Page 1

1XLp Installation & Configuration, June 2010

GERBERSERVICE

XLp GERBERplotter Family

Installation & Configuration

Presented by Ronny Sprangers

Page 2

2XLp Installation & Configuration, June 2010

Training Outline

• Overview of XLp Plotter

• Hardware Installation

• Software Installation

• Gerber Device Configuration

• The XLp Interface

• Calibrations

• Maintenance

Page 3

3XLp Installation & Configuration, June 2010

Overview

• The XLp 50/95 plotters are easy to use, wide format,

inkjet plotters that provide features such as high

reliability, accuracy and low operation costs.

• They have a multi-functional operator panel with

large LCD display

• They are compatible with existing Gerber products

and they offer a Windows based graphical interface

for intuitive control and status messaging.

• Like the Infinity range, the XLp is also based on the

HP 51645 inkjet cartridge.

Page 4

4XLp Installation & Configuration, June 2010

Overview

1.Nip Bar Lever : This

lever controls the Nip

Bar and Pinch Rollers.

2.Front Cover

3.Control Panel : Allows

the operator to perform

manual functions.

Currently only English

and Chinese

4.Feed Roll Bar

5.Paper Take-Up Bar : The

paper can be dropped

onto the floor or wound

up on the Paper TakeUp Bar (CW or CCW)

