Page 1

Signet 2250 Hydrostatic Level Sensor

English

*3-2250.090*

3-2250.090 Rev. E 06/13 English

Safety Instructions

1. Prior to installation or removal:

• Depressurize and vent system

• Drain below sensor level

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. Dispose of properly; DO NOT INCINERATE!

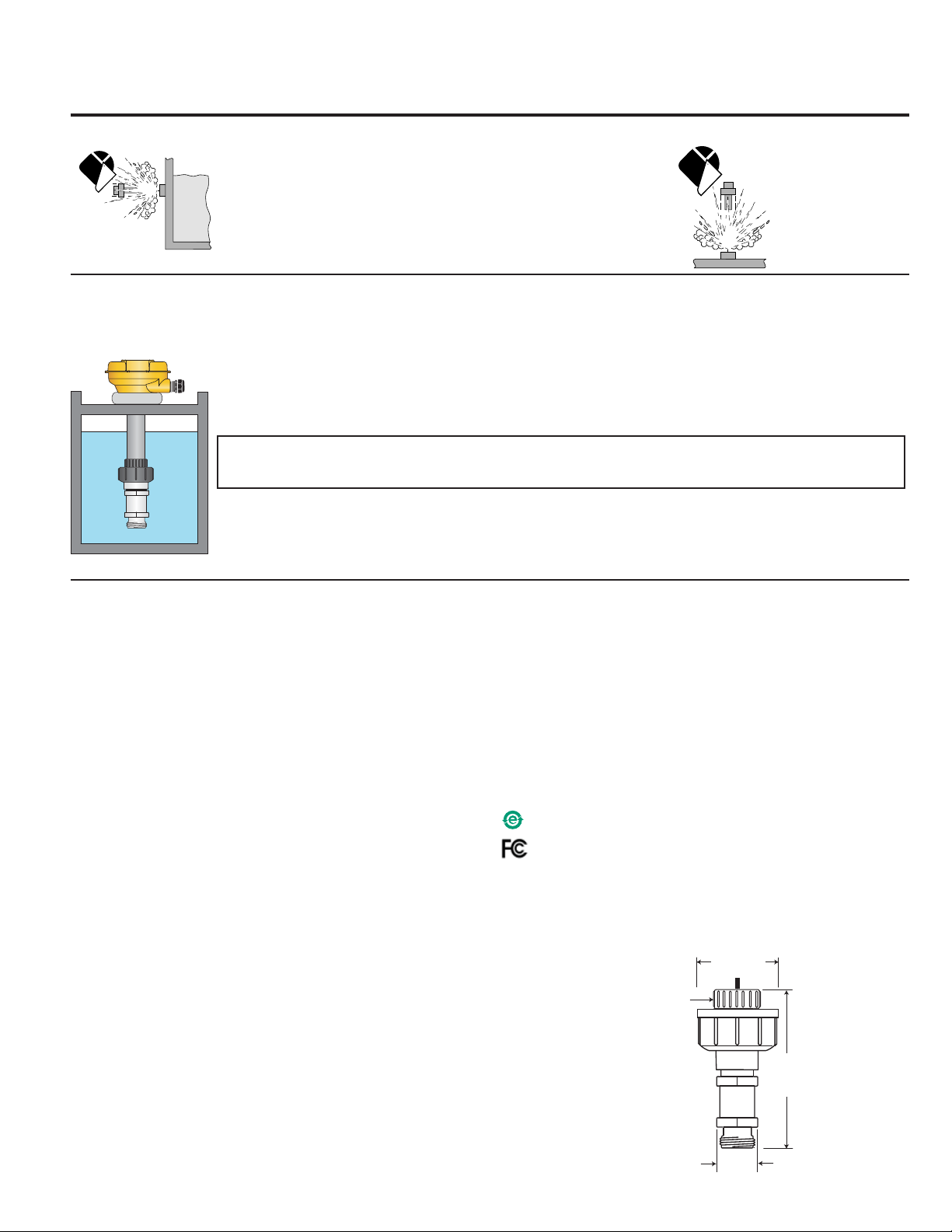

1. Description

The Signet 2250 Hydrostatic Level Sensor uses a gauge pressure sensor to calculate the level of fl uid in a tank.

