Page 1

Signet 2350 Temperature Sensor

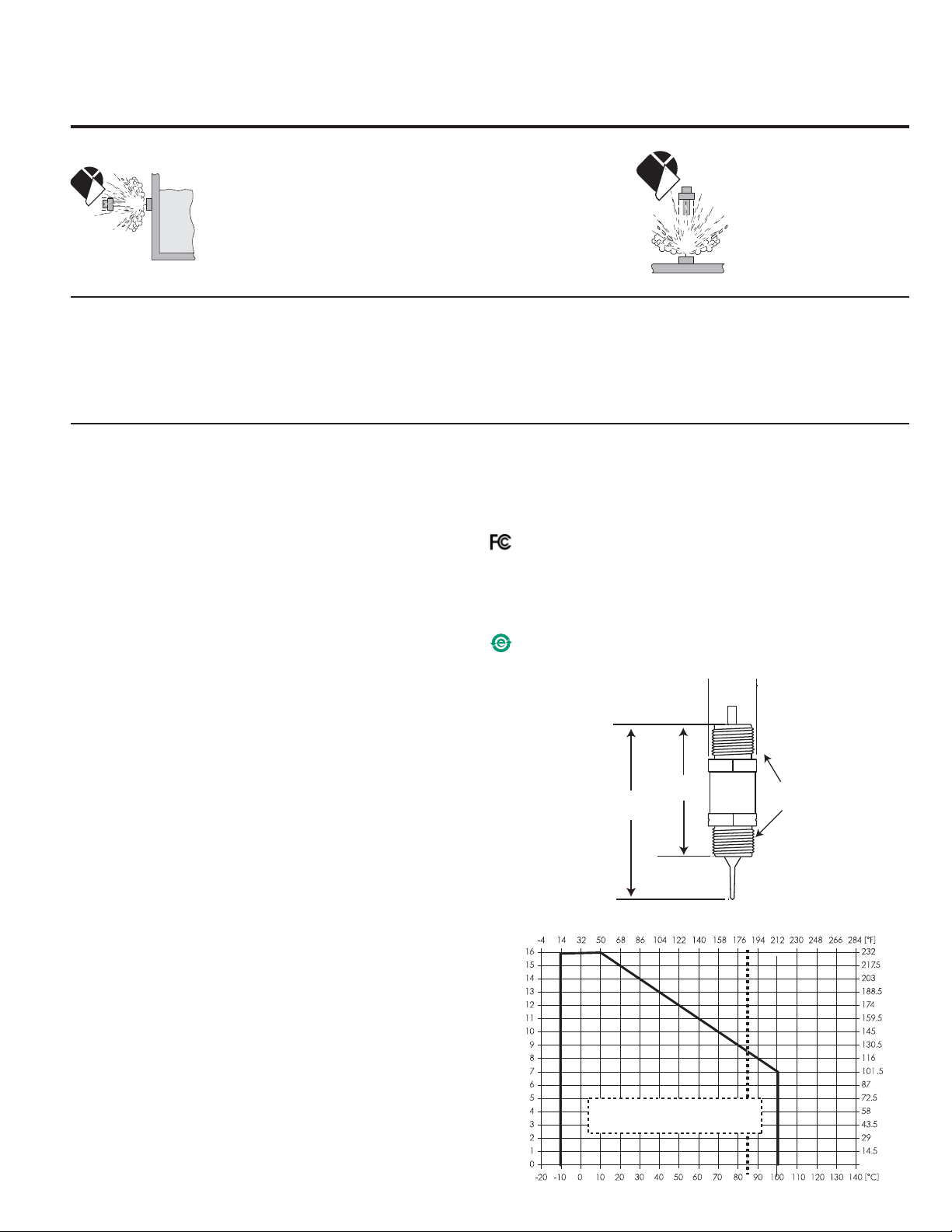

109 mm

(4.27 in.)

82 mm

(3.22 in.)

¾ in. NPT

30 mm

(1.18 in.)

Submersible installations

are limited to 85 °C (185 °F)

Application Limits

Pressure (bar)

Pressure (psi)

Temperature

*3-2350.090-1*

3-2350.090-1 Rev. K 03/13 English

English

Safety Instructions

1. Prior to installation or removal:

• Depressurize and vent system

• Drain below sensor level

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. Dispose of properly; DO NOT INCINERATE!

