Page 1

Signet 2537 Paddlewheel Flowmeter

English

*3-2537.090*

3-2537.090 Rev G 9/12 English

SAFETY INSTRUCTIONS

1. Depressurize and vent system prior to installation or removal.

2. Con rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure speci cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. If this equipment is used in a manner not speci ed by the manufacturer, the protection provided

by the equipment may be impaired.

7. This device is not approved for use or installation in hazardous locations.

Description

The 2537 Paddlewheel Flowmeter Series offer low ow, low power and high resolution with various output options such as a Volumetric

Pulse, Pulse Divider, Flow Switch, Digital (S

interface.

• The 4 to 20 mA model provides a blind current loop output.

• The Digital (S

3

L) model provides a Digital (S3L) output for use with the Signet 8900 Multi-Parameter Controller or 9900 Transmitter.

• The Multi model uses a single relay (mechanical or solid state) and has three selectable operating modes:

• Divider Mode scales the paddlewheel frequency down to accommodate low frequency input devices.

• Total Mode outputs one pulse per a set volume of uid.

• Flow Switch Mode uses a single relay for Hi or Lo alarm operation.

A small LCD enables the 2537 to be programmed without any external equipment. During normal operation the display is not visible.

3

L), or 4 to 20 mA. This unit can be con gured on-site directly through the built-in user

For earlier versions of this sensor, please visit our manual archives at www.gfsignet.com and download the 2537 rev C manual.

Specifi cations

General

Wetted Materials

Model Suffi x Sensor Body Rotor Pin O-ring

-P0, -P1 glass- lled PP PVDF, Black;

optional ETFE

w/ or w/o carbon

ber reinforced

PTFE sleeve

-T0 PVDF, Natural PVDF, Natural;

optional ETFE

w/ or w/o carbon

ber reinforced

PTFE sleeve

Titanium FPM

PVDF,

Natural

FPM

Paddlewheel Sensor Performance Specifi cations

Pipe Size Range: DN15 to DN200 (½ in. to 8 in.)

Min. Reynolds Number: 4500

Paddlewheel Frequency: 49 Hz per m/s nominal

(15 Hz per ft/s nominal)

Operating Range: 0.1 m/s to 6 m/s (0.3 ft/s to 20 ft/s)

Linearity: ±1% of max. range @ 25 °C (77 °F)

Repeatability: ±0.5% of max. range @ 25 °C (77 °F)

Electronics Performance Specifi cations

Input Frequency Range: 1 to 1000 Hz

System Response: 100 ms update rate nominal

Environmental Requirements

Enclosure Rating: NEMA 4X/IP65

Storage Temperature: -10 to 75 °C (14 to 167 °F)

Case: PBT, yellow

Inside Cover: Valox, black

Wiring Ports: ½ in. NPT threads; liquid-tight

connector accepts cables 7 to

Ambient Temperature: 0 to 65 °C (32 to 150 °F)

Relative Humidity: 0 to 90% RH, non-condensing

Altitude: 2000 m (6,562 ft)

Pollution Degree: 2

10 mm OD (0.275 in. to 0.394 in.)

Output Specifi cations

Power Requirements

Multi:

Signal Averaging: Programmable 0 to 100 seconds

Sensitivity Response: Programmable 0 to 9 scale

with Dry-Contact Relay: 24 VDC nominal, ±10%, regulated

30 mA max. current

with Solid-State Relay: 5 to 24 VDC nominal, ±10%, regulated

30 mA max. current

Digital (S

3

L): 5.0 VDC min. to 6.5 VDC max.

Pulse Divider/Total Pulse Output

Pulse Divider Setting: 1.0000 to 99999

Maximum pulse rate: 300 Hz

Maximum pulse width: 50 ms

30 mA max. current (1.5 mA nominal)

4 to 20 mA: 400 mV max. ripple voltage

30 mA max. current

Reverse Polarity and Short Circuit Protected: Up to 40 V, 1 hour

Over-Voltage Protection: > 40 VDC over 1 hour

Page 2

Flow Switch Output

Relay Modes: Low, High

Time Delay: 0.0 to 6400.0 seconds

Hysteresis: Adjustable in Engineering Units

Relay Specifi cations

Dry Contact SPDT: 5 A @ 30 VDC, 5 A @ 250 VAC

Solid-State Relay: 100 mA @ 40 VDC, 70 mA @ 33 VAC

3

Digital (S

Type: Serial ASCII, TTL level 9600 bps

Maximum Cable Length: See Digital (S

L) output

3

L) speci cations

Current output (Passive 4 to 20 mA)

Loop Accuracy: ±32 A (@ 25 °C @ 24 VDC)

Loop Resolution: 5 A

Temp. Drift: ±1 A per °C max.

Power Supply Rejection: ±1 uA per V

Maximum Cable Length: 305 m (1,000 ft)

