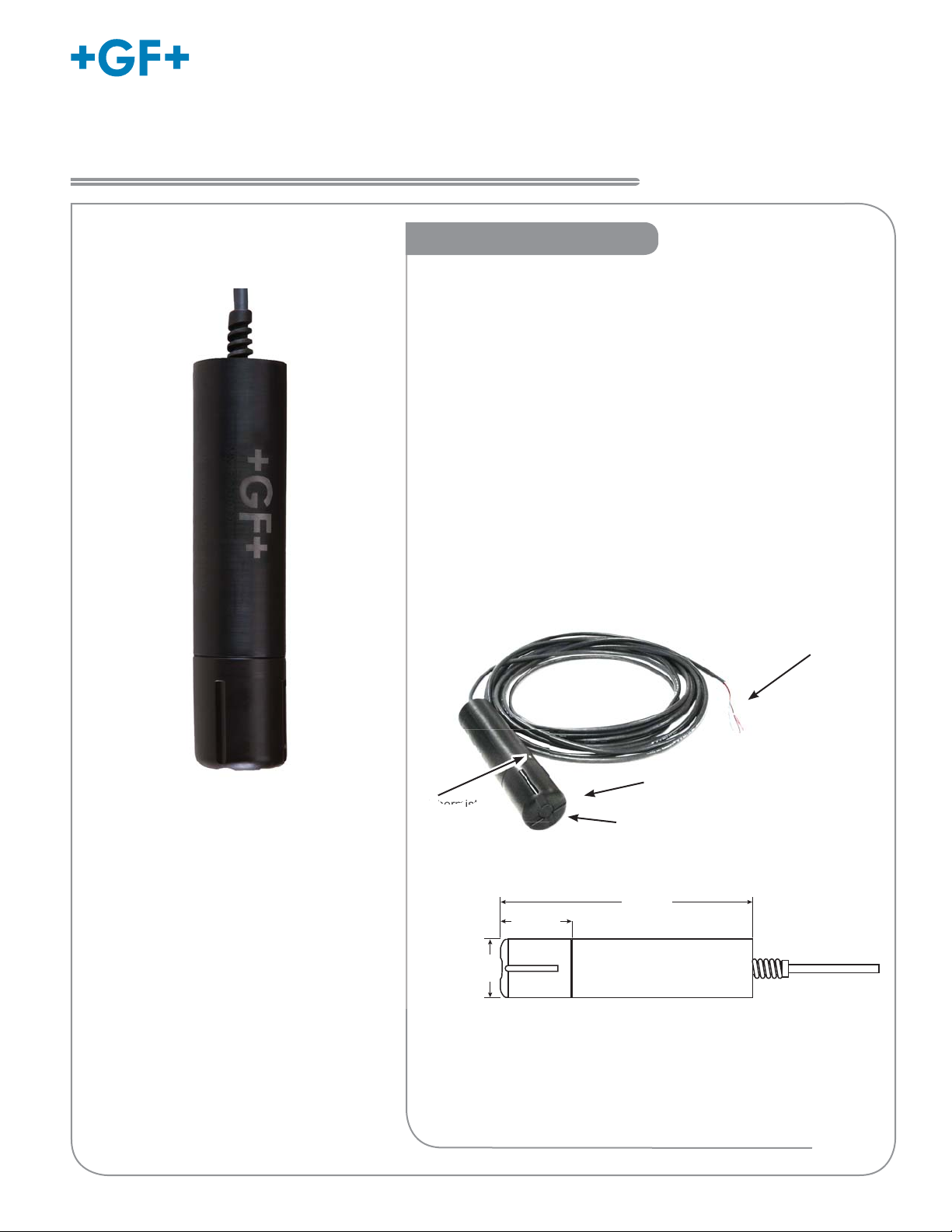

Signet 2610 Process Optical Dissolved Oxygen Sensor

TheTrmi

sto

r

*3-2610.090*

3-2610.090 Rev. C 08/13

Introduction

System Description

Your new RDO® Pro is a rugged, reliable sensor designed to

deliver accurate dissolved oxygen (DO) data across a wide

measuring range while reducing maintenance costs. It features

the latest optical technology for DO measurement.

The RDO Pro system is available in two versions. The 3-2610-31

has 4 to 20mA current loop output, Modbus RS485, and SDI-12

connectivity. The 3-2610-41 includes S3L communications to

support both the 8900 and 9900 Signet products in place of the

SDI-12 output.