Gauge pressure sensors measure the difference in pressure between the process on one side of a diaphragm and the atmospheric

pressure on the opposite side of the diaphragm. A tiny capillary tube running from inside the sensor body and

up the length of the cable provides the reference to atmospheric pressure.

Hydrostatic level measurement can be a simple and practical solution to those applications where the fl uid

temperature is stable and constant.

IMPORTANT! This method of level measurement is not recommended if the fl uid is subject to

temperature variations or any other variable that causes the density of the fl uid to change.

The 2250 Hydrostatic Level Sensor has excellent chemical compatibility.

The wetted materials are PVDF, Ceramic and FPM.

Several different hardware mounting kits are available to accommodate every installation requirement.

2. Specifi cations

General

Compatibility: Signet 8900 Multi-Parameter Controller

Signet 9900 Transmitter

Wetted Material

• Sensor housing: PVDF

• Union nut/bushing: PVC-U

• Diaphragm: Ceramic

• Diaphragm seal: FPM (optional EPDM)

Cable type: 22 AWG, 3 conductor+capillary tube

Cable length: 10 m (32.8 ft) supplied

max. extension 120 m (400 ft)

Operating Temperature: 15 °C to 85 °C (5 °F to 185 °F)

Storage Temperature: -20 °C to 100 °C (-4 °F to 212 °F)

Operating Pressure: -XU: 0 to 0.7 bar (0 to 10 psig)

-XL: 0 to 3.4 bar (0 to 50 psig)

Electrical

Digital (S

• Format: Serial ASCII, TTL level 9600 bps.

• Accuracy: ±1% of full scale (±0.001 psi)

• Power: 5 VDC nominal, 1.5 mA max. current

(5 VDC min, 6.5 VDC max)

• Reverse polarity and short circuit protected

4 to 20 mA Output:

• Factory span:

• Accuracy: ± 32 μA

• Resolution: < 5 μA

• Response Time: < 100 ms

3

L) Output:

• -XU: 0 to 0.7 bar (0 to 10 psig) =

0 m to 7 m (0 ft to 23 ft) of water

• -XL: 0 to 3.4 bar (0 to 50 psig) =

0 m to 34 m (0 ft to 115.5 ft) of water

• Loop Power Required: 12 to 24 VDC nominal, 22.1 mA max

(10.8 VDC min. to 26.4 VDC max.)

• Max. Loop Impedance:

100 Ω @ 12 V

325 Ω @ 18 V

600 Ω @ 24 V

Standards and Approvals:

• CE

• RoHS Compliant

• Manufactured under ISO 9001 for Quality,

ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety.

China RoHS (Go to www.gfsignet.com for details)

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Dimensions

½ in. (ANSI) or

25 mm (ISO)

Solvent Socket,

PVC-U

53 mm

(2.09 in)

115 mm

(4.55 in)

34 mm

(1.32 in)

Page 2

Installation

IMPORTANT!

A tiny capillary tube inside the sensor body is used to ensure that the back of the diaphragm remains at atmospheric pressure.

If the capillary tube is blocked or damaged, the sensor cannot operate properly.

• If moisture is allowed to propagate down this tube to the rear of the diaphragm, the sensor may be damaged.

• Do not allow the cable to be bent or compressed.

• The ceramic diaphragm in the 2250 can be permanently damaged by over-pressure conditions or by mechanical contact.

HANDLE THESE SENSORS WITH CARE.