Max Loop Resistance: 600 @ 24 VDC, 1 K @ 32 VDC

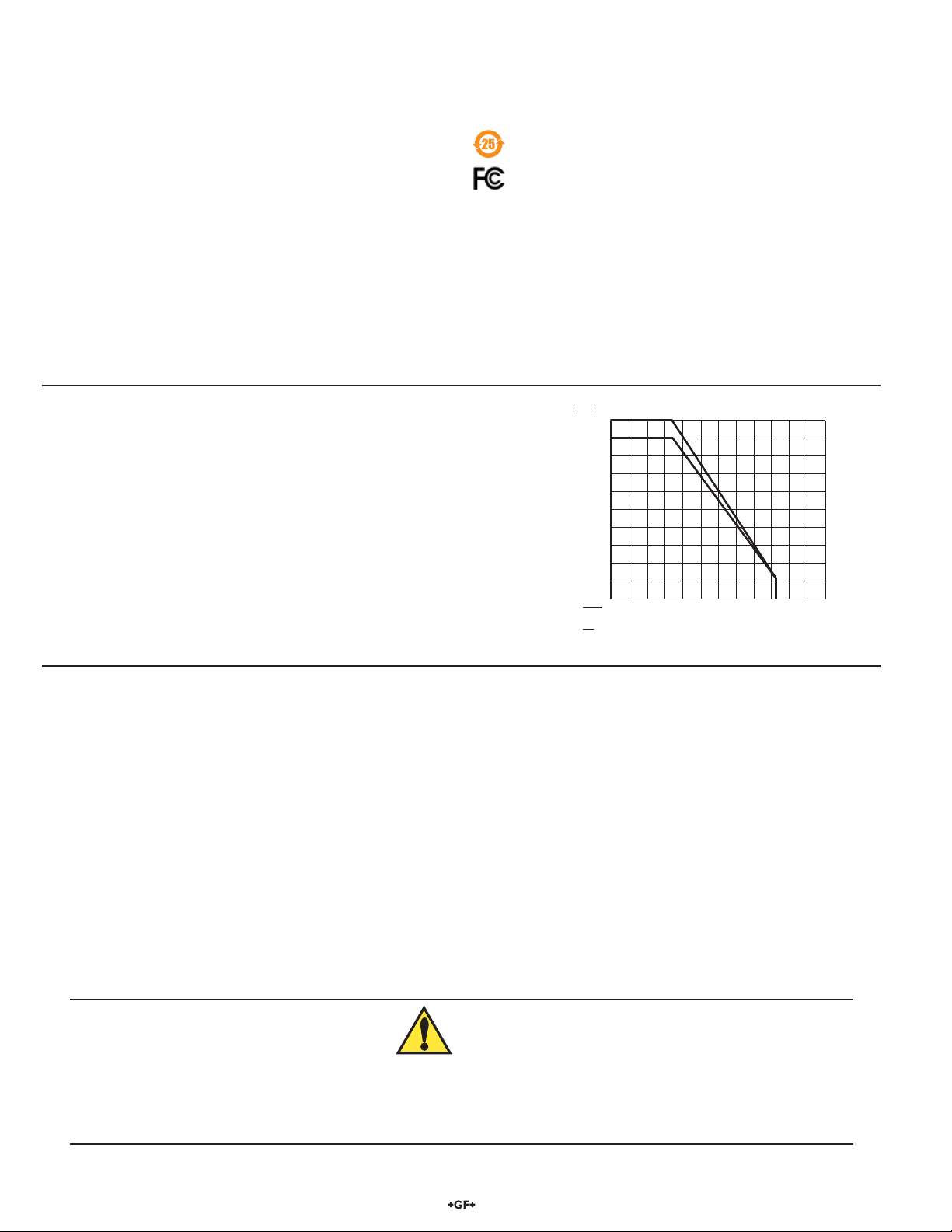

Fluid Conditions

Pressure/Temperature Ratings:

Polypropylene Body:

• 12.5 bar (180 psi) max. @ 20 °C (68 °F)

• 1.7 bar (25 psi) max. @ 85 °C (185 °F)

PVDF Body:

• 14 bar (200 psi) max @ 20 °C (68 °F)

• 1.7 bar (25 psi) max @ 85 °C (185 °F)

Standards & Approvals

• UL

• CE

• Manufactured under ISO 9001 for Quality, ISO 14001

for Environmental Management and OHSAS 18001 for

occupational health and safety.

China RoHS (Go to www.gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received, including

interference that may cause undesired operation.

ps

i

bar

14

200

11

160

8

120

6

80

PVDF

Polypropylene

3

40

Intended Use: This product is intended for use in industrial water treatment

and wastewater treatment applications where the chemical content and the uid

temperatures are consistent with the speci cations listed herein.

This device is not approved for use or installation in fl ammable liquids.

°F

0 40 80 120 160 200

°C

-18 4

27

49

71 93

240

115

Chemical Compatibility

Georg Fischer Signet products are manufactured in a variety of wetted materials to suit various liquids and chemicals.

All plastic materials including typical piping types (PVC, PVDF, PP and PE) are more or less permeable to contained media, such as

water or volatile substances, including some acids. This effect is not related to porosity, but purely a matter of gas diffusion through the

plastic.

If the plastic material is compatible with the medium according to the application guidelines, the permeation will not damage the plastic

itself. However, if the plastic encloses other sensitive components, as is the case with GF Signet plastic paddlewheel sensors, these

may be affected or damaged by the media diffusing through the plastic body and rotor.

PVDF paddlewheel sensors may experience failure when used in hot nitric acid applications. PVDF is known to allow for substantial

permeation of nitric acid constituents without being damaged itself. No clear guideline can be given here, since the damaging effect to

the sensor is highly dependent on temperature, pressure and concentration.

Utilizing sensors in applications with aggressive substances is possible. On special request GF Signet can provide sensors with a

different internal resin encapsulation (potting) that will delay the damaging effect of acids to the sensors.

WARNING

The retaining nuts of paddlewheel sensors are not designed for prolonged contact with aggressive substances. Strong acids,

caustic substances and solvents or their vapor may lead to failure of the retaining nut, ejection of the sensor and loss of the

process fl uid with possibly serious consequences, such as damage to equipment and serious personal injury. Retaining nuts

that may have been in contact with such substances, e.g. due to leakage or spilling, must be replaced.

For all Special Product inquiries or to place an order, please email

signet-specialproduct@georgfi scher.com.

2 Signet 2537 Flowmeter

Page 3

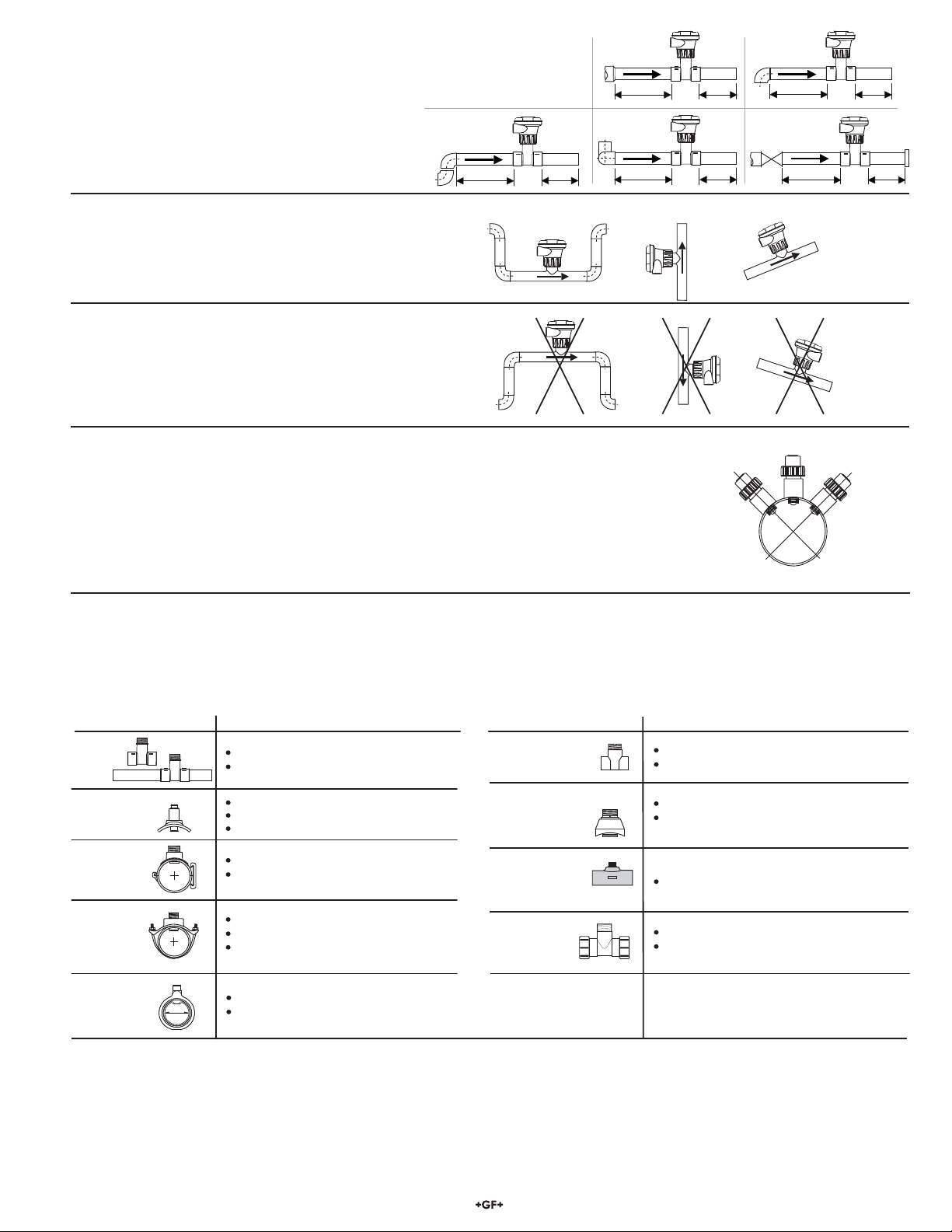

Location of Fitting

+45°

-45°

0°

Process

Pipe

Recommended sensor upstream/downstream mounting

requirements:

Reducer

15 x I.D. 5 x I.D.