Page 5

5XLp Installation & Configuration, June 2010

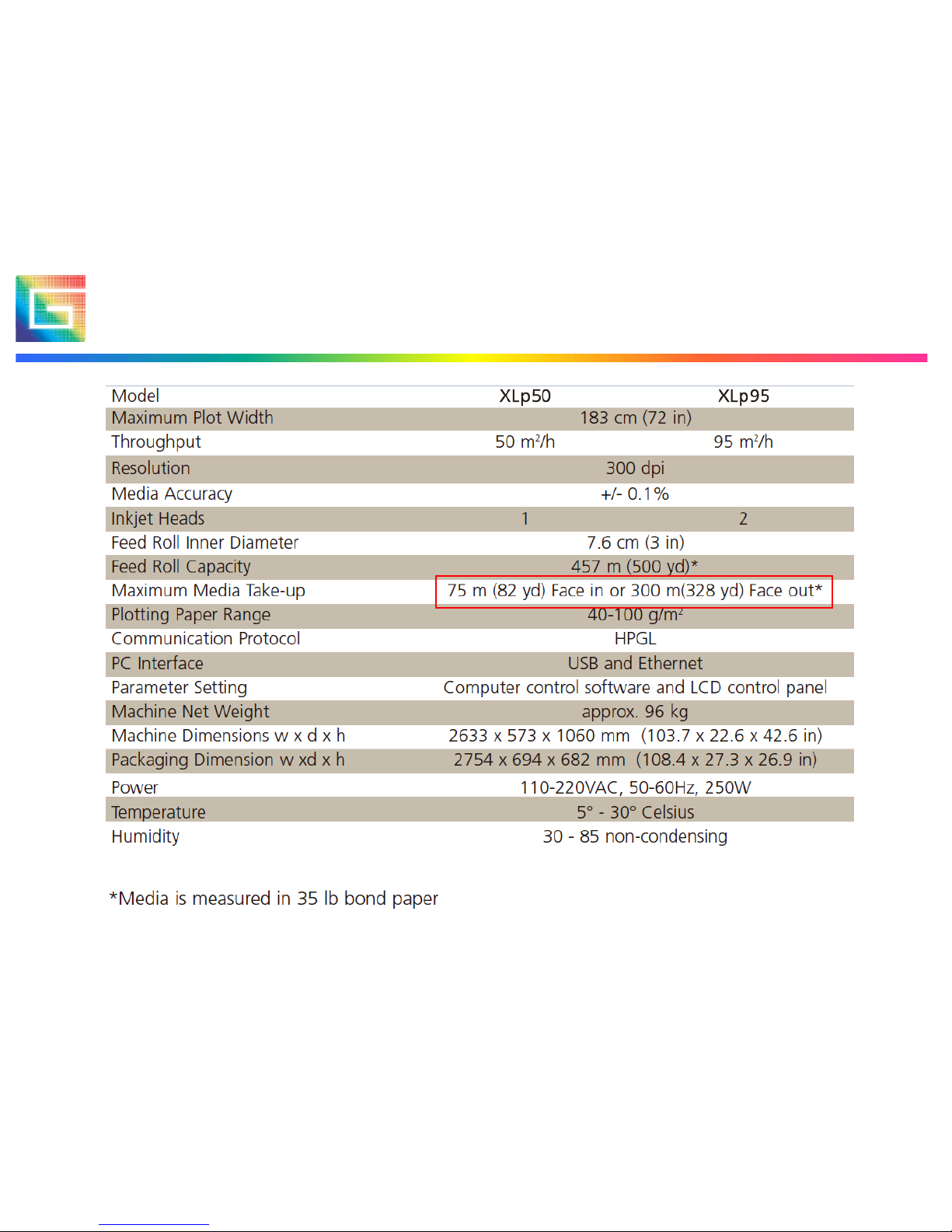

Overview: Technical Specifications

Page 6

6XLp Installation & Configuration, June 2010

Hardware Installation

• Unpack and assemble the plotter.

• Assembly is fairly simple and you should refer

to the XLp Getting Started Manual and the

XLp Installation Instructions available on

GERBERnet technical library.

• For a live demonstration you can view the

XLp Installation Video, also available on

GERBERnet.