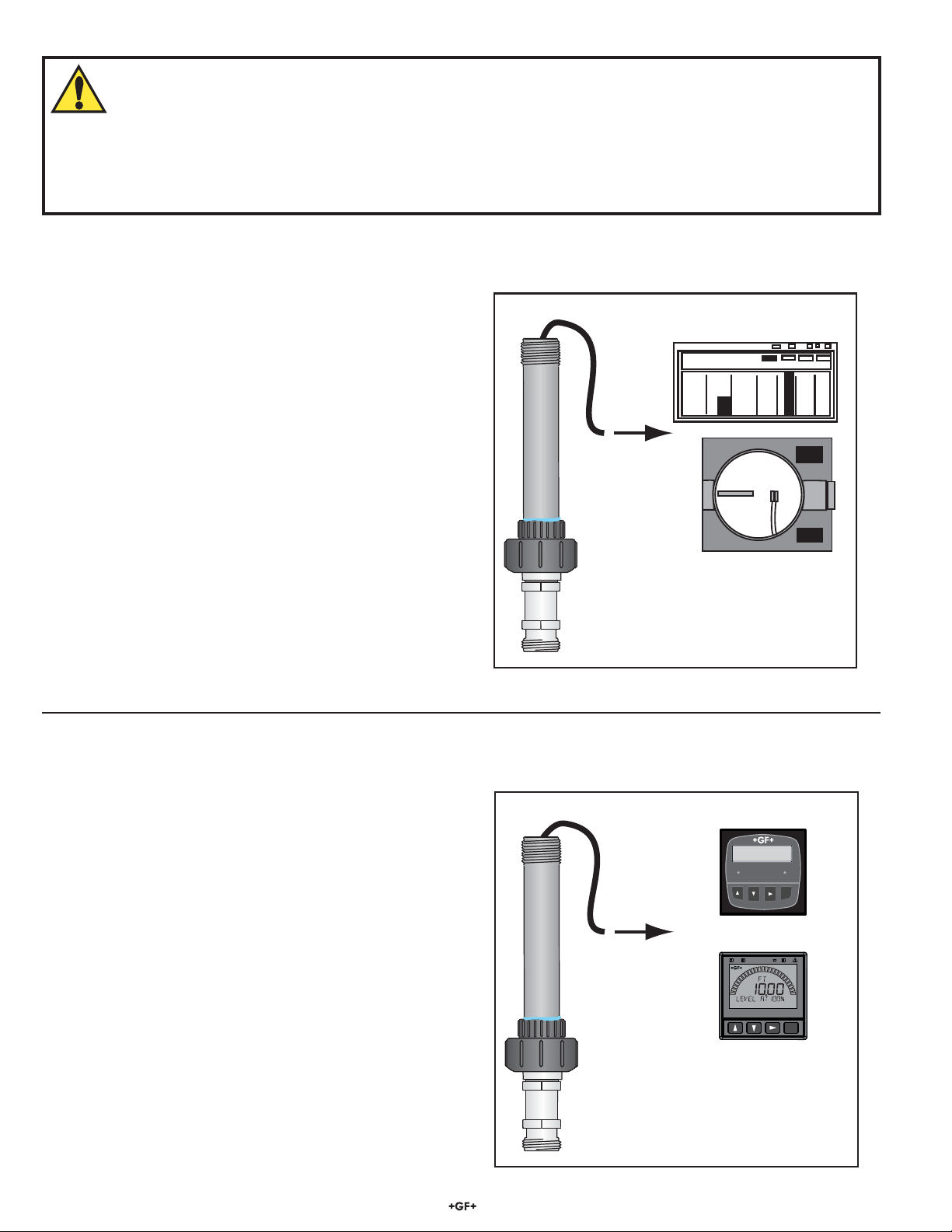

Direct 4 to 20 mA output

The 2250 can be assembled as a blind 4 to 20 mA signal connected

by cable to a PLC, chart recorder or other 4 to 20 mA device.

This type of installation requires no additional hardware.

The user must provide the ¾ in. conduit to protect the cable from

PLC

damage. The 2250 cable is not suitable for direct submersion.