The RDO Pro system consists of the following:

English

Operator's Manual

• 10 m (32.8 ft.) cable with stripped and tinned ends

• Black sensor body with removable nose cone

• Optical DO sensing cap

• Titanium thermistor

Cable end, stripped and tinned

Nose cone

Thermistor

Sensor cap

(not visible)

Dimensions

20.3 cm

68.6 mm

(2.7 in.)

43.7 mm

(1.72 in.)

(8.0 in.)

Serial Numbers

The instrument part number, code number and serial number is

engraved on the side of the unit.

RDO is a registered trademark of In-Situ® Inc., Fort Collins, CO USA

Page 2

Introduction

Unpacking the Sensor

Sensor

Shipping/Storage sleeve

Dust cap

Nose cone

1. Remove the RDO

®

sensor from the box and other

packaging materials.

2. Unscrew the nose cone from the sensor and

remove the red protective dust cap from the

sensor. Save the dust cap for later use.

3. Remove the sensor cap from its shipping/storage

sleeve.

4. Align the two lines on the cap with the fl at part of

the sensor and fi rmly press (DO NOT TWIST) the

cap onto the sensor until it seals over the probe

body.

• CAUTION: Twisting the sensor cap can

permanently damage both the cap and the

sensor.

• Avoid allowing moisture, including atmospheric

humidity, inside the cap. Keep the cap in its

sealed packaging until you are ready to install

it. Install promptly. Make sure that O-ring

grooves are dry and the O-ring is not rolled or

pinched inside the cap.

• The cap's lifetime is 1 year after the fi rst

reading has been taken. Install by the date

printed on the packaging.

Align flat side of the tip

with lines on cap

5. Reattach the nose cone

Calibration

Calibration is not required. The unit, as shipped from

the factory, will measure within 2% of reading for the

life of the sensor cap.

Replacing the sensor cap will keep the reading within

2% accuracy.