Page 7

7XLp Installation & Configuration, June 2010

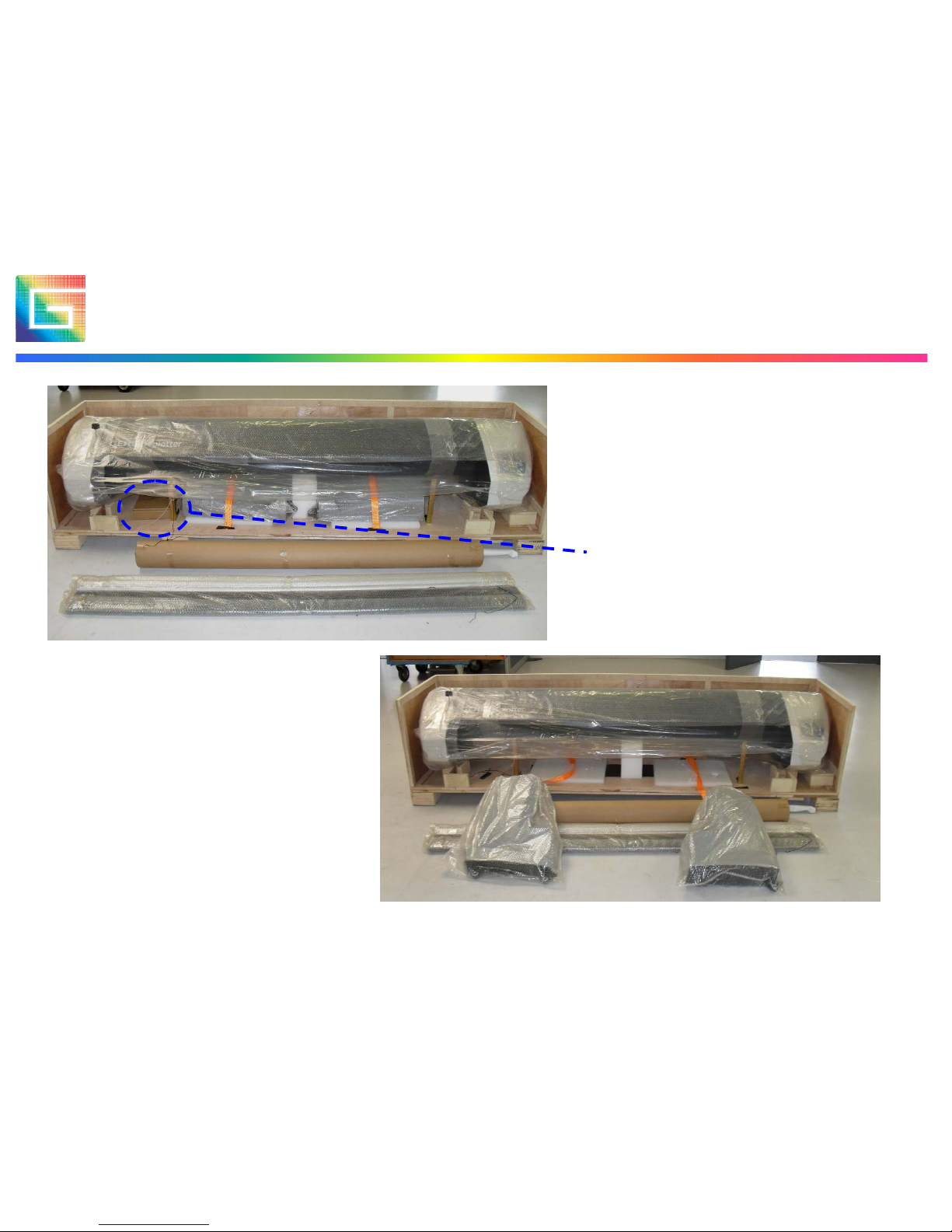

Hardware Installation (step by step)

1. Upon reception of the

system, please check the

crate for visible damage

and report back to your

local Gerber representative.

2. Remove the top and front

of the plotter crate.

Page 8

8XLp Installation & Configuration, June 2010

Hardware Installation (step by step)

3. Remove foam blocks,

paper roll, cross member

and paper bars from the

crate.

Also remove the cardboard

box that is glued on the

bottom of the crate

4. Remove the left and

right base assy from the

crate.

Page 9

9XLp Installation & Configuration, June 2010

Hardware Installation (step by step)

5. Unpack and assemble

the plotter stand, using the

M6 screws and 5mm Allen

wrench supplied in the

cardboard box.

6. Remove all protective

plastic from the plotter top

and place it on the stand.