4 to 20 mA

The 2250 can be assembled as a digital sensor connected

directly to a Signet 8900 Multi-Parameter Controller or Signet

9900 Transmitter.

3-2250-2xx-x

Direct Digital output

Digital (S

C1 2.50 μS/cm

L2 58.43 M

Multi-Parameter

Controller

Relay 1

Relay 2

ENTER

3-8900

3

L)

ENTER

3-9900

3-2250-1xx-x

2 2250 Hydrostatic Level Sensor

Page 3

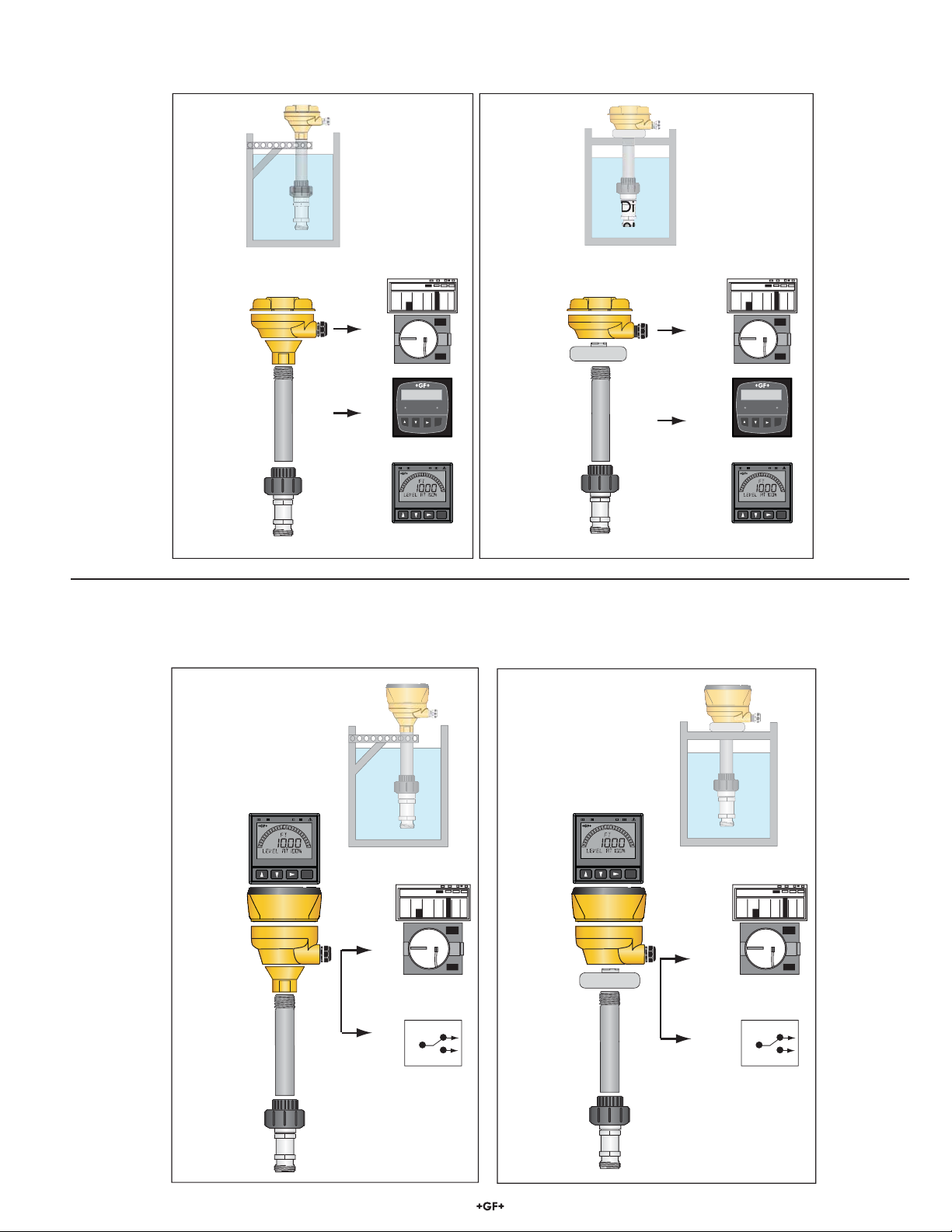

2250 with 4 to 20 mA or Digital (S3L) Output: Remote Mounting

The 2250 can provide a digital (S3L) signal to a 9900 Transmitter or 8900 Multi-Parameter Controller.

