Page 1

GE

EST Fire & Life Safety

Security

Overview

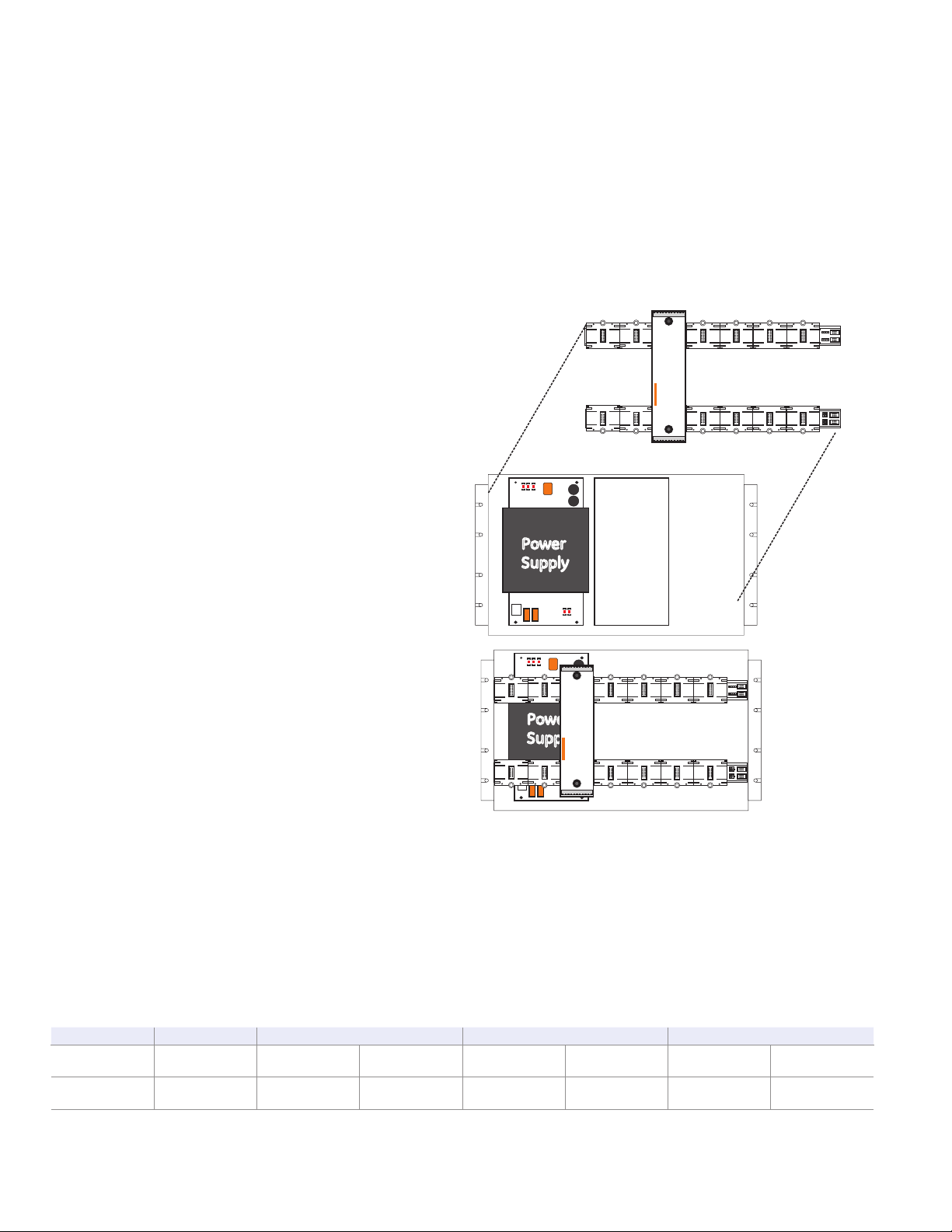

EST3 Power supplies consist of two assemblies, a high efficiency

switch mode power supply card and a power supply monitor

module. The monitor module mounts to the local rail and distributes

the power from its supply to the local rail. The local rail distributes

power from all power supplies to other local rail modules and user

interface cards resulting in “Shared Power” throughout the system.

By paralleling the power supplies on a rail maximum utilization of

available power is possible, resulting in fewer power supplies. Up to

four power supplies combine in a single enclosure providing up to

28 amps of available power. Battery backup is provided using from

one to four sets of batteries, depending on standby power requirements.

Power supplies mount to the back of the chassis units or wallboxes.

The associated power supply monitor module mounts on the local

rail providing system power distribution and mounting space for

any control display module. Access to auxiliary power is via easily

accessible terminal blocks located on the power supply monitor module. Each power supply produces 7 Amps of filtered and

regulated power. With four power supplies located in an enclosure

(one primary and three booster power supplies) 28 amps of current

is available for local rail modules, control display modules and the

eight auxiliary 3.5 amp power outputs (two per supply).