2 persons will be needed

for the lifting

Page 10

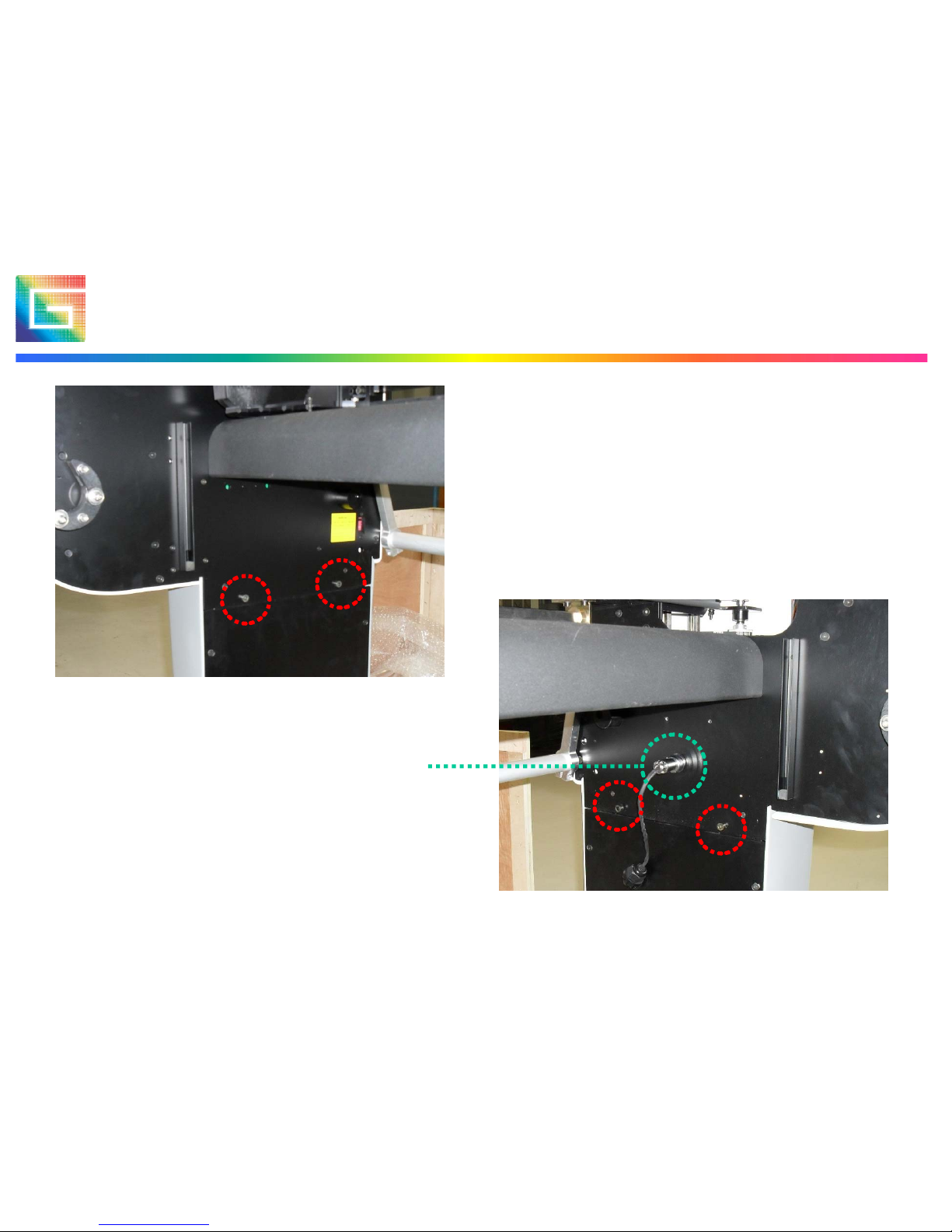

10XLp Installation & Configuration, June 2010

Hardware Installation (step by step)

7. Secure the plotter top to the

base using the 4 remaining M6

screws and 5mm Allen wrench

supplied.

8. Do not forget to plug in the

connector for the paper supply

motor in the right base assembly

Page 11

11XLp Installation & Configuration, June 2010

Hardware Installation (step by step)

9. Make sure the voltage

selection switch on the left

base assembly is set for the

correct value (usually 220V)

10. Remove the screw that

blocks the carriage for

transport.