The 2250 can provide a 4 to 20 mA signal to a PLC or to a chart recorder.

4-20 mA or Digital (S3L) signal out

Clamped to Tank support

3-8052-1

4-20 mA Out

OR

Digital (S3L)

¾ in. conduit

(customer supplied)

3-2250-xx

PLC

C1 2.50 μS/cm

L2 58.43 M

Relay 1

3-8900

3-9900

Multi-Parameter

Controller

4-20 mA or Digital (S

Mounted through Tank Cover

3-8050-1

Relay 2

ENTER

ENTER

¾ in. conduit

(customer supplied)

3-2250-xx

3

L) signal out

4-20 mA Out

OR

3

Digital (S

PLC

C1 2.50 μS/cm

L2 58.43 M

L)

Multi-Parameter

Controller

Relay 1

Relay 2

ENTER

3-8900

ENTER

3-9900

2250 with Digital Output: Integral mounting

The 2250 can be assembled as an integral system, with the 3-9900-1 Transmitter mounted directly atop the sensor. This confi guration

provides a local display at the measurement site, plus the 4 to 20 mA and open-collector output features of the 9900 Transmitter.

Integral Transmitter

Clamped to Tank support

3-9900-1

3-8052

¾ in. conduit

(customer supplied)

3-2250-X

ENTER

4-20 mA Out

AND

Control Relay Out

Integral Transmitter

Mounted through Tank Cover

3-9900-1

PLC

3-8050

NC

C

NO

¾ in. conduit

(customer supplied)

3-2250-XX

ENTER

4-20 mA Out

Control Relay Out

PLC

AND

NC

C

NO

32250 Hydrostatic Level Sensor

Page 4

2250 Assembly Detail

1.

Glue the union bushing onto the conduit.

2.

Thread the sensor cable through the O-ring, Union

and through the ¾ in. conduit.

3.

6A.

Remote system

Cut the cable to length and terminate

the wires at the terminal block inside the

conduit base.

CAUTION

The capillary tube that runs

the length of the sensor

cable must remain open to

the atmosphere. Do not allow

it to be crimped or blocked.

4-20 mA Out

OR

Digital (S

3

L)

PLC

C1 2.50 μS/cm

L2 58.43 M

Multi-Parameter

Relay 1

3-8900

Controller

Relay 2

ENTER

ENTER

3-9900

Thread the Union nut onto the Union bushing.

CAUTION

Hand tighten the nut. Do not use tools.

4.

Thread the ¾ in. conduit adapter or the

universal adapter onto the top of the

conduit. Use a suitable thread sealant to

provide a watertight connection.

5.

6B.

Integral system

Cut the cable to length and terminate

the wires at the terminal block of a

fi eld-mounted 9900-1 Transmitter.

CAUTION

The capillary tube that runs the

length of the sensor cable must

remain open to the atmosphere.

Do not allow it to be crimped or

blocked.

4-20 mA Out

PLC

AND

Mount the conduit base onto the adapter and

secure the assembly with the locking ring.

C

Control Relay Out

4 2250 Hydrostatic Level Sensor

NC

NO

Page 5

Digital (S3L) wiring

• 3-2250-11X-X options provide Digital (S3L) output when powered with 5 VDC from a 9900 Transmitter or a 8900 Multi-Parameter Controller.

• Connecting the SHIELD to a direct Earth ground may reduce electrical noise interference.

• The maximum Digital (S

Consult the instrument manual for details.