90° Elbow

20 x I.D. 5 x I.D.

Select a location with suf cient length of straight pipe

immediately upstream of the sensor.

Locating the sensor in a trap or where the ow is upward

2 x 90° Elbow

25 x I.D. 5 x I.D.

2 x 90° Elbow

3 dimensions

40 x I.D. 5 x I.D.

OKOK OK

helps to protect the sensor from exposure to air bubbles

when the system is in operation.

These con gurations are not recommended because it is

dif cult to keep the pipe full.

+GF+

+GF+

+

GF

+

Sensor Mounting Position

• Horizontal pipe runs: Mount sensor in the upright (0°) position for best performance. Mount at a

maximum of 45° when air bubbles are present (pipe must be full). Do not mount on the bottom of the

pipe when sediments are present.

• Vertical pipe runs: Mount sensor in any orientation; however, downward ow is not recommended.

Upward ow is preferred to ensure full pipe.

Pump/Valve

50 x I.D. 5 x I.D.

+

GF

+

Vertical flow is OK if the pipe remains full at all times.

+

GF

+

Installation: Pipe fi ttings

Georg Fischer Signet offers a wide selection of installation ttings that control the position of the paddlewheel in relation to the

dimensions of the pipe.

Type Description

Plastic

tees

PVC

Glue-on

Saddles

PVC

Saddles

Iron

Strap-on

saddles

Metric

Wafer Fitting

d

0.5 to 2 inch versions (MPVC or CPVC)

2.5 to 4 inch versions (PVC)

Available in 10 and 12 inch sizes only

Cut 2-1/2 inch hole in pipe

Weld in place using solvent cement

2 to 4 inch, cut 1-7/16 inch hole in pipe

6 to 8 inch, cut 2-1/8 inch hole in pipe

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/8 inch hole in pipe

Special order 14 in. to 36 in.

For pipes DN65 to 200 mm

PP or PVDF

Type Description

Iron, Carbon Steel,

316 SS Threaded

tees

Carbon steel &

stainless steel

Weld-on

0.5 to 2 in. versions

Mounts on threaded pipe ends

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/8 inch hole in pipe

Weldolets

Fiberglass

tees

Metric

Union

Fitting

FPT

1.5 in. to 2 in. PVDF insert

For pipes from DN 15 to 50 mm

PP or PVDF

3Signet 2537 Flowmeter

Page 4

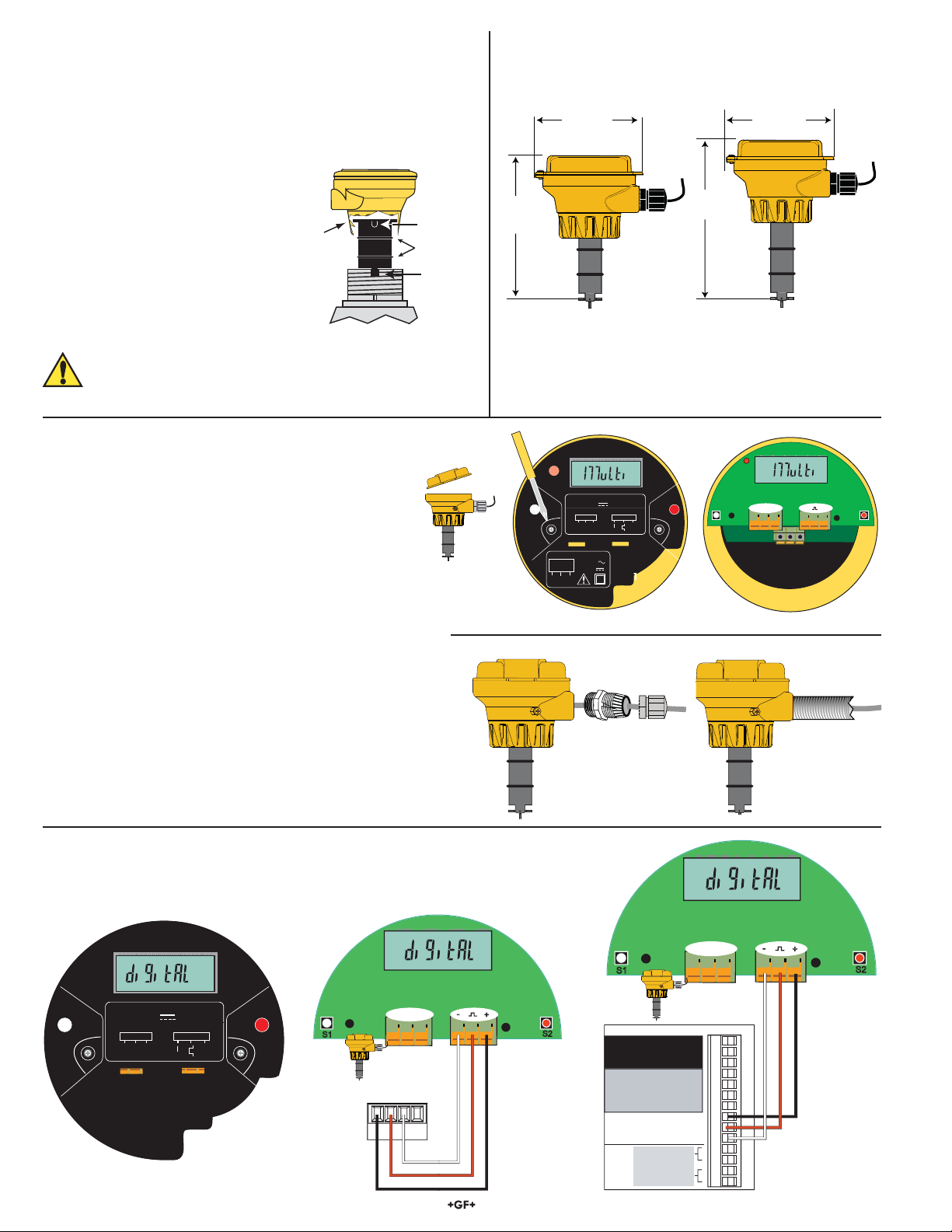

Installation

sensor

cap

tab

notch

Lubricate

O-rings

-

+

-

+

-

+

-

+

-

+

-

+

T

P

t

T

P

t

T

P

t

T

P

t

-

+

Plastic sensor installation tips

• Inspect the sensor O-rings for nicks and other damage that

may compromise the seal.

• Lubricate O-rings with a non-petroleum based, viscous

lubricant (grease) compatible with the system.

• Using an alternating/twisting motion,

lower the sensor into the tting, making

sure the conduit ports on the yellow

housing are pointing in the direction

of ow.

• Engage one thread of the sensor cap

then turn the sensor until the alignment

tab is seated in the tting notch.

