Page 1

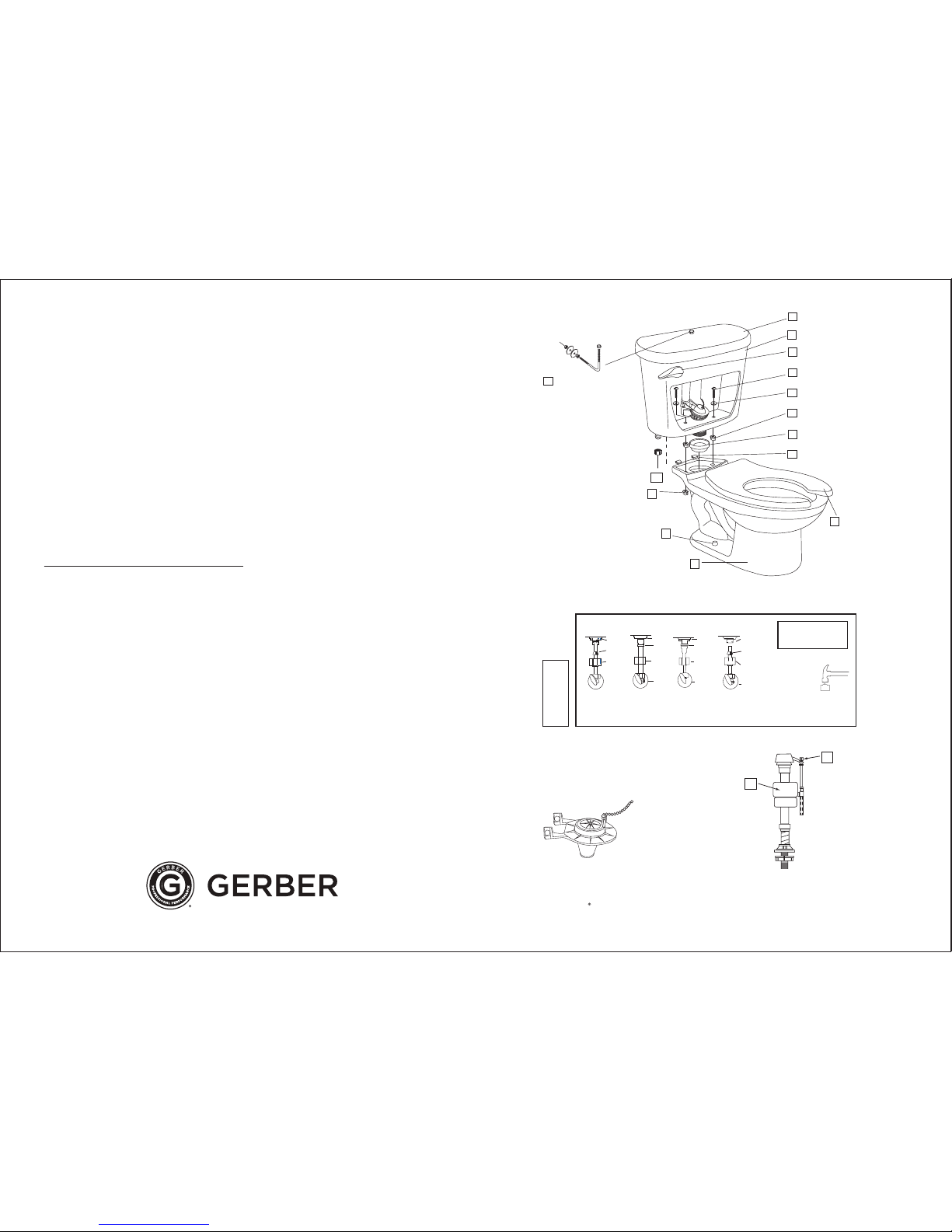

I

A

B

C

D

E

F

F

G

H

J

K

O

(A) TC-HE-28-601 Tank Cover

Couvercledu réservoir

Tapa del tanque

GA700590-GEG1 Lid Locker

Verrou de couvercle

Seguro de tapa

(C) 99-840-WH Tank Lever

Levier du réservoir

Palanca del tanque

*(2) Tank Bolt

Boulon de réservoír

Tornillo de tanque

*(2) Rubber Washer

Rondelle en caoutchouc

Arandela de goma

*(1) Tank to Bowl Gasket

Joint réservoir/cuvette

Junta de la cisterna y el inodoro

*(2) Channel Pads

Coussinet de canal

Tacos acanalados

P

GC55011943-GEG1 Toilet Seat

siège de toilette

Taza de inodoro

*(1) B/C Coupling Nut

Écrou de raccordement

B/C Tuerca de unión

(2) 99-287 Plastic Bolt Caps & Washer

Rondelle et chapeau de boulon en plastique

Casquete plástico para tornillo y arandela

NOTE: Parts with * are included in unit bag, 99-828

REMAQUE: Les piéces portant un * sont incluses dans ie sac.

AVISO: Las partes con * están incluidas en la bolsa de la unidad.

(k) Bowl

Cuvette

Taza

*(4) Plastic Wing Nut

Écrou papillon en plastique

Tuercas de orejas plásticas

(B) Tank

Réservoir

Tanque

METAL/COPPER

TUBING

GALVANIZED

PIPE (SEE NO TE)

METAL FLANGED

TUBING

METAL SPIRAL

TUBING

LOCK NUT

CONE

WASHER

COUPLING

NUT

WATER

SHUT-OFF

WATER

SHUT-OFF

LOCK NUT

LOCK NUT

LOCK NUT

O-RNG

COUPLING

NUT

WATER

SHUT-OFF

WATER

SHUT-OFF

EXISTING

WASHER

EXISTING

CONE

WASHER

EXISTING

COUPLING

NUT

COUPLING

NUT

These parts must be used as illustrated to insure

water-tight connection. Use of existing a coupling

nut may result in water leakage. Water supply tube

or pipe must extend at least 1/2'' inside threaded

shank of valve(does not apply to flanged tubing).