3-2250-11X-X to 8900 Multi-Parameter Controller

Digital (S3L) Sensors

3-2250-11U

3-2250-11L

3-2250-11U-1

3-2250-11L-1

3

L) cable length is dependent upon the instrument to which the sensor is connected.

Lvl1 4.20 m

Black

White

Lvl2 8.53 m

Multi-Parameter

Controller

Relay 1

Red

Relay 2

ENTER

Shield

I/O Module 3-8900.401-X

Frequency

Input

Frequency

Input 2

OR

S3L

Input

S3L

Input

1

+5VDC (Black)

Freq. Input (Red)

1

GND (Shield)

+5VDC (Black)

Freq. Input 2 (Red)

2

GND (White/Shield)

+5VDC (Black)

GND (White/Shield)

Analog Output 1

(if applicable)

Analog Output 2

(if applicable)

3

S L (Red)

3

S L (Red)

3-8900.621C

1

2

3

4

5

6

7

8

9

10

11

+

12

-

13

+

14

-

Optional

Earth ground

3-2250-11X-X to 9900 Transmitter

Digital (S3L) Sensors

3-2250-11U

3-2250-11L

3-2250-11U-1

3-2250-11L-1

V+

DATA

SHLD

GND

Shield

White

Red

Black

ENTER

52250 Hydrostatic Level Sensor

Page 6

4 to 20 mA Loop Wiring

• The 3-2250-21X-X models provide a 4 to 20 mA loop output when powered with 24 VDC.

• Connecting the SHIELD to a direct Earth ground may reduce electrical noise interference.

Black (Loop +)

Red (no connection)

White (Loop -)

Cable shield

Optional Earth ground

Programmable Logic

Controller (PLC)

4-20 mA Loop Monitor

Chart Recorder

Datalogger

4 to 20 mA Sensors

3-2250-21U

3-2250-21L

3-2250-21U-1

3-2250-21L-1

Power Supply

+

DC 12 - 24 V

-

+

-

4 to 20 mA Span

The 2250 is available in two factory-set span ranges:

• Models numbers ending with "U" or "U-1" have a factory span of 0 to 10 psig.

• Model numbers ending in "L" or "L-1" are spanned for 0 to 50 psig.

The chart below lists the factory span of all available models.

The level ranges in meters and feet are based on the mass of water.

Mfr. Part No. Code 4 to 20 mA Span

3-2250-21U 159 001 248 0 to 0.7 bar (0 to 10 psig) 0 m to 7 m (0 ft to 23.09 ft)

3-2250-21L 159 001 247 0 to 3.4 bar (0 to 50 psig) 0 m to 34 m (0 ft to 115.5 ft)

3-2250-21U-1 159 001 482 0 to 0.7 bar (0 to 10 psig) 0 m to 7 m (0 ft to 23.09 ft)

3-2250-21L-1 159 001 483 0 to 3.4 bar (0 to 50 psig) 0 m to 34 m (0 ft to 115.5 ft)

6 2250 Hydrostatic Level Sensor

Page 7

Respanning the 4 to 20 mA output

• The 4 to 20 mA span can be set to accommodate any application within the operating range of the sensor.

• The respanning procedure requires that the sensor be subjected to the actual pressure that will represent 4 mA and 20 mA.

• The procedure illustrated here assumes that the application requires that the sensor output is 4 mA when the tank is empty

and 20 mA

when the tank is full. To reverse the range, reverse steps 3 and 5.

1. 2.

Black (Loop +)

Red (no connection)

White (Loop -)

+

Power Supply

-

DC 12 - 24 V

Install the sensor.

3.

= 4 mA

Fill tank to the level

represented by 4 mA.

= 20 mA

Programmable

Logic Controller

4-20 mA loop monitor

Chart Recorder

Datalogger

Wire the 4-20 mA Loop and turn the power ON.

4.

Carefully remove the heat shrink tube that is protecting

the red wire.

