Page 1

GFB DV+

Installation Instructions

Part #T9351

Page 2

The DV+ difference

Whilst the DV+ might look pretty basic, there is a very significant difference in the way it operates compared to

the factory diverter valves, and other aftermarket products on the market.

The factory diverter valves use the solenoid to directly actuate the valve. The problem with this method is the

actuating forces are very weak – the return spring is weak, and the solenoid coil is weak when the valve is fully

closed because of the long 5mm stroke (magnetic force diminishes significantly as distance increases). So

increasing the spring pre-load of the factory valve doesn’t help, since the solenoid coil will have trouble opening

the valve.

The GFB DV+ uses the factory solenoid coil, but its role is to control the pressure signal used to actually open and

close the piston, which is known as “pilot actuation”. This means the forces that the solenoid coil needs to

actuate are much lower, and its operation is therefore reliable at much higher pressure. The solenoid operates a

plunger than controls pressure to the back of the piston. When the solenoid is off, there is equal pressure on both

sides of the piston, but importantly, the area the pressure acts on is about 25% LARGER on the back of the piston

than the front. So there is 25% more force holding the piston shut than there is pushing it open. The bottom line

is, it doesn’t matter how much boost you run, the DV+ will never crack open.

When the solenoid activates, the pressure on the back of the piston is relieved, and it can then open. The benefits

of this system are reliable valve actuation at high boost, no leakage, and being all metal parts, no failures due to

increased temperature.

Because the DV+ has a higher closing force than opening force, it doesn’t actually NEED a return spring behind the

piston to work – it will open and shut, and hold boost, just as reliably with or without the spring.

However, using the spring means that unlike the factory diverter, the GFB DV+ will open in response to both

boost pressure AND the ECU signal operating the solenoid. That is, if the solenoid is triggered but there is no

boost, it won’t open. If the solenoid is triggered and there is boost, the valve will open only as long as there is

boost pressure pushing it open. It will close itself as boost pressure in the intercooler drops, even if the ECU is

telling it to open. This operation method results in less turbo lag, because the valve is not opened unnecessarily.