EST3 Multiplexed Fire Alarm System

Standard Features

High efficiency switch mode

•

Increased power distribution efficiency

•

- power supplies parallel allowing up to 28 amps in a single node

120 or 230 Vac operation

•

7 AMP filtered and regulated

•

Two 3.5 AMP outputs

•

Temperature compensated, dual rated battery charger

•

Electronic power limiting

•

Automatic load testing of batteries

•

EST3 Power Supplies

3-PPS/M series, 3-BPS/M series,

3-BBC/M series

Power

Supply

Monitor

Module

and EN54-4:1997+A1:2002+A2

Data Sheet 85010-0059 Issue 10

Not to be used for installation purposes. Page 1 of 4

EN54-2:1997+A1

pending

Page 2

Application

J8

J9

J10

J11

J8

J9

J10

J11

Power

Supply

L

R

M

Power

Supply

J8

J9

J10

J11

J8

J9

J10

J11

L

R

M

Power

Distribution

Module

(EN-54 only)

Power

Supply

J8

J9

J10

J11

J8

J9

J10

J11

L

R

M

The primary power supply provides the system with battery charging and voltage regulation. Software configures the charger to

either 10-24 AH batteries or 30-65 AH batteries and controls the

high/low charge rates. Batteries mounted in the same enclosure as

the power supply, have their charge rate monitored and adjusted

based on the local enclosure temperature, keeping charging rates

within battery specification. For remote batteries a temperature

probe is monitored in the remote battery cabinet and charge rates

are adjusted automatically. Battery damage is unlikely to occur

when environmental short term conditions are outside of normal

operating ranges.

The EST3 power supplies automatically load test batteries by

shutting down the battery charger and placing a load across the

battery. If the battery voltage is outside the specification range the

power supply reports a trouble. The trouble clears if the battery is

able to recover and pass future load tests.

Battery leads are electronically short circuit protected. If a short

occurs in the battery leads the charger automatically disables

itself and causes a trouble. The system will constantly look to see if

the short has cleared. If the short clears the system automatically

restores.

During operation on standby batteries, battery voltage is constantly monitored. A trouble is reported if the battery voltage falls below

a specified value.

EST3 power supplies provide specific information back to the 3CPU(1) designed to help speed trouble shooting of system functions.

Should a power supply detect a fault, specific diagnostic codes

are available to speed trouble shooting. The 3-LCD will display the

power supplies address, a specific trouble code, and a text message

describing the specific trouble. Text messages are easy to understand and include items like: Battery Trouble, Aux Power Overload

Circuit 1, Aux Power Overload Circuit 2.

Engineering Specification

The fire alarm power supplies must be capable of being paralleled

and to load share. Multiple power supplies must be capable of being

backed up with a single 24 volt battery set. Each power supply shall

be capable of charging up to 65 AH batteries. The power supply

must be able to perform an automatic load test of batteries and

return a trouble if the batteries fall outside a predetermined range.

Power supplies must incorporate the ability to adjust the charge

rate of batteries based on ambient temperatures. It shall be possible to adjust for ambient temperature changes in local cabinets as

well as remote cabinets.

Installation and Mounting

Power Supply Rules

1. Each battery set needs one charger, either a 3-PPS/M or a 3-BBC/M.

2. Each power supply must be connected to a battery set using an identical length and gauge of wire to keep voltage drops identical.

3. Distribute power supplies and loads evenly across rails.

4. All battery sets for a panel must be the same capacity (AH), same manufacturer, and same manufacturing date code.

The Table below illustrates the combinations of power supplies and batteries that meet all the power supply rules.

24 VDC Power Supply Output Current

7A 14A 21A 28A

Battery

Requirements

Required

Modules

One Set,

65 AH max

1 3-PPS/M

One Set,

65 AH max

1 3-PPS/M

1 3-BPS/M

Two Identical

Sets, 65 AH max

1 3-PPS/M

1 3-BBC/M

1 3-PPS/M 2 3-

One Set,

65 AH max

BPS/M

Three Identical

Sets, 65 AH max

1 3-PPS/M

2 3-BBC/M

Not to be used for installation purposes. Page 2 of 4

One Set,

65 AH max

1 3-PPS/M

3 3-BPS/M

Data Sheet 85010-0059 Issue 10

Four Identical

Sets, 65 AH max

1 3-PPS/M

3 3-BBC/M

Page 3

Primary

Power

Supply

Booster

Power

Supply

24Vdc *

2 x 3.5A

24Vdc *

2 x 3.5A

124 3

Utility

Power

Power

To Rail

Auxillary

Power

Takeoff

2 x 3.5A

Primary

Power Supply

Monitor Module

Power

Supply

Monitoring

Rails

[1] From battery temperature probe terminals.

[2] From battery and from temperature probe terminals if 3-BTSEN-E used.