2

2610 DO Sensor

Page 3

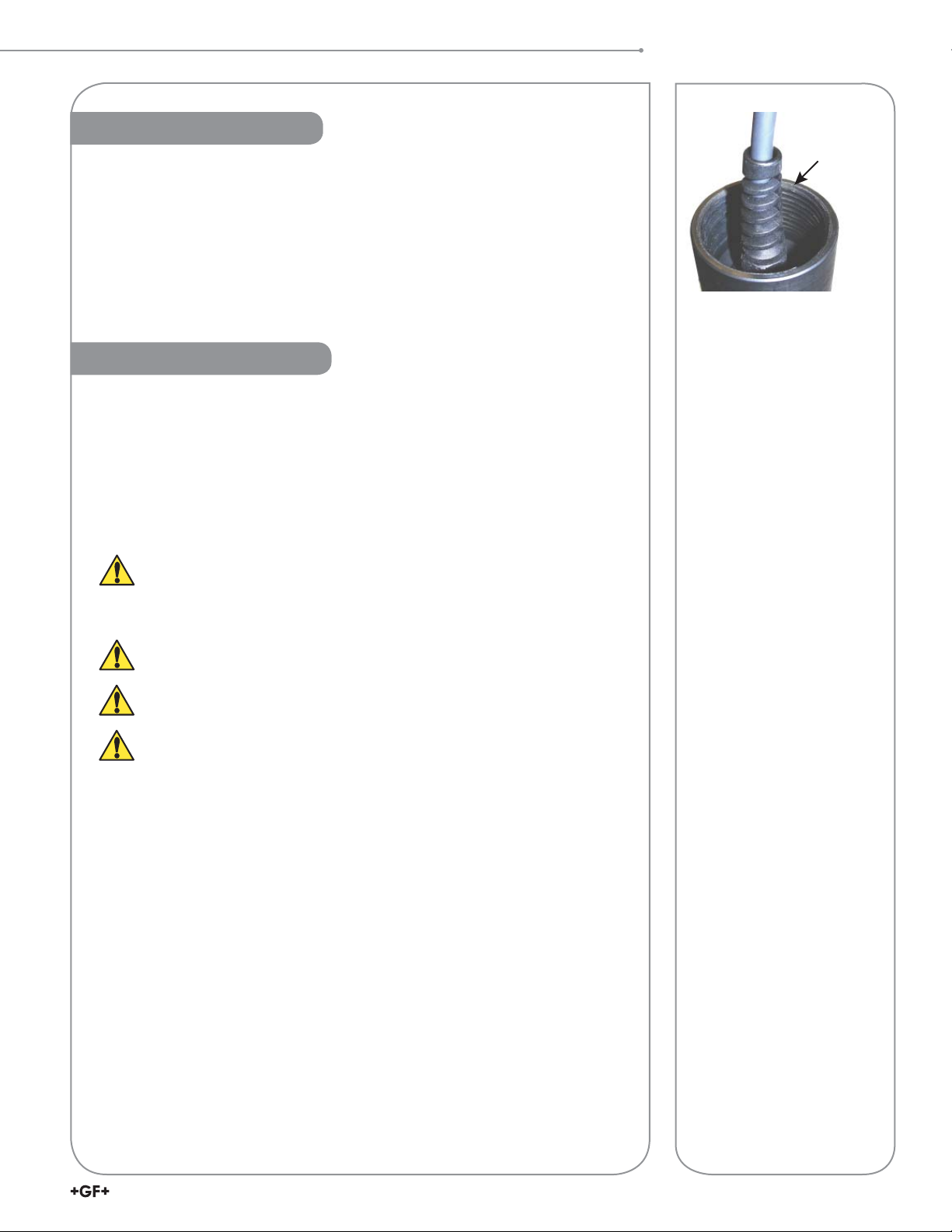

Sensor Deployment

The cable end of the RDO® Pro is internally threaded (1¼ - 11½ NPT) and can

be attached to a externally threaded pipe.

When deployed, make sure that the nose cone and thermistor are completely

submerged.

Care and Maintenance

Cleaning the Sensor Cap

1. Leave the cap and nose cone on the sensor!

2. Rinse the sensor with clean water from a squirt bottle or spray bottle.

3. Gently wipe with a soft-bristled brush or soft cloth if biofouling is present.

Use Alconox® to remove grease.

4. If extensive fouling or mineral build-up is present, soak the cap end in

vinegar for 15 min., then soak in deionized water for 15 min.

Sensor Deployment

1¼ in. NPT

with 10 m cable

Do not use organic solvents - they will damage the foil.

Do not remove the cap from the sensor prior to brushing.

Cleaning the Optical Window

Perform only when changing the cap. See full instructions in the sensor

replacement cap kit.

Do not wet the lens area with water or any solution.

Remove the cap and gently wipe the window with the supplied lens wipe.

Use only the supplied lens wipe for cleaning. Do not use any other wipe

or material.

Cleaning the Sensor Body

With the sensor cap installed on sensor, gently scrub sensor body with a softbristled brush or nylon dish scrubber. Use Alconox to remove grease or other

matter. Soak in vinegar and deionized (DI) water to remove mineral deposits or

extensive fouling as in step 4, above.

Cap Storage

• Prior to installation: Store in factory supplied container.

• Installed: Keep or store in the calibration chamber with the storage cap

attached and a few drops of clean water.