Table of Contents

1. Description

2. Specifi cations

3. Installation

4. Digital (S

3

L) wiring

5. 4 to 20 mA wiring

6. 4 to 20 mA

span adjustment

7. Ordering information

1. Description

The Signet 2350 Temperature Sensor has a one-piece injection molded PVDF body that is ideal for use in high purity applications. It

also outlasts metal sensors in aggressive liquids and eliminates the need for costly custom thermowells. These sensors are available

with Digital (S3L) or fi eld-scaleable 4 to 20 mA output. Dual threaded ends (3/4 in. NPT) allow submersion in process vessels, or in-line

installation with conduit connection. Integral adapters (sold separately) may be used to create a compact assembly with fi eld mount

versions of the 8350 Temperature Transmitter.

2. Specifi cations

General

Compatibility: Signet 8350 Temperature Transmitters

Signet 8900 Multi-Parameter Controller

Signet 9900 Transmitter

Wetted material: PVDF

Measurement range:

• In-line installation: -10 °C to 100 °C (14 °F to 212 °F)

• Submersible installation: -10 °C to 85 °C (14 °F to 185 °F)

Response time, : 10 seconds

Process connection:

Rear connection:

Cable type: 3 cond + shield, 22 AWG

Standard cable length: 4.6 m (15 ft)

Shipping weight: 0.22 kg (0.5 lb)

3

/4 in. NPT male thread

3

/4 in. NPT male thread

Approvals & Standards

• CE

• RoHS Compliant

• Manufactured under ISO 9001 for Quality,

ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety.

Declaration of Conformity according to FCC Part 15.

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

China RoHS (Go to www.gfsignet.com for details)

Dimensions

Electrical

Power requirements:

• (S

• 4 to 20 mA models: 12-24 VDC ±10%

Short circuit & reverse polarity protected

Digital (S

• Accuracy: ±0.5 °C (±0.9 °F)

• Repeatability: ±0.1 °C (±0.2 °F)

• Resolution: 0.01 °C (0.02 °F)

• Update rate: <100 ms

4 to 20 mA output:

• Accuracy: ±32 μA

• Repeatability: ±0.1 °C (±0.2 °F)

• Resolution: <5 μA

• Factory Span: 0 °C to 100 °C, fi eld-scaleable.

• Max loop impedance: 50 Ω @ 12 V

325 Ω @ 18 V

600 Ω @ 24 V

• Update rate: <100 ms

Environmental

• Relative humidity: 0 to 95% (Non-condensing)

• Storage temperature: -55 °C to 100 °C (-67 °F to 212 °F)