Dimensions

130 mm

(5.12 in.)

97 mm

(3.82 in.)

171 mm

(6.73 in.)

97 mm

(3.82 in.)

HAND-TIGHTEN THE THREADED NUT ONTO THE INSTALLATION FITTING. DO NOT USE TOOLS! DO NOT

USE THREAD SEALANT OR LUBRICANTS ON THE

FITTING THREADS OR THE SENSOR CAP.

Wiring

Electrical connections to this product should be made only by

quali ed personnel.

To access the wiring terminals:

• Turn yellow cap ¼ turn counterclockwise to remove.

• Remove the two retaining screws and remove the black

cover.

• Route all cables through the conduit ports before connecting

them to the terminals.

• Wiring terminals are rated for 16 to 22 AWG conductors.

• The cable must be 7 to 10 mm in diameter (0.275 to

0.394 in.) to seal properly in the liquid tight connector.

• The conduit ports have ½ inch NPT threads. After routing the

cables, seal the port with a liquid tight conduit connector

(3-9000.392-1) or with conduit.

• For conduit installations:

• Thread conduit with ½ in. NPT threads directly into the

conduit port.

• For conduit with ISO threads, use the black thread adapter

included with the connector kit.

• To comply with NEC requirements, do not use any metal

conduit in the installation.

2537 Paddlewheel Flowmeter

for ½ in. to 4 in. pipe

Power Rating:

24VDC 0.03 AMP

WIRING DIAGRAM

Sensor

PW/OUT

+

RED

SHLD

Dry-Contact

N/O

Relay

Relay Rating:

5A @ 250VAC

5A @ 30VDC

N/C

COM

BLK

Using the liquid-tight

connector

2537 Paddlewheel Flowmeter

for 5 to 8 in. pipe

Blk Red Shld

3-2505.611A

S1

S2

Using conduit

Wiring: Digital (S3L) Output

The Digital (S3L) output is compatible with the 3-8900 Multi-Parameter Controller

and the 3-9900 Transmitter.

Blk Red Shld

T

Power Rating:

5 - 6.5VDC 0.03 AMP

WIRING DIAGRAM

Sensor

Blk Red Shld

BLK

RED

S1

SHLD

PW/OUT

-

+

+

3-2505.613A

S2

S1

Blk Red Shld

DATA

V+

GND

SHLD

-

+

S2

Connection to

9900 Transmitter

S1

I/O Module 3-8900.401-X

+5VDC (Black)

Frequency

Input

Freq. Input (Red)

1

GND (Shield)

+5VDC (Black)

Frequency

Input 2

Freq. Input 2 (Red)

OR

S3L

Input

2

S3L

Input

1

3

S L (Red)

GND (White/Shield)

+5VDC (Black)

3

S L (Red)

GND (White/Shield)

Analog Output 1

(if applicable)

Analog Output 2

(if applicable)

1

2

3

4

5

6

7

8

9

10

11

+

12

-

13

+

14

-

4 Signet 2537 Flowmeter

-

3-8900.621C

Connection to

8900 Controller

+

S2

Page 5

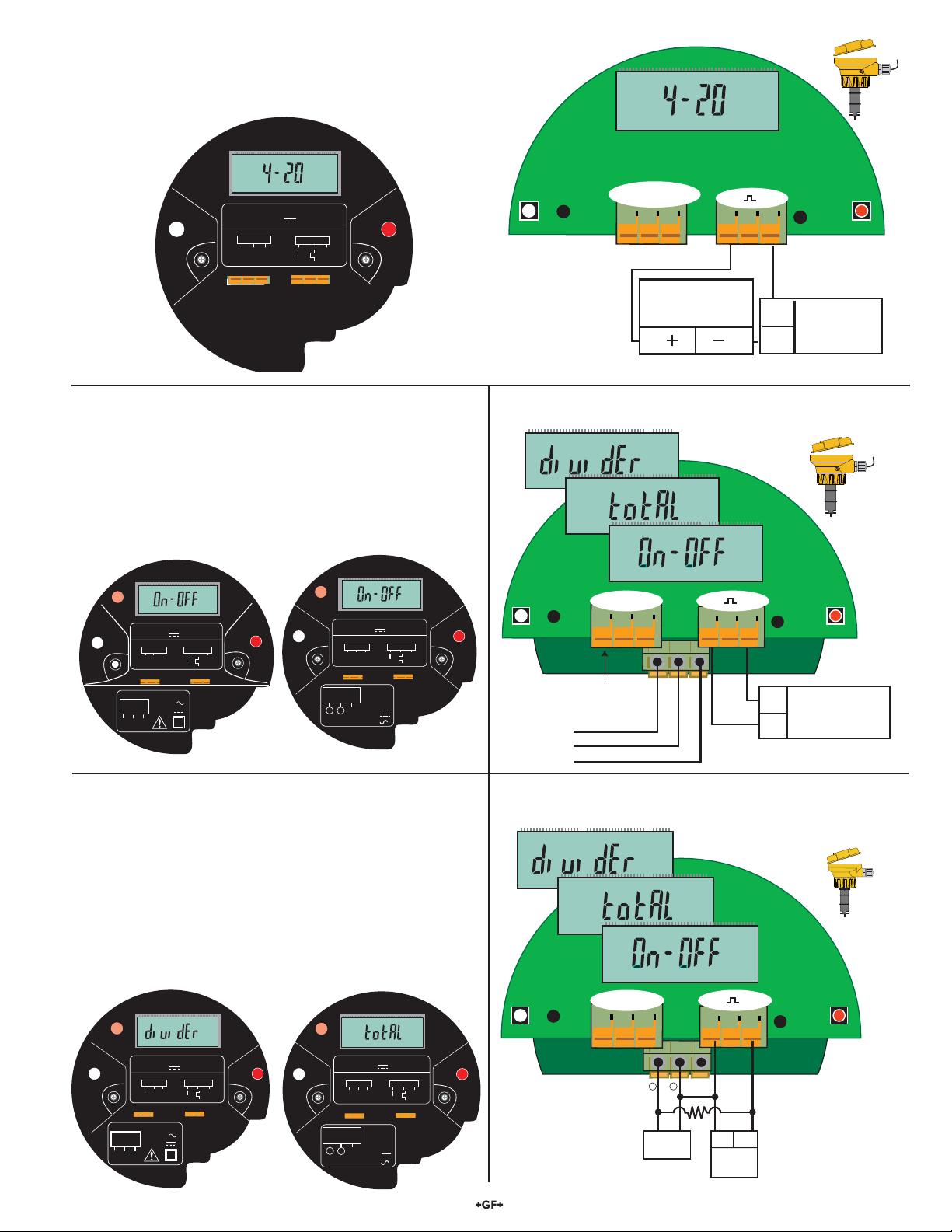

Wiring: 4 to 20 mA Output

-

+

-

+

-

+

-

+

-

+

-

+

T

P

t

T

P

t

-

+

-

+

T

P

t

T

P

t

-

+

-

+

-

+

-

+

T

P

t

T

P

t

The 4 to 20 mA output can be connected to Chart Recorders, PLCs or

any device that requires a 4 to 20 mA signal.

The 4 to 20 mA model requires an external power source of

12 to 32 VDC.