32610 DO Sensor

Page 4

Care and Maintenance

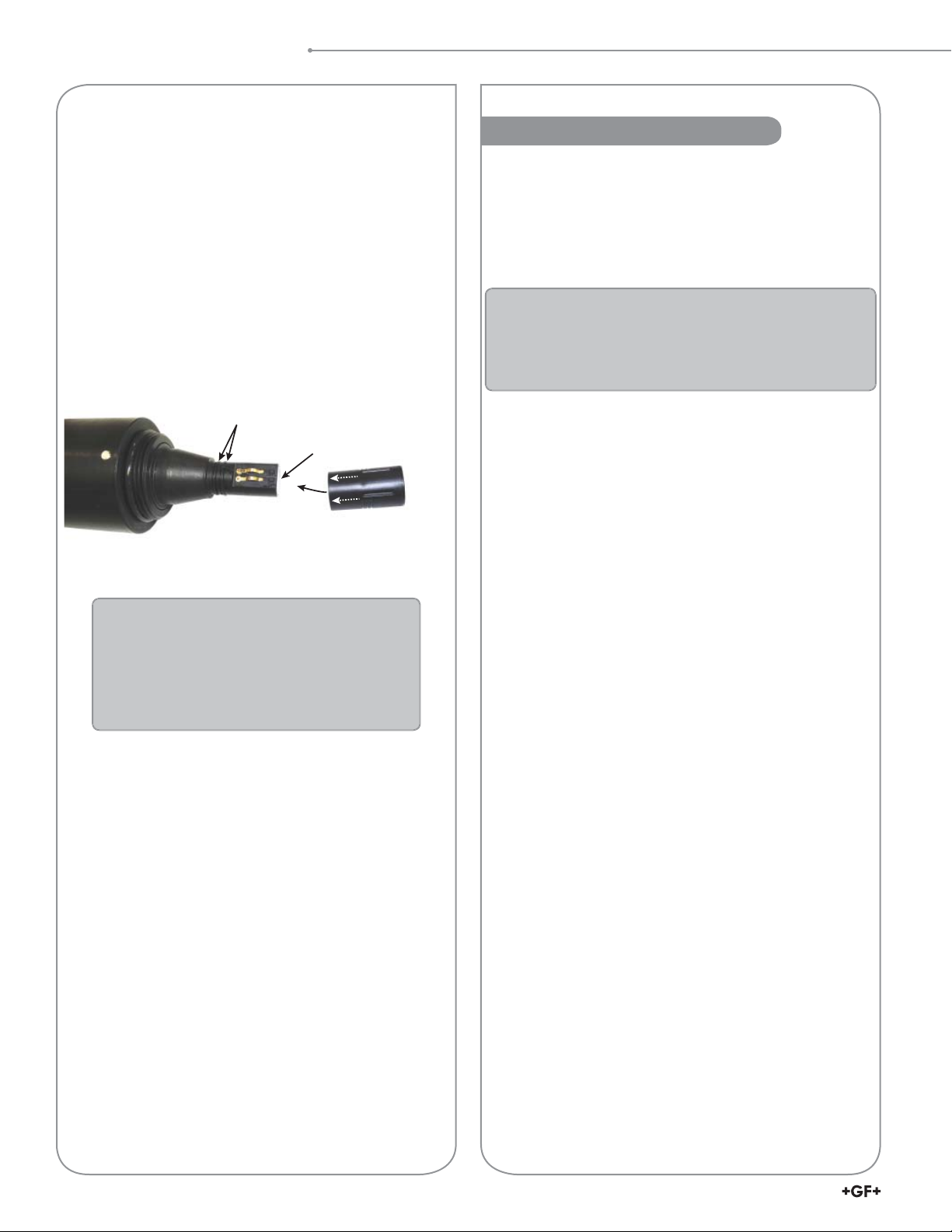

Sensor Cap Replacement

Replace the Sensor Cap

The sensor cap has a 1-year life after the instrument

takes its fi rst reading. Install the cap by the date

printed on the package. Replacement caps are

available from Georg Fischer, part number 3-2610.392

(159 310 122).

Avoid allowing moisture, including atmospheric humidity,

inside the cap. Keep the cap in its sealed package until

you are ready to install it. Install promptly. Make sure

that O-ring grooves are dry and that the O-rings are not

rolled or pinched inside the cap.

Lightly coat with lubricant

Install 2 O-rings

Clean lens and allow to dry

Replace cap in

a dry environment

Sensor Cap Replacement Kit Contents:

• Sensor cap

• O-rings (2)

• O-ring lubricant

• Lens wipe

• Instruction sheet

1. Pull the used sensor cap off of the sensor. DO

NOT TWIST!

2. Remove the existing O-rings from the sensor.

3. Use a lint-free cloth to remove any moisture from

the sensor body. NOTE: Make sure that the O-ring

grooves are dry. Avoid touching or cleaning the

lens with anything other than the supplied lens

wipe.

4. Use your fi nger to apply a thin layer of lubricant

around the O-ring grooves. Place the O-rings on

the sensor. NOTE: Do not transfer lubricant to the

lens or sensor pins.

5. Clean the lens on the sensor with the wipe

provided in the kit and allow to dry thoroughly.

Inspect for scratches or dirt.

6. Remove the new cap from its sealed package.

7. Align the arrow on the cap with the index mark on

the sensor and press it fi rmly until it seals over the

probe body. DO NOT TWIST. Make sure that the

O-rings are not pinched or rolled between the cap

and sensor.

8. Replace the nose cone on the sensor.

4

2610 DO Sensor

Page 5

Wiring and Set Up

Wiring and Set Up

3-2610-31 to 8900 Set Up

1. Connect the 8058, 2610-31, and 8900 as shown in the diagram.

2. Press and hold ENTER key for 5 seconds.

3. The display should fl ash “System Setup”.

4. Press ENTER key.

5. Scroll to the desired channel for Dissolved

Oxygen.

6. Press the ► key.

7. Enter the password.

8. Repeatedly press the ▼ key until the lower

line of the display reads “Other (4-20)”.

