Page 1

Mach 1 Blow-off Valve

Installation Instructions

P.O. Box 1017 Riverwood NSW 2210

Ph: +612 9534 0099 Fax: +612 9534 3999

Website: www.gfb.com.au Email: sales@gfb.com.au

Page 2

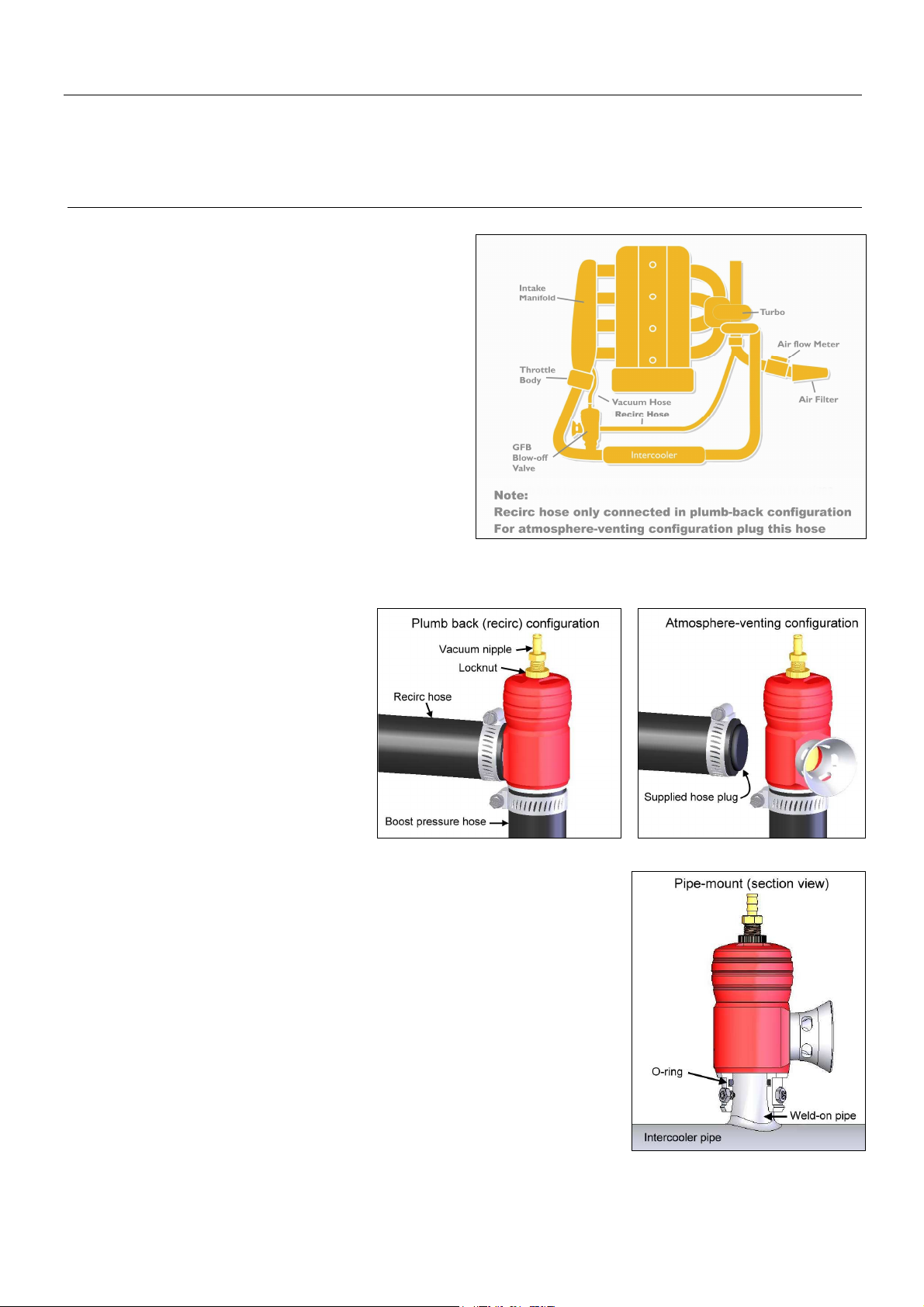

Installation Instructions for GFB Mach 1 Blow-off Valve

Included in kit (unless ordered with fittings other than standard):

• Mach 1 BOV, fitted w/ 35mm base & 30mm recirc outlet

• 1 x screw-in trumpet

• 1 x o-ring

The Mach 1 comes complete with all the parts required to set

it up as either a vent-to-atmosphere or a plumb back blow-off

valve. It comes pre-assembled in the atmosphere venting

configuration, and to switch to plumb back, you only need to

swap the trumpet for the supplied plumb back outlet.