T

P

Power Rating:

12 - 32VDC 0.03 AMP

WIRING DIAGRAM

Sensor

Blk Red Shld

BLK

RED

SHLD

S1

PW/OUT

-

t

+

3-2505.614A

S2

S1

Blk Red Shld

Internal sensor

connections

Programmable Logic Controller

Datalogger

Chart Recorder

4 to 20 mA Loop monitor

S2

+

Power Supply

12 to 32 VDC, 0.03 A

-

Wiring: Flow Switch Output (On-OFF)

• The Flow Switch mode allows a single relay that is

programmable as a HIGH setpoint or LOW setpoint.

• The relay may be a dry-contact type or a solid state type.

• The dry contact relay requires an external power source of

24 VDC ± 10%.

• The solid state relay requires an external power source of

5 to 24 VDC.

T

T

P

Power Rating:

24VDC 0.03 AMP

WIRING DIAGRAM

Sensor

BLK

Blk Red Shld

Dry-Contact

N/O

Relay

RED

Relay Rating:

5A @ 250VAC

5A @ 30VDC

N/C

COM

S1

SHLD

PW/OUT

-

t

+

3-2505.611A

+

S2

S1

P

Power Rating:

5 - 24VDC 0.03 AMP

WIRING DIAGRAM

Sensor

Blk Red Shld

BLK

RED

SHLD

Solid-State

Relay

Relay Rating:

1 2

100mA @ 40VDC

Load

70mA @ 33VAC

3-2505.616A

PW/OUT

-

t

+

3-2505.612A

+

Wiring: Pulse Output

• The "Multi" mode allows a single relay that is programmable

as a Flow Switch, Volumetric pulse output or as a simple pulse

divider output.

• The relay may be a dry-contact type or a solid state type.

• The Dry Contact Relay requires an external power source of

24 VDC ± 10%.

• The Solid State Relay requires an external power source of

5 to 24 VDC.

• Solid State Relay requires a pull-up resistor (10K ohm

recommended). Consult your instrument/PLC manual for

wiring information.

Dry Contact Relay Wiring

• The wiring is identical for On-OFF and Pulse modes.

Blk Red Shld

S1

S2

Internal sensor

connections

Normally Open

Common

Normally Closed

S2

+

Power Supply

24 VDC, 0.03 A

-

Solid State Relay Wiring

• The wiring is identical for On-OFF and Pulse modes

Blk Red Shld

.

S1

Power Rating:

24VDC 0.03 AMP

WIRING DIAGRAM

Sensor

PW/OUT

+

Blk Red Shld

BLK

RED

Relay Rating:

Relay

N/C

COM

5A @ 250VAC

5A @ 30VDC

SHLD

S1

Dry-Contact

N/O

3-2505.611A

-

+

S2

S1

Power Rating:

5 - 24VDC 0.03 AMP

WIRING DIAGRAM

Sensor

BLK

RED

Blk Red Shld

SHLD

3-2505.616A

Solid-State

Relay

Relay Rating:

1 2

100mA @ 40VDC

Load

70mA @ 33VAC

PW/OUT

-

Load

+

3-2505.612A

+

S2

1 2

I/O

10KΩ

Power Supply

5 to 24 VDC,

0.03 A

+–

S2

5Signet 2537 Flowmeter

Page 6

Operation

T

P

t

T

P

t

T

P

t

T

P

t

The 2537 Flowmeter is available in three different

models. The programming menus vary signi cantly

from one model to another.

This chart is provided inside the yellow cover to assist

in navigating the menus in the 2537.

Mode Action

View Display Flow Rate Go to MENU Go to VIEW

Menu 1X Next Menu 1X Display Current Value Previous Mode

Go to Edit Previous Mode

1X Shift digit to right Previous Mode

Edit 1X Increment Value Go to SAVE Previous Mode

SAVE 1X Toggle 1X Store Change N/A

Menus

3-2537-1C-XX, 3-2537-2C-XX 3-2537-5C-XX 3-2537-6C-XX

T

P

t

View Mode Function

• All models display the model name: Multi, Digital or 4-20.

• If the white key (S1) is held down for three seconds, the ow rate is displayed for 10 minutes before

reverting back to the model name.

• In the Multi Model, if the “Multi” menu item is set to “divider”, then the divided pulse output will be

displayed in pulses/seconds (p/s).

6 Signet 2537 Flowmeter

Page 7

Menu Details

This table shows the de nition of each menu function, the setting parameters and the page where detailed instructions can be located.

Menu Function Defi nition Setting Parameters

Flow Unit Liters or Gallons per sec, min., hour or day See list on page 8 page 8

K-Factor Set PULSES per VOLUME UNIT 0.0001 to 999999 page 8

Average Smooths out erratic ow conditions 0 to 100 seconds page 9

Sensitivity Overrides Average for large rate changes 0 to 9 page 9

Mode Select the output mode Total or Divider or On-OFF page 10

P-Factor As PULSE DIVIDER, divides input freq. 1.0000 to 99999 page 10

P-Factor As PULSE TOTAL, multiplies K-Factor 1.0000 to 99999 page 10

Relay Logic Select Hi alarm or Lo alarm mode Hi or Lo page 11

Relay Set Set Relay Setpoint 0.0000 to 99999 page 11

Relay Hysteresis Rate inside Setpoint to DEENERGIZE relay 0.0000 to 99999 page 11

Relay Delay Time delay before relay is ENERGIZED 0000.0 to 6400.0 page 11

4 Set Set ow RATE to be represented by 4 mA 0.0000 to 99999 page 8

20 Set Set ow RATE to be represented by 20 mA 0.0000 to 99999 page 8

Contrast Adjust visibility of liquid crystal display 1 to 3 page 8

More

Information

7Signet 2537 Flowmeter

Page 8

t

t

T

P

t

T

P

t

T

P

t

T

P

t

t

T

P

t

t

T

P

Flow Units

T

P

t

T

P

t

T

P

t

T

P

t

T

P

t

T

P

t

T

P

t

T

P

t

This function is available on these

versions of the 2537.

Select the volumetric units for the ow measurement.

Liters/second

Liters/minute

(Factory setting)

Gallons/second

Gallons/minute

T

P

T

P

t

t

K-Factor

A K-Factor is the number of pulses

a sensor will generate for each

engineering unit of uid that passes

T

P

T

P

t

t

the sensor. The factory setting is

60.0000. Locate the K-Factor in the

tables on page 12 and 13.

This function is

available on the above

versions of the 2537.

Minimum value

Maximum value

Liters/hour

Liters/day

Gallons/hour

Gallons/day

Example: Set the Flow Units to Gallons per minute:

Save the new setting:

.

.

2s

2s

.

2s

Go to next

menu item

Return to

Normal Operation

Set 4 and Set 20

This function is available on

these versions of the 2537.

These two functions are used to span the 4 to 20 mA output

signal to the required range.

The factory setting is 4 to 20 mA = 0 to 10.000

Only the 20 mA span is illustrated here.

Example: Set 20 mA = 500 GPM.

2s

x5

2s

Save the new setting:

2s

Example: Set the K-Factor to 63.5 Pulses per Gallon:

1.

2s

2.

3.

2s

4.

5.

x2

x3

Save the new setting:

2s

6.

Return to

T

P

T

P

Normal Operation

7.

x5

Set Contrast

This function is available on

these versions of the 2537.

