Page 1

GE

Security

250-CO Carbon Monoxide

Detector Installation Sheet

Description

The 250-CO Carbon Monoxide Detector monitors the levels of CO

gas and gives early warning when potentially dangerous levels

exist. It does not detect fire, smoke, or any other gas.

The 250-CO provides a multicolored LED and a sounder to indicate

the detector status. Use Table 1 to determine the status of the

detector. The detector automatically resets when CO is no longer

detected.

The 250-CO Carbon Monoxide Detector is intended for indoordwelling unit applications in both residential and commercial

occupancies, including single/multiple family residential

occupancies, hotel rooms, dorm rooms, and other areas approved

by the authority having jurisdiction (AHJ).

The 250-CO detector can connect to either UL 985 (Household Fire

Warning) or UL 864 (Commercial Fire) control panels. It is not

intended for use in industrial applications such as gasoline

refineries or parking garages, which require different listings.

The 250-CO detector is not intended to meet the requirements of

CAN/CSA-6.19 (Residential Carbon Monoxide Alarming Devices).

Please check with the local codes concerning the applicability of

this requirement for each installation.

The 250-CO detector has an optional adapter mounting plate. To

purchase the plate order P/N 250-COPLT-5PKG.

The built-in sounder is a supplementary alarm notification device.

The control panel is considered the primary alarm notification

device.

WARNING: Use only with a UL Listed control panel that recognizes

different alarm types (fire, burglary, CO, etc.) and that provides a

distinct notification for each type.

Sensor end of life indicator: The detector uses both a flashing

green LED and intermittent sounder chirps to indicated that the

detector needs replacing. The detector also signals a trouble

condition when the CO sensor reaches end-of-life. When

connected to a UL Listed control panel, the trouble relay can

report a trouble condition locally at the panel and optionally at the

central station, if the system is monitored.

Common trouble relay: The trouble relay opens to indicate a

trouble condition upon lost power, CO sensor cell trouble, or cell

end-of-life.