Short the RED and WHITE wires together for 15 seconds.

mA should go to 3 to 6 mA

Disconnect red wire

Black (Loop +)

Red (no connection)

White (Loop -)

Programmable

Logic Controller

4-20 mA loop monitor

Chart Recorder

Datalogger

6.5.

Black (Loop +)

Red (no connection)

White (Loop -)

+

-

+

Power Supply

DC 12 - 24 V

-

+

-

15s

+

Power Supply

DC 12 - 24 V

-

Wire Nut

WARNING!

Not protecting the

red wire may cause

the 4 to 20 mA

span to be reset.

Fill the tank to the level to be

represented by 20 mA.

Programmable

Logic Controller

4-20 mA loop monitor

Chart Recorder

Datalogger

Short the RED and BLACK wires together for 15 seconds.

mA should go to 22 mA

Disconnect red wire

After adjusting the 4 to 20 mA span, protect the red wire by

installing the provided wire nut.

For easier re-spanning use the Signet 0250 USB to Digital (S

Configuration/Diagnostic Tool.

+

-

15s

3

L)

72250 Hydrostatic Level Sensor

Page 8

Ordering Information

Sensor Part Number

3-2250 Hydrostatic Level Sensor

Sensor Output

-1 Digital (S

-2 Current (4 to 20 mA), 10m (32.8 ft.)

Threaded Connection

1 ½ in. union connector

3-2250 -1 1 U Example Part Number

2250 Hydrostatic Level Sensor

Mfr. Part No. Code Description

3-2250-11U 159 001 242 0 to 0.7 bar (0 to 10 psi), Digital (S

3-2250-11L 159 001 241 0 to 3.4 bar (0 to 50 psi), Digital (S3L), ½ in. union, ¾ in. PVC-U Union

3-2250-21U 159 001 248 0 to 0.7 bar (0 to 10 psi), 4 to 20 mA, ½ in. union, ¾ in. PVC-U Union

3-2250-21L 159 001 247 0 to 3.4 bar (0 to 50 psi), 4 to 20 mA, ½ in. union, ¾ in. PVC-U Union

3-2250-11U-1 159 001 478 0 to 0.7 bar (0 to 10 psi), Digital (S

3-2250-11L-1 159 001 479 0 to 3.4 bar (0 to 50 psi), Digital (S3L), ½ in. union, Metric PVC-U Union

3-2250-21U-1 159 001 482 0 to 0.7 bar (0 to 10 psi), 4 to 20 mA, ½ in. union, Metric PVC-U Union

3-2250-21L-1 159 001 483 0 to 3.4 bar (0 to 50 psi), 4 to 20 mA, ½ in. union, Metric PVC-U Union

3

L), 10 m (32.8 ft.)

Operating Pressure Range

U 0 to 0.7 bar (0 to 10 psi)

L 0 to 3.4 bar (0 to 50 psi)

PVC-U Union Connection

- ¾ in. socket

-1 Metric pipe connector

3

L), ½ in. union, ¾ in. PVC-U Union

3

L), ½ in. union, Metric PVC-U Union

Accessories and Replacement Parts

Mfr. Part No. Code Description

5523-0322 159 000 761 Sensor cable (per ft.). 3 conductor plus shield, 22 AWG (black/red/white/shield)

3-9000.392-1 159 000 839 Liquid tight connector kit, NPT (1 pc.)

3-9000.392-2 159 000 841 Liquid tight connector kit, PG 13.5 (1 pc.)

3-8050 159 000 184 Universal mount kit

3-8052 159 000 188 ¾ in. Integral mount kit

3-8050-1 159 000 753 Universal Mount w/Junction terminals

3-8052-1 159 000 755 ¾ in. Integral mount w/Junction terminals

3

3-0250 159 001 538 USB to Digital (S

L) Confi guration/Diagnostic Tool

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2250.090 Rev. E 06/13 English © Georg Fischer Signet LLC 2013

Loading...

Loading...