Go to next

menu item

All models of the 2537 have the CONTRAST adjustment. It is

always located at the end of the menu.

1.

2.

Repeat until

To access the adjustment, enter the

2s

menu and scroll until the Contrast

display appears.

x1

Three levels of adjustment are

available. The factory setting of

3 is the highest contrast setting.

Choose:

OR OR

Save the new setting:

2s

t

t

x4

x2

8 Signet 2537 Flowmeter

Return to

Go to next

menu item

Normal Operation

Go to next

menu item

Return to

Normal Operation

Page 9

t

T

P

t

T

P

t

T

P

t

T

P

t

t

T

P

t

T

P

t

10 s2 s 20 s 30 s 40 s 50 s 60 s 70 s

No AVERAGING, no SENSITIVITY

AVERAGING only

AVERAGING and SENSITIVITY

Averaging and Sensitivity Settings

P

T

t

T

P

t

T

P

t

• Because ideal ow conditions are often impossible to achieve, the ow rate is often erratic, which causes erratic readings in control

features (e.g., relays, 4 to 20 mA loops, etc.) that are associated with the ow rate.

• The best solution to these problems is to correct any piping de ciency that causes the instability. This may involve longer straight

runs upstream, reducing the pipe size to maintain a full pipe at all times, and other installation changes. In many situations, however,

these measures are simply not possible.

• The 2537 meter provides two tools that are designed to "work around" these de ciencies. The Averaging and the Sensitivity features

should be studied before making adjustments.

Averaging Time in Seconds (Factory set: 0 seconds)

• Set the time the meter will use as the averaging period. The range is from 0 (no average applied to input) to 100 (seconds of

averaging applied to input).

Use higher averaging times to smooth the display and current output where the ow in the pipe is erratic.

Quick Response Sensitivity (Factory set: 0)

• Set the relative degree of change in the ow rate required to allow the 2537 to disable the AVERAGING and jump to a new ow rate

immediately. The scale is from 0 (least sensitive, averaging is never disabled.) to 9 (a very small change in ow rate will disable the

averaging).

With AVERAGING set to 0 (zero) and with SENSITIVITY set to zero,

the 2537 responds to every unstable shift in the ow. The dashed

red line represents the actual output of the ow sensor in unstable

ow conditions.

With AVERAGING set to 50 seconds and SENSITIVITY still set to

zero the ow rate is stabilized, but a sharp change in ow rate is not

represented for 50 seconds or longer (dotted green line).

With AVERAGING at 50 seconds and SENSITIVITY set to 4 OR 5,

the ow rate is stabilized, while the sudden shift in ow is re ected

very quickly (solid blue line).

NOTE: The SENSITIVITY function is ineffective if the AVERAGING function is set to zero (seconds).

Set Averaging

This function is available on

these versions of the 2537:

The factory setting is 0 (zero). The factory setting is 0 (zero).

Minimum value

T

P

T

P

t

t

Set Sensitivity

This function is available on

these versions of the 2537:

Maximum value

Example:

Set the Averaging for 50 seconds.

1.

2.

3.

x2

4.

2s

2s

Save the new setting:

2s

Return to

Go to next

menu item

Normal Operation

Example: Set the Sensitivity to 5.

1.

2s

2.

3.

4.

x3

2s

x5

T

P

Minimum value

Maximum value

Save the new setting:

2s

Go to next

menu item

T

P

T

t

P

t

t

Return to

Normal Operation

5.

x5

9Signet 2537 Flowmeter

Page 10

Mode

t

t

T

P

T

P

t

t

T

P

t

t

P

T

T

P

t

T

P

t

This function is available on

these versions of the 2537:

Select DIVIDER or TOTAL operation.

The factory setting is TOTAL.

P-Factor

This function is available on

these versions of the 2537:

The factory setting is 1.0000

T

P

t

PULSE DIVIDER Output = Input pulses ÷ P-Factor

DIVIDER allows you to set a scaling value (P-Factor) from

1.0000 to 99999.

Example: If the P-Factor is set for 2, then the 2537 will output

one pulse for every 2 pulses received from the sensor.

This selection enables the output frequency to be scaled down

to match associated equipment capabilities.

When using the PULSE DIVIDER output, associated equipment

must divide the K-Factors in this manual by the P-Factor for

correct calibration.

123579468

1110 12

Pulses IN

123 4

56

Pulses OUT

PULSE TOTAL Output = Input pulses ÷ (K-Factor × P-Factor)

TOTAL is a traditional pump pulser function. This selection will

allow the entry of a K-Factor to de ne a volumetric unit, then set

a P-Factor to de ne the number of volumetric units required to

generate one pulse out.

Example:

Set the Total Pulse output so there is one pulse out for each

2 gallons that passes the sensor if the K-Factor is 3.0.

Minimum value

Maximum value

In PULSE DIVIDER mode the P-Factor divides:

The pulse stream from the paddlewheel sensor will be divided

by the P-Factor. The resulting frequency is output through a

relay.

In PULSE TOTAL mode the P-Factor multiplies:

The pulse stream from the paddlewheel sensor is divided

by the K-Factor MULTIPLIED by the P-factor. The resulting

frequency is output through a relay.

1.

2s

2.

3.

4.

5.

2s

x4

x2

1. K-Factor = 3.0 (pulses in per gallon)

Save the new setting:

2. P-Factor = 2 (gallons out per pulse)

1 Gal 4 Gal

2 Gal 3 Gal

2s

2135468791110 12

Pulses IN

1

2

Pulses OUT

.

2s

.

2s

.

2s

10 Signet 2537 Flowmeter

Go to next

Save the new setting:

2s

Go to next

menu item

Return to

Normal Operation

menu item

Return to

Normal Operation

Page 11

t

T

P

t

T

P

t

Set Relay Operation

T

P

t

T

P

t

t

t

T

P

t

T

P

t

P

T

t

t

T

P

t

T

P

t

t

T

P

The On-OFF mode has one relay (SPDT or solid-state) that can be programmed as a HIGH (Hi)

alarm or a LOW (Lo) alarm.

1. Select HI or LO Relay Alarm logic

A HI alarm will be activated when the

ow rate rises ABOVE the setpoint.

A LO alarm will be activated when the

ow rate falls BELOW the setpoint.

The factory setting is Hi(gh).

2. Program the SETPOINT.

The SETPOINT is the ow rate

where the relay will be energized.

The factory setting is 5.0000.

Minimum value

Maximum value

Example: Change the Relay Logic to Low:

1.

2.

3.

4.

2s

x4

2s

Example: Change the Setpoint to 8.0000:

1.

2.

3.

4.

5.

2s

x5

2s

x3

Save the new setting:

2s

Return to

Go to next

menu item

Normal Operation

Save the new setting:

2s

Return to

Go to next

menu item

Normal Operation

3. Program the HYSTERESIS.

Hysteresis holds a relay energized until the

Example: Change the Hysteresis to 5.0000:

1.

2s

Save the new setting:

2s

ow rate moves this amount past the setpoint.

The factory setting is 0.5000

Minimum value

Maximum value

4. Program the DELAY.

When the ow rate reaches the setpoint, the

2537 will wait this long (in seconds) before

triggering the alarm.

The factory setting is 0000.0 seconds.

Minimum value

Maximum value

2.

3.