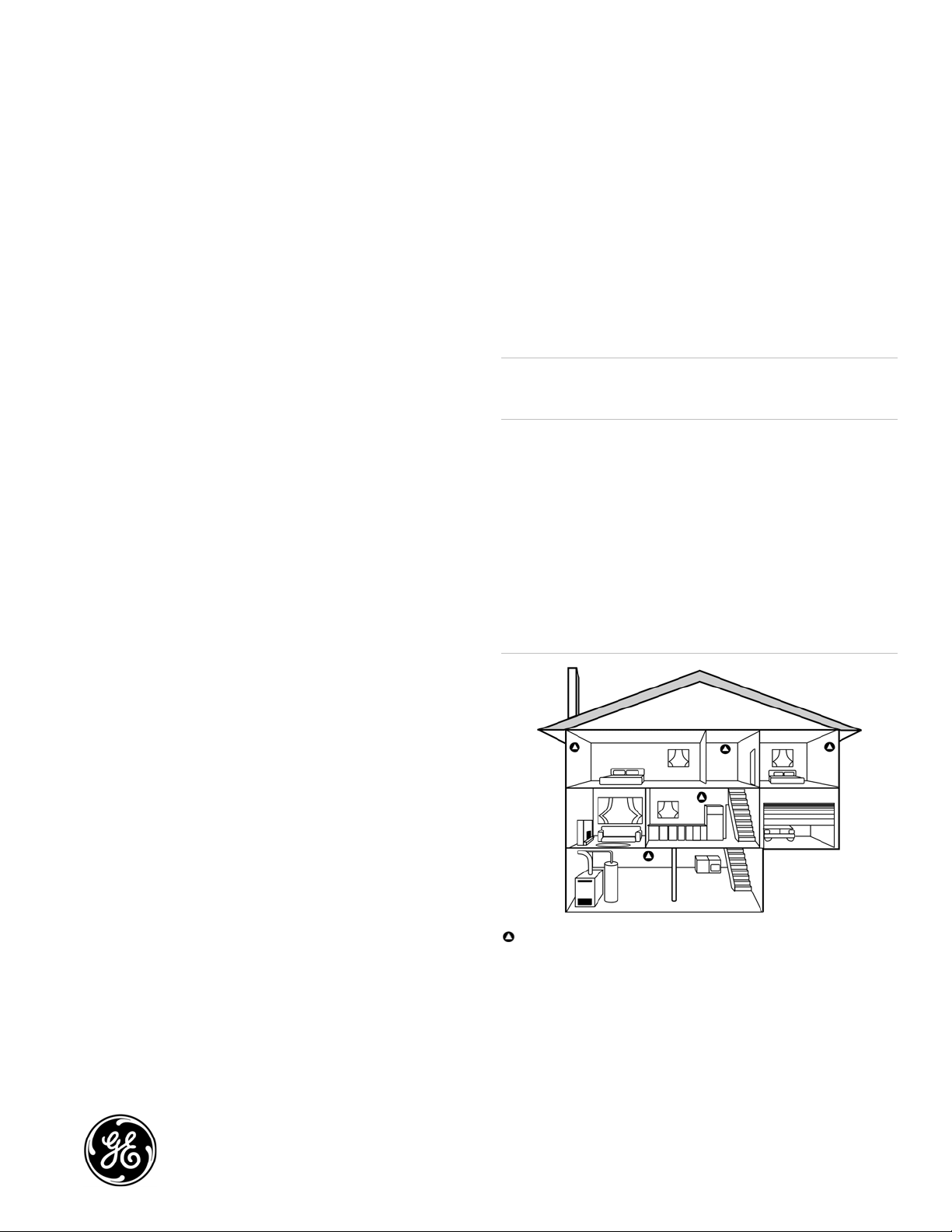

Figure 1: Recommended CO detector locations

Features

Test/hush button: Use the test/hush button to test the alarm and

silence an activated alarm. Pushing the test/hush button silences

the integral sounder for five minutes. The red alarm light stays on,

and if CO is still present after five minutes, the detector once again

sounds in the temporal-four pattern. The hush feature does not

operate at CO levels above 350 ppm (parts per million).

Distinct 85 dB temporal-four sounder alarm: The 85 dB

temporal-four sounder provides a distinctive alarm notification

that is easy to differentiate from smoke alarm notification devices.

The alarm beeps four times, pauses five seconds and then repeats

the pattern.

© 2010 GE Security, Inc.

CO detector locations

P/N 1061018 • REV D • ISS 10FEB10

1 of 6

Page 2

Table 1: Detector status indications

Status LED Sounder Description

Safe air Green, 1 pulse every 15

seconds

Alarm Red, pulses with

sounder

Trouble Amber, pulses with

sounder

End of sensor life Amber, pulses with

sounder

Loss of power No LED No sounder Activates the trouble relay.

Detector locations

Selecting a suitable location is critical to the operation of CO

detectors. Install the 250-CO in accordance with NFPA 720

Standard for the Installation of Carbon Monoxide (CO) Detection

and Warning Equipment. Place wall-mounted detectors at least

No sound The detector has power and is functioning properly.

Sounds four rapid beeps

every five seconds or every

minute after five minutes in

the alarm state

Sounds one rapid beep

every 45 seconds

Sounds one rapid beep

every 15 seconds

Dangerous levels of CO are present. Evacuate the premises.

Press the test/hush button to silence the sounder for five minutes.

Activates the alarm relay. If connected, the alarm panel activates.

There is a problem with the detector and the detector is not working

properly. Contact the service company to correct the trouble and

replace the detector, if necessary.

Press the test/hush button to silence the detector for nine hours.

Activates the trouble relay.

The sensor is no longer working. Replace the detector as soon as

possible.

Press the test/hush button to silence the detector for 36 hours.

Activates the trouble relay.

Notes

• Do not install CO detectors until after final construction

cleanup (unless otherwise specified by the AHJ).

• Leave this installation sheet with the owner/user of this

carbon monoxide (CO) detection equipment.

5 ft. (1.5 m) up from the floor. For ceiling mounted applications,

place the detector at least 1 ft. (0.3 m) from any wall.

The recommended CO detector locations are:

• Within 10 ft. (3 m) of all sleeping areas, including areas such

as hotel rooms and dorm rooms.

The 250-COPLT adapter plate

Use the 250-COPLT adapter plate when replacing a 240-COe with

a 250-CO to cover the footprint of the 240-COe. For example, use

the plate to cover different wall colors.

• In a suitable environment: areas with a temperature range of

32 to 104°F (0 to 40°C) and with a relative humidity range of 0

to 90% noncondensing.

• In residential dwellings, locate detectors in every bedroom,

within 10 ft. (3 m) of sleeping areas, and on each level. At a

minimum, place one detector outside the sleeping areas. See

Figure 1 on page 1.

The recommended CO detector locations in commercial

occupancies are:

• On every habitable level of the building based on an

engineering evaluation considering potential sources and

Installation

The 250-CO Carbon Monoxide Detector is a four-wire device

designed to use a Class 2 output from a UL 985 or 864 Listed

control panel or auxiliary power supply.