Page 12

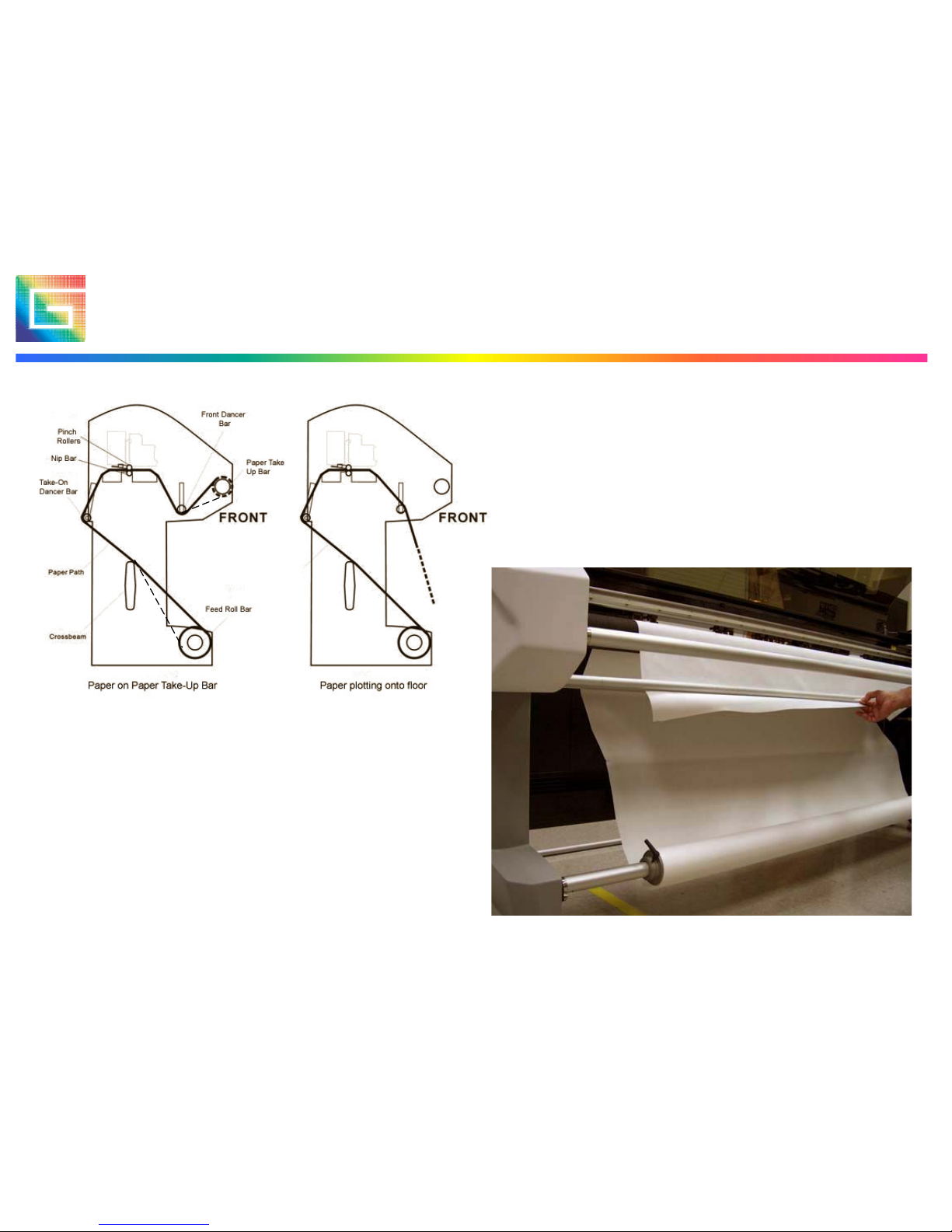

12XLp Installation & Configuration, June 2010

Hardware Installation (step by step)

11. Feed the paper through the

system as shown on the drawing to

the left.

Paper can go either clock wise or

counter clock wise depending on

the roll.

Either take up or drop on floor

Page 13

13XLp Installation & Configuration, June 2010

Hardware Installation (step by step)

12. Open the little door at the

side of the plotter crate to find

your power cable

13. Plug the cable in the back of

the left base assembly and

power up. After initializing the

carriage and cleaning station the

screen should look like this.

Don’t forget to put the

cartridge(s) in or you will get an

error message.

Page 14

14XLp Installation & Configuration, June 2010

Software Installation

• The XLp Plotter operates in a similar way as an

Infinity Plotter. You can plot using either Winplot or

AccuMark 8.3.0. or higher. If the customer doesn’t

want to upgrade the AccuMark software then they will

have to supply a separate networked Windows PC to

run Winplot.

• Software installation is best done without the XLp

connected to the computer.

• Insert the WinPlot CD delivered with the system and

install Winplot first, then install the XLp update.

Page 15

15XLp Installation & Configuration, June 2010

Software installation

Install Winplot first

Then install the XLp Update

Page 16

16XLp Installation & Configuration, June 2010

Software installation

• Now insert the XLp CD to install the interface

program (V2.7.1 or higher)

• After the installation of the XLp interface you

can plug the USB connector in the plotter and

Windows will automatically install the required

drivers.

Page 17

17XLp Installation & Configuration, June 2010

Software installation

Page 18

18XLp Installation & Configuration, June 2010

Gerber Device Configuration

• On the Start menu, point to Control Panel.

• Double click the Gerber Device icon.

• The Gerber Device Configuration window will

appear.

• Click the Plotter tab (only on AccuMark systems).

• In the Type box, select XLP USB PLOTTER (XLP-

PLOTTER).