4.

x6

2s

x5

Example: Change the Delay to 10.0:

1.

2.

3.

4.

5.

2s

x7

2s

Return to

Go to next

menu item

Normal Operation

Save the new setting:

2s

Return to

Go to next

menu item

Normal Operation

11Signet 2537 Flowmeter

Page 12

K-Factors

When using the PULSE DIVIDER mode, associated equipment must divide the K-Factors by the P-Factor.

A K-Factor is the number of pulses a sensor will generate for each engineering unit of uid that passes the sensor. K-Factors for water

are listed below in U.S. gallons and liters. For example, in a 1 inch SCH 80 PVC pipe, using the MPV8T010 PVC tting, the 2537

paddlewheel generates 335.53 pulses per gallon of water passing the rotor.

Molded Tees Saddles Metal Tees

PIPE

SIZE

(IN.)

SCH 80 MOLDED TEES FOR SCH 80 PVC PIPE

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2 PV8T025 42.994 11.359

3 PV8T030 26.652 7.0414

4 PV8T040 15.006 3.9645

FITTING

MPV8T005F

MPV8T005

MCPV8T005F

MPV8T007F

MPV8T007

MCPV8T007F

MPV8T010F

MPV8T010

MCPV8T010F

MPV8T012F

MPV8T012

MCPV8T012F

MPV8T015F

MPV8T015

MCPV8T015F

MPV8T020F

MPV8T020

MCPV8T020F

2537 SENSOR

U.S.

GAL

1027.1 271.37

583.19 154.08

335.53 88.65

178.79 47.24

121.42 32.08

71.44 18.87

LITERS

PIPE

SIZE

(IN.)

SCH 80 PVC SADDLES FOR SCH 80 PVC PIPE

2 PV8S020 66.739 17.633

2-1/2 PV8S025 42.994 11.359

3 PV8S030 26.652 7.0414

4 PV8S040 15.006 3.9645

6 PV8S060 8.3246 2.1994

8 PV8S080 5.0164 1.3253

SCH 80 PVC SADDLE ON SCH 40 PVC PIPE

2 PV8S020 54.700 14.452

2-1/2 PV8S025 37.159 9.8175

3 PV8S030 23.697 6.2608

4 PV8S040 13.456 3.5552

6 PV8S060 7.4594 1.9708

8 PV8S080 4.5292 1.1966

FITTING

2537 SENSOR

U.S.

GAL

LITERS

PIPE

SIZE

(IN.)

CARBON STEEL TEES ON SCH 40 PIPE

1/2 CS4T005 756.00 199.74

3/4 CS4T007 438.69 115.90

1 CS4T010 286.78 75.768

1-1/4 CS4T012 121.22 32.026

1-1/2 CS4T015 91.139 24.079

2 CS4T020 54.468 14.391

STAINLESS STEEL TEES ON SCH 40 PIPE

1/2 CR4T005 734.20 193.98

3/4 CR4T007 412.10 108.88

1 CR4T010 252.70 66.764

1-1/4 CR4T012 128.12 33.849

1-1/2 CR4T015 77.320 20.428

2 CR4T020 45.780 12.095

GALVANIZED IRON TEES ON SCH 40 PIPE

1 IR4T010 213.01 56.277

1-1/4 IR4T012 127.75 33.751

1 1/2 IR4T015 94.401 24.941

2 IR4T020 59.420 15.699

BRONZE TEES ON SCH 40 PIPE

1 BR4T010 213.01 56.277

1-1/4 BR4T012 127.75 33.751

1-1/2 BR4T015 94.401 24.941

2 BR4T020 59.420 15.699

COPPER TEE FITTINGS ON COPPER PIPE

SCH K

1/2 CUKT005 917.84 242.50

3/4 CUKT007 428.27 113.15

1 CUKT010 256.43 67.749

1-1/4 CUKT012 176.44 46.615

1-1/2 CUKT015 115.69 30.565

2 CUKT020 63.385 16.746

COPPER TEE FITTINGS ON COPPER PIPE

SCH L

1/2 CUKT005 858.22 226.74

3/4 CUKT007 385.74 101.91

1 CUKT010 241.64 63.841

1-1/4 CUKT012 170.90 45.152

1-1/2 CUKT015 112.03 29.598

2 CUKT020 61.74 16.310

FITTING

2537 SENSOR

U.S.

GAL

LITERS

12 Signet 2537 Flowmeter

Page 13

K-Factors

Union Tees

PIPE

SIZE

POLYPROPYLENE TEES (DIN/ISO AND BS AND ANSI)

DN15 PPMT005 952.87 251.75

DN20 PPMT007 563.10 148.77

DN25 PPMT010 291.60 77.042

DN32 PPMT012 169.22 44.709

DN40 PPMT015 103.90 27.450

DN50 PPMT020 60.789 16.060

DN65 PPMT025 41.498 10.964

DN80 PPMT030 26.786 7.0769

DN100 PPMT040 17.415 4.6011

DN125 PPMT050 10.168 2.6864

DN150 PPMT060 7.3119 1.9318

DN200 PPMT080 3.9946 1.0554

FITTING

2537 SENSOR

U.S. GAL LITERS

Union Tees

PIPE

SIZE

PVDF FITTINGS (DIN/ISO AND BS AND ANSI)

DN15 SFMT005 827.26 218.56

DN20 SFMT007 489.87 129.42

DN25 SFMT010 283.55 74.915

DN32 SFMT012 158.59 41.899

DN40 SFMT015 86.980 22.980

DN50 SFMT020 50.385 13.312

PVC FITTINGS (DIN/ISO) - EUROPE ONLY

DN15 PVMT005 972.37 256.90

DN20 PVMT007 485.69 128.32

DN25 PVMT010 297.27 78.540

DN32 PVMT012 170.25 44.980

DN40 PVMT015 103.71 27.400

DN50 PVMT020 59.500 15.720

DN65 PVMT025 34.973 9.2400

DN80 PVMT030 24.981 6.6000

DN100 PVMT040 16.275 4.3000

DN150 PVMT060 8.1756 2.1600

DN200 PVMT080 4.0878 1.0800

FITTING

2537 SENSOR

U.S. GAL LITERS

Wafer Fittings

PIPE

SIZE

POLYPROPYLENE WAFER FITTINGS (DIN/ISO)

DN65

DN80

DN100

DN125

DN150

DN200

PVDF WAFER FITTINGS (DIN/ISO)

DN65 SFMTF025 36.133 9.5465

DN80 SFMTF030 24.715 6.5297

DN100 SFMTF040 16.120 4.2589

DN125 SFMTF050 8.8624 2.3415

DN150 SFMTF060 6.4543 1.7052

DN200 SFMTF080 4.0720 1.0758

FITTING

PPMTE025

PPMTF025

PPMTE030

PPMTF030

PPMTE040

PPMTF040

PPMTE050

PPMTF050

PPMTE060

PPMTF060

PPMTE080

PPMTF080

2537 SENSOR

U.S. GAL LITERS

41.498 10.964

26.786 7.0769

17.415 4.6011

10.168 2.6864

7.3119 1.9318

3.9946 1.0554

Weldolets and Brazolets

PIPE

SIZE

(IN.)