All wiring must conform to the NFPA 70 National Electric Code, UL

2075 Standard for Gas and Vapor Detectors and Sensors, NFPA 720

Standard for the Installation of Carbon Monoxide (CO) Detection

and Warning Equipment, and applicable codes. Use 14 to 22 AWG

wire.

migration of carbon monoxide

• In any area required by local building codes, legislation, or

authorities having jurisdiction

• On a firm, permanent surface

Do not install the CO detector:

• Within 10 ft. (3 m) of a fuel-burning appliance

• Near air conditioners, heating registers, or any other

WARNINGS

Connect the CO detector only to a zone dedicated exclusively to

CO detection and that is monitored 24 hours a day. Do not

connect to an initiating circuit with fire or security devices.

Failure to properly install, test, and maintain a CO detector may

cause it to fail, potentially resulting in loss of life.

ventilation source that may interfere with CO gas entering the

detector

• Where furniture or draperies may obstruct the airflow

• In a recessed area

To install the detector (without the adapter plate):

1. Run the 250-CO detector wiring to the detector location.

2. Carefully remove the cover from the detector using a small,

flat screwdriver blade in the slot on the left side of the

detector cover.

2 of 6 P/N 1061018 • REV D • ISS 10FEB10

Page 3

3. The mounting hole pattern is for single-gang spacing. Use the

base for a template to mark the two screw hole locations on

the mounting surface or mount on a single-gang box (not

provided).

4. Install two screws on the marks. If necessary, use wall

anchors.

5. Line up the base with the screws, pull the wires through the

square holes, and slide the base down the screws to the wall.

For surface wiring, pull the wires through the wiring channel

at the bottom of the base.

6. Strip 3/8 in. of insulation from each wire.

7. Determine the correct wiring (see "Wiring" and Figures 3 to 5

below) and insert the wires under the appropriate screw

terminals.

8. Tighten both screws to secure the base to the wall.

9. Replace the detector cover.

10. Apply power. The LED should flash green for approximately

four seconds and then pulse green.

11. Test per the testing instructions below.

To install the detector using the adapter plate:

1. Run the 250-CO detector wiring to the detector location.

2. Using the 250-COPLT wall plate for a template, trace the

perimeter of the two square holes on the mounting surface.

Also mark the two screw locations.

3. Cut out the two square holes.

4. Install two screws on the marks. If necessary, use wall

anchors.

5. Mount the wall plate but do not fully tighten down the screws.

6. Carefully remove the cover from the detector using a small,

flat screwdriver blade in the slot on the left side of the

detector cover.

7. Pull the wires through the square holes on both the wall plate

and the 250-CO base. Then slide the detector base over the

screws.

8. Strip 3/8 in. of insulation from each wire.

9. Determine the correct wiring (see "Wiring" and Figures 3 to 5

below) and insert the wires under the appropriate screw

terminals.

10. Tighten both screws to secure the base to the wall plate.

11. Replace the detector cover.

12. Apply power. The LED should flash green for approximately

four seconds and then pulse green.

13. Test per testing instructions below.

Figure 2: Screw terminals

3

1 2

4

1. Sounder

2. Sensor

3. Alarm relay

4. Terminals ”−” and “+” are for power; terminals “NC” and “C”

are the common trouble relay shown in the normal state for

this detector

Testing

Test the detector after installation and regularly to verify that it is

functioning properly.

To test the CO detector:

1. To test the alarm and trouble relay panel connection, first

notify all persons and facilities that receive an alarm and

trouble signals (to prevent unnecessary response).

2. Momentarily press the test/hush button to start a test cycle.

During the test cycle the detector should beep four times with

a five second pause, then beep four more times. The LED

should flash red at each sounder beep. At the end of the test

cycle, the green LED illuminates for approximately four

seconds.

3. Momentarily disconnect the power supply from the detector

and verify that the common trouble relay opens.

4. Verify that the panel reacts correctly to the alarm relay

activation.

5. If the detector fails the test, verify that the power leads are

connected properly, wait briefly then try again. If the detector

fails again, replace it.

Maintenance

Clean the detector as needed with a clean cloth (either dry or

dampened with water) to keep openings free from dust and dirt.

Test the detector regularly.

Do not paint the detector or expose it to cleaning solutions.

Notification

Notification of carbon monoxide detectors should be consistent

with NFPA 720 and the local AHJ. Notification zones should be

consistent with the emergency plan for the protected premises.

P/N 1061018 • REV D • ISS 10FEB10 3 of 6

Page 4

Wiring

There are three typical wiring configurations:

• Single device and single zone (Figure 3)

• Multiple devices in a single zone (Figure 4)

• Multiple devices with separate alarm and trouble zones

(Figure 5)

CO detector replacement

The 250-CO Carbon Monoxide Detector has a long-life carbon

monoxide electrochemical sensor. Replace the detector with a

new 250-CO detector after six years from the date of manufacture

or when an audible and visible annunciation occurs signaling endof-life.

