Page 1

Instructions for GFB Short Shift Kit for MY97-07 WRX 5-speed

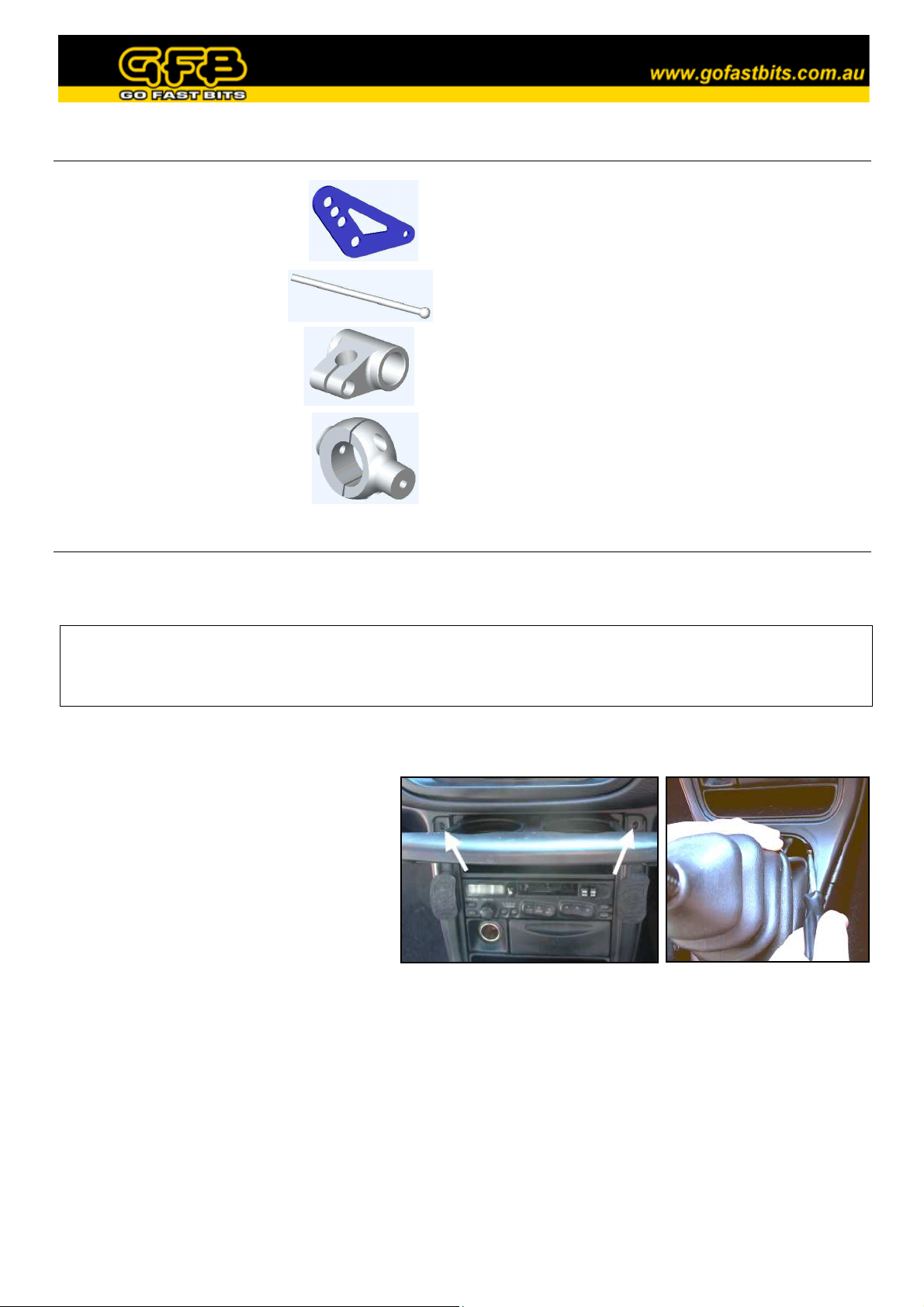

Included in kit:

• 2 x side plates

• 1 x shift stick

• 1 x shift pivot

• 1 x linkage knuckle,

including:

2 x M4 x 12 socket screws*

2 x M4 x 8 socket screws**

* These parts are used only on MY01-07 (GDA) models

** These parts are used only on MY97-00 (GC8) models

• 2 x M8 x 16 button head screws with nuts

• 2 x M8 washers*

• 2 x M5 x 8 button head screws

• 1 x M8 x 55 bolt**

• 1 x 3mm hex key

• 1 x 4mm hex key

• 1 x 5mm hex key

• M12 x 1.25 threaded nut

• Steel sleeve**

Required tools:

• 12mm spanner

• Shifting spanner

• Flat-blade screwdriver

• Large hammer or mallet

• Phillips head screwdriver (MY97-00)

GFB Short Shift Kits carry a 12 month warranty from the date of purchase which covers faulty components or

manufacturing. Warranty is limited only to the repair or replacement of GFB products provided they are used as

intended and in accordance with all appropriate warnings and limitations. No other warranty is expressed or implied.

1. Unscrew the gear knob and remove the plastic surrounds from the gearstick following the appropriate

instructions below for your year model.