STAINLESS STEEL WELDOLETS ON SCH 40 PIPE

2-1/2 CR4W025 37.600 9.9339

3 CR4W030 24.340 6.4306

4 CR4W040 13.920 3.6777

5 CR4W050 10.860 2.8692

6 CR4W060 7.5200 1.9868

8 CR4W080 4.3400 1.1466

CARBON STEEL WELDOLETS ON SCH 40 PIPE

2-1/2 CS4W025 37.600 9.9339

3 CS4W030 24.340 6.4306

4 CS4W040 13.920 3.6777

5 CS4W050 10.860 2.8692

6 CS4W060 7.5200 1.9868

8 CS4W080 4.3400 1.1466

COPPER/BRONZE BRAZOLETS ON SCH 40 PIPE

2-1/2 BR4B025 37.600 9.934

3 BR4B030 24.340 6.431

4 BR4B040 13.920 3.678

5 BR4B050 10.860 2.869

6 BR4B060 7.5200 1.987

8 BR4B080 4.3400 1.147

FITTING

2537 SENSOR

U.S. GAL LITERS

Iron Saddles

PIPE

SIZE

(IN.)

SCH 80 IRON SADDLES ON SCH 80 PIPE

2 IR8S020 64.720 17.099

2-1/2 IR8S025 42.480 11.223

3 IR8S030 26.420 6.980

4 IR8S040 14.700 3.884

5 IR8S050 12.180 3.218

6 IR8S060 8.4400 2.230

8 IR8S080 4.9000 1.295

SCH 80 IRON SADDLE ON SCH 40 PIPE

2 IR8S020 53.640 14.172

2-1/2 IR8S025 37.600 9.934

3 IR8S030 23.220 6.135

4 IR8S040 13.260 3.503

5 IR8S050 11.040 2.917

6 IR8S060 7.2400 1.913

8 IR8S080 4.4000 1.162

FITTING

2537 SENSOR

U.S. GAL LITERS

13Signet 2537 Flowmeter

Page 14

H-Dimensions

The plastic insert in Weldolet ttings MUST be removed during the welding process. When reinstalled, it is important that the insert be

threaded to the proper height ("H" dimension).

Weldolet “H” dimension

Part number inches mm

CS4W020 2.38 60.45

CS4W025 2.33 59.18

CS4W030 2.32 58.92

CS4W040 2.30 58.42

CS4W050 3.09 78.48

CS4W060 2.96 75.18

CS4W080 2.73 69.34

"H"

Weldolet “H” dimension

Part number inches mm

CR4W020 2.38 60.45

CR4W025 2.33 59.18

CR4W030 2.32 58.92

CR4W040 2.30 58.42

CR4W050 3.09 78.48

CR4W060 2.96 75.18

CR4W080 2.73 69.34

Maintenance and Cleaning

The 2537 requires very little maintenance.

• If the paddlewheel becomes fouled, it can be cleaned with mild detergents and a small brush.

• The electronics portion of the 2537 does not require maintenance or cleaning.

Rotor Replacement Procedure

1. To remove the rotor, insert a small screwdriver between the rotor and the ear of the sensor.

2. Twist the screwdriver blade to ex the ear outward enough to remove one end of the rotor and pin.

DO NOT ex the ear any more than necessary! If it breaks, the sensor cannot be repaired.

3. Install the new rotor by inserting one tip of the pin into the hole, then carefully ex the opposite ear

back enough to slip rotor into place.

14 Signet 2537 Flowmeter

Page 15

Notes

15Signet 2537 Flowmeter

Page 16

Ordering Information

Mfr. Part No. Code Description

2537 system for 0.5 in. to 4 in. pipes, with polypropylene body, Black PVDF rotor, Titanium pin, FPM O-rings

3-2537-1C-P0 159 001 291 Pulse/Flow Switch, DCR, -P0, Integral Mount

3-2537-2C-P0 159 001 292 Pulse/Flow Switch, SSR, -P0, Integral Mount

3-2537-5C-P0 159 001 295 Digital (S

3

L), Integral Mount

3-2537-6C-P0 159 001 296 4 to 20 mA, Integral Mount

2537 system for 5 in. to 8 in. pipes, with polypropylene body, Black PVDF rotor, Titanium pin, FPM O-rings

3-2537-1C-P1 159 001 303 Pulse/Flow Switch, DCR, -P1, Integral Mount

3-2537-2C-P1 159 001 304 Pulse/Flow Switch, SSR, -P1, Integral Mount

3-2537-5C-P1 159 001 307 Digital (S3L), Integral Mount

3-2537-6C-P1 159 001 308 4 to 20 mA, Integral Mount

2537 system for 0.5 in. to 4 in. pipes, with natural PVDF body, rotor and pin, FPM O-rings

3-2537-1C-T0 159 001 315 Pulse/Flow Switch, DCR, -T0, Integral Mount

3-2537-2C-T0 159 001 316 Pulse/Flow Switch, SSR, -T0, Integral Mount

3-2537-5C-T0 159 001 319 Digital (S

3

L), Integral Mount

3-2537-6C-T0 159 001 320 4 to 20 mA, Integral Mount

Accessories

Mfr. Part No. Code Description

3-2536.320-1 198 820 052 Rotor, PVDF Black

3-2536.320-2 159 000 272 Rotor, PVDF Natural

3-2536.320-3 159 000 273 Rotor, ETFE

3-2536.321 198 820 054 Rotor and Pin, PVDF Natural

3-2536.322-1 198 820 056 Sleeved Rotor, PVDF Black

3-2536.322-2 198 820 057 Sleeved Rotor, PVDF Natural

3-2536.322-3 198 820 058 Sleeved Rotor, ETFE

M1546-1 198 801 182 Rotor Pin, Titanium

M1546-2 198 801 183 Rotor Pin, Hastelloy-C

M1546-3 198 820 014 Rotor Pin, Tantalum

M1546-4 198 820 015 Rotor Pin, Stainless Steel

P51545 198 820 016 Rotor Pin, Ceramic

1220-0021 198 801 186 O-Ring, FPM

1224-0021 198 820 006 O-Ring, EPDM

1228-0021 198 820 007 O-Ring, FFPM

P31536 198 840 201 Sensor Plug, Polypro

3-8050.390-1 159 001 702 Retaining Nut Replacement Kit, NPT, Valox

3-8050.390-3 159 310 116 Retaining Nut Replacement Kit, NPT, PP

3-8050.390-4 159 310 117 Retaining Nut Replacement Kit, NPT, PVDF

3-8050.391 159 001 703 Retaining Nut Replacement Kit, NPT, Stainless Steel

3-9000.392-1 159 000 839 Liquid tight connector kit, NPT (1 piece)

3-9000.392-2 159 000 841 Liquid tight connector kit, PG 13.5 (1 piece)

3-9000.392-3 159 001 430 Liquid-tight connector kit, dual-cable gland

7300-7524 159 000 687 24 VDC Power Supply 7.5 W, 300 mA

7300-1524 159 000 688 24 VDC Power Supply 15 W, 600 mA

7300-3024 159 000 689 24 VDC Power Supply 30 W, 1.3 A

7300-5024 159 000 690 24 VDC Power Supply 50 W, 2.1 A

7300-1024 159 000 691 24 VDC Power Supply 100 W, 4.2 A

®

Georg Fischer Signet LLC, 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2537.090 Rev G 9/12 English © Georg Fischer Signet LLC 2012

Loading...

Loading...