Select the mode of venting you wish to use, and then begin the

installation by locating and removing the factory blow-off

valve, taking note of the hoses that connect to it. If the fittings

on your GFB Mach 1 do not match the factory hoses, or a bolton flange is required, check the adaptor listing at the end of

these instructions.

For cars without a factory blow-off valve, a suitable location

must be found on the inlet piping between the turbo and the

throttle body (see diagram opposite), and a hose or pipe

attached onto which to mount the Mach 1. The standard base

fitting of the Mach 1 can be mounted in two ways. It can

either be clamped into rubber/silicone hose, or it can be pipe mounted directly onto the turbo piping. These methods are

described below:

1) Hose mounting: The standard base

fitting of the GFB Mach 1 will fit inside 3236mm I.D. hose, and should be secured using a

hose clamp (not supplied). Make sure that the

supplied o-ring and grub screws are not used

for this application, and that the hose clamp

band is seated on the straight section of the

collar, rather than on the retaining bead.

For atmosphere venting configuration, plug the

factory recirc hose as shown using the plastic

plug supplied. If you choose the plumb back

configuration, connect the recirc hose to the

supplied plumb back outlet as shown.

2) Pipe mounting: For cars without an existing blow-off or diverter valve, weld

a short length of 1” O.D. pipe to a suitable location on the turbo piping as shown in the

schematic engine diagram above (and the pipe-mount configuration cut-away diagram

opposite). Also available from GFB are alloy and stainless steel weld-on adaptors to

suit different intercooler pipe materials.

If your car has a flange-mounted factory valve, GFB has a range of vehicle-specific

bolt-on flange adaptors - check the adaptor guide at the end of these instructions for

available types.

Insert the supplied o-ring into the internal groove in the base of your GFB valve as

shown, and partially thread the three grub screws into the tapped holes. Slide the valve

onto the 1” (25.4mm) O.D. pipe, making sure that the o-ring slides completely over the

end of the pipe, and then fasten the valve in place with the grub screws and lock nuts.

MAKE SURE TO MOUNT THE BOV IN A POSITION WHERE DIRT OR

WATER CANNOT FALL INTO THE VENTING OUTLET.

• 3 x M5 grub screws and nuts

• 1 x 30mm hose plug

Page 3

3) Depending on the configuration you choose to set up your GFB valve (vent-to-atmosphere or plumb back), ensure the

factory recirc hose that returns vented air to the intake is either plugged, or connected to your GFB valve’s outlet – do NOT

leave it open to the atmosphere. Various sized plugs and plumb back outlets are also available if required.

4) Connect the vacuum nipple on the top of the GFB valve to the inlet manifold AFTER the throttle body (see schematic

engine diagram). For best performance, where possible keep the hose run as short as possible and ensure that there are no

other accessories connected to this hose (such as fuel pressure regulator, brake booster, boost controller or boost gauge).

If you must connect other devices or increase the length of the hose, ensure that you use tee joins and vacuum hose with and

internal diameter of at least 4mm. Small diameter tee joins/hose or too many additional devices can slow the response of the

valve, or cause erratic performance.

Adjusting the spring pre-load

Contrary to popular belief, the spring DOES NOT need to be adjusted to hold different boost levels. The valve will stay shut

regardless of boost pressure or spring pre-load as long as the vacuum hose at the top receives the same full-throttle boost

pressure as the intercooler pipes. Rather, the spring adjustment changes how easily the valve opens when you close the

throttle, and how long it stays open when it vents. It is also used to accommodate variations in manifold vacuum levels on

different cars.

When the plumb back configuration is chosen, or your car does NOT have an airflow meter, the spring adjustment is not

critical and you can adjust it to suit your own preference. If your car does have an airflow meter AND you have chosen the

vent-to-atmosphere configuration, you will need to ensure the spring is set correctly, as follows:

Start by first loosening the locknut on the vacuum nipple (see second diagram on previous page) to allow it to turn easily. Set

the spring to the softest setting by turning the vacuum nipple anti-clockwise until you feel the turning resistance release. With

the car running at normal operating temperature, watch the piston through the venting outlet (not too closely!) as you stab the

throttle sharply and then release it. The piston should lift quickly and vent as you release the throttle, then close smoothly. It

should be completely closed by the time the engine drops back to idle.