9. Press ENTER key.

10. The 8900 will warn that “Channel Data will

be Reset. Are you sure?” Press the ▼ key

so that “Yes” is fl ashing and press ENTER

key.

11. Simultaneously press the▲ and ▼ keys to

return to the Menu Directory.

12. Press the ▼ key to select the “Channel

8900 Sensor Inputs

6

7

BLACK (5 VDC)

8

RED (S

9

WHITE (GND)

10

11

12

13

14

3

L)

8058-2

+GF+ SIGNET

3 2 1

6 5 4

Loop1

PWR

Loop2

PWR

S L

DATA

N/C

7 8 9

3

Settings” menu and press ENTER key to

select.

13. Use the ▼ key to select the channel used

in step 5.

14. Press the ► key to change the label and press ENTER when done.

15. Press the ▼ key to select the

abbreviation.

16. Press the ► key to change the

label and press ENTER when

done. Press the ▼ key to select

the Units.

Regulated

Power Supply

24 VDC

V–

V+

BLACK

SHIELD

(no connection)

RED

4-20 mA

Input

4-20 mA input S3L Output

17. Press the ► key to change

the Units. The 2610 shipped

with default units of mg/L or

ppm, either can be used. Press

ENTER when completed.

DO Sensor

3-2610-31

GREEN

BLUE

WHITE

BROWN

No connection

18. Press the ▼ key to select the 4

mA Set Point.

19. Press the ► key to change the set point. By default the 4 mA set point for the 2610 is 0.0. Press the ENTER

key when complete.

20. Press the ▼ key to select the 20 mA Set Point.

21. Press the ► key to change the set point. By default the 20 mA set point for the 2610 is 20.0. Press the

ENTER key when complete.

22. Press the ▼ key to select the Decimal location.

23. Press the ► key and change the decimal position if desired. Press ENTER when complete.

24. Simultaneously press the ▲ and ▼ keys to exit out of the channel menu.

25. Continue programming other options in the 8900 or simultaneously press the ▲ and ▼ keys to return to the

View Mode.

+GF+

BLACK

BROWN

Signet 8058 i-Go™

4-20 mA to S

8058-1

BLACK

BROWN

RED

RED

BLACK

3

L Converter

DO

3-2610-31

No connection

DO

3-2610-31

No connection

+

24 VDC

Regulated

Power Supply

-

L

3

S

Output

(no connection)

Sensor

Sensor

BLACK

RED

WHITE

SHIELD

1

2

6

7

8

9

10

11

12

13

14

8900 Sensor Inputs

52610 DO Sensor

Page 6

Wiring and Set Up

3-2610-41 to 8900 Set Up

The 3-2610-41 Optical Dissolved Oxygen Sensor with S3L was designed to emulate a 4 to 20 mA current

input device, e.g., Signet 3-8058, on the 8900 controller. This allows the 3-2610-41 to be backward

compatible with all existing 8900 controllers.

1. Connect the 3-2610-41, and 8900 as shown in the diagram

NOTE: The wiring of the 3-2610-41 is non-standard:

• Red wire is connected to 12 to 24 VDC

• White wire is connected to S3L Data

• Black wire is connected to VDC Ground

• A jumper wire must be connected between the VDC Ground and S3L Gnd.

2. Press and hold Enter key for 5 seconds. The display will read “System Setup”.

3. Press Enter key.

4. Scroll to the channel that will be dissolved oxygen.

5. Press the ► key.

6. Enter the password.

7. Repeatedly press the ▼ key until the lower

3-2610-41

line of the display reads “Other (4-20)”.

8. Press Enter key.

9. The 8900 will warn that “Channel Data will

3-2610-41

be Reset. Are you sure?” press the ▼ key so

that “Yes” is fl ashing and press Enter key.

10. Simultaneously press the ▲ and ▼ keys to

return to the Menu Directory.

11. Press the ▼ key to select the menu “Channel

Settings” and press Enter key to select.

12. Use the ▼ key to select the channel used in

step 4.

13. Press the ► key to change the label and

press Enter when done.

14. Press the ▼ key to select the abbreviation.

15. Press the ► key to change the label and

press Enter when done.