3

L) models: 5 VDC ±10%, <1.5 mA

3

L) output: Serial ASCII, TTL level 9600 bps

Page 2

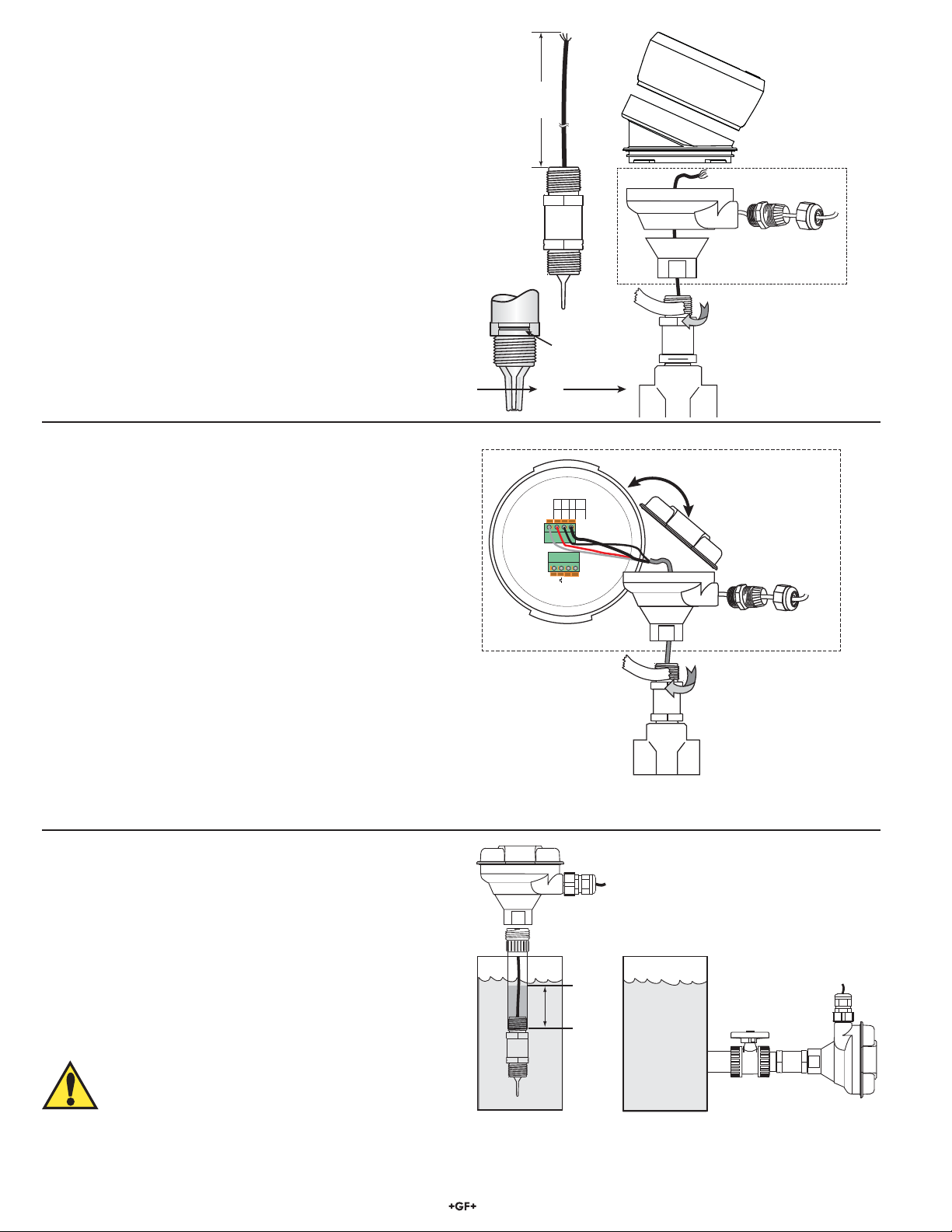

3. Installation

*

3-8052

Integral mount kit

3-9900

3-8350

3-9900.396

Angle Adjustment Adapter Kit

*Customer supplied extension cable

must not exceed 305 m (1000 ft.)

The compact integral assembly can be installed using the

following directions:

3.1 2350-1 Integral Assembly Sensor Modifi cation

• Modify sensor part number 3-2350-1 per fi gure 1.

• Apply sealant or PTFE tape to the process connection threads

per fi gure 2, after inspecting threads to ensure integrity. Do not

install a sensor with damaged threads.

• Thread the sensor into the 3-8052 mounting kit.

• Tighten the sensor 1½ turns past fi nger tight into the process

connection.

• Make sure the fl ow alignment indicator is in correct position in

the pipe. Damage to the sensor tip can occur if the sensor tip is

installed improperly.

• Install 8350 transmitter

(refer to 8350 or 9900 manual for wiring information).

• The 3-8052 Integral kit includes:

• 3/4 in. NPT process connection

• 3-9000.392-1 liquid tight connector,

• Conduit base to attach 8350.

3.2 2350-3 In-line Remote Assembly

or 9900

1

/2 in. NPT

152 mm

Figure 1

(6 in.)

Align with

flow stream

Flow

Figure 2

The optional 3-8052-1 Integral Junction box with ¾ in. process

connection offers a convenient terminal point to extend the 2350

cable over distances greater than 4.6 m (15 ft).

• The kit includes:

• ¾ in. NPT process connection

• Conduit base and cap with junction terminals

• 3-9000.392-1 liquid tight connector, ½ in. NPT

To extend the wires longer than 4.6 m (15 ft):

• Modify sensor 3-2350-1 or 3-2350-3 as described in fi gure 1.

• Terminate the three wires to the terminal board located in the

cap assembly.

• Add customer-supplied wire to extend the cable.

• Terminate to the transmitter or the 4 to 20 mA input device.