If you notice any of the following symptoms, turn the nipple clockwise one turn at a time until the problem disappears:

• The piston is open at idle

• The valve continues to vent too long, causing the engine to “stumble” as it returns to idle speed (the revs may drop

below idle and then come back up again, or it may “hunt” for a stable idle RPM)

• When driving, the car stalls as you pull up to a stop

• When driving you notice a hesitation between gears or loud/excessive backfiring from the exhaust

If when driving a significant fluttering noise is heard (at full throttle or high RPM), turn the nipple anti-clockwise a few turns.

A little flutter can sometimes occur at lower RPM under certain conditions (or certain turbo systems), this is quite normal.

Note that the venting characteristics and sound of the valve can change in the first week or so, this is because the valve is

assembled using a protective grease which can slow the movement of the piston slightly during initial use.

Troubleshooting

Problem: The valve does not vent or blow off at all.

• Check the vacuum hose as described in section 4. Ensure that the hose you are using is indeed a vacuum source,

putting your finger over the end of it whilst the engine is running will tell you if it is or not.

• Check the orientation of the valve. Boost MUST enter the bottom of the valve, and dump through the side. This is

particularly important to check on Audi/VW engines, and any others that use plastic Bosch-style factory valves.

• Move the piston by hand to ensure it is not physically jammed or damaged.

• Set the spring to its softest setting.

Problem: The valve is leaking boost.

There are many symptoms that are often incorrectly interpreted to be a leaking valve. The design of the valve is such that

regardless of the boost pressure, if the car is at full throttle the pressure in the manifold should be the same as the pressure in

the intercooler piping. This means there is equal and opposite pressure pushing on the piston, which effectively cancels itself

out. So unless there is less pressure reaching the top of the valve via the vacuum connection, it will NOT open under boost.

Still got problems? For a comprehensive blow-off valve ‘Troubleshooting’ guide, visit our website (www.gfb.com.au) or

contact GFB directly on +612 9534 0099 or at

support@gfb.com.au.

Page 4

Maintenance

GFB products are designed and manufactured in a way that, in most circumstances, requires little or no regular maintenance.

Cleaning and/or disassembly are only necessary if the piston does not move smoothly or if there is damage from dirt or other

foreign objects. The following is a list of symptoms that might indicate cleaning is required:

• The venting sound becomes irregular or noticeably different

• The piston is covered with a sticky grey film

• The car begins to stall or idle badly where it didn’t previously

• Physical damage (vertical score marks) can be seen on the piston surface

To disassemble the Mach 1, use

a 1.5mm hex key to remove the

grub screw at the bottom of the

valve body. Unscrew the base,

taking care as the spring is preloaded with about 5kg of force,

and the valve will want to pop

apart as the base comes free.

Wipe all internal parts clean with a rag. Inspect the piston and bore for visual damage, then slide the piston into the bore dry to

check that it slides smoothly and freely. If any damage is found or the piston does not slide freely, contact GFB for advice.

Otherwise, smear the piston and bore with engine oil and re-assemble.

Accessories available

Base adaptors (screw on in place of existing base):

5020 – 20mm hose base

5025 – 25mm hose base

5030 – 30mm hose base

5035 – 35mm hose/1” pipe mount base (standard supplied base)

5038 – 38mm (1.5”) pipe mount base (compatible with Turbosmart adaptors)

Plumb back outlets (to replace trumpet):

5220 – 20mm

5225 – 25mm

5230 – 30mm (standard outlet supplied)

5233 – 33mm

Hose plugs:

5520 – 20mm

5525 – 25mm

5530 – 30mm (standard supplied plug)

5533 – 33mm

Model-specific flange adaptors:

5101 – MY99-00 WRX/Forester GT

5104 – R33/34 Skyline

5107 – MY03-04 Forester XT

5108 – MY01-07 WRX/STi, MY05-08 Forester XT

This product is intended for racing use only, and it is the owner’s

responsibility to be aware of the legalities of fitting this product in

his or her state/territory regarding noise, emissions and vehicle

modifications. GFB recommends that only qualified motor

engineers fit this product.

Materials and workmanship of this product are covered by a

lifetime warranty. Moving components subject to wear are covered

for a period of one year from the date of purchase. Warranty is

limited only to the repair or replacement of GFB products provided

they are installed and used as intended, and in accordance with all

applicable warnings and limitations. No other warranty is

expressed or implied.

GFB products are engineered for best performance, however

incorrect use or modification of factory systems may cause damage

to or reduce the longevity of the engine or drivetrain components.

5109 – S14 & S15 200SX

Loading...

Loading...