• MY97-98 – Open the cup holder tray

and remove the two Phillips head

screws found behind (figure 1), then

gently lift the rubber gearstick boot at

the front corners to expose another two

Phillips head screws (figure 2). Remove

these also and the surround will lift off.

Figure 1 Figure 2

• MY99-00 – Lift the lid of the centre console, and remove the two Phillips head screws that hold down

the handbrake shroud. Lift the handbrake shroud off (it clips in at the front), and then the gearstick

surround simply clips off.

• MY01-07 - Lift the lid of the console between the seats above the handbrake. On the plastic handbrake

shroud there are two slots, using the flat-blade screwdriver padded with a rag, carefully lever the shroud

up on each side (there is a pop-type fastener on each side). Lift the handbrake shroud out, giving you

access to the gearstick surround. Simply lift the plastic shroud off, it is only lightly clipped in and does

not need much force.

Page 2

2. Using the 12mm spanner and shifter, undo and remove the bolt

that holds the linkage to the shift stick.

3. Remove the factory shift stick by levering the ball out of the

socket. Simply push the top of the stick towards the back of the

car until it pops out (figure 3).

Figure 3

4a) IMPORTANT: The linkage knuckle is designed to fit the two different diameter shafts that are found

in different models and as such, it comes with two

different length pairs of screws. For all MY00 and

earlier models (16mm diameter shaft), use the shorter

pair of screws (M4 x 8), and for all later models

(19mm diameter shaft), use the longer pair (M4 x 12).

Also note that a small handful of US MY02 models

came with the earlier shift mechanism, in which case

simply refer to the notes regarding early models.

b) Fit the two parts around the linkage with the long side

facing up (figure 4).

c) Place the two correct length M4 screws into the holes

and screw them in until there is no slack, making sure

there is an equal gap between both sides of the two

parts. Figure 4

d) Now loosen the left screw just enough to allow the knuckle to be rotated horizontal (so that the two ends

of the knuckle are parallel to the sides of the shift linkage), but DO NOT tighten it back up just yet.

5. Fix the two side plates to the linkage by first

inserting an M8 screw through the plate and

then through the hole in the linkage fork.

Thread an M8 nut partially on, but DO NOT

tighten yet. Repeat on both sides (figure 5).

6. On both side plates, insert an M5 screw

through the matching 5mm hole and thread it

into the linkage knuckle. Now tighten all

screws and nuts. As long as the lower M4

screw on the linkage knuckle was set to the

right distance as per step 4c, you should only

have to tighten the top screw to clamp it tight.

Figure 5

Page 3

7. Smear a small amount of grease onto the shift stick ball. Thread the

supplied M12 x 1.25 hex nut onto the threaded gear knob end, until

the top of the stick is just a fraction lower than the top of the nut.

This nut is used to protect the thread of the stick for the next step.

8. Holding the stick upright, press the ball against the socket and strike

the top of the M12 nut with a hammer to pop the ball into the socket

(figure 6). This takes a solid blow to achieve, so the heavier the

hammer, the easier it will be (slow pressure simply does not work).

This process will not damage the ball or the cup, as the cup is

designed to spread apart for assembly. Make sure to remove the M12

nut before continuing.

Figure 6

9. Slide the shift pivot onto the shift stick, then remove the urethane

bushes from the factory shift stick and insert them, along with

the suitable steel sleeve, into the GFB unit (NOTE: For

MY97-00 models, use the provided steel sleeve. For MY01-04

models, use the factory sleeve instead). DO NOT tighten the

screw to clamp the shift pivot to the stick just yet.

10. Decide on how short you want the shift (pick one of the three

holes in the side plates, the higher the hole, the shorter the

shift), as a guide GFB recommends using the middle hole to

begin with. Line up the steel sleeve in the shift pivot with the

selected hole, then hold one of the M8 washers between the

sleeve and the side plate (NOTE: For MY97-00 models do not

use the washers, the sleeve is the correct length to fit between

the plates. It is not possible to use the lowest hole setting in

MY97-00 models).

Figure 7

Slide the M8 bolt (use the supplied one for MY97-00, the factory one for MY01-current) through the

side plate, the washer, and into the sleeve (figure 7). Then hold the remaining washer in the same place

on the other side, and push the bolt through fully. Thread the nut onto the end and tighten.

11. Slide the shift pivot up and down until the factory linkage does

not hit the metal plate above it, or drag on the rubber boot

below, then re-tighten the screw firmly (figure 8). Do a final

check to ensure the linkage clears its surroundings in all gears.

12. Replace the plastic shrouds in the reverse order of removal.

NOTE:

• Always make sure that no part of the shift mechanism is contacting

any of the surroundings in all gears.

•

As the shift throw is reduced by a percentage, the principle of levers

means that the force required to shift gears is proportionally

increased. THIS DOES NOT MEAN IT WILL WEAR YOUR

GEARBOX! THE SHIFTER IS MERELY A LINKAGE TO

THE GEARBOX - DRIVER ABUSE IS THE ONLY THING

RESPONSIBLE FOR GEARBOX WEAR OR DAMAGE.

Figure 8

Loading...

Loading...