• Apply sealant or PTFE tape to the process connection threads

per fi gure 3, after inspecting threads to ensure integrity.

DO NOT install a sensor with damaged threads.

• Tighten the sensor 1½ turns past fi nger tight into the process

connection.

3.3 2350-1 or 2350-3 Submersible Installation

• Use the 2350-1 or 2350-3 sensor with 4.6 m (15 ft) cable.

• Mount the sensor to an extension pipe or watertight conduit

using thread sealant.

• Use a cable gland at the top of the extension to prevent

moisture intrusion/accumulation inside the pipe.

• For additional defense against possible accumulation of

condensation at the back seal area of the sensor, fi ll the lower

75 mm to 100 mm (3 in. to 4 in.) of conduit or extension pipe

with a fl exible sealant such as silicone.

WHT WHT

4-20

BLU BLK

N/C RED

mA

SHIELD

FREQ/

DATA

SENSOR

INPUT

+

SHIELD

–

FREQ/

DATA

MXQFWLRQER[UHFRPPHQGHG

Fill with

3 to 4 in.

of sealant

3-8052-1

Integral junction box,

3/4 in. NPT

*

*Customer supplied extension cable

must not exceed 305 m (1000 ft.)

Figure 3

CAUTION!

The fl uid temperature must not exceed 85 °C (185 °F)

in submersible installations.

NOTE:

The 8050-1 or the 8052-1 junction boxes can be useful

accessories for this installation option.

2

2350 Temperature Sensor

Page 3

+

-

3-8052

3-8050.521

Loop Input +

4 to 20 mA

loop monitor

Power Supply

DC 12 - 24 V

Black (Loop +)

Optional

Earth Ground

Loop Input -

Shield

White (Loop - )

Red

4. Digital (S3L) Wiring

• All models of the 2350 provide Digital (S3L) output when powered with 5 VDC.

• Connecting the SHIELD to a direct Earth ground may reduce electrical noise interference.

• The maximum Digital (S3L) cable length is dependent upon the instrument to which the sensor is connected. Consult the instrument

manual for details.

• Connect the 2350 cable directly to

Digital (S

3

L) I/O terminals.

3-8052

3-9900

3

L connector

S

3

S L (Red)

3

S L (Red)

Shield

White

Red

Black

3-8900.621C

1

2

3

4

5

6

7

8

9

10

11

+

-

12

13

+

-

14

White

Red

Black

Optional

Earth ground

SHLD

GND

DATA

V+

3-8900

I/O Module Connector

I/O Module 3-8900.401-X

+5VDC (Black)

Frequency

Input

Freq. Input (Red)

1

GND (Shield)

+5VDC (Black)

Frequency

Input 2

Freq. Input 2 (Red)

OR

S3L

Input

2

GND (White/Shield)

+5VDC (Black)

S3L

Input

1

GND (White/Shield)

Analog Output 1

(if applicable)

Analog Output 2

(if applicable)

3-8350

Temperature Transmitter

GND

7

IN

6

V+

5

White

Red

Black

White

Black

Red

Shield

WHT WHT

4-20

BLU BLK

N/C RED

mA

SHIELD

FREQ/

DATA

SENSOR

INPUT

+

SHIELD

–

FREQ/

DATA

3-8052-1

• When the 2350 includes a junction

box, connect the 2350 terminals to any

Digital (S3L) I/O port as shown.

5. 4 to 20 mA Loop Wiring

• The 2350-3 provides a 4 to 20 mA loop output when powered with 24 VDC.

• Connecting the SHIELD to a direct Earth ground may reduce electrical noise interference.

• Red wire is not used, do not remove the heat shrink. See Section 6, 4 to 20 mA Span Adjustment.

5.1 Current Loop With No Junction Box 5.2 Current Loop With Junction Box

Black

+

-

White

+

-

• Connect the 2350 cable directly to a loop device as shown.

2350 Temperature Sensor

Power Supply

DC 12 - 24 V

Loop Input

Loop Input

• When the 2350 includes a junction box, connect the 2350

terminals to a loop device as shown.