• In the Settings box COM-W will appear.

• Click Apply.

• Click OK.

Page 19

19XLp Installation & Configuration, June 2010

Gerber Device Configuration

Select this plotter

type

Page 20

20XLp Installation & Configuration, June 2010

XLp Interface

• Unlike the Infinity Interface. The XLp Interface

has two different windows to chose from (when

you right click on the plotter icon).

• System Setting:

Allows you to

perform all

adjustments and

calibrations to the

XLp.

• Plotter Status: Allows

for monitoring ink

and paper usage

Page 21

21XLp Installation & Configuration, June 2010

XLp Interface: Plotter Status

Percentage of ink

remaining in cartridge

(estimate)

Progress bar to indicate

how much of the current

job has been send to the

XLp

This window will allow you to monitor the ink levels

in the cartridges, check the status of the plotted job

(length and width) and monitor the remaining paper

and even show the temperature inside the plotter.

Page 22

22XLp Installation & Configuration, June 2010

Machine Setting: Plot Tab

Line thickness in dots, setting

depends on the type of paper

used.

After much testing we have

discovered for best print quality

/ ink usage change the Line

Width to 3 and select the

Economy Mode.

This value is the start of plot in

reference to system 0.

Value can be set manually.

Page 23

23XLp Installation & Configuration, June 2010

Machine Setting: Ink Tab

Ink contents can be

manually set (i.e. when

putting back used

cartridges after

overnight printing)

For every cartridge

there will be an input

box available

Page 24

24XLp Installation & Configuration, June 2010

Machine Setting: Paper Tab

Initial length of new paper

roll.

Change take up direction

(default is CW)

Perform paper edge

sensing at initialize

Change paper feed

direction (default is CW)

Page 25

25XLp Installation & Configuration, June 2010

Machine Setting: System Tab

Sets the units of measurement for the parameters

(except for calibration).

Detects and stops plotting

when cover is opened.

Performs extended

cartridge test at every

initialize

Prevents cartridge clean

during jobs

Page 26

26XLp Installation & Configuration, June 2010

Machine Setting: Communication

Used to select the means

of communication

between Winplot and the

XLP.

When selecting TCP/IP

an additional field to fill

out the IP address will

show.

Currently only USB

communication is

available on XLp.

Page 27

27XLp Installation & Configuration, June 2010

Machine Setting: Calibration tab

Used to perform the required

calibrations at first install and

at cartridge change.

XLp50 does not have

cartridge overlap & cartridge

separation alignments'

Each plotter leaves the

factory “Calibrated” and the

values stored in the firmware

will be uploaded to the XLp

I/F after communication

between the plotter and XLp

I/F has been done.

Page 28

28XLp Installation & Configuration, June 2010

Cartridge Alignment : XGap

1. Click the X Gap button to run the X Gap calibration.

NOTE: The plotter will begin printing.

2. Check the plot for the line and corresponding numeric value that

represents the best match of the two printed lines

3. Add or subtract this value from the displayed value in the XGap

box (i.e. if best match is 3 and current X Gap value is -9, the new

value will be -6)

4. Enter the new numeric value from step 3 in the XGap box.

5. Click Apply.

6. Repeat the Calibration if required until the zero value displays

the best match of the two drawn lines.

Page 29

29XLp Installation & Configuration, June 2010

Cartridge Alignment: Overlap

1. Click the Start Cartridge Overlap Alignment button to run the

Cartridge Overlap calibration.

NOTE: The plotter will begin printing.

2. Check the plot for the line and corresponding numeric value that

represents the best match of the two printed lines.

3. Enter the numeric value from step 2 in the Cartridge box.

4. Click Apply.

5. Repeat the calibration if required.

NOTE: This alignment is not present on XLp50

Page 30

30XLp Installation & Configuration, June 2010

Cartridge Alignment: Separation

1. Click the Start Cartridge Separation Alignment button to run

the Y Head calibration.

NOTE: The plotter will begin printing.

2. Check the plot for the line and corresponding numeric value that

represents the best match of the two printed lines.