16. Press the ▼ key to select the Units.

17. Press the ► key to change the Units. The

No Connection:

Green

Blue

Brown

I/O Module 3-8900.401-X

Frequency

Frequency

Input 2

Input

Input

Freq. Input (Red)

1

Freq. Input 2 (Red)

OR

S3L

Input

2

GND (White/Shield)

S3L

1

GND (White/Shield)

Analog Output 1

(if applicable)

Analog Output 2

(if applicable)

+5VDC (Black)

GND (Shield)

+5VDC (Black)

+5VDC (Black)

2610 shipped with default units of mg/L, or

ppm, either can be used. Press Enter when

completed.

18. Press the ▼ key to select the 4mA Set Point.

19. Press the ► key to change the set point. By default the 4mA set point for the 2610 is 0.0. Press the Enter key

when complete.

20. Press the ▼ key to select the 20mA Set Point.

21. Press the ► key to change the set point. By default the 20 mA set point for the 2610 is 20.0. Press the Enter

key when complete.

22. Press the ▼ key to select the Decimal location..

23. Press the ► key and change the decimal position if desired. Press Enter when complete.

24. Simultaneously press the ▲ and ▼ keys to exit out of the channel menu.

25. Continue programming other options in the 8900 or simultaneously press the ▲ and ▼ keys to return to

View Mode.

3

S L (Red)

3

S L (Red)

Channel 1

Channel 2

1

2

3

4

5

6

7

8

9

10

11

+

12

-

13

+

14

-

White

Black

Red

POWER

DC ONLY

SENSOR INPUTS

COMM PORT /

OUT 2 OUT 1

Red

Black

OUT 4 OUT 3

3-8900

V+

24 VDC

Regulated

V-

Power Supply

C

N

L

+

-

+

-

+

-

NO

NC

NO

NC

C

RELAY 2 RELAY 1

C

NO

NC

NO

NC

C

6

2610 DO Sensor

Page 7

3-2610-31 to 9900 Set Up

Wiring and Set Up

1. Wire the 9900, 2610-31, and 8058 as shown in the diagrams.

BLACK

RED

WHITE

SHIELD

9900 S3L Inputs9900 Power Inputs

SHLD

DATA

GND

V+

2. On the 9900 press and

hold the ENTER key for 2

seconds.

3. Press the ▼ key to select the

INPUT menu item.

4. Press the ENTER key to

access the INPUT menus.

5. Press the▲ key to select the

TYPE menu item.

6. Press the ► key to change

the TYPE selection.

7. Enter the password code.

8. Repeatedly press the ▼ key

until the “4-20 mA INPUT”

24 VDC

Regulated

Power Supply

DO Sensor

3-2610-31

PWR+

PWR–

LOOP+

LOOP–

V–

V+

BLACK

SHIELD

(no connection)

RED

BROWN

GREEN

BLUE

WHITE

4-20 mA

+GF+

Input

4-20 mA input S3L Output

No connection

Signet 8058 i-Go™

4-20 mA to S

8058-1

3

L Converter

3

Output

L

S

menu item is fl ashing and

then press the ENTER key.

9. The 9900 will prompt “All

settings will be reset”, press the

▲ key to select “Yes” and then press the ENTER key.

10. The 9900 will return to the View Mode display.

9900 Power Inputs

PWR+

PWR–

LOOP+

LOOP–

RED

BLACK

BROWN

DO

Sensor

3-2610-31

1

11. Press and hold the ENTER key for 2 seconds.

RED

BLACK

No connection

+

24 VDC

Regulated

Power Supply

-

12. Press the ▼ key to select the INPUT menu item.

13. In the NAME menu item, press the ► key to change the

displayed name from “4-20 mA INPUT” to a more descriptive

name (e.g., "DISSOLVED O2") and press ENTER when done.

14. Press the ▼ key to select SENSOR UNIT menu item.

15. Press the ► to change the label from UNIT to MG/L or PPM

and press ENTER.

16. Press the ▼ key and ensure the 4 mA VALUE is set to 0.0000.

17. Press the ▼ key and change the 20 mA VALUE from

9900 S

V+

8058-2

3

L Inputs

DATA

GND

SHLD

+GF+ SIGNET

3 2 1

6 5 4

Loop1

PWR

Loop2

PWR

DATA

N/C

7 8 9

3

S L

5.0000 to 20.000 and press ENTER.

18. Press both the▲ and ▼ keys simultaneously to return to

the Menu.

19. Press the ▼ to select the LOOP menu and press ENTER.

RED (S

BLACK (5 VDC)

3

L)

WHITE (GND)

20. Set the 4 MA SET POINT to your desired value. The 2610 is

factory set for a 0 to 20 mg/L output. Press ENTER when done.

