Page 1

Instructions for GFB STi 6 speed short shift kit upgrade (part # 4202)

This kit is intended for use only in conjunction with GFB’s STi 6-speed basic shift kit (part # 4003), which

is assumed to have already been installed before fitting this upgrade kit.

This 4202 upgrade kit allows your existing GFB 4003 shifter to be adjusted to even shorter throw settings

than is possible with the 4003 kit alone, and these two kits combined.

Included in kit:

• 2 x side plates

• 1 x linkage knuckle, including:

2 x M4 x 12 socket screws

• 2 x M8 washers

We HIGHLY recommend you read through the instructions and familiarise yourself with the steps

before starting installation of this product.

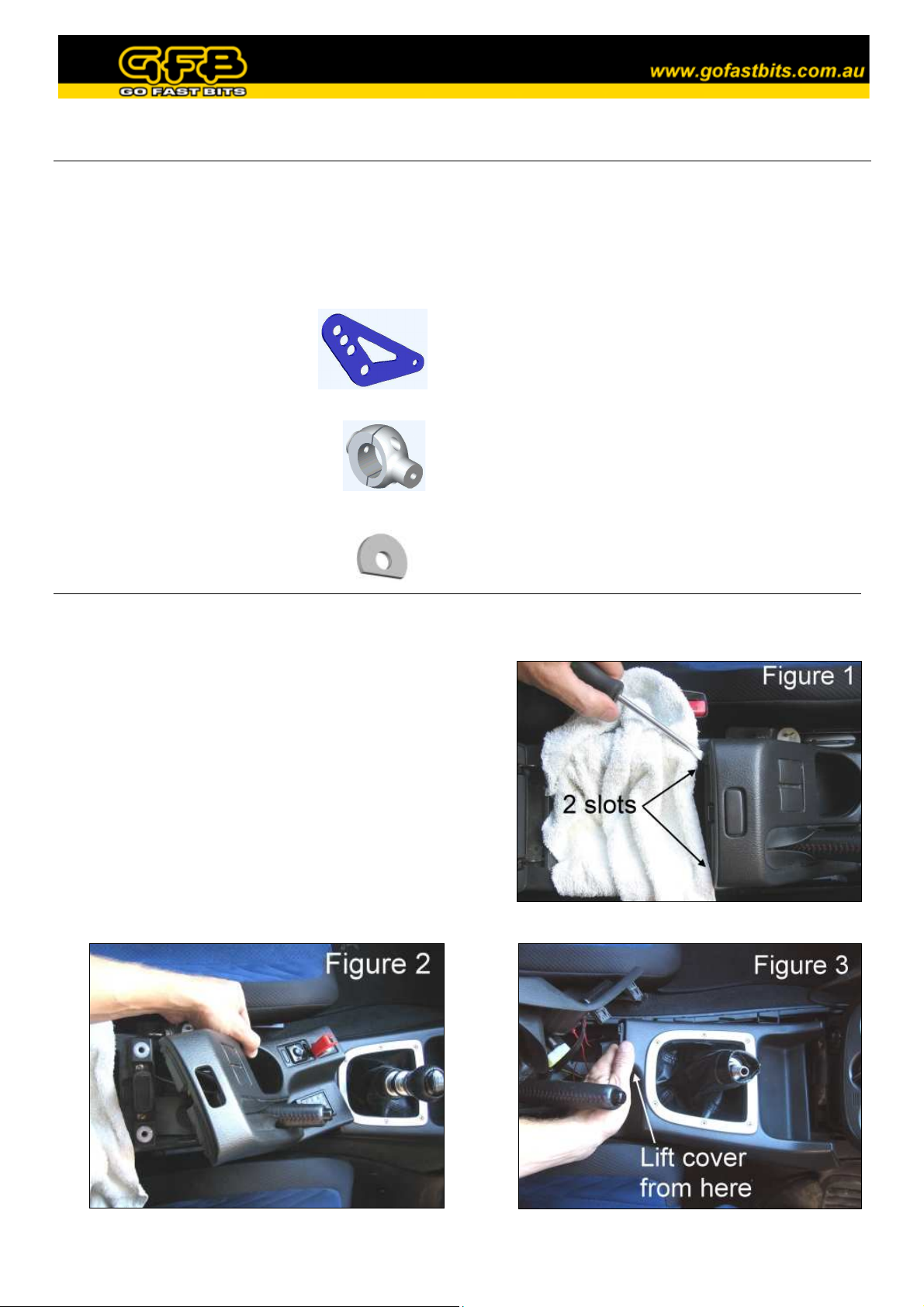

1. Lift the lid of the centre console between the seats above the

handbrake. On the plastic handbrake shroud there are two

slots, using the flat-blade screwdriver padded with a rag,

carefully lever the shroud up on each side (there is a poptype fastener on each side).