* Nominal Voltage

124 3

Auxillary

Power

Takeoff

2 x 3.5A

Booster

Power

Supply

Booster

Power

Supply

24Vdc *

2 x 3.5A

24Vdc *

2 x 3.5A

124 3

Auxillary

Power

Takeoff

2 x 3.5A

Booster

Power Supply

Monitor Module

Rails

124 3

Auxillary

Power

Takeoff

2 x 3.5A

[1]

[2] [2] [2]

Typical Wiring

Specifications

Catalog Number 3-PPS/M & 3-BBC/M 3-BPS/M

3-PPS/M-230 & 3-

BBC/M-230

3-BPS/M-230

Agency Approvals UL, ULC U L, ULC UL, ULC UL, ULC LPCB EN54*, CE EN54*

Input Voltage 120 Vac (+10%, -15%), 50-60 Hz 230 Vac (+10%, -15%), 50-60 Hz

Brownout Level < or = 102 Vac 96 Vac < or = 195 Vac 184 Vac < or = 195 Vac 188 Vac

3-PPS/M-230

included with 3-CPU3

current

3-BBC/M-230

Alarm: 70 mA

Standby: 70 mA

Alarm: 50 mA

Standby: 50 mA

Current

Requirements

3-PPS/M included

with 3-CPU3 current

3-BBC/M

Alarm: 70 mA

Standby: 70 mA

Alarm 50mA

Standby 50mA

Input Current 3.0 A 1.5 A

Total Output Current Special Applications: 7.0 Amps

Battery Charging

Capacity

65 AH Sealed

Lead-Acid

None

65 AH Sealed

Lead-Acid

None

Low Battery Trouble 24 Vdc 22.5 Vdc

Deep Discharge

Cutoff

Mounting

Requirements

Output Voltage 24 Vdc Nominal

Auxiliary Output

Current

Auxiliary Output

Terminal Capacity

Output Protection Electronic power limiting & heat sink temperature

Ground Fault

Detection

*EN54-2:1997+A1 and EN54-4:1997+A1:2002+A2 pending

19.5 Vdc 20.0 Vdc

1 LRM space,

1 chassis footprint

Two sources of 3.5 Amps each taken from total output current

18 AWG to 12 AWG (1 mm² to 2.5 mm²)

< 10K Ohms

3-PPS/M-230-E &

3-BBC/M-230-E

3-BPS/M-230-E

3-PPS/M-230-E

included with 3-CPU3

current

3-BBC/M-230-E

Alarm: 50 mA

Standby: 50 mA

Alarm: 70 mA

Standby: 70 mA

30 AH Sealed

Lead-Acid

1 LRM Space +

3-PPS: 2 footprints

3-BBC: 1 footprint

Data Sheet 85010-0059 Issue 10

Not to be used for installation purposes. Page 3 of 4

None

1 LRM space,

1 chassis footprint

Page 4

GE

Security

U.S.

T 888-378-2329

F 866-503-3996

Canada

T 519 376 2430

F 519 376 7258

Asia

T 852 2907 8108

F 852 2142 5063

Australia

T 61 3 9259 4700

F 61 3 9259 4799

Europe

T 32 2 725 11 20

F 32 2 721 86 13

Latin America

T 305 593 4301

F 305 593 4300

www.gesecurity.com/est

© 2008 General Electric Company

All Rights Reserved

Ordering Information

Catalog Number Description Ship Wt., lb. (kg)

3-PPS/M Primary Power Supply w/ local rail module 120V 50/60 Hz 5 (2.3)

3-BPS/M Booster Power Supply w/ local rail module 120V 50/60 Hz 5 (2.3)

3-PPS/M-230 Primary Power Supply w/ local rail module 230V 50/60 Hz 5 (2.3)

3-BPS/M-230 Booster Power Supply w/ local rail module 230V 50/60 Hz 5 (2.3)

3-PPS/ M-230-E

3-BPS/ M-230-E

3-BBC/M Booster/Charger Supply w/local rail module 120V 50/60Hz 5 (2.3)

3-BBC/M-230 Booster/Charger Supply w/local rail module 230V 50/60Hz 5 (2.3)

3-BBC/ M-230-E

3-BBCMON(-E)

3-BTSEN

3-BTSEN-E

*EN54-2:1997+A1 and EN54-4:1997+A1:2002+A2 pending

Primary Power Supply w/local rail module 230V 50 Hz,

EN54* Certified, CE

Booster Power Supply w/local rail module 230V 50 Hz,

EN54* Certified, CE

Booster/Charger Supply w/local rail module, 230V 50/60Hz,

EN54* Certified, CE

Booster/Charger Monitor Module with charger capability

(upgrade 3-BPS/M(-230)(-E) to 3-BBC/M-(230)(-E))

Distribution Module required when battery installed

in remote cabinet

Distribution and Temperature Sensor Module. Required in

EN54* Markets when battery installed in a remote cabinet.

5 (2.3)

5 (2.3)

5 (2.3)

5 (2.3)

.5 (.22)

.5 (.22)

Not to be used for installation purposes. Page 4 of 4

Data Sheet 85010-0059 Issue 10

Loading...

Loading...