21. Press the ▼ key to select the 20 MA SET POINT and set to your desired value. The 2610 is factory set for a

0 to 20 mg/L output. Press ENTER when done.

22. Press both the ▲ and ▼ keys simultaneously to return to the Menu.

23. Press the ▼ key twice to select the OPTION menu and press ENTER.

24. Press the ▼ key twice to select the SET BAR MIN option. Change this option if desired. The 2610 is factory

set for a 0 to 20 mg/L output. Press the ENTER key when done.

25. Press the ▼ key to select the SET BAR MAX option. Change this option if desired. The 2610 is factory set for

a 0 to 20 mg/L output. Press ENTER when done.

26. Press both the▲ and ▼ keys simultaneously to return to the Menu.

27. ENTER the other menus and set the unit as desired for your application.

28. Press both the▲ and ▼ keys simultaneously to return to the View Menu.

Technical Notes:

• The cable length from the 8058 to the 9900 must not exceed 60 m (200 ft).

• When using the 8058-2 with the 9900, connect the loop source to 8058-2 Channel 1 input

ONLY as shown in the fi gure.

• See the 8058 manual for more information.

72610 DO Sensor

Page 8

Wiring and Set Up

3-2610-41 to 9900 Set Up

The 3-2610-41 Optical Dissolved Oxygen Sensor with S3L was designed to emulate a 4 to 20 mA current input

device, 8058, on the 9900 controller. This allows the 3-2610-41 to be backward compatible with all existing 9900

controllers.

1. Wire the 9900 and 3-2610-41 as shown in the diagram.

9900 S3L Inputs

NOTE: The wiring of the 3-2610-41 is nonstandard:

• 3-2610-41 Red wire is connected to 12 to 24 VDC

• 3-2610-41 White wire is connected to S3L Data

• 3-2610-41 Black wire is connected to VDC Ground

• A jumper wire must be connected between the VDC

Ground and S3L Gnd.

2. On the 9900 press and hold the ENTER key for 2

seconds.

3. Press the ▼ key to select the INPUT menu item.

4. Press the Enter key to access the INPUT menus.

24 VDC

Regulated

Power Supply

V+

RED

BLACK

V-

SHIELD

RED

5. Press the ▲ key to select the TYPE menu item.

6. Press the ► key to change the

TYPE selection.

3-2610-41

7. Enter the code.

8. Repeatedly press the ▼ key until the “4-20 mA INPUT”

menu item is fl ashing and then press ENTER.

9. The 9900 will prompt “All settings will be reset”. Press the ▲ key to select “Yes” and then press ENTER.

10. The 9900 will return to the View Mode display.

11. Press and hold the ENTER key for 2 seconds.

12. Press the ▼ key to select the INPUT menu item.

13. In the NAME menu item, press the ► key to change the displayed name from “4-20 mA INPUT” to a more

descriptive name (e.g., "DISSOLVED O2") and press ENTER when done.

14. Press the ▼ key to select SENSOR UNIT menu item.

15. Press the ► to change the label from UNIT to MG/L or PPM and press ENTER.

16. Press the ▼ key and ensure the 4 mA VALUE is set to 0.0000.

17. Press the ▼ key and change the 20 mA VALUE from 5.0000 to 20.000 and press ENTER.

18. Press both the ▲ and ▼ keys simultaneously to return to the Menu.

19. Press the ▼ to select the LOOP menu and press ENTER.

20. Set the 4 MA SET POINT to your desired value. The 2610 is factory set for a 0 to 20 mg/L output. Press

ENTER when done.

21. Press the ▼ key to select the 20 MA SET POINT and set to your desired value. The 2610 is factory set for a 0

to 20 mg/L output. Press ENTER when done.

22. Press both the ▲ and ▼ keys simultaneously to return to the Menu.

23. Press the ▼ key twice to select the OPTION menu and press ENTER.

24. Press the ▼ key twice to select the SET BAR MIN option. Change this option if desired. The 2610 is factory

set for a 0 to 20 mg/L output. Press ENTER when done.

25. Press the ▼ key to select the SET BAR MAX option. Change this option if desired. The 2610 is factory set for

a 0 to 20 mg/L output. Press ENTER when done.