3. Add or subtract the numeric value from step 2 from the current

value.

4. Enter the numeric value from step 3 in the Y Head Calibration

box.

5. Click Apply.

6. Repeat the calibration if required.

NOTE: The default value is 261 (2.61 cm or 26.1 mm) on XLp95

Page 31

31XLp Installation & Configuration, June 2010

Cartridge Alignment: Forward Reverse

1. Click the YGap button to run the Y Gap calibration.

NOTE: The plotter will begin printing.

2. Check the plot for the line and corresponding numeric value that

represents the best match of the two printed lines.

3. Add or subtract the value from step 2 from the actual value.

4. Enter the numeric value from step 3 in the Y Gap box.

5. Click Apply.

6. Repeat the calibration if required.

Page 32

32XLp Installation & Configuration, June 2010

Calibration : Box Test

Box Test is used to calibrate the

step size of the plotter. It will

print a 1m square, which you

then measure and input the

exact size (in actual length

fields).

After input of the values you

click Confirm and then Apply.

Exit the XLp interface before you

do the test again (Actual Length

values will be reset to 1 then).

Note: X-axis step size calibration

needs to be checked if customer

changes paper type

Page 33

33XLp Installation & Configuration, June 2010

Service Level

To enter the service level of the XLp interface

program you are required to enter a password.

The password is unique to every system as it is

the serial number +1 for every digit.

In this case: serial number 2042100809

password 315321191:

(9 becomes : not 0)

After you click on ‘confirm’ additional

parameters will become visible.

Page 34

34XLp Installation & Configuration, June 2010

Service Level : Plot Tab

To get additional spacing

between jobs.

Set the plotting speed to

a lower value.

Make sure no one changes

the values of X and Y

scaling. They have to be

set at 1 and NOTHING

ELSE.

Allows to switch to unidirectional printing (slower

but better quality)

Page 35

35XLp Installation & Configuration, June 2010

Service Level : Ink Tab

Can be set to 1 if required

(note that the system will

then react as an XLp50)

Will give a message

when ink in cartridge

becomes low

Page 36

36XLp Installation & Configuration, June 2010

Service Level : Paper Tab

Signals when paper take

up motor is running too

long (paper slipping).

Signals when paper feed

motor is running too long

(paper slipping).

Uncheck for drop on floor

(can also be set on plotter

itself, but will reset after

job).

Leave like this.

Signals when system is out

of paper.

Page 37

37XLp Installation & Configuration, June 2010

Service Level : System Tab

Do not touch these

values (result unknown)

Resolution should

always be on 300DPI

Page 38

38XLp Installation & Configuration, June 2010

Service Level : Updating Firmware

• Latest firmware will be made available via

GERBERnet.

• When you click Update Firmware a standard

browsing window will pop up instructing you to

select the firmware file to upload (the XLp uses

*.hex files).

• Once selected the system will ask you to confirm

twice before it uploads the firmware to the plotter

(takes only a few seconds).

• After firmware update the plotter will restart

automatically.

Page 39

39XLp Installation & Configuration, June 2010

Maintenance

• To keep a smooth Y-axis movement it is

recommended to clean and slightly oil both

round ways at regular intervals (2-3 weeks

depending on usage). Make sure you do not

touch the Code Strip with oil (use a small

piece of oiled rag to sweep the round ways).

• Make sure the Y Encoder Strip is free of dust

and debris. If not then the head may take-off

at a high speed and slam into the Cleaning

Station.

Page 40

40XLp Installation & Configuration, June 2010

Maintenance

• Over time ink will build up in the cleaning

station due to the cleaning cycles where the

system purges the jets. This can cause print

quality issues if the ink builds up near the jets.

If this occurs, it is recommended to (remove

and) clean the capping rubbers using warm

water and soap.

Page 41

41XLp Installation & Configuration, June 2010

Components: left side

Page 42

42XLp Installation & Configuration, June 2010

Components: Operator Side

Page 43

43XLp Installation & Configuration, June 2010

Questions ?

Loading...

Loading...