To silence the detector, push the test/hush button

Figure 4: Multiple devices, single zone configuration

1

Figure 3: Single device, single zone configuration

1

PWR

PWR

1. Alarm IDC (NO)

2. End-of-line device (provided by the life safety system)

Note: Relay is shown in the normal state for this detector

2

2

PWR

PWR

1. Alarm IDC (NO)

Note: Relay is shown in the normal state for this detector

Figure 5: Multiple devices, separate alarm, trouble zone configuration

1

2

PWR

PWR

1. Alarm IDC (NO)

2. Supervisory IDC (NC)

Note: Relay is shown in the normal state for this detector

2. End-of-line device (supplied by life safety system)

3

3

3. End-of-line device (supplied by life safety system)

4 of 6 P/N 1061018 • REV D • ISS 10FEB10

Page 5

General limitations of CO detectors

CO detectors require a source of power to work. Verify that the

green LED on the detector is flashing at all times. Since this unit is

powered by a control panel, it may not operate during a power

failure or if the control panel is disabled.

WARNING: This product is intended for use in ordinary indoor

locations of family living units. It is not designed to meet

compliance with Occupational Safety and Health Administration

(OSHA) commercial or industrial standards.

The 250-CO detector is not intended to meet the requirements of

CAN/CSA-6.19 (Residential Carbon Monoxide Alarming Devices).

Please check with the local codes concerning the applicability of

this requirement for each installation.

People with special medical problems should consider using

specialized detection devices with less than 30 ppm (parts per

million) alarming capabilities.

This detector only indicates the presence of carbon monoxide gas

at the detector. CO may be present in other areas. Anything

preventing CO from reaching the detector, such as closed doors,

could delay or prevent detector activation.

If the unit is in trouble or at the end of its life, it may not sense CO

and cannot be relied upon to monitor carbon monoxide levels.

CO detectors are not smoke detectors: This detector is designed

to detect CO from any combustion source. It is not designed to

detect smoke, fire, or any other gas.

CO detectors may not be heard: A sound sleeper, or someone

who has taken drugs or alcohol, may not awaken if the detector is

installed outside a bedroom. Normal noise due to stereos,

television, etc. may also prevent the detector from being heard if

distance or closed or partly closed doors muffle the sounder. This

unit is not designed for the hearing impaired.

CO detectors are not a substitute for life insurance: Though

these detectors will warn against increasing CO levels, we do not

warrant or imply in any way that they will protect lives from CO

poisoning. They should only be considered as an integral part of a

comprehensive safety program.

Specifications

Input voltage 12 or 24 VDC supplied by control panel or

resettable auxiliary power supply

Current consumption

Normal

Alarm

Alarm relay

Type

UL rating

Common trouble relay

Type

UL rating

CO alarm level 70 ppm/60 to 240 minutes

Sounder 85 dB

Compatible control panel UL 985 or UL 864 Listed

Compatible electrical box North American 2-1/2 in. (64 mm) deep single-

Wire size 14 to 22 AWG (0.25 to 2.0 mm²)

Dimensions (W x L x D)

Detector

Adapter plate

Weight

Detector

Adapter plate

Color White

Operating environment

Temperature

Relative humidity

Altitude

20 mA

40 mA (75 mA in test)

150 mA at 33 VDC

Form C

Zone

150 mA at 33 VDC

Normally opened held closed with power

applied

Common

gang

3.1 x 4.6 x 1.3 in. (7.8 x 11.7 x 3.2 cm)

4.5 x 6.5 x 0.2 in. (11.4 x 16.5 x 0.5 cm)

4.7 oz. (133 g)

1.6 oz (46 g)

32 to 104°F (0 to 40°C)

0 to 90%, noncondensing

Less than 6,000 ft. above sea level

Regulatory information

Manufacturer GE Security, Inc.

HQ and regulatory responsibility:

GE Security, Inc., 8985 Town Center Parkway,

Bradenton, FL 34202, USA

Year of

manufacture

UL rating 12 VDC, 24 VDC

North American

standards

The first two digits of the product serial number

(located on the product identification label) are the

year of manufacture.

UL 2075

This detector has been evaluated to the CO alarm

sensitivity limits of UL 2034.

Contact information

For contact information see our Web site: www.gesecurity.com

P/N 1061018 • REV D • ISS 10FEB10 5 of 6

Page 6

6 of 6 P/N 1061018 • REV D • ISS 10FEB10

Loading...

Loading...