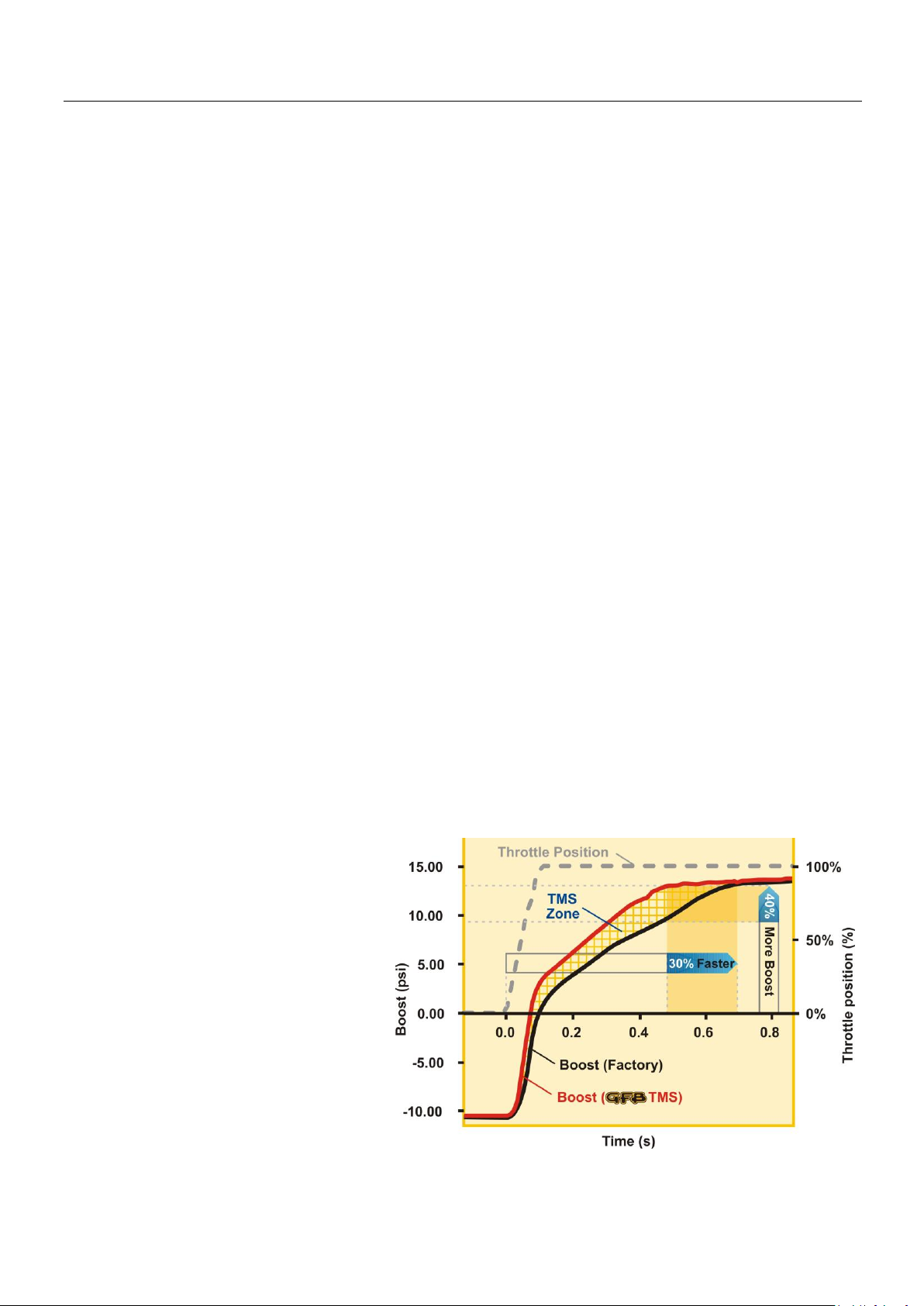

This is the basis behind GFB’s TMS principle,

which is this; turbo lag is minimised when

the valve only vents just enough air to

prevent compressor surge – the graph

opposite illustrates the reduction in lag. To

read more about the TMS principle, visit our

website: www.gfb.com.au

Page 3

Installation Instructions for GFB DV+ TMS valve (part # T9351)

Locate factory diverter valve solenoid. It will

either be mounted directly on the turbo

compressor cover, or can be mounted

remotely on cars like the Golf R

Unclip the wiring connector from the top of the

solenoid coil – note there is a small locking tab

that needs to be pulled in the same direction (as

indicated by the arrow opposite) as you pull the

connector to release it

Unscrew the 3 mounting screws and remove the

factory valve from the car

Now separate the factory valve mechanism from the solenoid coil, and install the GFB valve mechanism onto the

factory solenoid as follows:

Pull on the plastic “basket”

(revision D) or the diaphragm

shroud (revision G), the whole

assembly will pop off leaving the

bare solenoid coil. Keep the

yellow o-ring

Install the GFB parts onto the solenoid as shown below, using a little engine oil on the outside of the

piston. Make sure to use the GFB supplied spring inside the solenoid coil – the only factory parts you reuse are the solenoid coil and the yellow o-ring:

Fit the valve/solenoid assembly to the car in the factory location using the supplied longer bolts, and re-

connect the wiring loom

Page 4

This product is intended for racing use only, and it is the owner’s responsibility to be aware of the legalities of fitting t his

product in his or her state/territory regarding noise, emissions and vehicle modifications. GFB recommends that only

qualified motor engineers fit this product.

Materials and workmanship of this product are covered by a lifetime warranty. Moving components subject to wear are

covered for a period of one year from the date of purchase. Warranty is limited only to the repair or replacement of GFB

products provided they are installed and used as intended, and in accordance with all applicable warnings and limitations.

No other warranty is expressed or implied.

GFB products are engineered for best performance, however incorrect use or modification of factory systems may cause

damage to or reduce the longevity of the engine or drivetrain components.

GFB

P.O. Box 1017

Riverwood, NSW 2210, Australia

Ph: +612 9534 0099 Fax: +612 9534 3999

Website: www.gfb.com.au Email: sales@gfb.com.au

Loading...

Loading...