INPUT

SENSOR

WHT WHT

4-20

BLU BLK

N/C RED

mA

SHIELD

FREQ/

DATA

SHIELD

+

–

FREQ/

DATA

3-8052-1

3

Page 4

6. 4 to 20 mA Span Adjustment

+

-

3-8052

3-8050.521

Loop Input +

4 to 20 mA

loop monitor

Power Supply

DC 12 - 24 V

Black (Loop +)

Optional

Earth Ground

Loop Input -

Shield

White (Loop - )

Red

The 4 to 20 mA endpoint values are independent of one another

and may be adjusted in the fi eld. For example, to reduce the 20 mA

endpoint value from the factory setting of 100 °C, but to allow the 4 mA

endpoint to remain at 0 °C, perform only the steps listed in 6.2 below.

NOTE: The RED wire, which is not connected during normal

4 to 20 mA operation, assumes an important role in the

following procedures.

6.1 To adjust the 4 mA endpoint in the fi eld:

• Carefully remove the heat shrink tube protecting the red wire.

• Expose the sensor to the temperature desired to correspond with 4 mA

-10 °C to 100 °C (submersible: -10 °C to 85 °C).

(Be sure to allow suffi cient time for the sensor to reach equilibrium.)

• With power applied as described in Section 5, connect the RED wire to the WHITE wire for 15 seconds.

(After about 10 seconds the output will drop to 3.6 mA and remain there until the RED wire is disconnected.)

• Disconnect the RED wire from the WHITE wire; the 4 mA endpoint has been adjusted.

• NOTE: The output will act as a switch if the 4 and 20 mA endpoints are set very near to the same value.

6.2 To adjust the 20 mA endpoint in the fi eld:

• Expose the sensor to the temperature desired to correspond with 20 mA -10 °C to 100 °C (submersible: -10 °C to 85 °C).

(Be sure to allow suffi cient time for the sensor to reach equilibrium to this temperature.)

• With power applied as described in Section 5, connect the RED wire to the BLACK wire for 15 seconds.

(After about 10 seconds the output will rise to 22 mA and remain there until the RED wire is disconnected.)

• Disconnect the RED wire from the BLACK wire; the 20 mA endpoint has been adjusted.

NOTE: The output will act as a switch if the 4 and 20 mA endpoints are set very near to the same value.

• Minimum span is ±2% of maximum range.

• After adjusting the 4 to 20 mA span, protect the red wire by installing the provided wire nut.

• For easier re-spanning use the Signet 0250 USB to Digital (S3L) Confi guration/Diagnostic Tool.

Wire Nut

6.3 To restore the factory setting:

• Disconnect power to the sensor. Wait 10 seconds for circuit to discharge.

• Connect the RED wire to the WHITE wire.

• Apply power as described in Section 5, but with the RED wire connected to the WHITE wire for 15 seconds.

(After about 10 seconds the output will drop to 3.6 mA and remain there until the RED wire is disconnected.)

• Disconnect the RED wire from the WHITE wire; factory settings have been restored.

Mfr. Part No. Factory Span

3-2350-3 4 to 20 mA = 0 °C to 100 °C

7. Ordering Information

Mfr. Part No. Code Description

3-2350-1 159 000 021 Temperature sensor, (S

3-2350-3 159 000 920 Temperature sensor, 4 to 20 mA output,

Accessories

Mfr. Part No. Code Description

3-8050-1 159 000 753 Universal mount junction box

3-8052 159 000 188

3-8052-1 159 000 755

3

/4 in. Integral mounting kit

3

/4 in. NPT mount junction box

3-9000.392-1 159 000 839 Liquid tight connector kit, NPT (1 piece)

3-9000.392-2 159 000 841 Liquid tight connector kit, PG13.5 (1 piece)

3-9900.396 159 001 701 Angle Adjustment Adapter Kit

5523-0322 159 000 761 Cable, 3 conductor + shield, 22 AWG, black/red/white/shield

3-0250 159 001 538 USB to digital (S

3

L) output, 3/4 in. NPT, 4.6 m (15 ft) cable

3

L) confi guration/diagnostic tool

3

/4 in. NPT, 4.6 m (15 ft) cable

WARNING!

Not protecting the

red wire may cause

the 4 to 20 mA span

to be reset.

* Custom cable length available, contact the factory.

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2350.090-1 Rev. K 03/13 English © Georg Fischer Signet LLC 2013

Loading...

Loading...