2. Lift the handbrake shroud out (taking care of wiring still

attached), to give you access to the gearstick surround

(figure 2).

3. Unscrew the gear knob and unclip the button fastener on the

leather shift boot. Gently lift the plastic gearstick shroud up

from the back, it is only lightly clipped in and does not need

much force.

• 2 x M8 x 16 button head screws & nuts

• 2 x M5 x 8 button head screws

• 1 x 3mm hex key

• 1 x 5mm hex key

Required tools:

• 2 x 12mm spanner/wrench

• Medium flat-blade and phillips screwdriver

Page 2

4. Remove the linkage bolt that joins the gearstick to the shift

linkage, and let the gearstick rest towards the back of the car

out of the way for the next step.

5. Fit the two parts of the linkage knuckle around the factory

shift linkage with the long side facing up (fig. 4). The top of

the long side should lean towards the back of the car. If it

leans toward the dashboard, turn it around the other way.

Place the two M4 screws into the holes and screw them in

until they are finger tight, making sure there is an equal

gap between both sides of the two parts.

6. Now loosen the left screw just enough to allow the knuckle

to be rotated horizontal (so that the two ends of the knuckle

are parallel to the sides of the shift linkage), but DO NOT

tighten it back up just yet.

7. Fix the two side plates to the linkage by first inserting an M5

screw through the matching 5mm hole and thread it into the

linkage knuckle (fig. 5), but do not tighten it yet.

8. Insert an M8 screw through the plate and then through the

hole in the shift linkage fork. Thread an M8 nut partially on,

but DO NOT tighten yet. Repeat step 7 & 8 on both sides

(fig. 5). Now tighten all screws and nuts. As long as the

lower M4 screw on the linkage knuckle was set to the right

distance as per step 10, you should only have to tighten the

top screw to clamp it up tight.

9. At this point you will need to decide how short you want the shift

throw to be. This is determined by the height of the clamp on the

gearstick relative to the pivot ball – the higher the clamp, the

shorter the throw (Note: the shorter you make the throw, the more

force will be required to shift, this is normal). The 3 holes in the

blue plates simply ensure that the gearbox linkage remains at the

correct angle (so it doesn’t foul on the transmission tunnel)

regardless of the clamp position. We suggest beginning with the

middle hole.

Make sure the factory steel sleeve is still in the white bushings of

the gearstick clamp, then line up the sleeve with the middle hole.

Hold one of the M8 washers between the sleeve and the side plate, then slide the factory bolt through the side

plate, the washer, and into the sleeve. Note that you may have to adjust the height of the clamp on the gearstick

to get the bolt through the holes. Position the second washer on the other side (fig 6), and push the bolt fully

through. Partially thread the nut onto the end of the bolt, tighten the screw in the gearstick clamp and test the

shift feel. If the throw is too short or long, make an adjustment to the height of the clamp, and if necessary, select

a different hole on the side plates so that the gearbox linkage does not rub or foul in any gear.

Note that as you slide the clamp up and down, the neutral position of the gearstick will move slightly. By using

the combination of the clamp height and hole position, you can tailor the shift feel to your liking. Once you are

satisfied tighten the clamp screw and linkage bolt, then perform a final check to ensure that you can select all

gears (including reverse) smoothly, without binding. Replace the plastic shrouds in the reverse order of removal.

GFB Short Shift Kits carry a lifetime warranty which covers faulty components or manufacturing. Warranty is limited only to the

repair or replacement of GFB products provided they are used as intended and in accordance with all appropriate warnings and

limitations. No other warranty is expressed or implied.

Loading...

Loading...