Use existing

coupling nut

and washer.

Use existing spiral cone

washer. Fluidmaster cone

washer may not seal

completely on spiral type

supply line.

FOR GALVANIZED

PIPE ONLY. you

must break out

the center of

COUPLING NUT

by striking it lightly with ahammer

or blunt end of screw driver handle.

Discard center portion. Also,use

O-RING instead of cone washer.

CAUTION: Overtightening of

LOCK NUT or COUPLING NUT

could result in breakage and

potentiial flooding.

CAUTION:

DO NOT

USE

CONE

WASHER

OR

O-RING

WITH

PLASTIC

SUPPLY

LINE.

Float Cup

Coupelle flottante

Flotador

M

Flapper Assembly Replaced by 99-788

L’etancheite Du Clapet

Asamblea De Flotador

PEEWEE™ is a trademark of GERBER PLUMBING FIXTURES LLC.

FLUIDMASTER is the registered trademark of Fluidmaster lnc.

8CGE0091 , rev. 07-15

L

Water Level

Adjusting Screw

La vis de réglage de

niveau d’eau

El tornillo de reglaje del

nivel de agua

Replaced by GA700132-GEG1

PEEWEE™ TOILET

DIRECTIONS FOR TANK TO BOWL ASSEMBLY

This water closet has been designed for easy installation. Conventional

fittings have been used throughout so that the working parts and operation

of this assembly may be easily understood.

1. Before assembling tank (B) to bowl (K) check tightness of lock nuts on both flush valve

and fill valve.

2. Assemble tank bolts (D) in tank with rubber washers (E) and plastic wing nuts (F). Wing

nuts should be tightened by hand sufficiently to compress rubber washers and insure

water seal.

3. Assemble tank to bowl gasket (G) to flush valve shank so that lock nut is enclosed in recess,

making sure that the entire surface of the washer is in contact with the tank bottom.

4. Place two channel pads (H) in recesses on back of bowl ledge to prevent china-to-china

contact.

5. Place tank assembly in position. All parts are supplied. USE NO PUTTY. Plastic wing nuts

(F) are tightened by hand sufficiently to prevent rocking; and since the tank bolts are

already sealed, the tank can be leveled by the relative amount that each wing nut is pulled

down on the three points of contact-tank to bowl gasket (G) and two channel pads (H).

6. Plastic bolt caps and washers (J) are provided to be used as indicated in the illustration.

7. The fill valve coupling nut (l) is provided to connect the water supply line to the fill valve.

USE NO PlPE DOPE! HAND TIGHTEN ONLY! OVERTIGHTENING MAY SPLIT THE FILL

VALVE AND WILL VOID THE WARRANTY!

8. Make sure refill tube adaptor is attached to the top of the flush valve overflow tube.

Note: Flow from the refill tube must be positioned directly over the overflow tube.

9. IMPORTANT: Always clear sand and rust from system.

• Remove valve top by lifting arm and rotating top 1/8 turn counterclockwise.

• While holding a container over the uncapped valve to prevent splashing, turn

water supply on and off a few times. Leave water supply off.

• Replace TOP by engaging lugs and rotating 1/8 turn clockwise. MAKE CERTAIN TOP IS

TURNED TO THE LOCKED POSITION. VALVE MAY NOT TURN ON IF TOP IS NOT FULLY

TURNED TO THE LOCKED POSITION.

10. Adjust water level in tank to marked water line. Turn the water level adjustment screw (L)

to move the float cup (M) up or down.

1 1. Check action and nut tightness (left hand thread) of tank lever (C). Also, check looseness of

flapper chain (there should be slight slack in chain when at rest) and seal of flush valve flapper.

1 2. Install the tank cover into the tank with lid locker (O).

1 3. Install toilet seat (P) per manufacturer’s instruction.

DO NOT EXPOSE PLASTIC TRIM PARTS TO STRONG OXIDIZING AGENTS, CHLORINE,

OR ACID LEVELS OF LOWER THAN 5.0 pH. SOME BOWL/TILE CLEANERS CONTAIN

SUCH AGENTS.

TANK TYPE BOWL CLEANERS CAN CAUSE TANK COMPONENT FAILURE AND

DAMAGE. OUR WARRANTY EXCLUDES SUCH FAILURES.

DO NOT USE IN-TANK DROP-IN TOILET BOWL CLEANERS CONTAINING

CHLORINE OR BLEACH. Use of in-tank drop-in cleaners containing chlorine or

bleach VOIDS FLUIDMASTER™ WARRANTY and WILL RESULT IN DAMAGE to tank

components and may cause flooding and property damage.

www.gerberonline.com

Page 2

TOILETTE PEEWEE™ INODORO PEEWEE™

12. Installer le couvercle de réservoir sur le réservoir avec verrou de couvercle (O).

13. Installer le siège de toilette (P) en suivant les instructions du fabricant.

12. Coloque la cubierta del depósito con el seguro de tapa (O).

13. Coloque la taza del inodoro (P) siguiendo las instrucciones del fabricante.

Loading...

Loading...