26. Press both the ▲ and ▼ keys simultaneously to return to the Menu.

27. Enter the other menus and set up the unit as desired for your application.

28. Press both the ▲ and ▼ keys simultaneously to return to the View Menu.

SHLD

DATA

GND

V+

9900 Power Inputs

RED

BLACK

WHITE

Blue

Green

No connection

Brown

PWR+

PWR–

LOOP+

LOOP–

9900 Generation III supports 3-2610-41 direct connection.

Please refer to the 9900 product manual for setup instructions.

8

2610 DO Sensor

Page 9

Wiring and Set Up

3-2610 to 4 to 20 mA Set Up

Red

Black

Brown

Green

Blue

White

OR

Programmable

Logic Controller

NOTE: The S

3-2610-31

or 3-2610-41

+ In

- In

Chart

Recorder

3

L and Modbus connectors can

be used simultaneously with the 4 to 20 mA.

3-2610 to Modbus Set Up

3-2610-31

or 3-2610-41

NOTE: The S

be used simultaneously with the 4 to 20 mA.

Modbus programming manual is available

on the web at www.gfsignet.com.

3

L and Modbus connectors can

Red

Black

Blue

Green

Brown

White

No connection

+ In

PLC

No connection

Programmable Logic Controller

Regulated

+

Power Supply

–

12 to 24 VDC

4 to 20 mA

Input

- In

Regulated

+

Power Supply

–

12 to 24 VDC

+

Modbus

RS485

PLC

–

Modbus

RS485

or

Other Modbus Master

92610 DO Sensor

Page 10

Notes

10

2610 DO Sensor

Page 11

Specifi cations

General

Sensor type: .....................................Luminescent dissolved oxygen sensor

Transmitter/local display: ..................Optional, not required

Communications options: .................Modbus (RS-485), 4 to 20 mA, Digital S3L

Maximum cable length:.....................Up to 4000 ft (Modbus and 4 to 20 mA)

Up to 100 ft (S3L)

Internal mounting thread:..................1¼ NPT

Performance

Salinity range: ...................................0 to 42 PSU, fi xed or real-time capable

pH range: ..........................................2 to 10 pH

Barometric range: .............................507 to 1115 mbar, fi xed or real-time capable

Idle current:.......................................160 μA typical at 24 VDC

Maximum pressure: ..........................300 psi

Range: ..............................................0 to 20 mg/L concentration, 0 to 200% saturation

Accuracy (DO): .................................±0.1 mg/L, 0 to 8 mg/L,

±0.2 mg/L, 8 to 20 mg/L

Response time:.................................Cap T90: 30 sec

Cap T95: 37 sec @ 25 °C

Resolution:........................................0.01 mg/L

Measure current: ..............................6 mA typical at 24 VDC

Specifi cations

Environmental

Wetted Materials: ..............................ABS, Titanium, FPM

Usage life of cap: ..............................1 year from the fi rst instrument reading

Shelf life of cap: ................................24 months from date of manufacture (install w/in 12 mo. of manufacture)

Operating temperature: ....................0 °C to 50 °C (32 °F to 122 °F)

IP rating: ...........................................IP-67 with cap off, IP-68 with cap installed

Storage conditions, cap: ...................1 °C to 60 °C (33 °F to 140 °F), in factory container

Storage conditions, sensor: ..............-5 °C to 60 °C (23 °F to 140 °F)

Warranty

Sensor: .............................................3 years from date of manufacture

Cap: ..................................................2 years from date of manufacture or one year from fi rst reading

whichever comes fi rst

Standards and Approvals

CE

RoHS Compliant

China RoHS (Go to www.gfsignet.com for details)

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and, (2) This device must accept any interference

received, including interference that may cause undesired operation.

112610 DO Sensor

Page 12

Ordering Information

Ordering Information

2610 Optical DO Sensor

Mfr. Part No Code Description

3-2610-31 159 001 753 Optical DO Sensor (0-20 ppm) with Modbus, SDI, and 4 to 20 mA output

3-2610-41 159 001 754 Optical DO Sensor (0-20 ppm) with S3L, Modbus, and 4 to 20 mA output

Accessories and Replacement Parts

Mfr. Part No Code Description

3-2610.392 159 310 122 Replacement Optical Dissolved Oxygen Sensor Cap (0 to 20 ppm)

3-2610.501 159 500 413 DO Threaded Pipe Adapter, 2 in. Male NPT

861-170 –– 1¼ in. Close Nipple

–– 721 914 211 63 mm Cement Socket to 2 in. NPT Female Adapter Fitting

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2610.090 Rev. C 08/13 English © Georg Fischer Signet LLC 2013

Loading...

Loading...